Join Us On Social Media!

THE AMPHITRUCK

25 Posts · 19 Followers · 145 Photos · 185 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 days ago by

| Oldest posts shown first (Show Newest First) | (Print Booklet) |

📝 THE AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 164 Views · 10 Likes · 9 Comments

Flag

💬 Add Comment

Decided to do something other than a boat this time, but still with a nautical purpose,- a 6 wheel twin diff twin prop swimming truck. Been done before, but I thought I'd have a go at one of my own design. Drew up some side and end templates and made a start, Purchased all the mechanical bits, (diffs, front axle, prop shafts, props, ESC, wheels,) over a few months from uncle ALI and added them to stuff I had in my collection.

Using cheap 3mm packing ply, I made the floor base ( to suit the diff and front axle widths) and strengthened it with 10x10 ally angle. Next,-cut out the sides and front and back panels. The floor was scored at the front and back to allow it to be bent up to the sides for gluing. Holes were cut in the floor to allow the diff heads to protrude through.

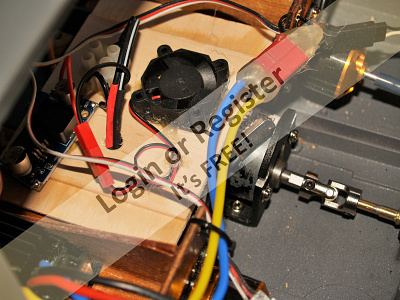

I had to modify the front axle to suit the width of the diffs by adding in an ally angle center section. Also had a play with setting the diffs and drive-shafts up with universals. Drive motor is a 380 1500 RPM @ 12v geared reduction drive, which is the one I first used in my Jeep tow wagon for my Hartley, (replaced it with a 1000 RPM version for more torque) and uses a 3s LiPo and Quicrun 40A ESC.

Using cheap 3mm packing ply, I made the floor base ( to suit the diff and front axle widths) and strengthened it with 10x10 ally angle. Next,-cut out the sides and front and back panels. The floor was scored at the front and back to allow it to be bent up to the sides for gluing. Holes were cut in the floor to allow the diff heads to protrude through.

I had to modify the front axle to suit the width of the diffs by adding in an ally angle center section. Also had a play with setting the diffs and drive-shafts up with universals. Drive motor is a 380 1500 RPM @ 12v geared reduction drive, which is the one I first used in my Jeep tow wagon for my Hartley, (replaced it with a 1000 RPM version for more torque) and uses a 3s LiPo and Quicrun 40A ESC.

▲

⟩⟩

stevedownunder

Julio

MouldBuilder

fireboat

Martin555

SimpleSailor

ChrisF

Colin H

Peejay

Graham93

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 55 Views · 1 Like

Flag

Hi JB,

Great project, I have a bit to catch up on. Cheers, Stephen. ▲

⟩⟩

jbkiwi

|

|

Login To

Remove Ads 💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 132 Views · 3 Likes

Flag

Hi Peter, they are just standard RC truck diffs which I'll fill with grease and seal all the joints.

JB. ▲

⟩⟩

stevedownunder

Julio

MouldBuilder

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 141 Views · 2 Likes

Flag

This is interesting JB. Are they special axles. How are they sealed from water or am I missing the plot somewhere. 🤔

▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇬🇧 mistyoptic (

Midshipman) Midshipman)✧ 144 Views · 2 Likes

Flag

Can't wait to see it on the pond.

Great ingenuity! Geoff ▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 166 Views · 2 Likes

Flag

Hi JB,

Nice to see something a little different. Martin555. ▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇬🇧 jacko (

Lieutenant Commander) Lieutenant Commander)✧ 156 Views · 2 Likes

Flag

works on water... will have to take a video as soon as I can get to the pond

▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 151 Views · 1 Like

Flag

Hi Jacko, looks really good, are you going to power it, or is it just a static model ? Saw Your blog a while back, but don't think I saw the end result.

JB ▲

⟩⟩

stevedownunder

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇬🇧 jacko (

Lieutenant Commander) Lieutenant Commander)✧ 160 Views · 3 Likes

Flag

|

|

💬 Re: IS IT A BOAT, IS IT A TRUCK? - IT'S A BIT OF BOTH,- THE AMPHITRUCK

2 years ago by 🇬🇧 ChrisF (

Lieutenant Commander) Lieutenant Commander)✧ 177 Views · 1 Like

Flag

Interested to see this one progress.

For a bit of a change I'm building a Tamiya Unimog at the moment in between my boat builds. Chris ▲

⟩⟩

stevedownunder

|

Login To

Remove Ads

Remove Ads

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 154 Views · 5 Likes

Flag

💬 Add Comment

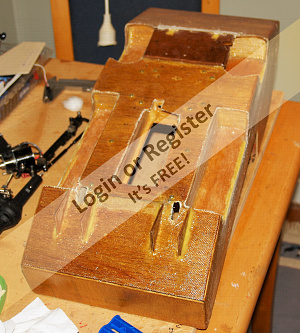

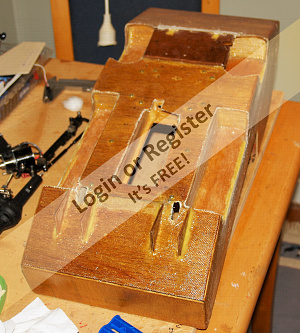

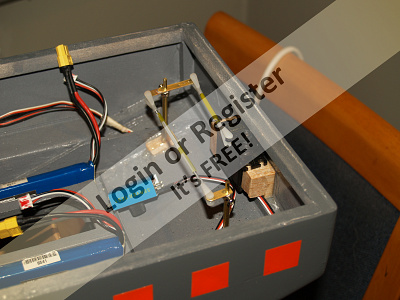

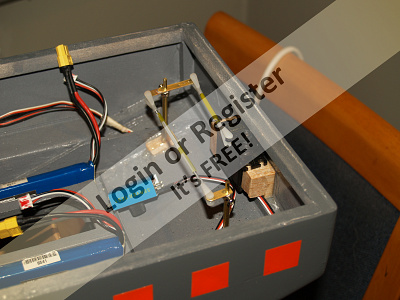

Knees made for the floor ends and floor ends bent up and epoxied. Ally frame and running gear temporarily in place.

▲

⟩⟩

stevedownunder

fireboat

Martin555

jacko

Colin H

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 145 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

Making the inner guards (before attaching the sides) and making an alteration to the ally frame to make fitting the front axle easier. Offsetting the inner guards to let the sides in over the bottom floor. A large 5mm ply plate was glued to the bottom (pic 3&4) to mount the front axle on, rather than the inner frame. Raises the front slightly, taking the load off the first diff to make steering easier (both diffs fully driving would want to push it straight ahead, as they are not proper differentials, just fixed axles)

Found some plastic garden irrigation pipe saddles at the big hardware, which were exactly the right size for the diffs, so had a play fitting them at this stage, Also made a box for the diff heads to sit up in. While doing these jobs, I'm constantly working out what will go where next, and making sure everything will be accessible later (even certain screws. This is another of my 'chainsaw as you go' projects, which usually include many remodels and changes to make things work out.

Found some plastic garden irrigation pipe saddles at the big hardware, which were exactly the right size for the diffs, so had a play fitting them at this stage, Also made a box for the diff heads to sit up in. While doing these jobs, I'm constantly working out what will go where next, and making sure everything will be accessible later (even certain screws. This is another of my 'chainsaw as you go' projects, which usually include many remodels and changes to make things work out.

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

Rogal118

Colin H

dave976

Ronald

|

💬 Re: AMPHITRUCK

2 years ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 147 Views · 2 Likes

Flag

Very interesting, I will be following your build.

Ron ▲

⟩⟩

Martin555

jbkiwi

|

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 141 Views · 5 Likes

Flag

💬 Add Comment

The sides are now glued on using epoxy with a filler powder to make it a glue, seals really well and is a good gap filler. Also bored some rough holes for the prop shafts, and glued on some flow directors for the props.

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

Ronald

Graham93

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 143 Views · 5 Likes

Flag

💬 Add Comment

Hull front and rear panels glued on, and hull glassed to the waterline. Remainder of resin applied to the exterior topsides above the waterline at the same time.

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

Rogal118

pressonreguardless

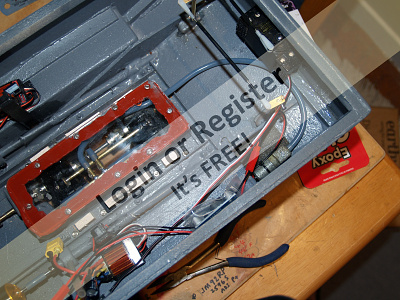

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 137 Views · 7 Likes · 3 Comments

Flag

💬 Add Comment

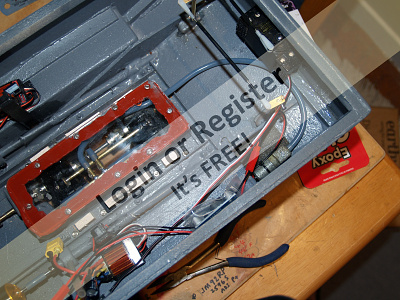

The hull was sealed with a timber preservative thin resin inside. Screen surround and roof then fitted and removable rear screen made. all now painted with a sealer, primer and topcoat. Shafts were epoxied in at this stage, complete with clamp on oilers.

[ Clamps were made earlier while waiting for F/G to dry,- turned and bored for a press fit on the shaft tubes, then slit, flats milled and holes drilled and tapped for 3mm machine screws for clamping.]

Holes were drilled in the shaft tubes and the nylon filler tube holders located over them and clamped on. Shafts and tubes had to be shortened as well (bearings tapped out, tubes cut, bearings replaced).

The large hole in the front of the diff cover box is for the driveshaft seal.

ADDITION -

Forgot to add these pics of the buoyancy test with full weight on board, after sealing and glassing the hull. Taped up all the bolt holes etc and chucked it in the big blue clam, floated well, no leaks except for a few drops around the tape.

[ Clamps were made earlier while waiting for F/G to dry,- turned and bored for a press fit on the shaft tubes, then slit, flats milled and holes drilled and tapped for 3mm machine screws for clamping.]

Holes were drilled in the shaft tubes and the nylon filler tube holders located over them and clamped on. Shafts and tubes had to be shortened as well (bearings tapped out, tubes cut, bearings replaced).

The large hole in the front of the diff cover box is for the driveshaft seal.

ADDITION -

Forgot to add these pics of the buoyancy test with full weight on board, after sealing and glassing the hull. Taped up all the bolt holes etc and chucked it in the big blue clam, floated well, no leaks except for a few drops around the tape.

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

pressonreguardless

Graham93

jacko

Ronald

|

💬 Re: AMPHITRUCK

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 134 Views · 1 Like

Flag

I'm with you Ron👍👍

Trev ▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: AMPHITRUCK

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 134 Views · 3 Likes

Flag

Can't wait to see it in action😀😀

Top Notch work👍 Clamp on oilers is a great idea i wish i had them on my Typhoon. Trev ▲

⟩⟩

stevedownunder

Martin555

jbkiwi

|

|

💬 Re: AMPHITRUCK

2 years ago by 🇨🇦 Ronald (

Admiral) Admiral)✧ 141 Views · 5 Likes

Flag

Looking forward to seeing this Mud splattered, water Hog, motoring through the swaps chasing gators real soon! Another Crock Dundee movie soon to appear on your mud splattered tv screen...😎😁

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

jbkiwi

pressonreguardless

|

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 138 Views · 4 Likes

Flag

💬 Add Comment

Rudders were fitted (std stuff and easy to get at) extra blocks glued to their bases for strength. Rudders themselves were made alongside other jobs (painting etc) so they were ready to fit. Arms are soldered to aircraft wheel collars. All holes for the equipment were drilled before glassing, and just needed re-drilling through the glass and parts bolting in place.

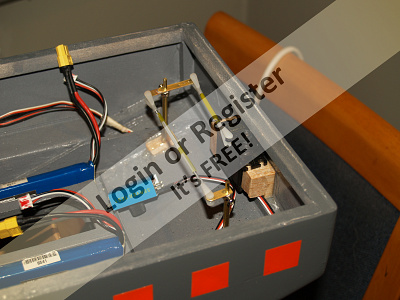

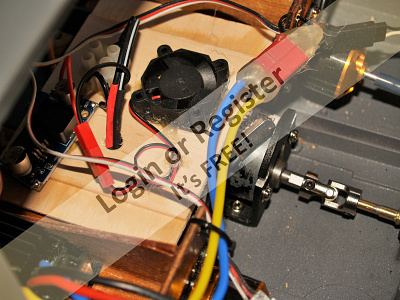

Trial fitted the swim motors ( 28mm 2200kv out-runners) on their ply brackets to check for alignment, (and made a few adjustments,) and found suitable positions for the twin 20A TrackStar ESCs . (excellent little ESC with a fully adjustable programme.

Also fitted the wheel steering servo on the pre set nylon bolts (servo screws to drilled blocks which slide down the bolts and are secured with nylon nuts, - see bolts pic 3 previous post) The main drive motor was also trial bolted back in place. Props and shafts were re fitted to check for clearance. A bit of colour was added as well. Next to be fitted will be the running gear and wheel steering linkage.

Makes things a lot easier you trial fit each item in its' position as you go along, as it's easier to work on an open area. If everything is pre fitted, and access to every bolt/screw is planned for, it only takes a short time to bolt everything back on after painting or glassing. Much better than trying to drill holes later in confined spaces. Even if you have to drill a hole above a difficult to access screw (which may need removing later) and disguise the hole (I've used punched discs of masking tape,- painted over), it can make life so much easier later .

Trial fitted the swim motors ( 28mm 2200kv out-runners) on their ply brackets to check for alignment, (and made a few adjustments,) and found suitable positions for the twin 20A TrackStar ESCs . (excellent little ESC with a fully adjustable programme.

Also fitted the wheel steering servo on the pre set nylon bolts (servo screws to drilled blocks which slide down the bolts and are secured with nylon nuts, - see bolts pic 3 previous post) The main drive motor was also trial bolted back in place. Props and shafts were re fitted to check for clearance. A bit of colour was added as well. Next to be fitted will be the running gear and wheel steering linkage.

Makes things a lot easier you trial fit each item in its' position as you go along, as it's easier to work on an open area. If everything is pre fitted, and access to every bolt/screw is planned for, it only takes a short time to bolt everything back on after painting or glassing. Much better than trying to drill holes later in confined spaces. Even if you have to drill a hole above a difficult to access screw (which may need removing later) and disguise the hole (I've used punched discs of masking tape,- painted over), it can make life so much easier later .

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

pressonreguardless

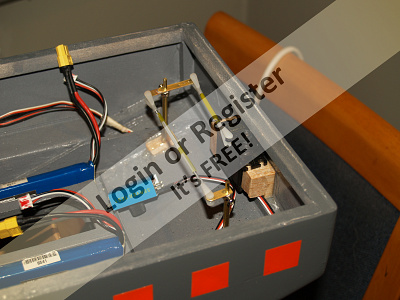

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 130 Views · 5 Likes

Flag

💬 Add Comment

Fitted the diffs/driveshafts (both pre filled with marine outboard grease and sealed) with the plastic saddles and marine silicone to hold them still. The diffs have each been fitted with an air pressure tube in the tops for a future pressurising system (tube can be seen in pic 5). Ply posts for the water drive ESCs arming switches epoxied in place as well. A link bar was also made for the tops of the diffs to stop them rotating under drive torque.

▲

⟩⟩

stevedownunder

MouldBuilder

Martin555

Rogal118

Ronald

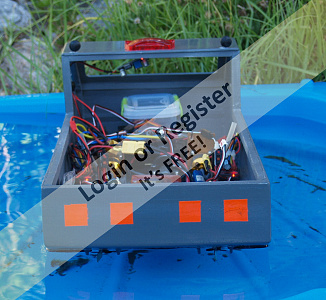

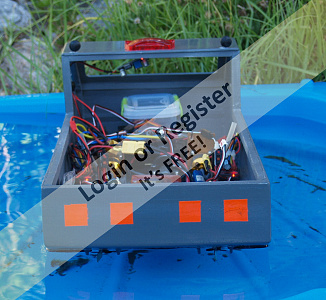

📝 AMPHITRUCK (second flotation test)

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 129 Views · 9 Likes · 10 Comments

Flag

💬 Add Comment

I've included some belated pics here to show various attachments better. These were all tested in position before painting and sealing the hull, then all removed for the next stages of work.

Swim motors, main drive/gearbox, wheel steering servo with waterproof boot, driveshaft seal, rudder servo and now diff pressurising system fitted.

The pressure is provided from air from a tiny air pump sitting behind the left rear wheel arch , which is linked to a brass tube manifold in the diff cover box by silicone hose. The 2 diffs are linked to the manifold tube which has an 'open to atmosphere' tube extending into the box. This pressurises the box and provides a small amount of constant positive pressure to the diffs to keep water out, (they are completely packed with marine grease and all seams sealed, but that's no guarantee water won't get in, hence the pressurisation)

A Perspex cover was made to fit the box and screwed down with a silicone sealer. (as it turned out in the water test, no water enters the box, and the tops of the diffs don't even get wet (sort of diving bell effect). Excess pressure just bubbles out under the hull. A small waterproof plastic box was used to house the RX in the cab, and screwed through the bottom to a ply plate glued to the front hull knees, with a slot near the lip just big enough to push the servo plugs through. The truck won't be going out in the 'open sea', so it should be sufficient.

A few lights being added (spots don't work as the polyester resin I poured in killed them, don't think LEDs like MEKP.) Flashing top light being made.

Swim motors, main drive/gearbox, wheel steering servo with waterproof boot, driveshaft seal, rudder servo and now diff pressurising system fitted.

The pressure is provided from air from a tiny air pump sitting behind the left rear wheel arch , which is linked to a brass tube manifold in the diff cover box by silicone hose. The 2 diffs are linked to the manifold tube which has an 'open to atmosphere' tube extending into the box. This pressurises the box and provides a small amount of constant positive pressure to the diffs to keep water out, (they are completely packed with marine grease and all seams sealed, but that's no guarantee water won't get in, hence the pressurisation)

A Perspex cover was made to fit the box and screwed down with a silicone sealer. (as it turned out in the water test, no water enters the box, and the tops of the diffs don't even get wet (sort of diving bell effect). Excess pressure just bubbles out under the hull. A small waterproof plastic box was used to house the RX in the cab, and screwed through the bottom to a ply plate glued to the front hull knees, with a slot near the lip just big enough to push the servo plugs through. The truck won't be going out in the 'open sea', so it should be sufficient.

A few lights being added (spots don't work as the polyester resin I poured in killed them, don't think LEDs like MEKP.) Flashing top light being made.

▲

⟩⟩

stevedownunder

RNinMunich

MouldBuilder

Commodore-H

Rookysailor

Ronald

Graham93

Colin H

Martin555

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 99 Views · 0 Likes

Flag

Hi Trev, I think it's by good luck rather than good management. LL The hull allows a for lot of adjustment weight wise, (sort of the theory)

JB ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 99 Views · 0 Likes

Flag

Hi Doug missed your question (and Julios'-, no notifications for some reason) I think because it is constructed like a barge with a big flat bottom ( reminds me of a song) it takes a lot to sink it. Weighing in at the moment at around 6kg, but is basically just floating on the 'I' shaped pan inside the wheel arches. The constant air pressure in the diff box helps too. Was so buoyant in the stern, I had to move the batteries back from around the center.

JB ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 99 Views · 2 Likes

Flag

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 109 Views · 1 Like

Flag

Her waterline is perfect. Well-engineered👍👍👍

Trev ▲

⟩⟩

jbkiwi

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 116 Views · 1 Like

Flag

With all those gizmos on board JB I'm surprised that it doesn't float lower, much lower!

Eagerly awaiting the trials, maybe towing your Hartley 🚤 directly into the wet stuff?😀 Cheers, Doug 😎 ▲

⟩⟩

jbkiwi

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇪🇸 Julio (

Petty Officer 1st Class) Petty Officer 1st Class)✧ 115 Views · 1 Like

Flag

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇭🇺 MouldBuilder (

Vice Admiral) Vice Admiral)✧ 121 Views · 1 Like

Flag

Brilliant JB. I was wondering how you would keep the water out of the on road drive train.👍😀

▲

⟩⟩

jbkiwi

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 127 Views · 1 Like

Flag

Great Attention to the Mechanics of the Truck👍👍

▲

⟩⟩

jbkiwi

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 129 Views · 1 Like

Flag

Almost packed to the 'gunwales' Martin (can trucks have gunwales ?) , 3 drive systems = 3x the spaghetti LL. Want sound, but where do I put it ? (think I need a bigger truck)!

JB ▲

⟩⟩

Ronald

|

|

💬 Re: AMPHITRUCK (second flotation test)

2 years ago by 🇬🇧 Martin555 (

Fleet Admiral) Fleet Admiral)✧ 148 Views · 1 Like

Flag

Great work JB.

The truck has come along well. Looks like it is packed with all sorts of electrickery LOL!! Martin555. ▲

⟩⟩

jbkiwi

|

📝 AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 123 Views · 8 Likes · 3 Comments

Flag

💬 Add Comment

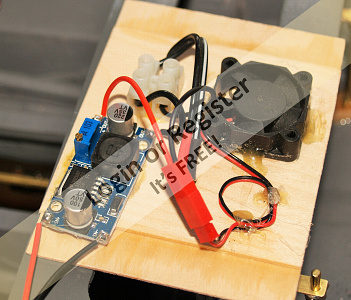

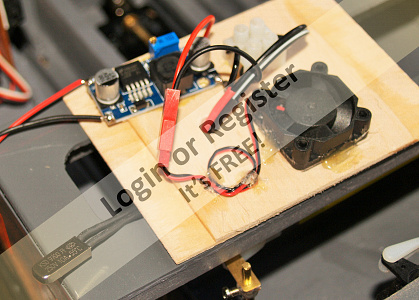

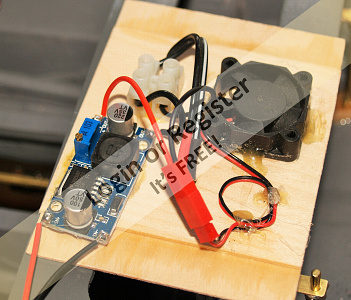

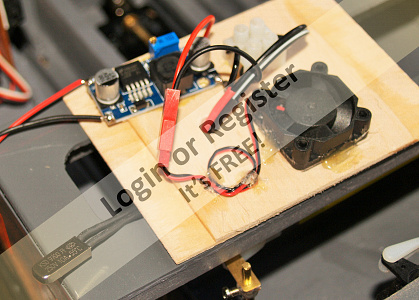

Windows in and tinted (PETG with car tint applied.) Front screen removable for access. Also made up a thermostatically controlled fan for the motor, as I found it got a bit hot under heavy going on a long grass test in the back yard. It uses a 55C thermo switch which is strapped to the motor, and in the power circuit for the fan. Fan is 3v and run from a small voltage reg, with power coming from the main 3s drive battery. All mounted on a ply shelf which attaches over the motor with 2 Neo magnets. (shelf shown unpainted).

Almost ready here for the big actual 'sea trials'.

Almost ready here for the big actual 'sea trials'.

▲

⟩⟩

stevedownunder

Martin555

Colin H

MouldBuilder

ToraDog

Julio

Commodore-H

pressonreguardless

|

💬 Re: AMPHITRUCK

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 118 Views · 1 Like

Flag

👍👍👍😁

▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: AMPHITRUCK

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 122 Views · 2 Likes

Flag

Few more bits to stick on yet Trev, then It'll be testing time.

JB ▲

⟩⟩

Martin555

pressonreguardless

|

|

💬 Re: AMPHITRUCK

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 119 Views · 2 Likes

Flag

Would love to see a vidio of her in action 😊

Water Trials ? Trev ▲

⟩⟩

Martin555

jbkiwi

|

New Zealand

New Zealand