Join Us On Social Media!

Build Blogs

9 Posts

4 Followers

21 Likes

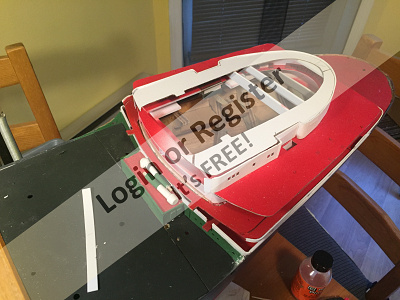

Wave master boat

This is a classic wave master it was built in the fifty's a nd a internet buy I have stripped out the rc engine and its tanks now on the research stage there are a few issues rear end smack thats had a poor repair done and the spray rails do not fit well of its history I know nothing

🇬🇧 Stephen T

3 hours ago

41 Posts

8 Followers

216 Likes

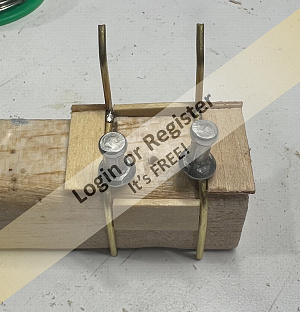

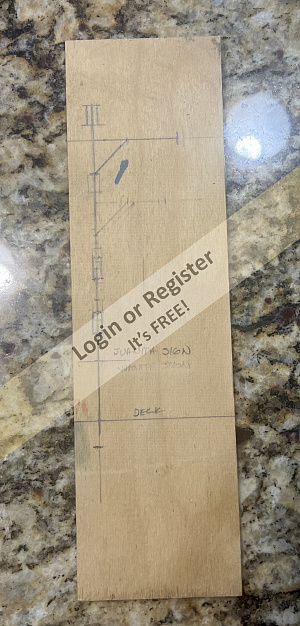

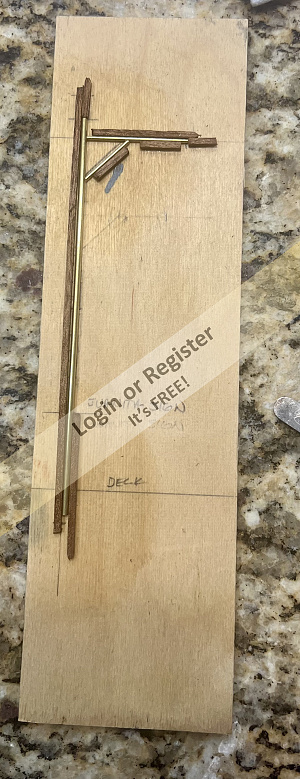

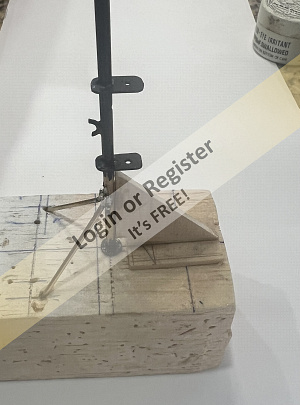

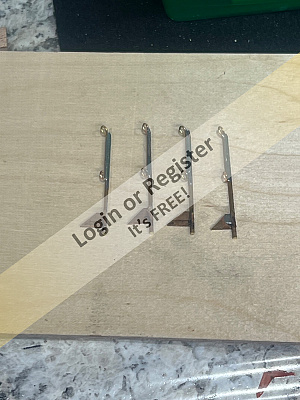

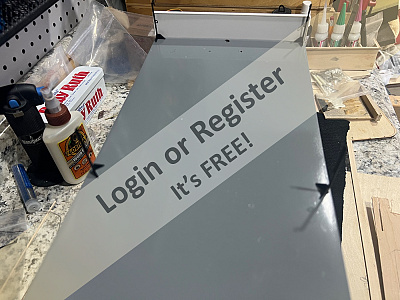

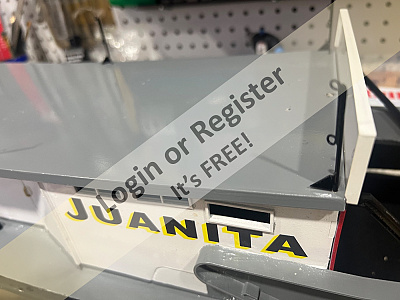

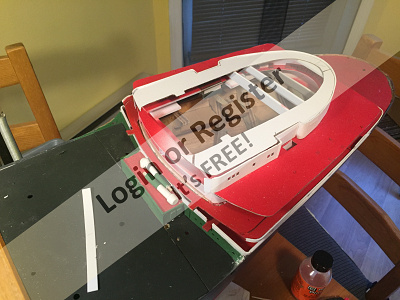

JUANITA STERN WHEELER

A good hello to all members.

Now that I finished The Fireboat, I would like to add to the forum my favorite build, one you are all familiar with.Hello fellow members.

The Juanita Stern Wheeler.

This an amazing, high end kit that that when finished will be 40" LOA & should weigh under 10lbs ballasted.

According to online sources the JUANITA was built in 1954 by O. F. Shearer & Sons at Cedar Grove, West Virginia. Another source on the internet says that the JUANITA has been "in operation since 1977."

The present owner of the JUANITA is Tom Cook of Dunbar, West Virginia on the Kanawha River.

I was lucky enough to be a part of the first clients that purchase the first run of this fantastic model and I got it for a very reasonable price.

With that being said, I would like to show you guys a building log for this model but buy no means I will say that this is the best way to build the Juanita but this is how Im building it with my limited knowledge and the help of the instructions emailed to me by the designer.

I also like to say that this kit does not have written instructions since this kit was produced in a rush job before kits had to be sent out; the only instructions is a PDF file containing drawings showing the main steps of building process, but the designer himself is very helpful in answering all of my emails about specific needed details in the build.

So, lets get started.

I will start by showing the real Juanita.

🇺🇸 chugalone100

4 hours ago

5 Posts

2 Followers

40 Likes

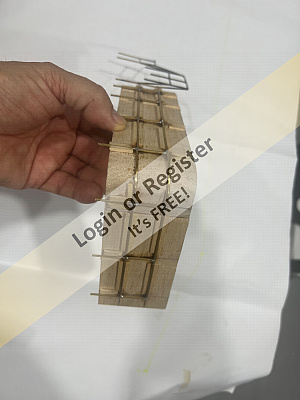

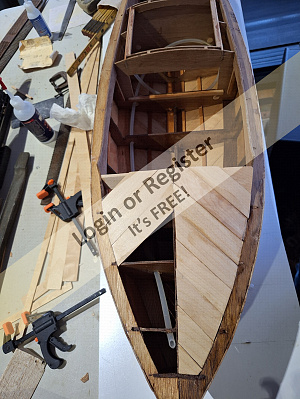

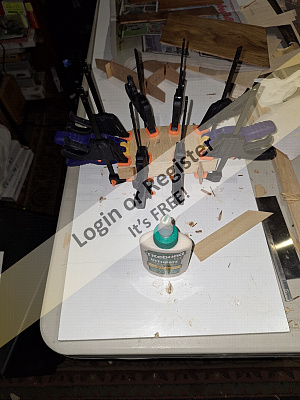

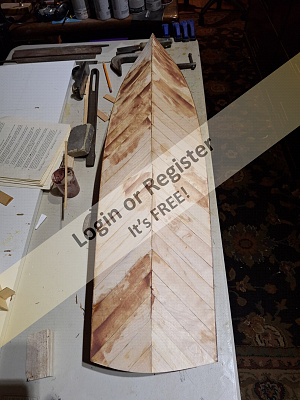

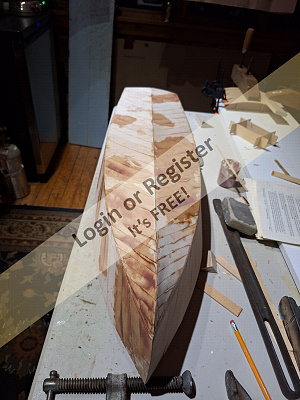

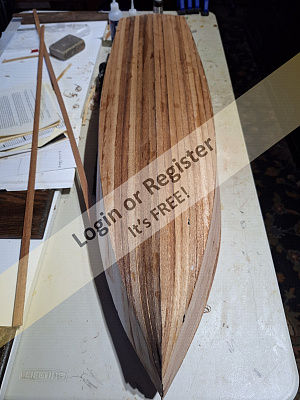

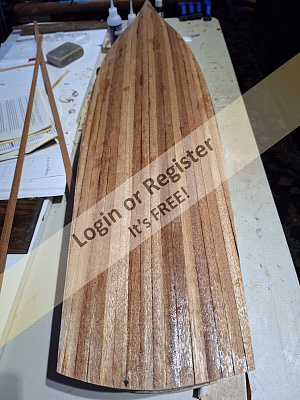

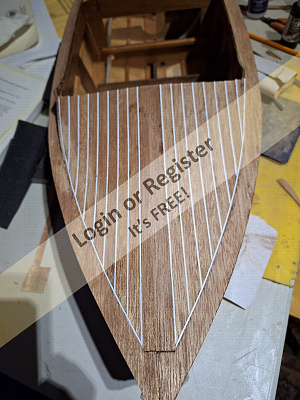

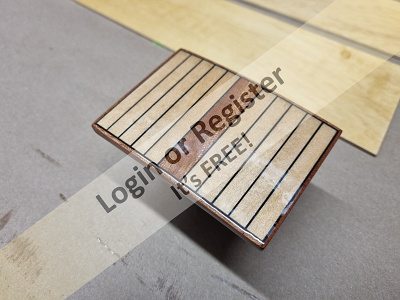

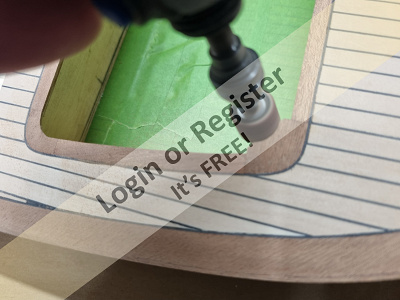

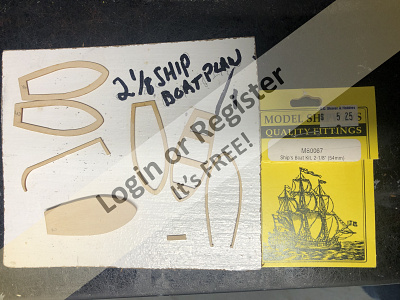

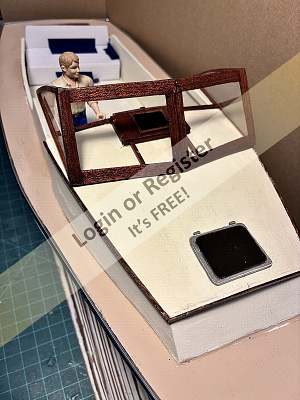

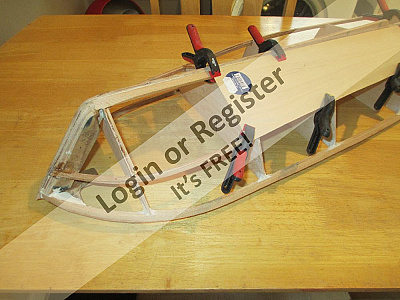

1930 Cris Craft Runabout Dumas Kit 1230

Started the Runabout.

Using my Lion Miter trimmer to cut the planks, and my block plane to

trim to the chine. Then a sanding block for the final fit.

🇺🇸 pressonreguardless

2 days ago

30 Posts

30 Followers

402 Likes

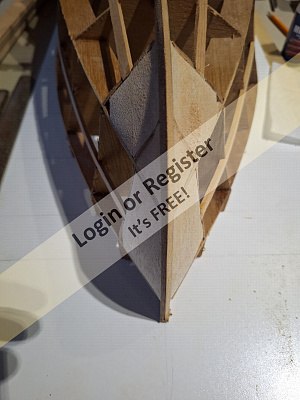

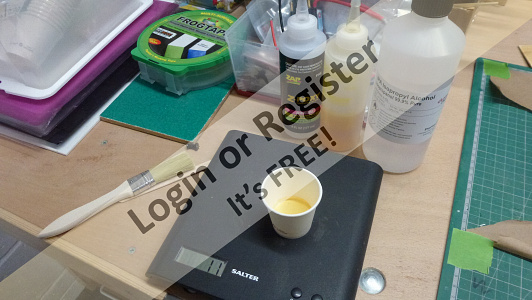

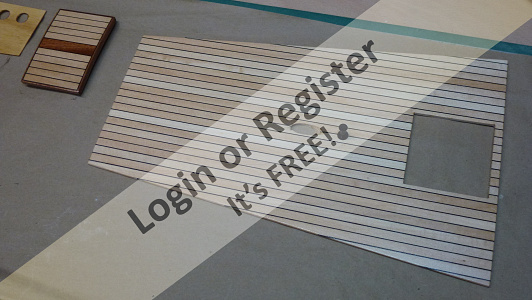

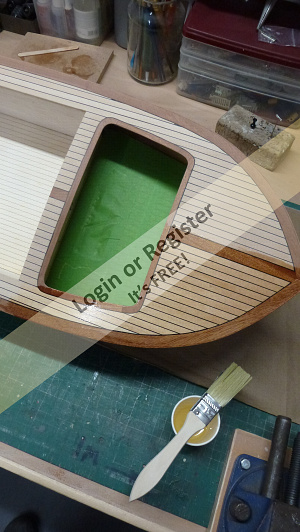

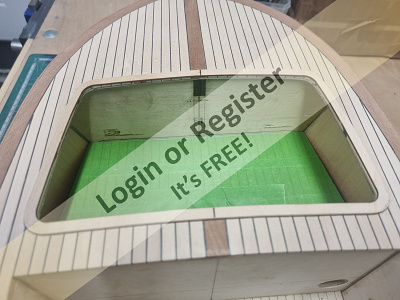

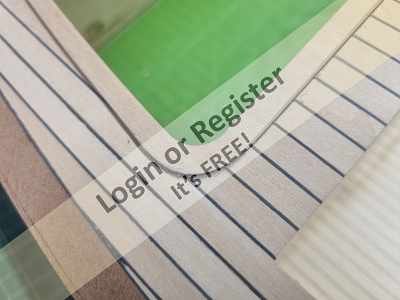

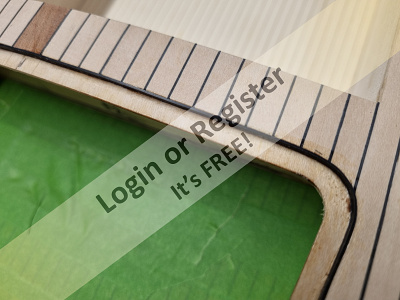

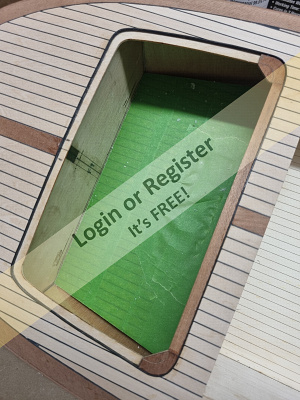

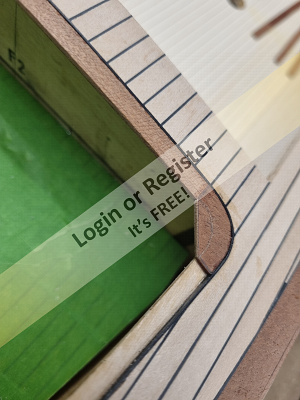

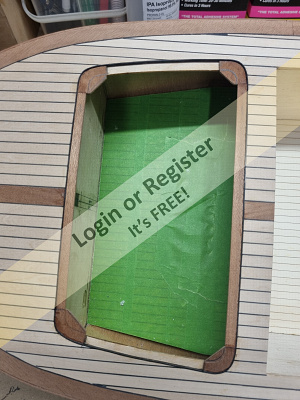

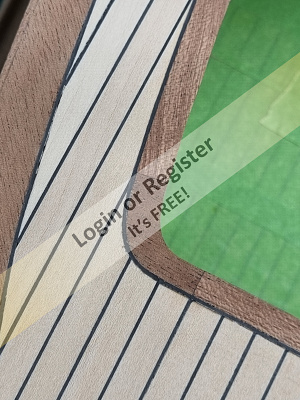

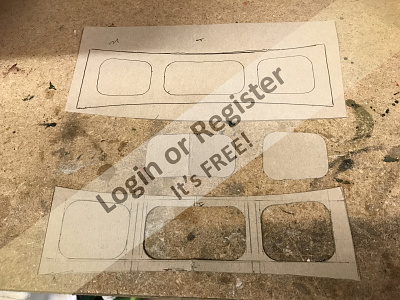

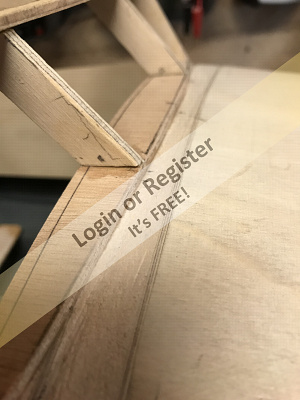

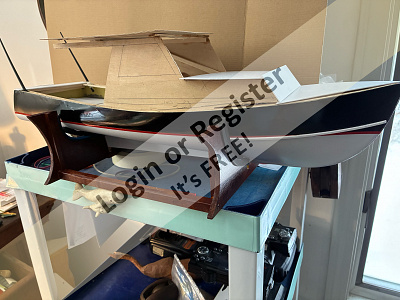

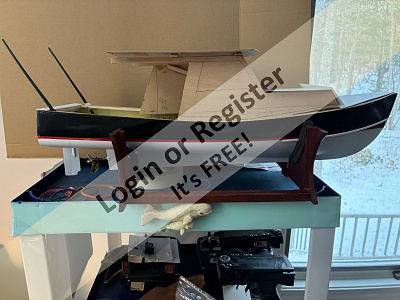

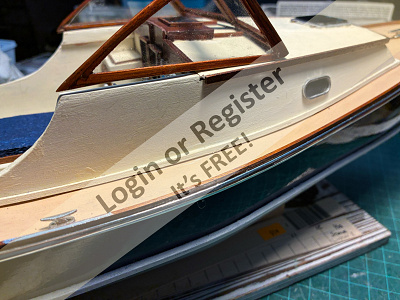

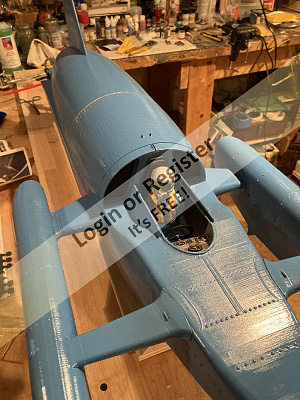

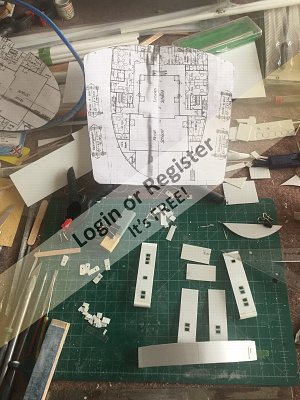

The VMW Marlin Cabin Cruiser by Robbob

The VMW Marlin Cabin Cruiser by Robbob

Preface.

At the time of writing, I’ve had the construction of this boat on ‘the back burner’ since July 2022. By then I had spent about two months on and off constructing the boat to a stage where I could consider applying a glassfibre cloth and epoxy finish to the hull. However I couldn’t spend any more time on the Marlin project as I had a more important project to undertake, which was to paint, decorate, refurbish and prepare our house for sale so that we could downsize and move to a new area now that our kids had all fled the nest.

Fast forward to today (mid-April 2025) and it’s taken a while to get the new house and gardens into shape and settle in, with the emphasis on converting my internal garage into a great new workshop, I can finally pick up from where I left off.

Introduction to the kit.

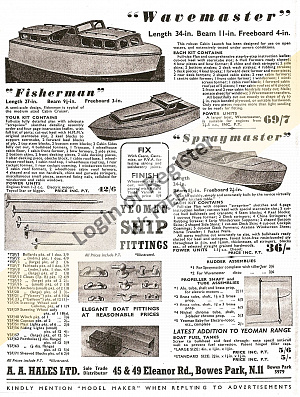

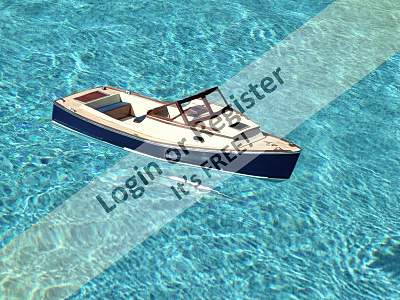

This new model is the latest undertaking by Vintage Model Works, now famous for their very popular models of the RAF Crash Rescue Tender and Thames River Police Boat kits which are based on old Aerokits and Veron designs.

The Marlin is a re-working of an original Veron design by the late Phil Smith in 1953. His son Colin Smith, who was also responsible for the re-design of the Thames River Police Boat, has made some changes to his father’s design to take advantage of more modern materials and production methods such as CNC and laser cutting.

The photograph below is of a prototype built by Colin Smith to give you an idea of how the boat looks in finished form. And there is also a review of the Marlin that appeared in Model Maker magazine, November 1953.

The size remains at 36” and it employs the same construction method as the original. The spacious cabins of the boat makes it very easy to accommodate all the latest control hardware required, not that the original was lacking in that area even when the radio systems used valves and large batteries and the propulsion was usually IC or a large electric motor.

Even the pre-production sample the Vintage Model Works kit supplied to me is well presented with a full size drawing including a pictorial construction sequence and separate pages of building instructions.

All the required materials are supplied in quality ply, balsa, strip-wood and dowel including clear plastic sheets for the windscreens, and various white metal deck fittings. The builder is of course required to supply their own adhesives and paint of choice, as well as the propulsion, drive train and radio control gear. In the latter respect I will likely restrict control to throttle and rudder and not add any lighting or other features. That has already been done magnificently by Mike Turpin.

Construction.

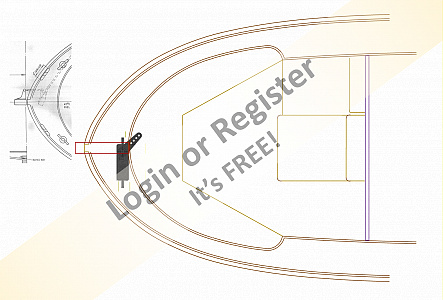

As with the Thames river police boat, another Veron design, construction starts with the assembly of a box structure onto which formers and bulkheads are attached to make the basic hull shape.

I will be tackling this in the first part of my build blog which I hope you will enjoy following and I encourage you to ask questions, leave comments and hopefully some ‘likes’ as I make progress.

Robbob.

🇬🇧 robbob

2 days ago

6 Posts

11 Followers

38 Likes

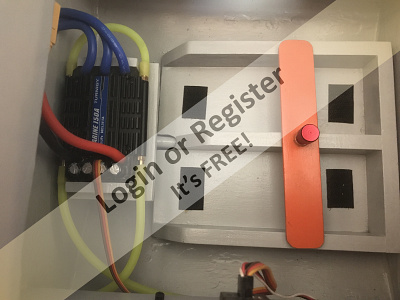

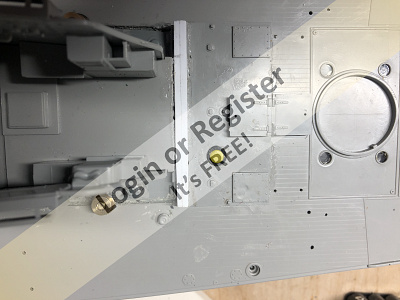

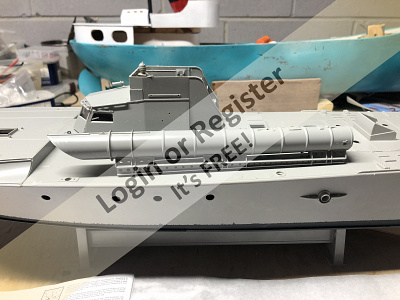

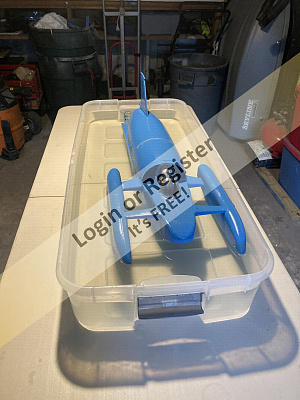

LesRo Rapier.

Rapier1.

When the first lock-down came along I dug out a couple of old wrecks that had been thrown away and had been saved from a skip some years previously, and this looked like a good time to see if they could be rescued.

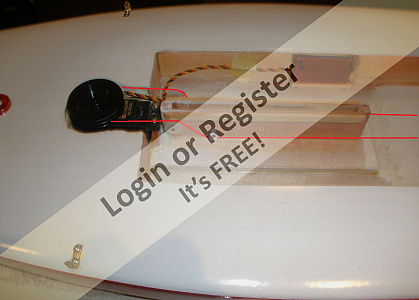

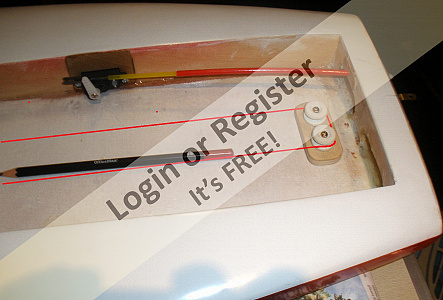

The first was a badly built and abandoned LesRo Rapier (shown here after the rebuild as my photos showing the full rebuilding sequence will not load).

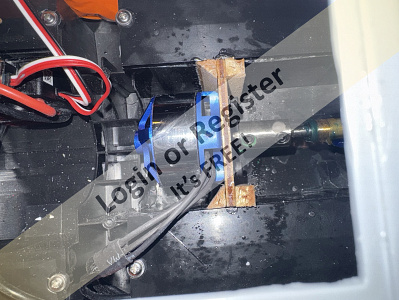

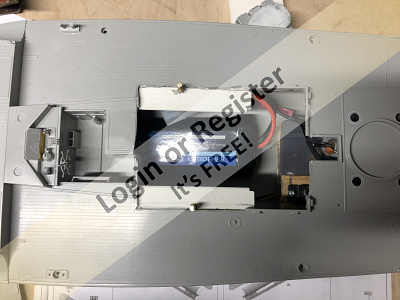

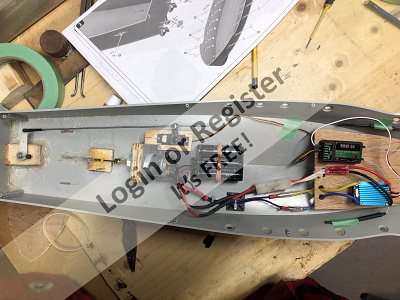

The LiPo tray carries two large 2C 5600Mah LiPo cells, but only one is connected up at a time - the unused LiPo acts as ballast to keep the hull running straight, but makes for a nice quick change when the first one runs down

Any basic tools that I may need when I am "pond side" to change a prop or brushless motor are carried on small magnets in the rear compartment to save me forgetting to take them with me and this has proven to be very helpful!

Bob.

🇬🇧 zooma

3 days ago

2 Posts

2 Followers

18 Likes

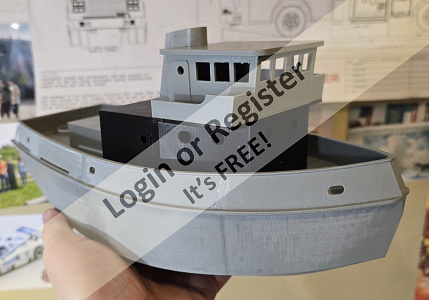

Something a little different-Horizon Harbor Tug

Hi y’all. I turned 65 last month, and in preparation for celebrating making it this far without getting myself seriously injured or spending time in jail I sold a few boats and cashed out some excess pto so I could do something I normally don’t do…spend more than usual for my birthday.

So, I had a budget, and my goal was to use as much as possible from my savings from boat sales without disturbing the family Kitty much if at all. I was successful, came in under budget, my wife got me two kits and I picked up this-the Horizon Harbor Tug.

Now, I’m not usually a RTR or RTF kind of person. The few times I’ve purchased a hobby grade ready to run or fly model I’m usually disappointed. But…this boat has been praised by modelers of all stripes, and Horizon has kept it in production for 4 years, which I think is some sort of record, as usually Horizons scale offerings last maybe a year, 2 years tops. Also, we have 2 members who are dedicated builders of tugs and submarines that love them to death. So here goes…

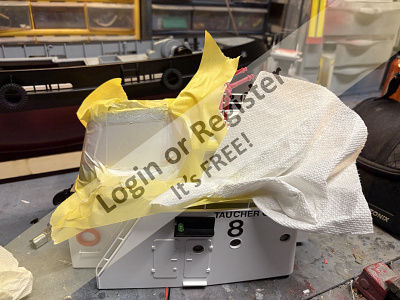

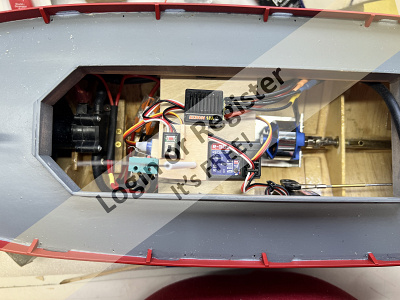

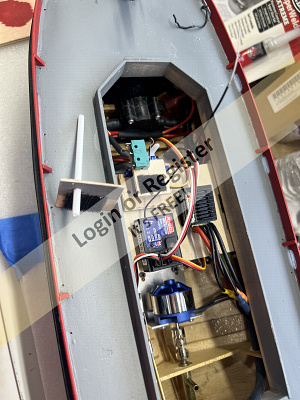

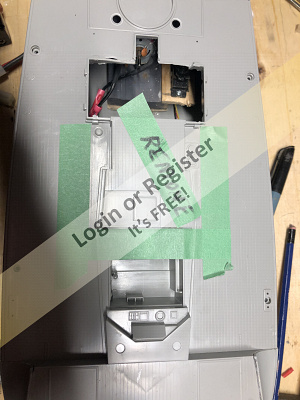

I was not allowed to touch my birthday presents until my birthday, so I had time to figure out what I wanted to do with the Harbor. Once I got her on the bench, I gutted her like a fish.

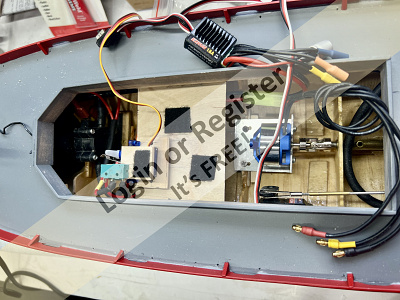

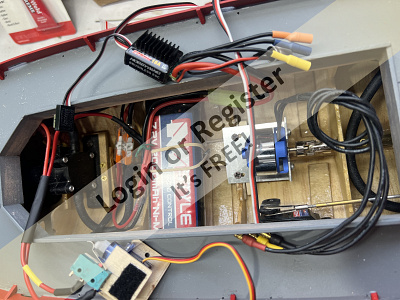

The Harbor Tug comes with a barely hobby grade pistol grip radio capable of 4 channels, a combo brushed esc/receiver, an esc for the fire monitor pump, and a radio controlled electronic on off switch for the led lights. Power is a 700 size motor, this is all supposed to be powered by 3 cells. It does NOT come with the water pump, that’s 60 dollars more, and from what I’ve seen it’s not as strong as I like.

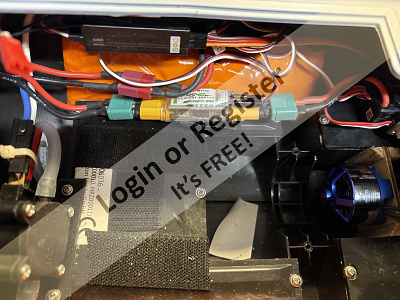

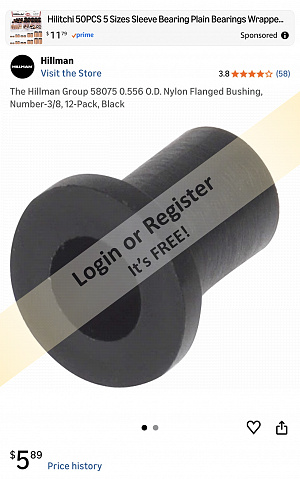

So, I had to make a mount for my preferred motor, the Zippkits 650 brushless outrunner, that’s coupled to the shaft with a good solid coupler. Esc is a HobbyWing 16BL30 30 amp unit. I had to do some modifications to mount my preferred Amazon sourced pump, which included drilling out the molded in water pickup and epoxying in a brass pickup, and changing the mounting location of the pump. Pump is powered by a 10 amp brushed aircraft esc-the original that came with the boat works well, but is set up for 3 cells, and doesn’t give me enough voltage at the pump. Originally I was going to use a FrSky 7 channel receiver, but I wanted to try my hand at telemetry. So I used a FrSky X8R so I could run the FrSky FAS40 module, which gives my real Tim battery voltage and current draw. I also added ballast to bring her up to 12 pounds, as the stock weight of 9.5 or so is seriously under ballasted.

Now, the first production runs of this boat had some issues, leaks near the stern and along the bulwarks were common. It seems to me that Horizon did what Joysway did with the DF65, and listened to feedback, as my boat ran dry. There was a bit of water in the hull before the maiden as I was checking ballast and leaks the day before, and there was no appreciable water in the hull after. All systems worked well, and the boat exceeded my expectations.

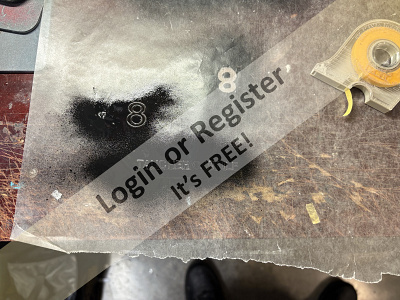

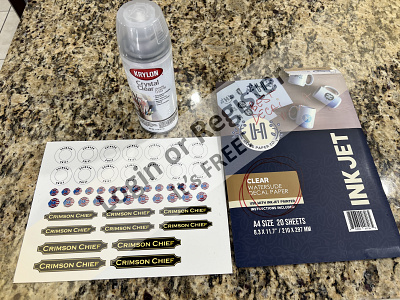

Now, y’all know me. You’ve seen my build logs. Probably wondering why I’m loving a boat that I don’t have much time at the bench with. You see, the story doesn’t stop here, oh no, I have more work to do. The real boat this was modeled after is the Taucher O Wulf 8. Horizon put just enough detail to please the average boat modeler, and decaled it with an H on the funnel. My goal is to get her recognizable as the Taucher. I have to do some detail work, add some things that’s missing, do some lettering, etc. The end game is a stand off scale model of the Taucher. So stay tuned, we’re going for a ride!

Cash

https://youtu.be/DIf4v8KvfSk?si=9Ya4HaEL1Sq_q__J

🇺🇸 Cashrc

3 days ago

6 Posts

5 Followers

35 Likes

Fairey Fisherman 27

Made the bilge keels from two laminations of mahogany sheet to get the correct thickness and then glued them in place. Once this was done I was able to return to the superstructure. Drilled the holes for the portholes and then glued the cabin sides in position.

Made the forward cabin front window and glued in followed by that for the rear cabin. Bolted and screwed the upper support for the drop keel whilst I still had easy access.

Really starting to take shape now but still a long way to go!

Chris

🇬🇧 ChrisF

3 days ago

10 Posts

11 Followers

89 Likes

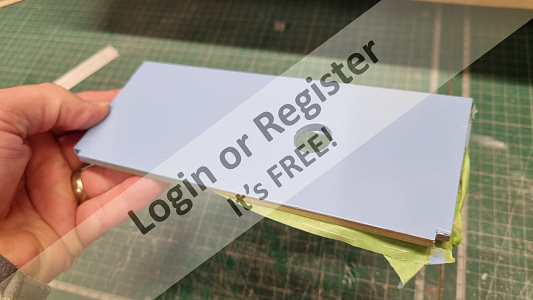

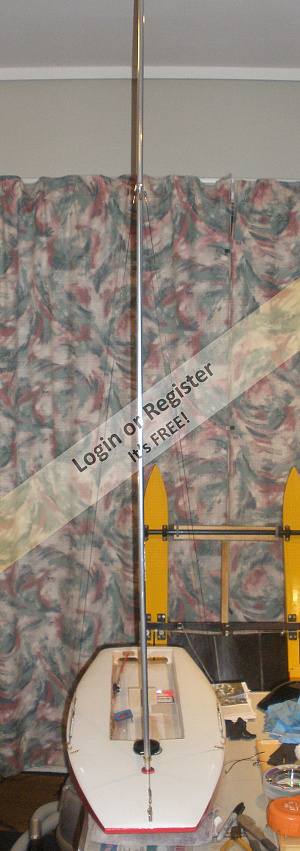

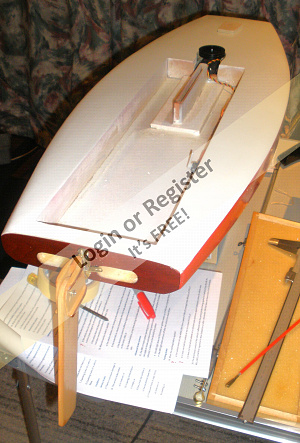

New Moth MKII semi scale yacht

Haven't built anything for a while due to lack of space (too many models) but the urge to build something was too great. After looking at many options, I decided to go with something 'easy' to build. I found some full size plans for an Australian MkI Moth which I'm building to a MKII (double chine) style.

I'm building in foam and glass again to make things easier. It's 850mm long and 310 wide which is roughly 1/4 scale (original is 11 ft)

Started by converting all the lofting measurements on the redrawn 1953 plan to metric and dividing them by 4 to get the scale.

Next was creating the ply deck, then contact gluing onto it a piece of dense 50mm building polystyrene. This was then shaped with a surform file and the chines shaped afterwards using eyeometry. Then the 10mm deck foam was glued on so the deck sheer could be shaped.

Next the cockpit foam was routered out, and basswood sides and inner transom piece epoxied in. After that, the ply outer transom piece and hardwood nose block was epoxied on.

The centerboard case upper and lower ply braces were routered out (using the mill and a 1/2" slotting bit) large enough to accept the case sides, leaving enough room for the 6mm aluminium keel (can't use a centerboard for obvious reasons) which will have to have a bulb fitted.

A rebate in the bottom of the hull was routered out for the lower c/board brace. These braces are needed to form part of a box structure with the floor and cockpit sides which the c/board can lever on. Once everything is eventually glassed in, it will make it very strong unit, so the foam will just be the shape surrounding the box, and not having any strain put on it. The ply deck will take the strain of the stays/mast.

The cockpit floor was cut, and will be slotted the same as the braces, then the c/board case will be built.

The mast on this is 1.486m tall, - sail is -luff -11.295, foot 609mm, so quite large for a small boat. The full sized boat is a lot of fun to sail, so this model will be interesting to sail. Unfortunately, without the human input required, and being a performance boat, it may assume the attributes of a submarine in a stiff breeze, - time and testing will tell.

The basic mast was made from 12mm ally tube, boom from 10mm. Sail pattern was cut from art card to the plan. All laid out on the floor to get an idea of what it will look like.

PDF is the history of the Moth. There were a number of versions round the world as it went along,- scow, international moth (dinghy type) and todays high speed foiling moth.

Lots more to do yet

JB

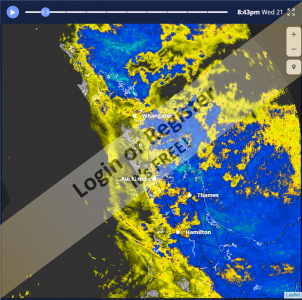

2025 world champs, off the Whangaparaoa peninsula, just up from where I live.

https://www.youtube.com/watch?v=FuLhJ-yRLmc

https://australianclassicdinghynetwork.org/moth

https://www.youtube.com/watch?v=wWkd2e8apSI

https://www.moth.asn.au/

https://www.youtube.com/watch?v=gAifFN0RJ0M

🇳🇿 jbkiwi

5 days ago

2 Posts

4 Followers

22 Likes

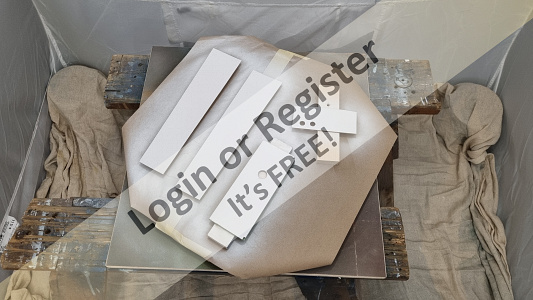

Dumas Pay n' Pak

Hey gang! As you may already know I have the Bluebird K-7 on the shelf for final detailing, the C-2 cargo ship Matson "Pacific Trader" awaiting rigging, and 22 inches of snow on the ground. So I wanted a challenge and grabbed an ancient Dumas Pay n' Pak Hydroplane kit to keep myself from going nuts. This may or may have not been a mistake!

And...you may already know that I've already labeled this build as my "3 day running knife fight" as a boat made of 100% warped plywood is not a walk in the park. Here are some pix starting from frame up to a primer. And yes, to fight this beauty from becoming a warped "banana boat" those are bricks and carpenter's clamps helping me keep her straight! The The bottom is glassed and the rest resin covered. The primer is meant to assist in showing all my mistakes and assist in final sanding prior to a finish coat.

Tough build, but it does look like something out of "Star Wars!"

More to follow.

🇺🇸 jumpugly

7 days ago

1 Post

3 Followers

11 Likes

3D printed tugboat

This was my first attempt at 3D printing an RC boat. With plans to print a large navy ship I wanted to confirm that I could actually get a 3d printed boat running so I tried this file from Thingiverse. It still needs lights and paint but it runs surprisingly well. Power is from a 3s lipo and a brushless outrunner - pics in a later post. I'm planning to make an autonomous boat this year and this is a potential candidate

Printed from ASA and ABS filament on a Bambu X1 Carbon and glued together with acetone. Acetone dissolves ABS and ASA so it's also nice to dissolve the support scraps in a jar of acetone to make a filler putty.

You might notice the different colors on the suprtstructure, that's because it's just resting on top and can be knocked off and lost requiring a reprint

Does anyone have suggestions for a colour scheme?

🇨🇦 JSS4

7 days ago

1 Post

3 Followers

5 Likes

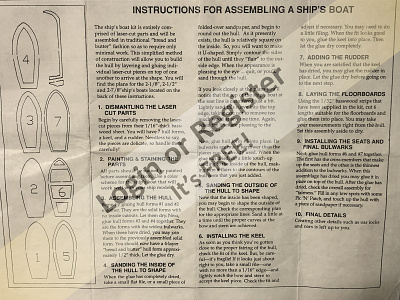

Model Shipways

Monday, February 16 2026, is a holiday called Family Day in Canada so I decided to build a lifeboat that a fellow in the boat club gave me. Read over the instructions, and that took a while, and then started building at 11.00 am today, after 1/2 hour stop got two parts built.I am surprised that ModelShipways is still in business It's a real tiny boat.

🇨🇦 GARTH

8 days ago

1 Post

2 Followers

12 Likes

1008 tug mods

Here's another Aliexpress boat, I got inspired after seeing another build on facebook. I don't have the skills to meet his build but I figured I'd give it a shot. For $20 CAD I couldn't say no. It's even smaller than the tiny 686 tug!

I gutted the electronics and replaced the receiver with a small all in one unit with dual esc and steering mixing built in. Due to the funky channel assignments on the board I had to use my Radiomaster MT12. The stock 100 mAh battery was replaced with a 250 mAh to enhance runtime and ballast.

I added mast and navigation lights, the mast lights are switchable between off, white, and red. The factory spotlight was retained and put on a switch along with the worklight. I might make a new spotlight eventually and I plan to redo some of the details as well.

It doesn't like large ponds or waves of any sort really but is fun in a water feature type pond or in Little Canada's Bay of Fundy display (when the tide doesn't leave me stranded)

🇨🇦 JSS4

8 days ago

5 Posts

6 Followers

30 Likes

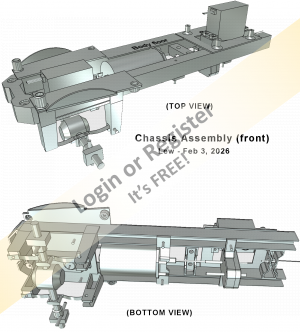

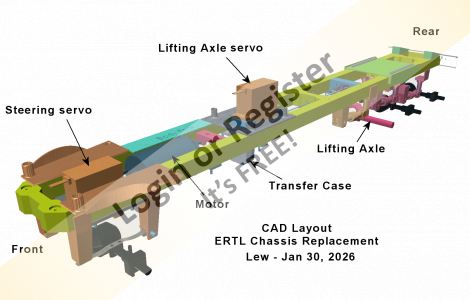

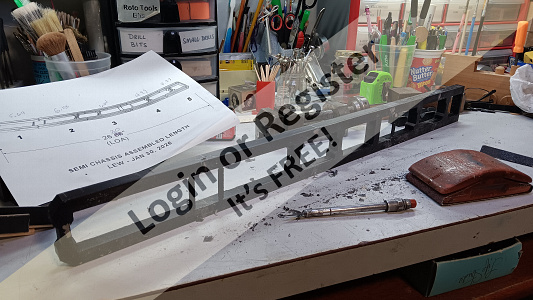

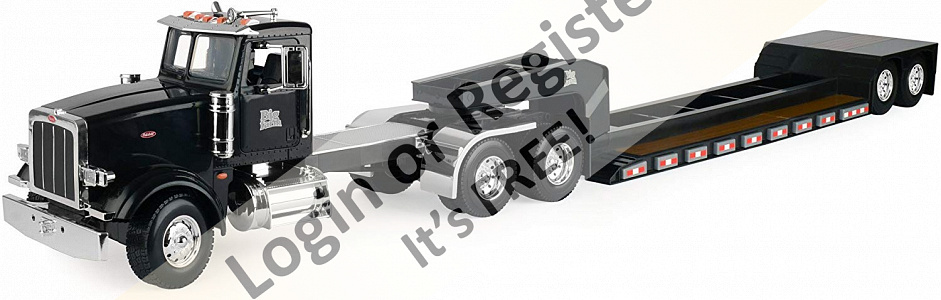

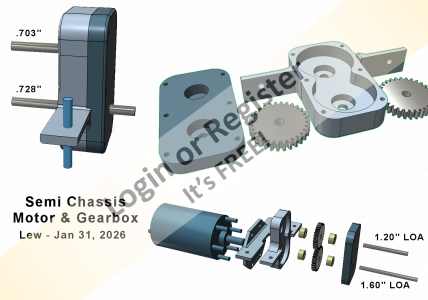

Converting a toy semi tractor trailer into a decent RC model Unit

Another RC hobby? I'm already into RC scale model boats (since the early 1970's) and RC armor (since 2015) I am branching out to RC scale vehicles (but not too many). Notice the word scale in each of these three segments of RC hobbies.

This topic is for a RC semi tractor and lowboy trailer being converted from an inexpensive toy. It is already in 1/16 scale and should be compatible with my Springer ("truckable") tugs and Armor (tanks, etc.). I plan to use it at both Model Boat and Armor meets.

This first segment involves the selections I have made and my plan to make the necessary modifications to the toy.

I bought two ERTL about three years ago with the intent to convert them into RC. I paid about $70 (US) for the pair of them on sale. They are currently in the $70-80 range (each). They look good enough to use although not to exact scale. The project goal is to keep the cost down and have a fun functional vehicle.

Why buy two units? When done, I will be using parts from the second vehicle for the first, like wheels for extra axles and other parts.

Right now I am working on the semi-tractor. The new unit will have another axle, this one to lift by RC. It will also have the extra sleeper cabin and other accessories. I am planning to make the "gooseneck" (the part that connects to the trailer) RC controlled. Unfortunately the model's lowboy trailer suffers problems like the real trailers do. Too close to the ground. I will need to elevate the trailer sufficiently so it will not get stuck. I do not have to contend with railroad tracks which makes the vehicles good targets for fast moving trains.

The latest:

This evening I am cementing the chassis frame together. I had to print it in five pieces due to the limitations of my 3D printer. There will be rectangular steel tubing epoxied inside the frame for extra strength.

Lew

🇺🇸 LewZ

11 days ago

16 Posts

9 Followers

98 Likes

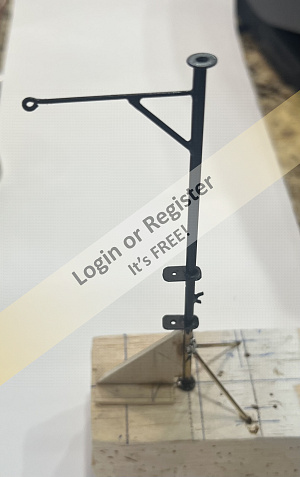

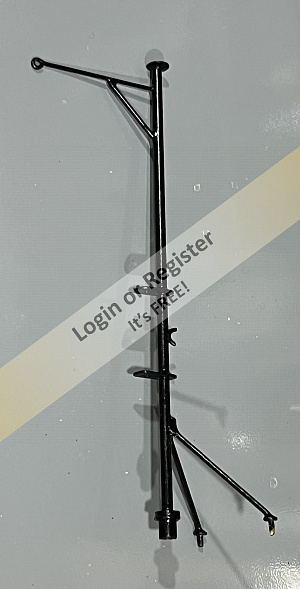

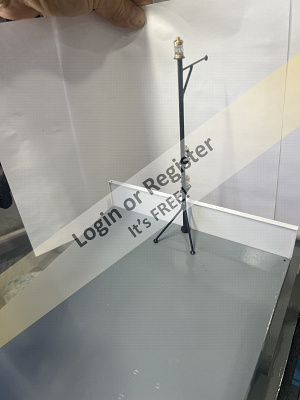

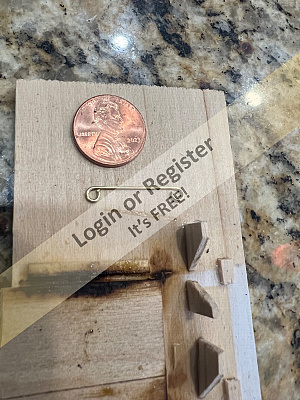

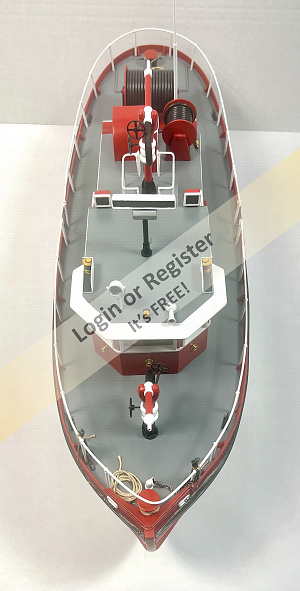

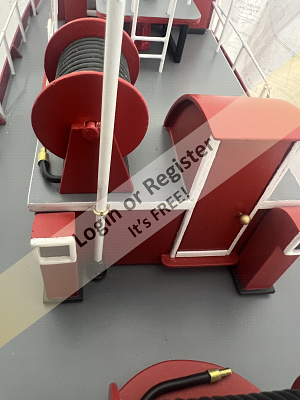

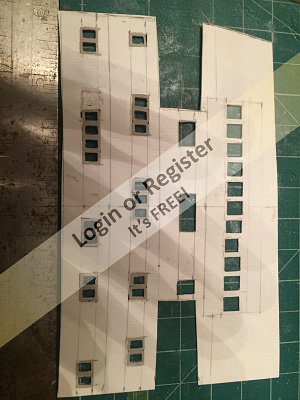

Midwest/Model Expo Fireboat

Model Expo has confirmed that production will soon begin on a new Midwest kit: the Fireboat, presented at a scale of 1/2" = 1 foot.

To clarify, Model Expo has acquired the licensing rights from Midwest to produce all of their models. At the moment, they have 27 kits in production, with more on the way. I previously worked with Model Expo in customer service, answering model-building questions and handling replacement-part requests. Now, I am one of the model builders who assemble their prototypes—the models they intend to release to the public.

With that being said, I invite all of you to follow along with this build. I introduced only a limited number of modifications—mostly to make the vessel more suitable for radio-control operation and to enhance its realism—while preserving the essential character of the original design.

Many of you have probably built this classic kit before; however, this is my first time working with it. Please feel free to share your opinions and past experiences with this charming little model.

History of the Fireboats

This model represents a small fireboat equipped with twin monitors, a type of vessel historically stationed in nearly every major working harbor throughout the United States and abroad. Its configuration is based on a combination of plans and photographic references from several representative examples. Because of this, it serves as an accurate portrayal of the smaller fireboats—many of which are still in service in various ports today.

🇺🇸 chugalone100

12 days ago

8 Posts

5 Followers

57 Likes

36 ft Northern Bay sport fisherman

The Northern Bay lobster and sport fishing boats are built in Qgunquit, Maine. Known as Down East boats they are semi-displacement hulls. They are very good sea boats stable in heavy seas. Compared to semi-vee hulls common to many other sport fisherman boats in the U.S. the Down East hulls tend to be wet boats. As with everything else, boat design is always a compromise.

1&2 The inspiration

3&4 Beginning steps

🇺🇸 Chum444

12 days ago

1 Post

2 Followers

9 Likes

Classic Water-Cooled Model Power Boat Engines.

Back in the 1960's when I made my first Classic Model Power Boat kit (an Aerokits Swordsman) almost everyone that ran model power boats chose to power them with a glow plug engine, occasionally a diesel engine, sometimes a petrol engine (in the bigger sized models), and only a few were powered by electric motors.

My Swordsman was powered by a 6.5cc OS40 Marine glow engine, and later by a 10cc Merco 61 Twin-Plug glow engine.

In those days, Classic Model Power Boats were probably at their most popular with lots of us building and running them in almost any stretch of water that could be found.

Places that I run my first model boat included various locations on the River Avon, the local Avon and Kennet canal, in the open sea off Torquay and Exmouth, several different village ponds (!) and the occasional visit to Victoria Park in Bath where the boating lake was filled with the sights and sounds of various r/c power boats hammering around making lots of noise and exhaust smoke!

These Classic Water-Cooled Model Engines have now been excluded from almost all waters where they were previously accepted, and most model boat clubs now actually ban their use.

Electric motors are much cleaner and easier to use, and can easily produce more power too - but they lack the "soul" of these internal combustion engines - and this is something that I really miss.

Part of the "operating procedure" included buying the correct grade of glow fuel (or diesel fuel) with the appropriate amount nitro content, making sure that your battery was charged enough to give a good bright glow when connected to the glow plug, remembering to pack the leather bootlace to start the engine with (electric starters came much later) and of course making sure that your radio equipment was working with fresh batteries too.

The procedure needed to bring the motor to life became a classic "starting ceremony" that often intrigued the casual onlooker as the owner/operator enthusiastically gripped the model by whatever means was preferred (I used my knees) to stop it jumping upwards as the leather starting lace was rocked backwards and forwards until the motor spluttered into life - when the bootlace was rapidly withdrawn in a flourish leaving the motor running (hopefully in the right direction!) and ready for action.

This was followed fairly quickly by the need to get the boat into the water before it overheated, when any final needle valve adjustment could be made (when the boat was in the water) before opening the throttle and seeing the model take-off and run until the fuel run out.

Judging the running time available (the amount of fuel that was left after starting it) became quite an art - especially when running in the fast flowing river waters as a model with a "dead" engine could be swept away causing all kinds of "interesting" recovery problems!

Anyone that had a small inflatable dingy became an instant friend and companion who was able to paddle after the stricken model and haul it onboard before paddling against the river flow to return it safely - often at a point some way further down-stream when the current was too strong to paddle against!

After the model was run (and recovered) the model needed to have a good clean to wipe away any spilled fuel and to remove any exhaust "goo" - before removing the glow plug to turn the motor over and placing a few drops of oil into the bore and then turning the motor over to give a good coating of oil all around the inside of the engine.

This after-run oiling procedure prevented the caster oil in the fuel from gumming-up the engine and the nitro content of any fuel that remained in the engine from eating into the chrome/nickel coating of the bore and the engine bearings!

Diesel engine operators could sometimes be compared to "wizards" as they balanced the compression needed to start the engine with that needed for it to run cleanly - with the same need to adjust the carburettor once the boat was in the water.

Compared with running an electric motor, these water-cooled model engines were hard work that could also be dirty and time consuming too - BUT - I really enjoyed the whole event - every time I took my Classic Model Power Boat out for a run it became a real occasion that plugging-in the battery on my current model boats can never compare with!

This "blog" gives an opportunity for others like myself that really miss these nitro and diesel fuelled engines to reminisce and picture their Classic Model Power Boat Water-Cooled Glow and Diesel Engines.

Bob.

🇬🇧 zooma

12 days ago

27 Posts

11 Followers

199 Likes

Lindsay M a scratch built Wasque 26 ft

Awaiting graphics to finish off THUNDER& METEOR so pulled this one off the shelf to resume the build. I’ll start at the beginning posting highlights so as not to take up too much time.

Photo 1&2 One of the many real boats. These are iconic around Cape Cod, Martha’s Vineyard, Nantucket, & other Atlantic bordering states.

Photo 3 Starting the frame & keel.

🇺🇸 Chum444

14 days ago

3 Posts

4 Followers

9 Likes

Krick Paula | Work / Crane Boat

Kit Build bought from Krick. Formerly a Robbe Kit but now known as Romarin by Krick.

72cm length with a 600 motor ( eventually!)

🇬🇧 Heners2332

16 days ago

8 Posts

5 Followers

50 Likes

Vosper

Today was another part constructed. The motor mount is built, the propeller shaft and the propeller is installed need to wait till the glue sets and then I'll glue the motor in place.

🇨🇦 GARTH

17 days ago

2 Posts

2 Followers

14 Likes

LISA M Motor Yacht

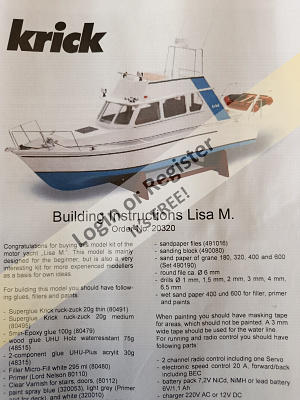

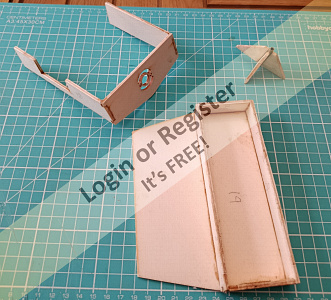

I've bought the above kit to keep me busy during these dark dank winter months. Originally I had planned to build a 880mm (34.6") Bluebird of Chelsea plank on frame kit. It is a famous pleasure craft built for Sir Malcolm Campbell and took part in rescuing soldiers from the beaches of Dunkirk under 'Operation Dynamo' in 1940. Unfortunately much to my bitter disappointment only the larger 52" version now is available which is too big for myself.

I'm hoping some kit builder will make a kit of this craft at about 36" so in the meantime here goes with LISA M

The kit has an ABS hull (a bonus for my hands these days!) and laser cut plywood parts. The kit also comes with an electric motor so all you need is a servo and speed control plus the usual R/C gear and battery.

A set of English instructions were also provided which are a reasonable translation with the odd error here and there! I feel they could be a bit more specific in places so study the photos.

The ABS hull comes with about 1 1/4" (about 300mm) extra height above the deck level which needs cutting down to be about 2mm above the temporary fitted deck level. This wasn't that easy but in the end I used a pair of tin snips to cut it which proved to be better than using a Stanley Knife. I have drilled and filed the holes in the ABS hull for the prop shaft tube and rudder tube. I've now assembled the deck coaming, motor mount, battery box and supports for the rudder tube. Next job is to waterproof the deck on both sides, and all the other assembled plywood parts. Having seen another blog, I've decided to strengthen the wood around the rudder tube by using an offcut from the wood provided for the boat stand. I will smooth the edges when the glue has set!

🇬🇧 DuncanP

18 days ago

20 Posts

19 Followers

214 Likes

Bluebird k-7

Hello all! Before my two week sojourn out to California starting tomorrow...

Here she is, all 31 inches and 4.8 pounds of 3D printed 1/10th scale madness. And the questions are starting arise after more than a few hours spent in research. How to get her to plane even close to scale?

1) EDF? Probably not, actually I don't think even a 90mm fan, (which will, in fact, push a faomy jet) will ever get this boat to plane.

2) Prop? Maybe with dual 6s and a killer motor, monster cooling etc. But, nowhere near scale with a big prop hanging out the back.

3) Turbine? probably yes, but way out of my league in mechanicals and $$. There will be tons of head-scratching my quickly balding head on this experiment.

This is going to go on the shelf for the long haul as my freighter needs finishing and the big Sterling Chris Craft Corvette is screaming at me. But, off to Cali for now...I will drop some pix from time to time of our travels.

Best to all!

🇺🇸 jumpugly

19 days ago

2 Posts

5 Followers

12 Likes

Seaway tug boat

This boat was built in the 1990s from an unknown kit I know what it isn't it isn't a mount fleet models tug nor is mobile marine its a model of seaway a tug boat from the clyde its from a deceased friend on checking her out the old radio gear is us as is the speed controller lets hope this isn't a omen to the motor thats geared as I sort out ill post more on her

🇬🇧 Stephen T

19 days ago

15 Posts

10 Followers

123 Likes

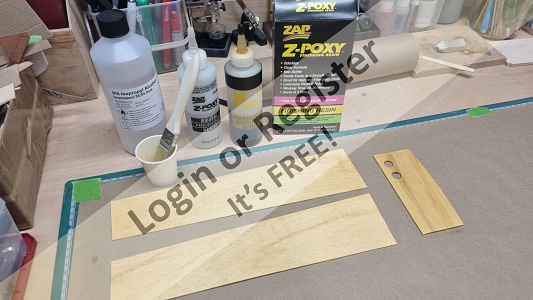

Scratchbuilt Esso Deutschland 1:150

When I first posted a thread under ... a dreamproject.. I didn't realize it was the wrong forum category. So here is my built blog. I will spare you the original introduction as I have made progress which and most of you are already familiar with my project.

The hull was built merging 2 methods on a simple keel plate from plywood, bow and stern structure bread and butter and hull in between 3mm planks on frame.

The entire main deck is intended to be removable with a drainage irrigation system of plastic corner moulding (from a building supplier) along top of hull and flush at poop and back deck structure. The deck is made of 1/4" plywood skeletal structure incorporating midship deckhouse. Hull glassed with lightest cloth available after 2 coats 2-epoxy sealer and paint primer followed by final coat except top (above waterline) grey will be applied once I have finished doing any necessary adjustments. There have been a lot of them since I realized many inaccuracies in dims etc. I wasn't happy with.

Here are photos in the progress (some may have already been posted in the original post.

More a bit later next week.

🇨🇦 JockScott

21 days ago

7 Posts

3 Followers

27 Likes

MTGMB

Easier to form lower skins than I thought, laminating from the 32thou helped a lot.

🇬🇧 fid2b

23 days ago

1 Post

1 Follower

11 Likes

Palfinger PB-950A (kinda)

I saw this little jetboat on Aliexpress and wondered what it might take to get it properly running. After seeing some breakdown videos on jetboats and modifying my Proboat PBR, I decided to give it a try. It's a decent 1s powered brushless jetboat but it lacks a decent control system and reverse. I gutted the control system and added a small 1s brushless esc/receiver unit for a micro plane. The reverse is controlled by a 9g servo, and the bucket is scaled down from a file meant for the Proboat PBR. It's run off a logical switch within Edgetx. When reverse throttle is applied the motor runs forward and the bucket drops automatically. I might change it to a 2s system and it still needs detailing and lights. I'm thinking about repainting it in Canadian Coast Guard markings

🇨🇦 JSS4

24 days ago

1 Post

1 Follower

5 Likes

HAGGIS 150 Outboard

This came about from wanting to build a harbour support vessel though couldn't find the correct outboard. I spotted some Stl files for an outboard that was poorly designed and had been proven not to work. I took these files and amended several parts and altered the shape of the leg slightly.

Instead of working with a shaft and gears its a flexshaft coupled to a 540 brushed motor with a realistic water cooling inlet and outlet. It's designed for high torque and low speeds. Its fitted with my own designed 3 blade high pitch propeller for maximum thrust at low rpm.

Has been tested in the bath so far and works very well. Just needing to build or find that harbour support to attach a couple or 4 of these too

Here it is running on the test hull.

🇬🇧 HappyHaggis

27 days ago

1 Post

0 Followers

10 Likes

A Beginners Vessel

Testing the water with this one as although i enjoy building boats from scratch i also enjoy designing them and printing them which takes up many many hours.

I'm still indecisive to what it should be called as in my eyes it's not a flat plan build so cannot be classed as scratch built.

So here she is. Her name is "Le Boat" and a very small just under 26cm long very basic mock up multiple old french trawlers i was basing her on.

The idea behind her was to provide newcomers to our club a very basic, cheap and easy to glue together model that the first timer would still be proud of.

They still have to paint and fit the running gear so it's a short but positive learning curve that will hopefully have them wanting to progress from there.

The actual model is right now printing and will be finished in 20 hours so will update how she will really look then.

Motor 280-380

10-15amp esc

9g servo though smaller might work just as well

2s li-ion 800mah

Will probably print some netting along with a couple of sailors for the deck, maybe a box of fish though will see how she comes out

🇬🇧 HappyHaggis

28 days ago

1 Post

5 Followers

13 Likes

Building a rowboat 1:6 scale from Model Boat magazine

Building a rowboat 1:6 scale from this month's Model Boat magazine.

I have made many changes to the drawing and it's operation it's been interesting and fun I have a 1:6 scale doll to add to it.

It's the only way I can get the video installed to show how the Oars are working to propel the boat. I removed the link to my face book video

🇺🇸 bruce1946

1 month ago

5 Posts

5 Followers

46 Likes

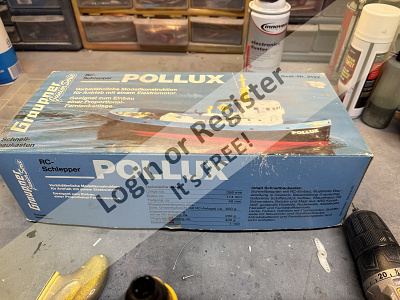

Graupner Pollux

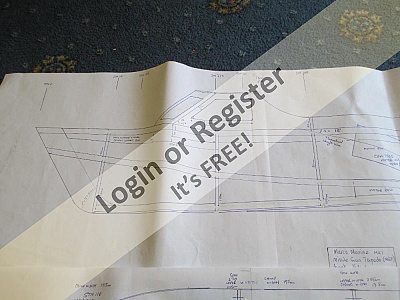

Hi y’all..it’s been a minuet since I’ve been on here. Getting ready for Christmas, the annual NTMS Christmas party, work, etc. I haven’t been at my bench for a few weeks, so I decided to drag a simple kit out of my stash and build it up…the Graupner Pollux.

This kit has been gone thru, some of the vac formed parts have been cut out but not finished, but it’s very buildable. First thing I had to do is build a stand. I pulled my trusty Ryobi scroll saw out from its hiding spot under the bench, got it set up, then the blade broke…and I couldn’t remember where I put my spare blades. So I built the stand up using plasticard for the uprights which I reinforced with 1/8 in ply strip, and used dowels to connect them together. I then looked at the kit and plans.

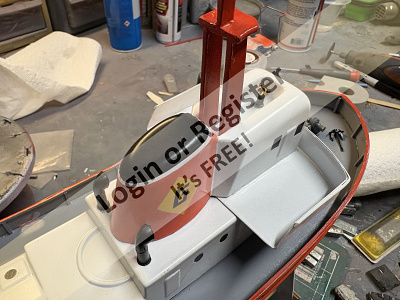

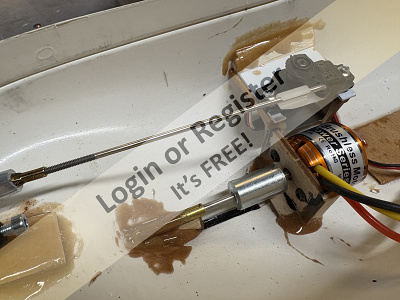

I did not have anything similar to the Speed 180 gearbox called for, so after I trimmed and sanded the hull I made up a motor mount for a 28mm outrunner. The motor I’m using is a little hotter than I would like, it’s 750KV, which is not a “hot” motor in any stretch but is a little hotter than I would have liked…but it’s in my stock, so I used it. The shaft was missing from the kit, so I had an 1/8 in I.D Dumas tube and shaft that I cut down to suit. I have a few 3 blade props in the right size for this boat, they’re set up for a drive dog or pin style shaft. They are made for a 3 mm shaft, so it was easy to clean out with a 3.2 (1/8) drill bit to fit my chosen hardware. I also am using a rudder from my parts stock, which I started to mount in the original location, didn’t like that so I moved it aft a bit to give a little more clearance for prop installation. The original hole is filled from the inside by the rudder tube support, the rest of the fill will be done later. After I got every thing ready I checked fit and alignment then glued every down. I then built up a servo mount and did a Buick install and test on the linkage, after that I glued down a battery floor.

That’s where’s she’s at now, I’m going to get the ESC and receiver mounted using Velcro, and once I’m statisfied that I can access them via the hatch I’ll start on the deck.

Cash

🇺🇸 Cashrc

1 month ago

1 Post

5 Followers

9 Likes

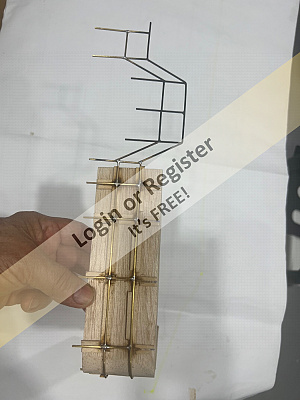

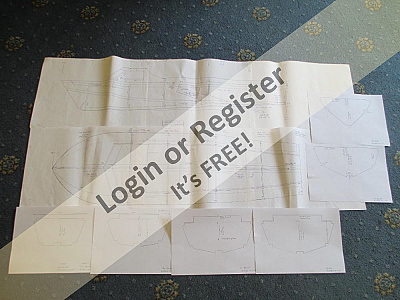

VIC SMEED'S VIVACITY

Hi all,

just posting a summary of (mainly) previously posted pics to kick off this build log and show progress to date since I first started researching the building of this 'leviathan' last year.

I'm currently at a stage where I have acquired the necessary propshaft/tube/propellor assembly and awaiting delivery of my chosen powertrain. The timber for most of the build has been sourced, so now I have finished other projects, all that really remains is to get on with it!!

1)The plan...

2)Drawing bulkhead and keel templates from plan

3)Bulkhead paper shapes stuck to 3/8 ply - I chose to make the bulkheads slightly thicker for extra gluing area and because I need to have ply-skin joins across certain bulkhead positions as standard modelling ply lengths do not go to 54". Some of these may have lightening holes cut in them for better internal access to equipment - haven't decided yet.

4)bulkheads cut out and trimmed/notched for stringers. Waiting for keel cut out, as a couple of issues regarding installation of the prop tube into the keel pieces have arisen; I need to accommodate the two oilers somehow, and the original keel pieces need to have another piece added to support the prop shaft all the way to the prop bearing - I'll post details when I've sorted it out...I hope

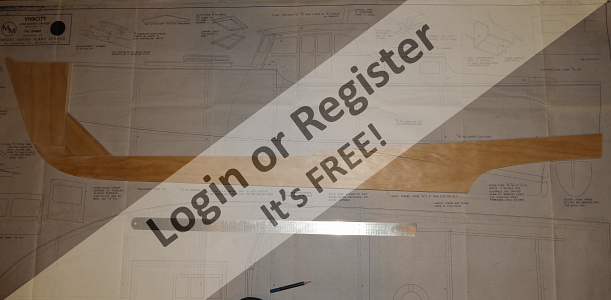

5)Original 10mm pine keel pieces cut out and assembled over plan - not yet glued up as an extra piece still required

6),7) & 8) Lots of spruce strips!! - spliced together to make up pieces approx. 70" in length for 3/16x3/8 chine stringer laminations, 1/4sq. sub-stringers, 3/6 sq spray rails and keel doublers.

9)18" 3-bush 3/8dia prop tube with oilers/tubes at two bearing positions, 3" diameter 3 blade propellor fashioned from 1mm brass sheet to be fitted to M5 thread on 3/16 steel shaft. I had this specially made up by Bill Nordmeyer who owns SAB Model Boat Fittings - thanks Bill!

The brushless motor and speed controller should be arriving in the next week or two. When they do, I intend to set up an engine/propshaft test to see what the performance specs are like prior to installing the tube in the keel. Once this has taken place I'll be able to post again.

Until then , best regards,

Nick

🇳🇿 Nick Ward

1 month ago