Join Us On Social Media!

South Africa

Recent Posts

📝 FT Bates

12 days ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 2 Views · 11 Likes · 1 Comment

Flag

💬 Add Comment

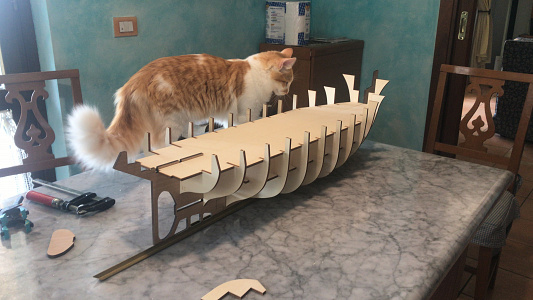

An old lady in dry dock for restoration. 1:48 Scale South African Railways and Harbours Tug.

Vessel built in Glasgow 1950.

Vessel built in Glasgow 1950.

▲

⟩⟩

ChrisG

Ray

roycv

Frankiesays1953

IanL1

RodC

Len1

hermank

MartinW

AlessandroSPQR

Wolle

Login To

Remove Ads

Remove Ads

💬 Re: Water Cannon

5 months ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 18 Views · 0 Likes

Flag

💬 Add Comment

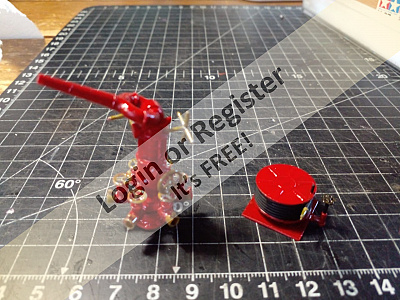

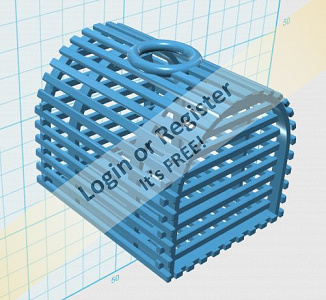

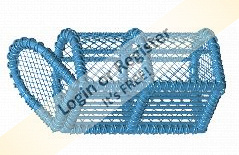

Hi all. The STL files for the water cannon, both working and non-working are available in 3D Trader. Other ships items (Anchor Winch and Fire Hose on Reel) are also available.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Water Cannon

6 months ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 84 Views · 21 Likes · 11 Comments

Flag

💬 Add Comment

▲

⟩⟩

Mike Stoney

boatmam

flaxbybuck

RossM

ARL58

ToraDog

Rookysailor

hermank

Commodore-H

DuncanP

Peejay

RNinMunich

Doogle

AlessandroSPQR

Len1

Colin H

jumpugly

BarryS

Fred

EdW

Wolle

📝 Mount Washington

7 months ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 14 Views · 25 Likes · 10 Comments

Flag

💬 Add Comment

Old Dumas kit dug out from pile of forgotten rubbish in a shed (with many missing pieces) resurrected and now ready to sail. 1:48 Scale

▲

⟩⟩

Cashrc

GaryLC

Commodore-H

DuncanP

EdW

Peejay

Rogal118

LewZ

Ray

RodC

Wolle

Colin H

Doogle

AlessandroSPQR

River Rat

jumpugly

BarryS

Mike Stoney

Ronald

roycv

boatmam

ChrisG

Jerry Todd

AndyN

DWBrinkman

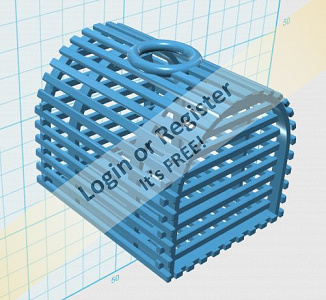

💬 Re: Trap Play

11 months ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 33 Views · 1 Like

Flag

💬 Add Comment

If anyone is interested I've designed lobster pots and cages in 3D for 3D printing. Available as stl files and can be printed at any scale.

▲

⟩⟩

RNinMunich

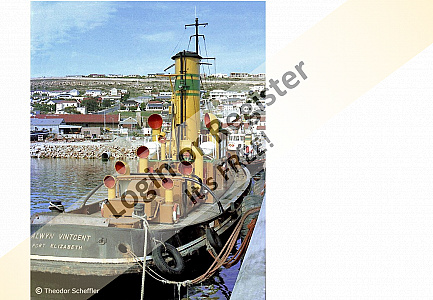

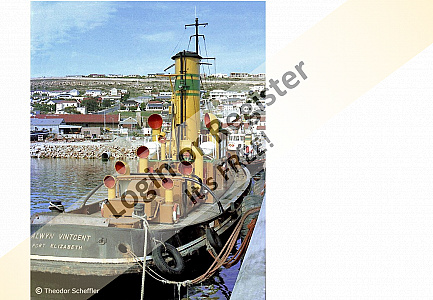

📝 Alwyn Vintcent Launched

1 year ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 30 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

Finally launched Alwyn Vintcent at Gauteng Model Boat Club facility, Johannesburg, South Africa. Unfortunately, green and choppy water.

▲

⟩⟩

pickieboater

Peejay

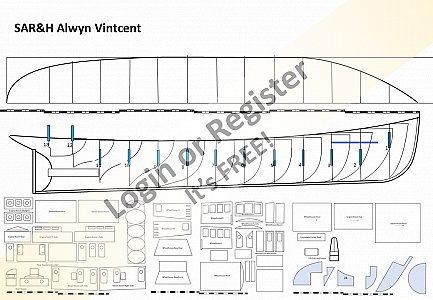

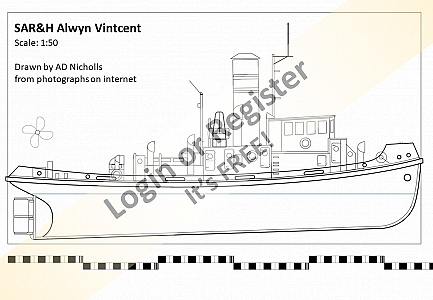

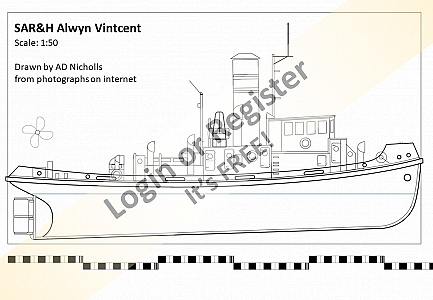

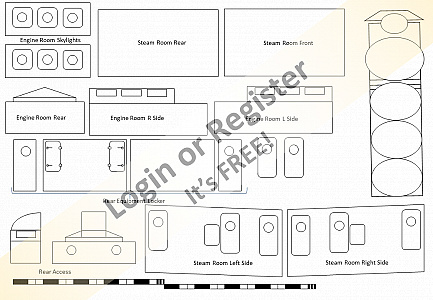

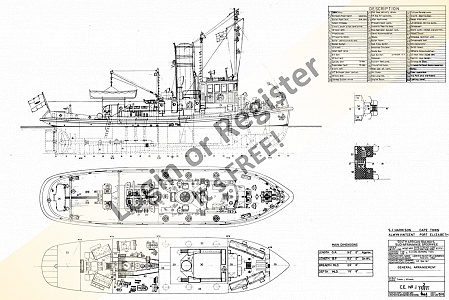

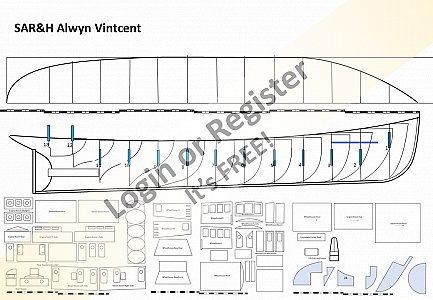

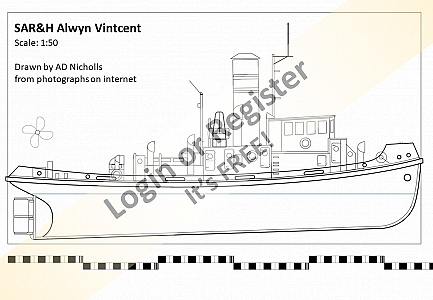

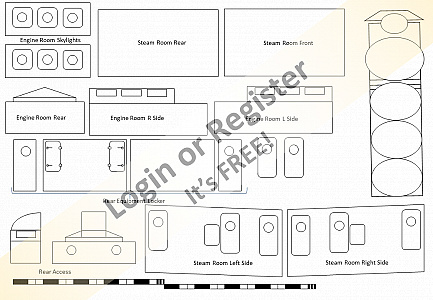

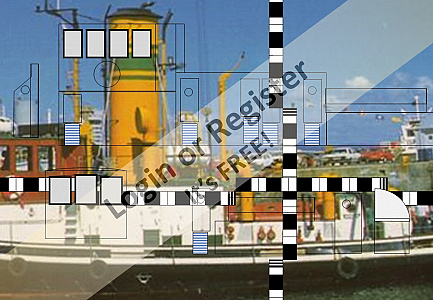

📝 Alwyn Vintcent Steam Tug 1:32

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 86 Views · 12 Likes

Flag

💬 Add Comment

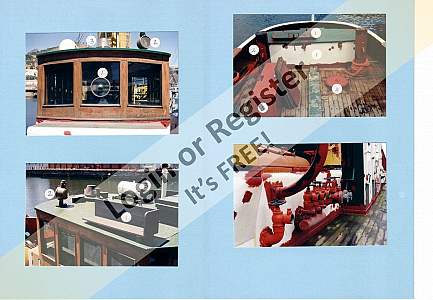

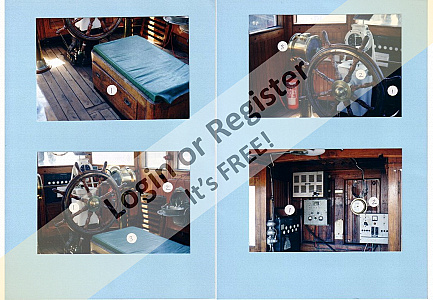

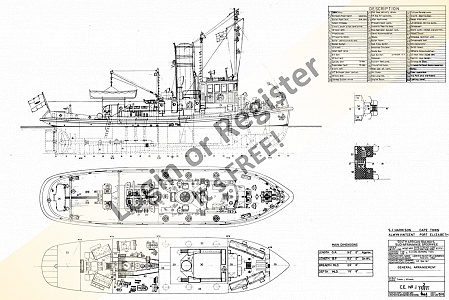

Originally scratch built in 1:50 scale using plans drawn from photographs. Obtained copy of Constructors Drawings to verify dimensions and details (dated 1959) and completed 4 more display models (scratch built). Rescaled all my drawings and plans to 1:32 scale. Computer Designed and 3D Resin printed all fittings (winch, portholes, anchors etc.) verifying accuracy against photographs and drawing supplied by current restorers of actual vessel (Villiersdorp Vintage Tractor and Engine Club). Designed and produced 2 1:32 Scale Model Kits (including hull, laser cut structural elements, all fittings etc.). I've just completed a "proof build" on one of the kits to verify accuracy and fit of all components.

▲

⟩⟩

pickieboater

jbkiwi

luckyduck

Albert90

GaryLC

pressonreguardless

Ronald

martyvz

LewZ

Colin H

Brightwork

firepaddy1617

📝 Water up prop shaft.

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 89 Views · 0 Likes

Flag

📝 Reply

I love this mix. Thanks for sharing

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

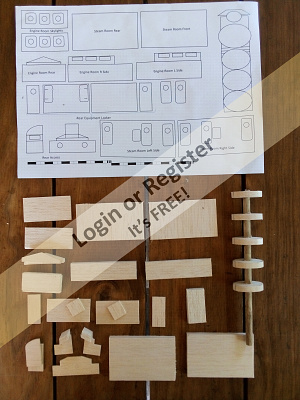

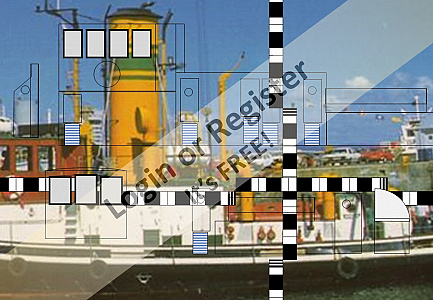

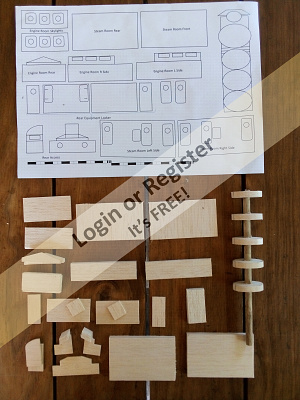

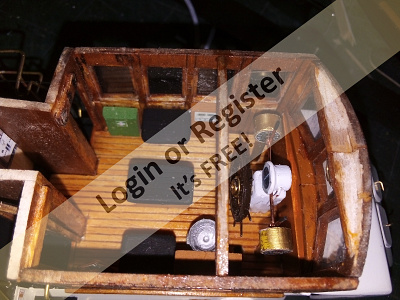

📝 Alwyn Vintcent Steam Tug 1:32

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 71 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

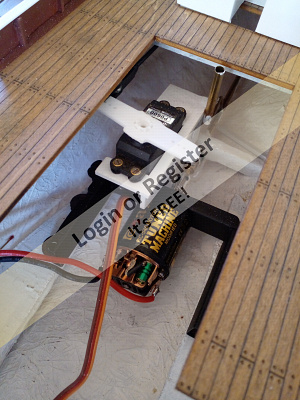

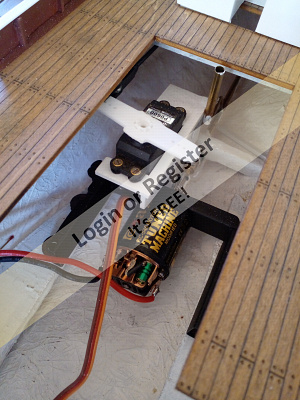

Having finished all components for the "Alwyn Vintcent" 1:32 Scale Tug Kit I'm now proof building the "kit" making sure everything fits.

Model is detailed scale replica of actual tug (currently being restored in Villiersdorp, South Africa.)

Kit includes full set of plans and reference photographs, detailed Fibre-Glass Hull, laser cut 3mm birch ply structure elements, laser etched and cut deck and all fittings (designed from original drawings and photos and 3D Resin printed).

Have completed the hull, including raised lettering, installation of deck and gunwales and installation of power-train.

Now working on superstructure.

Model is detailed scale replica of actual tug (currently being restored in Villiersdorp, South Africa.)

Kit includes full set of plans and reference photographs, detailed Fibre-Glass Hull, laser cut 3mm birch ply structure elements, laser etched and cut deck and all fittings (designed from original drawings and photos and 3D Resin printed).

Have completed the hull, including raised lettering, installation of deck and gunwales and installation of power-train.

Now working on superstructure.

▲

⟩⟩

Dumaspittman

Derek 151

Rookysailor

jacko

Colin H

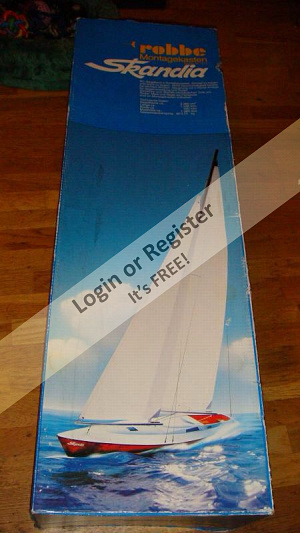

💬 Re: 3 "Robbe" Classic yachts

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 290 Views · 1 Like

Flag

💬 Add Comment

▲

⟩⟩

philcaretaker

💬 Re: 3 "Robbe" Classic yachts

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 290 Views · 1 Like

Flag

💬 Add Comment

So lovely to see. I have a Comtesse that I bought 40 years ago, and still sail on the occasional weekends.👍

▲

⟩⟩

philcaretaker

Login To

Remove Ads

Remove Ads

💬 Re: Alwyn Vintcent Steam Tug 1:32

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 40 Views · 1 Like

Flag

💬 Add Comment

Hi. Model is 857 x 190 x 510mm. Please see the PDF files for all the details. Alan

▲

⟩⟩

stevedownunder

📝 Alwyn Vintcent Steam Tug 1:32

2 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 84 Views · 7 Likes · 5 Comments

Flag

💬 Add Comment

Using plans I drew using photographs and origional constructors drawings I've created a 1:32 scale kit of the Alwyn Vintcent, the last operational steam tug in South Africa (see attached pdf). I'm now building the kit to ensure fits of all the structural components.

▲

⟩⟩

Double Rum

stevedownunder

mturpin013

GaryLC

MouldBuilder

Northernflotsam

Ronald

💬 Re: Atlantic Tug "Amsterdam"

3 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 60 Views · 1 Like

Flag

💬 Add Comment

Awesome. A beautiful model of an iconic tug 😊

▲

⟩⟩

Brightwork

📝 Building a Tug

3 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 59 Views · 0 Likes

Flag

📝 Reply

Enjoy. Once you've built one you will be hooked. 😀 I started with a model kit ("Sanson") and have since built 6 more from scratch, all at 1:50 Scale. "Anteo", "JR More", "Eland" and x3 "Alwyn Vintcent's".

My current projects are the "Alwyn Vintcent" at 1:32 Scale for RC (all previous boats primarily for display).

I've cast 2 hulls, one of which I've already sold, and am now in the last stages of completing the kitting of a second model for sale. Unfortunately the kit is not designed for the novice.

It is a pity that you are so far away, postage or courier would be exorbitant and would put the cost way above what you would pay for an equivalent model in the UK.☹️

Enjoy your model making. 😀

My current projects are the "Alwyn Vintcent" at 1:32 Scale for RC (all previous boats primarily for display).

I've cast 2 hulls, one of which I've already sold, and am now in the last stages of completing the kitting of a second model for sale. Unfortunately the kit is not designed for the novice.

It is a pity that you are so far away, postage or courier would be exorbitant and would put the cost way above what you would pay for an equivalent model in the UK.☹️

Enjoy your model making. 😀

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Building a Tug

3 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 69 Views · 1 Like

Flag

📝 Reply

If you are feeling truly adventurous and would like to do a "scratch build" I have plans for the "Alwyn Vintcent", the last operational steam tug in South Africa. I can also supply the 3D models of all the fittings for you to have printed.

Alan

Alan

▲

⟩⟩

SimpleSailor

💬 Re: S Boat

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 44 Views · 1 Like

Flag

💬 Add Comment

Really love all the detail. Great job 😀

▲

⟩⟩

Martin555

💬 Re: Tug Brent

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 59 Views · 2 Likes

Flag

💬 Add Comment

Great job. Looks awesome on the water. Similar lines to Alwyn Vintcent, South African Tug. Last project was 1:50 scale scratch build, next project same tug 1:24 scale for RC

▲

⟩⟩

Inkoust

Martin555

💬 Re: Update of project

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 32 Views · 1 Like

Flag

💬 Add Comment

Awesome. Love the detailing, especially considering scratch built. I applaud your patience, perseverance and attention to detail.

▲

⟩⟩

Martin555

💬 Re: AWLB PENLEE

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 26 Views · 1 Like

Flag

💬 Add Comment

I love the waves. Excellent job, done like a pro 😀

▲

⟩⟩

Martin555

💬 Re: Steam Capstan

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 30 Views · 3 Likes

Flag

💬 Add Comment

Great job. I love the detail, especially the mounting bolts.

▲

⟩⟩

billmcl61

Hillro

Martin555

Login To

Remove Ads

Remove Ads

💬 Re: HMT Resolve

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 53 Views · 3 Likes

Flag

💬 Add Comment

Awesome job. Love the detail and admire the patience you must have had. 😀

▲

⟩⟩

cormorant

Scratchbuilder

Martin555

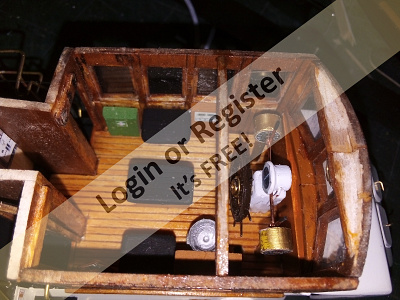

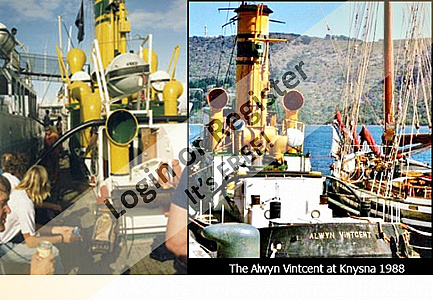

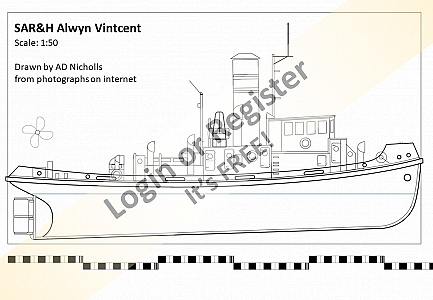

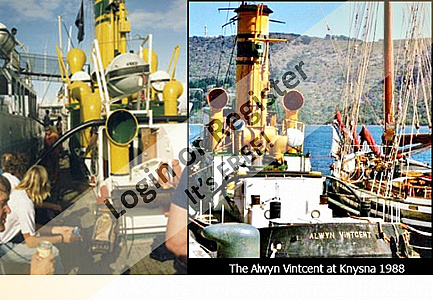

📝 Alwyn Vintcent Build

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 31 Views · 6 Likes · 2 Comments

Flag

💬 Add Comment

Scratch built 1:50 scale model of Steam Tug Alwyn Vintcent. Last operating steam tug in South Africa. model.

Having completed Sanson (Artesania Latina kit) and Anteo (scratch built using plans from internet scaled to 1:50) I had the "Tug Bug".

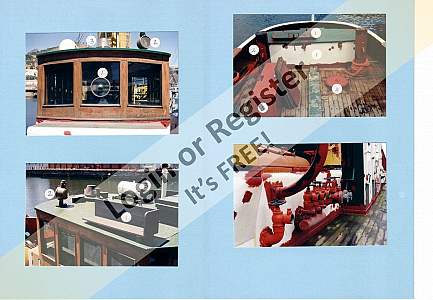

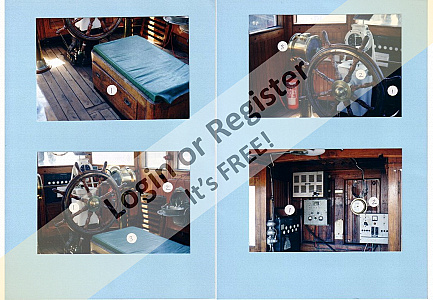

Wanting to do a South African tug I scanned the internet and found the Alwyn Vintcent. Not only did she "have the look" but there were numerous photographs, and as a bonus I found she was being restored in Villiersdorp, South Africa. Alas I could find no plans.

Using photos resized to 1:50 scale I traced all lines (using MS PowerPoint) producing a set of plans to scale. The photos I used for reference attached.

I finally found a set of plans, but only after I completed the model. My plans were nearly a perfect match 😊

Hull was plank on frame construction, using balsa, which was then used as a blank to make a fibre glass mold. The hull was then cast using the mold to facilitate converting the tug to RC.

The rest, with the exception of the anchor chain, was scratch built.

Balsa for all structural elements, 1mm brass rod for all railings, 0.5mm for handles, hinges, portholes, hydrant wheels, pill containers for barrels, wood dowel for vents, liferafts and tyres.

Detail photos posted in Harbour.

Took just over 3 months to complete. My next challange is to scratch build the JR More (South African Steam Tug) in 1:50 scale.

Having completed Sanson (Artesania Latina kit) and Anteo (scratch built using plans from internet scaled to 1:50) I had the "Tug Bug".

Wanting to do a South African tug I scanned the internet and found the Alwyn Vintcent. Not only did she "have the look" but there were numerous photographs, and as a bonus I found she was being restored in Villiersdorp, South Africa. Alas I could find no plans.

Using photos resized to 1:50 scale I traced all lines (using MS PowerPoint) producing a set of plans to scale. The photos I used for reference attached.

I finally found a set of plans, but only after I completed the model. My plans were nearly a perfect match 😊

Hull was plank on frame construction, using balsa, which was then used as a blank to make a fibre glass mold. The hull was then cast using the mold to facilitate converting the tug to RC.

The rest, with the exception of the anchor chain, was scratch built.

Balsa for all structural elements, 1mm brass rod for all railings, 0.5mm for handles, hinges, portholes, hydrant wheels, pill containers for barrels, wood dowel for vents, liferafts and tyres.

Detail photos posted in Harbour.

Took just over 3 months to complete. My next challange is to scratch build the JR More (South African Steam Tug) in 1:50 scale.

▲

⟩⟩

ianed57

Dibdawg

RonH

Ronald

Graham93

Martin555

💬 Re: Tug Boat Alwyn Vintcent

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 30 Views · 1 Like

Flag

💬 Add Comment

Build photos posted in Alwyn Vintcent Build Blog. Please advise where I can post reference photos I used to drawup plans and find details

▲

⟩⟩

Martin555

📝 Tug Boat Alwyn Vintcent

4 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 28 Views · 6 Likes · 8 Comments

Flag

💬 Add Comment

1:50 Scale scratch built model of last operating steam tug in South Africa. Built using plans I drew up using photographs as reference.

Alwyn Vintcent currently being restored by Villiersdorp Vintage Tractor and Engine Club in Villiersdorp, South Africa.

Alwyn Vintcent currently being restored by Villiersdorp Vintage Tractor and Engine Club in Villiersdorp, South Africa.

▲

⟩⟩

Harris

RNinMunich

ianed57

Joe727

redpmg

Martin555

💬 Re: "ANTEO" Italian Tug

5 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 39 Views · 1 Like

Flag

💬 Add Comment

Awesome. Well done, a beautiful model

▲

⟩⟩

Martin555

📝 Alwyn Vintcent Steam Tug

5 years ago by 🇿🇦 Alannicholls ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 30 Views · 4 Likes

Flag

📝 Reply

I have plans I made off photographs on internet. From these plans I completed a 1:50 scale model of the Alwyn Vintcent. Alan

▲

⟩⟩

jbkiwi

marky

figtree7nts

Martin555

Liked Re: Water Cannon 5 months ago

Liked Re: Water Cannon 5 months ago

Liked Zwarte Zee 2 years ago

Liked Zwarte Zee 2 years ago

Liked Tugboat Anteo 2 years ago

Liked Tugboat Anteo 2 years ago

Liked Final Assembly 4 years ago

Liked Final Assembly 4 years ago

Liked Hull and decking 4 years ago

Liked Hull and decking 4 years ago