Join Us On Social Media!

Russian K100D waterjet work boat project

86 Posts · 25 Followers · 391 Photos · 620 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 1 day ago by

| Oldest posts shown first (Show Newest First) | (Print Booklet) |

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 188 Views · 9 Likes · 12 Comments

Flag

💬 Add Comment

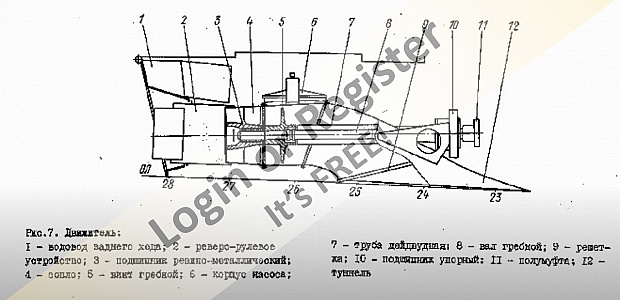

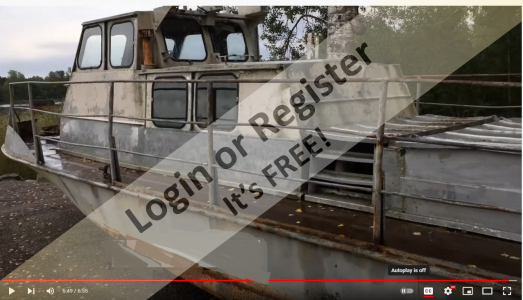

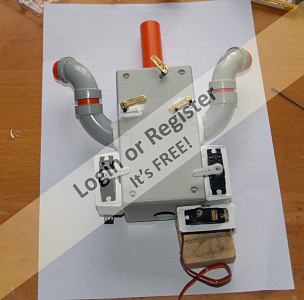

Just having a play with an idea for a model of a early Russian KS 100D general purpose work boat. These were used for river work towing logs etc in shallow rivers . The water jet is unusual, as it has a rear shute with twin rudder type deflectors, and rear hull side ports for reverse (independent controls for each port). Someone on the site mentioned a steam powered water pump driven ship from the 1800s ? a while back on the site which used a similar principal.

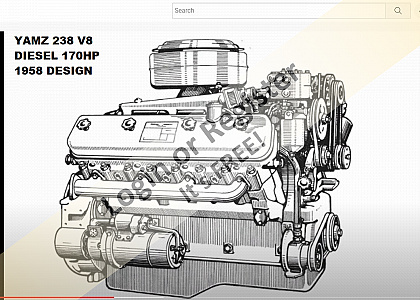

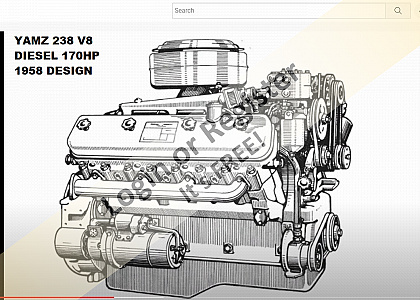

The boats were made by the Yaroslavl shipyard, and were very common in the late 50s till (I think) the 70s. Not much info on them but a few guys have rebuilt old ones for pleasure boats. They have a speed of around 16-18knts and used a Yamz 170hp V8 diesel. I've contacted (YT) a guy who has rebuilt one of these boats, and he has fitted the V6 version of this engine.

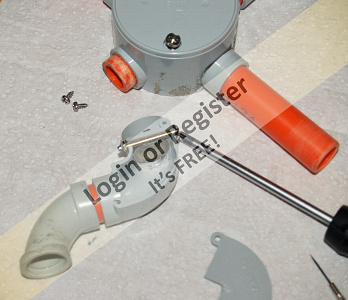

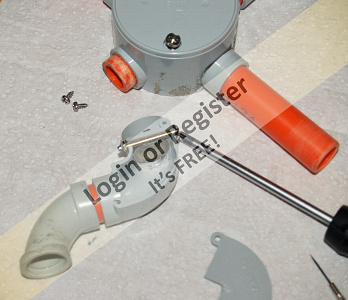

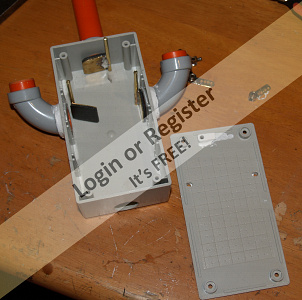

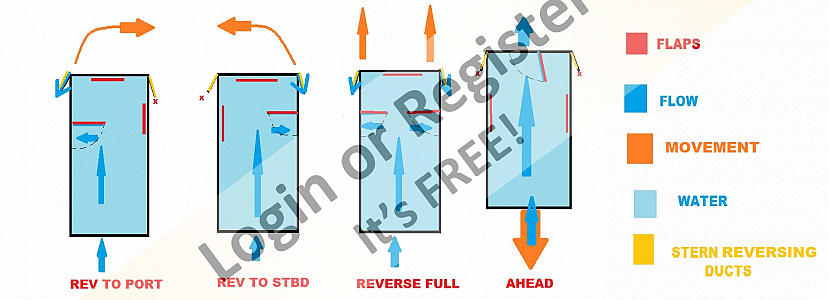

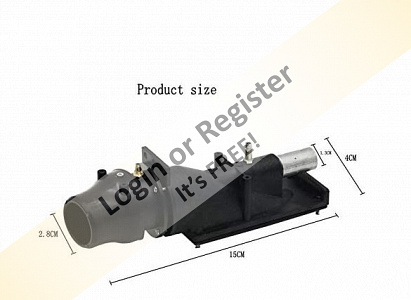

My attempt is not like the original, as there is no info on the complicated internal deflector system, so I've gone with the next best thing using modified electrical conduit fittings with flap valves. Seems to work ok, but not sealed yet so leaks like a sieve. I'd use a 26mm jet unit for the pump in front of the unit. I'll have to reduce the diameter of the side outlets to get more force behind the jets. Might have to fit the unit in a waterproof tray with a bilge pump. as I think, even though it will be sealed, it will still leak slightly round the 3 shafts.

The boats were made by the Yaroslavl shipyard, and were very common in the late 50s till (I think) the 70s. Not much info on them but a few guys have rebuilt old ones for pleasure boats. They have a speed of around 16-18knts and used a Yamz 170hp V8 diesel. I've contacted (YT) a guy who has rebuilt one of these boats, and he has fitted the V6 version of this engine.

My attempt is not like the original, as there is no info on the complicated internal deflector system, so I've gone with the next best thing using modified electrical conduit fittings with flap valves. Seems to work ok, but not sealed yet so leaks like a sieve. I'd use a 26mm jet unit for the pump in front of the unit. I'll have to reduce the diameter of the side outlets to get more force behind the jets. Might have to fit the unit in a waterproof tray with a bilge pump. as I think, even though it will be sealed, it will still leak slightly round the 3 shafts.

▲

⟩⟩

Martin555

RonBMK2

Rowen

Graham93

Dumaspittman

DWBrinkman

stevedownunder

Colin H

pressonreguardless

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 138 Views · 1 Like

Flag

Hi stotty, thanks for the suggestion. I thought about modifying the TX, but a lot of people have ended up with TXs which don't work after trying this, so I'd rather not risk it. it works ok using the pots so I think I'll keep it simple. Not sure if the jet unit idea will work sufficiently well yet,- have to wait till the jet drive arrives to see if it's worth proceeding with building a boat for it.

JB ▲

⟩⟩

Martin555

|

|

Login To

Remove Ads 💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇫🇷 stotty1111 (

Chief Petty Officer 1st Class) Chief Petty Officer 1st Class)✧ 170 Views · 1 Like

Flag

It is also possible to buy a small board to mount in the tx, this uses the pads, without a need for soldering, and it makes flashing the tx simple.

Have you looked at the ER9X.com website? ▲

⟩⟩

jbkiwi

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇫🇷 stotty1111 (

Chief Petty Officer 1st Class) Chief Petty Officer 1st Class)✧ 170 Views · 0 Likes

Flag

Hi,

Try posing a question re your mixing want on openrcforums.com in the appropriate section, omeone will no doubt be able to help --- I use ER9X and derivatives, I have always successfully rexeiver suggestions / solutions that work. There are 2 or 3 developers of the systems on the platform! ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 164 Views · 2 Likes

Flag

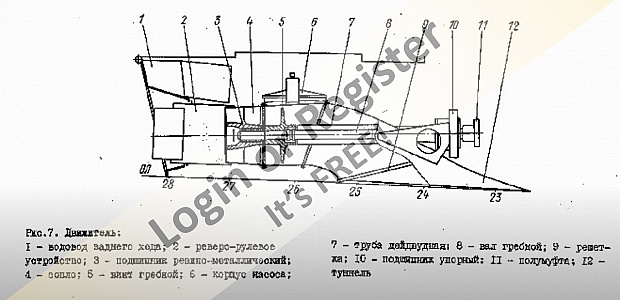

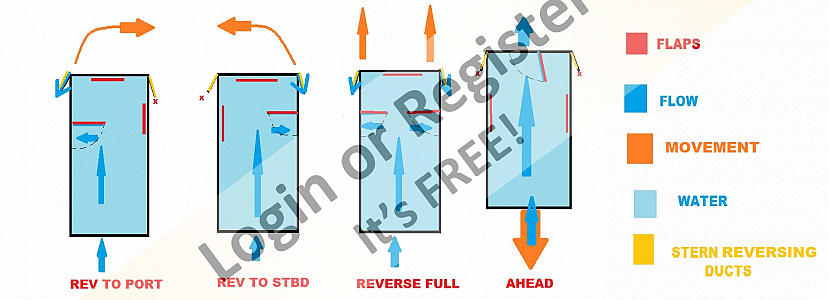

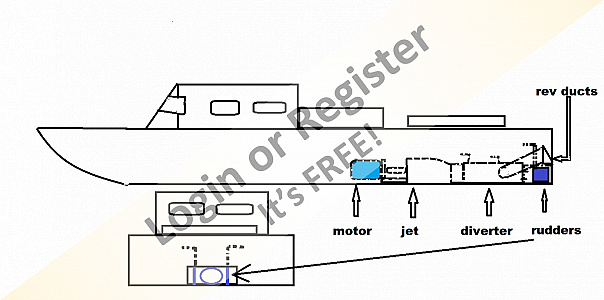

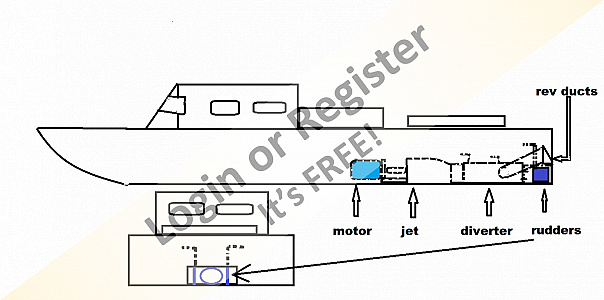

Hi Mike, problem is that you need to shift a large volume of water and need either fwd or reverse flows, with reverse using both pipes at once or side to side. The Russian jet does this with a set of flaps inside a sort of closed Y shaped box- pic 6 (No 2 in the diagram,-above the 28 are the rear rudders/flow directors, No 1 is the rev ducts)-pic 8, all individually moved with an air ram system, (a lot of Russian stuff is pneumatically operated due to the freezing conditions in a lot of places, a good example is a Yak 52 which has air everything,-start, flaps, brakes etc)

Quite a complex device,- a Hamilton jet or similar is far simpler and much more compact. JB ▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 171 Views · 2 Likes

Flag

I'm sure she would JB 😊

However very interesting project I look forward to your solutions How about using the rotating ball system as in a domestic 15/20mm shut/off valve Im sure you can get varying sizes of plastic balls these could be drilled out and then at 90 degrees a spindle through to each side of your pipe to rotate it with the servo. ▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 166 Views · 2 Likes

Flag

Sorry Mike, made them before she moved on. Have made improved MK 2 now anyhow, so sensitivity problem solved 😁. (you could have called it the Queens' contribution to modelling,- she might have even been amused.)

JB ▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 176 Views · 3 Likes

Flag

Hi JB,

Looking forward to this build. I’ll be interested to see how you solve the leakage problem 💦 ▲

⟩⟩

Martin555

jbkiwi

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 176 Views · 2 Likes

Flag

Really ! Not very thoughtful using the Queens head, bearing in mind the present circumstances please replace with a piece of brass sheet. come on JB

▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 174 Views · 2 Likes

Flag

Hi JB,

I like to work on more than one project at a time. It breaks it up for me. Trev ▲

⟩⟩

stevedownunder

jbkiwi

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 180 Views · 0 Likes

Flag

Hi JB,

Interesting project. Cheers, Stephen. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 184 Views · 3 Likes

Flag

Hi Trev, hopefully it will do the trick, but will need some refining. Not too worried about speed, just getting the the jet action working well. Just something to do alongside the Stiletto when I have time.

JB ▲

⟩⟩

Martin555

pressonreguardless

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 185 Views · 3 Likes

Flag

Looks like a great project, JB😎😎

And you already have the propulsion system worked out👍👍👍 Looking forward to the build!! Trev ▲

⟩⟩

Rowen

stevedownunder

jbkiwi

|

Login To

Remove Ads

Remove Ads

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 167 Views · 6 Likes · 4 Comments

Flag

💬 Add Comment

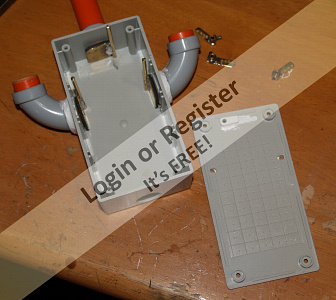

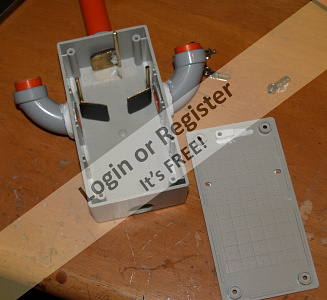

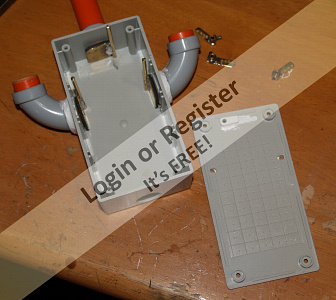

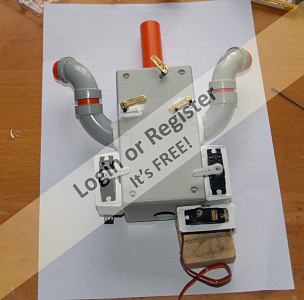

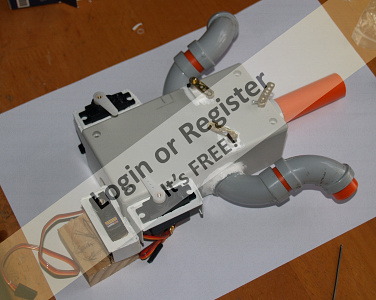

MK 2 version started now which should be an improvement. Has 3 internal flaps, rather than them being outside on the bends, which should make the shafts easier to seal as there are only 3 shaft exit holes. Might be able to use a smaller box, depending on where the screw pillars are located, as they could interfere with the shaft placement. Jet unit will hopefully be bolted to the front of the box. This version is narrower than the MK 1 which gives room to play with the reverse outlets.

▲

⟩⟩

Martin555

RonBMK2

Colin H

Graham93

stevedownunder

pressonreguardless

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 164 Views · 4 Likes

Flag

Hi Graham, definitely will need a bit of pressure, but I'll be reducing the size of the reverse outlets to give it some help. The 26mm jets put out a fair bit of pressure once modified with a 3 blade cut down racing prop, minimum blade clearance and revised intake with vertical bars like the Hartley one, so with luck it will get things moving.

I'll have to wait till I get a jet unit before I can play with pipe sizes, and I'll probably be making a dummy hull to test things on first. Re the box,- the electronics shop has lots of different types (including alloy), but the waterproof ones they have are a lot larger (and expensive!) I thought of the waterproof cell phone boxes with clip on lids (for out in the boat etc) but they are polycarbonate and very heavy. Bound to be a better box, but finding who'd sell them is the hard part. As long as this one will hold the pressure with a silicone seal, (I'll glue a wider rim inside for better coverage) it should be ok for testing/proving the idea (or not ) at least. JB ▲

⟩⟩

Martin555

Graham93

Colin H

stevedownunder

|

|

Login To

Remove Ads 💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 Graham93 (

Vice Admiral) Vice Admiral)✧ 168 Views · 3 Likes

Flag

Hi JB,

I think it is going to need a lot of water pressure to get a sufficient flow from the reverse outlets. For sealing the box, try to find an IP66 rated version. These have a built in sealing gasket for the lid. It might be difficult to find one small enough. Graham93 ▲

⟩⟩

Martin555

stevedownunder

jbkiwi

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 165 Views · 4 Likes

Flag

Hi Trev, I'd probably just use a silicone gasket, but I need to glue in some center screw lugs to tighten it down evenly. Once sorted, it shouldn't need opening that often. Might be able to mould a silicone gasket in the lid, as the sides are really too thin for an o-ring.

JB ▲

⟩⟩

Martin555

Colin H

stevedownunder

pressonreguardless

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇺🇸 pressonreguardless (

Rear Admiral) Rear Admiral)✧ 167 Views · 2 Likes

Flag

Hi JB,

Could you use 'O' rings sandwiched between two lids? Trev ▲

⟩⟩

stevedownunder

jbkiwi

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 164 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

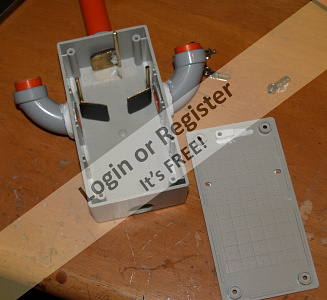

Finished the flaps, -except for a few bits of tube for spacers to stop them lifting up in the box) All seem quite airtight now with the thin sponge seals, so will get another test soon. Looking a lot better than the MK 1.

▲

⟩⟩

Martin555

pressonreguardless

Colin H

stevedownunder

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 156 Views · 3 Likes

Flag

Hi Mike, I am going to glue stops behind the flaps to stop the flaps possibly being pushed back at the end of the servo travel. This might only be necessary with the reverse flaps, although there will be no water going past them to deliver any force, (water taking the path of least resistance and the end of the box being full of water) but if I make the fwd flap open a few degrees past 90, (a bit better for flow) I'll add one behind that as well.

JB. ▲

⟩⟩

Martin555

Colin H

pressonreguardless

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 167 Views · 3 Likes

Flag

Thats looking a great improvement JB

only one observation - when water is flowing through each pipe in turn there may be excessive force trying to close the flap and maybe putting excess pressure on the servo - just a thought, the flap needs to be at exactly 90 degrees to the pipe when open ? ▲

⟩⟩

pressonreguardless

jbkiwi

stevedownunder

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 159 Views · 6 Likes · 3 Comments

Flag

💬 Add Comment

A diagram showing how this system works (for anyone scratching their heads )😁 Three flaps,- 4 operations

JB

JB

▲

⟩⟩

Martin555

Colin H

stevedownunder

mturpin013

Graham93

pressonreguardless

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇺🇸 Len1 (

Sub-Lieutenant) Sub-Lieutenant)✧ 155 Views · 1 Like

Flag

Thanks. This helps.

▲

⟩⟩

jbkiwi

|

|

Login To

Remove Ads 💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 156 Views · 2 Likes

Flag

Hi Steve, thought I'd do a diagram, as when you say that 3 flaps perform 4 functions in a jet unit, it's a bit hard to envisage. Russians do seem to have a knack for making unusual machines 😁 Beside a modern jet unit, they look pretty agricultural, but they seem to work ok.

JB ▲

⟩⟩

Martin555

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 158 Views · 2 Likes

Flag

Lovely diagram JB,

Defiantly quite a bit involved for this system. Certainly more complex than a bucket arraignment. Cheers, Stephen. ▲

⟩⟩

jbkiwi

pressonreguardless

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 156 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

Started fitting the servos, also sorting out the programming on the 9X TX, Unfortunately it's not clever enough to mix 2 Aux channels with the L&R pump outlets for single stick steering in reverse (like flaperons) I've worked it so 2 pots operate the 2 reverse nozzles independently, flap switch operates fwd flap, rudders on aileron ch and normal throttle ch.

I tried mixing the 2 rev nozzles (using the pots), with the rudder channel - switching the mixing on and off with the 3 pos sw on pos 1, but it will only operate one servo on one aux channel. You can't add pos 2 on the sw for both servos,- probably has to be on another channel. I can get both servos operating together for reverse, but it's not much use for steering.

Would have been nice to have it on one stick but it would need a non centering rudder stick, then you could add flaperons, (switched on with the 3 pos). My 9XR would probably do it all, but that's set up for planes.

I've ordered a 26mm jet unit to modify,- hopefully I can bolt it straight onto the front of the box.

I tried mixing the 2 rev nozzles (using the pots), with the rudder channel - switching the mixing on and off with the 3 pos sw on pos 1, but it will only operate one servo on one aux channel. You can't add pos 2 on the sw for both servos,- probably has to be on another channel. I can get both servos operating together for reverse, but it's not much use for steering.

Would have been nice to have it on one stick but it would need a non centering rudder stick, then you could add flaperons, (switched on with the 3 pos). My 9XR would probably do it all, but that's set up for planes.

I've ordered a 26mm jet unit to modify,- hopefully I can bolt it straight onto the front of the box.

▲

⟩⟩

Martin555

Colin H

pressonreguardless

stevedownunder

Graham93

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 155 Views · 3 Likes

Flag

Hi Steve, thanks for the suggestion. My 9x is an early one and hasn't got a data port (just a trainer plug). I think if you want to do anything with these, you have to use the pads on the board. Early on, a number of people on the HK forums, tried downloading upgrades etc and killed their TXs, so I'm not game to give it a go. You have to know what you are doing with that. There were instructions with pics on the HK site, but it's all gone now. It's not as nice using the pots, but for the amount the model will be used, it will have to do for now, (not even sure if the jet will work yet😁)

JB ▲

⟩⟩

Martin555

pressonreguardless

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 154 Views · 2 Likes

Flag

Hi JB,

Have you got Open TX Companion this is a great free program that allows you to program your 9X and other TXs on a computer then download the program onto the 9X. Maybe that might help. Cheers, Stephen. ▲

⟩⟩

pressonreguardless

jbkiwi

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 153 Views · 5 Likes

Flag

💬 Add Comment

Finally got a chance to give the MK2 version a test after spending the morning doing car repairs. Going to have to be seriously waterproofed and screwed together, as the box is a bit flimsy on high pressure with all the valves shut (to be expected) I have center lid screw pads glued in which will help hold the center of the lid in place. Will have to make sure at least one of the valves is open under power. Better than MK 1 at least

I Might see if I can find a small adjustable relief valve which can prevent over pressurising. All the outlets will be reduced in diameter to help with pressure. Won't know how it will perform till the jet is bolted to it and tested in water. Getting there slowly, but needs perfecting before committing to a boat to put it in.

I Might see if I can find a small adjustable relief valve which can prevent over pressurising. All the outlets will be reduced in diameter to help with pressure. Won't know how it will perform till the jet is bolted to it and tested in water. Getting there slowly, but needs perfecting before committing to a boat to put it in.

▲

⟩⟩

Martin555

pressonreguardless

Colin H

Graham93

stevedownunder

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 146 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

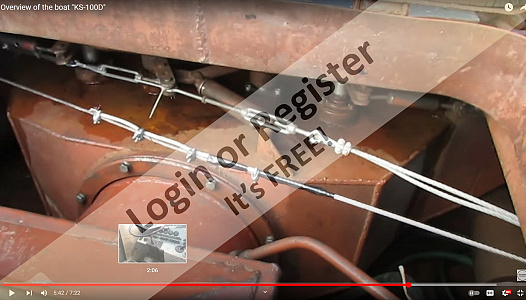

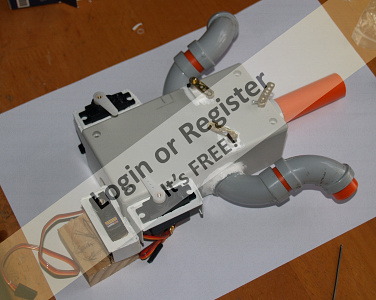

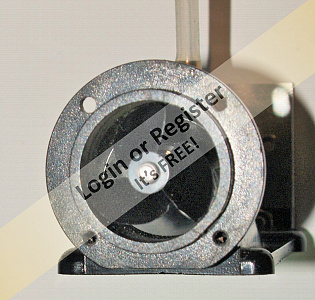

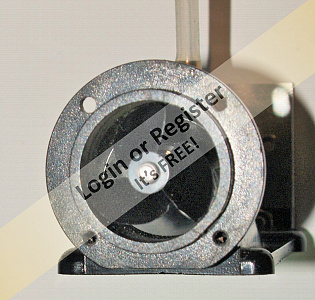

Jet unit arrived from Ali Exp in record time,-6 days ! Drilled out the end of the box and fitted the 26mm jet unit to the front end. I'll need a spacer or 2.5mm O ring to fill the gap, as the box is only 2mm thick. Modified the jet the same way as the Hartley model, by drilling and tapping the lower body screw holes for M3 machine screws, (bit of dremeling required) and the drilling the motor mount lower screw holes and plate for M3 x 10mm machine screws and nuts. The cheap self tapping screws are rubbish and will rust easily, making them impossible to remove later. Stainless cap screws would be even better.

The end of the motor needs supporting with these, as the mount plastic is thin and flexible. When I modified the previous unit, I filled the slot with resin to beef it up a bit.

Have also glued internal tabs and now can screw the center of the lid down, as it was bowing under water pressure. The unit will have to be glued together once everything is ready, as I don't think silicone will be enough of a seal. Easy enough to get apart if necessary. I found a couple of tiny O rings (from an old pressure sprayer trigger) to go under the servo arms (need 1 more) which should stop any leaks. Where the flap shafts go through the box at the bottom, I've glued plates over them.

The bottom screws on the jet inside, were accessed by drilling 5mm holes in the exit end of the box for a long shaft Philips screwdriver, and will be sealed once everything is ready, (plastic plate glued on the inside, re drilled if necessary for service).

The impeller will need modifying as well and the shaft will be grooved for a circlip where it exits the front bearing, to replace the coil spring. The coupler will go in the bin, (sloppy fit) and I'll make one of my own again. Intake grill will be remade as well with vertical bars.

If anyone is interested in the mods, they are all on my Hartley build blog. Worth doing, as they make a big difference in performance.

Hopefully the jet will move enough water for this to work, if not it's plan B.

The end of the motor needs supporting with these, as the mount plastic is thin and flexible. When I modified the previous unit, I filled the slot with resin to beef it up a bit.

Have also glued internal tabs and now can screw the center of the lid down, as it was bowing under water pressure. The unit will have to be glued together once everything is ready, as I don't think silicone will be enough of a seal. Easy enough to get apart if necessary. I found a couple of tiny O rings (from an old pressure sprayer trigger) to go under the servo arms (need 1 more) which should stop any leaks. Where the flap shafts go through the box at the bottom, I've glued plates over them.

The bottom screws on the jet inside, were accessed by drilling 5mm holes in the exit end of the box for a long shaft Philips screwdriver, and will be sealed once everything is ready, (plastic plate glued on the inside, re drilled if necessary for service).

The impeller will need modifying as well and the shaft will be grooved for a circlip where it exits the front bearing, to replace the coil spring. The coupler will go in the bin, (sloppy fit) and I'll make one of my own again. Intake grill will be remade as well with vertical bars.

If anyone is interested in the mods, they are all on my Hartley build blog. Worth doing, as they make a big difference in performance.

Hopefully the jet will move enough water for this to work, if not it's plan B.

▲

⟩⟩

Martin555

Graham93

pressonreguardless

stevedownunder

GaryLC

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 143 Views · 3 Likes

Flag

Hi Steve, more a proof of concept, but the theory is, that the water will take the path of least resistance and 'go with the flow' when the box is full😁. Seems to work ok with the hose, so hoping the jet will have enough grunt. If it works ok, I'll build the boat, ( I have purchased items for plan B -just in case.)

JB ▲

⟩⟩

Martin555

pressonreguardless

stevedownunder

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 144 Views · 1 Like

Flag

Hi JB,

Great stuff, the only thing that bothers me is how much turbulence that will be created within the box. Are you thinking of rounding off some of the internal edges or is this more a proof of concept? Cheers, Stephen. ▲

⟩⟩

jbkiwi

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 146 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

Have added another mod to the jet unit to give it more go, as I did with a previous model. First thing was replacing the small self tapping screws supplied and replacing them with 3mm machine screws (as described in the last post). Next was the prop which is just a std 3 blade 26mm with round tips and a .6mm tip gap. This is useless for jet efficiency, as half the thrust is lost round the tip clearance. This was replaced with a cut down RH 30mm racing prop which has a better rake. It was drilled to 4mm from a 3mm shaft hole to suit the jet shaft.

The prop was fitted to the shaft and placed in the unit, and the blades marked for the diameter. They were them carefully cut and sanded for a close fit. When this is done, the flow correcting vanes needed cutting back to miss the blade tips, as well as sanding the front of the hub to gain a bit more clearance. A circlip or collar is needed at the front of the shaft to prevent any movement backwards.

There is also an important mod for the flat strip intake grill, (ie make a new one),- as this restricts and disturbs the flow a lot (see the mod in my Hartley blog if you are interested) a bit of work but well worth it. With the mods, the jet loaded 30A on the motor shown (last post) Surpass F540 36/50 3000kv brushless) in the Hartley model, which weighs around 6kg,- a lighter boat will draw less). Before the mods it was around 20A and no real performance.

To get the best from these cheap jets you need power, around 3000kv, 36/50 motor or similar on 2/4s LiPo, and a few mods. Smoothness and speed of flow is king. Another mod I'd like to try, is making a ball end for the output to fit into the steering nozzle, as these units lose efficiency with the huge gap, (draws in air and aerates the flow,- you need a solid flow not foam). There should be a minimum gap there as well, especially when in reverse, as a lot of water gets lost there.

The prop was fitted to the shaft and placed in the unit, and the blades marked for the diameter. They were them carefully cut and sanded for a close fit. When this is done, the flow correcting vanes needed cutting back to miss the blade tips, as well as sanding the front of the hub to gain a bit more clearance. A circlip or collar is needed at the front of the shaft to prevent any movement backwards.

There is also an important mod for the flat strip intake grill, (ie make a new one),- as this restricts and disturbs the flow a lot (see the mod in my Hartley blog if you are interested) a bit of work but well worth it. With the mods, the jet loaded 30A on the motor shown (last post) Surpass F540 36/50 3000kv brushless) in the Hartley model, which weighs around 6kg,- a lighter boat will draw less). Before the mods it was around 20A and no real performance.

To get the best from these cheap jets you need power, around 3000kv, 36/50 motor or similar on 2/4s LiPo, and a few mods. Smoothness and speed of flow is king. Another mod I'd like to try, is making a ball end for the output to fit into the steering nozzle, as these units lose efficiency with the huge gap, (draws in air and aerates the flow,- you need a solid flow not foam). There should be a minimum gap there as well, especially when in reverse, as a lot of water gets lost there.

▲

⟩⟩

Martin555

CB90

pressonreguardless

stevedownunder

Graham93

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 139 Views · 3 Likes

Flag

Hi Roy, I think the jets are just like most of the Chinese stuff and not accurately made. The jet units I have are just the same (hole is out of round). I ended up making my own couplings as I couldn't find an accurately bored coupling. The shafts on motors etc seem to be ok, but they stuff all their couplings up, (far too much slop for high revs) They also mix imperial and metric sizes for shafts which is a major pain in the butt, 1/8", 4mm and 5mm for common motors.

Pretty sure the couplings are drilled to size not reamed, as the slop suggests that, (I've tried every type of coupling on Ali Exp, and they are all the same (best of them was the TFL brand, but still vibrated too much) Bought some 3mm and 4mm reamers from Ali Exp and my couplings are a firm fit with no play. Makes all the difference to noise. The best looking Chinese jet units are sold by Ocean Works in HK. JB ▲

⟩⟩

Martin555

stevedownunder

pressonreguardless

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 CB90 (

Commander) Commander)✧ 142 Views · 2 Likes

Flag

Thanks to reading your water jet mods I have been lucky to find two contra rotating props (one left handed and one right handed) at 40mm diameter in my prop box, both 4mm centred and dog fitments.

only 2 bladed, and about the same depth as the original so no cutting back the stator. Using a pillar drill I inserted the short 4mm shaft into the chuck, gave it a spin and used a sandpaper sheet glue to a block of wood to grind them down to size. Unsurprisingly they had to be made a little smaller than I would have liked due to the fact that the shafts were not perfectly central in the jet tube. I wonder if the ones of this type with the small prop, were a way of making the rejects (impeller binding due to shaft misalignment) saleable. regards Roy

▲

⟩⟩

stevedownunder

jbkiwi

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 141 Views · 7 Likes · 5 Comments

Flag

💬 Add Comment

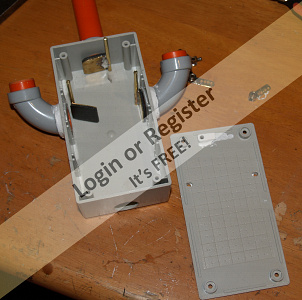

Had a sudden surge of electrons in the grey matter while looking at a spare fitting, a few nights back, and now there is the flow director MK3. Half the size now, - 60x70mm (as small as it can go) and looking like having a better reverse flow with everything closer together. The 2 'T' pieces are glued and filled back to back, with the bottoms inside milled flat for the flaps, and channels milled in the sides for the shafts. A bit of external filling was required, as it was necessary to mill through the body in places to get it all flat, due to the small size.

I made a one piece 4mm Perspex lid for it, as the 2 original lids were a bit thin, and radiused where they needed to be flat. I've left the lid a bit oversize, as I may need to screw something like pushrod guides on later. The idea is, that this and the jet will be mounted on a ply base, and incorporated into the hull (as I did with the Hartley cabin jet model)

The whole thing cost around $6, and around a day mucking around with it, so a very cheap experiment. Will give it the hose test once it stops raining here.(if it ever will)

I made a one piece 4mm Perspex lid for it, as the 2 original lids were a bit thin, and radiused where they needed to be flat. I've left the lid a bit oversize, as I may need to screw something like pushrod guides on later. The idea is, that this and the jet will be mounted on a ply base, and incorporated into the hull (as I did with the Hartley cabin jet model)

The whole thing cost around $6, and around a day mucking around with it, so a very cheap experiment. Will give it the hose test once it stops raining here.(if it ever will)

▲

⟩⟩

Martin555

philcaretaker

Colin H

GaryLC

stevedownunder

Graham93

pressonreguardless

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 138 Views · 3 Likes

Flag

Hi Roy, actually doesn't flow too badly,- (no bubbles) and flows through as fast as the hose on full. Won't really know if its any good until I can hook the jet to it. The main thing is to get it looking the part, not too fussed about performance (yet) Definitely will need sealing well and a few more screws, and maybe some reinforcement strips round the lid. I 've added a plate in the exit 'chamber' which is parallel to the flap when it's fully open, to channel the water evenly (see latest post)

JB ▲

⟩⟩

Martin555

pressonreguardless

Colin H

|

|

Login To

Remove Ads 💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 CB90 (

Commander) Commander)✧ 138 Views · 3 Likes

Flag

Hi JB,

Nice job will be great to be able to see the inside of the distribution box when it in operation, perhaps some colour dye in the water to see any flow improvements that could be made, or not. But make sure its not permanent dye or you could look a mess if you spring a leak!😉 regards Roy ▲

⟩⟩

stevedownunder

Colin H

jbkiwi

|

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi (

Fleet Admiral) Fleet Admiral)✧ 138 Views · 0 Likes

Flag

Hi Mike, it had better work well after that !😁

JB ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇦🇺 stevedownunder (

Captain) Captain)✧ 140 Views · 0 Likes

Flag

Looks great JB,

Looking forward to seeing the hose test. Cheers, Stephen. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

💬 Re: Russian K100D waterjet work boat project

2 years ago by 🇬🇧 mturpin013 (

Admiral) Admiral)✧ 147 Views · 2 Likes

Flag

Great job JB Im sure people will copy this design, its really a great piece of work, be careful its not picked up by a manufacturer

▲

⟩⟩

jbkiwi

stevedownunder

|

📝 Russian K100D waterjet work boat project

2 years ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 140 Views · 7 Likes

Flag

💬 Add Comment

Glued on the sponge flap seals today and gave it a bit of a test with the hose (no vid sorry as it was drizzling all day) and it all works well. As mentioned , I'll only know how effective it will be once I get it sealed and try the jet on it. I'll also have to play with nozzle sizes for the best effect.

I decided to try the glass on foam approach for the hull, as It's a lot quicker than a built up one to do. I did it with a 40" tug about 1980 and it worked very well. Picked up a 2400x1200x50mm sheet of polystyrene from the hardware,($36) and had the basic hull form done in about an hour for a cost of around $3 and still have 1-3/4 half sheets left for more projects - (or a stand up paddleboard for a rescue boat😁)

2x 36"x11"x 50mm sheets were laminated using polystyrene safe contact glue and surformed and sanded to shape. The hull will have pre drilled and shaped ply inserts for the jet/diverter and jet rudder box and a ply transom fitted before fiberglassing, and any cutouts made above the jet/motor plate etc made at that stage (will save trying to dig the foam out later). The hull will have a good coating of PVA and maybe tissue to prevent the Polyester resin eating the foam. The whole hull and deck will be glassed, with cutouts made under the cabin (cabin will be balsa) later for R/C gear etc.

I decided to try the glass on foam approach for the hull, as It's a lot quicker than a built up one to do. I did it with a 40" tug about 1980 and it worked very well. Picked up a 2400x1200x50mm sheet of polystyrene from the hardware,($36) and had the basic hull form done in about an hour for a cost of around $3 and still have 1-3/4 half sheets left for more projects - (or a stand up paddleboard for a rescue boat😁)

2x 36"x11"x 50mm sheets were laminated using polystyrene safe contact glue and surformed and sanded to shape. The hull will have pre drilled and shaped ply inserts for the jet/diverter and jet rudder box and a ply transom fitted before fiberglassing, and any cutouts made above the jet/motor plate etc made at that stage (will save trying to dig the foam out later). The hull will have a good coating of PVA and maybe tissue to prevent the Polyester resin eating the foam. The whole hull and deck will be glassed, with cutouts made under the cabin (cabin will be balsa) later for R/C gear etc.

▲

⟩⟩

Martin555

philcaretaker

GaryLC

Graham93

stevedownunder

pressonreguardless

Colin H

New Zealand

New Zealand