|||

|

|

🗝 Login

🤖 Create Account

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Plans & Docs

• Useful Links

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (7,882)

📖 Quick Site Guide

📣 Support

👥 Membership

Hobby Supplies

🛍️ Online Shop

Not Registered

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

For A Whole Year!

£25

£45

£65

Donate

You Will Be Helping Towards:

Domain Fees

Security Certificates

iOS & Android App Fees

Website Hosting

Fast Servers

Data Backups

Upkeep & Maintenance

Administration Costs

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Model Boats Website

Home

Forum

Build Blogs

Media Gallery

Boat Clubs & Lakes

Events

Boat Harbour

How-To Articles

Plans & Docs

Useful Links

Welcome to the Model Boats Website! A place for all model boaters!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Login To

Remove Ads

Remove Ads

Today's Question

Where is scuba equipment usually used?

ANSWER >>

>

Today's Wordle

7 LETTERS

>

Trending Now

Forum

In Loving Memory of my dad Peter, aka Mallory.

Passing along prayers of strength to you Stephen and your family; on (as you described) a life well lived.

🇺🇸 jumpugly

17 minutes ago

Forum

UK Coastal Forces

I have just found this splendid film from WW2. Some great footage of MTBs.

https://youtu.be/lzJDVhuMaI8?si=lbiJJizuXVkdwoHr

🇬🇧 Nickthesteam

2 hours ago

Forum

Quick snap on coupling

Aquarium shops are a good source of tubing and small fittings...

🇬🇧 Nickthesteam

2 hours ago

Forum

Light at the end of the tunnel?

It may be taking a while, but progress is now possible.

🇺🇸 Peejay

3 hours ago

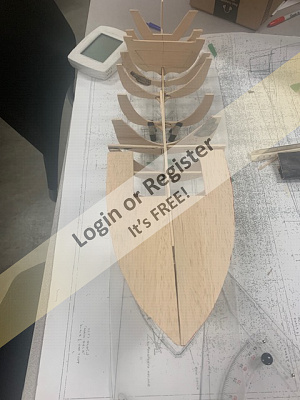

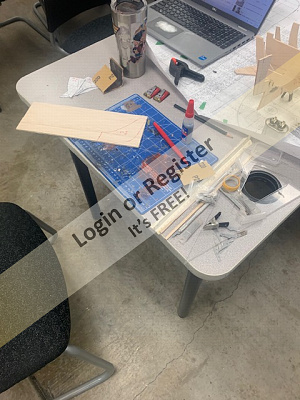

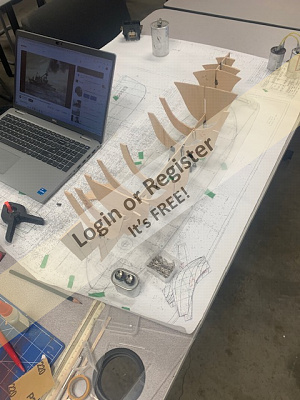

Blog

More Progress

There are a lot of frames on this bad boy. It is going to be heavier than I expected. I am going to get more done Thursday through Sunday as I recover. Hoping to begin planking. Have to verify placement and height of the frames, deck, then plank.

🇺🇸 KevinH

5 hours ago

Place

Stade, Germany

Hello Doug Yes, that is the jetty on the "Schwinge" directly at the "Stadeum" Have you already been here in Stade?

🇩🇪 Wolle

6 hours ago

Forum

2nd competition

You may find something useful in this thread that would give you the confidence to fill the boiler and light the flame! >>>>>>

https://www.modelboatmayhem.co.uk/forum/index.php?topic=68100.0

🇬🇧 Razor1955

6 hours ago

Forum

Question of the Day?

Garth yes. They were taught by humans.

🇿🇦 Rudy-M

7 hours ago

Blog

Re: About to start the glass fibre

Feel free to ask any questions Alessandro, and I will do my best to answer.

🇬🇧 Trident73

8 hours ago

Harbour

Re: Artesania Latina 20201 Amsterdam

Thank you all for the kind comments.

I agree, my boat does look like the currently offered "Atlantic".

However, it is indeed the now discontinued "Amsterdam".

I am not aware of what the differences are, as they look VERY similar.

*I see some differences at the top of the superstructure. It looks to be somewhat simplified.

There must be some reason Artesania Latina reintroduced it as the Atlantic.

If anybody knows the history or reasoning behind this, I'd love to hear it.

Here is all I can find about it:

If you loved Amsterdam RC, our new Atlantic RC will shock you.

This model has become one of our best-sellers. His wonderful finishing and his capabilities in the water makes Atlantic RC simply wonderful.

Moreover, this maquette made in wood and plastic is a faithful replica of the tugboats of the 70s and 80s.

Do you want to know more about this model? Then, you have to follow this link: https://bit.ly/3hOOirh

🇺🇸 DWBrinkman

11 hours ago

Blog

British Power Boat 70ft Motor Gunboat.

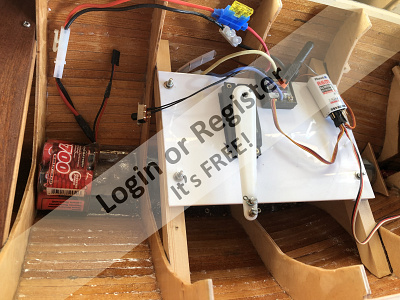

Crew figures from Shapeway 3d print not cheap.Motors are two brushed 545 with a 3s lipo for each motor.

Nomally i would use brushless motors for this boat i used what i had in workshop

Real boat was 70ft in length model is 35" length at 1/24 scale.

🇦🇺 grahams

16 hours ago

Forum

Wordle of the Day?

Started with a trawler and ended with a galleon in 3. No gold ️ to go with it though

🇬🇧 Doogle

20 hours ago

Forum

Flight Link Control Launch Link 2 channel radio control set

Yes Isaac, my main hobby is predominantly model flying!

🇬🇧 Stuart Mackay

1 day ago

Blog

Re: NQD PX-16

I'm not too sure what your are trying to achieve with the two motors, two ESCs, and a "Y" cable plug and the mixing.

I watched the video and I also use a few I6X radios (plus others). I don't see how this all would work on one channel. Several of my boats have multiple motors and props.

Perhaps if you could sketch out a schematic or an explanation on what you are trying to do, one or more of us can help.

Lew

Florida ️, USA

🇺🇸 LewZ

1 day ago

Forum

Edina Model Yacht Club Season Opener

Great place Dave, thanks for sharing your videos with us.

I feel sorry for the sailboats, it seems there was no wind for them.

🇮🇹 AlessandroSPQR

1 day ago

Forum

If only

It was always my ambition to build a full size dinghy - albeit somewhat smaller than the one in the picture. I have to accept this will never happen now.

Selway Fisher designs often follow similar construction to model boats and indeed he has a series of designs specifically to be built as models >>

https://www.selway-fisher.com/sfdesign_model_boats.htm

🇬🇧 Razor1955

1 day ago

|

New Member

United Kingdom

FrankJ

FrankJ10 hours ago

New Member

United Kingdom

Robin Starfish

Robin Starfish11 hours ago

New Member

United Kingdom

DouglasS

DouglasS13 hours ago

New Member

United Kingdom

Farlam

Farlam17 hours ago

New Member

Australia

PeterJ2

PeterJ21 day ago

New Member

Germany

AudronisB

AudronisB1 day ago

New Member

United Kingdom

Gsf1250

Gsf12501 day ago

New Member

United Kingdom

BarryM

BarryM1 day ago

New Member

United Kingdom

gary2

gary22 days ago

New Promotion

Leading Seaman

grahams

grahams2 days ago

New Member

Italy

FrancescoF

FrancescoF2 days ago

New Member

United Kingdom

BrianC2

BrianC22 days ago

New Promotion

Midshipman

Isaac

Isaac3 days ago

New Member

United States

LeeA

LeeA3 days ago

Birthday This Week

Turns 64

Rob

Rob4 days ago

New Promotion

Leading Seaman

Stuart Mackay

Stuart Mackay4 days ago

New Member

Canada

RayR

RayR4 days ago

Birthday This Week

Turns 66

ARL58

ARL584 days ago

New Member

United Kingdom

DavidS6

DavidS64 days ago

New Member

United Kingdom

IAND2

IAND24 days ago

Account Updated

Changed Avatar

Stuart Mackay

Stuart Mackay4 days ago

New Member

United Kingdom

NancyR

NancyR4 days ago

New Promotion

Leading Seaman

Razor1955

Razor19555 days ago

New Member

Australia

PhilipS1

PhilipS15 days ago

New Member

United Kingdom

N1ck down the quay

N1ck down the quay5 days ago

New Member

United Kingdom

JohnG1

JohnG15 days ago

Account Updated

Updated 'About Me'

LOBOLONDON

LOBOLONDON5 days ago

Birthday This Week

Turns 73

firepaddy1617

firepaddy16176 days ago

New Member

United Kingdom

Stuart Mackay

Stuart Mackay6 days ago

New Member

Germany

RalfZ

RalfZ6 days ago

New Member

Canada

BubR

BubR6 days ago

New Promotion

Commander

jumpugly

jumpugly6 days ago

New Member

United Kingdom

StephenM

StephenM6 days ago

New Member

United Kingdom

RogerS1

RogerS18 days ago

New Member

Belgium

JohnF3

JohnF38 days ago

New Member

United Kingdom

Alan1

Alan18 days ago

New Member

United Kingdom

PeterS6

PeterS68 days ago

New Member

United Kingdom

geoff parkes

geoff parkes8 days ago

New Member

United Kingdom

Whites123

Whites1239 days ago

New Member

Canada

BrianR

BrianR9 days ago

New Member

Netherlands

willemn

willemn10 days ago

New Member

United Kingdom

MarkF

MarkF10 days ago

Birthday This Week

Turns 66

jugge

jugge10 days ago

New Member

Germany

RainerG

RainerG10 days ago

Account Updated

Updated 'About Me'

RayJ

RayJ11 days ago

New Member

New Zealand

RayJ

RayJ11 days ago

New Member

United Kingdom

robertc3

robertc311 days ago

New Member

United Kingdom

Ostuartg

Ostuartg11 days ago

See More

Forum Topics

In Loving Memory of my dad Peter, aka Mallory.

Passing along prayers of strength to you Stephen and your family; on (as you described) a life well lived.

17 minutes ago by 🇺🇸 jumpugly ( Commander)

Commander)

Commander)

Commander)

Non-Hobby Chat

13 Posts

57 Likes

57 Likes

Started

14 hours ago

by fireboat

14 hours ago

by fireboat

Latest

17 minutes ago

by jumpugly

17 minutes ago

by jumpugly

UK Coastal Forces

I have just found this splendid film from WW2. Some great footage of MTBs.

https://youtu.be/lzJDVhuMaI8?si=lbiJJizuXVkdwoHr

2 hours ago by 🇬🇧 Nickthesteam ( Commander)

Commander)

Commander)

Commander)

Hobby Chit Chat

1 Post

0 Likes

0 Likes

Started

2 hours ago

by Nickthesteam

2 hours ago

by Nickthesteam

No Replies Yet

Quick snap on coupling

Aquarium shops are a good source of tubing and small fittings...

2 hours ago by 🇬🇧 Nickthesteam ( Commander)

Commander)

Commander)

Commander)

Building Related

3 Posts

1 Like

1 Like

Started

14 hours ago

by hermank

14 hours ago

by hermank

Latest

2 hours ago

by Nickthesteam

2 hours ago

by Nickthesteam

Light at the end of the tunnel?

It may be taking a while, but progress is now possible. 🤗

3 hours ago by 🇺🇸 Peejay ( Midshipman)

Midshipman)

Midshipman)

Midshipman)

Non-Hobby Chat

6 Posts

21 Likes

21 Likes

Started

17 hours ago

by Doogle

17 hours ago

by Doogle

Latest

3 hours ago

by Peejay

3 hours ago

by Peejay

2nd competition

You may find something useful in this thread that would give you the confidence to fill the boiler and light the flame! >>>>>>

https://www.modelboatmayhem.co.uk/forum/index.php?topic=68100.0

6 hours ago by 🇬🇧 Razor1955 ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)

General Resources

9 Posts

23 Likes

23 Likes

Started

16 hours ago

by hermank

16 hours ago

by hermank

Latest

6 hours ago

by Razor1955

6 hours ago

by Razor1955

|

|

Login To

Remove Ads

Remove Ads

Build Blogs

4 Posts

3 Followers

19 Likes

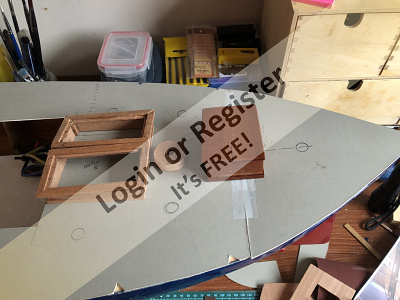

52' Motor Lifeboat Victory

One of my nine-year projects is coming to an end. I am sad to see it completed in some ways, overjoyed in others. Many projects have been begun and shelved over those nine years; some are in the trash now.

What is known is the 213' WMEC-168 Yocona is hit or miss whether my attempts to waterproof a static hull will be successful. So on hold or a side project.

The Gunboat Philadelphia is on-going at work between shifts.

PBY that doesn't Fly I will place on hold, pending possible actual flight. (That will put three aircraft inline to be completed.)

The battleship North Carolina....Big. Not so complex as physically large undertaking.

SO, begin at the beginning as I tell my students. I pondered purchasing the laser-cut kit from Canada, but it is just frames, deck, and pilothouse. Yes, it is 1" to one foot scale, and would match my 44' MLB perfectly, but $286 plus shipping? For me too much, I will build at 1/24th scale for now. Small enough to store, big enough to detail and outfit with running gear.

My 44 MLB, is a leaky, but I am installing an automatic bilge pump. I get so much joy out of running it, and I will have the tri-fecta of MLB's 36', 44', and 52'. The 213 should be complete around the time I finish, so four CG projects in a years time, plus the Philly is a quick build. So, it is a year, year and a half plan.

This will be a slow one.

Non Boat picture is project that is almost complete.

Kevin

🇺🇸 KevinH

5 hours ago

2 Posts

5 Followers

30 Likes

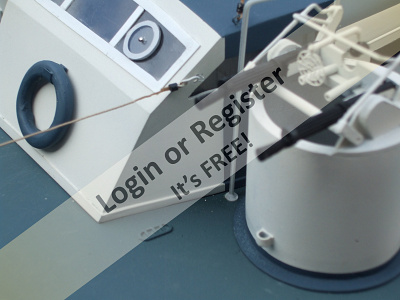

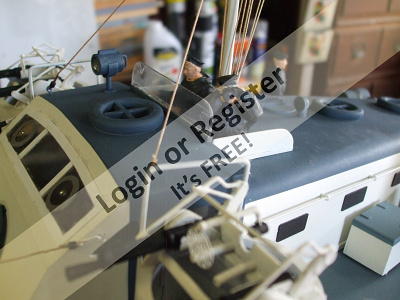

British Power Boat 70ft Motor Gunboat.

Scratch build of my WW2 B.P.B. 70ft Motor Gun Boat at 1/24 scale.

🇦🇺 grahams

16 hours ago

12 Posts

5 Followers

63 Likes

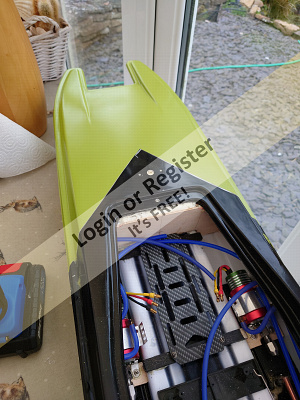

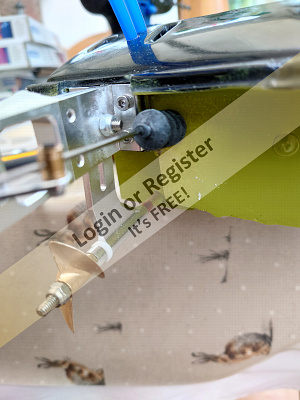

NQD PX-16

Hi Shipmates,

After many years I finally found one at a good price £20 plus £10 p&p on good old Ebay.

I have a load of hardware sitting around, motors rudders etc. So I decided to play about with this boat.

Generally it is considered a waste of time and money to do anything with these boats.

So I don't expect any 'Likes' on this project, its a bit of a daft thing to do.

Information about 32in long twin stepped catamaran hull, beam 9.25 inches, thin ABS plastic.

First stage.

Unpack and check, strip out all of the hardware, generally unscrew components, most difficult thing was removing the propeller shafts.

Second stage wash hull with warm soapy water (in the Bath) and remove stickers.

🇬🇧 CB90

1 day ago

3 Posts

7 Followers

30 Likes

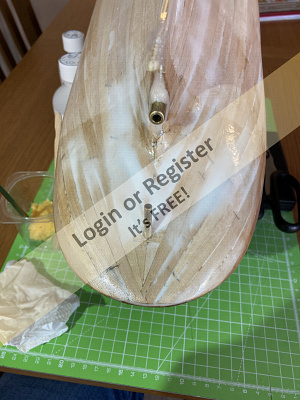

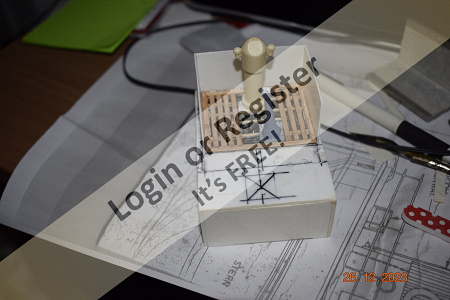

Graupner Krabbe Ton 12…the kit, not the boat😁

Hi y’all. After building the Caldercraft Clyde Puffer, and taking a break from building for a few weeks, I decided it was time to crank up my bench again. I had originally started on a kit that I got in a trade, a Deans Wacht Am Rhein…this boat had been started some time ago, probably a good decade before I got my hands on it, and it’s been in my kit stash for a good 5 years or so now. The original builder got the rudder and tube installed and the aft and mid deck in place, and some bulwark detail. I was working on a motor mount when I decided I just didn’t want to deal with masts and rigging at this time. At some point I’m going to finish that boat…just not now.

I’ve had a Graupner Krabbe Ton 12 in my kits stash for a bit. It’s the second version, when Graupner reorganized and sent the kit production to Asia, probably KYmodel. Same people who did the SAR rescue boat and the Taucher Wulf did this. It’s a nice little kit, well made, instructions are somewhat between the Tauchers “guidelines” and a Billings kit…better, but not quite there. Now, I know I said I didn’t want to fool around with a bunch of masts and booms and rigging, and the Krabbe has that in spades…so I decided to make something different. I thought about a slightly different take on a Kriegsfischkutter, or maybe a fishing boat to yacht conversion…but, I decided on a simple tug. Basically a 1930s or so diesel or converted steam tug, something smaller that you might see in the Great Lakes.

With that decision out of the way I went to work. First thing I did was to make up a 4mm shaft and tube. I used a Caldercraft Fineline tube that I had stolen the shaft from. I have a small collection of tubes and shafts, and a very few that are complete. Anyway, the kit uses a 3mm unit, and that’s just an odd size. Nothing wrong with it, just most of the props and fittings I’ve seen are for 1/8th, 3/16th, 2mm and 4mm. The 3 mm props and such are just harder to get…so I made up the tube by cutting down the Caldercraft unit to the length I wanted, and using the bushing from the discarded end I built up the tube, and added an oiler.

I then took on the task of choosing my power plant. The kit comes with a motor, a knock off of a Mabuchi RS380. My experience with these motors is that they make good model boat anchors. My first SAR that I built was completely stock, and I ran it on the recommended 6 cell nimh pack. After I had the boat completed and had about 6 good runs on it, she went dead in the water at Towne Lake. We retrieved it, and the motor had gotten hot, and the brush holders had softened from the heat and the brushes were not making contact….never again. I was thinking about my usual outrunner brushless, when I remembered I had a brand new MFA 2.5 to 1 380 sized geared motor in my possession. Went with that. After making up a mount and installing the shaft and tube I did a test run on the bench. At full chat, but no load it’spulling 0.07 amps on a 3 cell lipo.

Once that was squared away I used part of the motor mount/radio tray combo to mount the rudder servo, got the rudder mounted, and started to make up the deck houses.

One nice feature of this kit is that the deck slots into a groove in the hull. There are under deck stringers that are laser cut in the kit, once installed they give the deck a slight beam to beam curve. I used the kit parts to make up the aft coaming and house/hatch, and built up my fwd deckhouse and coming from plasticard. I then built up the wheelhouse using kit components..however, I built the deck and house “inside out”, i.e I’m not using the printed “decking” side as I’m probably going to paint the deck and house vs staining them.

That’s where I’m at now. I think the wheelhouse, as built looks a little too tall. I might leave it as this is supposed to be a small, River or Great Lakes tug, not an ocean going boat, and in some of the pics I looked up to get an idea of how I wanted her to look, some of the real boats had tallish pilot houses. I might cut it down about a half inch, but haven’t made the choice yet. Once I make that decision I’ll finish up the house and start figuring out details and what job this boats going to have…

Cash

🇺🇸 Cashrc

3 days ago

13 Posts

16 Followers

143 Likes

Occre Ulises

Was given the Occre kit of the “Ulises” ocean going tug for Christmas. Started the build this weekend but I reckon it is going to be a bit of a drawn-out build for a while as I have a lot going on with work and other things. I will gradually add photos of my progress…

Re comment about kit suppliedpropshaft - I agree, I didn’t like the look of that one in the kit so I cut down an old one I had from something else, put the bearing back in with the addition of a touch of solder To make sure it stayed there and I added the oiler tube as well by soldering that on.

🇬🇧 Trident73

3 days ago

23 Posts

20 Followers

266 Likes

CGINGA IV

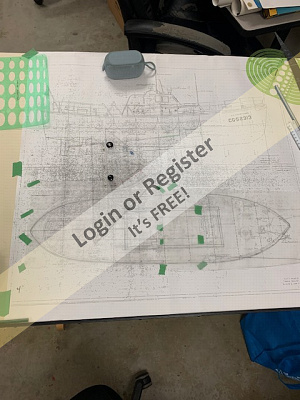

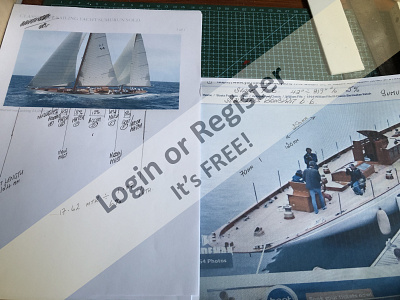

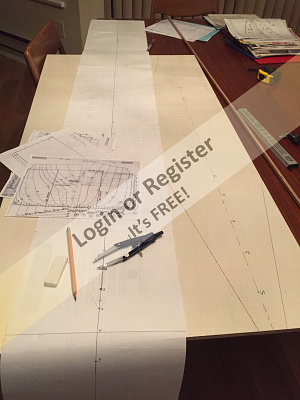

I am pushing the boat out really early in fact in its embryonic stage for this build blog and I might regret it but hope not.

It has been my dream of some weeks that my preferred build for the future would be a great looking motor sailor and the one I settled on was Inga 1v and with encouragement from roycv who has in his harbour a splendid example set the ball rolling.

There does not seem to be much interest out there for this model mainly due to there being is no kits available, nor plans, nor plastic hulls being produced simply lots of pictures and of course some beautiful completed models.

First step and many thanks to tiggy_cat for sending me a set of plans for this model which arrived today. They are produced by Revell and are for the topsides which is great but leaves me with one of the challenges of my life that of drawing, stealing, borrowing whatever a plan of the hull shape. I fear that if I attempt to accurately draw the frames for the hull it might end sailing sideways.

Anyway as somebody once said `I have started so I will finish` interested then watch this space. Regards ChrisG

🇬🇧 ChrisG

4 days ago

16 Posts

10 Followers

130 Likes

1/72 Clyde Puffer

Hi One & All

Back in 1997 I purchased two vacform hull for a 1/72 Clyde Puffer along with the drawings from Sarik (drawing MM1410), as we have been having some bad weather of late and due to their size they started to look like a good boat to start building in the house. (just to keep warm), over the last few weeks I have joined the two half’s of the hull, fitted the motor and shaft, alone with the deck, I have made a mistake when it comes to fixing the rudder, I should have made some form of fixing that went into the hull, so that the rudder had some were to fasten to, (will sort that out later on in the build) also I need to make some form of support for the shaft as I think it will in time work its way lose, moving on, the stern deck has been started and over half has now been planked.

Fred

🇬🇧 Fred

6 days ago

87 Posts

24 Followers

627 Likes

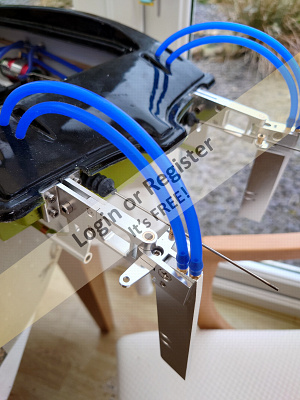

Russian K100D waterjet work boat project

Just having a play with an idea for a model of a early Russian KS 100D general purpose work boat. These were used for river work towing logs etc in shallow rivers . The water jet is unusual, as it has a rear shute with twin rudder type deflectors, and rear hull side ports for reverse (independent controls for each port). Someone on the site mentioned a steam powered water pump driven ship from the 1800s ? a while back on the site which used a similar principal.

The boats were made by the Yaroslavl shipyard, and were very common in the late 50s till (I think) the 70s. Not much info on them but a few guys have rebuilt old ones for pleasure boats. They have a speed of around 16-18knts and used a Yamz 170hp V8 diesel. I've contacted (YT) a guy who has rebuilt one of these boats, and he has fitted the V6 version of this engine.

My attempt is not like the original, as there is no info on the complicated internal deflector system, so I've gone with the next best thing using modified electrical conduit fittings with flap valves. Seems to work ok, but not sealed yet so leaks like a sieve. I'd use a 26mm jet unit for the pump in front of the unit. I'll have to reduce the diameter of the side outlets to get more force behind the jets. Might have to fit the unit in a waterproof tray with a bilge pump. as I think, even though it will be sealed, it will still leak slightly round the 3 shafts.

https://youtu.be/7Lgb7hH6ln8

https://www.youtube.com/watch?v=altwiMdZlIA

https://www.youtube.com/watch?v=yWSI8moMeZg&t=33s

https://www.youtube.com/watch?v=87PsJVdPNhE

https://www.youtube.com/watch?v=CQ3U7XmeG1A (similar later model showing manoeuvrability)

https://www.youtube.com/watch?v=hblw4_44FB8

The big lid on the jet is for clearing weed or similar which might get into the unit.

🇳🇿 jbkiwi

8 days ago

19 Posts

11 Followers

138 Likes

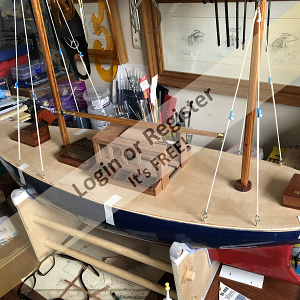

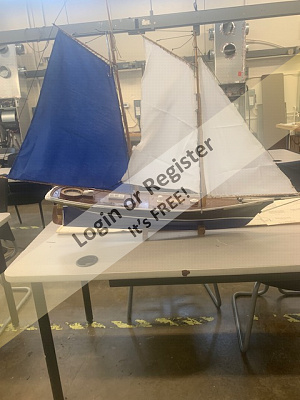

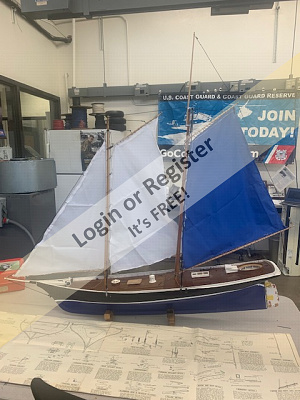

1965 Sterling Yacht America

My last words were "Complete the 44' MLB, then work on a non-boat project." The problem was, as you can see in the back-round inside that large sailboat hull, a 110' WPB patrol boat hull, with plans, not seen, the gunboat Philadelphia in a box in the truck, on top of that in the backseat is the 75% finished hull of a PBY flying boat. There are also unbuilt R/C aircraft kits X2 somewhere in the area, plus two ARF aircraft. (DHC-2 Beaver, and a Cessna 182, also in that ship's hull.)

But my friends, last night I had a dream, and in it was of a gloss black, full rigged sailing yacht. Reasons, number one, the hull is straight and already built, I purposely purchased a hand-held sewing machine for sails, I figure i will need it for the Philadelphia as well.

So, this week we begin, the rigging, and instructions for the same are pretty clear. I included that note from "Rob", because "Mark, or Rob" if you are out there, your "once vision" will be challenging the British in about nine months.

I hope Fair Winds are in all of our futures.

Kevin

🇺🇸 KevinH

9 days ago

1 Post

1 Follower

4 Likes

CalMac landing craft ferry-Mv Carvoria

I’ve been gifted a ready- made wooden pontoon style hull which I’m adapting into a model of the smallest CalMac ferry operating to the island of Kerrera from Gallanach(Oban)

The vessel is 12 m long and can carry up to 12 pax & 1 small vehicle . Motive power is a pair of Honda 80 outboard motors.

My model will be approx 1:24 scale powered by a brushed motor, with twin rudders. Eventually I intend to make dummy motors for the stern .

I am in dire need of some suitable CalMac decals . If anyone still has any surplus BECC ones from their own build I’d gladly make you an offer!

First pic with mock-up wheelhouse( probably oversize at moment!)

Progress reports in due course

🇬🇧 Peewit83

9 days ago

6 Posts

9 Followers

49 Likes

Scratchbuilt Esso Deutschland 1:150

When I first posted a thread under ... a dreamproject.. I didn't realize it was the wrong forum category. So here is my built blog. I will spare you the original introduction as I have made progress which and most of you are already familiar with my project.

The hull was built merging 2 methods on a simple keel plate from plywood, bow and stern structure bread and butter and hull in between 3mm planks on frame.

The entire main deck is intended to be removable with a drainage irrigation system of plastic corner moulding (from a building supplier) along top of hull and flush at poop and back deck structure. The deck is made of 1/4" plywood skeletal structure incorporating midship deckhouse. Hull glassed with lightest cloth available after 2 coats 2-epoxy sealer and paint primer followed by final coat except top (above waterline) grey will be applied once I have finished doing any necessary adjustments. There have been a lot of them since I realized many inaccuracies in dims etc. I wasn't happy with.

Here are photos in the progress (some may have already been posted in the original post.

More a bit later next week.

🇨🇦 JockScott

13 days ago

53 Posts

16 Followers

258 Likes

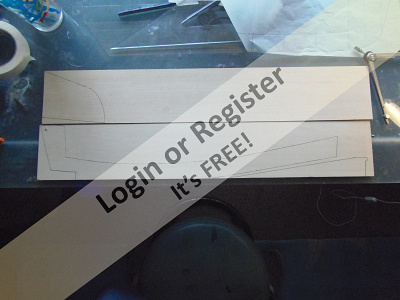

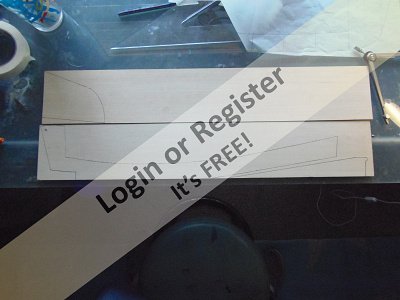

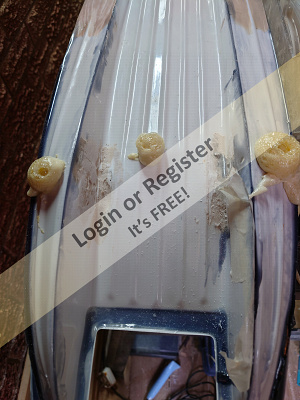

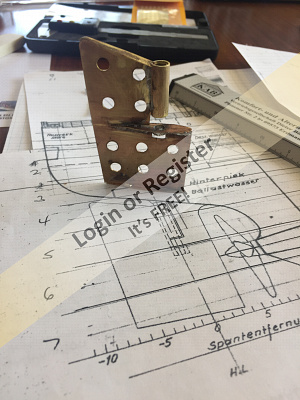

BLUENOSE

Started 2020 with plans by P F Eisnor from Nova Scotia

34 pairs of ribs

🇨🇦 RossM

18 days ago

|

|

Media Gallery

INGA IV

19 days ago by philcaretaker

Lake Union Dreamboat

21 days ago by Brightwork

1958/9 50/55' Chris Craft Constellation

22 days ago by Brightwork

Filming "Dinghy Dan"

1 month ago by philcaretaker

"Dinghy Dan"

1 month ago by philcaretaker

"Dan, Dan the Dinghy Man"

1 month ago by philcaretaker

"Dinghy Dan"

1 month ago by philcaretaker

RNLI Severn Class

1 month ago by Rudy-M

Onboard a Focus 2 RC yacht

1 month ago by Rudy-M

Andy sails Topaz with df65's

1 month ago by MartinH2

RC Shark vs Orca?

1 month ago by Rudy-M

Topaz 60" J class yacht

1 month ago by MartinH2

|

|

Login To

Remove Ads

Remove Ads

Boat Clubs & Lakes

Recent Updates In Places

|

Stade, Germany

6 hours ago by 🇩🇪 Wolle (

Lieutenant Commander) Lieutenant Commander) |

|

Model Boating Association of South Africa

27 days ago by 🇿🇦 Rudy-M (

Warrant Officer) Warrant Officer) |

|

BUXTON MODEL BOAT CLUB

1 month ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

Rawdon Model Boat Club

1 month ago by 🇬🇧 MikeC3 (

Petty Officer 2nd Class) Petty Officer 2nd Class) |

|

Sonstraal Dam

2 months ago by 🇿🇦 Rudy-M (

Warrant Officer) Warrant Officer) |

|

|

Upcoming Events

|

May

5 2024

|

1 Day Only!

|

Edina Model Yacht Club - Spring Breakfast

Ended 3 days ago

|

|

Jun

8 2024

|

1 Day Only!

|

RAWDON MBC OPEN DAY

Starts 1 months time

|

|

Jun

9 2024

|

1 Day Only!

|

Edina Model Yacht Club - Parade of Boats at Centennial Lakes Ponds

Starts 1 months time

|

|

Aug

11 2024

|

1 Day Only!

|

Edina Model Yacht Club - Lighthouse Night #1

Starts 3 months time

|

|

Sep

7 2024

|

1 Day Only!

|

Edina Model Yacht Club - Lighthouse Night #2

Starts 4 months time

|

|

|

Boat Harbour

1 Photo

18 Likes

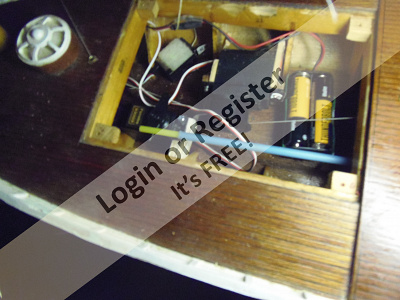

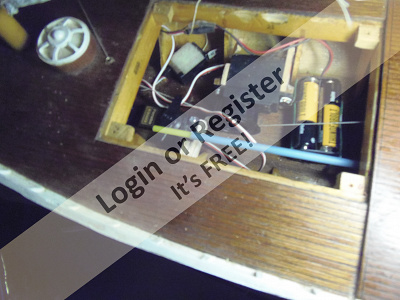

Artesania Latina 20201 Amsterdam

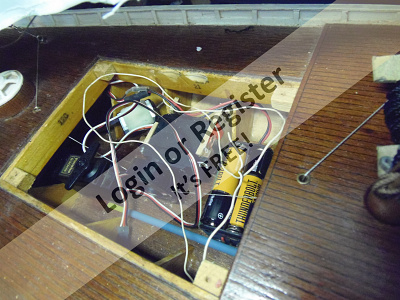

I picked this up from the estate of a young man. As with most of my boats, it is sort of a "rescue". It is basically sound, but somebody before me cut all the wiring out of it.

It is equipped with all the lights the kit is supposed to have, as well as a bow thruster. I have started resoldering all the electrical connections, still working through what kind of wiring harnesses I will need to build for the various light circuits.

Some of the railings, etc. need rebuilding or re-attaching.

It should be a nice boat when finished.

Dave B

🇺🇸 DWBrinkman

24 hours ago

6 Attributes

6 Comments

9 Photos

10 Likes

Springer #4 USACOE Stoplog

This is my fourth Springer tug. It was built to resemble the U.S. Army's Corps of Engineers stoplog tug located at Little Goose Dam in Washington State. The scale is about 1/17. The model had to be modified slightly because the length to beam ratio between the real tug and a Springer ae slightly different. This keeps the model within the Springer class rules.

🇺🇸 LewZ

8 days ago

10 Attributes

1 Comment

11 Photos

10 Likes

City of Sheffield

Tyne type lifeboat, moulded hull and deck very strong and light. Front and rear cabins remove over moulded deck combings leaving massive access to spacious hull.

🇬🇧 Rogal118

12 days ago

9 Attributes

5 Comments

4 Photos

19 Likes

Lulonga River Tug

Lulonga steam river tug. Broad beam twin stern paddles. Very stable and graceful on the water. Single motor (12 volt)chain driven from geared motor. Fitted with smoke mister, lights and sound. Unusual model built from plan. Lovely to sail on a summer evening.

🇬🇧 wmbc40

15 days ago

0 Attributes

19 Comments

7 Photos

10 Likes

Oppie

Way back when, there used to be a company producing grp hulls, they were based in Holyhead(?) or nearby, the business was sold, and I discovered they had some pieces for the Oppie, I bought them, constructed the model, sailed it, was impressed, so much so I embarked on the construction of the other exact 1:4 scale models.

🇫🇷 stotty1111

20 days ago

0 Attributes

3 Comments

3 Photos

17 Likes

Graupner Commodore

I acquired this Commodore and made some modifications so she is now a Chris Craft Roamer 37'

🇨🇦 Brightwork

23 days ago

4 Attributes

12 Comments

2 Photos

18 Likes

Billings Smit Nederalnd

I aquired this for free and did some restoration on her. I will probably give her to my brother.

🇨🇦 Brightwork

23 days ago

4 Attributes

9 Comments

5 Photos

13 Likes

1949 40' Chris Craft Challenger

This is based on the Dumas model plans. Model was produced by dumas as a kit in the 50's. I semi scratch built her from the plans.

🇨🇦 Brightwork

23 days ago

8 Attributes

6 Comments

9 Photos

11 Likes

Steam Power

Not strictly marine based, but the Stuart D10 is destined for a 1:12 Customs Launch, Active, built by Cox & Co Falmouth 1912, and stationed at Gravesend until the '30's.

Kit of castings, machined and built by myself along with the horizontal engine.

The others have been bought at knock down prices over the years!

They all need sprucing up!

The boiler was bought several years ago from an Australian outfit, at the time it seemed incredibly cheap, but was probably caused by the exchange rates between the Australian dollar and the pound!

It came complete with lagging, planking and other bits and pieces, cannot be exact as I cannot find the box with the pieces in, cannot remember if it was complete with burner!

I now have the thermal blocks (ex night storage heater) to construct a hearth to continue with the installation etc.

Photos of 'Active' to follow it is stored at the club house!

🇫🇷 stotty1111

29 days ago

0 Attributes

2 Comments

|

|

How-To Articles

Need help trying to find some lights for my USCG MLB 47 foot 1:16 scale

Revised 4 days ago

By bruce1946

Question on Painting order

Revised 11 days ago

By bruce1946

LED – SERIES AND PARALLEL CIRCUITS – FLASHING CIRCUITS - Compendium of information

Revised 1 month ago

By AlessandroSPQR

Transmitter Camera Mount

Revised 2 months ago

By cjanik001

NAVAL PROPELLERS. Compendium of information.

Revised 2 months ago

By AlessandroSPQR

Lipo Battery Reference charts

Revised 2 months ago

By CB90

K.M.Y.C.A. Monthly magazine

Revised 3 months ago

By hermank

CALCULATION OF THE IMMERSED VOLUME (SIMPLE MATHEMATICAL/GEOMETRIC METHOD) OF YOUR MODEL

Revised 5 months ago

By AlessandroSPQR

Basic Model Boat Operations

Revised 5 months ago

By LewZ

Fiberglass boat hull

Revised 6 months ago

By northark

|

|

Login To

Remove Ads

Remove Ads

🛍️ Basket

Main menu transported here on mobile

Login

Create New Account

Trending Topics

Members Online

Forum

In Loving Memory of my dad Peter, aka Mallory.

jumpugly

17 minutes ago

Forum

UK Coastal Forces

Nickthesteam

2 hours ago

Forum

Quick snap on coupling

Nickthesteam

2 hours ago

Forum

Light at the end of the tunnel?

Peejay

3 hours ago

Blog

More Progress

KevinH

5 hours ago

Place

Stade, Germany

Wolle

6 hours ago

Forum

2nd competition

Razor1955

6 hours ago

Forum

Question of the Day?

Rudy-M

7 hours ago

Blog

Re: About to start the glass fibre

Trident73

8 hours ago

Harbour

Re: Artesania Latina 20201 Amsterdam

DWBrinkman

11 hours ago

Blog

British Power Boat 70ft Motor Gunboat.

grahams

16 hours ago

Forum

Wordle of the Day?

Doogle

20 hours ago

Forum

Flight Link Control Launch Link 2 channel radio control set

Stuart Mackay

1 day ago

Blog

Re: NQD PX-16

LewZ

1 day ago

Forum

Edina Model Yacht Club Season Opener

AlessandroSPQR

1 day ago

Forum

If only

Razor1955

1 day ago

Blog

Re: CGINGA1V

Len1

1 day ago

Forum

Boat storage complete

Ronald

2 days ago

Blog

Re: MAS 562 update

grahams

2 days ago

Forum

Edine Model Yacht Club 2024 Events

DWBrinkman

2 days ago

Forum

Smoke spaghetti

jbkiwi

2 days ago

Blog

Re: Larger rudder, deck install, more mods

jumpugly

3 days ago

Forum

World Engines/ Ace Commander 6 channel radio

Stuart Mackay

3 days ago

Forum

May the Fourth

KevinH

3 days ago

Harbour

Re: 3. Old Commodore / Graupner

Mike Stoney

3 days ago

Forum

When a model shipbuilder travels the country . . .

Mike Stoney

3 days ago

Forum

Coast Guard 47 MLB 1:16 scale build

bruce1946

3 days ago

Wiki

Need help trying to find some lights for my USCG MLB 47 foot 1:16 scale

bruce1946

4 days ago

BOATSHED

Lieutenant

1,970 Points

4 seconds ago

DWBrinkman

Lieutenant Commander

2,496 Points

24 seconds ago

MikeS1

Able Seaman

21 Points

13 minutes ago

RodC

Lieutenant

1,672 Points

13 minutes ago

jumpugly

Commander

2,562 Points

16 minutes ago

gcladd

Petty Officer 2nd Class

187 Points

24 minutes ago

Rowen

Captain

3,481 Points

39 minutes ago

jennovids

Recruit

0 Points

51 minutes ago

Chum444

Midshipman

967 Points

1 hour ago

je8031ej

Recruit

0 Points

1 hour ago

melian

Recruit

0 Points

2 hours ago

dash8man

Able Seaman

26 Points

2 hours ago

Peejay

Midshipman

1,090 Points

2 hours ago

Nickthesteam

Commander

2,641 Points

2 hours ago

peterd

Midshipman

1,016 Points

2 hours ago

tj6287

Recruit

0 Points

2 hours ago

Pdj

Recruit

12 Points

2 hours ago

Myford

Recruit

4 Points

2 hours ago

Newby7

Fleet Admiral

10,648 Points

3 hours ago

Rookysailor

Commodore

4,797 Points

3 hours ago

Rudy-M

Warrant Officer

875 Points

3 hours ago

KevinH

Chief Petty Officer 1st Class

597 Points

3 hours ago

bruce1946

Midshipman

957 Points

3 hours ago

Monty6

Recruit

0 Points

3 hours ago

Maurice

Recruit

12 Points

3 hours ago

roycv

Rear Admiral

5,344 Points

3 hours ago

PhilipS1

Recruit

0 Points

3 hours ago

Hhager2

Midshipman

1,024 Points

3 hours ago

BarryW

Recruit

0 Points

4 hours ago

MervG

Recruit

0 Points

4 hours ago

terrymiff

Master Seaman

104 Points

4 hours ago

Rogal118

Lieutenant Commander

2,466 Points

4 hours ago

ChrisF

Lieutenant Commander

2,181 Points

4 hours ago

RossN

Recruit

2 Points

4 hours ago

DGoss999

Warrant Officer

670 Points

4 hours ago

RNinMunich

Fleet Admiral

35,706 Points

5 hours ago

hermank

Captain

3,386 Points

5 hours ago

andrewandrachelh

Recruit

13 Points

5 hours ago

bruced

Able Seaman

47 Points

5 hours ago

Razor1955

Leading Seaman

91 Points

5 hours ago

Trident73

Warrant Officer

704 Points

5 hours ago

DaveWhittaker

Recruit

12 Points

5 hours ago

grahammileham

Recruit

4 Points

5 hours ago

Wolle

Lieutenant Commander

2,381 Points

5 hours ago

Len1

Sub-Lieutenant

1,502 Points

5 hours ago

AlessandroSPQR

Commodore

4,811 Points

5 hours ago

IanTurk

Master Seaman

122 Points

5 hours ago

Aerodecked

Able Seaman

31 Points

5 hours ago

sirscapa

Recruit

0 Points

5 hours ago

astromorg

Able Seaman

21 Points

5 hours ago

Login To

Remove Ads

Remove Ads

🏠

Home

Home

📰

Trending

Trending

💬

Forum

Forum

🗝

Login / Join

Login / Join

|

Cookies are used for ads personalisation.

By using this website you agree to our use of cookies. More Info |

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Useful Links

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (7,882)

📣 Support

Hobby Supplies

🛍️ Online Shop

Login

🗝 Login

🗝 Create New Account

▼

Media Gallery

X

1 of 4

► |

◄ |

Media Viewer

^

_

X

Share

X

Flag Inappropriate Post

X

| Select Reason | |

| Sexual content Includes graphic sexual activity, nudity, and other sexual content. | |

| Violent or repulsive content Violent or graphic content, or content posted to shock viewers. | |

| Hateful or abusive content Content that promotes hatred against protected groups, abuses vulnerable individuals, or engages in cyberbullying. | |

| Harmful dangerous acts Content that includes acts that may result in physical harm. | |

| Child abuse Content that includes sexual, predatory or abusive communications towards minors. | |

| Promotes terrorism Content intended to recruit for terrorist organisations, incite violence, glorify terrorist attacks, or otherwise promote acts of terrorism. | |

| Spam or misleading Content that is massively posted or otherwise misleading in nature. | |

| Infringes my rights Privacy, copyright and other legal complaints. | |

Basket Updated

X

Loading...

Loading

Loading Uploader...