|||

|

|

🗝 Login

🤖 Create Account

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Plans & Docs

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,803)

📖 Quick Site Guide

📣 Support

👥 Membership

Hobby Supplies

🛍️ Online Shop

Not Registered

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

For A Whole Year!

£25

£45

£65

Donate

You Will Be Helping Towards:

Domain Fees

Security Certificates

iOS & Android App Fees

Website Hosting

Fast Servers

Data Backups

Upkeep & Maintenance

Administration Costs

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Model Boats Website

Home

Forum

Build Blogs

Media Gallery

Boat Clubs & Lakes

Events

Boat Harbour

How-To Articles

Plans & Docs

Useful Links

The Games Chest

Welcome to the Model Boats Website! A place for all model boaters!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Login To

Remove Ads

Remove Ads

Trending Now

Forum

Nigel Trafford-Jones

Hi Zippy, he is on LinkedIn but don’t know if he is active.

If you want me to I will give him a negative write up on LinkedIn and see if that jolts him to contact you.

Ed

🇬🇧 EdW

19 hours ago

Forum

Question of the Day?

Hi All,

I think Stephen is doing a sterling job considering he does it out of love for the site. If more people subscribed it would help with the hosting costs and make his life easier.

Without pointing a finger I have noticed that some people post unnecessary club logos over and over again, multiple times on some posts, this is a waste of storage on the server.

Stephen must be a lot more tolerant than I am. In the past I have maintained and run large Intranet sites and users that post unnecessary content only got one warning then were locked out until their manager had pushed them to change their behaviour.

I doubt most members would appreciate how much time it takes to maintain a web site like this, let alone modifying anything on it.

My 2 pence worth

Ed

🇬🇧 EdW

19 hours ago

Forum

And Now For Something Completely Different

Lew, you have a good selection there.

Partly because i was late to the hobby I have enough on my plate with the boats and my Tamiya Unimog and other hobbies. A neighbour, who was partly the reason for my getting into model boats, is also interested in trains, including a garden layout, and planes. He has offered to teach me to fly on more than one occasion but I have resisted! I nearly built a plane though, when helping to look after my mother but didn't in the end.

🇬🇧 ChrisF

1 day ago

Forum

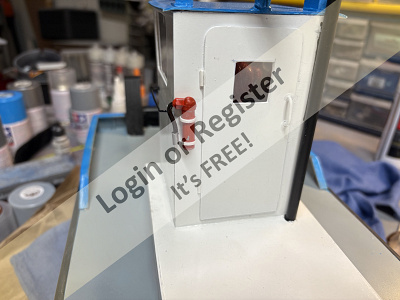

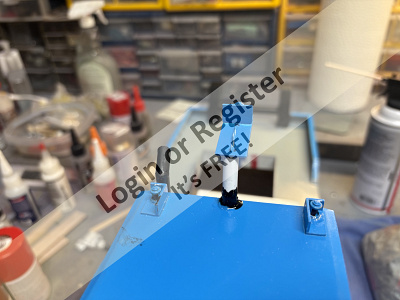

Tools

Having mentioned the drill chuck and screw driver set earlier I had a use for it today! Needed to drill a very small hole through the end of a paint brush I was using as part of the throttle assembly - it was ideal to start the hole which I then completed using my small battery drill and the chuck.

🇬🇧 ChrisF

1 day ago

Forum

I Hate Painting!

Well, it's more of a love/hate relationship as I like the result when it turns out well, but I find the process frustrating!

Case in point is the roof of the Faun I'm working on. I use good quality International Paints enamel and primer-undercoat and brushes. Couple of coats of primer-undercoat followed by a couple of coats of enamel and all well so far. Followed by what I was hoping to be the final top coat.

When dry it looked pretty good apart from a piece of air-borne detritus which had landed on it. Should have left it, but no I decided to rub it down and give it another coat. Result was that I rubbed through the gloss slightly on the top of the curve of the roof. Thought it would be Ok but it wasn't. ️ Also there was what looked like lots of bits in the paint or maybe inclusions? Ahhh! I do use a tack cloth. Not air-borne as the "bits" were appearing as i was painting.

So I spot primed it followed by a light sanding and gave it another coat. Result is that it looks even worse as you can see the enlarged primed area and still bits even though a new brush and can of paint, even more ahhhh!

I know it's user error but it is so frustrating. I've painted a few hulls now, not perfect but generally good results and found the white easier than the blues where the primer-undercoat has to be very uniform if a good result is to be obtained.

I much prefer working with timber and metal where I am more in control and mistakes, if made, can usually be rescued more easily.

With the roof I am probably going to have to almost start again by primer-undercoating the whole roof and enameling again.

Chris

🇬🇧 ChrisF

1 day ago

Forum

Sailing barge sails

Rick

It appears that in this photo there is a ruler of sorts? Using it along with the fill size ruler, measure the following:

Foot

Head

Luff

Leach

Send a photo of this when done.

Ron

🇨🇦 Ronald

1 day ago

Blog

Re: Fairey Faun - RC Installation

Hi Chris,

I think every one of your Fairey Marine models all count as a Classic Model Power Boat and all originate from the time period that we enjoy modelling (and then driving !).

As each one is completed, it would be really good to see them individually pictured with any additional info that could be of some interest.

I have also noticed the decline in the huge amount of interest and support that the Fairey Marine boats used to enjoy, but this could all change when people get to see your diverse collection of boats that this fine company produced over the years.

Picture of your boats "in action" do not need to show the boat going very fast - especially if they were never intended to be fast (like your river cruiser), but that does not lessen their interest.

Nice static pictures are in some ways even better as more of the model can be seen in greater detail, but both would be nice to see as they are all most definately Classic Model Power Boats.

Bob.

🇬🇧 zooma

1 day ago

Forum

Sprite

I won't show any pictures of the thumb, but this is the device that chopped a lump out of it !

This is very good sharp clean cutting little plane that made light work of trimming away the keel and the doublers ready to fit the bottom skins.

The small accident was my fault entirely, I was trying to hold the frame of the boat against my chest with the left hand as I was planing it with the right hand and obviously failed to control either the boat or the plane adequately.

Not to worry, most of the woodwork washed up OK with clean cold water and so "alls well the ends well" as they say

Bob.

🇬🇧 zooma

2 days ago

Forum

Early Radio Control Experiences

As far as RC gear, I had a Derek Olley switch job which was excellent. Then an Acoms set and possibly another. Then I saw the Micron 6 ch. 27Mhtz FM kit. I bought and soldered up a 6 ch. Tx. and a rx. I subsequently made 3 more rx's and also converted the servo o/p sockets to current type.

At the time the Futaba rx. was all tuning coils and my one was 'difficult' The Micron rx. was excellent and easy to set up and use. This was all 27Mhtz FM and I have a few pairs of crystals for FM.

When the 35Mhtz band came out I bought a 27Mhtz FM Futaba M3 with rx. lovely thing and still use it. The rx. not so good.

The FM Futaba rx I sent off for repair to a specialist company for repair or to get it working. Putting a note with the Rx that it was 27Mhtz.

I got it back quite quickly but it did not work. I phoned the company and told them and also said it was tuned to 35 when I has specifically said it was 27. The guy at the other end hotly denied it and went on a bit about the company etc.

I let him finish and asked him, "Did he want the 35Mhtz crystal back that was in the rx.?"

It was retuned after I sent it back but it was nowhere near as good as the Micron one.

Roy

🇬🇧 roycv

2 days ago

Blog

Re: Extending the cable routes.

Not that your a masochist or anything, you just like doing 'a proper job'

🇬🇧 tonyb2

2 days ago

Forum

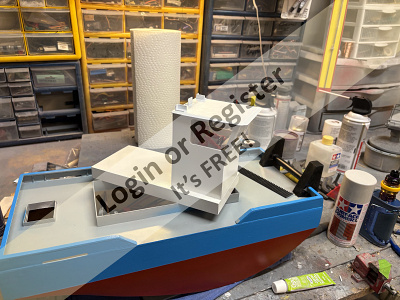

Motor Mounts

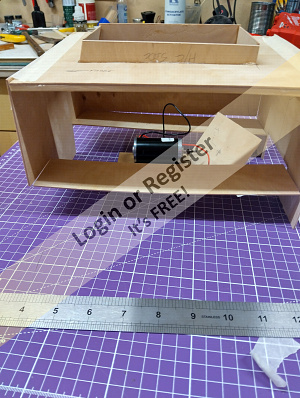

I generally 3D design and print my own motor mounts, servo mounts and most everything that goes inside the hull. The photos are my Graupner "Dusseldorf" fireboat under complete rebuild (if I can get back to it).

Even if you buy motor mounts you still need to fasten them to something. This method (3D work) is easier for me. Temporarily hold the motor(s) in place, take measurements, then make the mounts.

Lew

🇺🇸 LewZ

2 days ago

Blog

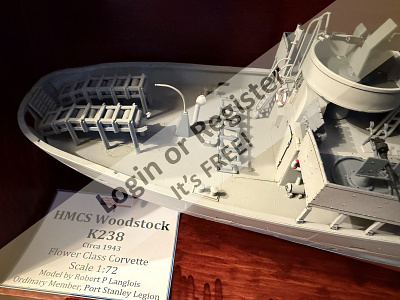

Re: Woodstock Research and Build, Errors and Blunders

RP!!! What a beauty and 100% museum scale. She's absolutely...

🇺🇸 jumpugly

2 days ago

Blog

Re: Classic Model Power Boats

Suzie Q.

Drawn up by Vic Smeed and featured in the March and April 1965 Model Maker magazine, the prototype for this model was built from balsa and controlled with a single channel radio.

I bought the plans and built mine from plywood as I wanted to power it with an ENYA 19 water-cooled glow plug engine.

The super little boat 27" long model of a "typical" (at the time) off-shore racer shape proved to be another winner from Vic Smeed that I enjoyed running along with another of his Classic Model Power Boats from that same time period - the Remora "steering boat".

Both of these two models have aged rather better than may have been expected when they were first penned, and both respond really nicely to being driven fast with a modern brushless motor !

Bob

🇬🇧 zooma

2 days ago

Forum

Double Jointed Universal Couplings

Have you tried TEMU as they are really good with both quality (check any referrals on the products) and delivery, certainly to New Zealand. Cheers Ian

🇳🇿 IanL1

2 days ago

Forum

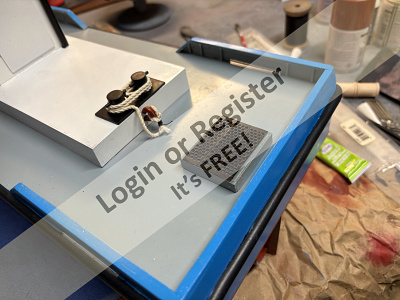

How do you create the coiled ropes?

I created a very short video on rope coils hope it uploads OK. It should explain how I do it. I think with a bit of luck you can finish off the coils in different ways.

I have used this jig on a number 72 scale models.

Bob

🇦🇺 BobbyN

3 days ago

Forum

Animal and nature photos to enjoy.

Incredible, what a spectacle! Thanks for sharing.

🇩🇪 Wolle

3 days ago

|

New Member

Belgium

ArneV

ArneV21 hours ago

New Member

United Kingdom

Juppy

Juppy2 days ago

New Promotion

Chief Petty Officer 2nd Class

RPLedm

RPLedm2 days ago

New Member

United Kingdom

DavidC12

DavidC122 days ago

New Promotion

Chief Petty Officer 1st Class

BobbyN

BobbyN2 days ago

Birthday This Week

Turns 70

Nickthesteam

Nickthesteam3 days ago

New Member

United Kingdom

SimonH

SimonH3 days ago

New Member

United Kingdom

tonyp3

tonyp33 days ago

New Promotion

Sub-Lieutenant

Oxford-Dave

Oxford-Dave4 days ago

New Member

Spain

PedroG

PedroG4 days ago

New Member

Norway

john-richards

john-richards5 days ago

New Promotion

Rear Admiral

Nickthesteam

Nickthesteam6 days ago

New Member

United Kingdom

StephenB3

StephenB36 days ago

New Member

United Kingdom

allant1

allant17 days ago

New Member

United Kingdom

JeremyP

JeremyP7 days ago

New Promotion

Able Seaman

Fogwall

Fogwall7 days ago

New Promotion

Commander

DuncanP

DuncanP7 days ago

New Promotion

Able Seaman

ian j

ian j7 days ago

New Member

United States

MIke1

MIke17 days ago

New Member

United Kingdom

WilliamW2

WilliamW27 days ago

New Member

United Kingdom

davem2

davem28 days ago

Account Updated

Updated Signature

paull5

paull58 days ago

Account Updated

Updated 'About Me'

paull5

paull58 days ago

New Member

United States

RevellW

RevellW8 days ago

Birthday This Week

Turns 70

SouthportPat

SouthportPat8 days ago

Account Updated

Changed Avatar

Otto

Otto9 days ago

New Member

Canada

PEI

PEI9 days ago

New Member

Switzerland

Otto

Otto9 days ago

New Member

United Kingdom

RobS1

RobS110 days ago

New Member

United Kingdom

coll351

coll35110 days ago

Birthday This Week

Turns 73

Chris W

Chris W10 days ago

New Promotion

Chief Petty Officer 1st Class

algon

algon11 days ago

New Member

United Kingdom

MikeD3

MikeD312 days ago

New Member

United Kingdom

Fogwall

Fogwall12 days ago

New Member

Ireland

DavidM10

DavidM1013 days ago

New Member

Canada

JohnD9

JohnD914 days ago

Account Updated

Updated 'About Me'

Millwall Steve

Millwall Steve14 days ago

New Member

United States

ezratic

ezratic17 days ago

New Member

United Kingdom

PapaSmurf

PapaSmurf17 days ago

Account Updated

Updated 'About Me'

oefranz

oefranz17 days ago

New Member

United Kingdom

TommyH

TommyH18 days ago

New Member

New Zealand

poppy

poppy18 days ago

New Member

United Kingdom

paull5

paull518 days ago

New Member

Sweden

sorenJ

sorenJ18 days ago

New Member

Canada

oldflyer

oldflyer19 days ago

New Member

United Kingdom

FredE11

FredE1119 days ago

Birthday This Week

Turns 78

jennyr

jennyr19 days ago

Birthday This Week

Turns 78

Mike Stoney

Mike Stoney19 days ago

See More

Forum Topics

Nigel Trafford-Jones

Hi Zippy, he is on LinkedIn but don’t know if he is active.

If you want me to I will give him a negative write up on LinkedIn and see if that jolts him to contact you.

Ed

19 hours ago by 🇬🇧 EdW ( Commander)

Commander)

Commander)

Commander)

Hobby Chit Chat

3 Posts

6 Likes

6 Likes

Started

2 days ago

by zippy

2 days ago

by zippy

Latest

19 hours ago

by EdW

19 hours ago

by EdW

Question of the Day?

I no longer hear speeches that question the leading positions and this makes me think.

9 hours ago by 🇮🇹 AlessandroSPQR ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Website Related

5089 Posts

13024 Likes

13024 Likes

Started

3 years ago

by fireboat

3 years ago

by fireboat

Latest

9 hours ago

by AlessandroSPQR

9 hours ago

by AlessandroSPQR

And Now For Something Completely Different

HAYA Centurion Mk5.

Hi Lew,

My 3D printed Conquerer is not fully assembled yet, but I will loosely put the parts together later and take some pictures for you.

To compensate, here are some pictures of my 1/16 scale r/c Centurion that I built from the HAYA Centurion Mk3 kit and modified it to a Mk5 as used in the Berlin Brigade.

These tanks in the Berlin Brigade were unique in being painted in Olive Drab - all other Centurions and British tanks in Germany were painted in the more usual (at the time) Bronze Green.

It is not so far off the mark as the Conquerer was brought in to supplement the Centurions in Germany to boost the available NATO firepower, but was short-lived as the Centurion's own upgrades made the Conquerer redundant and saved the army having to carry spares and parts for two different types of main battle tanks (MBT).

I am still working on the weathering and final paint but I have some spray masks made so that I can airbrush on the unit markings and the name of the tank etc in due course

The tank has a revolving commanders cupola, metal tracks and sprockets, authentic Rolls Royce meteor engine sound with machine gun and main gun sound via a Clarke board and has engine exhaust smoke as well as gun flash and barrel smoke following each shot of the main gun.

Future plans include adding more powerful motors to drive the two steel gearboxes to help the tank when running across some of the more demanding terrain that it has to encounter.

My tanks are like my Classic Model Power Boats insomuch that they are not "shelf queens" - they are driven often and enjoyed - and worked hard.

Bob.

16 hours ago by 🇬🇧 zooma ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)

Hobby Chit Chat

19 Posts

60 Likes

60 Likes

Started

18 days ago

by zooma

18 days ago

by zooma

Latest

16 hours ago

by zooma

16 hours ago

by zooma

Tools

I used a David razor blade plane in my school days when I was shaping the aerofoil section of my control line model aircraft , and that would be over 65 years ago!

This plane took the single edge razor blades that were commonly available then, and I often held the blade in my hand to cut balsa wood as it cut better than the Xacto knives !

The David razor blade plane that I have now is probably a lot newer (maybe only 40 years old?), but I think the original one had a metal wing nut rather than the black plastic moulded one shown here.

I also had a small Xacto moulded plastic tool case that had a number 1 (small) , number 2 (medium) and number 5 (large) sized handles in it with a selection of different blades and a razor saw blade to fit the number 5 handle.

There is every possibility that the Xacto moulded "plastic" tool case was actually moulded in Bakalite as it was a bit fragile around the points where the metal hinges fitted........and sadly it has failed to survive!

The number 5 Xacto saw handle had a moulded handle on it and the razor saw blade that it took was very handy for cutting some of the hardwood engine bearers - but was not a patch on the Tamiya razor saws that I use these days.

In the Xacto moulded tool case was also this red cast iron miniature smoothing plane that came in handy when shaping leading edges although I always preferred to final shape these with sandpaper wrapped around a suitably size hardwood block.

This is my original Xacto miniature smoothing plane and so it is probably over 65 years old!

During my time at home I wanted to strip and clean these olde tools but until the wound on my thumb has mended a bit I am reluctant to risk splashing any oils etc into it, but if I can dig-out my pack of black plastic "mechanics" gloves, I may do it in-between time when waiting for the glue to dry as I continue t work on the Sprite Plus.

Xacto tools have been copied by several different manufacturers sine the 1950's, but I have never seen the Xacto miniature plane copied by anyone.

Bob.

11 hours ago by 🇬🇧 zooma ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)

Building Related

41 Posts

147 Likes

147 Likes

Started

18 days ago

by ChrisF

18 days ago

by ChrisF

Latest

11 hours ago

by zooma

11 hours ago

by zooma

I Hate Painting!

Wow, I read this & thought I must have typed it without knowing. I feel your pain. I have a boat built by my dad many years ago, & I am renovating it from years of sitting in top of a cabinet. Its a Billings kit & unfortunately the wood had dried out so much, there are lots of splits in the hull. So after methodically rubbing it back to bare wood, sorting it out, I am going through the exact problems with painting. Thank you for making me no longer feel alone in this issue.

15 hours ago by 🇬🇧 LazyFerret ( Recruit)

Recruit)

Recruit)

Recruit)

Building Related

1 Post

3 Likes

3 Likes

Started

1 day ago

by ChrisF

1 day ago

by ChrisF

Latest

15 hours ago

by LazyFerret

15 hours ago

by LazyFerret

|

|

Login To

Remove Ads

Remove Ads

Build Blogs

1 Post

0 Followers

1 Like

Fire boat Florián 1:7, Construction (second attempt) from scratch

Based on old and new photos, and based on previous experiences, I will show the progress of working on the model here.

So far, it's more of a carpentry job than a modeler's work..I am adding a photo of two more ribs - 26.5.2025. I glue the ribs right away, but I will cut or drill them as needed. Even though I already have one experience - it's not enough. Sometimes the right result is on the second or third try - but that doesn't bother me. I welcome any practice in this size of model.

🇨🇿 premecekcz

9 hours ago

0 Posts

0 Followers

1 Like

Cheap unsinkable airboat

For a bit of fun i decided to knock up another airboat for rescue and camera work. made from a $19 body board with a 3542 1000kv TGY outrunner running on a 4s Lipo, with a 10x6 pusher prop. Went fairly well on it's first test using only about 30% power, but needed some up thrust and rudder trim for much more throttle. Probably needs some small bottom strakes to limit the drifting tendency and make it easier to control, (did this with the first airboat which manages 30kph)

Could quite easily run on 3s for more economy, as it planes very easily. I got 20mins almost continuous running at the speed in the video, (on 30%) which is more than adequate, as it would be just idling around for videos. Quick to make and lots of fun. Motor mount screws onto 4 -30mm dowels epoxied into the body board.

JB

https://www.youtube.com/watch?v=EBcKXAVqrEE

🇳🇿 jbkiwi

15 hours ago

10 Posts

6 Followers

43 Likes

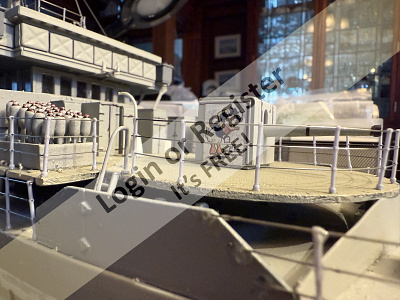

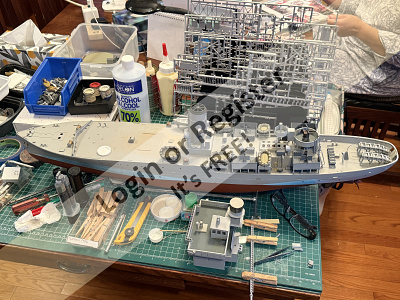

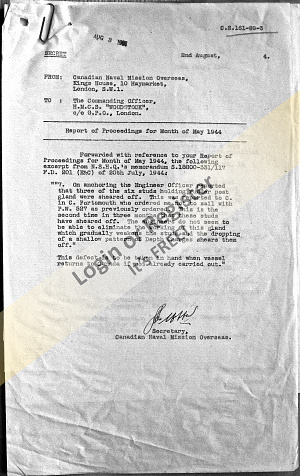

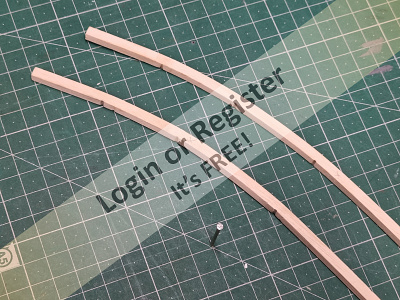

HMCS Woodstock from a Kitbashed Revell Flower Class Corvette

Starting the dig into the Ottawa Archives and The Great Lakes Museum in Kingston:

🇨🇦 RPLedm

2 days ago

19 Posts

22 Followers

230 Likes

The VMW Marlin Cabin Cruiser by Robbob

The VMW Marlin Cabin Cruiser by Robbob

Preface.

At the time of writing, I’ve had the construction of this boat on ‘the back burner’ since July 2022. By then I had spent about two months on and off constructing the boat to a stage where I could consider applying a glassfibre cloth and epoxy finish to the hull. However I couldn’t spend any more time on the Marlin project as I had a more important project to undertake, which was to paint, decorate, refurbish and prepare our house for sale so that we could downsize and move to a new area now that our kids had all fled the nest.

Fast forward to today (mid-April 2025) and it’s taken a while to get the new house and gardens into shape and settle in, with the emphasis on converting my internal garage into a great new workshop, I can finally pick up from where I left off.

Introduction to the kit.

This new model is the latest undertaking by Vintage Model Works, now famous for their very popular models of the RAF Crash Rescue Tender and Thames River Police Boat kits which are based on old Aerokits and Veron designs.

The Marlin is a re-working of an original Veron design by the late Phil Smith in 1953. His son Colin Smith, who was also responsible for the re-design of the Thames River Police Boat, has made some changes to his father’s design to take advantage of more modern materials and production methods such as CNC and laser cutting.

The photograph below is of a prototype built by Colin Smith to give you an idea of how the boat looks in finished form. And there is also a review of the Marlin that appeared in Model Maker magazine, November 1953.

The size remains at 36” and it employs the same construction method as the original. The spacious cabins of the boat makes it very easy to accommodate all the latest control hardware required, not that the original was lacking in that area even when the radio systems used valves and large batteries and the propulsion was usually IC or a large electric motor.

Even the pre-production sample the Vintage Model Works kit supplied to me is well presented with a full size drawing including a pictorial construction sequence and separate pages of building instructions.

All the required materials are supplied in quality ply, balsa, strip-wood and dowel including clear plastic sheets for the windscreens, and various white metal deck fittings. The builder is of course required to supply their own adhesives and paint of choice, as well as the propulsion, drive train and radio control gear. In the latter respect I will likely restrict control to throttle and rudder and not add any lighting or other features. That has already been done magnificently by Mike Turpin.

Construction.

As with the Thames river police boat, another Veron design, construction starts with the assembly of a box structure onto which formers and bulkheads are attached to make the basic hull shape.

I will be tackling this in the first part of my build blog which I hope you will enjoy following and I encourage you to ask questions, leave comments and hopefully some ‘likes’ as I make progress.

Robbob.

🇬🇧 robbob

2 days ago

30 Posts

19 Followers

237 Likes

Fairey Marine Builds

I haven’t done anything on my builds since before last Christmas for various reasons but am looking forward to starting again in the next couple of weeks.

I’ve been working on a number of builds for some years and not finished one yet! Main reason is that I reach a certain point, maybe something I’m hesitant about, and so start another! Which is the reason I’ve got five on the go.

I’m building all the classic Faireys; Huntsman 28, Huntsman 31 and Swordsman 33 and a rarer Huntress 23 with a stern drive and longer cabin. Also a River Cruiser 23 (the one and only full-size build was a prototype was based on a modified Huntress hull but with more freeboard which disappeared) and I have the plans drawn up to start a Fisherman 27 motor sailer and a Faun 17 river/lake cruiser. All builds are at a scale of 1:12.

The River Cruiser and Huntress are further on as they have had lake trials with the others being at the painting stage which I will be taking up again soon.

I use a Hitec Flash 8 Tx and Rx’s and Hitec servos with Overlander brushless motors (even in my slower models) and HobbyWing Quicrun and Seaking ESC’s along with LiPo batteries though will probably use NiMh in the Fisherman and Faun.

🇬🇧 ChrisF

2 days ago

7 Posts

8 Followers

48 Likes

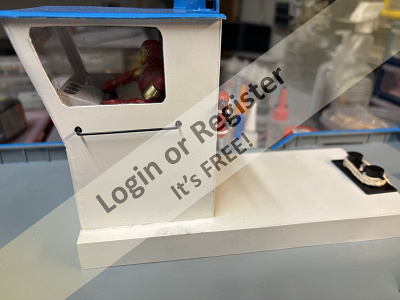

Trawler

Saw this on my Facebook feed, and I'm a little bored, so I will try to convert one of my model boats to a deep-sea trawler. The first photo is mine. I need to rebuild the bridge layout & hopefully we will have a Trawler. To be continued, maybe.

🇨🇦 GARTH

5 days ago

10 Posts

11 Followers

96 Likes

Another Springer tug!!

Hi y’all. Since Dickey has maidened I decided I wanted to do one more project before I attempt to overhaul my garage workshop. I’m thinking I’ll be down a month or more if I get done what I want to get done. In that vein, I’ve decided to attempt another Springer tug. Some years ago I built one before I really had ballasting down right..she ran okay, but I kept messing around with the ballast, epoxying it in, and when I tried to remove it to make changes I severely damaged the hull. So, I removed all equipment, fittings, etc and scrapped the hull. I’ve been wanting another go at it, so I ordered the Zippkits tugster, just the kit no hardware, and started to lick my calf over (old country phrase for a “do-over”)

I built the hull proper per the instructions, and that’s where that ends. I’m using a 4mm shaft, the smaller Robbe/Krick Kort nozzle, and a home made stuffing box. She will be powered by my fave working boat motor, the Zippkits 650 kv outrunner fed by 2 6 cell nimh in parallel.

My stuffing box is made up of a thick wall brass tube that accepts a Traxxas 4mm i.d flanged oilite bushing. The bushing is tapped in with a hammer, and I use an old 4mm shaft to make sure the bushings stay aligned as I install the other bushing. The 1mm thick wall allows me to drill a hole the same size as the brass I’m using for an oiling tube. I’ll grind down the fitted end just a bit to get a decent, thight mechanical joint. That way when I silver solder it in place it stays put and is a good strong joint. The reason I’m so picky is that I use a mini grease gun from Horizon Hobbies, I can old it in place and pump, and I get just a wee bit of grease showing at the bushing under pressure, that way I know darn well it’s full.

I used part of the keel parts to fit the tube, cutting it shorter to allow me to swing the Kort nozzle hard over to make it easier to change props without removing the Kort nozzle, depending on the size of the prop. I cut an oversized slot for the tube as I use solid couplers, and with the motor fitted I could get everything lined up and tack the tube in place with ca, that way I have no binding. I don’t like using universal joint couplers unless I really have to. I get my couplers from Servo City, as they are steel, use larger socket screws, and don’t have any runout. Very solid.

The kit uses a radio plate to to mount the servo, receiver and esc. I cut that down and built up a servo mount, and it’s installed on the same bulkhead shown in the manual, but I mounted it to the fwd side vs the aft as in the instructions. My deck opening is going to be different. I’m using Dubro pushrods, but good old Amazon was out of the ones with metal quick links, so I ordered the ones with nylon. I dug thru my junk box of hardware that I have been collecting since 95 or so, and I found gold!! A few Dubro and Sullivan threaded metal clevises, and some solder clevises too. I mounted the servo, made sure everything worked correctly, then uninstalled everything and gave the inside of the bow and transom and the bottom of the hull a coat of 30 minute epoxy.

That’s where she’s at now. I’m thing I’ll spray the rest of the inside of the hull with clear lacquer ro finish waterproofing, then I have to make a decision. I dont know if I need to glass this thing, or maybe glass the bottom and the just seal and paint the heck out of the sides, or….I’ve also heard that some people just epoxy coat the outer ull with thinned epoxy, then prime and paint. She’s gonn be a working boat, used as an emergency push boat when needed, so she needs to last…if I can get her ballasted properly this time, that is…

Cash

🇺🇸 Cashrc

7 days ago

3 Posts

4 Followers

11 Likes

Another Pusher Tug

While doing research for my Springer/Pusher tug I discovered these drawings David Metcalf’s Motorflot Pusher Tug and I had all the materials to build it so I put the other pusher I am building aside and started on this one. I am easily distracted

All the hull parts have been cut out one after yesterdays power outage, I will stat the assembly today.

Pictures to follow.

🇬🇧 EdW

9 days ago

5 Posts

6 Followers

22 Likes

Titan Tug

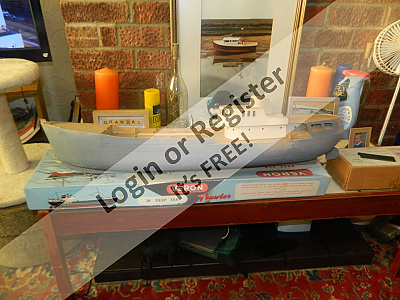

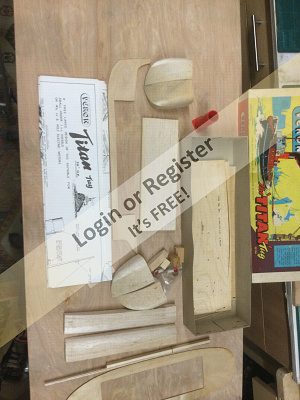

As I promised here is where I am with the build of my Veron Titan Tug

🇬🇧 EdW

10 days ago

4 Posts

3 Followers

10 Likes

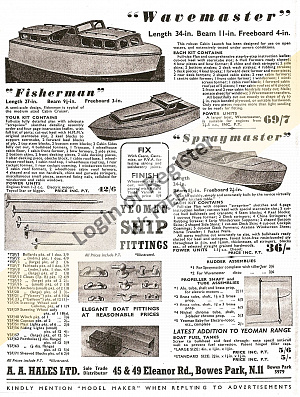

Wave master boat

This is a classic wave master it was built in the fifty's a nd a internet buy I have stripped out the rc engine and its tanks now on the research stage there are a few issues rear end smack thats had a poor repair done and the spray rails do not fit well of its history I know nothing

🇬🇧 Stephen T

12 days ago

1 Post

1 Follower

7 Likes

Original LesRo Sportsman Restoration.

The original shape LesRo Sportsman is a model that had eluded me for many years, but I always liked the look of it, so when one came up on eBay, I matched the opening price with my first bid, and ended up winning it as nobody else placed a bid.

It could well be that everyone else was a lot wiser than me, but I have ended-up with it and it will be a long-term restoration project that will have to be fitted in-between a lot of other build/repair work that I already have stacked-up waiting for my attention.

This boat came with a fitted glow-plug engine of unknown size or type, so the first job was to remove the engine, fuel tank and silencer etc to see just how bad and fuel soaked the inside of the hull was, and then try to work-out how to dry it out and make any repairs that may be needed.

Bob.

🇬🇧 zooma

16 days ago

9 Posts

11 Followers

88 Likes

FLYING Christine II

This is a build of a HA-Kits Flying Christine II which is a model of the St. John's Ambulance service boat which is used to take patients from the Isle of Guernsey (UK) for treatment elsewhere - probably with more facilities! I'm getting my nearly twelve year old grandson to build it with just guidance from myself and I assisted with cutting of the tabs off the laser cut parts on the thicker plywood. We need to get the younger generation interested in our great hobby!

The box contains all the plywood laser cut parts on varying thicknesses of plywood. In addition there is a bag of plastic window frames and plastic window inserts. There is no propeller shaft, rudder or other bits to complete the model.

Construction so far seems to be fairly straight forward and it is something that my grandson is enjoying doing. It is the first model of any kind that he has built.

As he doesn't live near us he is here for just 10 days and we hope to get it completed by the time he goes home. The kit says use thick and thin cyno or Aliphatic glue. I have chose to use Aliphatic so we don't get little fingers stuck together! It will be slower but hope to speed up the process by starting building the cabin whilst the hull is fully curing before adding the skins - the order laid out in the instruction.

BEWARE when initially gluing both halves of the deck together it says you may strengthen the joint by gluing some scrap on the back of the joint. We unfortunately chose a piece about 2mm too long so later in the build it came into contact with one of the bulkheads - so we had to trim it back!

The only other thing was the instructions didn't clearly mention gluing two of the cabin bulkheads together to make one. After a bit of thought and looking at the cabin layout it became obvious that C2 and C3 needed to be first glued together. Having said that when attaching to the cabin frame C3 follows C1 (as one part) and C2 is then before C4!

Make sure you use plenty of masking tape to ensure that the cabin structure doesn't get glued onto the deck! See photos

So this is where we are at the end of Day 2 - more to follow!

Apologies in that the photos are not in the correct sequence!

🇬🇧 DuncanP

17 days ago

|

|

Media Gallery

SSMBC (Seminole, Florida) meet, Nov. 2, 2025

12 days ago by LewZ

Spooky - (Evening sail November)

15 days ago by philcaretaker

Gaff Rigged Bristol Pilot Cutter Autumn / Fall

18 days ago by philcaretaker

Only 2 days left

28 days ago by GARTH

Professional Photographer at Southport

1 month ago by SouthportPat

Filming over water

1 month ago by philcaretaker

"Sailor Sam" greets onlookers at the Sunday morning "Run In The Park".

2 months ago by philcaretaker

Light up the Night on the September 25th 2025 including safety cautions

2 months ago by GARTH

Second navigation (4 September 2025) to Lake Turano.

2 months ago by AlessandroSPQR

Maritime Drone

2 months ago by teledrone

Canadian Coast guard 44 Lifeboat

2 months ago by GARTH

War ship regatta

2 months ago by GARTH

|

|

Login To

Remove Ads

Remove Ads

Boat Clubs & Lakes

Recent Updates In Places

|

Buxton Model Boat Club

4 days ago by 🇧🇪 hermank (

Rear Admiral) Rear Admiral) |

|

Southport Model Boat Club

14 days ago by 🇬🇧 SouthportPat (

Commodore) Commodore) |

|

BUXTON MODEL BOAT CLUB

15 days ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

New Brighton Model Boat Club

26 days ago by 🇬🇧 zooma (

Rear Admiral) Rear Admiral) |

|

Wallesey Model Boat Club

27 days ago by 🇬🇧 SouthportPat (

Commodore) Commodore) |

|

|

Upcoming Events

|

Nov

15 2025

|

Nov

16 2025

|

Model Boat Show

Ended 2 hours ago

|

|

|

Boat Harbour

5 Photos

7 Likes

My ARTR Plastic Yachts

I bought the HydroPro Affinity not long after I started the hobby to learn to sail and do some club racing. It is 650mm long and complies with the DF65 racing regulations. Like the more common DragonForce 65 it was built by Joysway and was introduced as a slightly cheaper model but as it used many parts from the DragonForce I doubt it was very viable and wasn't available for very long. I built it with the B Suit of sails for windier days.

A few years later I wanted something a little more competitive (the HydroPro is quite beamy) and so bought a DragonForce 65 which I fitted with the A suit of sails for less windy days - saves having to change sails!

🇬🇧 ChrisF

7 days ago

0 Attributes

5 Comments

3 Photos

7 Likes

Wavemaster HMH boat winter restoration project

Got this 1950s model boat on line website I have been after a vintage wave master for a while she has had a rear end smash so a bit of repair work there and the top assembly doesn't quite fit more on this in due course mine doesn't look like the photo off line

In side the boat says Harvey A Adams 17 June 1954

🇬🇧 Stephen T

22 days ago

5 Attributes

2 Comments

19 Photos

8 Likes

RSO Steyr 1/6th German ww2 field tractor (yes not another NONE boat) although it could do a small be

This is my scratch build German WW2 field tractor, ongoing process but does drive and currently undergoing a gearbox rebuild as the old drill motors felt the pain on tight turns.. Also has new prototype body from the Version 3 which I think only a few were ever in filed use.

Has sound and lights. A combination of 3d printed parts and aluminium, all the drives shafts are with bearings along with the road wheels.. Still a way to go, but time ain't the issue I hope. Although nothing is a given ..

🇬🇧 Northernflotsam

22 days ago

0 Attributes

2 Comments

3 Photos

1 Like

VOLVO C304 1/10th

Heres some shots of the Volvo C304 scratch build, more complete right now that current pictures but have been busy.. life eh

6x6 conversion complete via 3d printed parts and 2 FTX chassis as donors.. drives quite well .

🇬🇧 Northernflotsam

22 days ago

0 Attributes

1 Comment

1 Photo

8 Likes

Landrover 101 1/10 scale

Not a boat or is it.. landrover 101 FC 1/10th scale rc.. build from rc crawler chassis kit and scratch build body .. works fine and sounds pretty good

🇬🇧 Northernflotsam

22 days ago

0 Attributes

3 Comments

1 Photo

8 Likes

In progress Bearospace EMMA

this one is now almost ready for the epoxy skin, sail winch to fit and thats still on the bench as of today, started this as Ive never done a working sail model..

🇬🇧 Northernflotsam

22 days ago

0 Attributes

3 Comments

1 Photo

6 Likes

1/12 figure conversion ..

I converted a figure (spock) in a lifeboat coxwain for a friend.. greenstuff miliput and apoxy.. old but thought I pop it up

🇬🇧 Northernflotsam

24 days ago

0 Attributes

3 Comments

3 Photos

4 Likes

Vintage Hull rescue and re-imagining

Got the hull for this form a person whom had it in a junk pile, glassed inside with crap and car filler. Did my very best to rescue the hull and spent a whie pulling and rotary tool removing as much as I could, had a few ideas what to creat from it so as is a WIP.

Its beeb a while since on here but now things are beginning to find a level we'll see how I go

🇬🇧 Northernflotsam

24 days ago

0 Attributes

4 Comments

13 Photos

13 Likes

Northumberland cobble static model

This was built from the enterprise cobble drawings. I started this as a learning process

🇬🇧 Northernflotsam

24 days ago

0 Attributes

7 Comments

|

|

How-To Articles

Essential or useful tools and utensils for the ship modeler. A final appendix lists the most common

Revised 19 days ago

By AlessandroSPQR

stop email notifications

Revised 22 days ago

By Ace23

painting epoxy over Humbrol and varnish enamels

Revised 3 months ago

By roycv

Cardan joint, Homokinetic joint, universal joint. Problems related to the junction between the engin

Revised 5 months ago

By AlessandroSPQR

various electrical connection diagrams for two motors

Revised 7 months ago

By tomarack

Lifeboats or work boats?

Revised 10 months ago

By AlessandroSPQR

Permanent magnet brushed electric motors. Main features. Basic elements of distinction. How to evalu

Revised 10 months ago

By AlessandroSPQR

When wooden planking the sides of hulls What Glues are you using?

Revised 1 year ago

By bruce1946

Fibreglassing a wooden hull

Revised 1 year ago

By DuncanP

Building Veron Marlin

Revised 1 year ago

By jonb

|

|

Login To

Remove Ads

Remove Ads

Model Boats Website

This is the alert text. You can customize this text to be as long or short as needed. The modal height will adjust accordingly.

🛍️ Basket

Main menu transported here on mobile

Login

Create New Account

Trending Topics

Members Online

Forum

Nigel Trafford-Jones

EdW

19 hours ago

Forum

Question of the Day?

EdW

19 hours ago

Forum

And Now For Something Completely Different

ChrisF

1 day ago

Forum

Tools

ChrisF

1 day ago

Forum

I Hate Painting!

ChrisF

1 day ago

Forum

Sailing barge sails

Ronald

1 day ago

Blog

Re: Fairey Faun - RC Installation

zooma

1 day ago

Forum

Sprite

zooma

2 days ago

Forum

Early Radio Control Experiences

roycv

2 days ago

Blog

Re: Extending the cable routes.

tonyb2

2 days ago

Forum

Motor Mounts

LewZ

2 days ago

Blog

Re: Woodstock Research and Build, Errors and Blunders

jumpugly

2 days ago

Blog

Re: Classic Model Power Boats

zooma

2 days ago

Forum

Double Jointed Universal Couplings

IanL1

2 days ago

Forum

How do you create the coiled ropes?

BobbyN

3 days ago

Forum

Animal and nature photos to enjoy.

Wolle

3 days ago

Forum

A little bit of luck

Ronald

3 days ago

Blog

Re: Jetty for model boats

ChrisF

4 days ago

Forum

Dutch sailing barge

AndyB2

4 days ago

Forum

Back to Model Boat Building (replaced 3D printers)

LewZ

5 days ago

Forum

Post-Scotland inspiration

Ronald

5 days ago

Blog

Re: A few details

wingsounds13

5 days ago

Blog

Trawler

GARTH

5 days ago

Forum

EMYC Annual Dry Dock Dinner & Annual Swap Meet

AlessandroSPQR

5 days ago

Event

Model Boat Show

PhilH

6 days ago

Harbour

Re: My ARTR Plastic Yachts

jumpugly

6 days ago

Blog

Re: Aerokits Sea Commander. Strange Handling ?

zooma

7 days ago

Forum

Fairey Swordsman Plans

ChrisF

7 days ago

BOATSHED

Commander

2,671 Points

1 second ago

RPLedm

Chief Petty Officer 2nd Class

339 Points

13 seconds ago

RossM

Captain

3,093 Points

21 seconds ago

Steves-s

Chief Petty Officer 2nd Class

421 Points

24 minutes ago

roycv

Admiral

9,818 Points

43 minutes ago

Ronald

Fleet Admiral

12,576 Points

1 hour ago

GARTH

Captain

3,856 Points

1 hour ago

Rowen

Captain

3,547 Points

1 hour ago

ChrisF

Rear Admiral

5,583 Points

2 hours ago

RonH

Warrant Officer

793 Points

2 hours ago

zippy

Master Seaman

123 Points

2 hours ago

RM

Recruit

0 Points

2 hours ago

thadlietz

Petty Officer 1st Class

299 Points

3 hours ago

d dubya

Recruit

6 Points

3 hours ago

ekoral

Master Seaman

128 Points

3 hours ago

DWBrinkman

Commodore

4,262 Points

3 hours ago

GaryLC

Captain

3,449 Points

3 hours ago

Chum444

Captain

3,794 Points

3 hours ago

AustinG

Warrant Officer

664 Points

4 hours ago

zooma

Rear Admiral

5,619 Points

4 hours ago

DuncanP

Commander

2,506 Points

4 hours ago

OliverK

Recruit

0 Points

4 hours ago

Steamrod

Recruit

7 Points

5 hours ago

AndyB2

Chief Petty Officer 2nd Class

349 Points

5 hours ago

RogerA1

Warrant Officer

680 Points

5 hours ago

radu022003

Recruit

7 Points

5 hours ago

mturpin013

Admiral

8,495 Points

6 hours ago

RonB

Recruit

0 Points

6 hours ago

Oxford-Dave

Sub-Lieutenant

1,220 Points

6 hours ago

dash8man

Able Seaman

26 Points

7 hours ago

premecekcz

Master Seaman

114 Points

7 hours ago

IORYellow40

Recruit

0 Points

7 hours ago

hermank

Rear Admiral

5,226 Points

8 hours ago

Monty6

Recruit

0 Points

8 hours ago

AlessandroSPQR

Fleet Admiral

11,884 Points

9 hours ago

luckyduck

Lieutenant

1,834 Points

9 hours ago

Robidoo

Recruit

0 Points

9 hours ago

Softie

Able Seaman

22 Points

10 hours ago

Landlubber

Recruit

0 Points

10 hours ago

SouthportPat

Commodore

4,769 Points

10 hours ago

Capt Bob

Recruit

0 Points

10 hours ago

trowley

Recruit

0 Points

10 hours ago

JEANFRANCOIS G

Recruit

0 Points

10 hours ago

robertc3

Recruit

3 Points

11 hours ago

PEI

Recruit

0 Points

11 hours ago

JOHN

Midshipman

1,094 Points

11 hours ago

Hhager2

Sub-Lieutenant

1,458 Points

11 hours ago

Wolle

Commodore

4,810 Points

11 hours ago

AdrianG

Recruit

10 Points

12 hours ago

PeteJev

Petty Officer 2nd Class

162 Points

12 hours ago

Login To

Remove Ads

Remove Ads

🏠

Home

Home

📰

Trending

Trending

💬

Forum

Forum

🗝

Login / Join

Login / Join

|

Cookies are used for ads personalisation.

By using this website you agree to our use of cookies. More Info |

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,803)

📣 Support

Hobby Supplies

🛍️ Online Shop

Login

🗝 Login

🗝 Create New Account

▼

Media Gallery

X

1 of 4

► |

◄ |

Media Viewer

^

_

X

Share

X

Flag Inappropriate Post

X

| Select Reason | |

| Sexual content Includes graphic sexual activity, nudity, and other sexual content. | |

| Violent or repulsive content Violent or graphic content, or content posted to shock viewers. | |

| Hateful or abusive content Content that promotes hatred against protected groups, abuses vulnerable individuals, or engages in cyberbullying. | |

| Harmful dangerous acts Content that includes acts that may result in physical harm. | |

| Child abuse Content that includes sexual, predatory or abusive communications towards minors. | |

| Promotes terrorism Content intended to recruit for terrorist organisations, incite violence, glorify terrorist attacks, or otherwise promote acts of terrorism. | |

| Spam or misleading Content that is massively posted or otherwise misleading in nature. | |

| Infringes my rights Privacy, copyright and other legal complaints. | |

Basket Updated

X

Loading...

Loading

Loading Uploader...