Join Us On Social Media!

Sport fisherman build blog

8 Posts · 3 Followers · 56 Photos · 32 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 8 months ago by

| Oldest posts shown first (Show Newest First) | (Print Booklet) |

📝 Sport fisherman build blog

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 101 Views · 2 Likes

Flag

💬 Add Comment

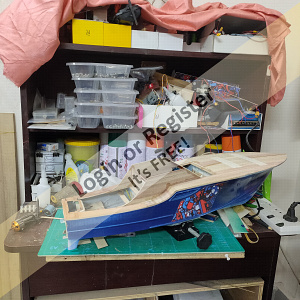

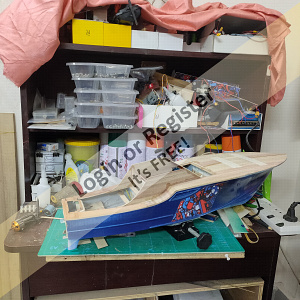

Always wanted to build a sportfisher. Now building one.

24" L, 7" Beam

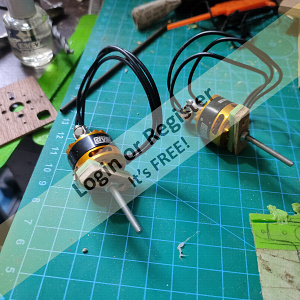

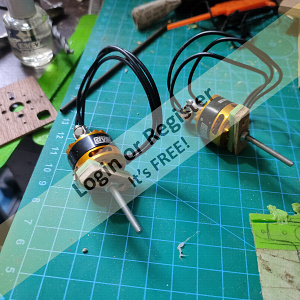

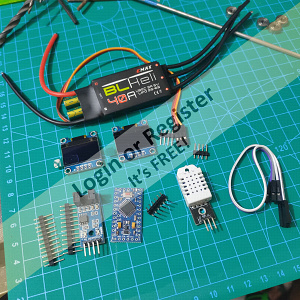

Flashhobby 2300kv outrunner x2

360 A single brushless ESC

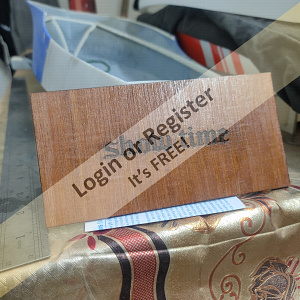

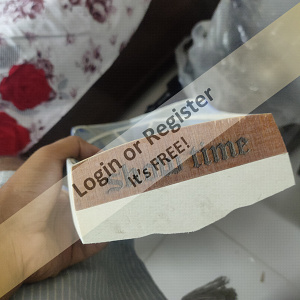

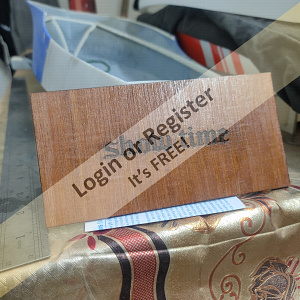

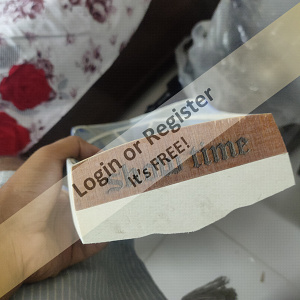

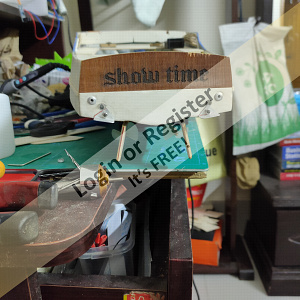

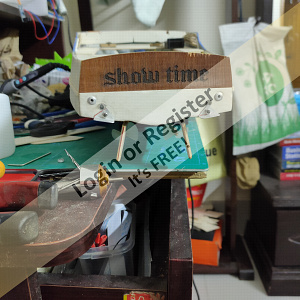

Name plate was laser cut on 3mm ply. Decided to call it "Show Time".

24" L, 7" Beam

Flashhobby 2300kv outrunner x2

360 A single brushless ESC

Name plate was laser cut on 3mm ply. Decided to call it "Show Time".

▲

⟩⟩

RNinMunich

Colin H

Login To

Remove Ads

Remove Ads

📝 Setting the motors and propeller shaft

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 100 Views · 2 Likes · 2 Comments

Flag

💬 Add Comment

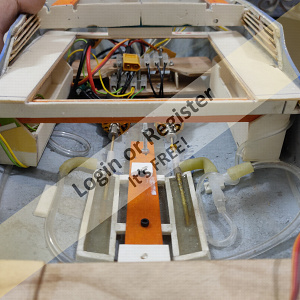

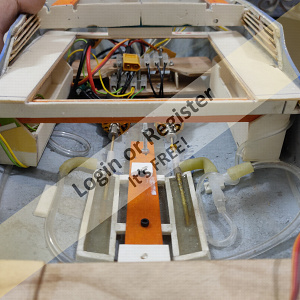

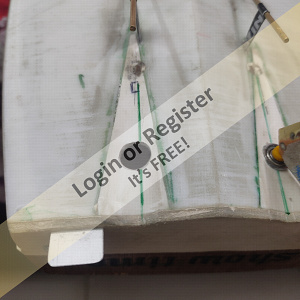

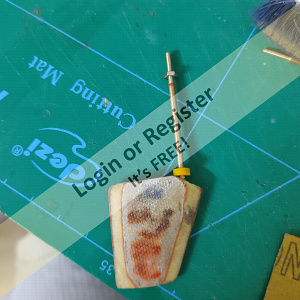

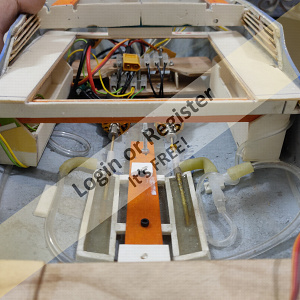

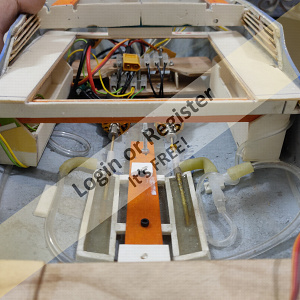

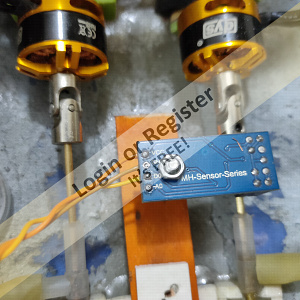

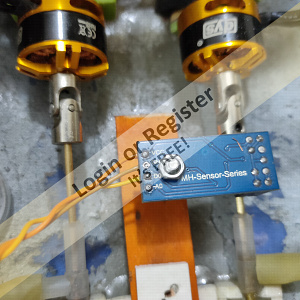

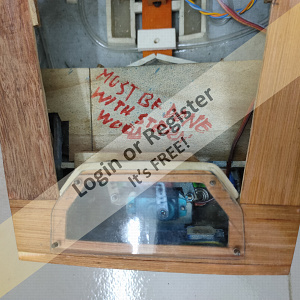

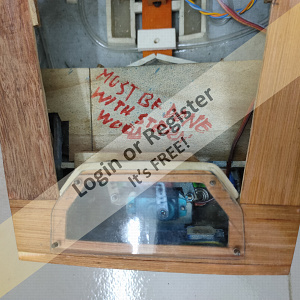

I had to find a way,how to set up the motor so it can run and vibrate. I found this way myself and it looks promising,till now.

Conventional motor mounting used,made a lot sound and sometimes the universal joints just came out one side.

The way i set the motors now can run free and vibrate.

I wanted to know,how do you do it? Do you ever tried to make a flexible motor mount? If yes,how was it?

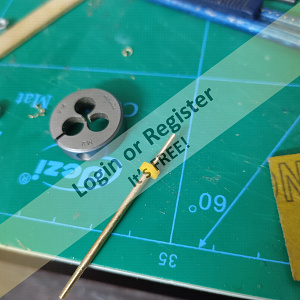

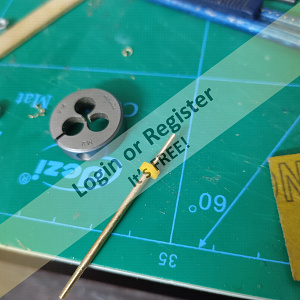

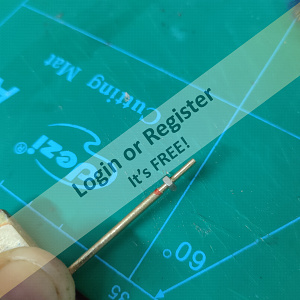

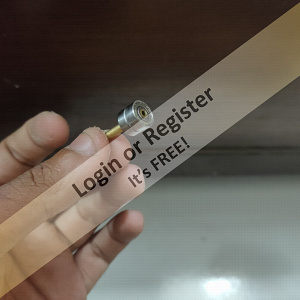

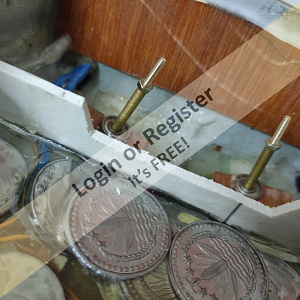

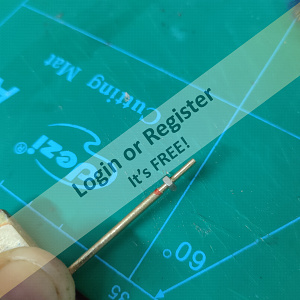

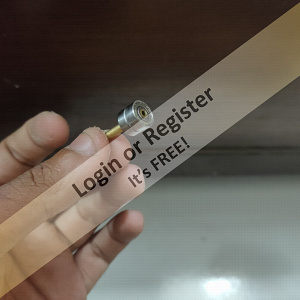

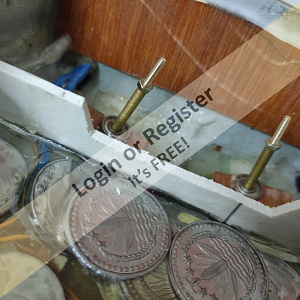

On the propeller shaft,im using brass rod,m2. Bought a thread cutter to cut threads on the shafts. It wasn't to hard. Using brass gives me a painless rust free running time.

I would use stainless steel but ss ain't easy to cut threads on it.

Conventional motor mounting used,made a lot sound and sometimes the universal joints just came out one side.

The way i set the motors now can run free and vibrate.

I wanted to know,how do you do it? Do you ever tried to make a flexible motor mount? If yes,how was it?

On the propeller shaft,im using brass rod,m2. Bought a thread cutter to cut threads on the shafts. It wasn't to hard. Using brass gives me a painless rust free running time.

I would use stainless steel but ss ain't easy to cut threads on it.

▲

⟩⟩

RNinMunich

Colin H

|

💬 Re: Setting the motors and propeller shaft

2 years ago by 🇧🇹 Sakibian (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 98 Views · 1 Like

Flag

I chose brass because it doesn't catch rust. And i had to cut some threads on the shaft. Brass is softer than SS.

I tried to thread my ss shafts but my drill machine can't handle it. I don't have lathe either so brass was my only option. Im putting some photos,there you can see i used brass shaft on them both and they didn't let me down,till now. 😐 So i had to keep faith! -Sakib

▲

⟩⟩

RNinMunich

|

|

💬 Re: Setting the motors and propeller shaft

2 years ago by 🇬🇧 Colin H (

Fleet Admiral) Fleet Admiral)✧ 102 Views · 0 Likes

Flag

Sakabian, I like your setup, but find it hard to understand why you used brass for the prop shafts as brass is brittle and will snap very easily if there is any vibration or sudden shock from props hitting submerged obstacle.

Cheers Colin. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

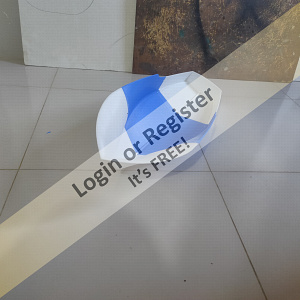

📝 Lube supply

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 99 Views · 2 Likes

Flag

💬 Add Comment

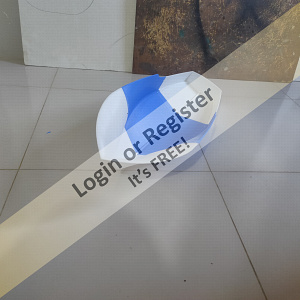

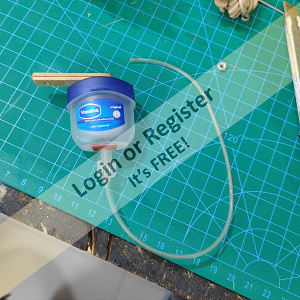

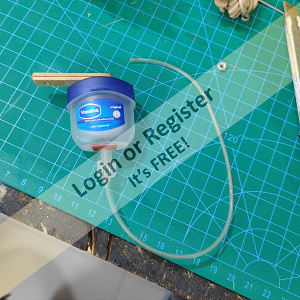

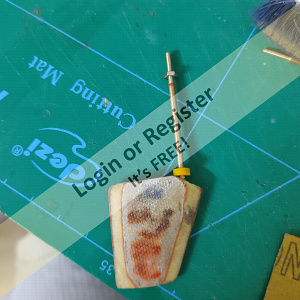

Another thing i tried myself was the Lubricant supply to the propeller shafts. The oil supply box will hold the lube and slowly deliver to shaft sleeves. It's kinda funny but it works.

▲

⟩⟩

RNinMunich

Colin H

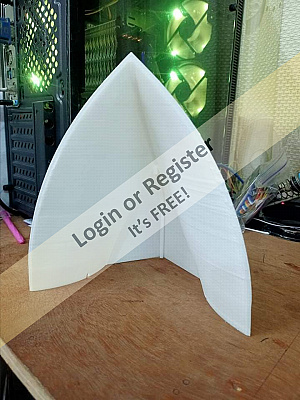

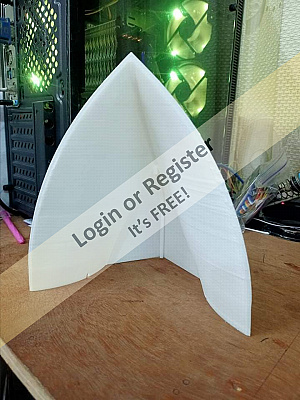

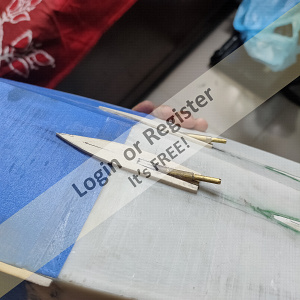

📝 The rudder blades are angled!

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 99 Views · 2 Likes

Flag

💬 Add Comment

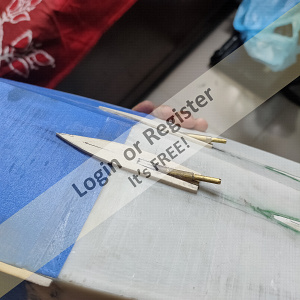

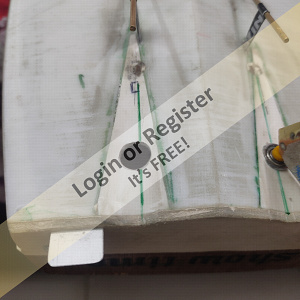

This is one confusing test I'm doing on the boat.

Normally rudder blades are vertical but on this one i tried a bit angle on them. Sail boats has these kind of angle's.

I'm still not sure,if these will work or not but I'm gonna give a try.

I put a couple of bearings,the the copper pipe and then the shaft. I wasn't sure if the bearings would stop the water so i kept another way to rotate the rudder shafts. But the bearings are good enough. I will put some more white grease on them.

Had some changes on the rudder's arm. Servo arm's are better that the handmade wooden arms.

Any help appreciated!

Normally rudder blades are vertical but on this one i tried a bit angle on them. Sail boats has these kind of angle's.

I'm still not sure,if these will work or not but I'm gonna give a try.

I put a couple of bearings,the the copper pipe and then the shaft. I wasn't sure if the bearings would stop the water so i kept another way to rotate the rudder shafts. But the bearings are good enough. I will put some more white grease on them.

Had some changes on the rudder's arm. Servo arm's are better that the handmade wooden arms.

Any help appreciated!

▲

⟩⟩

RNinMunich

Colin H

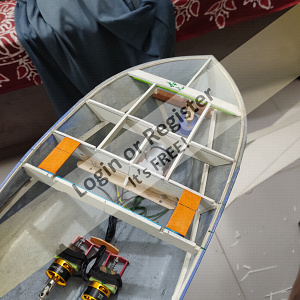

📝 Air vent and deck support

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 99 Views · 4 Likes · 3 Comments

Flag

💬 Add Comment

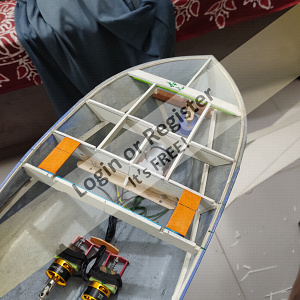

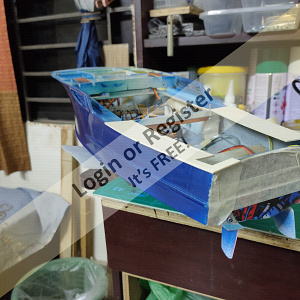

2mm balsa to make the air vent. 2/3mm PVC to build the supports. I will put a layer of balsa on top. The top will be wooden, hopefully.

▲

⟩⟩

RNinMunich

jbkiwi

MouldBuilder

Colin H

|

💬 Re: Air vent and deck support

2 years ago by 🇬🇧 ChrisF (

Lieutenant Commander) Lieutenant Commander)✧ 75 Views · 1 Like

Flag

Hi Sakib

As regards the rudders the theory is Ok but the wire used is very thin for a push/pull system. Also that vertical part of the bend is likely to flex a lot. Have you tried operating the servo and holding the rudder blades lightly? Also where the wire is bent to go into the arms it may spring out unless you have secured the ends on the underside which we can't see. Chris ▲

⟩⟩

Sakibian

|

|

Login To

Remove Ads 💬 Re: Air vent and deck support

2 years ago by 🇧🇹 Sakibian (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 89 Views · 2 Likes

Flag

Thanks a lot for the sharing,Chris!

Firstly, same here. I'm not sure how it will work or even if it will work or not. Hopefully the shafts wont bent, HOPEFULLY. And the rudder linkage, I'm not sure what you were talking about. I hope you will share some more ideas so i can do better with them. I live in Bangladesh and there's no Boat shop here. I am trying these ideas so i can know before opening a Boat shop/Hobbyshop. I do get the parts from China but bringing all the part's are kind of expensive so i tried to build some parts myself. R&D 😊 -Sakib ▲

⟩⟩

RNinMunich

Colin H

|

|

💬 Re: Air vent and deck support

2 years ago by 🇬🇧 ChrisF (

Lieutenant Commander) Lieutenant Commander)✧ 95 Views · 2 Likes

Flag

Given the slight angle of the rudders and the fact that they will cancel each out maybe they will be Ok.

Not so sure about the motor and prop shaft though! As well as being brass M2 is very thin and with flexible motor mounts you could very well get whip in the prop shaft which will give very bad vibration, particularly as the motors are high kV. Bit concerned about your motor mounting and rudder linkage! I don't know where you are but do you have difficulty in obtaining threaded stainless steel prop shafts? The motor and prop shaft always sound noisy when bench running, especially without the superstructure, but are much better once on the water. Be interesting to see how it works out but I wouldn't be surprised if you have problems and noise! Chris ▲

⟩⟩

Colin H

Sakibian

|

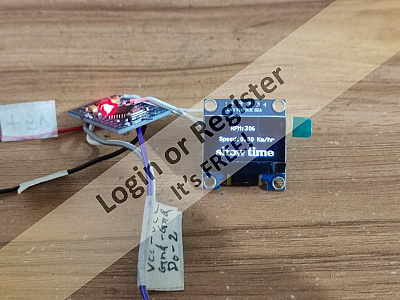

📝 Rpm seson set-up to get the RPM. Kinda fancy,uh?

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 89 Views · 4 Likes

Flag

💬 Add Comment

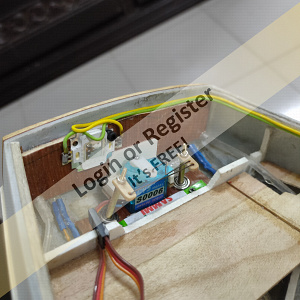

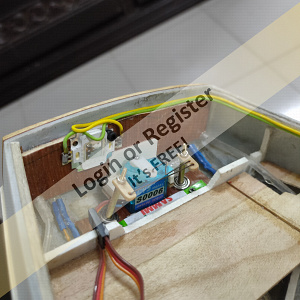

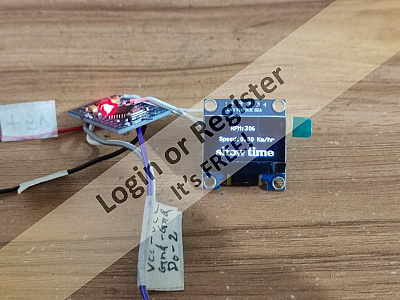

This was an idea from nowhere. Looking at the actual boat's from famous Jarrett Bay Boat work's,they all has Garmin display on the bridge.

Wanted to do the same but what could be a good mini display and what should i show?

My friend, who's good with electronics ,helped me to build these arduino oled displays and did all the coding stuff. So i can put on the Boat name,rpm, distance covered, engine temp.

The black fan is a 12v blower fan for 3d printer. Air cooling.

Wanted to do the same but what could be a good mini display and what should i show?

My friend, who's good with electronics ,helped me to build these arduino oled displays and did all the coding stuff. So i can put on the Boat name,rpm, distance covered, engine temp.

The black fan is a 12v blower fan for 3d printer. Air cooling.

▲

⟩⟩

RNinMunich

jbkiwi

mturpin013

Colin H

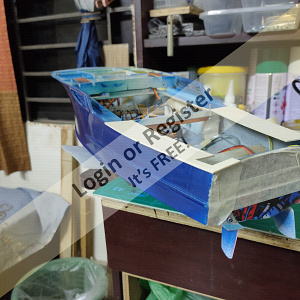

📝 Deck planking and bridge

2 years ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 89 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

2mm balsa on the whole deck.under the wood,there will be pvc.

Shame,the wood will be painted white.

Bridge is also wooden.

Shame,the wood will be painted white.

Bridge is also wooden.

▲

⟩⟩

RNinMunich

boatmam

GaryLC

hermank

Scratchbuilder

jbkiwi

Krampus

mturpin013

Colin H

|

💬 Re: Deck planking and bridge

2 years ago by 🇧🇹 Sakibian (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 69 Views · 0 Likes

Flag

All hail SPORT FISHERMAN 💪😅

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Deck planking and bridge

2 years ago by 🇺🇸 Krampus (

Warrant Officer) Warrant Officer)✧ 65 Views · 1 Like

Flag

|

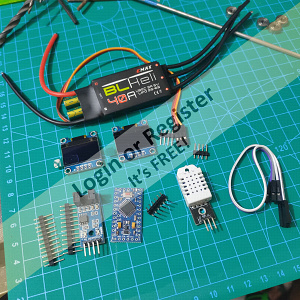

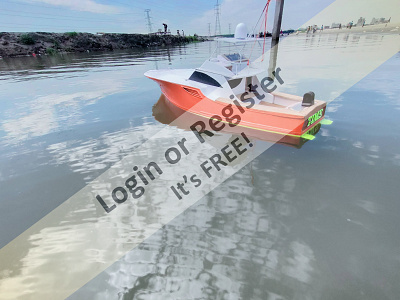

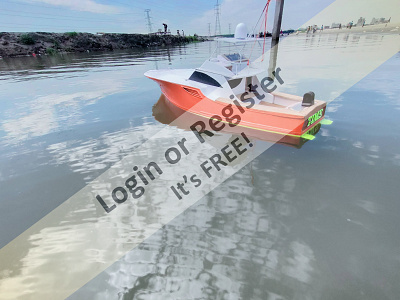

📝 Sportfish 24"

8 months ago by 🇧🇹 Sakibian ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 36 Views · 7 Likes · 3 Comments

Flag

💬 Add Comment

Sorry for the late update.

I have changed a lot spec's. It has 2x Emax 2212 1400kv , 35mm triple blade props, 35A opto x2 and a 5200mah 3s lipo with a metal gear 9g servo. Looks good,sails good.

I have changed a lot spec's. It has 2x Emax 2212 1400kv , 35mm triple blade props, 35A opto x2 and a 5200mah 3s lipo with a metal gear 9g servo. Looks good,sails good.

▲

⟩⟩

ChrisF

MouldBuilder

jbkiwi

RNinMunich

GaryLC

hermank

Scratchbuilder

|

💬 Re: Sportfish 24"

8 months ago by 🇧🇹 Sakibian (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 25 Views · 0 Likes

Flag

Hey,@Chum444

I missed a part of your comment. The boat is scratch built. The hull was a paid SOLIDWORKS design and turned into a 3d printable file. Everything but the hull is handmade, including the drive shafts. I specially ordered for the flare 🎃🔥 Photo: Hull no 3 -Sakib

▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: Sportfish 24"

8 months ago by 🇧🇹 Sakibian (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 25 Views · 3 Likes

Flag

Great observation,Chum444!

Yes, it was a stern heavy boat on the first trial. These are my first ever trial photos,i ran again but i don't have any other running photos. Originally,i didn't plan for opto ESC's. But i had some opto ESC's (these are usually used in drones and very lightweight) and end up using a couple of those. But the original boat ESC's are a bit heavier and the plan was to use them for some weight. Another problem i noticed,this was a small boat to use a 5200mah 3s lipo. I made a small space under the bridge section for the battery,and the 5200mah just fits. But it made the boat stern heavy while running fast. One more thing,i added some steel balls to gain some stability under the bridge section+ beside the rudder's. Those made the boat stern heavy as well. So ,now I'm trying fix them one by one. This was my first ever sportfish & made some silly mistakes,so i appreciate every little bit you guys suggest! Here, I'm gonna leave some photos of hull no3. She's a better boat than this one. It has bigger and heavier motors(i had emax 2212 1400kv) , front ESC's which are heavy ,and battery space at the center. I will try to upload a bunch of photos when i can.(it was a custom order) CHEER'S! -Sakib

▲

⟩⟩

boatmam

MouldBuilder

jbkiwi

|

|

💬 Re: Sportfish 24"

8 months ago by 🇺🇸 Chum444 (

Midshipman) Midshipman)✧ 37 Views · 2 Likes

Flag

Just. something for you to evaluate as you please. Sport fisherman at speed do not run in a bow up attitude. At most maybe 1/3 rd of that bow angle. A 1:1 SF typically runs 20-24 kts. A 35+ ft SF’s fuel consumption at that speed is between 50 to 75 gallons of fuel per hour. You might choose to set your throttle channel endpoints a fair amount lower.Just an observation on my part; certainly not being critical.

Great looking build. Was it from scratch? What did you use for plans? I really like the bow flair. ▲

⟩⟩

Sakibian

Ronald

|

Bhutan

Bhutan