|||

|

|

🗝 Login

🤖 Create Account

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Plans & Docs

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,786)

📖 Quick Site Guide

📣 Support

👥 Membership

Hobby Supplies

🛍️ Online Shop

Not Registered

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

Cancel

Anytime

Anytime

£2.50

£4.50

£6.50

Subscribe

Go AD FREE & get your membership medal

BRONZE

Less Ads

SILVER

GOLD

Ad Free

For A Whole Year!

£25

£45

£65

Donate

You Will Be Helping Towards:

Domain Fees

Security Certificates

iOS & Android App Fees

Website Hosting

Fast Servers

Data Backups

Upkeep & Maintenance

Administration Costs

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Without your support the website wouldn't be what it is today.

Please consider donating towards these fees to help keep us afloat.

Read more

All donations are securely managed through PayPal.

Many thanks for your kind support

Model Boats Website

Home

Forum

Build Blogs

Media Gallery

Boat Clubs & Lakes

Events

Boat Harbour

How-To Articles

Plans & Docs

Useful Links

The Games Chest

Welcome to the Model Boats Website! A place for all model boaters!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Feel free to browse through the website, ask your questions, upload your photos or even start your own blog!

Login To

Remove Ads

Remove Ads

Trending Now

Blog

Re: Tied to the dock.

Lew, how do you keep vessels from floating around after being run? Or do these get retrieved and only keep pre-tied models at the wharf for public viewing?

🇨🇦 Ronald

2 minutes ago

Harbour

Fairmount Alpine

Purchased Built

🇬🇧 Heners2332

2 hours ago

Forum

Before and after..

Looking good! I think scale sail boats are great. The Down side (here in Florida) is the wind. Either too much or not enough putting them in "chains". Mine does well on the shelf.

Lew

🇺🇸 LewZ

2 hours ago

Blog

Re: Need info on what these ships are

Hi!

the schooner

Yes, SIR WINSTON CHURCHILL (with MALCOLM MILLER)

🇨🇦 RossM

9 hours ago

Forum

Animal and nature photos to enjoy.

Wolfe, isn’t Google Earth amazing!

May this Third Advent be special for you too. PEACE. God offers us peace with Him through His Son Jesus Christ. He did the work - and invites us to follow Him in being peacemakers too.

🇨🇦 Ronald

9 hours ago

Blog

Re: She’s done!!

Hi, 4 years later I’ve got a question.

What battery did she have? Thinking of building one and need to know what is best to buy.

Thanks

🇬🇧 Heners2332

9 hours ago

Blog

Re: A bit more final finishing.

Thank you Phil. The boat will go to Florida with the builder who escapes the New England winters for three months. In the past my wife & I enjoyed the snow & winter sports but age caught up with us so skiing is no longer an option.

As mentioned earlier in this thread I usually do the maiden voyage early in the build. But rehabbing from knee surgery prevented that. So I will use the large test tank ( the condo association’s pool) for the first splash. Thus the crossed fingers.

🇺🇸 Chum444

10 hours ago

Forum

Question of the Day?

I was tossing up between A & D, but went for D. Didin't trust D with whats going on in the world at the moment ( with Russia??), plus I normally plumb for the longest answer.

Which is what I done in the end.Lucky I did and it was the correct answer.

🇬🇧 BOATSHED

13 hours ago

Blog

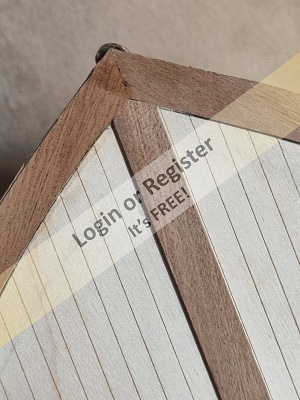

Re: Planking the deck. Part 1.

Hi Ronald.

"Are the planks of the upper decks to be the same width as the lower deck planks?"

Yes, they will also be 1.6 x 6.5mm lime wood with .5mm black caulking lines and a high gloss epoxy resin finish.

Rob.

🇬🇧 robbob

1 day ago

Harbour

Re: Port Area

Good Morning Lew,

Stackable . . I don't have that at home, but I found a small corner in the basement.

Much to my wife's chagrin . . but somehow we always come up with good ideas together. She thinks very practically, which she cultivates and practices in the household.

Well, sometimes I look for something again because she moved it or stored it to save space.

You see, Lew, even at my age, I'm still learning from a wife who is 10 years younger than me!

Your Michel-C.

🇨🇭 Mike Stoney

2 days ago

Gallery

Re: Christmas theme

Hi Garth,

That's great, Love the Christmas decorations.

is that the naughty elf in the boat.

Hope he'smnot taking with out consent.

Out of curiosity, what model boat is that??

🇬🇧 BOATSHED

2 days ago

Guestbook

Re: Guestbook

Am still around & kicking in the Middle Kingdom but saddled with other tasks at the moment so hobbies, sadly, as taking a lower priority nowadays.

🇨🇳 Chuck

2 days ago

Blog

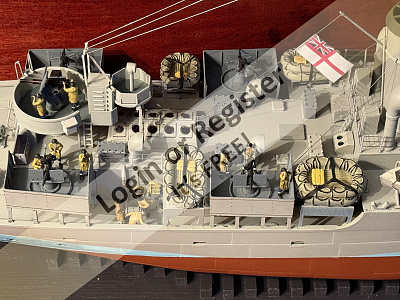

Re: HMCS Woodstock Crew From Etsy 3Djson

Good grieve! Seems like a lot of wasted material. Did you then cut and file the excess material off ? After the material is removed are the figures nicely detailed?

🇨🇦 Ronald

2 days ago

Forum

TVR1A Steam Engine.

A little more progress on the building front, and a few more decisions made with regards to exactly what I am trying to accomplish. So we now have planked decks front and rear of the engine, and maybe timber box grating around the engine. I have decided to cover up the servo at the side of the engine, so the full metal jacket now has a wooden over coat. I have also made a start on the pipe work and some serious silver soldering. Fluxed rods or easy-flow, that is the question? I have made a Windemere steam kettle, which will be fed from the bottom of the sight glass fitting, and it will be moved from its temporary location on the servo cover. Regards, Gary.

🇬🇧 GaryLC

4 days ago

Gallery

Re: SSMBC (Seminole, Florida) meet, Nov. 2, 2025

Hei Lew!

What a pond! We would love to have something like that, but the local council is thwarting our plans.

We wanted a little more inflow water, but even rainwater was not allowed. It could have been taken from the neighbouring houses at little expense and with little effort.

Let's see what happens...

There used to be three ponds for the mill further down. Unfortunately, the mills burned down completely in 1915. Oh well...

Greetings from Switzerland

Michel-C.

🇨🇭 Mike Stoney

4 days ago

Blog

Re: Seaspan HAWK with "Z" drive build

Graupner "Z" drive Astro flight geared motors

🇺🇸 bruce1946

4 days ago

|

New Member

United Kingdom

EsterP

EsterP5 hours ago

New Member

United Kingdom

IanR1

IanR110 hours ago

New Member

United Kingdom

Heners2332

Heners233215 hours ago

New Member

Germany

WalterB

WalterB1 day ago

New Member

Canada

WallaceG

WallaceG1 day ago

New Member

United Kingdom

PeterG5

PeterG51 day ago

New Member

Bermuda

JonandSusanT

JonandSusanT2 days ago

New Member

United Kingdom

MR H 17

MR H 172 days ago

New Member

United Kingdom

davef

davef2 days ago

Birthday This Week

Turns 65

Hook

Hook4 days ago

Birthday This Week

Turns 68

MouldBuilder

MouldBuilder4 days ago

New Member

United Kingdom

ShaunS

ShaunS4 days ago

Birthday This Week

Turns 74

JEANFRANCOIS G

JEANFRANCOIS G5 days ago

New Member

Bermuda

ArnoldP

ArnoldP5 days ago

New Member

Germany

PeterW2

PeterW26 days ago

Birthday This Week

Turns 68

Oxford-Dave

Oxford-Dave6 days ago

New Member

United Kingdom

RoyB1

RoyB16 days ago

New Member

Denmark

Arly

Arly7 days ago

New Member

United Kingdom

PatrickB1

PatrickB17 days ago

New Member

United States

John L

John L7 days ago

New Member

United Kingdom

NigelP1

NigelP17 days ago

New Member

United Kingdom

Bigun

Bigun9 days ago

New Member

Canada

philipG

philipG9 days ago

New Member

United Kingdom

PhilipP1

PhilipP19 days ago

New Promotion

Fleet Admiral

roycv

roycv9 days ago

New Promotion

Chief Petty Officer 1st Class

Steves-s

Steves-s10 days ago

New Promotion

Able Seaman

Dutton73

Dutton7310 days ago

New Promotion

Chief Petty Officer 2nd Class

thadlietz

thadlietz11 days ago

New Member

United Kingdom

Dutton73

Dutton7311 days ago

New Member

United Kingdom

JohnF5

JohnF511 days ago

New Member

United Kingdom

JimD1

JimD112 days ago

New Member

United States

mtnmnstr

mtnmnstr13 days ago

New Member

United States

WarrenJ

WarrenJ13 days ago

New Member

United Kingdom

sharpe

sharpe13 days ago

Account Updated

Changed Avatar

PEI

PEI13 days ago

Account Updated

Updated 'About Me'

PhilH

PhilH14 days ago

Birthday This Week

Turns 71

MikeN12

MikeN1214 days ago

New Member

United Kingdom

NickZ

NickZ15 days ago

Account Updated

Changed Avatar

ChrisF

ChrisF15 days ago

New Member

United Kingdom

AndrewD1

AndrewD116 days ago

New Member

United States

DavidW8

DavidW816 days ago

New Member

Greece

marligkg

marligkg16 days ago

New Promotion

Vice Admiral

zooma

zooma16 days ago

New Member

United States

NedR

NedR17 days ago

New Promotion

Able Seaman

Jshander

Jshander17 days ago

New Promotion

Master Seaman

ColinJ2

ColinJ218 days ago

Birthday This Week

Turns 78

JockScott

JockScott18 days ago

New Promotion

Captain

EdW

EdW19 days ago

See More

Forum Topics

Before and after..

Looking good! I think scale sail boats are great. The Down side (here in Florida) is the wind. Either too much or not enough putting them in "chains". Mine does well on the shelf.

Lew

2 hours ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)

Hobby Chit Chat

3 Posts

19 Likes

19 Likes

Started

12 hours ago

by Peter s

12 hours ago

by Peter s

Latest

2 hours ago

by LewZ

2 hours ago

by LewZ

Animal and nature photos to enjoy.

Wolfe, isn’t Google Earth amazing!

May this Third Advent be special for you too. PEACE. God offers us peace with Him through His Son Jesus Christ. He did the work - and invites us to follow Him in being peacemakers too.

9 hours ago by 🇨🇦 Ronald ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Non-Hobby Chat

245 Posts

1619 Likes

1619 Likes

Started

2 years ago

by Wolle

2 years ago

by Wolle

Latest

9 hours ago

by Ronald

9 hours ago

by Ronald

Question of the Day?

I was tossing up between A & D, but went for D. Didin't trust D with whats going on in the world at the moment ( with Russia??), plus I normally plumb for the longest answer.

Which is what I done in the end.Lucky I did and it was the correct answer.

13 hours ago by 🇬🇧 BOATSHED ( Commander)

Commander)

Commander)

Commander)

Website Related

5273 Posts

13322 Likes

13322 Likes

Started

3 years ago

by fireboat

3 years ago

by fireboat

Latest

13 hours ago

by BOATSHED

13 hours ago

by BOATSHED

TVR1A Steam Engine.

A little more progress on the building front, and a few more decisions made with regards to exactly what I am trying to accomplish. So we now have planked decks front and rear of the engine, and maybe timber box grating around the engine. I have decided to cover up the servo at the side of the engine, so the full metal jacket now has a wooden over coat. I have also made a start on the pipe work and some serious silver soldering. Fluxed rods or easy-flow, that is the question? I have made a Windemere steam kettle, which will be fed from the bottom of the sight glass fitting, and it will be moved from its temporary location on the servo cover. Regards, Gary.

4 days ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)

Building Related

15 Posts

89 Likes

89 Likes

Started

20 days ago

by GaryLC

20 days ago

by GaryLC

Latest

4 days ago

by GaryLC

4 days ago

by GaryLC

engine etc etc

Hi Bob, many thanks for this information, very much appreciated.

5 days ago by 🇬🇧 Guy O ( Recruit)

Recruit)

Recruit)

Recruit)

RC & Electrics

3 Posts

6 Likes

6 Likes

Started

6 days ago

by Guy O

6 days ago

by Guy O

Latest

5 days ago

by Guy O

5 days ago

by Guy O

|

|

Login To

Remove Ads

Remove Ads

Build Blogs

3 Posts

6 Followers

12 Likes

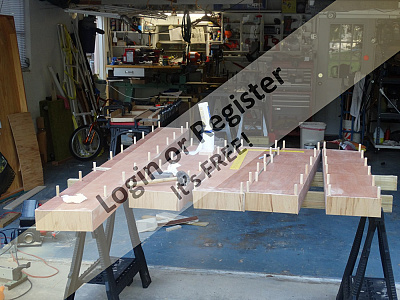

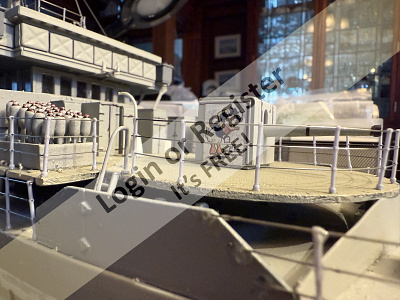

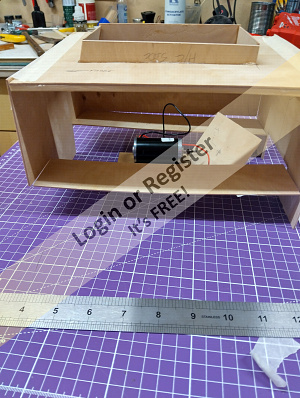

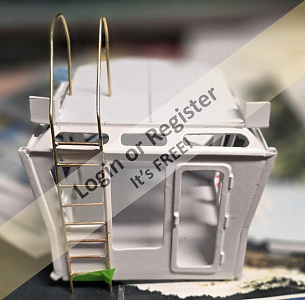

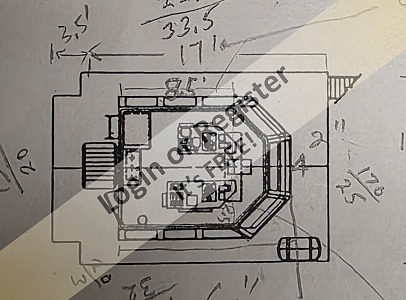

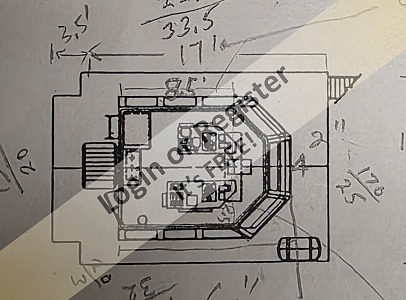

"Port Seminole" a SSMBC portable dock system for R/C model boats

Episode: Introduction

This is series of episodes will be about the features and updates of the SSMBC (Tampa Bay Area, Florida) Portable Dock System (PDS) I will post information on the original design and build of the PDS as well as requirements of have a PDS for the SSMBC.

First is why. Operating (R/C) model boats are fun to build and run. But take that to the next level. How do we improve that? We have a pond, OK? We have a floating dock for launching and retrieval; Nice. Every once and a while we have a few buoys (markers); Getting a little better. Now comes docks! Wow, how many of you "captains" out there would like to maneuver through a docking system? I know I like it. (Think it we ignite some of our casual members to come or entice new members to join?)

In March of 2014 I built most of the PDS with my son's help. There we no videos or even instructions on how to build a PDS back then. Only a few photos and videos that showed little to no detail on they were built.

It was fun to operate the boats but what a headache to setup for our two hour meets. Trudging through thick mud on the ponds bottom was very difficult. Trying to flat the sections out and attach them together while leaning over the docks edge was still an issue. ("No swimming".)

Thought: Why not assemble them on land gradually pushing them into the pond? How about a better way to attach them to the shore? I already made them stackable to ease storage and transport.

And that folks is where I am today. Most of the thinking was done. Now I am in the update phase. For two days (I'm 81, not as fast as I used to be) I have been not only updating the PDS but doing some badly need maintenance and strengthening.

The photos I am posting now are the original build of the PDS. They are simplistic, no additional details. (Some details may be added later.) You can see that the sections can be positioned for a variety of configurations.

In upcoming episodes I will add more information and photos. so others can see what we have done. Nothing hidden, all information. And, of course, suggestions are welcomed.

Lew

SSMBC event coordinator

🇺🇸 LewZ

2 hours ago

26 Posts

9 Followers

163 Likes

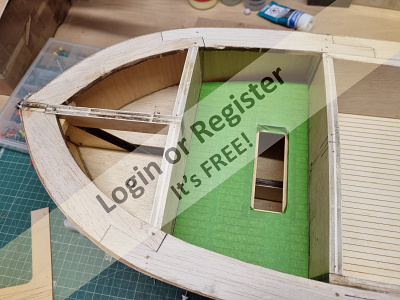

Lindsay M a scratch built Wasque 26 ft

Awaiting graphics to finish off THUNDER& METEOR so pulled this one off the shelf to resume the build. I’ll start at the beginning posting highlights so as not to take up too much time.

Photo 1&2 One of the many real boats. These are iconic around Cape Cod, Martha’s Vineyard, Nantucket, & other Atlantic bordering states.

Photo 3 Starting the frame & keel.

🇺🇸 Chum444

1 day ago

23 Posts

23 Followers

288 Likes

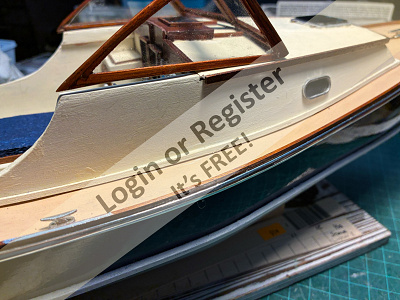

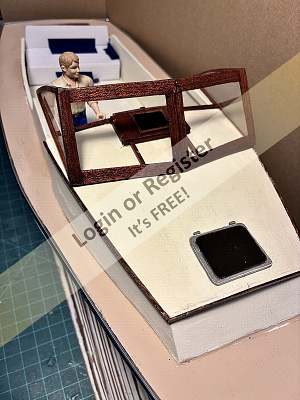

The VMW Marlin Cabin Cruiser by Robbob

The VMW Marlin Cabin Cruiser by Robbob

Preface.

At the time of writing, I’ve had the construction of this boat on ‘the back burner’ since July 2022. By then I had spent about two months on and off constructing the boat to a stage where I could consider applying a glassfibre cloth and epoxy finish to the hull. However I couldn’t spend any more time on the Marlin project as I had a more important project to undertake, which was to paint, decorate, refurbish and prepare our house for sale so that we could downsize and move to a new area now that our kids had all fled the nest.

Fast forward to today (mid-April 2025) and it’s taken a while to get the new house and gardens into shape and settle in, with the emphasis on converting my internal garage into a great new workshop, I can finally pick up from where I left off.

Introduction to the kit.

This new model is the latest undertaking by Vintage Model Works, now famous for their very popular models of the RAF Crash Rescue Tender and Thames River Police Boat kits which are based on old Aerokits and Veron designs.

The Marlin is a re-working of an original Veron design by the late Phil Smith in 1953. His son Colin Smith, who was also responsible for the re-design of the Thames River Police Boat, has made some changes to his father’s design to take advantage of more modern materials and production methods such as CNC and laser cutting.

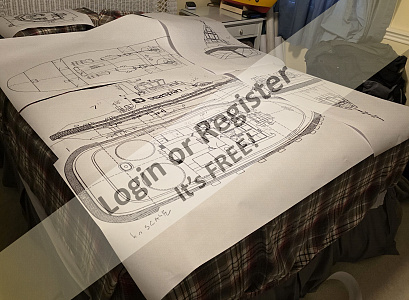

The photograph below is of a prototype built by Colin Smith to give you an idea of how the boat looks in finished form. And there is also a review of the Marlin that appeared in Model Maker magazine, November 1953.

The size remains at 36” and it employs the same construction method as the original. The spacious cabins of the boat makes it very easy to accommodate all the latest control hardware required, not that the original was lacking in that area even when the radio systems used valves and large batteries and the propulsion was usually IC or a large electric motor.

Even the pre-production sample the Vintage Model Works kit supplied to me is well presented with a full size drawing including a pictorial construction sequence and separate pages of building instructions.

All the required materials are supplied in quality ply, balsa, strip-wood and dowel including clear plastic sheets for the windscreens, and various white metal deck fittings. The builder is of course required to supply their own adhesives and paint of choice, as well as the propulsion, drive train and radio control gear. In the latter respect I will likely restrict control to throttle and rudder and not add any lighting or other features. That has already been done magnificently by Mike Turpin.

Construction.

As with the Thames river police boat, another Veron design, construction starts with the assembly of a box structure onto which formers and bulkheads are attached to make the basic hull shape.

I will be tackling this in the first part of my build blog which I hope you will enjoy following and I encourage you to ask questions, leave comments and hopefully some ‘likes’ as I make progress.

Robbob.

🇬🇧 robbob

1 day ago

2 Posts

4 Followers

12 Likes

Need info on what these ships are

My Uncle in NY passed away a few months ago. He was 96 n a model builder since a kid. He got me into it n we both were in the Navy. At one time he was my boss on a minesweeper. I inherited some of the ships he built. One is the last he worked on I will complete. Another is the same one I built n lost in a fire a Sterling Scout. The tall ships I have no info on n would like if anyone recognizes them? I will sell them as they are complete n all are display ships. I may RC the Hercules tugboat as it’s the unfinished one. His grankids bought it for him at price of $500. He still has more at his house the Robert e Lee, two rear paddle wheels and several multicast sailing ships. Here are pics I took of the four I have brought home.

🇺🇸 Hhager2

2 days ago

11 Posts

6 Followers

60 Likes

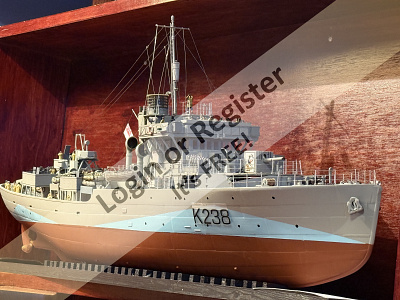

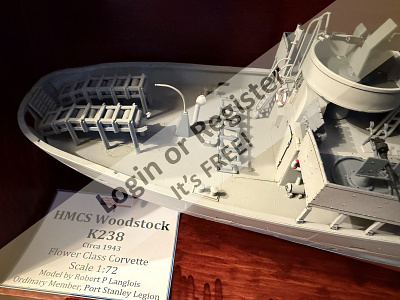

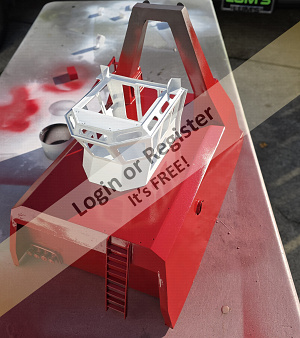

HMCS Woodstock from a Kitbashed Revell Flower Class Corvette

Starting the dig into the Ottawa Archives and The Great Lakes Museum in Kingston:

🇨🇦 RPLedm

3 days ago

6 Posts

7 Followers

22 Likes

Another Pusher Tug

While doing research for my Springer/Pusher tug I discovered these drawings David Metcalf’s Motorflot Pusher Tug and I had all the materials to build it so I put the other pusher I am building aside and started on this one. I am easily distracted

All the hull parts have been cut out one after yesterdays power outage, I will stat the assembly today.

Pictures to follow.

🇬🇧 EdW

6 days ago

1 Post

5 Followers

19 Likes

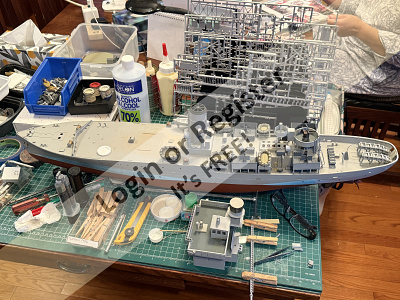

Seaspan HAWK with "Z" drive build

Progress on my Seaspan Hawk. this boat was just the hull and deck, with 2 Z drive motors. Everything from the deck up was destroyed. the drawing I could find had lines that were 1/8" thick so trying to get everything in proportion was interesting and challenging. it has been a fun build and challenged my old mind.

🇺🇸 bruce1946

6 days ago

2 Posts

6 Followers

22 Likes

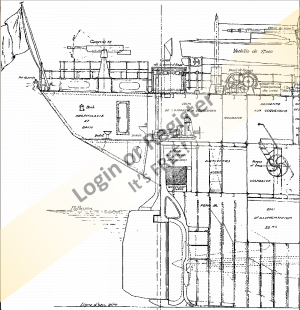

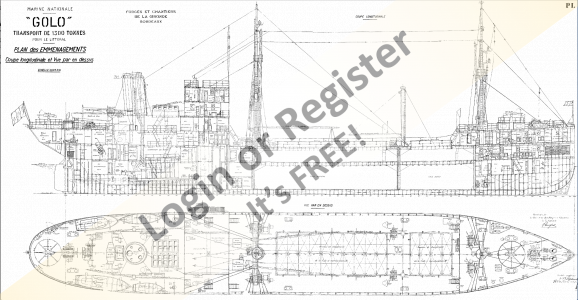

M. N. Golo, 1300 Tonne Coastal Freighter

This might be my next Build. Note that the 3inch gun is positioned right above the toilet. Do you think they yell "CLEAR" down into the toilet. Do customers "evacuate" when it goes off? Do their toe nails scratch through the linoleum?

🇨🇦 RPLedm

9 days ago

4 Posts

2 Followers

22 Likes

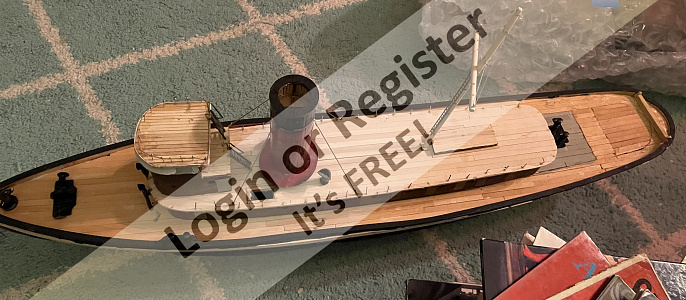

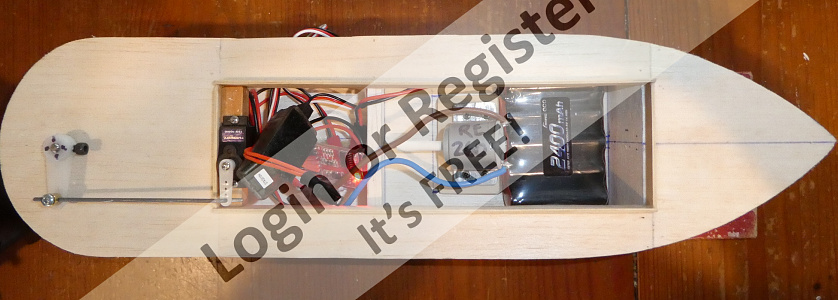

Chris-Craft Style

I think I mentioned this model on another blog.And now it's become a Build Blog. So here we go. This model required a battery box, so I had to make some modifications.So a few cuts were required to find a spot for a 7.2-volt NMH battery so see some photos.

🇨🇦 GARTH

11 days ago

1 Post

2 Followers

12 Likes

Vintage sea scout ?

Hi I’ve just bought a secondhand model wooden boat looks like an aero kit sea scout 24.5 inches long it has a very old made in Japan electric motor it smells old inside the boat and the paint is heavily crazed .i would like to know my about it / age etc if anyone could help me before I restore it many thanks Kraig. it also has a manual brass rudder knob it the back

🇬🇧 Dutton73

11 days ago

3 Posts

2 Followers

28 Likes

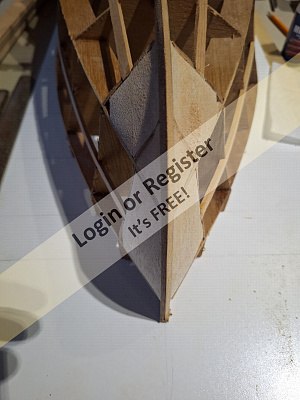

GLYNN GUEST KNOCKER WHITE TUG

I mentioned in the Vic Smeed Vivacity forum I would do a few smaller builds while chugging through the Vivacity project; the first of these I have started (while waiting on certain components/materials for Vivacity), based on Glynn Guest's Knocker White tugboat plan from his book 'Small Radio Control Boats'.

The Driving force behind choosing this particular design was the fact I had just filled my Backyard Model Boating Pond for the first time and sailed a couple of small free-running boats in it.

I had already made Arcady and Bredette many years ago when they were first issued as free plans in Model Boats, so Knocker White was the next project from the book with the necessary compact dimensions to sail happily on my pond, the first of (hopefully) several small such boat projects.

Here are the first stages of the build shown in the photos;

1) Paper template traced/assembled from the book - a little 'guestimation' was required as the plan was over two pages that didn't quite align...

2)Carcass pieces (deck, bottom, bulkheads, stem) marked out on 1/4" sheet

3)Carcass pieces cut out

4 & 5) carcass glued together, care taken to get as square as possible - note extra piece placed in stern to support rudder tube, making stern slightly deeper than original

6)Power train/RC components; Specktrum 410 RX, Ali Express 20A esc, RS 280 motor (was eventually replaced with an RS260 type when I clumsily broke off one of the contacts while trying to fit the battery), 100mm prop shaft/tube assembly with 25mm 3-blade prop.

7)Power train set up & tested on the bench to ensure everything worked

8)Prop tube skeg/support added

9)Prop tube epoxied in place, sandwiched between skeg support and lower skeg piece.

10)6mm ply motor mount glued into position after checking alignment.

More pics and comments to follow soon,

Best regards to all following this,

Nick

🇳🇿 Nick Ward

13 days ago

1 Post

1 Follower

12 Likes

1930 Cris Craft Runabout Dumas Kit 1230

Started the Runabout.

Using my Lion Miter trimmer to cut the planks, and my block plane to

trim to the chine. Then a sanding block for the final fit.

🇺🇸 pressonreguardless

15 days ago

|

|

Media Gallery

Christmas theme

5 days ago by GARTH

SSMBC (Florida) meet: 12/7/2025 military focus

7 days ago by LewZ

SSMBC (Seminole, Florida) meet, Nov 16, 2025

28 days ago by LewZ

SSMBC (Seminole, Florida) meet, Nov. 2, 2025

1 month ago by LewZ

Spooky - (Evening sail November)

1 month ago by philcaretaker

Gaff Rigged Bristol Pilot Cutter Autumn / Fall

2 months ago by philcaretaker

Only 2 days left

2 months ago by GARTH

Professional Photographer at Southport

2 months ago by SouthportPat

Filming over water

2 months ago by philcaretaker

"Sailor Sam" greets onlookers at the Sunday morning "Run In The Park".

3 months ago by philcaretaker

Light up the Night on the September 25th 2025 including safety cautions

3 months ago by GARTH

Second navigation (4 September 2025) to Lake Turano.

3 months ago by AlessandroSPQR

|

|

Login To

Remove Ads

Remove Ads

Boat Clubs & Lakes

Recent Updates In Places

|

Buxton Model Boat Club

15 days ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

Schiffsmodellclub Sömmerda/OT leubingen

19 days ago by 🇨🇭 Mike Stoney (

Rear Admiral) Rear Admiral) |

|

Southport Model Boat Club

1 month ago by 🇬🇧 SouthportPat (

Commodore) Commodore) |

|

BUXTON MODEL BOAT CLUB

1 month ago by 🇬🇧 philcaretaker (

Commodore) Commodore) |

|

New Brighton Model Boat Club

2 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral) |

|

|

Upcoming Events

|

(No Upcoming Events)

|

Boat Harbour

0 Photos

0 Likes

Fairmount Alpine

Purchased Built

🇬🇧 Heners2332

2 hours ago

6 Attributes

1 Comment

1 Photo

4 Likes

Schaufahren

Schaufahren des Schleppers "Smith"

🇩🇪 BernhardP

21 days ago

0 Attributes

1 Comment

1 Photo

4 Likes

Sumpfboot

Das Sumpfboot mußte mal sein. Fährt sehr stabil durch eine 15mm große Heckflosse.

🇩🇪 BernhardP

21 days ago

0 Attributes

5 Comments

1 Photo

4 Likes

Ponton

Der Ponton ist für den Hafenschlepper.

🇩🇪 BernhardP

21 days ago

0 Attributes

1 Comment

1 Photo

3 Likes

Regattaklasse

M-Boot kurz vor dem Start zur Regatta in unserem Verein.

🇩🇪 BernhardP

21 days ago

0 Attributes

1 Comment

1 Photo

2 Likes

Rennboot

Sehr schönes und schnelles Rennboot.

🇩🇪 BernhardP

21 days ago

0 Attributes

1 Comment

1 Photo

9 Likes

Yacht

Modell "Destriro"

🇩🇪 BernhardP

21 days ago

0 Attributes

3 Comments

1 Photo

8 Likes

Fahrmodell

Revell Gato-Class als Fahrmodell.

🇩🇪 BernhardP

21 days ago

0 Attributes

1 Comment

1 Photo

8 Likes

Hafenschlepper

smith nederland

🇩🇪 BernhardP

21 days ago

0 Attributes

2 Comments

|

|

How-To Articles

Electric Boat Engine Etc Etc

Revised 6 days ago

By Guy O

Essential or useful tools and utensils for the ship modeler. A final appendix lists the most common

Revised 2 months ago

By AlessandroSPQR

stop email notifications

Revised 2 months ago

By Ace23

painting epoxy over Humbrol and varnish enamels

Revised 4 months ago

By roycv

Cardan joint, Homokinetic joint, universal joint. Problems related to the junction between the engin

Revised 6 months ago

By AlessandroSPQR

various electrical connection diagrams for two motors

Revised 8 months ago

By tomarack

Lifeboats or work boats?

Revised 11 months ago

By AlessandroSPQR

Permanent magnet brushed electric motors. Main features. Basic elements of distinction. How to evalu

Revised 11 months ago

By AlessandroSPQR

When wooden planking the sides of hulls What Glues are you using?

Revised 1 year ago

By bruce1946

Fibreglassing a wooden hull

Revised 1 year ago

By DuncanP

|

|

Login To

Remove Ads

Remove Ads

Model Boats Website

This is the alert text. You can customize this text to be as long or short as needed. The modal height will adjust accordingly.

🛍️ Basket

Main menu transported here on mobile

Login

Create New Account

Trending Topics

Members Online

Blog

Re: Tied to the dock.

Ronald

2 minutes ago

Harbour

Fairmount Alpine

Heners2332

2 hours ago

Forum

Before and after..

LewZ

2 hours ago

Blog

Re: Need info on what these ships are

RossM

9 hours ago

Forum

Animal and nature photos to enjoy.

Ronald

9 hours ago

Blog

Re: She’s done!!

Heners2332

9 hours ago

Blog

Re: A bit more final finishing.

Chum444

10 hours ago

Forum

Question of the Day?

BOATSHED

13 hours ago

Blog

Re: Planking the deck. Part 1.

robbob

1 day ago

Harbour

Re: Port Area

Mike Stoney

2 days ago

Gallery

Re: Christmas theme

BOATSHED

2 days ago

Guestbook

Re: Guestbook

Chuck

2 days ago

Blog

Re: HMCS Woodstock Crew From Etsy 3Djson

Ronald

2 days ago

Forum

TVR1A Steam Engine.

GaryLC

4 days ago

Gallery

Re: SSMBC (Seminole, Florida) meet, Nov. 2, 2025

Mike Stoney

4 days ago

Blog

Re: Seaspan HAWK with "Z" drive build

bruce1946

4 days ago

Forum

engine etc etc

Guy O

5 days ago

Forum

Dutch sailing barge

AlessandroSPQR

5 days ago

Forum

RTTL2755 having a run out

AlessandroSPQR

5 days ago

Blog

Re: Look I’m aiming for

Rogal118

5 days ago

Forum

Sprite

zooma

5 days ago

Gallery

Re: SSMBC (Florida) meet: 12/7/2025 military focus

Chum444

5 days ago

Forum

WW 2 and radar

roycv

6 days ago

Forum

Nautical Nonsense: Cutlass Stand

LewZ

6 days ago

Wiki

Electric Boat Engine Etc Etc

Guy O

6 days ago

Gallery

Re: SSMBC (Seminole, Florida) meet, Nov 16, 2025

LewZ

7 days ago

Blog

Re: Classic Model Power Boats

BOATSHED

7 days ago

Blog

Re: Crew for next Project From Etsy 3djson

AlessandroSPQR

7 days ago

roycv

Fleet Admiral

10,065 Points

Today!

DWBrinkman

Commodore

4,340 Points

18 seconds ago

JockScott

Warrant Officer

720 Points

23 seconds ago

BOATSHED

Commander

2,715 Points

43 seconds ago

zooma

Vice Admiral

6,169 Points

2 minutes ago

Ronald

Fleet Admiral

12,761 Points

2 minutes ago

bruce1946

Midshipman

1,193 Points

13 minutes ago

melian

Recruit

0 Points

23 minutes ago

neilmc

Warrant Officer

886 Points

25 minutes ago

LeeA

Recruit

10 Points

25 minutes ago

ekoral

Master Seaman

128 Points

29 minutes ago

RodC

Lieutenant Commander

2,122 Points

29 minutes ago

Javelin1

Recruit

5 Points

31 minutes ago

Chum444

Captain

3,877 Points

55 minutes ago

RubaDub

Petty Officer 1st Class

239 Points

1 hour ago

eddyc

Recruit

6 Points

2 hours ago

RonB

Recruit

0 Points

2 hours ago

thadlietz

Chief Petty Officer 2nd Class

308 Points

2 hours ago

Hermione

Able Seaman

49 Points

2 hours ago

Heners2332

Recruit

11 Points

2 hours ago

Wolle

Commodore

4,857 Points

2 hours ago

Greg

Recruit

0 Points

2 hours ago

LewZ

Vice Admiral

7,115 Points

2 hours ago

RossM

Captain

3,166 Points

2 hours ago

EdwardG1

Recruit

0 Points

2 hours ago

pressonreguardless

Rear Admiral

5,307 Points

3 hours ago

Rowen

Captain

3,547 Points

3 hours ago

dash8man

Able Seaman

33 Points

3 hours ago

TonyAsh

Chief Petty Officer 1st Class

456 Points

3 hours ago

Northernflotsam

Chief Petty Officer 2nd Class

324 Points

3 hours ago

PeterJ

Chief Petty Officer 1st Class

470 Points

3 hours ago

Mike Stoney

Rear Admiral

5,268 Points

3 hours ago

xtramaths

Petty Officer 2nd Class

174 Points

3 hours ago

Oxford-Dave

Sub-Lieutenant

1,303 Points

4 hours ago

BernardB

Recruit

2 Points

4 hours ago

Newby7

Fleet Admiral

10,878 Points

4 hours ago

JEANFRANCOIS G

Recruit

0 Points

4 hours ago

trowley

Recruit

0 Points

4 hours ago

glassicus

Recruit

6 Points

4 hours ago

BarryS

Warrant Officer

836 Points

4 hours ago

hermank

Rear Admiral

5,260 Points

4 hours ago

Steves-s

Chief Petty Officer 1st Class

454 Points

4 hours ago

JOHN

Midshipman

1,136 Points

5 hours ago

KevinH

Warrant Officer

837 Points

5 hours ago

J23ARB

Recruit

0 Points

5 hours ago

jumpugly

Admiral

8,389 Points

5 hours ago

EsterP

Recruit

0 Points

5 hours ago

Otto

Recruit

10 Points

5 hours ago

Julio

Petty Officer 1st Class

249 Points

6 hours ago

Sinc5508

Able Seaman

21 Points

6 hours ago

Login To

Remove Ads

Remove Ads

🏠

Home

Home

📰

Trending

Trending

💬

Forum

Forum

🗝

Login / Join

Login / Join

|

Cookies are used for ads personalisation.

By using this website you agree to our use of cookies. More Info |

Main Menu

🚤 Model Boats

• Forum

• Build Blogs

• Media Gallery

• Boat Clubs & Lakes

• Events

• Boat Harbour

• How-To Articles

• Useful Links

• The Games Chest

This Website

🔍 Search

📝 Guestbook

👨👩👧👦 Members (1,786)

📣 Support

Hobby Supplies

🛍️ Online Shop

Login

🗝 Login

🗝 Create New Account

▼

Media Gallery

X

1 of 4

► |

◄ |

Media Viewer

^

_

X

Share

X

Flag Inappropriate Post

X

| Select Reason | |

| Sexual content Includes graphic sexual activity, nudity, and other sexual content. | |

| Violent or repulsive content Violent or graphic content, or content posted to shock viewers. | |

| Hateful or abusive content Content that promotes hatred against protected groups, abuses vulnerable individuals, or engages in cyberbullying. | |

| Harmful dangerous acts Content that includes acts that may result in physical harm. | |

| Child abuse Content that includes sexual, predatory or abusive communications towards minors. | |

| Promotes terrorism Content intended to recruit for terrorist organisations, incite violence, glorify terrorist attacks, or otherwise promote acts of terrorism. | |

| Spam or misleading Content that is massively posted or otherwise misleading in nature. | |

| Infringes my rights Privacy, copyright and other legal complaints. | |

Basket Updated

X

Loading...

Loading

Loading Uploader...