|||

|

|

🗝 Login

🤖 Create Account

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Plans & Docs

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,774)

📖 Quick Site Guide

📣 Support

👥 Membership

Hobby Supplies

🛍️ Online Shop

Not Registered

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

For A Whole Year!

£25

£45

£65

Donate

You Will Be Helping Towards:

Domain Fees

Security Certificates

iOS & Android App Fees

Website Hosting

Fast Servers

Data Backups

Upkeep & Maintenance

Administration Costs

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Model Boats Website

Home

Forum

Build Blogs

Media Gallery

Boat Clubs & Lakes

Events

Boat Harbour

How-To Articles

Plans & Docs

Useful Links

The Games Chest

Login To

Remove Ads

Remove Ads

Trending Now

Blog

New Moth MKII semi scale yacht

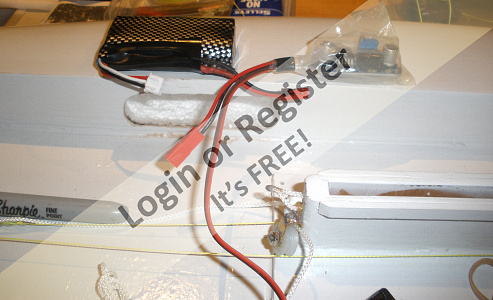

Sail's now fitted to the mast, and battens made from resin coated 1.5mm ply. The mainsheet hauler is now sorted also. Managed to find a suitable small Li-ion 7.4v 1500mah 2s battery for the boat, from a large Chinese owned model shop - https://hobbystation.co.nz/ (one of very few shops left) as they must have the biggest range of batteries in NZ, (to fit the dozens of different RC vehicles, tanks, diggers etc they sell) I've managed to find all sorts of batteries there for various projects (eg modifying TXs to last for numerous outings and doing away with the AA batteries in my FSi6 and 10x TXs)- very good service and prices there as well.

Did an 88 mile round trip to buy the batteries, so as not to risk couriers losing them, but well worth it as it solves a bit of a problem with hiding the battery in the boat. On that, - I've now managed to fit the new battery by cutting another bay in the port side of the cockpit, and tunneling out the foam. Because the battery is 7.4 v, I've used a cheap voltage regulator (Ali Express) to set the output to 6v for the winch and RX. The VR sits in front of the battery in the cutout in a plastic bag to hopefully keep moisture out, and has a JST plug so the battery can be removed for charging.

I have another waterproof cover to make for the battery pocket like the RX on the other side. The rudder servo has been silicone sealed, screwed in place and sealed in its' pocket with white exterior sealer. The foam pockets have been painted with acrylic artists paint to keep any water from penetrating the foam and getting behind the cockpit ply lining. Shouldn't get too much water in, as the covers will have EVA foam seals.

The boom vang has a nylon spacer captured by a clamp above it, and can rotate with the boom. Luff is tensioned with clamps top and bottom, and the foot is tensioned with a boom clamp. I've made a couple of pulleys for the mainsheet as well. Splash cover for the winch is a cut down scoop from a set of 3 for $4. Still to be painted and fitted.

JB

🇳🇿 jbkiwi

30 minutes ago

Forum

Programming a seaking brushless ESC challenges..

If you want to keep the (aircraft) Esc set up a reverse switch relay dpdt and switch on transmitter. It’s a channel control mechanical relay but make sure it can handle current. Other way is a servo to throw a mechanical slide switch. Used in old days to turn electric glider motor on/ off . Only other thing I found is the motor control on two stick RC transmitters is they aren’t centered. I used aileron stick for motor n rudder fir rudder on my DX6 when using as ship control. If you use relay then normal motor stick is fine as low is low then flip switch n its low reverse. I guess I’m still old school at 83. Working on multiple ships and my uncles ships to sell. Good winter projects.

🇺🇸 Hhager2

5 hours ago

Forum

Dumas Closing

One would think a good number of Florida residents would have model boats. We have plenty of ponds, lakes, and saltwater canals, etc., along the coast. But no. Third largest state in the US but I know of only a half dozen clubs here. We tend not to be like the old world and take up hobbies like this.

Being we run in a public park we do get people stopping by to look. Not many, but a few. There is just no interest.

I'll be 82 next week and keep my mind occupied with scale model RC boats, armor, other RC vehicles, photography, web site maintenance, and of course 3d printing (just about anything). In between I try to fit in my family. This year I think I will be giving up yard maintenance. Too hot in the summer. No bingo or trivia nights for me (yet).

Lew

🇺🇸 LewZ

11 hours ago

Forum

Question of the Day?

i don't even get the Question of the Day Emails.

I HAVEN'T HAD THEM FOR WEEKS NOW????????

Have I been BLACK BALLED ???

I DON'T seem to get hardly any Model Boat Website Emaiils come through.

I come on herer and search the site for the Question of the Day.

I fiirst joined the site as it was for RAF Crash Tenders,

There sre never any of those on here now either.

🇬🇧 BOATSHED

19 hours ago

Blog

Re: Trawler

Hi Roy,

I also shoot target rifle, but these days from the standing position! This is significantly more difficult to shoot precisely than from the prone position, but really satisfying when I get it right!

Like yourself I started my rifle shooting with a .22 rim fire, but I shot that from the prone position (with an old BSA Martini) but these days, if I was to lay down to shoot, I may not be able to get up again very elegantly!

Again the problem with having to wear glasses affects the way I look through the rear diopter as I wear vari-focal lenses in my regular glasses frames

Any very slight failure to reposition the head precisely aligned to the rear diopter sight will cause quite a disparity with the position of the shot that is magnified by the type of lens.

One answer is to set the sights up to shoot without wearing any glasses, but this can cause some fumbling when re-loading or making any small sight adjustments.

The other solution is the same one that I end up with in my workshop(shed) when I am working on my boats, and that is to switch to wearing a different pair of glasses that have standing fixed focal length type of lenses.

Shown here is my favourite Walther LG300 Anatomic match rifle.

Bob.

🇬🇧 zooma

1 day ago

Place

Southport Model Boat Club

I hope to be back on the Southport club lake again this Sunday Eric - although I often miss you as you tend to arrive and leave early, whereas I usually arrive late and leave late !

Bob.

🇬🇧 zooma

1 day ago

Blog

Re: Axial alignment of both paddle shafts

Some jigs and fixtures have been made to make some of the parts.

Simple Press tools and form tools have also been made to ensure uniformity. My milling machine and lathe both have digital read outs which have help enormously with the accuracy..

🇬🇧 Kevin55

1 day ago

Forum

Current project

Acrylic paint has been used on the hull and deck structures. Wheelhouse, hatch covers, and other parts.

Several applications of Minwax Polycrylic were applied after the paint was dry.

Pleased with the results.

🇨🇦 Ronald

1 day ago

Blog

Re: JUANITA STERN WHEELKER

I want to thank all of the ways that share with me their favorite way of applying a finish to their model.

So far, I have never used acrylics on my models just the thought that they are water base draws me away from them, but on the other hand I have to accept Ronald's positive experience with acrylics showing they are reliable.

Both Ronald and Jumpugly are correct about the Minwax products.

For many years I owned a door business and applied this products on many kind of wood with a very lasting results.

Some times when the doors where very exposed to the Miami sun for a very long time during the day, the customers will call me back after 3 or 4 years to refinish the door because the finish had dried and became very yellowish, but I guess that will be a good products to apply over models mahogany decks and after all we only take them out once in a wile.

After experimenting with several commercial rattle cans, my favorites so far are Tamiya, Vallejo, and Citadel.

After stripping the Juanita’s bottom hull four times and refinishing it, I finally achieved the finish I was looking for using Tamiya Black and Tamiya Clear. The only downside with this product is that the cans are small and don’t last very long.

Like Jumpugly said:

“Remember the old rule: If you think it's gassed out, it hasn't… and if you think it's dry, it's not.”

Very wise words when dealing with paints and finishes.

🇺🇸 chugalone100

1 day ago

Blog

Re: Thames Barge - Veronica

I have built this barge and its a lovely model. The video is a bit confusing at times in particular the method of making bowsies which did not make sense to me! The Model Barge Racing club has sadly been disbanded

🇬🇧 GrantH

1 day ago

Forum

Fiskebaten Trawler?

Hey Dave!

As a keen motorcyclist, cool trips are no problem for me!

In June and July, my wife usually joins me on my camper van tours . . .

But exceptions prove the rule . .

We'll see how everything goes with your tour.

Michel-C.

🇨🇭 Mike Stoney

2 days ago

Blog

Re: 1930 Runnabout Build Update

Thanks for the compliments, Mates, I hope the final result does not disappoint.

I do struggle with these clear finishes.

At least 3 more coats of varnish to be applied.

I'm having trouble with dust particles in the finish even after carefully wiping with a tack rag.

Maybe better tack rags?

I would rather not have to rub out the final finish as the captain's varnish lays out nicely.

🇺🇸 pressonreguardless

2 days ago

Blog

Re: 1/16th Model Slipway Trent deck splitting

When glueing plastics - and I believe the Trent has such a deck - you have at least 2 ways of approaching the issue - after ascertaining the chemistry of the plastic = important (ABS, PS, PVC, Epoxy, etc.):

o go to UHU or any other of the key adhesives companies. They offer (mostly) excellent Q&A tools to answer your question.

o navigate to some leading plastics companies. They do it other way round and tell you which adhesive to use for which plastic.

. . . and if you get the same answer, perfect!

For cracks I usually use car filler (they offer a certain elasticity)

Ian

🇨🇭 IGinBasel

3 days ago

Harbour

Re: Victorian Steam Launch

Wonderful workmanship!

🇨🇦 Ronald

3 days ago

Blog

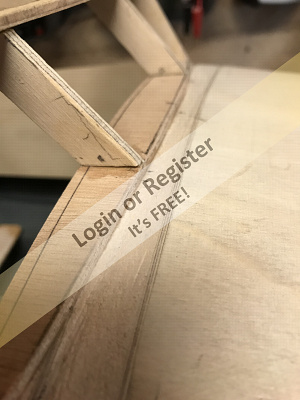

House assembly framing

After several days of contemplation I derived a method to frame the house assembly for the bulkheads. Very rigid yet allows above deck structure to be easily removed for access.

🇺🇸 Chum444

3 days ago

Gallery

Re: Suncoast Scale Model Boat Club - March 1, 2026 meet

Yes Dave, is was the Helen kit. I bought it (2016?) partially built (up to the deck) but had to rip it apart to get the big dead battery out.

Worst part was the entire hull was covered in masking tape for many years. What a pain it was to remove it. In the long run it worked out.

I renamed it "Elena" after my wife. It sits in our front room and is the first model one sees in our home. Still uses the old FM radio. Runs perfect as I have alluded to.

Lew

🇺🇸 LewZ

3 days ago

|

New Member

United States

KenG3

KenG338 minutes ago

New Member

United Kingdom

DavidStephenS

DavidStephenS1 day ago

New Member

United Kingdom

stevenH1

stevenH11 day ago

New Member

Italy

OmarL

OmarL2 days ago

New Promotion

Master Seaman

Kevin55

Kevin552 days ago

Birthday This Week

Turns 82

LewZ

LewZ2 days ago

New Promotion

Able Seaman

LeeA

LeeA3 days ago

New Member

United Kingdom

GrantH

GrantH3 days ago

Account Updated

Updated 'About Me'

Kevin55

Kevin553 days ago

Birthday This Week

Turns 81

paull5

paull54 days ago

New Promotion

Fleet Admiral

Cashrc

Cashrc4 days ago

Account Updated

Updated 'About Me'

Kennybeck

Kennybeck5 days ago

Birthday This Week

Turns 75

LOBOLONDON

LOBOLONDON5 days ago

Birthday This Week

Turns 75

DavidE

DavidE6 days ago

New Member

United Kingdom

tkel45

tkel456 days ago

Birthday This Week

Turns 75

Commodore-H

Commodore-H6 days ago

New Member

United Kingdom

SmithM

SmithM7 days ago

New Member

United Kingdom

DavidE3

DavidE37 days ago

New Member

United States

AngelA

AngelA8 days ago

New Member

United Kingdom

chrism6

chrism68 days ago

New Member

France

olivierb

olivierb9 days ago

New Member

United Kingdom

AndrewN

AndrewN9 days ago

New Member

United Kingdom

Kernewyk

Kernewyk9 days ago

Birthday This Week

Turns 76

DenisA

DenisA10 days ago

New Member

United Kingdom

MartinT3

MartinT310 days ago

New Member

United Kingdom

RodM

RodM10 days ago

New Member

New Zealand

alan56

alan5612 days ago

New Member

United States

Rlyon5700

Rlyon570012 days ago

New Member

Australia

CliveRoscoe

CliveRoscoe12 days ago

New Member

United Kingdom

MichaelP1

MichaelP113 days ago

New Member

United States

MarkM

MarkM13 days ago

New Member

Australia

DarylN

DarylN14 days ago

New Member

United States

patrickr1

patrickr114 days ago

Account Updated

Updated 'About Me'

VictorC

VictorC14 days ago

New Member

Ukraine

OleksiyC

OleksiyC14 days ago

New Member

United Kingdom

RickyW

RickyW14 days ago

New Member

United Kingdom

AlanO2

AlanO214 days ago

New Promotion

Able Seaman

VictorC

VictorC14 days ago

New Member

South Korea

dongjunk

dongjunk15 days ago

New Member

United Kingdom

AndyW1

AndyW115 days ago

New Member

United Kingdom

Nigel1

Nigel116 days ago

New Member

United Kingdom

TimH3

TimH316 days ago

New Member

Canada

JamesB1

JamesB117 days ago

New Promotion

Captain

chugalone100

chugalone10017 days ago

New Member

France

arioversa

arioversa17 days ago

New Member

Netherlands

PeterN

PeterN17 days ago

New Promotion

Leading Seaman

JSS4

JSS418 days ago

New Member

Slovakia

PeterC5

PeterC518 days ago

See More

Forum Topics

Programming a seaking brushless ESC challenges..

If you want to keep the (aircraft) Esc set up a reverse switch relay dpdt and switch on transmitter. It’s a channel control mechanical relay but make sure it can handle current. Other way is a servo to throw a mechanical slide switch. Used in old days to turn electric glider motor on/ off . Only other thing I found is the motor control on two stick RC transmitters is they aren’t centered. I used aileron stick for motor n rudder fir rudder on my DX6 when using as ship control. If you use relay then normal motor stick is fine as low is low then flip switch n its low reverse. I guess I’m still old school at 83. Working on multiple ships and my uncles ships to sell. Good winter projects.

5 hours ago by 🇺🇸 Hhager2 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

RC & Electrics

24 Posts

42 Likes

42 Likes

Started

5 days ago

by EricMB

5 days ago

by EricMB

Latest

5 hours ago

by Hhager2

5 hours ago

by Hhager2

Dumas Closing

One would think a good number of Florida residents would have model boats. We have plenty of ponds, lakes, and saltwater canals, etc., along the coast. But no. Third largest state in the US but I know of only a half dozen clubs here. We tend not to be like the old world and take up hobbies like this.

Being we run in a public park we do get people stopping by to look. Not many, but a few. There is just no interest.

I'll be 82 next week and keep my mind occupied with scale model RC boats, armor, other RC vehicles, photography, web site maintenance, and of course 3d printing (just about anything). In between I try to fit in my family. This year I think I will be giving up yard maintenance. Too hot in the summer. No bingo or trivia nights for me (yet).

Lew

11 hours ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)

General Resources

13 Posts

60 Likes

60 Likes

Started

4 days ago

by pressonreguardless

4 days ago

by pressonreguardless

Latest

11 hours ago

by LewZ

11 hours ago

by LewZ

Question of the Day?

i don't even get the Question of the Day Emails.😠

I HAVEN'T HAD THEM FOR WEEKS NOW????????🤔🤔🤔

Have I been BLACK BALLED ???🤔🤔

I DON'T seem to get hardly any Model Boat Website Emaiils come through.😠

I come on herer and search the site for the Question of the Day.

I fiirst joined the site as it was for RAF Crash Tenders,

There sre never any of those on here now either. 🤔🤔🤔

19 hours ago by 🇬🇧 BOATSHED ( Commander)

Commander)

Commander)

Commander)

Website Related

5525 Posts

13849 Likes

13849 Likes

Started

3 years ago

by fireboat

3 years ago

by fireboat

Latest

19 hours ago

by BOATSHED

19 hours ago

by BOATSHED

Current project

Acrylic paint has been used on the hull and deck structures. Wheelhouse, hatch covers, and other parts.

Several applications of Minwax Polycrylic were applied after the paint was dry.

Pleased with the results.

1 day ago by 🇨🇦 Ronald ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Hobby Chit Chat

12 Posts

71 Likes

71 Likes

Started

28 days ago

by Ronald

28 days ago

by Ronald

Latest

1 day ago

by Ronald

1 day ago

by Ronald

Fiskebaten Trawler?

Hey Dave!

As a keen motorcyclist, cool trips are no problem for me! 😍😍😍

In June and July, my wife usually joins me on my camper van tours . . .

But exceptions prove the rule . .

We'll see how everything goes with your tour.

Michel-C.

2 days ago by 🇨🇭 Mike Stoney ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)

Hobby Chit Chat

23 Posts

94 Likes

94 Likes

Started

6 days ago

by jumpugly

6 days ago

by jumpugly

Latest

2 days ago

by Mike Stoney

2 days ago

by Mike Stoney

|

|

Login To

Remove Ads

Remove Ads

Build Blogs

11 Posts

11 Followers

89 Likes

New Moth MKII semi scale yacht

Haven't built anything for a while due to lack of space (too many models) but the urge to build something was too great. After looking at many options, I decided to go with something 'easy' to build. I found some full size plans for an Australian MkI Moth which I'm building to a MKII (double chine) style.

I'm building in foam and glass again to make things easier. It's 850mm long and 310 wide which is roughly 1/4 scale (original is 11 ft)

Started by converting all the lofting measurements on the redrawn 1953 plan to metric and dividing them by 4 to get the scale.

Next was creating the ply deck, then contact gluing onto it a piece of dense 50mm building polystyrene. This was then shaped with a surform file and the chines shaped afterwards using eyeometry. Then the 10mm deck foam was glued on so the deck sheer could be shaped.

Next the cockpit foam was routered out, and basswood sides and inner transom piece epoxied in. After that, the ply outer transom piece and hardwood nose block was epoxied on.

The centerboard case upper and lower ply braces were routered out (using the mill and a 1/2" slotting bit) large enough to accept the case sides, leaving enough room for the 6mm aluminium keel (can't use a centerboard for obvious reasons) which will have to have a bulb fitted.

A rebate in the bottom of the hull was routered out for the lower c/board brace. These braces are needed to form part of a box structure with the floor and cockpit sides which the c/board can lever on. Once everything is eventually glassed in, it will make it very strong unit, so the foam will just be the shape surrounding the box, and not having any strain put on it. The ply deck will take the strain of the stays/mast.

The cockpit floor was cut, and will be slotted the same as the braces, then the c/board case will be built.

The mast on this is 1.486m tall, - sail is -luff -11.295, foot 609mm, so quite large for a small boat. The full sized boat is a lot of fun to sail, so this model will be interesting to sail. Unfortunately, without the human input required, and being a performance boat, it may assume the attributes of a submarine in a stiff breeze, - time and testing will tell.

The basic mast was made from 12mm ally tube, boom from 10mm. Sail pattern was cut from art card to the plan. All laid out on the floor to get an idea of what it will look like.

PDF is the history of the Moth. There were a number of versions round the world as it went along,- scow, international moth (dinghy type) and todays high speed foiling moth.

Lots more to do yet

JB

2025 world champs, off the Whangaparaoa peninsula, just up from where I live.

https://www.youtube.com/watch?v=FuLhJ-yRLmc

https://australianclassicdinghynetwork.org/moth

https://www.youtube.com/watch?v=wWkd2e8apSI

https://www.moth.asn.au/

https://www.youtube.com/watch?v=gAifFN0RJ0M

🇳🇿 jbkiwi

30 minutes ago

9 Posts

10 Followers

65 Likes

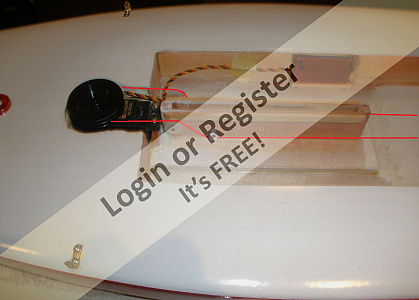

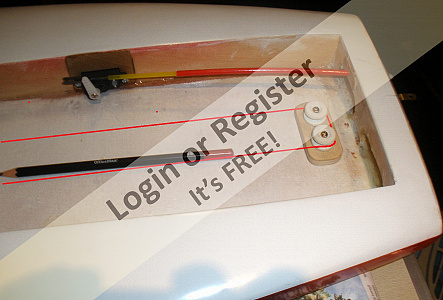

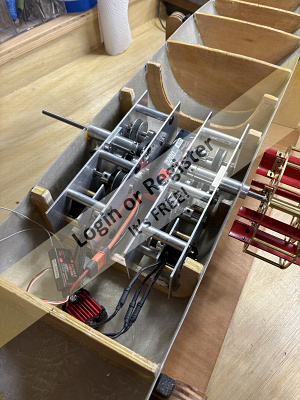

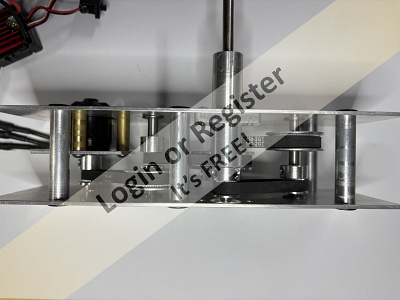

Forceful Directors Class Paddle tug

In the process of building a Directors class - Forceful paddle tug.

Brought the fibreglass hull.

Directors class - Forceful paddle tug plan drawing number 1292

Two magazines Marine modelling international jan 2017 & feb 2017 have been used as reference.

Paddle wheel drawing number 1293

All of the paddle wheel components have been machined by me from raw materials. Bearings and fixings are purchased as required.

So far I have Completed the feathering paddle wheels and drive. I have set up a test tank for a paddle wheel to ensure all is well before proceeding with the rest of the build.

I hope you find my efforts interesting

🇬🇧 Kevin55

1 day ago

6 Posts

5 Followers

50 Likes

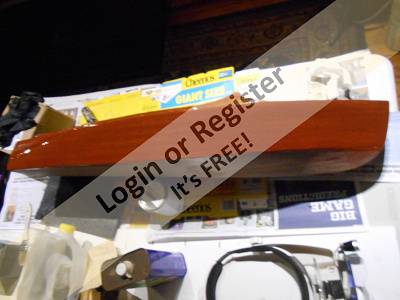

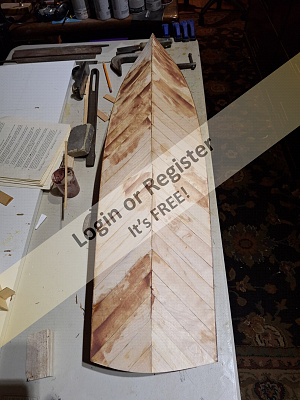

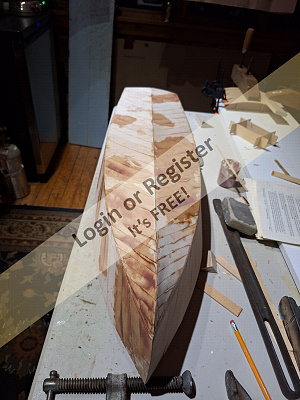

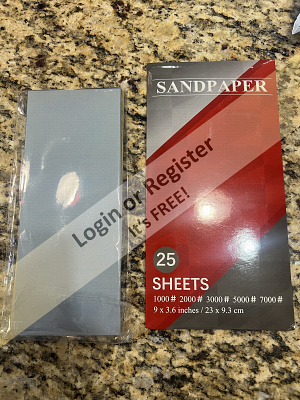

1930 Cris Craft Runabout Dumas Kit 1230

Started the Runabout.

Using my Lion Miter trimmer to cut the planks, and my block plane to

trim to the chine. Then a sanding block for the final fit.

🇺🇸 pressonreguardless

3 days ago

45 Posts

10 Followers

247 Likes

JUANITA STERN WHEELER

A good hello to all members.

Now that I finished The Fireboat, I would like to add to the forum my favorite build, one you are all familiar with.Hello fellow members.

The Juanita Stern Wheeler.

This an amazing, high end kit that that when finished will be 40" LOA & should weigh under 10lbs ballasted.

According to online sources the JUANITA was built in 1954 by O. F. Shearer & Sons at Cedar Grove, West Virginia. Another source on the internet says that the JUANITA has been "in operation since 1977."

The present owner of the JUANITA is Tom Cook of Dunbar, West Virginia on the Kanawha River.

I was lucky enough to be a part of the first clients that purchase the first run of this fantastic model and I got it for a very reasonable price.

With that being said, I would like to show you guys a building log for this model but buy no means I will say that this is the best way to build the Juanita but this is how Im building it with my limited knowledge and the help of the instructions emailed to me by the designer.

I also like to say that this kit does not have written instructions since this kit was produced in a rush job before kits had to be sent out; the only instructions is a PDF file containing drawings showing the main steps of building process, but the designer himself is very helpful in answering all of my emails about specific needed details in the build.

So, lets get started.

I will start by showing the real Juanita.

🇺🇸 chugalone100

3 days ago

10 Posts

5 Followers

68 Likes

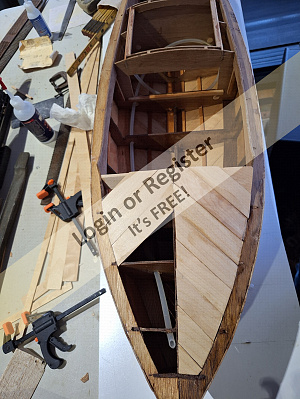

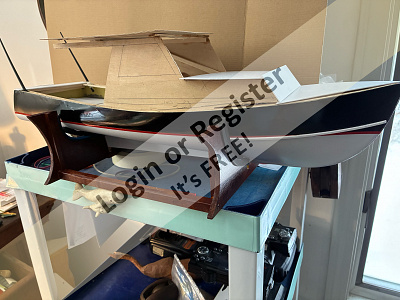

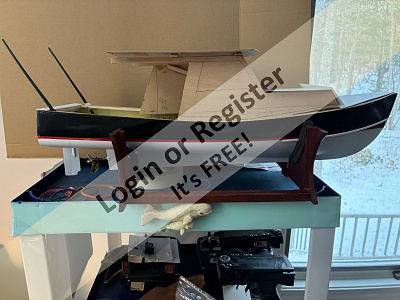

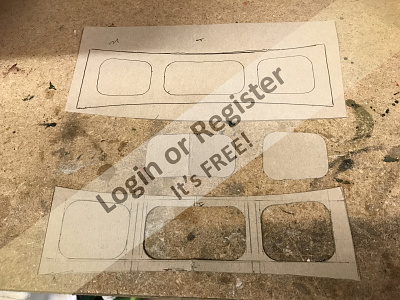

36 ft Northern Bay sport fisherman

The Northern Bay lobster and sport fishing boats are built in Qgunquit, Maine. Known as Down East boats they are semi-displacement hulls. They are very good sea boats stable in heavy seas. Compared to semi-vee hulls common to many other sport fisherman boats in the U.S. the Down East hulls tend to be wet boats. As with everything else, boat design is always a compromise.

1&2 The inspiration

3&4 Beginning steps

🇺🇸 Chum444

3 days ago

1 Post

1 Follower

1 Like

1/16th Model Slipway Trent deck splitting

The deck is splitting and cracking on the surface and join to the hull. What glue is recommended to prevent further cracking and fill the cracks?

Thanks

🇬🇧 Heners2332

4 days ago

6 Posts

9 Followers

42 Likes

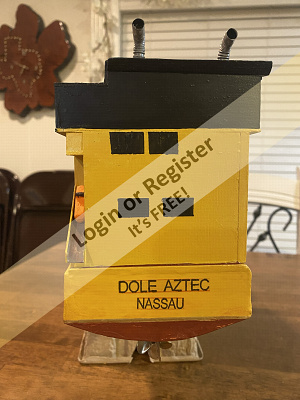

A Banana Boat??!

Happy Groundhog Day fellow model boaters. Seemed like a good day to start a build blog after the weather we have been having here in SE Texas. From hurricanes to snow fall, now nice sunny temps in the 70's.

I asked my grandson earlier this summer what boat would he want me to build next. Without hesitation, he said a cargo ship showing me a picture of a Maresk Lines container ship in a children's picture book. I thought about this one for several weeks wondering how to build a realistic replica of something that large. My dry dock isn't very big, and the Admiral frowns on large models. One morning at breakfast I was peeling my banana, and I realize the perfect boat. A quick google search verified my thinking of the perfect cargo ship.

I have lived in this area all my life, and my first job was in the small gulf port town of Freeport, Texas. In the early 80's it basically only served the shrimp boat operators and commercial fishermen as well as a few cargo ships for Dow Chemical and the like. The size does not compare to the Port of Houston or even Galveston. However, in the 90's the Dole Fruit Company started operations delivering containers of tropical fruit for distribution to the US.

At that time I was commuting to Houston for work, and would see the Dole container trucks on the road and would chuckle to myself "must be a banana boat in port!

The Dole company just celebrated 30 years of service in Freeport, and in 2023 launched two sister container ships, the Aztec and Maya, specifically for the Gulf of Mexico deliveries. These are smaller ships which I estimate carry only about 500 containers.

Since I could not find any plans on the internet for a smaller container ship, I decided to make my own. From pictures of the Aztec, I free handed a graph paper drawing of what I intended to build, and when satisfied, I produced a CAD version in Autosketch.

The attached pictures are of the Aztec in port at Gulfport MS.. The Maya being built in drydock. My hand drawn rendering on graph paper, and a .PDF of the cad version with bulkhead detail.

The model ship will be about 26.5 inches long with a width of about 4.5". I plan to have a brushless motor driving a 1 inch 5 bladed brass prop.

Chris

🇺🇸 cjanik001

5 days ago

3 Posts

4 Followers

31 Likes

Dumas Pay n' Pak

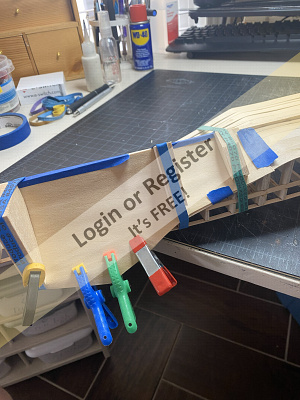

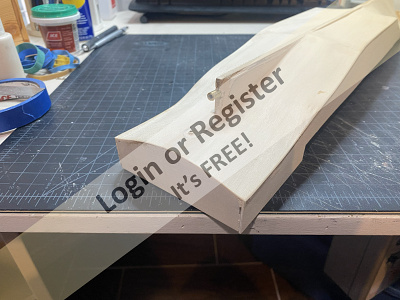

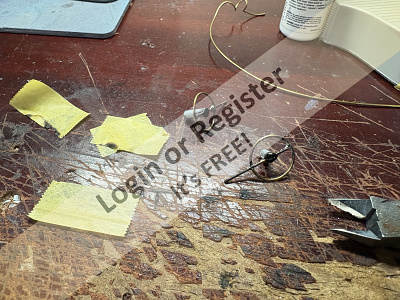

Hey gang! As you may already know I have the Bluebird K-7 on the shelf for final detailing, the C-2 cargo ship Matson "Pacific Trader" awaiting rigging, and 22 inches of snow on the ground. So I wanted a challenge and grabbed an ancient Dumas Pay n' Pak Hydroplane kit to keep myself from going nuts. This may or may have not been a mistake!

And...you may already know that I've already labeled this build as my "3 day running knife fight" as a boat made of 100% warped plywood is not a walk in the park. Here are some pix starting from frame up to a primer. And yes, to fight this beauty from becoming a warped "banana boat" those are bricks and carpenter's clamps helping me keep her straight! The The bottom is glassed and the rest resin covered. The primer is meant to assist in showing all my mistakes and assist in final sanding prior to a finish coat.

Tough build, but it does look like something out of "Star Wars!"

More to follow.

🇺🇸 jumpugly

5 days ago

1 Post

2 Followers

14 Likes

Thames Barge - Veronica

This is a well know model. I think there used to be an active group of TB modellers, this seems to have been maintained through a Facebook page - However, I don't use FB ! But Sarik models have put the original DVD on YouTube, which does help.

https://www.youtube.com/watch?v=Z4QeGUQ2KKg&t=4711s

Any experience or advice about making this model - always welcome and appreicated.

🇬🇧 AndyB2

6 days ago

3 Posts

3 Followers

27 Likes

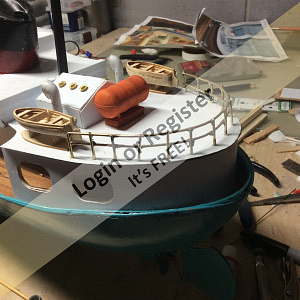

Something a little different-Horizon Harbor Tug

Hi y’all. I turned 65 last month, and in preparation for celebrating making it this far without getting myself seriously injured or spending time in jail I sold a few boats and cashed out some excess pto so I could do something I normally don’t do…spend more than usual for my birthday.

So, I had a budget, and my goal was to use as much as possible from my savings from boat sales without disturbing the family Kitty much if at all. I was successful, came in under budget, my wife got me two kits and I picked up this-the Horizon Harbor Tug.

Now, I’m not usually a RTR or RTF kind of person. The few times I’ve purchased a hobby grade ready to run or fly model I’m usually disappointed. But…this boat has been praised by modelers of all stripes, and Horizon has kept it in production for 4 years, which I think is some sort of record, as usually Horizons scale offerings last maybe a year, 2 years tops. Also, we have 2 members who are dedicated builders of tugs and submarines that love them to death. So here goes…

I was not allowed to touch my birthday presents until my birthday, so I had time to figure out what I wanted to do with the Harbor. Once I got her on the bench, I gutted her like a fish.

The Harbor Tug comes with a barely hobby grade pistol grip radio capable of 4 channels, a combo brushed esc/receiver, an esc for the fire monitor pump, and a radio controlled electronic on off switch for the led lights. Power is a 700 size motor, this is all supposed to be powered by 3 cells. It does NOT come with the water pump, that’s 60 dollars more, and from what I’ve seen it’s not as strong as I like.

So, I had to make a mount for my preferred motor, the Zippkits 650 brushless outrunner, that’s coupled to the shaft with a good solid coupler. Esc is a HobbyWing 16BL30 30 amp unit. I had to do some modifications to mount my preferred Amazon sourced pump, which included drilling out the molded in water pickup and epoxying in a brass pickup, and changing the mounting location of the pump. Pump is powered by a 10 amp brushed aircraft esc-the original that came with the boat works well, but is set up for 3 cells, and doesn’t give me enough voltage at the pump. Originally I was going to use a FrSky 7 channel receiver, but I wanted to try my hand at telemetry. So I used a FrSky X8R so I could run the FrSky FAS40 module, which gives my real Tim battery voltage and current draw. I also added ballast to bring her up to 12 pounds, as the stock weight of 9.5 or so is seriously under ballasted.

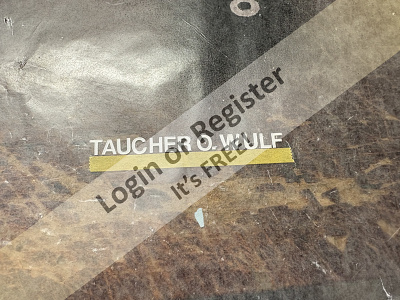

Now, the first production runs of this boat had some issues, leaks near the stern and along the bulwarks were common. It seems to me that Horizon did what Joysway did with the DF65, and listened to feedback, as my boat ran dry. There was a bit of water in the hull before the maiden as I was checking ballast and leaks the day before, and there was no appreciable water in the hull after. All systems worked well, and the boat exceeded my expectations.

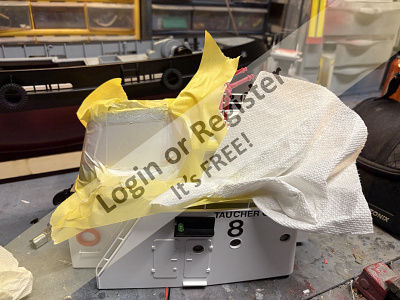

Now, y’all know me. You’ve seen my build logs. Probably wondering why I’m loving a boat that I don’t have much time at the bench with. You see, the story doesn’t stop here, oh no, I have more work to do. The real boat this was modeled after is the Taucher O Wulf 8. Horizon put just enough detail to please the average boat modeler, and decaled it with an H on the funnel. My goal is to get her recognizable as the Taucher. I have to do some detail work, add some things that’s missing, do some lettering, etc. The end game is a stand off scale model of the Taucher. So stay tuned, we’re going for a ride!

Cash

https://youtu.be/DIf4v8KvfSk?si=9Ya4HaEL1Sq_q__J

🇺🇸 Cashrc

7 days ago

1 Post

3 Followers

13 Likes

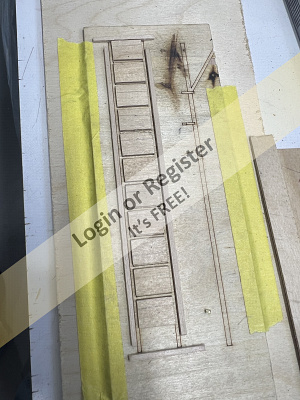

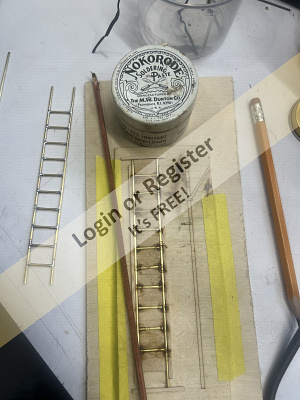

Trawler

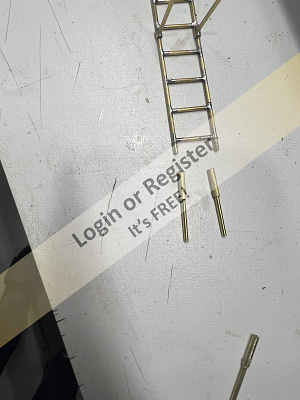

Haven't been working on my deep- sea trawler for a while. I needed to build some railings on the deck, but didn't want to wait and buy them and pay tariffs on them at an American hobby store, so I got some brass rod here at a local hobby store and soldered some up. I also decided to use the lifeboat kits for the ship. Next step: painting railings. Also need to do all the rigging yet.

🇨🇦 GARTH

7 days ago

7 Posts

11 Followers

44 Likes

LesRo Rapier.

Rapier1.

When the first lock-down came along I dug out a couple of old wrecks that had been thrown away and had been saved from a skip some years previously, and this looked like a good time to see if they could be rescued.

The first was a badly built and abandoned LesRo Rapier (shown here after the rebuild as my photos showing the full rebuilding sequence will not load).

The LiPo tray carries two large 2C 5600Mah LiPo cells, but only one is connected up at a time - the unused LiPo acts as ballast to keep the hull running straight, but makes for a nice quick change when the first one runs down

Any basic tools that I may need when I am "pond side" to change a prop or brushless motor are carried on small magnets in the rear compartment to save me forgetting to take them with me and this has proven to be very helpful!

Bob.

🇬🇧 zooma

8 days ago

|

|

Media Gallery

Suncoast Scale Model Boat Club - March 1, 2026 meet

6 days ago by LewZ

Media Gallery

18 days ago by philcaretaker

Suncoast Scale Model Boat Club

20 days ago by LewZ

Towboat pushing a large barge.

26 days ago by LewZ

Fishing Trawler build

2 months ago by lukeH

Christmas theme

3 months ago by GARTH

SSMBC (Florida) meet: 12/7/2025 military focus

3 months ago by LewZ

SSMBC (Seminole, Florida) meet, Nov 16, 2025

4 months ago by LewZ

SSMBC (Seminole, Florida) meet, Nov. 2, 2025

4 months ago by LewZ

Spooky - (Evening sail November)

4 months ago by philcaretaker

Gaff Rigged Bristol Pilot Cutter Autumn / Fall

4 months ago by philcaretaker

Only 2 days left

5 months ago by GARTH

|

|

Login To

Remove Ads

Remove Ads

Boat Clubs & Lakes

Recent Updates In Places

|

Southport Model Boat Club

1 day ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral) |

|

Buxton Model Boat Club

14 days ago by 🇬🇧 philcaretaker (

Rear Admiral) Rear Admiral) |

|

Clube de Aeromodelismo de Setúbal

14 days ago by 🇺🇸 PhilS1 (

Recruit) Recruit) |

|

Aberdeen Model Boat Club

1 month ago by 🇬🇧 tim morland (

Chief Petty Officer 1st Class) Chief Petty Officer 1st Class) |

|

Black Mountain Radio Sailing Club

2 months ago by 🇺🇸 oefranz (

Master Seaman) Master Seaman) |

|

|

Upcoming Events

|

Apr

18 2026

|

1 Day Only!

|

Crosby Model & Hobby Show

Starts 1 months time

|

|

|

Boat Harbour

14 Photos

16 Likes

Victorian Steam Launch

Built from scratch having just the vacuum formed hull from an old model.

The boiler and steam engine are faux as our club does not have permission to run real steam boats.

The Steam engine runs via an electric motor hidden behind the bulkhead see video

The boiler houses a smoke generator.

🇬🇧 Kevin55

6 days ago

5 Attributes

6 Comments

4 Photos

9 Likes

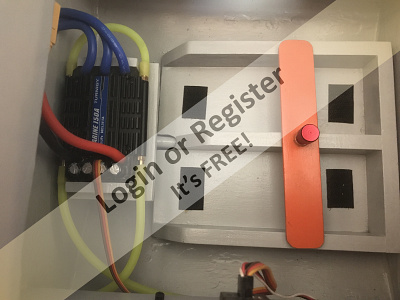

AIRBOAT No 2

Another airboat, this time made from a 33" x 18" foam body board, and powered by a TGY3542 1000kv 38A outrunner with a pusher prop, and 3s 4000mah LiPo

🇳🇿 jbkiwi

13 days ago

9 Attributes

4 Comments

6 Photos

16 Likes

SEMI SCALE 1953 EDSON SCHOCK 15FT DAY SAILER

A 1/5 semi scale model of my 15ft day sailer,- designed by US naval architect Edson I Schock in 1953. The original was built in NZ in the late 80s and I bought and restored it in 2008. Thought it would be nice to have an RC model of it, so measured the boat and made the model 1/5 scale.

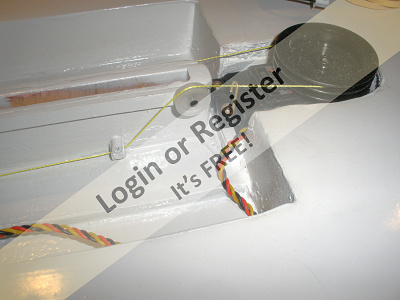

Model is made from polystyrene foam, shaped and f/glassed with a ply deck and ply lined cockpit and ply transom. Uses a HiTec winch with a floor mounted sheet hauler pulley system.

The skipper is servo powered and ducks under the boom when tacking

🇳🇿 jbkiwi

13 days ago

2 Attributes

8 Comments

1 Photo

7 Likes

Vosper

My latest build finished in December 2026. Waiting for water in Spencer's boat pond.

🇨🇦 GARTH

19 days ago

11 Attributes

4 Comments

3 Photos

17 Likes

Keilcraft ; Thornycroft Range Safety boat 7112

This is a Thornycroft range safety boat Having had this boat that was loaned to a club now back in my ownership she was built in the 1960s the number 7112 is at the end of ww2 and served in the English Channel stations

🇬🇧 Stephen T

22 days ago

9 Attributes

5 Comments

1 Photo

17 Likes

MS Tomahawk Tug

MS Tomahawk is my rescue boat to help retrieve a disabled sailboat back to our landing pad.

🇺🇸 oefranz

27 days ago

5 Attributes

8 Comments

1 Photo

4 Likes

DF95 Training

This boat is used for training new RC sailors who want to give the sport of Radio Sailing a try.

🇺🇸 oefranz

27 days ago

0 Attributes

3 Comments

1 Photo

3 Likes

DF95

This is my DF95 racing boat, which we race at the Black Mountain Radio Sailing Club.

🇺🇸 oefranz

27 days ago

0 Attributes

1 Comment

1 Photo

6 Likes

Edelweiss 65

This is my DF65 Racing boat.

🇺🇸 oefranz

27 days ago

0 Attributes

4 Comments

|

|

How-To Articles

LED – SERIES AND PARALLEL CIRCUITS – FLASHING CIRCUITS - Compendium of information

Revised 18 days ago

By AlessandroSPQR

Led Resister chart

Revised 19 days ago

By GARTH

Electric Boat Engine Etc Etc

Revised 3 months ago

By Guy O

Essential or useful tools and utensils for the ship modeler. A final appendix lists the most common

Revised 4 months ago

By AlessandroSPQR

stop email notifications

Revised 4 months ago

By Ace23

painting epoxy over Humbrol and varnish enamels

Revised 7 months ago

By roycv

Cardan joint, Homokinetic joint, universal joint. Problems related to the junction between the engin

Revised 9 months ago

By AlessandroSPQR

various electrical connection diagrams for two motors

Revised 10 months ago

By tomarack

Lifeboats or work boats?

Revised 1 year ago

By AlessandroSPQR

Permanent magnet brushed electric motors. Main features. Basic elements of distinction. How to evalu

Revised 1 year ago

By AlessandroSPQR

|

|

Login To

Remove Ads

Remove Ads

Model Boats Website

This is the alert text. You can customize this text to be as long or short as needed. The modal height will adjust accordingly.

🛍️ Basket

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Main menu transported here on mobile

Login

Create New Account

Trending Topics

Members Online

Blog

New Moth MKII semi scale yacht

jbkiwi

30 minutes ago

Forum

Programming a seaking brushless ESC challenges..

Hhager2

5 hours ago

Forum

Dumas Closing

LewZ

11 hours ago

Forum

Question of the Day?

BOATSHED

19 hours ago

Blog

Re: Trawler

zooma

1 day ago

Place

Southport Model Boat Club

zooma

1 day ago

Blog

Re: Axial alignment of both paddle shafts

Kevin55

1 day ago

Forum

Current project

Ronald

1 day ago

Blog

Re: JUANITA STERN WHEELKER

chugalone100

1 day ago

Blog

Re: Thames Barge - Veronica

GrantH

1 day ago

Forum

Fiskebaten Trawler?

Mike Stoney

2 days ago

Blog

Re: 1930 Runnabout Build Update

pressonreguardless

2 days ago

Blog

Re: 1/16th Model Slipway Trent deck splitting

IGinBasel

3 days ago

Harbour

Re: Victorian Steam Launch

Ronald

3 days ago

Blog

House assembly framing

Chum444

3 days ago

Gallery

Re: Suncoast Scale Model Boat Club - March 1, 2026 meet

LewZ

3 days ago

Forum

Dumas Products closing down!!!

Hsailer

3 days ago

Forum

Sunday at the pond

DWBrinkman

3 days ago

Forum

Faulty Spektrum TX

pmdevlin

5 days ago

Blog

Re: Second run of primer...

jumpugly

5 days ago

Blog

Re: Dole Aztec complete... Well almost!

jumpugly

5 days ago

Harbour

Re: Port Area

Mike Stoney

5 days ago

Forum

Beamsville interior

Mike Stoney

6 days ago

Blog

Re: Railing and door securing wheel…..thingy

jumpugly

6 days ago

Blog

Re: Railing and door securing wheel…..thingy

jumpugly

6 days ago

Forum

Dutch sailing barge

AndyB2

6 days ago

Forum

How to secure acccess deck covers /hatches

zooma

7 days ago

Forum

KD Perkasa Class Drawings.

zooma

8 days ago

roycv

Fleet Admiral

10,457 Points

0 seconds ago

BOATSHED

Commander

2,946 Points

22 seconds ago

Hsailer

Leading Seaman

80 Points

29 seconds ago

thadlietz

Chief Petty Officer 2nd Class

308 Points

31 seconds ago

RossM

Captain

3,265 Points

20 minutes ago

jbkiwi

Fleet Admiral

22,695 Points

29 minutes ago

chugalone100

Captain

3,327 Points

31 minutes ago

KenG3

Recruit

0 Points

36 minutes ago

NigelP1

Recruit

0 Points

45 minutes ago

zooma

Vice Admiral

7,218 Points

46 minutes ago

Ronald

Fleet Admiral

13,860 Points

49 minutes ago

CDE

Leading Seaman

54 Points

50 minutes ago

dash8man

Able Seaman

33 Points

56 minutes ago

Mike Stoney

Rear Admiral

5,641 Points

2 hours ago

SimpleSailor

Lieutenant

1,801 Points

2 hours ago

Kevin55

Master Seaman

131 Points

2 hours ago

JOHN

Midshipman

1,182 Points

2 hours ago

Stour-boy

Leading Seaman

71 Points

2 hours ago

Wolle

Rear Admiral

5,131 Points

3 hours ago

Westwind

Warrant Officer

784 Points

3 hours ago

gergelypalla

Recruit

0 Points

3 hours ago

robbob

Fleet Admiral

10,659 Points

3 hours ago

Northernflotsam

Chief Petty Officer 2nd Class

325 Points

4 hours ago

EricMB

Chief Petty Officer 1st Class

542 Points

4 hours ago

Herby

Recruit

0 Points

4 hours ago

JEANFRANCOIS G

Recruit

0 Points

4 hours ago

luckyduck

Lieutenant

1,925 Points

4 hours ago

jumpugly

Admiral

9,220 Points

4 hours ago

tomarack

Sub-Lieutenant

1,361 Points

5 hours ago

GaryLC

Captain

3,676 Points

5 hours ago

Hhager2

Sub-Lieutenant

1,521 Points

5 hours ago

ChrisF

Vice Admiral

6,500 Points

5 hours ago

DavidE3

Recruit

0 Points

5 hours ago

LIBERTY CAPTAIN

Recruit

17 Points

5 hours ago

cenbeth

Warrant Officer

617 Points

5 hours ago

Peeny

Recruit

0 Points

5 hours ago

DWBrinkman

Commodore

4,831 Points

5 hours ago

Heners2332

Petty Officer 2nd Class

196 Points

5 hours ago

GARTH

Commodore

4,183 Points

6 hours ago

SouthportPat

Commodore

4,862 Points

6 hours ago

jostro65

Leading Seaman

89 Points

9 hours ago

PeterB3

Recruit

0 Points

9 hours ago

Alain

Able Seaman

38 Points

9 hours ago

JimB2

Recruit

0 Points

9 hours ago

RonH

Warrant Officer

828 Points

9 hours ago

Chum444

Commodore

4,301 Points

9 hours ago

xtramaths

Petty Officer 2nd Class

174 Points

10 hours ago

hermank

Rear Admiral

5,532 Points

10 hours ago

LewZ

Vice Admiral

7,850 Points

11 hours ago

neilw

Lieutenant Commander

2,376 Points

11 hours ago

Login To

Remove Ads

Remove Ads

🏠

Home

Home

📰

Trending

Trending

💬

Forum

Forum

🗝

Login / Join

Login / Join

|

Cookies are used for ads personalisation.

By using this website you agree to our use of cookies. More Info |

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,774)

📣 Support

Hobby Supplies

🛍️ Online Shop

Login

🗝 Login

🗝 Create New Account

▼

Media Gallery

X

1 of 4

► |

◄ |

Media Viewer

^

_

X

Share

X

Flag Inappropriate Post

X

| Select Reason | |

| Sexual content Includes graphic sexual activity, nudity, and other sexual content. | |

| Violent or repulsive content Violent or graphic content, or content posted to shock viewers. | |

| Hateful or abusive content Content that promotes hatred against protected groups, abuses vulnerable individuals, or engages in cyberbullying. | |

| Harmful dangerous acts Content that includes acts that may result in physical harm. | |

| Child abuse Content that includes sexual, predatory or abusive communications towards minors. | |

| Promotes terrorism Content intended to recruit for terrorist organisations, incite violence, glorify terrorist attacks, or otherwise promote acts of terrorism. | |

| Spam or misleading Content that is massively posted or otherwise misleading in nature. | |

| Infringes my rights Privacy, copyright and other legal complaints. | |

Basket Updated

X

Loading...

Loading

Loading Uploader...