Join Us On Social Media!

United Kingdom

Recent Posts

📝 Plank on Frame

6 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 8 Views · 1 Like

Flag

📝 Reply

Thanks for that link Martin, very useful. Thanks.

Alan

Alan

▲

⟩⟩

Martin555

Login To

Remove Ads

Remove Ads

📝 Plank on Frame

6 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 8 Views · 1 Like

Flag

📝 Reply

What is the best way to feather (if I have the right name)the edges of the bulkheads to lay the planking on. A sanding block and guess work seem a bit hap hazard to me.

Alan

Alan

▲

⟩⟩

Martin555

📝 Grease

6 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 8 Views · 0 Likes

Flag

📝 Reply

Non float grease pops into mind, but I don't know where you get it from nowadays

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

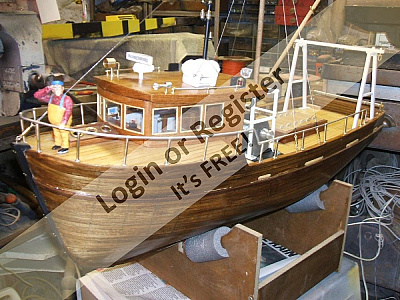

📝 Lady T

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 12 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

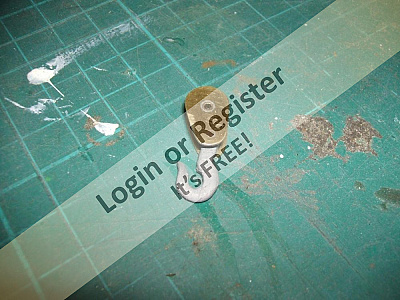

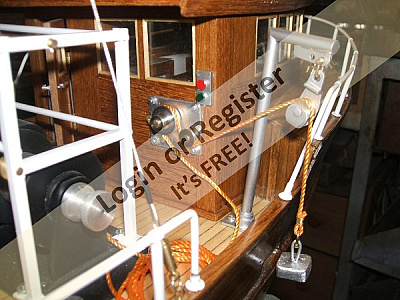

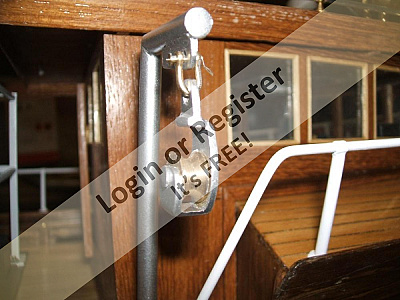

Dropping down aft from the boat deck are the tow hooks, why there are two hooks, I have no idea, but that's what is shown on the drawing. Taking the dimensions from the drawing the main part was made up of plasticard and bits of brass tube, the two hooks were made from brass sheet and soldered together, the hoop that these run on goes through the superstructure and is fastened with nuts on the inside.

To the side of the tow hooks is an exhaust with silencer, this was made out of aluminium on the lathe with bits of brass tube, also on this platform are two coal hatches, again made out of plasticard and wood with painted staples as handles.

To the side of the tow hooks is an exhaust with silencer, this was made out of aluminium on the lathe with bits of brass tube, also on this platform are two coal hatches, again made out of plasticard and wood with painted staples as handles.

▲

⟩⟩

Martin555

Inkoust

RNinMunich

📝 Aft mast

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 12 Views · 3 Likes

Flag

💬 Add Comment

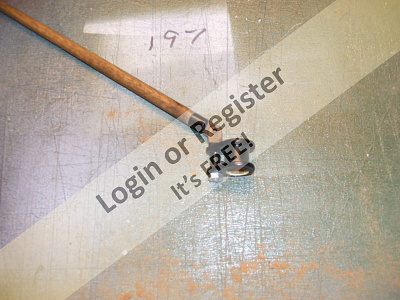

The aft mast was made out of a teak curtain rod turned down on my metal lathe (what a mess it made, wood dust all over the place 😱) it was made in two pieces with a hole drilled up each piece to take the lighting wires. The bit to take the boom, never sure if it is a swan neck or a goose neck was made out of bits of tubing and plasticard. All the other bits and pieces came out of the scrap box. The boom was just made from a piece of dowel and stained.

▲

⟩⟩

RNinMunich

Donnieboy

Fred

📝 Funnel

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 14 Views · 5 Likes

Flag

💬 Add Comment

The funnel was made out of 40mm plastic waste pipe, let into a piece of 3mm plasticard, thin strips of plasticard super glued around to simulate the sections. The hatch at the back made with plasticard, hinges and handles again made out of plasticard.

There are four stop cocks at the front, the bodies of these were made out of aluminium on the lathe, with 1mm rod and some hand wheels out of the scrap box.

There are four stays to hold the funnel and one at the top that goes to the aft mast, small hand rail knobs were used for this job.

The funnel was painted (no it isn't pink, its the flash from the camera that makes it look pink) small brass tube to the steam whistle and the whistle made out of a bigger dia tube, a ladder added out of the scrap box and the completed funnel ready for fitting

There are four stop cocks at the front, the bodies of these were made out of aluminium on the lathe, with 1mm rod and some hand wheels out of the scrap box.

There are four stays to hold the funnel and one at the top that goes to the aft mast, small hand rail knobs were used for this job.

The funnel was painted (no it isn't pink, its the flash from the camera that makes it look pink) small brass tube to the steam whistle and the whistle made out of a bigger dia tube, a ladder added out of the scrap box and the completed funnel ready for fitting

▲

⟩⟩

Inkoust

Fred

Donnieboy

figtree7nts

RNinMunich

💬 wheelhouse amd bridge

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 10 Views · 0 Likes

Flag

💬 Add Comment

Yes, PM is OK Fred

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 wheelhouse amd bridge

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 18 Views · 9 Likes · 3 Comments

Flag

💬 Add Comment

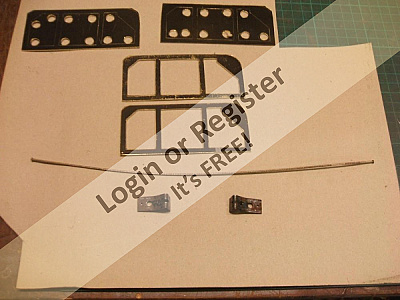

I don't have any photo's of the building of this, so I will try to explain.

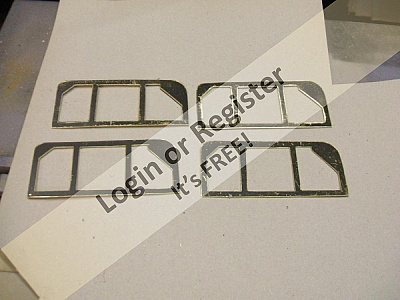

I cut all the pieces for the wheelhouse out of 1mm plasticard, the pieces were then fitted together with masking tape to make sure that they all fitted neatly together. The windows were then cut out of Perspex and their positions marked and put aside.

The floor of the wheelhouse was planked along with the rear wall, the five side pieces were then wooded (for want of a better word) light oak for the frames with teak for the infills, the windows were checked to make sure they still fitted.

The whole lot was fitted together with masking tape and glue run down the seams with a small brush.

After drying the outside of the wheelhouse was wooded 😁 over lapping the windows by a couple of thou, the windows were glued in place with canopy glue.

Aft of the wheelhouse are the battery boxes, these were made out of plasticard with doors made out of wood, kiss buttons used for the door knobs.

Two sliding doors were made out of wood, small plastic channel

for the runners.

The bridge was made using the same principal as the boat deck.

I cut all the pieces for the wheelhouse out of 1mm plasticard, the pieces were then fitted together with masking tape to make sure that they all fitted neatly together. The windows were then cut out of Perspex and their positions marked and put aside.

The floor of the wheelhouse was planked along with the rear wall, the five side pieces were then wooded (for want of a better word) light oak for the frames with teak for the infills, the windows were checked to make sure they still fitted.

The whole lot was fitted together with masking tape and glue run down the seams with a small brush.

After drying the outside of the wheelhouse was wooded 😁 over lapping the windows by a couple of thou, the windows were glued in place with canopy glue.

Aft of the wheelhouse are the battery boxes, these were made out of plasticard with doors made out of wood, kiss buttons used for the door knobs.

Two sliding doors were made out of wood, small plastic channel

for the runners.

The bridge was made using the same principal as the boat deck.

▲

⟩⟩

Inkoust

Fred

MouldBuilder

marky

Donnieboy

BigAlio

teejay

figtree7nts

RNinMunich

💬 wooden ladders

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 10 Views · 0 Likes

Flag

💬 Add Comment

Yes, I think it was Fred, they were given a couple of coats of clear lacquer after sanding to finish them off.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

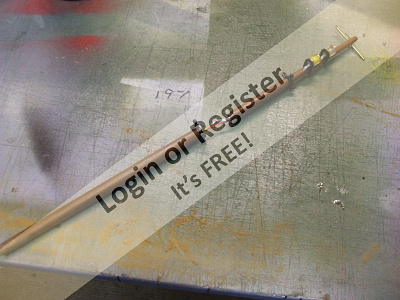

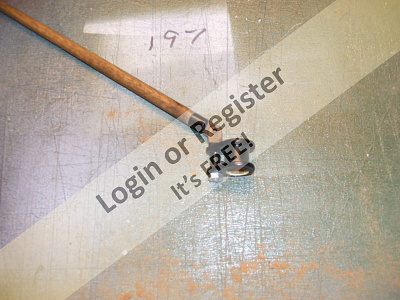

📝 wooden ladders

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 18 Views · 9 Likes · 5 Comments

Flag

💬 Add Comment

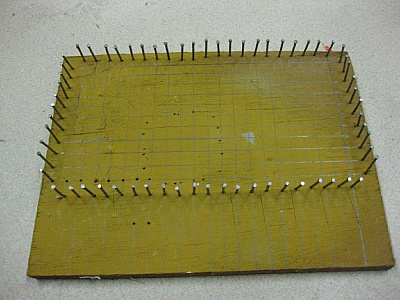

There are two long ladders from the deck to the boat deck and three shorter ones around the battery boxes.

I had a few goes at these free hand and they all ended up on the fire. So I made this jig, the two side rails are placed at each side with a piece of wood with the end cut at the angle of the treads, it is a snug fit between the side rails, a spacer is made to get equal spacing's between the treads. The inside of the jig is coated in candle wax to stop the glue sticking the ladders to the jig, Each tread is cut and sanded to be a tight fit between the side rails and glued in place using a tooth pick and super glue.

Well that explanation makes sense to me, but the photo's should make it clear.

I had a few goes at these free hand and they all ended up on the fire. So I made this jig, the two side rails are placed at each side with a piece of wood with the end cut at the angle of the treads, it is a snug fit between the side rails, a spacer is made to get equal spacing's between the treads. The inside of the jig is coated in candle wax to stop the glue sticking the ladders to the jig, Each tread is cut and sanded to be a tight fit between the side rails and glued in place using a tooth pick and super glue.

Well that explanation makes sense to me, but the photo's should make it clear.

▲

⟩⟩

Inkoust

hightide

mturpin013

Donnieboy

figtree7nts

RNinMunich

Fred

Baggie

Colin H

📝 Boatdeck bulwark & boatdeck planking

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 14 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

I haven't posted for a while as I have only been running on three cylinders, but all four firing now, so off we go.

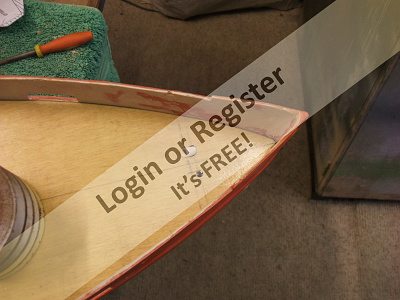

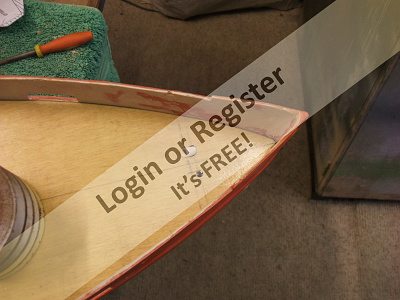

An edging is glued around the boatdeck, this then allows a thin piece of plasticard to be glued in place for the boatdeck bulwark, after the glue had dried, planks cut from a sheet of veneer were glued inside and out and the bulwark and finished with a teak capping.

A cardboard template was made for the boatdeck overlay planking, this was then transferred onto 1mm ply for the planking to be laid on. Using planks cut from a sheet of veneer and cotton thread for the caulking, Aliphatic glue, a tooth pick and my best glasses the planking was completed. The finished planking was given several coats of clear lacquer rubbing down in between coats to give it a nice finish.

Planking at this scale with fine thread as caulking is definitely a labour of love.

An edging is glued around the boatdeck, this then allows a thin piece of plasticard to be glued in place for the boatdeck bulwark, after the glue had dried, planks cut from a sheet of veneer were glued inside and out and the bulwark and finished with a teak capping.

A cardboard template was made for the boatdeck overlay planking, this was then transferred onto 1mm ply for the planking to be laid on. Using planks cut from a sheet of veneer and cotton thread for the caulking, Aliphatic glue, a tooth pick and my best glasses the planking was completed. The finished planking was given several coats of clear lacquer rubbing down in between coats to give it a nice finish.

Planking at this scale with fine thread as caulking is definitely a labour of love.

▲

⟩⟩

RNinMunich

Fred

Donnieboy

marky

mturpin013

Login To

Remove Ads

Remove Ads

💬 Doors

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 11 Views · 1 Like

Flag

💬 Add Comment

Hi Colin, I think the wood for the doors is about 2mm thick, a thin strip slightly wider than 2mm of plasticard is super glued around the edge, then using wet and dry sanded flush front and back. After drilling the hole for the porthole, the whole lot was given a couple of coats of Halfords clear lacquer and the knob stuck on. 👍

▲

⟩⟩

rolfman2000

💬 Superstructure

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 10 Views · 0 Likes

Flag

💬 Add Comment

😁😁😁😁😁😁

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Doors

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 15 Views · 6 Likes · 5 Comments

Flag

💬 Add Comment

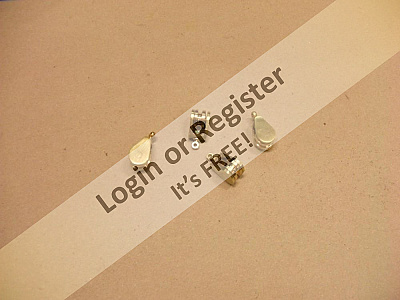

Here is a photo of the doors for the main superstructure, made out of a thin piece of Oak with a surround made from plasticard, brass portholes and dolls house knobs. The watertight doors made from plasticard and the hinges also made from plasticrd with the aid of a magnifying glass 😁

I bought the two sets of portholes from MMModels as it wasn't worth the trouble of making them all, lazy I know 😜

I bought the two sets of portholes from MMModels as it wasn't worth the trouble of making them all, lazy I know 😜

▲

⟩⟩

mturpin013

RNinMunich

MouldBuilder

figtree7nts

marky

Fred

💬 Superstructure

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 10 Views · 1 Like

Flag

💬 Add Comment

Hi Doug, just big lead acid batteries in this boat, I only use li po's in my fast electric boats.

Two of our club members have had fires with these so I am very careful with them.

Cheers Alan

Two of our club members have had fires with these so I am very careful with them.

Cheers Alan

▲

⟩⟩

RNinMunich

📝 Superstructure

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 13 Views · 4 Likes · 4 Comments

Flag

💬 Add Comment

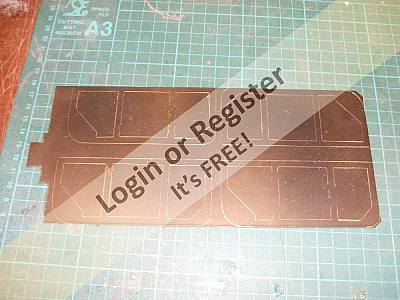

I have made the superstructure out of plasticard as it is much easier to paint, no filling in of the grain as there is with wood.

The main superstructure and the engine room structure are supposed to be as one, I am keeping these separate in the hope that I can house the switches and charging sockets under the engine structure.

I only have the two photo's of this stage I'm afraid.

The main superstructure and the engine room structure are supposed to be as one, I am keeping these separate in the hope that I can house the switches and charging sockets under the engine structure.

I only have the two photo's of this stage I'm afraid.

▲

⟩⟩

Fred

Baggie

RNinMunich

Donnieboy

📝 Anchor chain tubes

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 14 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

I forgot about this bit, it was done before the hull and decks were painted.

The tubes to take the anchor chain, there is probable a proper name for these but I have no idea what it is 😡

The positions on the deck were marked off and two holes drilled slightly smaller than the plastic tube that I was going to use, the same size holes were drilled on the hull, there are markings on the hull were the anchors go. Using a small round file the holes were opened up to take the tube, a small amount of super glue to hold the tubes in position and then the plastic tubes sanded off against the hull and deck. A bit of P38 around the tubes and sanded. Job done 😁

The tubes to take the anchor chain, there is probable a proper name for these but I have no idea what it is 😡

The positions on the deck were marked off and two holes drilled slightly smaller than the plastic tube that I was going to use, the same size holes were drilled on the hull, there are markings on the hull were the anchors go. Using a small round file the holes were opened up to take the tube, a small amount of super glue to hold the tubes in position and then the plastic tubes sanded off against the hull and deck. A bit of P38 around the tubes and sanded. Job done 😁

▲

⟩⟩

Fred

Donnieboy

figtree7nts

RNinMunich

Colin H

📝 Bulwark capping

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 13 Views · 4 Likes · 4 Comments

Flag

💬 Add Comment

So, here we go again. Bulwark capping, I didn't have a piece of teak wide enough to cut these out off, so two strips of teak were cut to the relevant size on the band saw and sanded. A large piece of plywood was laid on the top of the hull, the hull outline was drawn onto the plywood, blocks of wood were secured to the plywood to hold the strips of teak in place but exaggerating the curve. [To allow for spring back]

The teak was soaked overnight, the next day it was soaked in boiling water a few times, whilst still hot and wet it was placed in the blocks to dry.

I had to alter the blocks once to gain a bit more curve.

After the strips were properly dried, the top and sides of the strips were given two coats of finishing resin and left to dry, then the underside was coated with super glue and left the dry.

Then the tricky bit, wearing my best glasses I applied with the aid of a tooth pick super glue to the tops and bulwark supports and fitted the capping's.

The piece around the stern was cut out of one piece and looks alright.

The teak was soaked overnight, the next day it was soaked in boiling water a few times, whilst still hot and wet it was placed in the blocks to dry.

I had to alter the blocks once to gain a bit more curve.

After the strips were properly dried, the top and sides of the strips were given two coats of finishing resin and left to dry, then the underside was coated with super glue and left the dry.

Then the tricky bit, wearing my best glasses I applied with the aid of a tooth pick super glue to the tops and bulwark supports and fitted the capping's.

The piece around the stern was cut out of one piece and looks alright.

▲

⟩⟩

Baggie

Fred

RNinMunich

Colin H

📝 Bulwark supports

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 13 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

The deck and bulwarks were given another coat of paint, after this had dried the wash ports and rope hawsers were masked off and the hull given two coats of red primer, the water line was marked using a pencil on a block of wood, bottom part of the hull masked off and the top part given two coats of satin black. Starting to look like a boat now.

The rope crate was made out of plasticard to be a good tight fit on the coaming.

The bulwark positions were marked with pencil on the top of the bulwark. After cutting them all out of plasticard, each one was sanded to fit it's position, then keeping them in order and sticking them to upside down masking tape they were sprayed with paint.

All the supports were glued into position with super glue, a toothpick and my best glasses.

The rope crate was made out of plasticard to be a good tight fit on the coaming.

The bulwark positions were marked with pencil on the top of the bulwark. After cutting them all out of plasticard, each one was sanded to fit it's position, then keeping them in order and sticking them to upside down masking tape they were sprayed with paint.

All the supports were glued into position with super glue, a toothpick and my best glasses.

▲

⟩⟩

Fred

figtree7nts

RNinMunich

Colin H

📝 Decks

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 13 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

Templates were made out of cardboard, good job that I like Weetabix, a bit of messing about but eventually I got a good fit, these were transferred onto the 3mm ply for the deck.

Before fitting the deck the ply was given a couple of coats of Z-Poxy finishing resin rubbing down in-between coats, this filled in the grain ready for painting and also made it waterproof.

After the glue had dried the deck and bulwark were given a coat of primere, then two coats of the finishing colour. After a week of the paint left to harden the coamings (if that's the right spelling) were glued in place.

Before fitting the deck the ply was given a couple of coats of Z-Poxy finishing resin rubbing down in-between coats, this filled in the grain ready for painting and also made it waterproof.

After the glue had dried the deck and bulwark were given a coat of primere, then two coats of the finishing colour. After a week of the paint left to harden the coamings (if that's the right spelling) were glued in place.

▲

⟩⟩

Baggie

Fred

RNinMunich

figtree7nts

💬 Bulwarks and deck supports

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 10 Views · 1 Like

Flag

💬 Add Comment

Thanks Fred, you did pass on the information thanks, and I have read the builds. Thought I would post my build on this site as I have had a lot of help from people here. I am going to try to give a bit more detail of the build, bad bits and all.

Alan

Alan

▲

⟩⟩

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Bulwarks and deck supports

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 13 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

The next stage was to smooth out the Bukwarks so that a deck support could be fitted around the hull, the washports and rope hawsers were cut out, if I was to do this again I would cut these out after filling the bulwarks.

P38 was used to smooth out the Bulwarks, this really was a labour of love, lots of filling and sanding. For the deck support around the hull I used 3mm lime (Ikea blinds) two layers to give 6mm support glued with Araldite.

The rest of the deck supports were then glued in place, I think it was at this stage that I added the two battery placements after having the hull in the bath to work out were they had to go.

P38 was used to smooth out the Bulwarks, this really was a labour of love, lots of filling and sanding. For the deck support around the hull I used 3mm lime (Ikea blinds) two layers to give 6mm support glued with Araldite.

The rest of the deck supports were then glued in place, I think it was at this stage that I added the two battery placements after having the hull in the bath to work out were they had to go.

▲

⟩⟩

Fred

RNinMunich

Dave M

figtree7nts

💬 Lady T

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 14 Views · 5 Likes

Flag

💬 Add Comment

The next stage was to fit the prop tubes and motors, MMModels prop tubes and T4 motors were used. Now I will admit that getting the tubes lined up and getting them to come out of the hull nearly horizontal gave me a lot of headaches. The hull had different thicknesses and shapes of fibreglass were the motors had to be fitted, the A frame markings on the hull, especially the inboard ones were way out, all of this plus the fact that the motors had to be fitted more or less on the bottom of the hull. Aligning pieces were made on the lathe to go between the prop shafts and the motors. Motor mounts were made from hardwood and shaped on a belt sander to fit the hull bottom.

I think I had about five attempts at this stage using all sorts of pieces of ply with holes in them, wooden wedges and of course masking tape.

Motor mounts, I only have one photo of these, holes drilled in hardwood with a hole cutter, then cut in two on the bandsaw to give two halves that can clamp the motor, draught excluder stuck on the inside and the two halves fastened together with two wood screws.

I think I had about five attempts at this stage using all sorts of pieces of ply with holes in them, wooden wedges and of course masking tape.

Motor mounts, I only have one photo of these, holes drilled in hardwood with a hole cutter, then cut in two on the bandsaw to give two halves that can clamp the motor, draught excluder stuck on the inside and the two halves fastened together with two wood screws.

▲

⟩⟩

figtree7nts

SelwynWilliams

Donnieboy

Dave M

RNinMunich

📝 Lady T

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 13 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

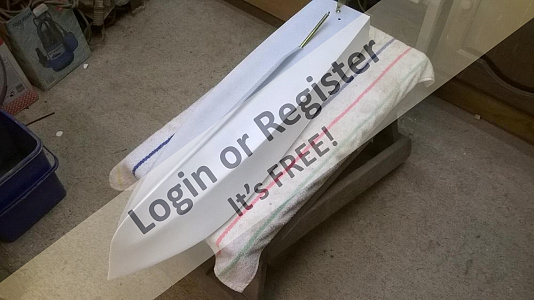

This is a build of the LadyT from Mobile Marine Models, I am quite a way into the build now and have not taken photo's of every part of the build and I may get things a bit out of sequence, but I will do my best.

The hull and a set of templates was given to me, I have found out that the templates in most cases are for guidence only. The hull is not one of the best mouldings I have had but with a bit of effort was knocked into shape.

In order that the rudder could be removed from the boat for repair I glued a piece of 3mm brass strip to the hull with Araldit and P38 filler, another piece of brass with a hole to take the rudder was laid on top and two 3.3mm holes drilled through both pieces, the brass on the hull was tapped 4mm and the piece with the hole for the rudder was drilled 4mm clear and countersunck.

By undoing the tiller arm and removing the two 4mm countersunk screws the rudder can be removed for repair.

The rudder was made with thin ply and P38 using the drawing to make a template of the shape.

The hull and a set of templates was given to me, I have found out that the templates in most cases are for guidence only. The hull is not one of the best mouldings I have had but with a bit of effort was knocked into shape.

In order that the rudder could be removed from the boat for repair I glued a piece of 3mm brass strip to the hull with Araldit and P38 filler, another piece of brass with a hole to take the rudder was laid on top and two 3.3mm holes drilled through both pieces, the brass on the hull was tapped 4mm and the piece with the hole for the rudder was drilled 4mm clear and countersunck.

By undoing the tiller arm and removing the two 4mm countersunk screws the rudder can be removed for repair.

The rudder was made with thin ply and P38 using the drawing to make a template of the shape.

▲

⟩⟩

Sinc5508

Dave M

figtree7nts

Donnieboy

RNinMunich

📝 Thurl pin rack

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 9 Views · 3 Likes

Flag

📝 Reply

Thank you all so much for the links and information. Every day is a school day 😁

Thanks Dave for the photo's, they have thrown light on something I was not sure of 👍

I will be making the Thurl pin rack out of some hard wood and tooth picks, eventually.

I have uploaded a photo (I hope) of the boat as far as I have got, its a slow build as there are a lot of little bits to make.

Alan

Thanks Dave for the photo's, they have thrown light on something I was not sure of 👍

I will be making the Thurl pin rack out of some hard wood and tooth picks, eventually.

I have uploaded a photo (I hope) of the boat as far as I have got, its a slow build as there are a lot of little bits to make.

Alan

▲

⟩⟩

SelwynWilliams

Dave M

RNinMunich

📝 Thurl pin rack

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 9 Views · 3 Likes

Flag

📝 Reply

Thanks for the reply Fred. I have looked on MMM site and found the Thurl pin rack made in white metal, can't say that it appeals to me, so I am going to make my own.

It's nice of you and Doug to take an interest and I appreciate it, it's a very nice model but there is a lot of work involved in the woodwork and making of the bits.

Thanks again

Alan

It's nice of you and Doug to take an interest and I appreciate it, it's a very nice model but there is a lot of work involved in the woodwork and making of the bits.

Thanks again

Alan

▲

⟩⟩

SelwynWilliams

Dave M

RNinMunich

📝 Thurl pin rack

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 9 Views · 2 Likes

Flag

📝 Reply

Thanks for the reply Doug. Just had a look at the drawing again and it definitely says Thurl pin rack, it's a mystery 😁

Alan

Alan

▲

⟩⟩

SelwynWilliams

Dave M

📝 Thurl pin rack

8 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 7 Views · 0 Likes

Flag

📝 Reply

I am building the Lady T steam tug. The drawing says that the halyards go to the Thurl pin rack, I have looked for images of these on google in order to make some and only come up with cycle racks for cars, but I have found belaying pins, would these be fitted in a rack and be the same thing as a thurl pin rack. As you will have gathered by now, I don't know what the hell I am talking about, so any help would be appreciated.

Alan

Alan

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Speranza 02

9 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 28 Views · 2 Likes

Flag

💬 Add Comment

Watching this with interest.👍

Alan

Alan

▲

⟩⟩

Martin555

Inkoust

📝 Li-Poly batteries

9 years ago by 🇬🇧 AlanP ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 8 Views · 2 Likes

Flag

📝 Reply

By gum, my post woke a lot of people up 😁😁😁

Alan

Alan

▲

⟩⟩

RNinMunich

John2

Commodore)

Commodore)

Liked Wooden ladders 9 years ago

Liked Wooden ladders 9 years ago

Liked 46 Inch Crash Tender - scramble nets 12 years ago

Liked 46 Inch Crash Tender - scramble nets 12 years ago

Liked fireboat update 12 years ago

Liked fireboat update 12 years ago

Liked RC model Lulonga river tug 12 years ago

Liked RC model Lulonga river tug 12 years ago

Followed davidm8 12 years ago

Followed davidm8 12 years ago