Join Us On Social Media!

United States

Recent Posts

📝 Calling it a day.

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 84 Views · 11 Likes

Flag

📝 Reply

It's difficult to find the correct words in circumstances like this, particularly when it involves friends not met.

Thank you for the many modeling insights you have, and will continue to provide.

I wish you peace and comfort in knowing you have friends all over the world.

Thank you for the many modeling insights you have, and will continue to provide.

I wish you peace and comfort in knowing you have friends all over the world.

▲

⟩⟩

Brightwork

BOATSHED

GaryLC

Len1

stevedownunder

Trident73

Wolle

Peejay

Colin H

hermank

Newby7

Login To

Remove Ads

Remove Ads

📝 Death of a member.

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 75 Views · 11 Likes

Flag

📝 Reply

It's a difficult time when one loses a son or daughter.

My heart-felt condolences to you and your family.

My heart-felt condolences to you and your family.

▲

⟩⟩

Ronald

Scratchbuilder

jumpugly

BOATSHED

Colin H

stevedownunder

Mike Stoney

Doogle

Peejay

Len1

hermank

💬 Re: Encore

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 28 Views · 1 Like

Flag

💬 Add Comment

Thank you all!

Chum, it'll be there! Already looking forward to the combined float.

Ron, we'll pin down the day as we get closer! 👍

Hermank, the figures came from a printer on Etsy.

Chum, it'll be there! Already looking forward to the combined float.

Ron, we'll pin down the day as we get closer! 👍

Hermank, the figures came from a printer on Etsy.

▲

⟩⟩

Len1

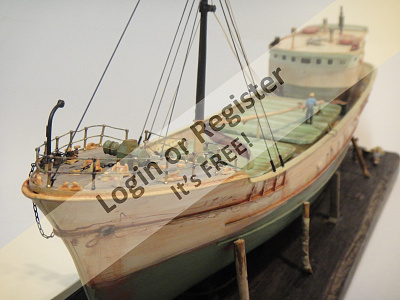

📝 Encore

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 39 Views · 15 Likes · 4 Comments

Flag

💬 Add Comment

I thought the last entry was the last entry. 😊

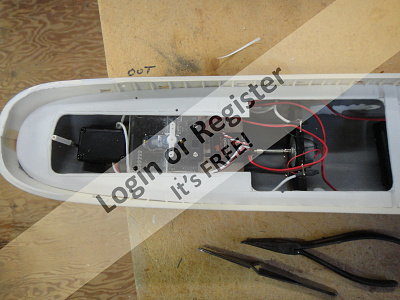

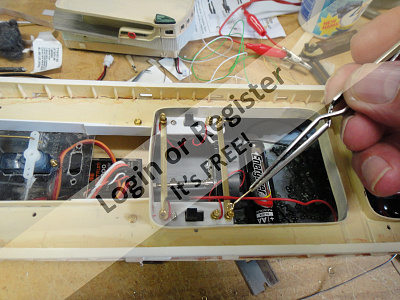

After shelving the launch to wait for the ice to go out and thinking about it a little, it seemed like a good time to add a few lights and a couple more details. I also didn't like having to remove the cabin roof to turn on and off the power. It seemed like an opportunity to break something particularly at pond-side, so moving the power switch was added to the list.

Interior, running, cockpit, and instrument lights were added. The main power switch was moved to a mount under the small hatch forward.

The anchor and boathook was also added.

The boat has been launched and run albeit in a very small area of a very small pond, but I suspect even with a six volt system it'll still operate at speeds somewhat above scale.

After shelving the launch to wait for the ice to go out and thinking about it a little, it seemed like a good time to add a few lights and a couple more details. I also didn't like having to remove the cabin roof to turn on and off the power. It seemed like an opportunity to break something particularly at pond-side, so moving the power switch was added to the list.

Interior, running, cockpit, and instrument lights were added. The main power switch was moved to a mount under the small hatch forward.

The anchor and boathook was also added.

The boat has been launched and run albeit in a very small area of a very small pond, but I suspect even with a six volt system it'll still operate at speeds somewhat above scale.

▲

⟩⟩

Commodore-H

AlessandroSPQR

Rookysailor

roycv

stevedownunder

Graham93

Doogle

Wolle

Len1

peterd

Ronald

EdW

Mike Stoney

Colin H

Chum444

📝 Boat colors

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 37 Views · 4 Likes

Flag

📝 Reply

If you're going to paint the entire bottom, matching a particular color isn't real critical. I've found any reddish-brown ("hot rod") primer to work in the majority of cases. I would agree with Jumpugly that test patches off the boat should be done in any case.

I also understand that enamel will work over lacquer, but lacquer won't do as well over enamel because of the different rates of expansion/contraction enamel being more forgiving.

I also understand that enamel will work over lacquer, but lacquer won't do as well over enamel because of the different rates of expansion/contraction enamel being more forgiving.

▲

⟩⟩

Len1

stevedownunder

Isaac

Colin H

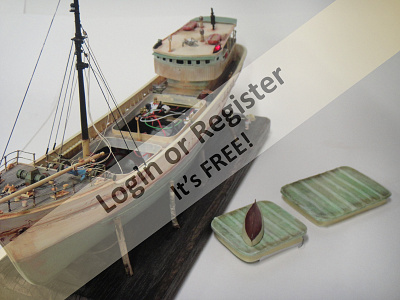

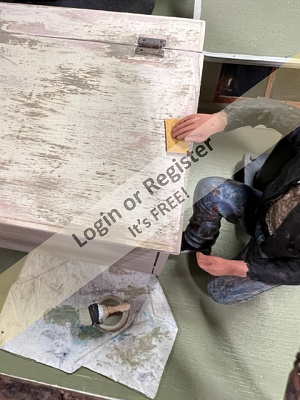

📝 Launch cushions

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 54 Views · 9 Likes · 3 Comments

Flag

💬 Add Comment

Hi Steve,

Glad you found the (probably) last installment of this build. I inadvertently posted it as a comment to a previous installment instead of a new "chapter" of the build log.

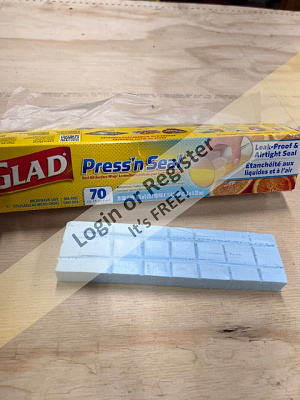

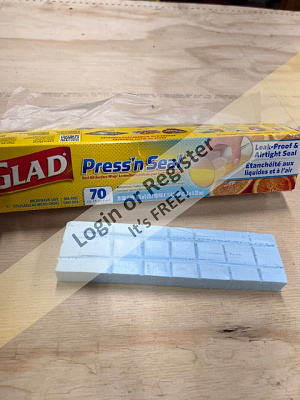

The cushions:

All they are is a piece of rigid closed cell foam used for insulation from a big box store or lumber yard. (I use it cut up and installed in voids for floatation as well.) It can also be found on construction sites as cut-offs in sizes good for our hobby.

The photos:

After a bit of experimenting, here's a quick summary of how these cushions came to be.

Cutting the cushions to size and shape, marking off, filing and sanding the grooves to create the pattern of the sections, rounding off the rough edges, wrapping the part with a kitchen wrapping product. (I have no stake in this company, it just happens to have a little texture to it, sticks well during this process, takes rattle-can paint well, and above all was available in the kitchen cabinet.👍 Some of the spray paints are too "hot" for the foam, but this wrap provides a barrier so the foam isn't effected. I recommend experimenting with the materials at hand to be sure they're compatible. )

Once the wrap is applied the pins were installed to simulate the buttons, CA glued on the backside and cut off if too long. A piece of cord is glued to the outside edge of the cushions to simulate the piping.

A couple light coats of primer, then a color coat.

Glad you found the (probably) last installment of this build. I inadvertently posted it as a comment to a previous installment instead of a new "chapter" of the build log.

The cushions:

All they are is a piece of rigid closed cell foam used for insulation from a big box store or lumber yard. (I use it cut up and installed in voids for floatation as well.) It can also be found on construction sites as cut-offs in sizes good for our hobby.

The photos:

After a bit of experimenting, here's a quick summary of how these cushions came to be.

Cutting the cushions to size and shape, marking off, filing and sanding the grooves to create the pattern of the sections, rounding off the rough edges, wrapping the part with a kitchen wrapping product. (I have no stake in this company, it just happens to have a little texture to it, sticks well during this process, takes rattle-can paint well, and above all was available in the kitchen cabinet.👍 Some of the spray paints are too "hot" for the foam, but this wrap provides a barrier so the foam isn't effected. I recommend experimenting with the materials at hand to be sure they're compatible. )

Once the wrap is applied the pins were installed to simulate the buttons, CA glued on the backside and cut off if too long. A piece of cord is glued to the outside edge of the cushions to simulate the piping.

A couple light coats of primer, then a color coat.

▲

⟩⟩

Mike Stoney

pressonreguardless

Len1

EdW

stevedownunder

River Rat

GaryLC

Colin H

RNinMunich

💬 Re: Harbor Launch

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 57 Views · 6 Likes

Flag

💬 Add Comment

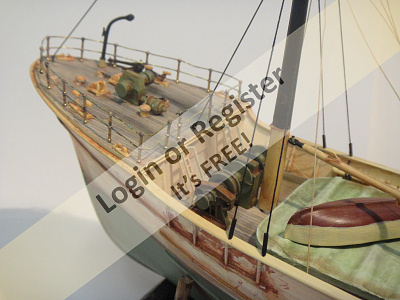

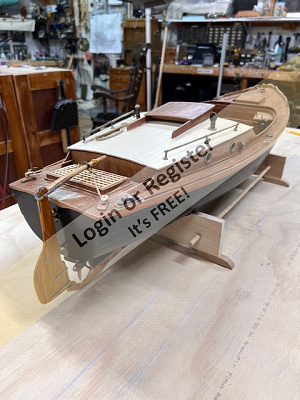

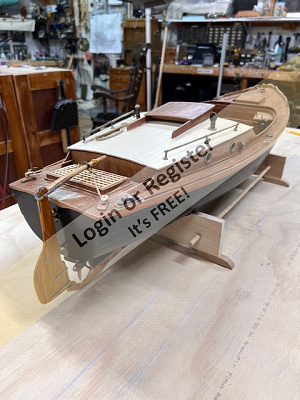

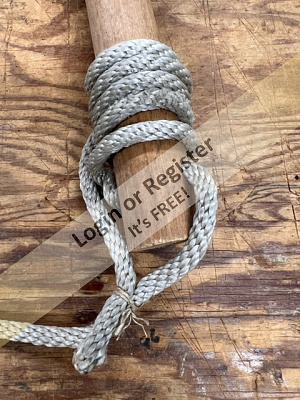

Things are wrapping up on the launch. Other than a "shake-down cruise" (delayed because of ice in the thoroughfare,) and a few added details this project is about as ready as it will be for a spring float.

There were a couple of experiments trying to get the cushions looking like I thought they should. A little more finessing and they should be OK.

The photos:

1. Overall shot of the cockpit.

2. The engine room roof.

3. Cushions

4. Cocks combing on the boat hook, and spliced

stern mooring line.

5. Forward deck and mooring line.

6. Control console. (The toggle switches are

actually very small scale belaying pins

mounted through an #090 nut and a .025"

hole drilled through the console panel.)

7. Rudder, gudgeons, pintles, and tiller mount.

It's difficult to pick out, but there had to be a

lock fabricated to keep the rudder from

floating up under wheel pressure and

disengaging from the gudgeons.

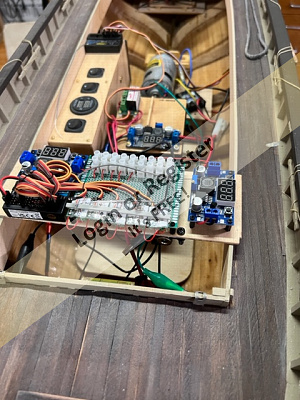

8. The "engine room" which is still being sorted

out. It's functional, but there's a couple more

electrical circuits that need to be added.

9., 10., & 11. Overall shots of the launch.

There were a couple of experiments trying to get the cushions looking like I thought they should. A little more finessing and they should be OK.

The photos:

1. Overall shot of the cockpit.

2. The engine room roof.

3. Cushions

4. Cocks combing on the boat hook, and spliced

stern mooring line.

5. Forward deck and mooring line.

6. Control console. (The toggle switches are

actually very small scale belaying pins

mounted through an #090 nut and a .025"

hole drilled through the console panel.)

7. Rudder, gudgeons, pintles, and tiller mount.

It's difficult to pick out, but there had to be a

lock fabricated to keep the rudder from

floating up under wheel pressure and

disengaging from the gudgeons.

8. The "engine room" which is still being sorted

out. It's functional, but there's a couple more

electrical circuits that need to be added.

9., 10., & 11. Overall shots of the launch.

▲

⟩⟩

Mike Stoney

MartinH2

Peejay

jbkiwi

stevedownunder

RNinMunich

💬 Re: Clinker built sailing dinghy

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 149 Views · 5 Likes

Flag

💬 Add Comment

A good size for some intricate detail!

In my limited skill-set I've found that transferring measurements and particularly converting from one system to another provide me with too many opportunities to go adrift. If I'm working from a set of plans that are correct for the scale I'm using I seldom know (or care,) what the numerical dimension is. Using a pair of navigation dividers I lift the size of a given timber directly from the plan and transfer the points to the material without trying to read a ruler where (for me ) there's too much room for error.😊

In my limited skill-set I've found that transferring measurements and particularly converting from one system to another provide me with too many opportunities to go adrift. If I'm working from a set of plans that are correct for the scale I'm using I seldom know (or care,) what the numerical dimension is. Using a pair of navigation dividers I lift the size of a given timber directly from the plan and transfer the points to the material without trying to read a ruler where (for me ) there's too much room for error.😊

▲

⟩⟩

philcaretaker

Ronald

Graham93

stevedownunder

Peejay

💬 Re: Harbor Launch

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 79 Views · 4 Likes

Flag

💬 Add Comment

Thank you all for the comments!

I spoke with the guy in the photos and shared the concerns posted by Doug. He responded;

"Please relay to Mr. Doug that even though my posture suggests otherwise, I am not enjoying the relief he suggests ~ although two more of these cans and I WILL be ready to pump bilges!

Carry on.....👍"

😊

I spoke with the guy in the photos and shared the concerns posted by Doug. He responded;

"Please relay to Mr. Doug that even though my posture suggests otherwise, I am not enjoying the relief he suggests ~ although two more of these cans and I WILL be ready to pump bilges!

Carry on.....👍"

😊

▲

⟩⟩

Peejay

stevedownunder

Ronald

RNinMunich

📝 Harbor Launch

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 86 Views · 20 Likes · 8 Comments

Flag

💬 Add Comment

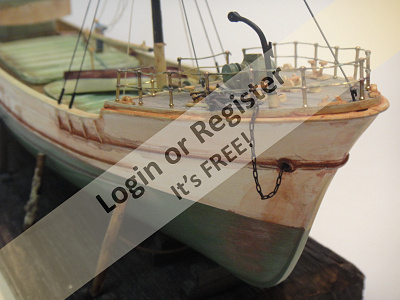

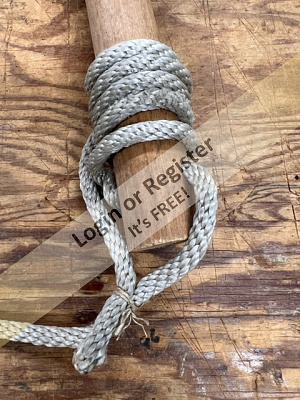

Back to The bench.

A summer of projects around the house, gardens, an old van, and the holidays used a lot of 2023. There were occasional evenings on the bench, but the weather has turned with the calendar and it's time to dust off the launch.

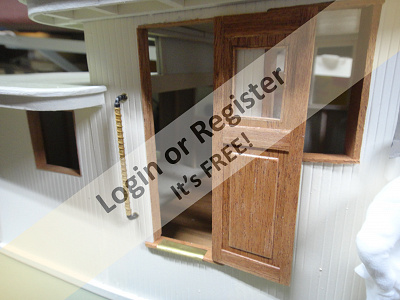

The original design had a sweeping arc as a coaming around the cockpit (shown in an earlier photo) and the foredeck continued under this and terminated in a straight horizontal line. To me it made the coaming look like an after-thought. I used a wall paper steamer and built a steam box to try some pretty severe curves in the cherry wood at the forward corners of the cockpit. There were a couple of pieces that split, but paying close attention to the grain of the wood enhanced the success of the bending. I built a buck just slightly smaller than the contour I needed and clamped the steamed strakes to it allowing them to cool and take a set for a day.

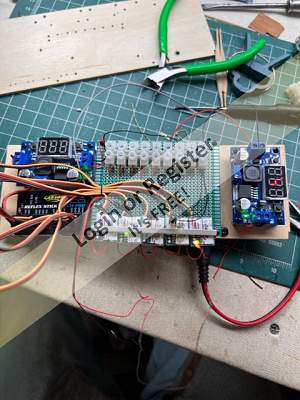

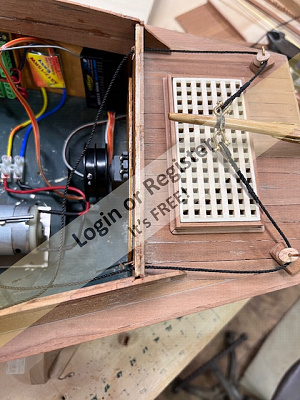

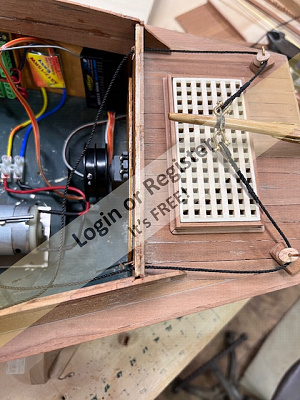

Most of the electronics and electrical components have been temporarily installed in order to prove their effectiveness and determine the trim/ballast requirements.

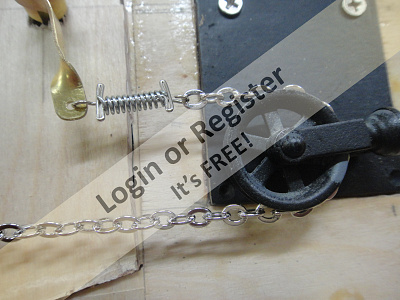

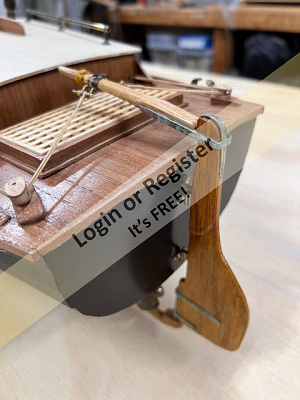

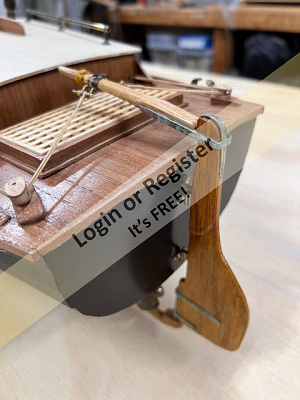

The steering apparatus is a little unusual, in that with an outboard rudder and tiller a conventional rudder post and quadrant inboard forward of the transom wasn't possible. A system of turning blocks and a vertically mounted servo answers to operate the tiller. I used the stock servo arm and although it's relatively short still provides close to the 35 degree rudder port and starboard which is considered maximum effectiveness. (The image below shows the winch pulleys which proved unnecessary. The original thought was a two part purchase that would have needed more line, but the rudder action and size has proved the single line to be sufficient.)

A float test has proven successful in the trim department although a full test under power couldn't be done as at that time the rudder rig wasn't sorted out yet.

Several coats of satin finish have been applied and weathering and fitting the hardware is in the process now. After this is completed it'll be disassembled, sanded, and final finish applied.

The detailing will follow with lines, "stuff", and perhaps running lights.

A summer of projects around the house, gardens, an old van, and the holidays used a lot of 2023. There were occasional evenings on the bench, but the weather has turned with the calendar and it's time to dust off the launch.

The original design had a sweeping arc as a coaming around the cockpit (shown in an earlier photo) and the foredeck continued under this and terminated in a straight horizontal line. To me it made the coaming look like an after-thought. I used a wall paper steamer and built a steam box to try some pretty severe curves in the cherry wood at the forward corners of the cockpit. There were a couple of pieces that split, but paying close attention to the grain of the wood enhanced the success of the bending. I built a buck just slightly smaller than the contour I needed and clamped the steamed strakes to it allowing them to cool and take a set for a day.

Most of the electronics and electrical components have been temporarily installed in order to prove their effectiveness and determine the trim/ballast requirements.

The steering apparatus is a little unusual, in that with an outboard rudder and tiller a conventional rudder post and quadrant inboard forward of the transom wasn't possible. A system of turning blocks and a vertically mounted servo answers to operate the tiller. I used the stock servo arm and although it's relatively short still provides close to the 35 degree rudder port and starboard which is considered maximum effectiveness. (The image below shows the winch pulleys which proved unnecessary. The original thought was a two part purchase that would have needed more line, but the rudder action and size has proved the single line to be sufficient.)

A float test has proven successful in the trim department although a full test under power couldn't be done as at that time the rudder rig wasn't sorted out yet.

Several coats of satin finish have been applied and weathering and fitting the hardware is in the process now. After this is completed it'll be disassembled, sanded, and final finish applied.

The detailing will follow with lines, "stuff", and perhaps running lights.

▲

⟩⟩

MartinH2

Mike Stoney

jbkiwi

Commodore-H

luckyduck

DuncanP

Wolle

mturpin013

EdW

Len1

River Rat

boatmam

Colin H

stevedownunder

hermank

Peejay

RNinMunich

Doogle

Ronald

AlessandroSPQR

💬 Re: A Tug Fort Valley Modification

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 40 Views · 1 Like

Flag

💬 Add Comment

Guessing the format was OK, but when I tried to link the youtube address I used the opposing arrows on either end like I do in an email and the site didn't like them.

Just the address was sufficient.

Just the address was sufficient.

▲

⟩⟩

RNinMunich

Login To

Remove Ads

Remove Ads

💬 Re: A Tug Fort Valley Modification

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 47 Views · 1 Like

Flag

💬 Add Comment

Here you go Doug...👍😊 \/ \/

▲

⟩⟩

RNinMunich

💬 Re: A Tug Fort Valley Modification

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 48 Views · 5 Likes

Flag

💬 Add Comment

Sorry, apparently I have to modify the format to have the forum recognize it.

Working on it...🤞

Working on it...🤞

▲

⟩⟩

Fred

Ronald

River Rat

stevedownunder

Scratchbuilder

💬 Re: A Tug Fort Valley Modification

2 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 50 Views · 3 Likes

Flag

💬 Add Comment

I had an opportunity to get on the pond early this past week. The air was brisk and the pond was like a glass surface.

I managed a short video before the sun got high enough to burn off the "sea smoke".

(This is with the Denes Design vapor "smoker")

I managed a short video before the sun got high enough to burn off the "sea smoke".

(This is with the Denes Design vapor "smoker")

▲

⟩⟩

Scratchbuilder

Ronald

RNinMunich

📝 Navigation lights

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 53 Views · 1 Like

Flag

📝 Reply

Agreed in all aspects of the virtues of the LED's. Cool operating, long life, and a host of available colors. The smallest "chips" can fit into tiny places and easily light up running lights, deck lights, and if run on lower voltage than what they're rated at will produce a lower brightness.

▲

⟩⟩

Len1

📝 Steamboat Paper Moon.

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 59 Views · 2 Likes

Flag

📝 Reply

Very reminiscent of "African Queen".

▲

⟩⟩

dave976

Scratchbuilder

💬 Re: A Tug Fort Valley Modification

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 68 Views · 9 Likes

Flag

💬 Add Comment

Thank you all.

Trev, the gals have been moving around. One talked the "Galley News" skipper into letting her aboard for a short trip, another is checking out the river scene from "Nonesuch", One is in the pilot house of "Fort Valley"(can't find her photo,) the cook in "Fort Valley" hasn't gone anywhere (who has the courage to tell her anything?) and alas, the "dock gal" is still holding down the drums on the RSC dock. 😉

Trev, the gals have been moving around. One talked the "Galley News" skipper into letting her aboard for a short trip, another is checking out the river scene from "Nonesuch", One is in the pilot house of "Fort Valley"(can't find her photo,) the cook in "Fort Valley" hasn't gone anywhere (who has the courage to tell her anything?) and alas, the "dock gal" is still holding down the drums on the RSC dock. 😉

▲

⟩⟩

Fred

Ronald

chugalone100

Colin H

RNinMunich

stevedownunder

Scratchbuilder

hermank

Wolle

💬 Re: A Tug Fort Valley Modification

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 86 Views · 9 Likes

Flag

💬 Add Comment

Chug, I have the sound, just contemplating a diverter valve for the "steam" to coincide with the whistle👍

Doug, There is a small water-side community that is launched and retrieved. "River Supply Co." is animated with sound, lights, doors that operate, and a fish cleaning station with running water.👍😊

Doug, There is a small water-side community that is launched and retrieved. "River Supply Co." is animated with sound, lights, doors that operate, and a fish cleaning station with running water.👍😊

▲

⟩⟩

Ronald

hermank

DWBrinkman

pressonreguardless

RodC

stevedownunder

River Rat

Colin H

chugalone100

💬 Re: A Tug Fort Valley Modification

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 90 Views · 8 Likes

Flag

💬 Add Comment

Thank you.

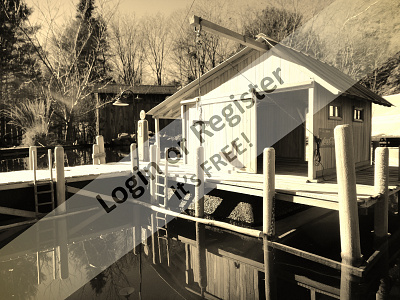

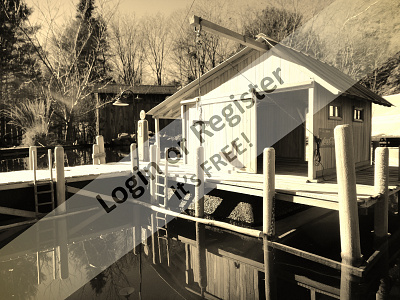

The pond used to be an inground swimming pool that us old folks seldom used. I suggested to my wife that we should convert it to a water garden. (Actually, I needed a small boat test facility bigger than the bath tub and without all the chemicals and maintenance.) Now that it's converted and matured, we spend much more time out there than we ever did when it was a pool.

One point that I need to make is the vapor unit must have a constant power source. It can't operate on the ESC's impulses alone. The module receives the input from the ESC and modifies that signal to control the intensity and pulsing of the vapor which is variable according to the pot(s) settings. There is also the "stand alone" function which is essentially a constant volume/fan setting determined by pot adjustment and (integral) switch position. (There are Youtube videos on this unit.)

The video shows a low speed setting.

The pond used to be an inground swimming pool that us old folks seldom used. I suggested to my wife that we should convert it to a water garden. (Actually, I needed a small boat test facility bigger than the bath tub and without all the chemicals and maintenance.) Now that it's converted and matured, we spend much more time out there than we ever did when it was a pool.

One point that I need to make is the vapor unit must have a constant power source. It can't operate on the ESC's impulses alone. The module receives the input from the ESC and modifies that signal to control the intensity and pulsing of the vapor which is variable according to the pot(s) settings. There is also the "stand alone" function which is essentially a constant volume/fan setting determined by pot adjustment and (integral) switch position. (There are Youtube videos on this unit.)

The video shows a low speed setting.

▲

⟩⟩

Ronald

RodC

stevedownunder

River Rat

Colin H

hermank

RNinMunich

Scratchbuilder

💬 Re: A Tug Fort Valley Modification

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 91 Views · 3 Likes

Flag

💬 Add Comment

Hi Ron, yes, the module in the photo is the control unit which allows adjusting the density and frequency of the vapor through two pots.

▲

⟩⟩

RodC

stevedownunder

Ronald

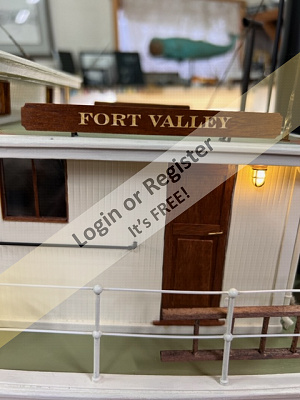

📝 A Tug Fort Valley Modification

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 91 Views · 21 Likes · 23 Comments

Flag

💬 Add Comment

This "chapter" is a follow-up on a modification I've done to the tug. At first it was just an experiment and I didn't know if I'd keep the mod or not, but find I lean towards the new system more than the one I described in the build narrative.

The previous smoker was a standard heated coil using a type of light oil as the smoke producer. It worked fine, produced an ample amount of smoke, and was relatively compact. One time the boat was a long way off when I realized it had run dry. I had no recourse but to run the boat back with fingers crossed that the element didn't burn out or worse. This concerned me and after a couple of conversations about it led me to install a switch on an open channel to isolate the unit if necessary.

I have since installed a water vapor "smoker" from Denes Design.

This vapor is essentially "cold steam" that DD has developed a control module for and provides several different modes of operation that includes vapor density, pulse length or continual. It can follow the ESC's RPM and operates on plain water. There's no heat, no oil, no mess, and the worst that may happen is a few drops of water may end up in the bilge if condensate from the stack runs back.

Topped up with water the unit weighs three-four ounces more than the oil based smoker I had installed, but for this tug that weight doesn't impact the stability even though the unit is mounted under the deckhouse roof. In a conventional mounting in the hull it wouldn't be an issue at all.

I don't recall the price of the oil per ounce, but do know a gallon of distilled water in this area is $3.00 USD - enough for most of an entire season.

I don't know if the video will come up, but I've also posted a couple of stills with the unit operating.

The previous smoker was a standard heated coil using a type of light oil as the smoke producer. It worked fine, produced an ample amount of smoke, and was relatively compact. One time the boat was a long way off when I realized it had run dry. I had no recourse but to run the boat back with fingers crossed that the element didn't burn out or worse. This concerned me and after a couple of conversations about it led me to install a switch on an open channel to isolate the unit if necessary.

I have since installed a water vapor "smoker" from Denes Design.

This vapor is essentially "cold steam" that DD has developed a control module for and provides several different modes of operation that includes vapor density, pulse length or continual. It can follow the ESC's RPM and operates on plain water. There's no heat, no oil, no mess, and the worst that may happen is a few drops of water may end up in the bilge if condensate from the stack runs back.

Topped up with water the unit weighs three-four ounces more than the oil based smoker I had installed, but for this tug that weight doesn't impact the stability even though the unit is mounted under the deckhouse roof. In a conventional mounting in the hull it wouldn't be an issue at all.

I don't recall the price of the oil per ounce, but do know a gallon of distilled water in this area is $3.00 USD - enough for most of an entire season.

I don't know if the video will come up, but I've also posted a couple of stills with the unit operating.

▲

⟩⟩

Fred

Rookysailor

Colin H

AlessandroSPQR

MartinW

dave976

MouldBuilder

boatmam

GaryLC

ChrisG

Len1

stevedownunder

River Rat

Doogle

hermank

pressonreguardless

chugalone100

Scratchbuilder

Wolle

RNinMunich

Ronald

Login To

Remove Ads

Remove Ads

📝 Steam Generator which is follow the throttle arm

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 29 Views · 3 Likes

Flag

📝 Reply

Concerning these smoker units- I have a couple of them and I like the concept of not developing unnecessary heat in my models, not to mention the water vapor is much more in keeping with a steam vessel as it reacts to atmospheric conditions and the only residue is water - topside and engine room.

Another perhaps even more important item about these units is the customer assistance provided by Denes Design. As I mentioned I have two of these units and both of them worked flawlessly when they arrived. Alas, after trying to operate them like I did the oil-type smoker I compromised both control modules.

At the risk of being too long winded, I'll explain my fault as it may save someone else the same fate:

I had the oil type smoker set up on an independent ESC so I could turn on/off the unit and increase or decrease the amount of smoke at will through a potentiometer in my transmitter. Obviously, the output of the ESC varied which the heating element didn't mind. The Denes Design units want a constant voltage to the control module and relies on a signal from the receiver to increase/decrease the volume of vapor consonant with the shaft RPM. The way I tried to hook up the unit (I used the ESC output as the power source to the DD control module,) allowed the voltage to fluctuate from 0 to 12V and if I wasn't careful the polarity could be changed (as the ESC thought the boat was backing up) which was also detrimental as voltage polarity is critical to the Denes Design.

I contacted DD via email, described what I had done and received a very civil and thorough trouble-shooting email within hours describing how to determine the severity of the failure and how to remedy the issue.

I suspect other providers would have been more than happy to just sell me another unit citing my failure to follow the instructions.

In short, the units work great and the help from DD is exceptional.👍

Another perhaps even more important item about these units is the customer assistance provided by Denes Design. As I mentioned I have two of these units and both of them worked flawlessly when they arrived. Alas, after trying to operate them like I did the oil-type smoker I compromised both control modules.

At the risk of being too long winded, I'll explain my fault as it may save someone else the same fate:

I had the oil type smoker set up on an independent ESC so I could turn on/off the unit and increase or decrease the amount of smoke at will through a potentiometer in my transmitter. Obviously, the output of the ESC varied which the heating element didn't mind. The Denes Design units want a constant voltage to the control module and relies on a signal from the receiver to increase/decrease the volume of vapor consonant with the shaft RPM. The way I tried to hook up the unit (I used the ESC output as the power source to the DD control module,) allowed the voltage to fluctuate from 0 to 12V and if I wasn't careful the polarity could be changed (as the ESC thought the boat was backing up) which was also detrimental as voltage polarity is critical to the Denes Design.

I contacted DD via email, described what I had done and received a very civil and thorough trouble-shooting email within hours describing how to determine the severity of the failure and how to remedy the issue.

I suspect other providers would have been more than happy to just sell me another unit citing my failure to follow the instructions.

In short, the units work great and the help from DD is exceptional.👍

▲

⟩⟩

Mike Stoney

Fred

Dainesh

📝 Losing interest.

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 70 Views · 13 Likes

Flag

📝 Reply

I lost a 17 year old son to a car accident in '87 and last Sept a 59 year old son to a brain tumor. I don't mention this for sympathy, but only to affirm that I understand.

There's not a day goes by that I don't think of both of them. There is certainly a period of grief that we endure, then it is up to us to decide how we move forward. How would the departed want us to continue?

I don't mean to come across trite, or to take these circumstances lightly because they are arguably the hardest things in life to deal with, but my thoughts are ~ as long as their memory and the good times are alive in my heart, my sons have only passed from view. They could be in another room or another town.

My faith tells me we will be reunited again.

There's not a day goes by that I don't think of both of them. There is certainly a period of grief that we endure, then it is up to us to decide how we move forward. How would the departed want us to continue?

I don't mean to come across trite, or to take these circumstances lightly because they are arguably the hardest things in life to deal with, but my thoughts are ~ as long as their memory and the good times are alive in my heart, my sons have only passed from view. They could be in another room or another town.

My faith tells me we will be reunited again.

▲

⟩⟩

HappyHaggis

Scratchbuilder

Ronald

stevedownunder

GaryLC

Rookysailor

RNinMunich

Newby7

jacko

Colin H

hermank

River Rat

Nickthesteam

📝 In for a Dip

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 34 Views · 5 Likes

Flag

📝 Reply

Hi folks, sorry I'm late.

I had a piece of wooden closet rod that I cut to length, and drilled 1/4" holes in each end to accommodate some braided nylon clothesline. I put several more inches of line on the rods then I needed just to make them a little adjustable. In practice we're not going to have our hands much higher than chest level when we pick up the boats anyway, so too much line will just get in the way.

I took the metal hooks off of a couple of rubber bungee/tie-down straps and replaced them with the clothes line which is seized at the eyes. The standing part of the line is passed through the drilled hole in the rods and a simple overhand knot maintains the correct length of line.

I had a piece of wooden closet rod that I cut to length, and drilled 1/4" holes in each end to accommodate some braided nylon clothesline. I put several more inches of line on the rods then I needed just to make them a little adjustable. In practice we're not going to have our hands much higher than chest level when we pick up the boats anyway, so too much line will just get in the way.

I took the metal hooks off of a couple of rubber bungee/tie-down straps and replaced them with the clothes line which is seized at the eyes. The standing part of the line is passed through the drilled hole in the rods and a simple overhand knot maintains the correct length of line.

▲

⟩⟩

stevedownunder

Commodore-H

Colin H

Len1

RodC

📝 In for a Dip

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 78 Views · 7 Likes

Flag

📝 Reply

Having had a couple of close calls myself I've resorted to straps. It seems the older one gets the higher the center of gravity becomes. I'm not particularly afraid of getting wet and incurring the mirth of the other captains in the area, but the potential damage to the boat concerns me.😊

▲

⟩⟩

pressonreguardless

cyril413

stevedownunder

DWBrinkman

Scratchbuilder

hermank

cdnfurball

📝 What Paint Do Members Use?

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 79 Views · 7 Likes

Flag

📝 Reply

All of my RC boats have been painted by brush with acrylic samples from Lowes or Home Depot. I like the water cleanup, no smell, and they're tough enough. If a boat gets scratched, I'd touch it up, but the paint is tough enough that so far I haven't had the need.

Another plus is any color can be made from the color cards in the rack. $6 (US) will paint a large tug (Fort Valley) three times with paint left over.

All of the colors can be mixed with each other with no worries.

Another plus is any color can be made from the color cards in the rack. $6 (US) will paint a large tug (Fort Valley) three times with paint left over.

All of the colors can be mixed with each other with no worries.

▲

⟩⟩

stevedownunder

Ronald

Colin H

firefighter

Mike Stoney

hermank

RodC

📝 Launch

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 101 Views · 13 Likes · 4 Comments

Flag

💬 Add Comment

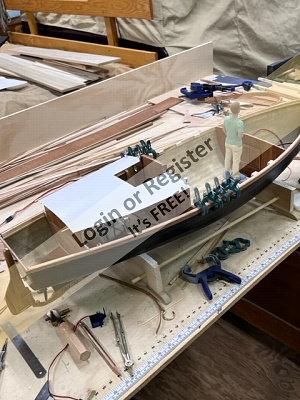

Managed to get the cockpit decking completed as well as the benches on either side. The benches will have a couple of turned spindles each to support them on the inboard side. I'll make a couple of cushions for the benches a little later.

I need to turn to the mechanical side before much more topside work, but I have to shelve the project for a week or better and get some yard work done since the majority of the snow is gone.

I need to turn to the mechanical side before much more topside work, but I have to shelve the project for a week or better and get some yard work done since the majority of the snow is gone.

▲

⟩⟩

MartinH2

Peejay

Doogle

pressonreguardless

MotoPilot

stevedownunder

RNinMunich

mturpin013

Colin H

flaxbybuck

MouldBuilder

hermank

jbkiwi

📝 Very sad news about Nerys plus update on her final boat project

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 93 Views · 13 Likes

Flag

📝 Reply

Alice, I just learned of Newry's passing. I'm so sorry to hear this. I wish I had met her in person as reading her posts I'm sure she would have been one of my favorite people instantly.

Please know that we all share in your loss.

Please know that we all share in your loss.

▲

⟩⟩

figtree7nts

hermank

Scratchbuilder

firefighter

stevedownunder

mturpin013

dave976

GaryLC

pressonreguardless

Newby7

Colin H

RNinMunich

MouldBuilder

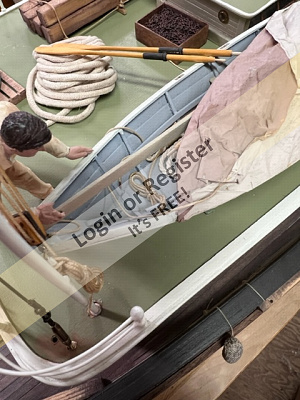

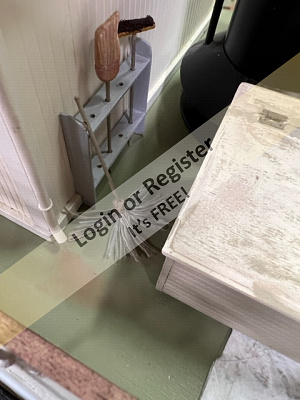

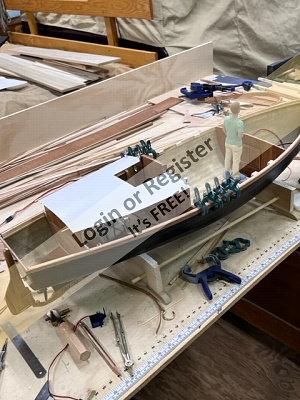

📝 Launch update part II

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 113 Views · 11 Likes · 2 Comments

Flag

💬 Add Comment

Thank you for the comments!

Just a very quick update before I begin the trying and fitting, trying and fitting, repeat, repeat, repeat.

These are the things that take such a long time and very little progress shows.

The first two photos show the general arrangement of the deck and coaming that will take some time to finesse.

I'm reluctant to hazard what the fellow in the third image is thinking. Most likely not appropriate for a family site such as this.

Just a very quick update before I begin the trying and fitting, trying and fitting, repeat, repeat, repeat.

These are the things that take such a long time and very little progress shows.

The first two photos show the general arrangement of the deck and coaming that will take some time to finesse.

I'm reluctant to hazard what the fellow in the third image is thinking. Most likely not appropriate for a family site such as this.

▲

⟩⟩

MartinH2

pressonreguardless

GaryLC

stevedownunder

RNinMunich

MouldBuilder

jbkiwi

flaxbybuck

Peejay

Colin H

hermank

📝 Launch update

3 years ago by 🇺🇸 Black Shoe ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 113 Views · 10 Likes · 3 Comments

Flag

💬 Add Comment

There hasn't been a lot of progress that shows, but some of the mundane items have been tended to. The forward and main bulkheads are epoxied in permanently after attaching the hatches closer hardware.

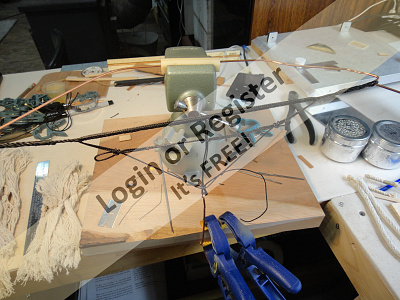

Patterns for the deck and cabin roof have been made and the false deck/roof laid out and roughed to shape. Still a lot of finesse is needed for a good fit.

I've also made up five sets of frames and marked the hull where they're to be installed. These frames are not required for this hull, but will be installed to facilitate attaching the floor stringers, fuel tank brackets, and seat stringer.

Photos:

1.thru 4. making up patterns and fitting the false deck and cabin roof, plus the rudder and wheel arrangement.

5. & 6. Laying out and marking the frame stations.

7. thru 9. The forward bulkhead and cabin hatches fastening method. these are just a small hook at the bottom of the hatch to retain the bottoms in place and a small magnet glued to the top corners which engage tin flashing shaped around and glued to the strip jams.

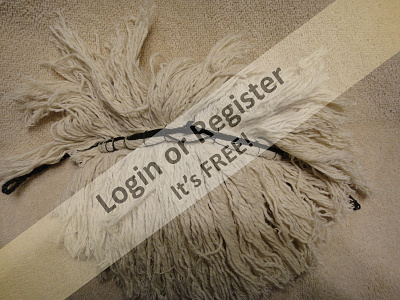

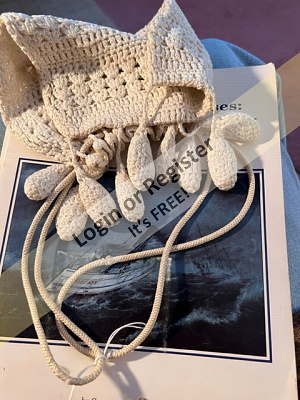

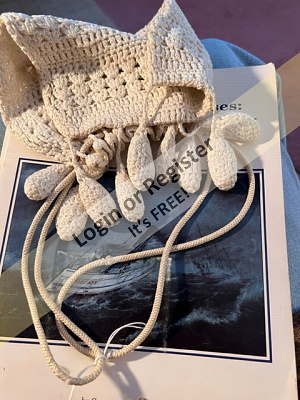

10. As with other builds I have found "fenders" in some most unlikely places. I have also "trained" my adult daughter (who frequents antique stores and flea markets ,) to keep an eye out for crochet tassels as found on some home made ladies purses and hand bags. She sent me this find recently which will produce nine excellent fenders for this build. With what she paid for the purse, the fenders come out to less than a dollar (US) a piece. I couldn't make them for that.

Patterns for the deck and cabin roof have been made and the false deck/roof laid out and roughed to shape. Still a lot of finesse is needed for a good fit.

I've also made up five sets of frames and marked the hull where they're to be installed. These frames are not required for this hull, but will be installed to facilitate attaching the floor stringers, fuel tank brackets, and seat stringer.

Photos:

1.thru 4. making up patterns and fitting the false deck and cabin roof, plus the rudder and wheel arrangement.

5. & 6. Laying out and marking the frame stations.

7. thru 9. The forward bulkhead and cabin hatches fastening method. these are just a small hook at the bottom of the hatch to retain the bottoms in place and a small magnet glued to the top corners which engage tin flashing shaped around and glued to the strip jams.

10. As with other builds I have found "fenders" in some most unlikely places. I have also "trained" my adult daughter (who frequents antique stores and flea markets ,) to keep an eye out for crochet tassels as found on some home made ladies purses and hand bags. She sent me this find recently which will produce nine excellent fenders for this build. With what she paid for the purse, the fenders come out to less than a dollar (US) a piece. I couldn't make them for that.

▲

⟩⟩

MartinH2

jbkiwi

Peejay

pressonreguardless

stevedownunder

RNinMunich

MouldBuilder

Colin H

hermank

Ronald

Commodore)

Commodore)

Rear Admiral)

Rear Admiral)

Fleet Admiral)

Fleet Admiral)

Liked The eve of another year 2 months ago

Liked The eve of another year 2 months ago