Join Us On Social Media!

Australia

Recent Posts

📝 nimih battery

3 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 47 Views · 5 Likes

Flag

📝 Reply

Stephen I regularly run two NiMhi 5 AH batteries in parallel. I always use identical batteries purchased at the same time. I would never use batteries of differing amp hour ratings in parallel. I have been unable to find any NiMHi battery rated above 6.5 AH.

▲

⟩⟩

thadlietz

hermank

Steves-s

RodC

AlessandroSPQR

Login To

Remove Ads

Remove Ads

📝 How do you create the coiled ropes?

3 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 25 Views · 4 Likes

Flag

📝 Reply

Hi All

I always thought the spiraled rope or concentric circles etc was referred to as cheesing the rope. My late dad who was a seaman rigger referred to lines prepared in this way as cheesed.

Bob

I always thought the spiraled rope or concentric circles etc was referred to as cheesing the rope. My late dad who was a seaman rigger referred to lines prepared in this way as cheesed.

Bob

▲

⟩⟩

Chum444

jumpugly

hermank

AlessandroSPQR

📝 How do you create the coiled ropes?

3 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 42 Views · 9 Likes

Flag

📝 Reply

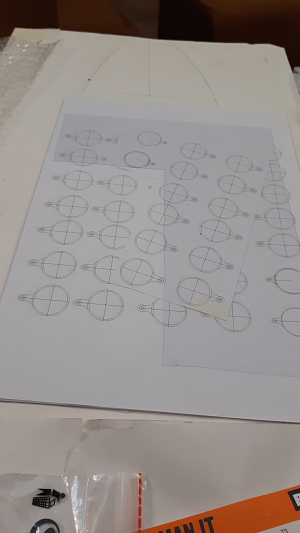

I created a very short video on rope coils hope it uploads OK. It should explain how I do it. I think with a bit of luck you can finish off the coils in different ways.

I have used this jig on a number 72 scale models.

Bob

I have used this jig on a number 72 scale models.

Bob

▲

⟩⟩

LIBERTY CAPTAIN

Madwelshman

SimpleSailor

JockScott

hermank

RNinMunich

AlessandroSPQR

EdW

jumpugly

📝 How do you create the coiled ropes?

4 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 51 Views · 2 Likes

Flag

📝 Reply

Alessandro Thanks for the reply but unsure what you mean by "do you all cross the grays or do you make them linear"

▲

⟩⟩

hermank

AlessandroSPQR

📝 How do you create the coiled ropes?

4 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 63 Views · 5 Likes

Flag

📝 Reply

No Youtube channel. But you just coil the line around the two teeth of the jig, tie the coil off and attach it to the rope on the boat. Looks quite effective and you can produce consistent looking coils.

▲

⟩⟩

Steves-s

hermank

Steve P

jumpugly

AlessandroSPQR

📝 How do you create the coiled ropes?

4 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 61 Views · 7 Likes

Flag

📝 Reply

▲

⟩⟩

Madwelshman

Steves-s

Chum444

jumpugly

hermank

AlessandroSPQR

LIBERTY CAPTAIN

📝 How do you create the coiled ropes?

4 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 59 Views · 5 Likes

Flag

📝 Reply

Hi All

I drew and 3d printed a little jig, in fact it can be scaled to suit. Just wrap the line around until you get the desired thickness. The gap in the teeth allows you to put a half hitch to hold the coil. If anyone is interested I could upload the STL file, but you will have to tell me how I can do this on our forum.

I drew and 3d printed a little jig, in fact it can be scaled to suit. Just wrap the line around until you get the desired thickness. The gap in the teeth allows you to put a half hitch to hold the coil. If anyone is interested I could upload the STL file, but you will have to tell me how I can do this on our forum.

▲

⟩⟩

Madwelshman

Steves-s

jumpugly

hermank

AlessandroSPQR

📝 3D Printed Models

5 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 28 Views · 5 Likes

Flag

📝 Reply

Tim

I have ABS 3D printed parts as small as 72 scale that are over 10 years old and have not deteriorated at all. Others in our Association have parts that are much older and still no signs of and breakdown. Granted they are painted but I do have parts in my spares boxes, some 15 years old and no sign of deterioration and they have not been painted.

I very much enjoy 3D modelling it is one the most attractive aspects of the hobby. Although these days I use a combination of 3D Printing, CNC and Styrene stock to make most parts. Determining just how the part will be manufactured is very enjoyable. I will admit I do not always get this right first time around but you learn from every mistake.

I have ABS 3D printed parts as small as 72 scale that are over 10 years old and have not deteriorated at all. Others in our Association have parts that are much older and still no signs of and breakdown. Granted they are painted but I do have parts in my spares boxes, some 15 years old and no sign of deterioration and they have not been painted.

I very much enjoy 3D modelling it is one the most attractive aspects of the hobby. Although these days I use a combination of 3D Printing, CNC and Styrene stock to make most parts. Determining just how the part will be manufactured is very enjoyable. I will admit I do not always get this right first time around but you learn from every mistake.

▲

⟩⟩

EdW

Steves-s

jumpugly

RodC

AlessandroSPQR

📝 3D Printed Models

5 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 44 Views · 5 Likes

Flag

📝 Reply

Thanks Lew that is clearer now. I use a combination of 3D printing, CNC for parts that are flat and styrene rods and bars both rectangular and round. Also I have used brass and regularly use cerated nuts which can be mounted into the 3D print using heat or softening with glue. This allows parts to be unscrewed. Whilst I still use 3D printing exclusively for my parts and swear by it I augment the manufacturing process as described above.

Bob

Bob

▲

⟩⟩

RodC

jumpugly

hermank

tim morland

LewZ

📝 3D Printed Models

5 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 46 Views · 3 Likes

Flag

📝 Reply

Lew not entirely sure what you are driving at but some time ago I tried some of the more exotic filaments including polycardonates. I even invested in a device that would smooth them using an alcohol bath. Whilst the parts themselves turned out very well the issue was sticking them to the model. I found the flexible superglue was best but the failure rate was just too high. The smooth surface was just too smooth I guess. Since then I have stuck exclusively with ABS + as I can reliably attach the fittings to the model.

I also use brass to make various fittings or parts of fittings. I also use styrene rods and pipes to augment some of the 3D printed parts.

Hope this is of some value.

I also use brass to make various fittings or parts of fittings. I also use styrene rods and pipes to augment some of the 3D printed parts.

Hope this is of some value.

▲

⟩⟩

hermank

RodC

RNinMunich

📝 Lost Transmitter

5 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 60 Views · 2 Likes

Flag

📝 Reply

Hope this is not too simplistic. Can you describe what electronics that you can see? for example can you identify the receiver, Speed controllers and servo? If so then there should be leads running to the receiver, and can these be unplugged? In this case you should be able to replace just the radio gear. If not then you probably have an integrated receiver and speed controller unit which only works with the transmitter provided. Hope this may be of some help

▲

⟩⟩

RodC

hermank

Login To

Remove Ads

Remove Ads

📝 Bloody AliExpress

5 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 64 Views · 7 Likes

Flag

📝 Reply

I have dealt with AliExpress for over a decade and overwhelmingly the service has been excellent. However, on a few occasions things have gone missing or have been damaged in transit. One thing I always do in such cases is deal directly with AliExpress and not the seller. I have had situations where the seller says they will refund or will do something and when I have brought this to the attention of AliExpress the matter has been dealt with expeditiously.

I did have one situation where I got a refund for a package that was not delivered, I re-ordered it and received the items. Some six weeks later I received the original package. I was happy to return the original package and contacted AliExpress they said to contact the seller. The seller took some time to get back to me and kept saying that they had refunded me, which they had. I even offered to pay for the item which I was happy to add to my stock but this proved difficult for them to understand. After 10 or so emails back and forth it appears they still thought I was trying to get a refund. So the AliExpress system does not seem to cope with anything out of the ordinary.

I did have one situation where I got a refund for a package that was not delivered, I re-ordered it and received the items. Some six weeks later I received the original package. I was happy to return the original package and contacted AliExpress they said to contact the seller. The seller took some time to get back to me and kept saying that they had refunded me, which they had. I even offered to pay for the item which I was happy to add to my stock but this proved difficult for them to understand. After 10 or so emails back and forth it appears they still thought I was trying to get a refund. So the AliExpress system does not seem to cope with anything out of the ordinary.

▲

⟩⟩

PeterL3

Steves-s

RodC

DuncanP

Madwelshman

Nickthesteam

SouthportPat

📝 White lead and glues?????? frustrated

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 31 Views · 1 Like

Flag

📝 Reply

Algon

They go hard but not brittle. The ones I have dry transparent. We, my building buddies and I, use this glue as our go to for attaching painted parts or anything to fiberglass. We had had excellent results with it.

Bob

They go hard but not brittle. The ones I have dry transparent. We, my building buddies and I, use this glue as our go to for attaching painted parts or anything to fiberglass. We had had excellent results with it.

Bob

▲

⟩⟩

hermank

📝 White lead and glues?????? frustrated

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 38 Views · 2 Likes

Flag

📝 Reply

Hi

Try this superglue we have successfully glued all manner of things including leather and various metals. It is the best superglue I have used.

Perhaps worth a try.

Try this superglue we have successfully glued all manner of things including leather and various metals. It is the best superglue I have used.

Perhaps worth a try.

▲

⟩⟩

hermank

algon

📝 3D Printed Models

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 49 Views · 7 Likes

Flag

📝 Reply

Hi All

Just thought I would add some more to the conversation. As I said before I have hundreds of hours invested into Fusion 360 the CAD program I use. Also I only use one filament ABS + and I know the settings to use depending on the size and intricacy of the model. When I go to print I just want the part to print as reliably as possible. For some people 3D printing seems to be a hobby in itself and they get a kick out experimenting with new filaments and good for them. On the other hand I am looking for the most efficient and reliable way to produce the part and it works for me.

Also as I work mainly in HIPS to make decks and superstructures etc. To attach 3D parts I can use a glue made from MEK and styrene which works very well. So whilst I can make almost anything from ships boats to armaments reliably down to 72 scale I stick to just a single way of production.

This thread has been very valuable in understanding how others use the technology and who knows perhaps I will get more adventurous in future. It does show that there are always other alternatives and perhaps we should experiment and move out of our comfort zone.

Again thanks to all those who have contributed.

Just thought I would add some more to the conversation. As I said before I have hundreds of hours invested into Fusion 360 the CAD program I use. Also I only use one filament ABS + and I know the settings to use depending on the size and intricacy of the model. When I go to print I just want the part to print as reliably as possible. For some people 3D printing seems to be a hobby in itself and they get a kick out experimenting with new filaments and good for them. On the other hand I am looking for the most efficient and reliable way to produce the part and it works for me.

Also as I work mainly in HIPS to make decks and superstructures etc. To attach 3D parts I can use a glue made from MEK and styrene which works very well. So whilst I can make almost anything from ships boats to armaments reliably down to 72 scale I stick to just a single way of production.

This thread has been very valuable in understanding how others use the technology and who knows perhaps I will get more adventurous in future. It does show that there are always other alternatives and perhaps we should experiment and move out of our comfort zone.

Again thanks to all those who have contributed.

▲

⟩⟩

Steves-s

hermank

Len1

SimpleSailor

tim morland

Nickthesteam

AlessandroSPQR

📝 3D Printed Models

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 40 Views · 6 Likes

Flag

📝 Reply

This is a very interesting topic and thanks to all those who have contributed. A few years ago I bought the parts for a stand alone CNC machine and made it. It took over three months to build and get right. For me this has been a game changer in that it can produce all the flat parts very accurately which can then be combined perfectly with 3D printed parts. This has required a slight shift in thinking in designing these combined parts but I have found it to be quite rewarding. Put simply the CNC has added yet another dimension to my modelling.

▲

⟩⟩

Steves-s

Len1

hermank

Nickthesteam

RodC

AlessandroSPQR

📝 3D Printed Models

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 58 Views · 4 Likes

Flag

📝 Reply

I agree with Lew. 3D modelling is a very significant part of the hobby for me, I spend many happy and rewarding hours drawing parts for my models. I have developed many useful techniques to be able to draw complex components for my models.

To simply buy a 3D printer and use existing designs is as far as I am concerned the same as simply buying parts and using them on models. To be able to draw your own parts and print them provides a certain freedom and creativity which greatly improves my hobby. I also use CNC to augment the 3d modelling that I do and this greatly improve the quality of the models produced. Once a part is produced you can determine if some components can be made using a CNC machine.

To sum up I have literally hundreds of hours invested in the 3D modelling skills I use in the hobby. I know many people who criticise 3D printing as cheating but I do not know of anyone who actually has the skills to do it and has this view.

Bob

To simply buy a 3D printer and use existing designs is as far as I am concerned the same as simply buying parts and using them on models. To be able to draw your own parts and print them provides a certain freedom and creativity which greatly improves my hobby. I also use CNC to augment the 3d modelling that I do and this greatly improve the quality of the models produced. Once a part is produced you can determine if some components can be made using a CNC machine.

To sum up I have literally hundreds of hours invested in the 3D modelling skills I use in the hobby. I know many people who criticise 3D printing as cheating but I do not know of anyone who actually has the skills to do it and has this view.

Bob

▲

⟩⟩

Len1

SimpleSailor

jumpugly

LewZ

📝 ESC For Twin Screwed Boats

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 44 Views · 7 Likes

Flag

📝 Reply

▲

⟩⟩

Len1

EdW

jumpugly

RodC

LewZ

AlessandroSPQR

hermank

📝 ESC For Twin Screwed Boats

7 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 44 Views · 3 Likes

Flag

📝 Reply

Pat

We always use two separate speed controllers and wire them up as shown. We have used this approach for over 15 years and have had no issues. Hope it may help

We always use two separate speed controllers and wire them up as shown. We have used this approach for over 15 years and have had no issues. Hope it may help

▲

⟩⟩

jumpugly

AlessandroSPQR

hermank

📝 Flysky radio behaving erraticly

10 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 34 Views · 3 Likes

Flag

📝 Reply

Apologies not all of the binding process copied across

Binding a Model

Binding is done to link the radio model setting to a receiver. The receiver is only able to connect to a single radio model. In other words if the receiver has been bound to model 3 then it will only work on model 3. If the radio is set to model 2 then it will not work. To bind a model complete the steps listed below. Binding requires the model to be switched on before radio which is opposite to the way you usually operate your radio.

1. Turn on the radio and ensure it is set to the correct model. This is quite critical because if the radio is not set correctly you will “break” the previous bind for that model and that previous link will no longer work.

2. Turn off the radio

3. Ensure the receiver is correctly connected to the model power supply. This will vary if you are using speed controller with a BEC or a separate battery for the receiver.

4. Turn on the boat and the receiver should flash. This checks the boat system

5. Turn off the boat and insert the bind plug into the B/VCC socket

6. Turn on the boat and the receiver should be flashing rapidly at least more rapidly that it did originally.

7. Before turning on your radio ensure all switches are up and the throttle is down.

8. Hold down the bind button and keep it down, now turn on the radio and it will say binding. The receiver will now stop flashing rapidly which means binding process is almost complete.

9. To complete binding remove the bind plug.

10. Then turn off the radio

11. Finally turn off the boat

12. Binding is now complete. You can now operate the model using the procedure for Operating a Boat described above.

Binding a Model

Binding is done to link the radio model setting to a receiver. The receiver is only able to connect to a single radio model. In other words if the receiver has been bound to model 3 then it will only work on model 3. If the radio is set to model 2 then it will not work. To bind a model complete the steps listed below. Binding requires the model to be switched on before radio which is opposite to the way you usually operate your radio.

1. Turn on the radio and ensure it is set to the correct model. This is quite critical because if the radio is not set correctly you will “break” the previous bind for that model and that previous link will no longer work.

2. Turn off the radio

3. Ensure the receiver is correctly connected to the model power supply. This will vary if you are using speed controller with a BEC or a separate battery for the receiver.

4. Turn on the boat and the receiver should flash. This checks the boat system

5. Turn off the boat and insert the bind plug into the B/VCC socket

6. Turn on the boat and the receiver should be flashing rapidly at least more rapidly that it did originally.

7. Before turning on your radio ensure all switches are up and the throttle is down.

8. Hold down the bind button and keep it down, now turn on the radio and it will say binding. The receiver will now stop flashing rapidly which means binding process is almost complete.

9. To complete binding remove the bind plug.

10. Then turn off the radio

11. Finally turn off the boat

12. Binding is now complete. You can now operate the model using the procedure for Operating a Boat described above.

▲

⟩⟩

AlessandroSPQR

Len1

DuncanP

📝 Flysky radio behaving erraticly

10 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 34 Views · 2 Likes

Flag

📝 Reply

Our Association has a Guide for members on the Flysky I6 Radio here is the section on setting up a new model below, hope it is of some help. The chattering with the servos can be caused by interference if they are digital servos. You can usually resolve this by winding the lead through a ferrite core. I have seen this work before when the servos were chattering like in your posted video.

Setting up a New Model

When you have completed or acquired a new model and want to set your radio to operate it follow these steps.

1. Turn on your radio

2. Press the OK key you will see two icons System and Setup

3. As System is highlighted press OK again

4. You will see model select as the first option highlighted press OK again to select

5. You can now move through your models see selecting models above, simply choose the next available model you are not currently using.

6. Press and hold the cancel button this will save your selection.

7. Always check that the radio is set to this new model by clicking the OK button again.

8. Once you have confirmed you have selected the correct model then turn off the radio and go through the binding process as below.

Binding a Model

Binding is done to link the radio model setting to a receiver. The receiver is only able to connect to a single radio model. In other words if the receiver has been bound to model 3 then it will only work on model 3. If the radio is set to model 2 then it will not work. To bind a model complete the steps listed below. Binding requires the model to be switched on before radio which is opposite to the way you usually operate your radio.

Setting up a New Model

When you have completed or acquired a new model and want to set your radio to operate it follow these steps.

1. Turn on your radio

2. Press the OK key you will see two icons System and Setup

3. As System is highlighted press OK again

4. You will see model select as the first option highlighted press OK again to select

5. You can now move through your models see selecting models above, simply choose the next available model you are not currently using.

6. Press and hold the cancel button this will save your selection.

7. Always check that the radio is set to this new model by clicking the OK button again.

8. Once you have confirmed you have selected the correct model then turn off the radio and go through the binding process as below.

Binding a Model

Binding is done to link the radio model setting to a receiver. The receiver is only able to connect to a single radio model. In other words if the receiver has been bound to model 3 then it will only work on model 3. If the radio is set to model 2 then it will not work. To bind a model complete the steps listed below. Binding requires the model to be switched on before radio which is opposite to the way you usually operate your radio.

▲

⟩⟩

AlessandroSPQR

Len1

Login To

Remove Ads

Remove Ads

📝 Rc connection issues

11 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 60 Views · 6 Likes

Flag

📝 Reply

Doogle

I had an issue with one of my Flysky I6 radios a few months ago. The rudder would work but the motor would not, I sought advice from fellow modellers on this forum but unsure how to link this thread. The bottom line was I solved the issue by going to a new model setting and it has worked fine since. It has resulted in the model 5 option on the radio being unusable because channel 3 does not work. On model 6 it all works well. Perhaps I could reset the radio but this would mean loosing all the settings I currently have for other models and I really do not want to resort to this.

So my advice would be to try resetting your radio to factory settings or just go to a new model and see if it works. If neither work then I guess it probably points to a wiring issue.

I had an issue with one of my Flysky I6 radios a few months ago. The rudder would work but the motor would not, I sought advice from fellow modellers on this forum but unsure how to link this thread. The bottom line was I solved the issue by going to a new model setting and it has worked fine since. It has resulted in the model 5 option on the radio being unusable because channel 3 does not work. On model 6 it all works well. Perhaps I could reset the radio but this would mean loosing all the settings I currently have for other models and I really do not want to resort to this.

So my advice would be to try resetting your radio to factory settings or just go to a new model and see if it works. If neither work then I guess it probably points to a wiring issue.

▲

⟩⟩

Len1

Mike Stoney

ToraDog

AlessandroSPQR

hermank

Doogle

📝 Glues

11 months ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 54 Views · 1 Like

Flag

📝 Reply

Westwind

Here is a general table we use for picking the type of glue. If you want to glue say GRP to wood then look for the most common stars. Not all materials are there but we have found it a good basis to select a glue.

Hope this is helpful

Bob

Here is a general table we use for picking the type of glue. If you want to glue say GRP to wood then look for the most common stars. Not all materials are there but we have found it a good basis to select a glue.

Hope this is helpful

Bob

▲

⟩⟩

hermank

📝 Solder

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 75 Views · 3 Likes

Flag

📝 Reply

Hi I use rosin cored solder mainly for electrical connections, but I also use solder paste which I find very good for most other jobs. For railing for example I apply the paste with a tooth pick then heat with a soldering iron. On almost every other job I apply the paste and heat with a butane gun. I have achieved great results using this method. I use only lead based solder paste purchased via Aliexpress, but you can get lead free. When browsing the cheaper lead free paste seems to come up first but you will find the lead based product if you look.

▲

⟩⟩

Len1

hermank

Doogle

📝 8 channel set up help

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 75 Views · 2 Likes

Flag

📝 Reply

I understand the flysky I6 can cope with 10 channels. I am familiar with the flysky radios and have found them to be generally reliable. I assume you are looking at just on/off switches apart from rudder and throttle, like lights etc. If you do want additional servo control raising and lowering booms etc then you may want to consider the I10 or equivalent in other brands. Does the boat have a receiver in it? If so check the branding which may provide some help.

Hope this is of some help.

Hope this is of some help.

▲

⟩⟩

Len1

AlessandroSPQR

💬 Re: Superglue!!

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 56 Views · 1 Like

Flag

💬 Add Comment

Bill

I will definitely try vaseline but I have used teflon plumbers tape which seals the lid OK but sometimes binds, although I have always been able to get it to release albeit with some effort.

Bob

I will definitely try vaseline but I have used teflon plumbers tape which seals the lid OK but sometimes binds, although I have always been able to get it to release albeit with some effort.

Bob

▲

⟩⟩

Len1

💬 Re: Superglue!!

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 92 Views · 6 Likes

Flag

💬 Add Comment

I use a small glue bottle I get from Aliexpress, see photo. If the metal nozzle glogs you can clear it with a short burst from butane torch. However be careful as this may induce a pop as the pressure is released. I clean the tip with an acupuncture needle. Unsure if you can still get these but they do sell nozzle cleaning needles to around 0.2mm. I have found this approach reliable over a long period.

Hope this helps

Hope this helps

▲

⟩⟩

hermank

wingsounds13

Gustoph

Len1

cenbeth

MartyV

📝 Extreme Adults

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 50 Views · 4 Likes

Flag

📝 Reply

Roy

We, Newcastle Marine Modellers Association, sail every Saturday at Tarro which is inbetween Maitland and Newcastle. We have a presence on facebook if you would like to join the group.

Cheers

Bob

We, Newcastle Marine Modellers Association, sail every Saturday at Tarro which is inbetween Maitland and Newcastle. We have a presence on facebook if you would like to join the group.

Cheers

Bob

▲

⟩⟩

hermank

roycv

Peejay

Mike Stoney

📝 Extreme Adults

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 87 Views · 4 Likes

Flag

📝 Reply

Roy

When you are in Australia if you happen to be near Newcastle NSW we sail every Saturday Morning. Just let me know if you would like to attend.

Bob N

When you are in Australia if you happen to be near Newcastle NSW we sail every Saturday Morning. Just let me know if you would like to attend.

Bob N

▲

⟩⟩

Peejay

hermank

roycv

jumpugly

💬 Re: Superglue!!

1 year ago by 🇦🇺 BobbyN ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 135 Views · 4 Likes

Flag

💬 Add Comment

When I get a blocked nozzle I heat with a small torch and this usually clears the blockage. I also use acapuncture needles to clear the tube. I do not get a lot of blockages as I try to remember to just squeeze the bottle and blow air through the rube before sealing it. This works well but if you forget a blockage will often result. I also clean the nozzle with a tissue because the tissue sticks to any remaining glue which then can be removed with a hobby knife.

Be carefull if you have to heat the tube as a tiny amount of glue can pop out, also the metal nozzle can discolour.

Be carefull if you have to heat the tube as a tiny amount of glue can pop out, also the metal nozzle can discolour.

▲

⟩⟩

hermank

Doogle

tim morland

RodC

Liked Model Expo/Nauticurso Pesqueiro 1:32 Scale 3 months ago

Liked Model Expo/Nauticurso Pesqueiro 1:32 Scale 3 months ago

Liked Our fellow Model-Boats contributor is ill 3 months ago

Liked Our fellow Model-Boats contributor is ill 3 months ago

Liked How do you create the coiled ropes? 4 months ago

Liked How do you create the coiled ropes? 4 months ago

Liked How do you create the coiled ropes? 4 months ago

Liked How do you create the coiled ropes? 4 months ago

Liked Professional Photographer at Southport 4 months ago

Liked Professional Photographer at Southport 4 months ago

Liked 3D Printed Models 5 months ago

Liked 3D Printed Models 5 months ago

Liked 3D Printed Models 5 months ago

Liked 3D Printed Models 5 months ago