|||

|

|

🗝 Login

🤖 Create Account

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Plans & Docs

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,789)

📖 Quick Site Guide

📣 Support

👥 Membership

Hobby Supplies

🛍️ Online Shop

Not Registered

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

For A Whole Year!

£25

£45

£65

Donate

You Will Be Helping Towards:

Domain Fees

Security Certificates

iOS & Android App Fees

Website Hosting

Fast Servers

Data Backups

Upkeep & Maintenance

Administration Costs

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Model Boats Website

Home

Forum

Build Blogs

Media Gallery

Boat Clubs & Lakes

Events

Boat Harbour

How-To Articles

Plans & Docs

Useful Links

The Games Chest

Login To

Remove Ads

Remove Ads

Trending Now

Blog

Re: The tub test

Hi Alessandro.

My tub test was in the garage in a low light, hence the shade change, but it's in the photos only.

Thanks for the well wishes. I'll need some luck moving forward!

🇺🇸 jumpugly

30 minutes ago

Forum

Peterd has passed away quietly this evening

I have received word that our colleague has quietly passed away. I don’t know his family other than Marilyn is his wife and there are family members too.

Remember them in your thoughts and prayers over these coming weeks.

Respectfully

Ronald

🇨🇦 Ronald

2 hours ago

Blog

Re: Making the Rear Hatch

Looking great, Robbob.

It’s always tricky to design a hatch that’s secure enough to withstand the wake generated by other models.

I used six 5 mm magnets, with a piece of galvanized steel on the hatch, and I’m hoping this setup will perform as well as yours.

🇺🇸 chugalone100

10 hours ago

Event

Edina Model Yacht Club at the Minneapolis Boat Show

I understand that the space is quite crowded, which is precisely why I would greatly appreciate seeing your setup.

🇺🇸 chugalone100

12 hours ago

Forum

Identify model

Hello Andy-W.,

Perfect winter work!

I would love to bring something like this to life too. But here at our club, the harbor construction is coming to an end.

Then I'll have time again for my “cellar skeletons.”

I'm excited to see your work! Good luck!

See you soon, your Michel-C.

PS: With a little imagination, you can achieve anything, as I did with my Dolores, a sternwheel steamboat.

🇨🇭 Mike Stoney

12 hours ago

Forum

Question of the Day?

Come on down to longest answer wins at least it gives me a fighting chance of knowing it

Phil uk

🇬🇧 PhilH

16 hours ago

Blog

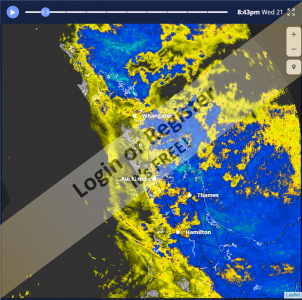

New Moth MKII semi scale yacht

Hull's back to red paint now after the Zinsser coat which fixed the fisheyes. Added some mahogany trim to the rudder stock, and have now cut out the self draining slots in the transom, (i think it's going to need them) The foam between the cockpit ply and transom will need filling and coating round the inside of the drains. Still have the deck to paint (over the white resin) and a veneer to go on the transom (varnished). After that,- fittings. Decided to leave the rudder unpainted, looks ok as is I think.

Rough weather slowing things down at the moment, heavy rain, landslides (unfortunately people missing,) slips everywhere, flooding etc . It's supposed to be summer !

JB

🇳🇿 jbkiwi

18 hours ago

Forum

Meet Selma from Norway 🇳🇴

Great stuff Ron! Many thanks to John!!!

🇺🇸 jumpugly

2 days ago

Blog

Re: Vosper

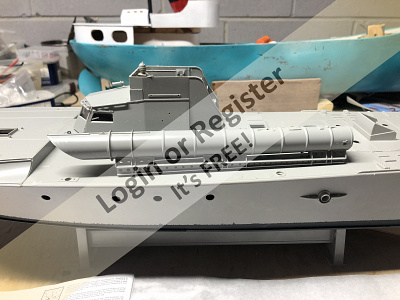

Doing a fine job Garth. Yes the torpedo tubes will hide the nuts. I see you went for a different battery.

I still don’t like the way you chose to put your receiver and ESC in the bow under the deck.

It is s easy to place them in your well of the wheelhouse. I know from our conversation this week that you are not going to be detailing it as I did. So, why not use the space?

🇨🇦 Ronald

2 days ago

Forum

Adhesives

You might look into this product it might work for your needs https://www.amazon.com/Welding-Repair%EF%BC%8CCar-Automotive-Plastics%EF%BC%8CMetals%EF%BC%8CStainless-Steel%EF%BC%8CAluminum%EF%BC%8CIron%EF%BC%8C1-76/dp/B0CYGZ5GYF/ref=sxbs_sbv_search_btf?content-id=amzn1.sym.37132d36-da68-4ed0-8d23-842f0825e4d6%3Aamzn1.sym.37132d36-da68-4ed0-8d23-842f0825e4d6&crid=29HX8HGY0UGZ4&cv_ct_cx=3m%2Bscotch-weld%2Bdp420ns&keywords=3m%2Bscotch-weld%2Bdp420ns&pd_rd_i=B0CYGZ5GYF&pd_rd_r=e9075470-a50a-4de2-a892-3238ccd96e80&pd_rd_w=G3CIe&pd_rd_wg=U9X5I&pf_rd_p=37132d36-da68-4ed0-8d23-842f0825e4d6&pf_rd_r=DKFEBY70BCKMBASKXD1A&qid=1769126599&sbo=RZvfv%2F%2FHxDF%2BO5021pAnSA%3D%3D&sprefix=scotch%2BDP420n%2Caps%2C159&sr=1-1-a61ee601-6e56-4862-a8a2-1d3da5a5406f&th=1

🇺🇸 bruce1946

2 days ago

Forum

Sailing at the Toronto Boat Show

The Toronto International Boat Show (the official name of the the show) has been running every January at the CNE grounds since 1959. It went virtual during Covid.

🇨🇦 ScouterChil

2 days ago

Blog

Last gasp before maiden splash in warm weather

A few more things done before we head to the warm weather.

1. Into the ballast test tank the other day. No leaks & initial ballast set. 16.5 oz in the stern. With 12 os NIMH an additional 9os of lead ballast. Right now float weight about 4 lbs. Might be a bit light.

2. Gloss black hull, white anti foul paint on bottom & red boot top.

3. Profile view.

🇺🇸 Chum444

3 days ago

Forum

How much is too much? (If it ain't free and I need to volunteer then I ain't joining.)

Lew i think that that is part if the problem. Too much offered to the youngsters. I started in the early sixties no mobile phones, most people didn’t even have a television, no internet, no asocial media. I m a (strong) believer that we have hit the bottom of the curve and that i will go up again. I spoke to parents at the pond on sunday and one of the questions was “ can we come back with the kids” because they have never been so laid back with the sailing. Times will change in the other direction( one day )

🇧🇪 hermank

3 days ago

Forum

motor for large paddle steamer. Advice required

here is the progress on the front deck. Still trying to sort out a place to work on the 3 metre 35kg hull!

🇬🇧 Hermione

4 days ago

Blog

Re: Fairey Fisherman 27

Jig Saw.

I think that the "foot" that rests on top of the wood is more or less essential on a jig saw to hold the wood down onto the surface plate when the action of the blade is trying to lift it up with every stroke!

The "foot" on my Hegnar jig saw is much smaller than yours, and often as the wood is turned, the "foot" looses contact with the wood and I have to press the wood down firmly to hold it onto the saw's baseplate (at the same time as guiding it) - with mixed results!

It is certainly much easier to "cut to the line" when the wood that is being cut it held firmly against the base plate of the jig saw.

Bob.

🇬🇧 zooma

4 days ago

Blog

Re: Fairey Fisherman 27

Jig Saw.

I think that the "foot" that rests on top of the wood is more or less essential on a jig saw to hold the wood down onto the surface plate when the action of the blade is trying to lift it up with every stroke!

The "foot" on my Hegnar jig saw is much smaller than yours, and often as the wood is turned, the "foot" looses contact with the wood and I have to press the wood down firmly to hold it onto the saw's baseplate (at the same time as guiding it) - with mixed results!

It is certainly much easier to "cut to the line" when the wood that is being cut it held firmly against the base plate of the jig saw.

Bob.

🇬🇧 zooma

4 days ago

|

New Member

United Kingdom

NeilP1

NeilP16 hours ago

New Member

United Kingdom

IanH5

IanH57 hours ago

New Member

France

hercule

hercule11 hours ago

New Member

United Kingdom

SimonC

SimonC2 days ago

New Member

United States

PaulD10

PaulD102 days ago

New Member

Argentina

ScoutS

ScoutS2 days ago

New Promotion

Able Seaman

Kennybeck

Kennybeck2 days ago

New Member

United Kingdom

snah73

snah733 days ago

New Promotion

Master Seaman

ScouterChil

ScouterChil3 days ago

Birthday This Week

Turns 87

geraldl

geraldl3 days ago

New Member

Australia

PeterJ5

PeterJ53 days ago

New Member

Canada

dond1

dond13 days ago

New Promotion

Sub-Lieutenant

bruce1946

bruce19463 days ago

New Member

United Kingdom

Amanda K

Amanda K3 days ago

New Promotion

Master Seaman

merchant67

merchant674 days ago

New Member

Indonesia

BayoeB

BayoeB4 days ago

New Promotion

Leading Seaman

Hermione

Hermione4 days ago

New Member

United Kingdom

RichardW

RichardW5 days ago

New Member

Australia

GaryPArmstrong

GaryPArmstrong5 days ago

New Member

United Kingdom

DavidR4

DavidR45 days ago

Birthday This Week

Turns 82

Peejay

Peejay6 days ago

New Member

Spain

JessO

JessO6 days ago

New Member

United Kingdom

HarryE

HarryE6 days ago

New Member

United Kingdom

CliveO

CliveO6 days ago

New Member

United Kingdom

DouglasG

DouglasG7 days ago

Birthday This Week

Turns 65

Cashrc

Cashrc7 days ago

New Member

United Kingdom

nicholasa

nicholasa8 days ago

Account Updated

Changed Avatar

PhilH

PhilH8 days ago

New Member

Vietnam

Bung

Bung8 days ago

Birthday This Week

Turns 55

Aerodecked

Aerodecked8 days ago

New Promotion

Leading Seaman

lukeH

lukeH8 days ago

New Promotion

Commodore

GARTH

GARTH9 days ago

New Member

United Kingdom

Adrian7pt

Adrian7pt9 days ago

New Member

United Kingdom

Sean

Sean10 days ago

Birthday This Week

Turns 74

DaveH2

DaveH210 days ago

New Member

New Zealand

KevinH1

KevinH110 days ago

Account Updated

Changed Avatar

lukeH

lukeH10 days ago

New Member

United States

JJFlanagan

JJFlanagan10 days ago

New Member

United Kingdom

twilight

twilight10 days ago

New Member

United Kingdom

richardl4

richardl411 days ago

New Member

United Kingdom

lukeH

lukeH11 days ago

New Member

United Kingdom

hunting

hunting12 days ago

New Member

Turkey

ilkers

ilkers12 days ago

New Member

United Kingdom

davidt6

davidt612 days ago

Account Updated

Changed Avatar

BOATSHED

BOATSHED13 days ago

New Member

United Kingdom

JoeS3

JoeS313 days ago

New Member

United Kingdom

SkyrayM

SkyrayM13 days ago

New Member

Australia

MauriceP

MauriceP13 days ago

See More

Forum Topics

Peterd has passed away quietly this evening

I have received word that our colleague has quietly passed away. I don’t know his family other than Marilyn is his wife and there are family members too.

Remember them in your thoughts and prayers over these coming weeks.

Respectfully

Ronald

2 hours ago by 🇨🇦 Ronald ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Non-Hobby Chat

1 Post

0 Likes

0 Likes

Started

2 hours ago

by Ronald

2 hours ago

by Ronald

No Replies Yet

Identify model

Hello Andy-W.,

Perfect winter work!

I would love to bring something like this to life too. But here at our club, the harbor construction is coming to an end.

Then I'll have time again for my “cellar skeletons.”

I'm excited to see your work! Good luck!

See you soon, your Michel-C.

PS: With a little imagination, you can achieve anything, as I did with my Dolores, a sternwheel steamboat.

12 hours ago by 🇨🇭 Mike Stoney ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)

Building Related

5 Posts

19 Likes

19 Likes

Started

5 days ago

by AndyW

5 days ago

by AndyW

Latest

12 hours ago

by Mike Stoney

12 hours ago

by Mike Stoney

Question of the Day?

Come on down to longest answer wins at least it gives me a fighting chance of knowing it 🤣🤣

Phil uk👍

16 hours ago by 🇬🇧 PhilH ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)

Website Related

5433 Posts

13656 Likes

13656 Likes

Started

3 years ago

by fireboat

3 years ago

by fireboat

Latest

16 hours ago

by PhilH

16 hours ago

by PhilH

Edina Model Yacht Club at the Minneapolis Boat Show

I understand that the space is quite crowded, which is precisely why I would greatly appreciate seeing your setup.

😎

12 hours ago by 🇺🇸 chugalone100 ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Event

0 Posts

31 Likes

31 Likes

Started

1 day ago

by DWBrinkman

1 day ago

by DWBrinkman

Latest

12 hours ago

by chugalone100

12 hours ago

by chugalone100

Meet Selma from Norway 🇳🇴

Great stuff Ron! Many thanks to John!!!

👍😊

2 days ago by 🇺🇸 jumpugly ( Admiral)

Admiral)

Admiral)

Admiral)

Hobby Chit Chat

3 Posts

14 Likes

14 Likes

Started

2 days ago

by Ronald

2 days ago

by Ronald

Latest

2 days ago

by jumpugly

2 days ago

by jumpugly

|

|

Login To

Remove Ads

Remove Ads

Build Blogs

27 Posts

26 Followers

368 Likes

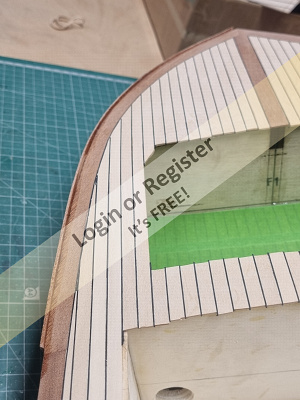

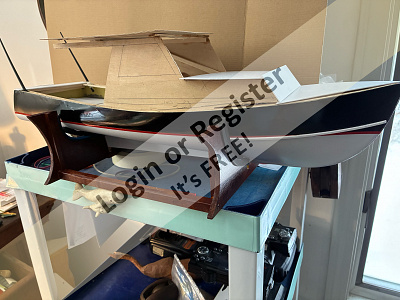

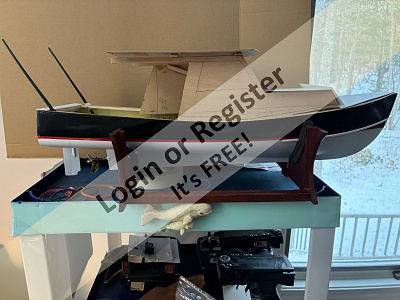

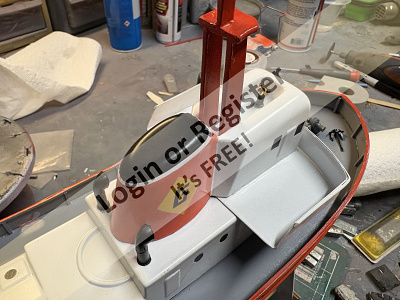

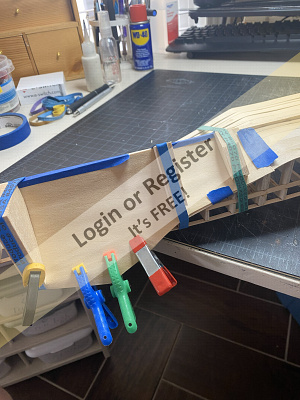

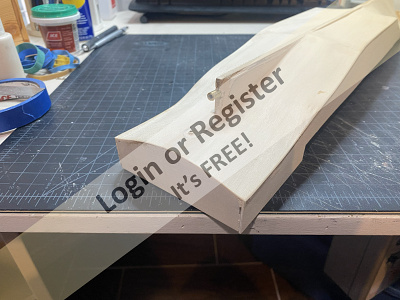

The VMW Marlin Cabin Cruiser by Robbob

The VMW Marlin Cabin Cruiser by Robbob

Preface.

At the time of writing, I’ve had the construction of this boat on ‘the back burner’ since July 2022. By then I had spent about two months on and off constructing the boat to a stage where I could consider applying a glassfibre cloth and epoxy finish to the hull. However I couldn’t spend any more time on the Marlin project as I had a more important project to undertake, which was to paint, decorate, refurbish and prepare our house for sale so that we could downsize and move to a new area now that our kids had all fled the nest.

Fast forward to today (mid-April 2025) and it’s taken a while to get the new house and gardens into shape and settle in, with the emphasis on converting my internal garage into a great new workshop, I can finally pick up from where I left off.

Introduction to the kit.

This new model is the latest undertaking by Vintage Model Works, now famous for their very popular models of the RAF Crash Rescue Tender and Thames River Police Boat kits which are based on old Aerokits and Veron designs.

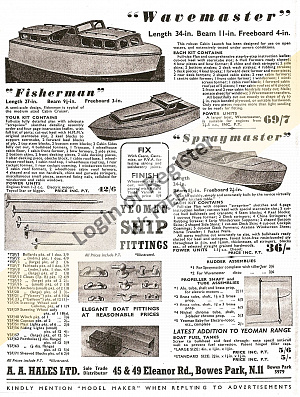

The Marlin is a re-working of an original Veron design by the late Phil Smith in 1953. His son Colin Smith, who was also responsible for the re-design of the Thames River Police Boat, has made some changes to his father’s design to take advantage of more modern materials and production methods such as CNC and laser cutting.

The photograph below is of a prototype built by Colin Smith to give you an idea of how the boat looks in finished form. And there is also a review of the Marlin that appeared in Model Maker magazine, November 1953.

The size remains at 36” and it employs the same construction method as the original. The spacious cabins of the boat makes it very easy to accommodate all the latest control hardware required, not that the original was lacking in that area even when the radio systems used valves and large batteries and the propulsion was usually IC or a large electric motor.

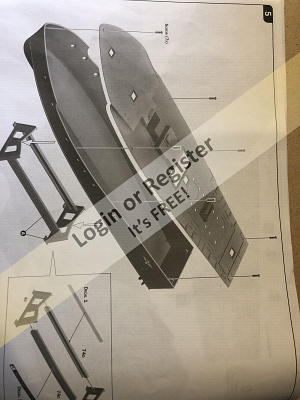

Even the pre-production sample the Vintage Model Works kit supplied to me is well presented with a full size drawing including a pictorial construction sequence and separate pages of building instructions.

All the required materials are supplied in quality ply, balsa, strip-wood and dowel including clear plastic sheets for the windscreens, and various white metal deck fittings. The builder is of course required to supply their own adhesives and paint of choice, as well as the propulsion, drive train and radio control gear. In the latter respect I will likely restrict control to throttle and rudder and not add any lighting or other features. That has already been done magnificently by Mike Turpin.

Construction.

As with the Thames river police boat, another Veron design, construction starts with the assembly of a box structure onto which formers and bulkheads are attached to make the basic hull shape.

I will be tackling this in the first part of my build blog which I hope you will enjoy following and I encourage you to ask questions, leave comments and hopefully some ‘likes’ as I make progress.

Robbob.

🇬🇧 robbob

13 hours ago

7 Posts

9 Followers

54 Likes

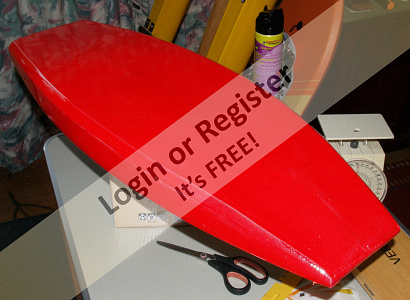

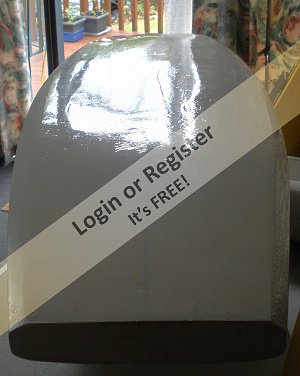

New Moth MKII semi scale yacht

Haven't built anything for a while due to lack of space (too many models) but the urge to build something was too great. After looking at many options, I decided to go with something 'easy' to build. I found some full size plans for an Australian MkI Moth which I'm building to a MKII (double chine) style.

I'm building in foam and glass again to make things easier. It's 850mm long and 310 wide which is roughly 1/4 scale (original is 11 ft)

Started by converting all the lofting measurements on the redrawn 1953 plan to metric and dividing them by 4 to get the scale.

Next was creating the ply deck, then contact gluing onto it a piece of dense 50mm building polystyrene. This was then shaped with a surform file and the chines shaped afterwards using eyeometry. Then the 10mm deck foam was glued on so the deck sheer could be shaped.

Next the cockpit foam was routered out, and basswood sides and inner transom piece epoxied in. After that, the ply outer transom piece and hardwood nose block was epoxied on.

The centerboard case upper and lower ply braces were routered out (using the mill and a 1/2" slotting bit) large enough to accept the case sides, leaving enough room for the 6mm aluminium keel (can't use a centerboard for obvious reasons) which will have to have a bulb fitted.

A rebate in the bottom of the hull was routered out for the lower c/board brace. These braces are needed to form part of a box structure with the floor and cockpit sides which the c/board can lever on. Once everything is eventually glassed in, it will make it very strong unit, so the foam will just be the shape surrounding the box, and not having any strain put on it. The ply deck will take the strain of the stays/mast.

The cockpit floor was cut, and will be slotted the same as the braces, then the c/board case will be built.

The mast on this is 1.486m tall, - sail is -luff -11.295, foot 609mm, so quite large for a small boat. The full sized boat is a lot of fun to sail, so this model will be interesting to sail. Unfortunately, without the human input required, and being a performance boat, it may assume the attributes of a submarine in a stiff breeze, - time and testing will tell.

The basic mast was made from 12mm ally tube, boom from 10mm. Sail pattern was cut from art card to the plan. All laid out on the floor to get an idea of what it will look like.

PDF is the history of the Moth. There were a number of versions round the world as it went along,- scow, international moth (dinghy type) and todays high speed foiling moth.

Lots more to do yet

JB

2025 world champs, off the Whangaparaoa peninsula, just up from where I live.

https://www.youtube.com/watch?v=FuLhJ-yRLmc

https://australianclassicdinghynetwork.org/moth

https://www.youtube.com/watch?v=wWkd2e8apSI

https://www.moth.asn.au/

https://www.youtube.com/watch?v=gAifFN0RJ0M

🇳🇿 jbkiwi

18 hours ago

18 Posts

18 Followers

182 Likes

Bluebird k-7

Hello all! Before my two week sojourn out to California starting tomorrow...

Here she is, all 31 inches and 4.8 pounds of 3D printed 1/10th scale madness. And the questions are starting arise after more than a few hours spent in research. How to get her to plane even close to scale?

1) EDF? Probably not, actually I don't think even a 90mm fan, (which will, in fact, push a faomy jet) will ever get this boat to plane.

2) Prop? Maybe with dual 6s and a killer motor, monster cooling etc. But, nowhere near scale with a big prop hanging out the back.

3) Turbine? probably yes, but way out of my league in mechanicals and $$. There will be tons of head-scratching my quickly balding head on this experiment.

This is going to go on the shelf for the long haul as my freighter needs finishing and the big Sterling Chris Craft Corvette is screaming at me. But, off to Cali for now...I will drop some pix from time to time of our travels.

Best to all!

🇺🇸 jumpugly

1 day ago

4 Posts

3 Followers

21 Likes

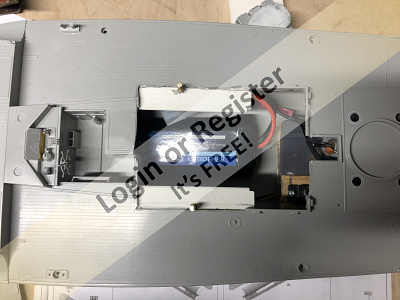

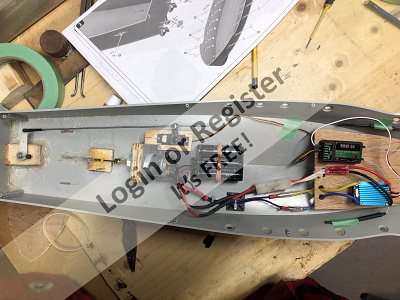

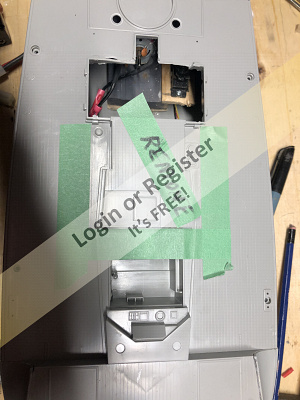

Vosper

Today was another part constructed. The motor mount is built, the propeller shaft and the propeller is installed need to wait till the glue sets and then I'll glue the motor in place.

🇨🇦 GARTH

2 days ago

7 Posts

5 Followers

47 Likes

36 ft Northern Bay sport fisherman

The Northern Bay lobster and sport fishing boats are built in Qgunquit, Maine. Known as Down East boats they are semi-displacement hulls. They are very good sea boats stable in heavy seas. Compared to semi-vee hulls common to many other sport fisherman boats in the U.S. the Down East hulls tend to be wet boats. As with everything else, boat design is always a compromise.

1&2 The inspiration

3&4 Beginning steps

🇺🇸 Chum444

3 days ago

1 Post

2 Followers

8 Likes

LISA M Motor Yacht

I've bought the above kit to keep me busy during these dark dank winter months. Originally I had planned to build a 880mm (34.6") Bluebird of Chelsea plank on frame kit. It is a famous pleasure craft built for Sir Malcolm Campbell and took part in rescuing soldiers from the beaches of Dunkirk under 'Operation Dynamo' in 1940. Unfortunately much to my bitter disappointment only the larger 52" version now is available which is too big for myself.

I'm hoping some kit builder will make a kit of this craft at about 36" so in the meantime here goes with LISA M

The kit has an ABS hull (a bonus for my hands these days!) and laser cut plywood parts. The kit also comes with an electric motor so all you need is a servo and speed control plus the usual R/C gear and battery.

A set of English instructions were also provided which are a reasonable translation with the odd error here and there! I feel they could be a bit more specific in places so study the photos.

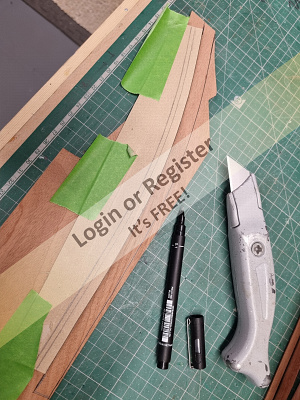

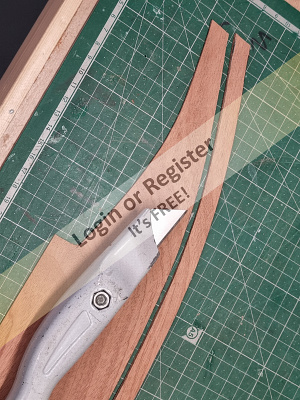

The ABS hull comes with about 1 1/4" (about 300mm) extra height above the deck level which needs cutting down to be about 2mm above the temporary fitted deck level. This wasn't that easy but in the end I used a pair of tin snips to cut it which proved to be better than using a Stanley Knife. I have drilled and filed the holes in the ABS hull for the prop shaft tube and rudder tube. I've now assembled the deck coaming, motor mount, battery box and supports for the rudder tube. Next job is to waterproof the deck on both sides, and all the other assembled plywood parts. Having seen another blog, I've decided to strengthen the wood around the rudder tube by using an offcut from the wood provided for the boat stand. I will smooth the edges when the glue has set!

🇬🇧 DuncanP

5 days ago

5 Posts

5 Followers

46 Likes

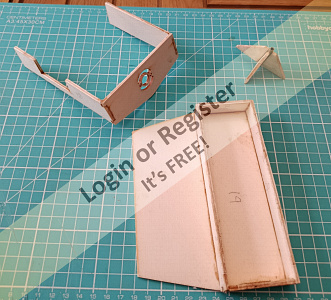

Graupner Pollux

Hi y’all..it’s been a minuet since I’ve been on here. Getting ready for Christmas, the annual NTMS Christmas party, work, etc. I haven’t been at my bench for a few weeks, so I decided to drag a simple kit out of my stash and build it up…the Graupner Pollux.

This kit has been gone thru, some of the vac formed parts have been cut out but not finished, but it’s very buildable. First thing I had to do is build a stand. I pulled my trusty Ryobi scroll saw out from its hiding spot under the bench, got it set up, then the blade broke…and I couldn’t remember where I put my spare blades. So I built the stand up using plasticard for the uprights which I reinforced with 1/8 in ply strip, and used dowels to connect them together. I then looked at the kit and plans.

I did not have anything similar to the Speed 180 gearbox called for, so after I trimmed and sanded the hull I made up a motor mount for a 28mm outrunner. The motor I’m using is a little hotter than I would like, it’s 750KV, which is not a “hot” motor in any stretch but is a little hotter than I would have liked…but it’s in my stock, so I used it. The shaft was missing from the kit, so I had an 1/8 in I.D Dumas tube and shaft that I cut down to suit. I have a few 3 blade props in the right size for this boat, they’re set up for a drive dog or pin style shaft. They are made for a 3 mm shaft, so it was easy to clean out with a 3.2 (1/8) drill bit to fit my chosen hardware. I also am using a rudder from my parts stock, which I started to mount in the original location, didn’t like that so I moved it aft a bit to give a little more clearance for prop installation. The original hole is filled from the inside by the rudder tube support, the rest of the fill will be done later. After I got every thing ready I checked fit and alignment then glued every down. I then built up a servo mount and did a Buick install and test on the linkage, after that I glued down a battery floor.

That’s where’s she’s at now, I’m going to get the ESC and receiver mounted using Velcro, and once I’m statisfied that I can access them via the hatch I’ll start on the deck.

Cash

🇺🇸 Cashrc

6 days ago

1 Post

4 Followers

8 Likes

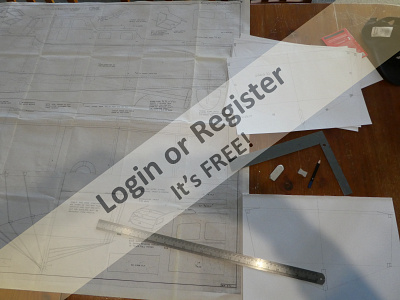

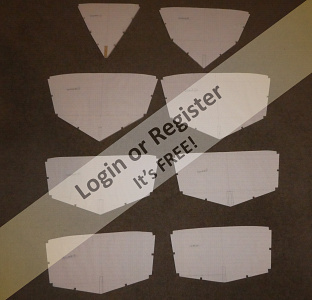

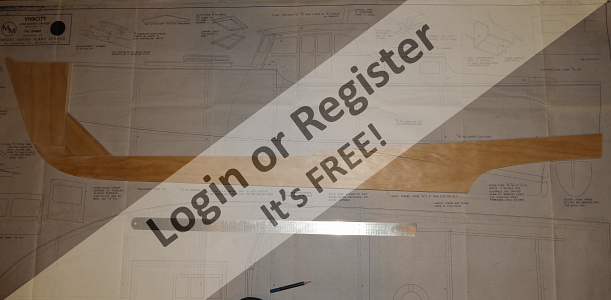

VIC SMEED'S VIVACITY

Hi all,

just posting a summary of (mainly) previously posted pics to kick off this build log and show progress to date since I first started researching the building of this 'leviathan' last year.

I'm currently at a stage where I have acquired the necessary propshaft/tube/propellor assembly and awaiting delivery of my chosen powertrain. The timber for most of the build has been sourced, so now I have finished other projects, all that really remains is to get on with it!!

1)The plan...

2)Drawing bulkhead and keel templates from plan

3)Bulkhead paper shapes stuck to 3/8 ply - I chose to make the bulkheads slightly thicker for extra gluing area and because I need to have ply-skin joins across certain bulkhead positions as standard modelling ply lengths do not go to 54". Some of these may have lightening holes cut in them for better internal access to equipment - haven't decided yet.

4)bulkheads cut out and trimmed/notched for stringers. Waiting for keel cut out, as a couple of issues regarding installation of the prop tube into the keel pieces have arisen; I need to accommodate the two oilers somehow, and the original keel pieces need to have another piece added to support the prop shaft all the way to the prop bearing - I'll post details when I've sorted it out...I hope

5)Original 10mm pine keel pieces cut out and assembled over plan - not yet glued up as an extra piece still required

6),7) & 8) Lots of spruce strips!! - spliced together to make up pieces approx. 70" in length for 3/16x3/8 chine stringer laminations, 1/4sq. sub-stringers, 3/6 sq spray rails and keel doublers.

9)18" 3-bush 3/8dia prop tube with oilers/tubes at two bearing positions, 3" diameter 3 blade propellor fashioned from 1mm brass sheet to be fitted to M5 thread on 3/16 steel shaft. I had this specially made up by Bill Nordmeyer who owns SAB Model Boat Fittings - thanks Bill!

The brushless motor and speed controller should be arriving in the next week or two. When they do, I intend to set up an engine/propshaft test to see what the performance specs are like prior to installing the tube in the keel. Once this has taken place I'll be able to post again.

Until then , best regards,

Nick

🇳🇿 Nick Ward

7 days ago

5 Posts

9 Followers

33 Likes

A Banana Boat??!

Happy Groundhog Day fellow model boaters. Seemed like a good day to start a build blog after the weather we have been having here in SE Texas. From hurricanes to snow fall, now nice sunny temps in the 70's.

I asked my grandson earlier this summer what boat would he want me to build next. Without hesitation, he said a cargo ship showing me a picture of a Maresk Lines container ship in a children's picture book. I thought about this one for several weeks wondering how to build a realistic replica of something that large. My dry dock isn't very big, and the Admiral frowns on large models. One morning at breakfast I was peeling my banana, and I realize the perfect boat. A quick google search verified my thinking of the perfect cargo ship.

I have lived in this area all my life, and my first job was in the small gulf port town of Freeport, Texas. In the early 80's it basically only served the shrimp boat operators and commercial fishermen as well as a few cargo ships for Dow Chemical and the like. The size does not compare to the Port of Houston or even Galveston. However, in the 90's the Dole Fruit Company started operations delivering containers of tropical fruit for distribution to the US.

At that time I was commuting to Houston for work, and would see the Dole container trucks on the road and would chuckle to myself "must be a banana boat in port!

The Dole company just celebrated 30 years of service in Freeport, and in 2023 launched two sister container ships, the Aztec and Maya, specifically for the Gulf of Mexico deliveries. These are smaller ships which I estimate carry only about 500 containers.

Since I could not find any plans on the internet for a smaller container ship, I decided to make my own. From pictures of the Aztec, I free handed a graph paper drawing of what I intended to build, and when satisfied, I produced a CAD version in Autosketch.

The attached pictures are of the Aztec in port at Gulfport MS.. The Maya being built in drydock. My hand drawn rendering on graph paper, and a .PDF of the cad version with bulkhead detail.

The model ship will be about 26.5 inches long with a width of about 4.5". I plan to have a brushless motor driving a 1 inch 5 bladed brass prop.

Chris

🇺🇸 cjanik001

10 days ago

2 Posts

4 Followers

12 Likes

Fairey Fisherman 27

Made the bilge keels from two laminations of mahogany sheet to get the correct thickness and then glued them in place. Once this was done I was able to return to the superstructure. Drilled the holes for the portholes and then glued the cabin sides in position.

Made the forward cabin front window and glued in followed by that for the rear cabin. Bolted and screwed the upper support for the drop keel whilst I still had easy access.

Really starting to take shape now but still a long way to go!

Chris

🇬🇧 ChrisF

13 days ago

6 Posts

4 Followers

19 Likes

Wave master boat

This is a classic wave master it was built in the fifty's a nd a internet buy I have stripped out the rc engine and its tanks now on the research stage there are a few issues rear end smack thats had a poor repair done and the spray rails do not fit well of its history I know nothing

🇬🇧 Stephen T

14 days ago

1 Post

1 Follower

4 Likes

Vosper

Well, I'm about to start my Vosper. I painted the crew, glued the transom in place. made a rudder up because I'm just thinking about how I'll propel the boat, rummage around in the drawers for a motor and drive shaft prop that may take a while. The model is about 24 inches in length, and the third photo shows that it takes 7 screws to hold it to the hull easily, but it may be a problem changing batteries. Lots of thinking will be needed to R/C the Vosper.P/S Ron gave me some ideas so thanks, Ron.

🇨🇦 GARTH

15 days ago

|

|

Media Gallery

Fishing Trawler build

10 days ago by lukeH

Christmas theme

2 months ago by GARTH

SSMBC (Florida) meet: 12/7/2025 military focus

2 months ago by LewZ

SSMBC (Seminole, Florida) meet, Nov 16, 2025

2 months ago by LewZ

SSMBC (Seminole, Florida) meet, Nov. 2, 2025

3 months ago by LewZ

Spooky - (Evening sail November)

3 months ago by philcaretaker

Gaff Rigged Bristol Pilot Cutter Autumn / Fall

3 months ago by philcaretaker

Only 2 days left

3 months ago by GARTH

Professional Photographer at Southport

3 months ago by SouthportPat

Filming over water

4 months ago by philcaretaker

"Sailor Sam" greets onlookers at the Sunday morning "Run In The Park".

4 months ago by philcaretaker

Light up the Night on the September 25th 2025 including safety cautions

4 months ago by GARTH

|

|

Login To

Remove Ads

Remove Ads

Boat Clubs & Lakes

Recent Updates In Places

|

Black Mountain Radio Sailing Club

11 days ago by 🇺🇸 oefranz (

Able Seaman) Able Seaman) |

|

Buxton Model Boat Club

2 months ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

Schiffsmodellclub Sömmerda/OT leubingen

2 months ago by 🇨🇭 Mike Stoney (

Rear Admiral) Rear Admiral) |

|

Southport Model Boat Club

3 months ago by 🇬🇧 SouthportPat (

Commodore) Commodore) |

|

BUXTON MODEL BOAT CLUB

3 months ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

|

Upcoming Events

|

Jan

23 2026

|

Jan

25 2026

|

Edina Model Yacht Club at the Minneapolis Boat Show

Ended 2 hours ago

|

|

|

Boat Harbour

3 Photos

11 Likes

Sterling Century Seamaid

I got this model from a fellow Cofederation modeller member. The Model boat needed a few things, like a battery box area and a steering wheel that I'm still working on installing, plus a few other small things. I always like to have a driver, so I'll use my Dail Ernhart junior figure that I had in my duel cockpit runabout . The model was a wooden Sterling model kit that was well-made by that member. found the kit on Google images

🇨🇦 GARTH

9 days ago

12 Attributes

3 Comments

7 Photos

4 Likes

LESRO SPRITE

Not sure what the run time will be with the new brushless set-up, so I've put 15mins as a start point; I know I can get 10-12+ mins with this size motor and a 3200mAh 4s Lipo in a 63ins span KK Super Sixty trainer plane revving an11x4" prop alot higher, so driving a 35mm prop in water at a range of speeds should get over 15 mins ( I hope...).

Same with the speed - I'll let you judge from the video, but it's difficult to tell how fast she can go in such a small area.

As for current draw - no idea at this stage, but I'll try and do an amp test in the future.

The photos on open water are with the original brushed motor set up. I've also included comparative photos of original motor set-up and the brushless set up. The short video should speak for itself, it's the same one as in the Classic Model Power Boats thread.

Best regards,

Nick

🇳🇿 Nick Ward

12 days ago

11 Attributes

3 Comments

0 Photos

4 Likes

Non-Classic Fairey Builds

These come from the era of classic boats, including the 1960s and 70s and were timber hulled. The Fisherman 27 could be called a classic as it was a popular boat but I'm talking here in the context of models. I don't know of any of these being built and there certainly weren't any drawings or kits produced unlike with the classics like the Huntsman 31 etc.

These builds were borne out of my desire to build something different but still Faireys and were inspired by photographs found in books, which in the case of the River Cruiser, a small B&W photograph being my only source of information though with the hull being based on the Huntress made things easier.

🇬🇧 ChrisF

19 days ago

0 Attributes

14 Comments

0 Photos

6 Likes

Other Classic Fairey Builds

In addition to the Huntress I'm building all the other classic Faireys at the same scale of 1:12. None of them are finished yet!

The first of these was the Huntsman 28, followed by the Swordsman 33 (raised aft cabin version) and the Huntsman 31 aft cabin version - this started off as the full rear cockpit version called the Sport which was primarily intended for off-shore powerboat racing, but as I'd sold off my big 47" aft cabin version and my number of rear cockpit versions was increasing I decided to convert it to the aft cabin version mid-build.

Chris

🇬🇧 ChrisF

19 days ago

0 Attributes

13 Comments

5 Photos

9 Likes

Fairey Huntresses

I mainly scratch build my own models but when Dave Milbourn offered me one of the prototypes he'd built for testing the drawings for his scale 1:12 model it was too good to miss. This then set me on the course to build all my models to the same scale.

This included a Huntress Long Cabin version which features a stern-drive. Whilst wanting to build the classic well known Faireys I like to build some of their less well known ones as well.

Dave sadly passed away but I was then given the opportunity to obtain the second prototype which was even more detailed.

🇬🇧 ChrisF

20 days ago

0 Attributes

11 Comments

3 Photos

12 Likes

GLYNN GUEST KNOCKER WHITE TUG

NB some of the stats above such as run time, max amps, speed, are estimated. The actual finished weight was 727grams,.

This boat was recently finished and maidened on Christmas day on our new back yard pond. Since then I have added some LED navigation lights and cabin lighting. I'm very pleased with the result and would thoroughly recommend Glynn Guests designs for small pond models. They are simple and relatively cheap to build, yet with a little effort can emerge with plenty of character.

Due to the success of this one, I intend to build a couple more of his small designs, as well as a couple of Hal Harrisons, so watch this space.

Full details of this build are on this website in the build blog section.

rgds,

Nick Ward

🇳🇿 Nick Ward

27 days ago

12 Attributes

5 Comments

11 Photos

10 Likes

Re: R.A.F Crash Tender

This is a reduced model down to 28" from the 34" Crash Tender.

I then built it out of balsa wood and covere the bottom balsa skin with 1/16th ply.

I will get around to finishing it one day. Only part painted up to now.

The propellor on it in the picture is not the one that it will be run on it will have

a 25mm 3 bladed brass one on it. But I do also have a 20mm as a back up incase thats too big.

🇬🇧 BOATSHED

1 month ago

6 Attributes

2 Comments

1 Photo

9 Likes

Fire Crash Tender

Original Aerokits 46’’

850 motor

🇬🇧 Heners2332

1 month ago

6 Attributes

18 Comments

2 Photos

5 Likes

Fairmount Alpine

Purchased Built

🇬🇧 Heners2332

1 month ago

6 Attributes

3 Comments

|

|

How-To Articles

Electric Boat Engine Etc Etc

Revised 2 months ago

By Guy O

Essential or useful tools and utensils for the ship modeler. A final appendix lists the most common

Revised 3 months ago

By AlessandroSPQR

stop email notifications

Revised 3 months ago

By Ace23

painting epoxy over Humbrol and varnish enamels

Revised 5 months ago

By roycv

Cardan joint, Homokinetic joint, universal joint. Problems related to the junction between the engin

Revised 7 months ago

By AlessandroSPQR

various electrical connection diagrams for two motors

Revised 9 months ago

By tomarack

Lifeboats or work boats?

Revised 12 months ago

By AlessandroSPQR

Permanent magnet brushed electric motors. Main features. Basic elements of distinction. How to evalu

Revised 12 months ago

By AlessandroSPQR

When wooden planking the sides of hulls What Glues are you using?

Revised 1 year ago

By bruce1946

Fibreglassing a wooden hull

Revised 1 year ago

By DuncanP

|

|

Login To

Remove Ads

Remove Ads

Model Boats Website

This is the alert text. You can customize this text to be as long or short as needed. The modal height will adjust accordingly.

🛍️ Basket

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Main menu transported here on mobile

Login

Create New Account

Trending Topics

Members Online

Blog

Re: The tub test

jumpugly

30 minutes ago

Forum

Peterd has passed away quietly this evening

Ronald

2 hours ago

Blog

Re: Making the Rear Hatch

chugalone100

10 hours ago

Event

Edina Model Yacht Club at the Minneapolis Boat Show

chugalone100

12 hours ago

Forum

Identify model

Mike Stoney

12 hours ago

Forum

Question of the Day?

PhilH

16 hours ago

Blog

New Moth MKII semi scale yacht

jbkiwi

18 hours ago

Forum

Meet Selma from Norway 🇳🇴

jumpugly

2 days ago

Blog

Re: Vosper

Ronald

2 days ago

Forum

Adhesives

bruce1946

2 days ago

Forum

Sailing at the Toronto Boat Show

ScouterChil

2 days ago

Blog

Last gasp before maiden splash in warm weather

Chum444

3 days ago

Forum

How much is too much? (If it ain't free and I need to volunteer then I ain't joining.)

hermank

3 days ago

Forum

motor for large paddle steamer. Advice required

Hermione

4 days ago

Blog

Re: Fairey Fisherman 27

zooma

4 days ago

Blog

Re: Fairey Fisherman 27

zooma

4 days ago

Forum

Interesting sail on this Catboat

luckyduck

4 days ago

Blog

Re: LISA M Motor Yacht

DuncanP

5 days ago

Forum

4 vessels for sale

Rogal118

5 days ago

Forum

Mary Ann 472

Ronald

6 days ago

Blog

Re: She’s done

DWBrinkman

6 days ago

Blog

Re: VIC SMEED'S VIVACITY

jumpugly

6 days ago

Forum

Sprite

zooma

6 days ago

Blog

Re: Construction report "Pilot Cutter Britannia" 1 : 24

Mike Stoney

7 days ago

Harbour

Re: Sterling Century Seamaid

jumpugly

8 days ago

Forum

VIC SMEED'S VIVACITY

Nick Ward

8 days ago

Gallery

Re: Fishing Trawler build

Mike Stoney

8 days ago

Forum

Speedline models RNLI 1/16 Shannon.

lukeH

8 days ago

LewZ

Vice Admiral

7,307 Points

23 seconds ago

stevedownunder

Commodore

4,242 Points

35 seconds ago

BOATSHED

Commander

2,872 Points

51 seconds ago

Harwind

Leading Seaman

87 Points

1 minute ago

melian

Recruit

0 Points

2 minutes ago

roycv

Fleet Admiral

10,327 Points

11 minutes ago

chugalone100

Lieutenant Commander

2,465 Points

27 minutes ago

Steves-s

Chief Petty Officer 1st Class

499 Points

28 minutes ago

jumpugly

Admiral

8,693 Points

29 minutes ago

RNinMunich

Fleet Admiral

40,180 Points

41 minutes ago

Ronald

Fleet Admiral

13,165 Points

49 minutes ago

Lauriem

Petty Officer 1st Class

241 Points

53 minutes ago

SouthportPat

Commodore

4,818 Points

59 minutes ago

RossM

Captain

3,224 Points

1 hour ago

ekoral

Master Seaman

137 Points

1 hour ago

neilw

Lieutenant Commander

2,364 Points

2 hours ago

RonH

Warrant Officer

806 Points

2 hours ago

GARTH

Commodore

4,035 Points

2 hours ago

MarkS3

Recruit

0 Points

2 hours ago

Rowen

Captain

3,547 Points

2 hours ago

AlessandroSPQR

Fleet Admiral

12,538 Points

2 hours ago

GaryLC

Captain

3,600 Points

3 hours ago

Andreas

Recruit

0 Points

3 hours ago

DavidT4

Recruit

5 Points

3 hours ago

ChrisF

Rear Admiral

5,958 Points

3 hours ago

Chum444

Commodore

4,105 Points

3 hours ago

Rookysailor

Commodore

4,986 Points

4 hours ago

zooma

Vice Admiral

6,537 Points

4 hours ago

DWBrinkman

Commodore

4,455 Points

4 hours ago

Mike Stoney

Rear Admiral

5,350 Points

5 hours ago

PhilH

Lieutenant

1,979 Points

5 hours ago

Capt Bob

Recruit

0 Points

6 hours ago

NeilP1

Recruit

0 Points

6 hours ago

stuartbell3553

Recruit

12 Points

7 hours ago

premecekcz

Master Seaman

123 Points

7 hours ago

IanH5

Recruit

0 Points

7 hours ago

Hsailer

Able Seaman

42 Points

7 hours ago

Wolle

Commodore

4,944 Points

7 hours ago

Missouri

Master Seaman

133 Points

7 hours ago

powell39

Recruit

0 Points

7 hours ago

RubaDub

Petty Officer 1st Class

245 Points

7 hours ago

dash8man

Able Seaman

33 Points

8 hours ago

JOHN

Midshipman

1,157 Points

8 hours ago

Gaggs

Recruit

0 Points

8 hours ago

eddyc

Recruit

6 Points

9 hours ago

Jay

Recruit

15 Points

9 hours ago

luckyduck

Lieutenant

1,903 Points

9 hours ago

pressonreguardless

Rear Admiral

5,315 Points

10 hours ago

hermank

Rear Admiral

5,393 Points

10 hours ago

hercule

Recruit

0 Points

10 hours ago

Login To

Remove Ads

Remove Ads

🏠

Home

Home

📰

Trending

Trending

💬

Forum

Forum

🗝

Login / Join

Login / Join

|

Cookies are used for ads personalisation.

By using this website you agree to our use of cookies. More Info |

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,789)

📣 Support

Hobby Supplies

🛍️ Online Shop

Login

🗝 Login

🗝 Create New Account

▼

Media Gallery

X

1 of 4

► |

◄ |

Media Viewer

^

_

X

Share

X

Flag Inappropriate Post

X

| Select Reason | |

| Sexual content Includes graphic sexual activity, nudity, and other sexual content. | |

| Violent or repulsive content Violent or graphic content, or content posted to shock viewers. | |

| Hateful or abusive content Content that promotes hatred against protected groups, abuses vulnerable individuals, or engages in cyberbullying. | |

| Harmful dangerous acts Content that includes acts that may result in physical harm. | |

| Child abuse Content that includes sexual, predatory or abusive communications towards minors. | |

| Promotes terrorism Content intended to recruit for terrorist organisations, incite violence, glorify terrorist attacks, or otherwise promote acts of terrorism. | |

| Spam or misleading Content that is massively posted or otherwise misleading in nature. | |

| Infringes my rights Privacy, copyright and other legal complaints. | |

Basket Updated

X

Loading...

Loading

Loading Uploader...