|||

|

|

🗝 Login

🤖 Create Account

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Plans & Docs

• Useful Links

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (7,851)

📖 Quick Site Guide

📣 Support

👥 Membership

Hobby Supplies

🛍️ Online Shop

Not Registered

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

For A Whole Year!

£25

£45

£65

Donate

You Will Be Helping Towards:

Domain Fees

Security Certificates

iOS & Android App Fees

Website Hosting

Fast Servers

Data Backups

Upkeep & Maintenance

Administration Costs

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Model Boats Website

Home

Forum

Build Blogs

Media Gallery

Boat Clubs & Lakes

Events

Boat Harbour

How-To Articles

Plans & Docs

Useful Links

Welcome to the Model Boats Website! A place for all model boaters!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Login To

Remove Ads

Remove Ads

Today's Question

What instrument is used to measure the speed of a boat through water?

ANSWER >>

>

Today's Wordle

7 LETTERS

>

Trending Now

Forum

THE MOST ORIGINAL, STRANGE AND FAILURE SHIPS EVER BUILT IN THE WORLD.

Thanks Alessandro , I'll certainly post some photos when completed, "before and after ". The existing boat shed is now too small. My stepson was in the process of moving rental accommodation recently and wondered if I could make use of some timber. Duly delivered, I was wondering what I could do with it all, a quick measure by hand ️ and realised that I could potentially now bridge the gap between house and garage hence another "home project "to finally cross of the list. Maybe one day...

🇬🇧 Doogle

14 minutes ago

Harbour

Re: Dart Belle Paddle Steamer.

Hello Colin.

I had seen this RC model some time ago but I no longer remembered that you also had a boat with paddle wheels.

Recently there has been talk about these models and their lack of governability.

In your case, however, there should be no problems because the hull is not flat but is a classic hull.

It can steer both with the rudder and with the use of the wheels that turn differently from each other, even without the rudder. Did I get it right?

🇮🇹 AlessandroSPQR

40 minutes ago

Forum

Dating ?????

I agree with the deletion of your original post. I read it and thought it wan not appropriate here.

There is absolutely no privacy on the internet. So whatever folks type even in private gets hacked and info is spread all over including criminals.

So if you want to meet someone with similar interests in the hobby, you need to do it on a one to one method. Lacking that, you need to seek out a club and meet folks in person. lacking that, then you are SOL.

It is OK to post specific technical questions.

My opinion.

Isaac

🇺🇸 Isaac

48 minutes ago

Forum

Question of the Day?

I think I may have to bow out of this Quiz.

If only to see how my new 'mit Quizzer' fairs.

Although my personal score is 90%, and has been for several days, since the last disastrous (for me) sailing questions, the Germany score has dropped and dropped to 79% and 9th place. I'm being sabotaged️ Never before has Germany recorded 8 wrong answers.

My worst was 5.

For the record I was correct today. OK I had an advantage having worked on many ship COMMS systems over a 40 year span. Including interfacing the Ship's Log to the radio systems.

Mind you, most ships these days rely on GPS to monitor speed and position - and then send the data to the Log recorder, equivalent of the 'Black Box' Flight Data Recorder on aircraft. Even the smallest boat can now be fitted with an inexpensive GPS receiver to do this.

Traditionally the LOG in nautical terms (or Logbook in earlier days) is simply a record of events in the operation of a ship; position, speed, arrivals departures, sightings, collisions, sinkings️ etc etc.

Cheers All, Doug

🇩🇪 RNinMunich

2 hours ago

Harbour

Re: Graupner Commodore

Elegant boat.

I really like the name "Centurion".

All that remains is to admire the RC navigation.

🇮🇹 AlessandroSPQR

6 hours ago

Blog

Re: Ballast Question

More than right, Jock.

I look forward to enjoying the developments of ESSO Deutschland.

🇮🇹 AlessandroSPQR

7 hours ago

Harbour

Re: Lulonga River Tug

Hello Tim, my boat uses one geared motor linked to the paddle wheels via a chain drive. Steering is very effective by making a clip on rudder extension. The driven paddle wheels are very effective at driving the boat. Be a shame to have paddles that just freewheel although I have seen this done on another model. My paddles sit just deepening to bite into the water. It also reverses quite well, much to my surprise! My hull does have shallow keel strips about 8 mm running fore to aft. Hope this helps. Tony

🇬🇧 wmbc40

11 hours ago

Harbour

Re: HMS Bluebell.

A lovely looking vessel scratch builder, as lewz commented on your weathering-great job. Personally on the weathering front, I like to add a touch to my boats; not only do I think it adds a touch of realism alongside figures, it also helps to cover up some of my mistakes

🇬🇧 Doogle

12 hours ago

Forum

Vertical boiler identification

Yea really sorry i missed this one. I have a Midwest fantail launch that I lengthened by 8 inches amidships and this would have been perfect for it. This body of this one was 3" diameter and 7" tall.

Hoping someone here has an idea who made this one or possibly has one or one similar they might be interested in selling.

🇺🇸 algon

16 hours ago

Forum

Wordle of the Day?

Learned the art of warfare on 4 with a clue

🇺🇸 Cashrc

20 hours ago

Forum

Looking for help identifying....

Looking for help identifying this vertical boiler. It was listed on ebay over the weekend and I missed bidding on it. Is this an early PM Research vertical boiler? If anyone knows or maybe has one like it for sale I am interested.

🇺🇸 algon

1 day ago

Forum

Aerokits pt boat bulkhead plans wanted

Glad you got sorted then and it's always good if folks post about their builds, even if just when completed.

🇬🇧 ChrisF

1 day ago

Forum

Calling it a day.

Bill, so sorry to hear the sad news. I am not a very wordy guy so I just want to echo the words and thoughts that have already been expressed.

Len

🇺🇸 Len1

1 day ago

Blog

Re: Russian K100D waterjet work boat

Hi LD, re air horns, odd thing is, they seem to prefer sirens on Russian boats. Hydrofoils, ferries etc all seem to have them. Also the 'ears' above the nav lights on this boat house front and back strobe lights for signaling various activities. I wondered what they were for when building the model, and a guy in the comments on the Russian YT channel ( showing the restoration of one) who had owned that model of boat, told me what they were for.

Added info,- boats are powered by a 165hp Yamz 238 V8 165hp diesel, set up as standard in a truck, ie radiator, fan etc, no connection to outside water.

JB

🇳🇿 jbkiwi

1 day ago

Forum

I miss Graupner!!! And Robbe too.

Hi cashrc, I have a small line drawing of full size changes which I was going to do myself but happy to share.

It looks like the update to the class I think it was Nos. 3, 8, and 11. A guess at mid 80s.

The Graupner kit was issued in 1974 and maybe one of the longest continuous runs of the same kit ever.

I can tell you a bit about Bugsier if you are interested as they are now the largest Towing company in the world, all done on English money!

Roy

🇬🇧 roycv

2 days ago

Forum

Useful Battery ???

Boatshed, as I'm not a speed freak, most of my boats run on 12v 7ah sla's, some have 2 of these giving me a good day out on the water. As LiFePO4 Battery is almost half the weight of sla's and the lifespan is greater the extra cost is well worth it for me.

Cheers Colin.

🇬🇧 Colin H

2 days ago

|

New Member

United Kingdom

KevinM

KevinM2 hours ago

New Member

United Kingdom

RobertH

RobertH11 hours ago

New Promotion

Chief Petty Officer 2nd Class

tim morland

tim morland1 day ago

New Member

United States

sjk

sjk1 day ago

New Member

Canada

SteveS1

SteveS12 days ago

New Member

United States

DavidF1

DavidF12 days ago

New Member

Belgium

janc

janc2 days ago

New Member

United Kingdom

WilliamS1

WilliamS12 days ago

New Member

United Kingdom

AlanS3

AlanS33 days ago

New Member

United Kingdom

FredE1

FredE13 days ago

New Promotion

Leading Seaman

wmbc40

wmbc403 days ago

New Member

United Kingdom

TommyT1

TommyT13 days ago

New Member

United Kingdom

KenC1

KenC13 days ago

New Member

United Kingdom

KenV

KenV3 days ago

New Member

Australia

Pdjones

Pdjones3 days ago

New Member

United Kingdom

malcolmr1

malcolmr14 days ago

New Member

Australia

PhillipH

PhillipH4 days ago

New Member

United Kingdom

JaneA

JaneA5 days ago

New Member

Turkey

MehmetAliB

MehmetAliB5 days ago

New Member

Australia

GeoffA1

GeoffA15 days ago

Birthday This Week

Turns 70

RossM

RossM5 days ago

Birthday This Week

Turns 46

Schmango

Schmango5 days ago

New Member

United States

CJ

CJ5 days ago

New Member

Slovakia

RomanS

RomanS5 days ago

New Member

United Kingdom

TonyF1

TonyF15 days ago

New Member

United States

Colin B Waitt

Colin B Waitt5 days ago

New Member

United States

fbcmhall

fbcmhall5 days ago

Birthday This Week

Turns 77

Lauriem

Lauriem6 days ago

New Member

United Kingdom

JollyRoger

JollyRoger6 days ago

New Member

United Kingdom

PhilipP

PhilipP6 days ago

New Member

United Kingdom

michaeld1

michaeld16 days ago

New Member

Switzerland

maran49

maran496 days ago

New Member

United Kingdom

jacks

jacks7 days ago

New Member

United Kingdom

georgeC2

georgeC28 days ago

New Member

United Kingdom

JohnJ1

JohnJ19 days ago

New Member

United Kingdom

Geoffreym1

Geoffreym19 days ago

New Member

Spain

JosLuisB

JosLuisB9 days ago

New Promotion

Midshipman

EdW

EdW10 days ago

New Member

Argentina

MatiasO

MatiasO10 days ago

New Member

United Kingdom

BridgetH

BridgetH10 days ago

New Member

United Kingdom

Jim1

Jim110 days ago

New Member

United States

DanO

DanO11 days ago

New Promotion

Able Seaman

Steves-s

Steves-s11 days ago

New Promotion

Captain

Brightwork

Brightwork11 days ago

Birthday This Week

Turns 67

Stephen T

Stephen T12 days ago

Birthday This Week

Turns 79

Robert 87

Robert 8712 days ago

New Member

Germany

UlfF

UlfF12 days ago

New Promotion

Leading Seaman

impartit

impartit12 days ago

See More

Forum Topics

THE MOST ORIGINAL, STRANGE AND FAILURE SHIPS EVER BUILT IN THE WORLD.

Thanks Alessandro 😊, I'll certainly post some photos when completed, "before and after ". The existing boat shed is now too small. My stepson was in the process of moving rental accommodation recently and wondered if I could make use of some timber. Duly delivered, I was wondering what I could do with it all, a quick measure by hand ✋️ 😀 and realised that I could potentially now bridge the gap between house and garage hence another "home project "to finally cross of the list. Maybe one day...😂

14 minutes ago by 🇬🇧 Doogle ( Commodore)

Commodore)

Commodore)

Commodore)

General Resources

22 Posts

96 Likes

96 Likes

Started

10 days ago

by AlessandroSPQR

10 days ago

by AlessandroSPQR

Latest

14 minutes ago

by Doogle

14 minutes ago

by Doogle

Dating ?????

I agree with the deletion of your original post. I read it and thought it wan not appropriate here.

There is absolutely no privacy on the internet. So whatever folks type even in private gets hacked and info is spread all over including criminals.

So if you want to meet someone with similar interests in the hobby, you need to do it on a one to one method. Lacking that, you need to seek out a club and meet folks in person. lacking that, then you are SOL.

It is OK to post specific technical questions.

My opinion.

Isaac

48 minutes ago by 🇺🇸 Isaac ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)

Non-Hobby Chat

3 Posts

9 Likes

9 Likes

Started

4 hours ago

by Wolle

4 hours ago

by Wolle

Latest

48 minutes ago

by Isaac

48 minutes ago

by Isaac

Question of the Day?

I think I may have to bow out of this Quiz.

If only to see how my new 'mit Quizzer' fairs.

Although my personal score is 90%, and has been for several days, since the last disastrous (for me🤔) sailing questions, the Germany score has dropped and dropped to 79% and 9th place.😭 I'm being sabotaged☹️ Never before has Germany recorded 8 wrong answers.

My worst was 5.

For the record I was correct today. OK I had an advantage having worked on many ship COMMS systems over a 40 year span. Including interfacing the Ship's Log to the radio systems.

Mind you, most ships these days rely on GPS to monitor speed and position - and then send the data to the Log recorder, equivalent of the 'Black Box' Flight Data Recorder on aircraft. Even the smallest boat can now be fitted with an inexpensive GPS receiver to do this.

Traditionally the LOG in nautical terms (or Logbook in earlier days) is simply a record of events in the operation of a ship; position, speed, arrivals departures, sightings, collisions, sinkings☹️😭 etc etc.

Cheers All, Doug😎

2 hours ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Website Related

2394 Posts

6108 Likes

6108 Likes

Started

1 year ago

by fireboat

1 year ago

by fireboat

Latest

2 hours ago

by RNinMunich

2 hours ago

by RNinMunich

Vertical boiler identification

Yea really sorry i missed this one. I have a Midwest fantail launch that I lengthened by 8 inches amidships and this would have been perfect for it. This body of this one was 3" diameter and 7" tall.

Hoping someone here has an idea who made this one or possibly has one or one similar they might be interested in selling.

16 hours ago by 🇺🇸 algon ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

For Sale/Wanted

3 Posts

7 Likes

7 Likes

Started

1 day ago

by algon

1 day ago

by algon

Latest

16 hours ago

by algon

16 hours ago

by algon

Wordle of the Day?

Learned the art of warfare on 4 with a clue

20 hours ago by 🇺🇸 Cashrc ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)

Website Related

1289 Posts

2644 Likes

2644 Likes

Started

10 months ago

by fireboat

10 months ago

by fireboat

Latest

20 hours ago

by Cashrc

20 hours ago

by Cashrc

|

|

Login To

Remove Ads

Remove Ads

Build Blogs

6 Posts

9 Followers

47 Likes

Scratchbuilt Esso Deutschland 1:150

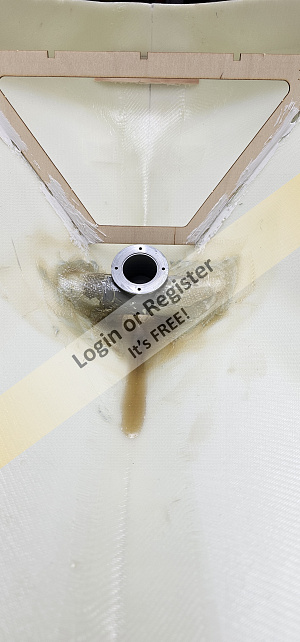

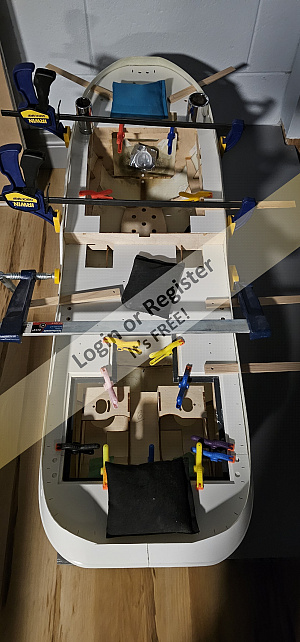

When I first posted a thread under ... a dreamproject.. I didn't realize it was the wrong forum category. So here is my built blog. I will spare you the original introduction as I have made progress which and most of you are already familiar with my project.

The hull was built merging 2 methods on a simple keel plate from plywood, bow and stern structure bread and butter and hull in between 3mm planks on frame.

The entire main deck is intended to be removable with a drainage irrigation system of plastic corner moulding (from a building supplier) along top of hull and flush at poop and back deck structure. The deck is made of 1/4" plywood skeletal structure incorporating midship deckhouse. Hull glassed with lightest cloth available after 2 coats 2-epoxy sealer and paint primer followed by final coat except top (above waterline) grey will be applied once I have finished doing any necessary adjustments. There have been a lot of them since I realized many inaccuracies in dims etc. I wasn't happy with.

Here are photos in the progress (some may have already been posted in the original post.

More a bit later next week.

🇨🇦 JockScott

19 hours ago

86 Posts

25 Followers

621 Likes

Russian K100D waterjet work boat project

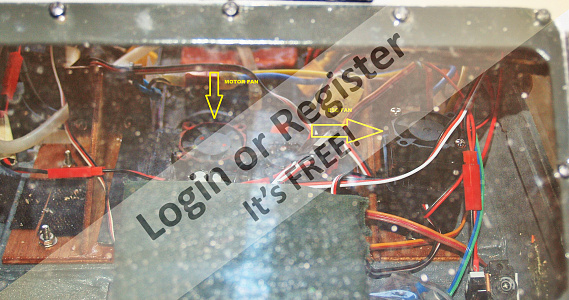

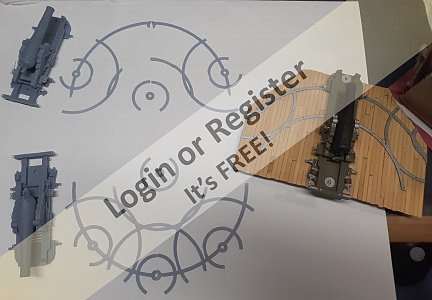

Just having a play with an idea for a model of a early Russian KS 100D general purpose work boat. These were used for river work towing logs etc in shallow rivers . The water jet is unusual, as it has a rear shute with twin rudder type deflectors, and rear hull side ports for reverse (independent controls for each port). Someone on the site mentioned a steam powered water pump driven ship from the 1800s ? a while back on the site which used a similar principal.

The boats were made by the Yaroslavl shipyard, and were very common in the late 50s till (I think) the 70s. Not much info on them but a few guys have rebuilt old ones for pleasure boats. They have a speed of around 16-18knts and used a Yamz 170hp V8 diesel. I've contacted (YT) a guy who has rebuilt one of these boats, and he has fitted the V6 version of this engine.

My attempt is not like the original, as there is no info on the complicated internal deflector system, so I've gone with the next best thing using modified electrical conduit fittings with flap valves. Seems to work ok, but not sealed yet so leaks like a sieve. I'd use a 26mm jet unit for the pump in front of the unit. I'll have to reduce the diameter of the side outlets to get more force behind the jets. Might have to fit the unit in a waterproof tray with a bilge pump. as I think, even though it will be sealed, it will still leak slightly round the 3 shafts.

https://youtu.be/7Lgb7hH6ln8

https://www.youtube.com/watch?v=altwiMdZlIA

https://www.youtube.com/watch?v=yWSI8moMeZg&t=33s

https://www.youtube.com/watch?v=87PsJVdPNhE

https://www.youtube.com/watch?v=CQ3U7XmeG1A (similar later model showing manoeuvrability)

https://www.youtube.com/watch?v=hblw4_44FB8

The big lid on the jet is for clearing weed or similar which might get into the unit.

🇳🇿 jbkiwi

2 days ago

2 Posts

3 Followers

14 Likes

52' Motor Lifeboat Victory

One of my nine-year projects is coming to an end. I am sad to see it completed in some ways, overjoyed in others. Many projects have been begun and shelved over those nine years; some are in the trash now.

What is known is the 213' WMEC-168 Yocona is hit or miss whether my attempts to waterproof a static hull will be successful. So on hold or a side project.

The Gunboat Philadelphia is on-going at work between shifts.

PBY that doesn't Fly I will place on hold, pending possible actual flight. (That will put three aircraft inline to be completed.)

The battleship North Carolina....Big. Not so complex as physically large undertaking.

SO, begin at the beginning as I tell my students. I pondered purchasing the laser-cut kit from Canada, but it is just frames, deck, and pilothouse. Yes, it is 1" to one foot scale, and would match my 44' MLB perfectly, but $286 plus shipping? For me too much, I will build at 1/24th scale for now. Small enough to store, big enough to detail and outfit with running gear.

My 44 MLB, is a leaky, but I am installing an automatic bilge pump. I get so much joy out of running it, and I will have the tri-fecta of MLB's 36', 44', and 52'. The 213 should be complete around the time I finish, so four CG projects in a years time, plus the Philly is a quick build. So, it is a year, year and a half plan.

This will be a slow one.

Non Boat picture is project that is almost complete.

Kevin

🇺🇸 KevinH

5 days ago

53 Posts

16 Followers

258 Likes

BLUENOSE

Started 2020 with plans by P F Eisnor from Nova Scotia

34 pairs of ribs

🇨🇦 RossM

5 days ago

4 Posts

11 Followers

39 Likes

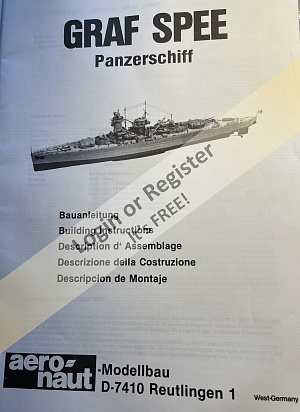

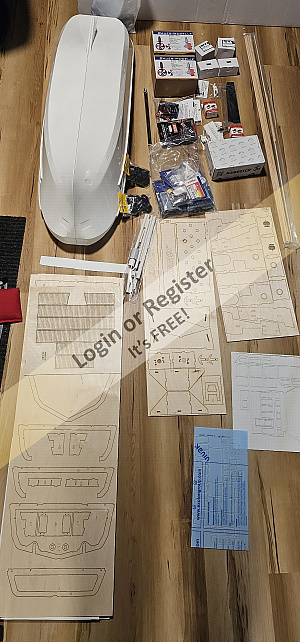

Aeronaut Graf Spee

I bought this kit about 10 years ago from a German model shop. It is definitely old-school, with great detailed plans, detailed stock list, but no instructions beyond a couple of paragraphs. I have not built a model in 20 years but was very active in my youth 50 years ago. I find that my skills have deteriorated and this will not be a great build, but it is enjoyable solving the problems and figuring out how to build this thing.

It has a plastic hull, a very nice plastic fitting set, but the rest of the kit is wood, with many pieces which have to be cut from printed sheets. Luckily, I have access to a wood shop with jigsaw and sanders.

I have fitted out the hull, added the motors, and started the superstructure. Stay tuned for further progress, I hope.

🇨🇦 whittonm

6 days ago

25 Posts

19 Followers

185 Likes

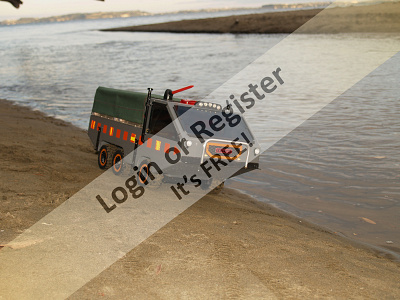

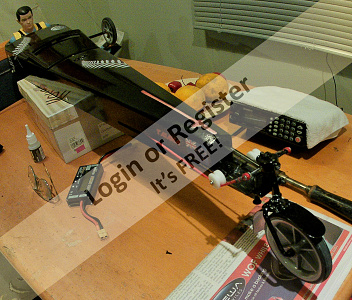

THE AMPHITRUCK

Decided to do something other than a boat this time, but still with a nautical purpose,- a 6 wheel twin diff twin prop swimming truck. Been done before, but I thought I'd have a go at one of my own design. Drew up some side and end templates and made a start, Purchased all the mechanical bits, (diffs, front axle, prop shafts, props, ESC, wheels,) over a few months from uncle ALI and added them to stuff I had in my collection.

Using cheap 3mm packing ply, I made the floor base ( to suit the diff and front axle widths) and strengthened it with 10x10 ally angle. Next,-cut out the sides and front and back panels. The floor was scored at the front and back to allow it to be bent up to the sides for gluing. Holes were cut in the floor to allow the diff heads to protrude through.

I had to modify the front axle to suit the width of the diffs by adding in an ally angle center section. Also had a play with setting the diffs and drive-shafts up with universals. Drive motor is a 380 1500 RPM @ 12v geared reduction drive, which is the one I first used in my Jeep tow wagon for my Hartley, (replaced it with a 1000 RPM version for more torque) and uses a 3s LiPo and Quicrun 40A ESC.

🇳🇿 jbkiwi

6 days ago

3 Posts

8 Followers

45 Likes

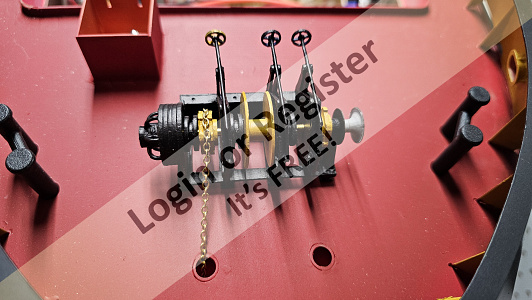

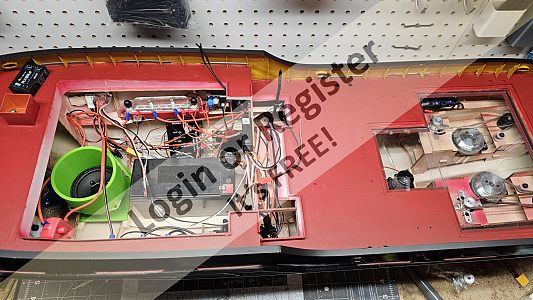

Aeronaut Jonny

Hi all, I started a new build during Christmas and I'm just about ready to start painting the haul so I figured its a good time to get the build log going.

I've had this kit for about a year now, purchased from Bauer in Germany along with with the recommended equipment including their Schottel Drive system. The plan is to have the two Schottel drives, a bow thruster, one working Anchor (possibly two in the future of off the same winch), a sound system, two working radars, working spot light with pivot in pitch and yaw, always on nav lights and interior lights, RC working main winch and manually operated bow and side winches, tow separate working fire monitors able to rotate individually, possibly a smoke generator and final an auto bilge system This comes to a total of 18 RC, unfortunately I only have 16 available so we will have to see what ends up in the ship.

So far I have the drives and bow thruster all fit and ready for assembly. I then built up the frame work and made the holes for the fire pumps and bilge. then had to build the lower deck house so I could fit the deck in the right place on the ship. Once the deck was dry fit I cut the scuppers then glued the deck down. I then set to work making the deck splash proof by installing and extending the kits coaming. I also add a drop floor under the aft hatch that I'm hoping will allow me to keep the water that gets on the deck from leaking down into the haul. Now I've got the Bulwark stanchions and handrails just about complete. I also started work on some of the deck items as I need the locations to work out some of the modifications I'm working through.

I hope to start painting the haul soon, I'm going to try brush painting this ship as I was able to find some nice paints at an Art supply store and I don't have much access to a place to spray paint in the winter. I do think I will spray on the primer first and hope it helps absorbed some of the brush marks.

🇨🇦 Westwind

7 days ago

56 Posts

16 Followers

344 Likes

Constellation

Made the framed glass portion of the skylight. They're hinged so I can get a finger inside to flip the power switch on or off.

They're made from clear plastic from some packaging, basswood, and brass wire.

🇺🇸 Jerry Todd

11 days ago

9 Posts

19 Followers

120 Likes

1949 40' Chris Craft Challenger

Hello all.... I have started a new project!! progress so far... she will be 32 " LOA and twin screw.

🇨🇦 Brightwork

11 days ago

29 Posts

19 Followers

370 Likes

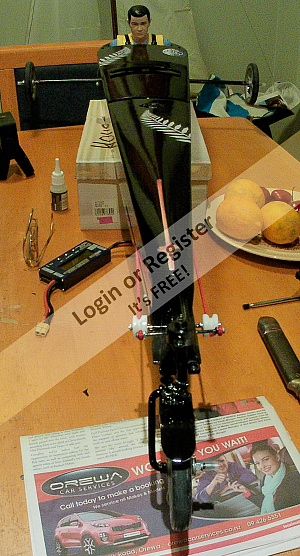

Ship of the desert ? new project

Started the latest project. Spotted these nice 105mm rubber tyred wheels in the big hardware store, and thought they deserved having something to be attached to,- hence the new project.

Scratch building using my 'cut it and see' method Started with a 20x20mm ally angle frame (main V from one piece angle cut and bent with bent and bolted rear cross bar) Rear axle is 10x1mm ally tube, with stub axles (from 10mm bright steel) turned down to fit inside and turned down for a 6mm securing Nyloc nut, and a rear shoulder for the wheels.

Stub axles and tube are drilled through 3mm and secured with 3mm machine screws.

Front axle is 6mm rod from an old sponge mop, and is bent and angled for a bit of reverse castor. 50x3mm ally strip added to the front of the frame for reinforcing and to mount 'stuff' to. The front steering head bush is 10mm bright steel drilled 6mm to be attached to?

Tune in next time for another thrilling instalment

JB

🇳🇿 jbkiwi

11 days ago

1 Post

5 Followers

3 Likes

To switch or not to switch ?

I wrongly entered my last post in the 'how to' section where, it seems, you are unable to respond. So here is my query for which I am seeking your guidance.

I have a motor circuit that comprises : 5S 5000mAh 30C Lipo; 40A fuse; 90A marine ESC; 3 x 20A fuses; 46 x 50 870KV brushless motor. There are no switches in the circuit yet.

1.Should I have a switch serving the battery ?

2. If yes, what rating ?

3. Should I have a switch between the ESC and the receiver ?

Any advice or guidance gratefully received.

🇬🇧 flaxbybuck

12 days ago

37 Posts

21 Followers

249 Likes

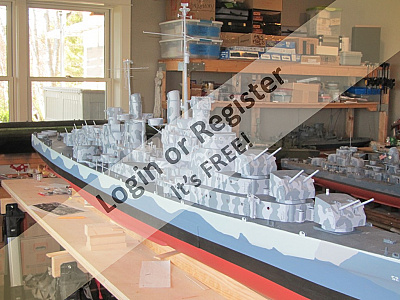

A new build

I will, most likely, have to rename this Blog, at some point.

In the mean time...please do not expect much for a while as she is in her very early stages.

First a disclosure: This hull was built for me by another gentleman. It was delivered in a not quite completed state. Therefore I have spent the last two month working on it to get to it's present state.

So.. what is it? She is one of four ships in a class that was later enlarged to around eight maybe ten members of the class. Her main armament was eight 5"/38 caliber twin turrets. She and her class namesake sister were both lost during the Naval Battle of Guadalcanal. This ship is most noted due to the loss of an entire generation of one family, five brothers.

This should be enough for identification.

She is being built in my preferred scale, 1/48th or 1/4"=1'.

This ship was used for numerous camouflage scheme experiments and, sadly, there is little definitive documentation to pinpoint her second to last and last schemes carried. That said, my plan, subject to change without notice or reason, is to present her as she appeared following her New York Navy Yard overhaul, or perhaps as she may have appeared after repainting in Placentia Bay NewFoundland, 1942.

She measures out to 11' 3" and her power plant is to be two 24 volt Buehler motors.

Pictures of her and the build to follow.

Wish me luck please, she will not fit in my van....

🇺🇸 ToraDog

12 days ago

|

|

Media Gallery

INGA IV

6 days ago by philcaretaker

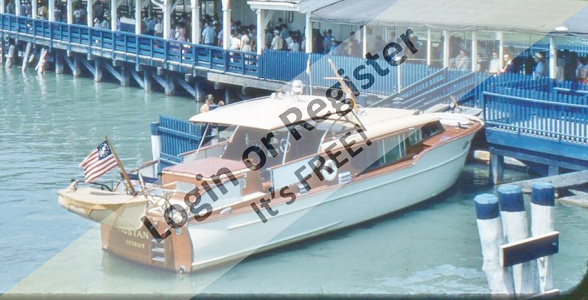

Lake Union Dreamboat

9 days ago by Brightwork

1958/9 50/55' Chris Craft Constellation

10 days ago by Brightwork

Filming "Dinghy Dan"

22 days ago by philcaretaker

"Dinghy Dan"

22 days ago by philcaretaker

"Dan, Dan the Dinghy Man"

25 days ago by philcaretaker

"Dinghy Dan"

25 days ago by philcaretaker

RNLI Severn Class

26 days ago by Rudy-M

Onboard a Focus 2 RC yacht

26 days ago by Rudy-M

Andy sails Topaz with df65's

26 days ago by MartinH2

RC Shark vs Orca?

28 days ago by Rudy-M

Topaz 60" J class yacht

1 month ago by MartinH2

|

|

Login To

Remove Ads

Remove Ads

Boat Clubs & Lakes

Recent Updates In Places

|

Model Boating Association of South Africa

15 days ago by 🇿🇦 Rudy-M (

Warrant Officer) Warrant Officer) |

|

BUXTON MODEL BOAT CLUB

25 days ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

Rawdon Model Boat Club

25 days ago by 🇬🇧 MikeC3 (

Petty Officer 2nd Class) Petty Officer 2nd Class) |

|

Sonstraal Dam

1 month ago by 🇿🇦 Rudy-M (

Warrant Officer) Warrant Officer) |

|

Cape Town Scale Model Boat Club

1 month ago by 🇧🇪 hermank (

Captain) Captain) |

|

|

Upcoming Events

|

May

5 2024

|

1 Day Only!

|

Edina Model Yacht Club - Spring Breakfast

Starts 9 days time

|

|

Jun

8 2024

|

1 Day Only!

|

RAWDON MBC OPEN DAY

Starts 1 months time

|

|

Jun

9 2024

|

1 Day Only!

|

Edina Model Yacht Club - Parade of Boats at Centennial Lakes Ponds

Starts 1 months time

|

|

Aug

11 2024

|

1 Day Only!

|

Edina Model Yacht Club - Lighthouse Night #1

Starts 4 months time

|

|

Sep

7 2024

|

1 Day Only!

|

Edina Model Yacht Club - Lighthouse Night #2

Starts 4 months time

|

|

|

Boat Harbour

4 Photos

19 Likes

Lulonga River Tug

Lulonga steam river tug. Broad beam twin stern paddles. Very stable and graceful on the water. Single motor (12 volt)chain driven from geared motor. Fitted with smoke mister, lights and sound. Unusual model built from plan. Lovely to sail on a summer evening.

🇬🇧 wmbc40

3 days ago

0 Attributes

19 Comments

7 Photos

10 Likes

Oppie

Way back when, there used to be a company producing grp hulls, they were based in Holyhead(?) or nearby, the business was sold, and I discovered they had some pieces for the Oppie, I bought them, constructed the model, sailed it, was impressed, so much so I embarked on the construction of the other exact 1:4 scale models.

🇫🇷 stotty1111

7 days ago

0 Attributes

3 Comments

3 Photos

17 Likes

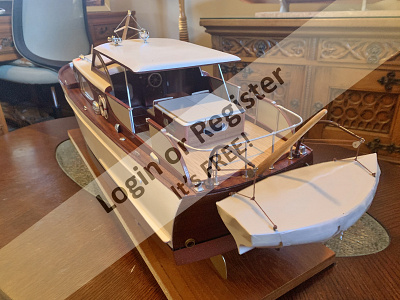

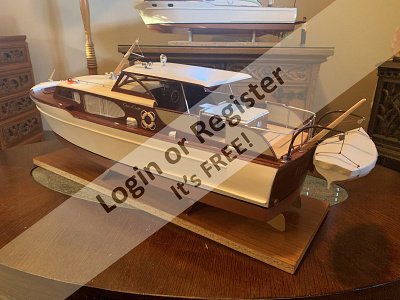

Graupner Commodore

I acquired this Commodore and made some modifications so she is now a Chris Craft Roamer 37'

🇨🇦 Brightwork

11 days ago

4 Attributes

12 Comments

2 Photos

18 Likes

Billings Smit Nederalnd

I aquired this for free and did some restoration on her. I will probably give her to my brother.

🇨🇦 Brightwork

11 days ago

4 Attributes

9 Comments

5 Photos

12 Likes

1949 40' Chris Craft Challenger

This is based on the Dumas model plans. Model was produced by dumas as a kit in the 50's. I semi scratch built her from the plans.

🇨🇦 Brightwork

11 days ago

8 Attributes

5 Comments

9 Photos

11 Likes

Steam Power

Not strictly marine based, but the Stuart D10 is destined for a 1:12 Customs Launch, Active, built by Cox & Co Falmouth 1912, and stationed at Gravesend until the '30's.

Kit of castings, machined and built by myself along with the horizontal engine.

The others have been bought at knock down prices over the years!

They all need sprucing up!

The boiler was bought several years ago from an Australian outfit, at the time it seemed incredibly cheap, but was probably caused by the exchange rates between the Australian dollar and the pound!

It came complete with lagging, planking and other bits and pieces, cannot be exact as I cannot find the box with the pieces in, cannot remember if it was complete with burner!

I now have the thermal blocks (ex night storage heater) to construct a hearth to continue with the installation etc.

Photos of 'Active' to follow it is stored at the club house!

🇫🇷 stotty1111

17 days ago

0 Attributes

2 Comments

9 Photos

22 Likes

Oystercatcher

Here we have Oystercatcher, another product of the noughties.

The full size boat is designed for inland waters, weekend cruising, it can be used as a floating tent using the spars and sails.

Designed by Conrad Natzio of East Anglia, it is designed for garage construction, using 6 sheets of marine ply or even water resistant ply.

I met Conrad at an exhibition at Alexandra Palace, had a chat with him was given plans of several of his designs, chose to build Oystercatcher, kept in touch and was invited to a weekend expo at Beale Park, adjacent to the Thames, he used my model on his stand, a very nice man!

The model is an exact scale of 1:4, I enjoyed the build, but the control was not an easy installation, the boat being so open.

Went on to sail her at an exhibition held in Swansea at the Maritime Museum, they had a pond there so was able to try sailing, it worked well, but I felt I needed to add a keel to bring a little more stability, but house moves etc got in the way.

Makes a nice static model!

I will endeavour to get more photos when the wind is calmer!

🇫🇷 stotty1111

20 days ago

0 Attributes

6 Comments

2 Photos

11 Likes

Mini Submarine

Another toy, courtesy of Amazon 7 or 8 years ago.

I bought the beast for about £12 / 15€. It was on offer!

I use it at model exhibitions where there is a pool.

The sub is about 15cm/6" in length, complete with basic r/c system.

It will sail forwards and reverse, turns to the right and left courtesy of water jets, and by use of 2 buttons on the top corners will submerge and resurface. It has rechargeable batteries inside, these are recharged by use of a fly lead from the tx!

The main users are children and sometimes adults who want to have a go!

It generates lots of interest, so much so that sometimes children join the club and go on to build small freelance fishing boats - the majority of models are fishing and military boats, we have the Brest naval base close by and several fishing ports.

🇫🇷 stotty1111

22 days ago

0 Attributes

6 Comments

13 Photos

24 Likes

1:4 scale Clinker Dinghy

Built around 2000 whilst I worked as a Technician in the Design Technology section of a local senior school, built at home, but with pieces produced in the woodworking shop, having access to a plethora of workshop equipment!

Sailed somewhat unsuccessfully back then, I had problems finding sail material for its Bermudan rig, my idea was to convert to gaff style rig, never got around to it, however now with more choice sail cloth wise I might have another go, however my sailmaker died some time ago!

The major problem sailing was the launching and retrieving, the weight was around 8 - 9 kgs(18lbs), and with age that is probably more of a problem, although here in France there is more attention given to those sort of problems!

The model won a gold award at a model show in Concarneau in 2003, after which I was invited to join my local club in Chateaulin -- the best move I made!

🇫🇷 stotty1111

24 days ago

0 Attributes

6 Comments

|

|

How-To Articles

LED – SERIES AND PARALLEL CIRCUITS – FLASHING CIRCUITS - Compendium of information

Revised 20 days ago

By AlessandroSPQR

Transmitter Camera Mount

Revised 1 month ago

By cjanik001

NAVAL PROPELLERS. Compendium of information.

Revised 2 months ago

By AlessandroSPQR

Lipo Battery Reference charts

Revised 2 months ago

By CB90

K.M.Y.C.A. Monthly magazine

Revised 3 months ago

By hermank

CALCULATION OF THE IMMERSED VOLUME (SIMPLE MATHEMATICAL/GEOMETRIC METHOD) OF YOUR MODEL

Revised 4 months ago

By AlessandroSPQR

Basic Model Boat Operations

Revised 5 months ago

By LewZ

Fiberglass boat hull

Revised 6 months ago

By northark

Bending Small Diameter Copper Tubing

Revised 6 months ago

By LewZ

Goodbye summer

Revised 6 months ago

By hermank

|

|

Login To

Remove Ads

Remove Ads

🛍️ Basket

Main menu transported here on mobile

Login

Create New Account

Trending Topics

Members Online

Forum

THE MOST ORIGINAL, STRANGE AND FAILURE SHIPS EVER BUILT IN THE WORLD.

Doogle

14 minutes ago

Harbour

Re: Dart Belle Paddle Steamer.

AlessandroSPQR

40 minutes ago

Forum

Dating ?????

Isaac

48 minutes ago

Forum

Question of the Day?

RNinMunich

2 hours ago

Harbour

Re: Graupner Commodore

AlessandroSPQR

6 hours ago

Blog

Re: Ballast Question

AlessandroSPQR

7 hours ago

Harbour

Re: Lulonga River Tug

wmbc40

11 hours ago

Harbour

Re: HMS Bluebell.

Doogle

12 hours ago

Forum

Vertical boiler identification

algon

16 hours ago

Forum

Wordle of the Day?

Cashrc

20 hours ago

Forum

Looking for help identifying....

algon

1 day ago

Forum

Aerokits pt boat bulkhead plans wanted

ChrisF

1 day ago

Forum

Calling it a day.

Len1

1 day ago

Blog

Re: Russian K100D waterjet work boat

jbkiwi

1 day ago

Forum

I miss Graupner!!! And Robbe too.

roycv

2 days ago

Forum

Useful Battery ???

Colin H

2 days ago

Forum

Cheddar Electronic gas control valve instructions

Dainesh

2 days ago

Harbour

Re: 3. Old Commodore / Graupner

Len1

2 days ago

Forum

LCM3 landing a Sherman M4A3(105) howitzer

Len1

2 days ago

Harbour

Re: 4. Fishing boat "Aline"

Mike Stoney

3 days ago

Forum

International Associations

Rudy-M

3 days ago

Harbour

Re: 5. Old Stern wheel steamer

Isaac

3 days ago

Forum

Modello RC scala 1/60, di piroscafo armato a goletta, liberamente ispirato alle cannoniere classe US

Len1

3 days ago

Forum

Blast from my past

jumpugly

3 days ago

Blog

Re: April 13 2024

flaxbybuck

3 days ago

Blog

Re: MLB Begin

flaxbybuck

3 days ago

Forum

keel weight information

Ronald

3 days ago

Forum

MATAKANA MODEL BOAT SHOW NEW ZEALAND 21.04.24

stevedownunder

4 days ago

RNinMunich

Fleet Admiral

35,650 Points

2 seconds ago

DWBrinkman

Lieutenant Commander

2,432 Points

15 seconds ago

LewZ

Captain

3,781 Points

34 seconds ago

mdsrecycles

Recruit

0 Points

44 seconds ago

MarkT

Recruit

0 Points

4 minutes ago

BOATSHED

Lieutenant

1,925 Points

7 minutes ago

IanTurk

Master Seaman

122 Points

11 minutes ago

Doogle

Commodore

4,152 Points

12 minutes ago

AlessandroSPQR

Commodore

4,535 Points

18 minutes ago

roycv

Rear Admiral

5,311 Points

26 minutes ago

Mike Stoney

Commander

2,718 Points

33 minutes ago

boatmam

Recruit

0 Points

39 minutes ago

Wolle

Lieutenant Commander

2,293 Points

39 minutes ago

Rudy-M

Warrant Officer

804 Points

39 minutes ago

vc killer

Able Seaman

24 Points

39 minutes ago

SimpleSailor

Chief Petty Officer 1st Class

524 Points

40 minutes ago

xtramaths

Master Seaman

128 Points

40 minutes ago

hermank

Captain

3,299 Points

41 minutes ago

BarryW

Recruit

0 Points

42 minutes ago

Isaac

Warrant Officer

784 Points

42 minutes ago

Waiting2Retire

Recruit

0 Points

52 minutes ago

Robidoo

Recruit

0 Points

56 minutes ago

melian

Recruit

0 Points

59 minutes ago

DuncanP

Sub-Lieutenant

1,545 Points

1 hour ago

powell39

Recruit

0 Points

1 hour ago

Len1

Sub-Lieutenant

1,436 Points

1 hour ago

Scratchbuilder

Vice Admiral

6,710 Points

1 hour ago

AlanR

Able Seaman

47 Points

1 hour ago

AustinG

Chief Petty Officer 2nd Class

432 Points

2 hours ago

KevinM

Recruit

0 Points

2 hours ago

ARL58

Petty Officer 1st Class

222 Points

2 hours ago

Scamp

Petty Officer 1st Class

260 Points

2 hours ago

Maurice

Recruit

12 Points

2 hours ago

Colin H

Fleet Admiral

12,604 Points

2 hours ago

Trident73

Warrant Officer

644 Points

2 hours ago

Homdadream67

Recruit

9 Points

3 hours ago

robbob

Admiral

8,563 Points

3 hours ago

jacko

Lieutenant Commander

2,479 Points

3 hours ago

Hhager2

Midshipman

1,016 Points

3 hours ago

luckyduck

Midshipman

984 Points

3 hours ago

hibbard

Recruit

0 Points

3 hours ago

janc

Recruit

0 Points

3 hours ago

LOBOLONDON

Able Seaman

23 Points

3 hours ago

Tug

Recruit

10 Points

3 hours ago

DanO

Recruit

0 Points

3 hours ago

Chum444

Midshipman

942 Points

3 hours ago

Singingpug

Leading Seaman

77 Points

3 hours ago

Schifty1

Recruit

13 Points

3 hours ago

Pdj

Recruit

12 Points

4 hours ago

mturpin013

Admiral

8,352 Points

4 hours ago

Login To

Remove Ads

Remove Ads

🏠

Home

Home

📰

Trending

Trending

💬

Forum

Forum

🗝

Login / Join

Login / Join

|

Cookies are used for ads personalisation.

By using this website you agree to our use of cookies. More Info |

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Useful Links

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (7,851)

📣 Support

Hobby Supplies

🛍️ Online Shop

Login

🗝 Login

🗝 Create New Account

▼

Media Gallery

X

1 of 4

► |

◄ |

Media Viewer

^

_

X

Share

X

Flag Inappropriate Post

X

| Select Reason | |

| Sexual content Includes graphic sexual activity, nudity, and other sexual content. | |

| Violent or repulsive content Violent or graphic content, or content posted to shock viewers. | |

| Hateful or abusive content Content that promotes hatred against protected groups, abuses vulnerable individuals, or engages in cyberbullying. | |

| Harmful dangerous acts Content that includes acts that may result in physical harm. | |

| Child abuse Content that includes sexual, predatory or abusive communications towards minors. | |

| Promotes terrorism Content intended to recruit for terrorist organisations, incite violence, glorify terrorist attacks, or otherwise promote acts of terrorism. | |

| Spam or misleading Content that is massively posted or otherwise misleading in nature. | |

| Infringes my rights Privacy, copyright and other legal complaints. | |

Basket Updated

X

Loading...

Loading

Loading Uploader...