Join Us On Social Media!

United States

Recent Posts

📝 Help from my Canadian modellers

1 day ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 11 Views · 2 Likes

Flag

📝 Reply

I think Harbor models has different sizes of brass stanchions, and I know for a fact that Cornwall Model Boats has them from different manufacturers in varying sizes and types.

▲

⟩⟩

Mike Stoney

chugalone100

Login To

Remove Ads

Remove Ads

📝 Dumas Closing

1 day ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 19 Views · 2 Likes

Flag

📝 Reply

Deans, Aeronaut, Krick, Billings and others seem to be doing all right. However, as someone who is the “spark plug” of the NTMS I can tell you that scale and scale type model boating is a hard sell in the middle of North Texas. There’s model boating here, but most of it is in the form of racing sailing yachts and either glow, gas or 4 cell and up racing boats. On the 2 coasts it’s different. There is more activity full scale in say, New England or San Francisco then here in DFW, as the biggest thing you’re going to see here is cabin cruisers or maybe a push tug. Houston has a sizable scale following too, but they’re near the Gulf Coast.In the UK and Europe scale model boating seems too be more prevalent too. I think it’s just harder here, as it’s just a huge amount of country between the 2 coasts. Also, I’ve seen younger people on non modeling forums such as Reddit do some scale type modelling via 3D printing. They’re out there guys, we just have to find them.

Anyway, I think SOMEONE is going to pick up a part of the Dumas line. Model Expo brought back

some of the Midwest line, it’s highly conceivable they might start producing some of the Dumas line too.

Cash

Anyway, I think SOMEONE is going to pick up a part of the Dumas line. Model Expo brought back

some of the Midwest line, it’s highly conceivable they might start producing some of the Dumas line too.

Cash

▲

⟩⟩

hermank

jumpugly

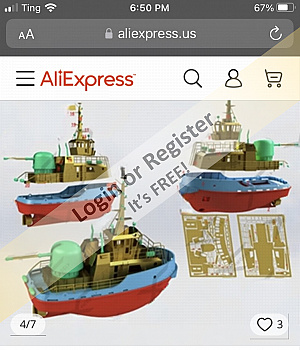

📝 Dumas Products closing down!!!

5 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 73 Views · 8 Likes

Flag

📝 Reply

I saw a thread on RCgroups and I think if I read the comment correctly that once Dumas closed their remaining stock goes to Model Expo. Now Model Expo brought back some of the Midwest line, wonder if they’ll do the same with Dumas?

▲

⟩⟩

algon

Ronald

chugalone100

DuncanP

Wolle

pressonreguardless

jumpugly

hermank

📝 Dumas Products closing down!!!

5 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 80 Views · 7 Likes

Flag

📝 Reply

I think Dumas had a bad rep from their older kits from say 20 years ago. I’ve built a few of their more recent kits and I can tell you the quality has come way up, I’d say almost to Billings level at the least. I think they’re the las major US supplier of rc scale boat kits. It’s a sad day indeed. However, we still have kits from across the pond, there’s 3D files for printing boats, and there’s always plans, wood, plastic and foam. Still hurts though.

▲

⟩⟩

DuncanP

pressonreguardless

chugalone100

Chum444

jumpugly

hermank

Wolle

📝 Dumas Products closing down!!!

5 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 73 Views · 6 Likes

Flag

📝 Reply

I have some money from selling off a few of my boats that I’m not in love with, nice boats but I had more fun building them than sailing them. Just spent most of that on a Lackawanna tug kit from Dumas, as I had almost bought one several times, but something else would show up on the radar, and I figured Dumas would be around after I’m dead and gone. If there’s something they have y’all like, I’d pull the trigger now.

Cash

Cash

▲

⟩⟩

chugalone100

pressonreguardless

Chum444

jumpugly

hermank

Wolle

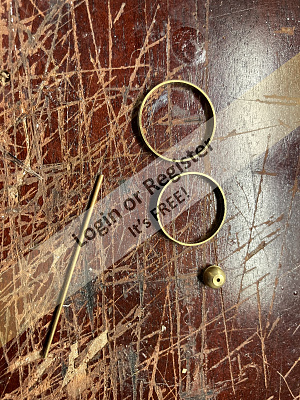

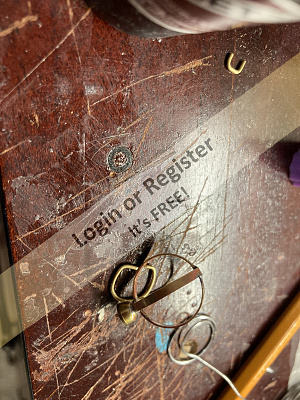

💬 Re: Railing and door securing wheel…..thingy

7 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 20 Views · 2 Likes

Flag

💬 Add Comment

Hi Bill, and thanks for the compliment!! I thought about removing the handle, but I would have to slice it off, sand and touch up and I’m not real sure my skills are up to making it look like it was never there. So I fudged it🤣 I might try later, once the new is off her.

Cash

Cash

▲

⟩⟩

hermank

Chum444

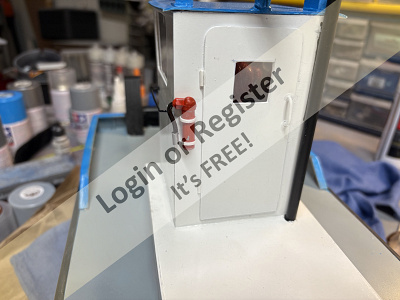

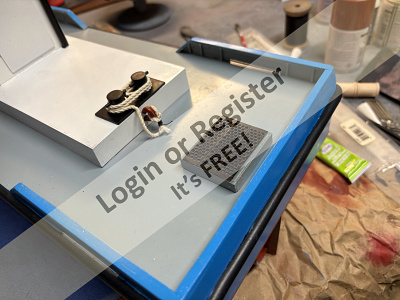

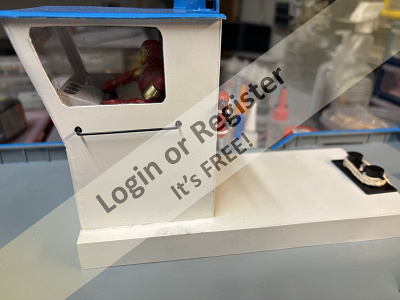

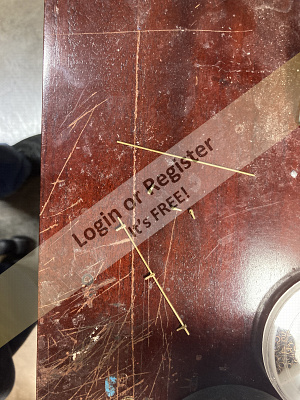

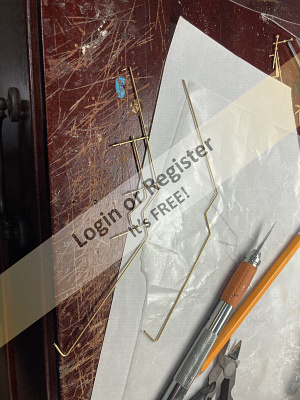

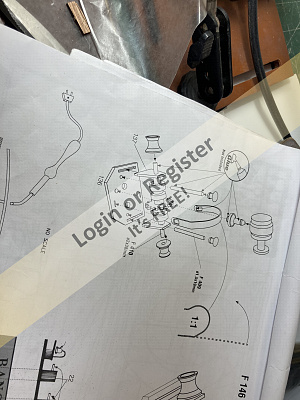

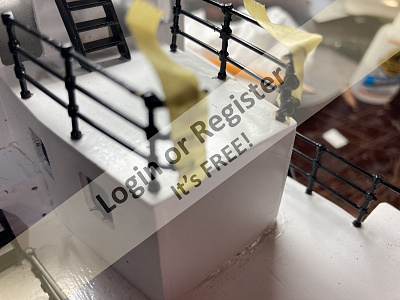

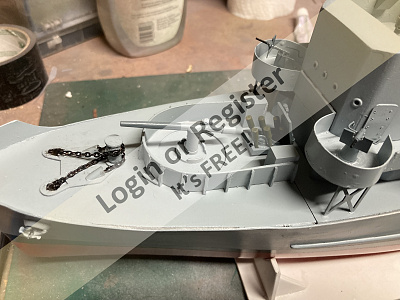

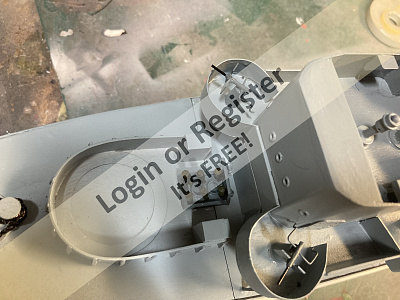

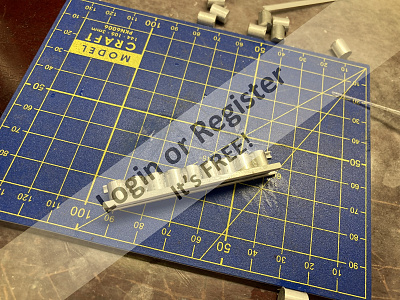

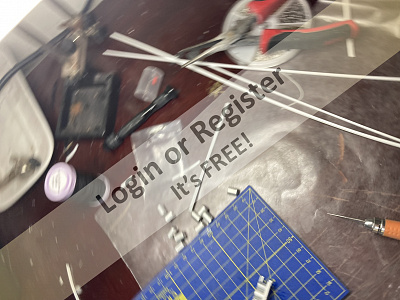

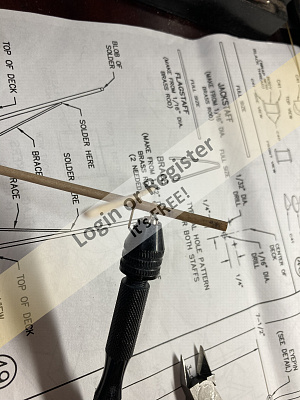

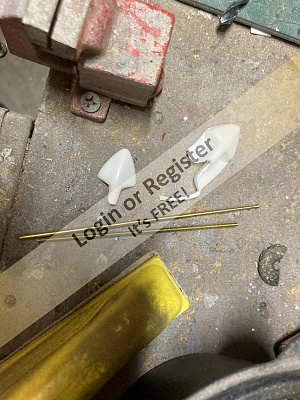

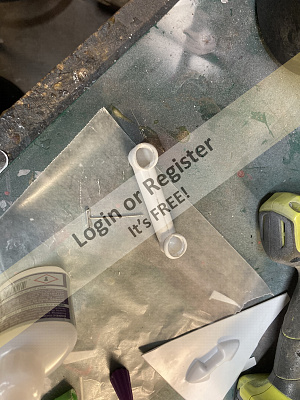

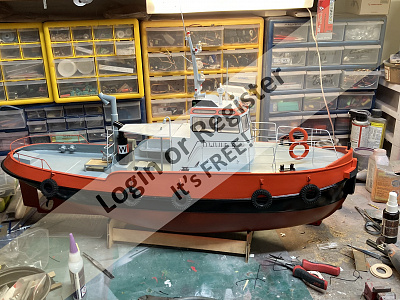

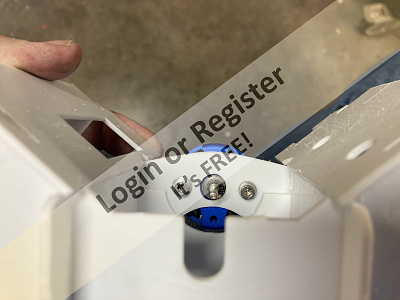

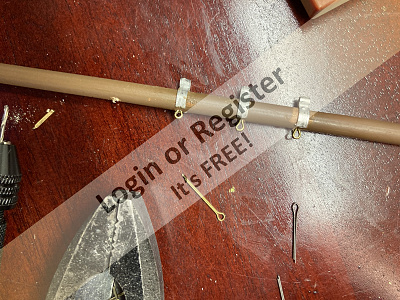

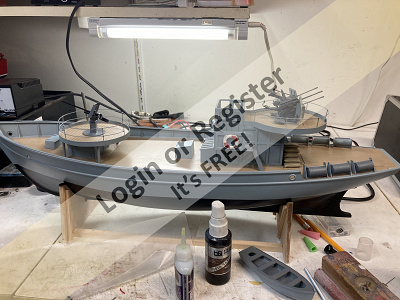

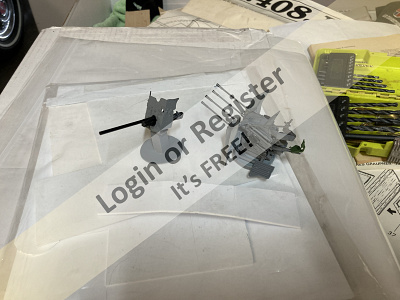

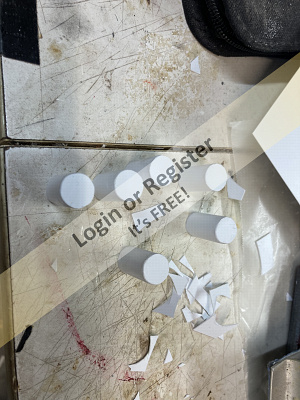

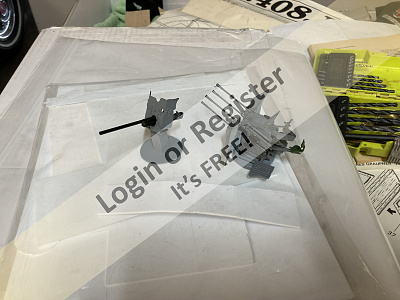

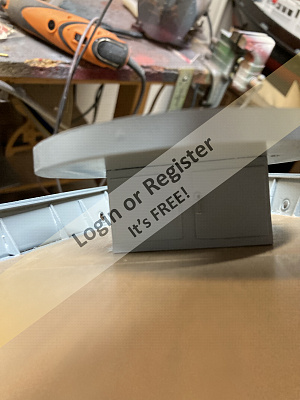

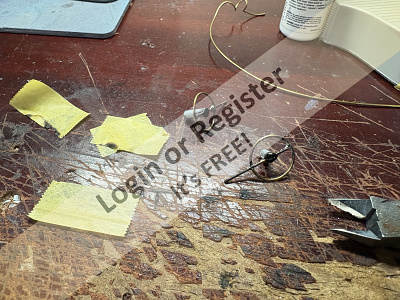

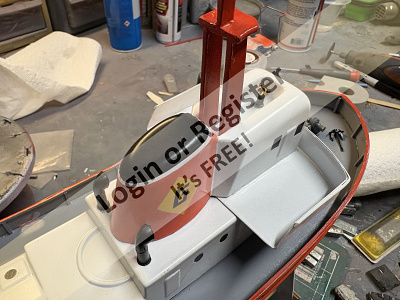

📝 Railing and door securing wheel…..thingy

7 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 25 Views · 7 Likes · 3 Comments

Flag

💬 Add Comment

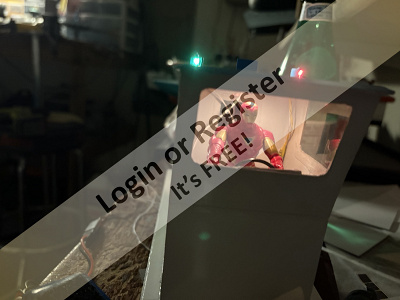

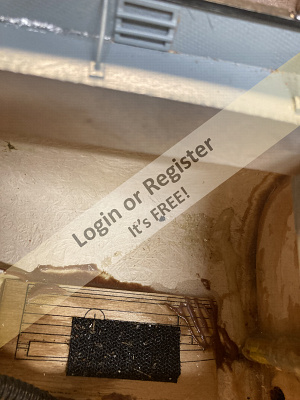

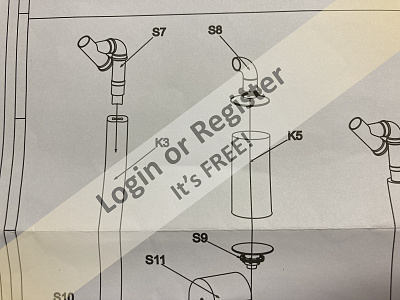

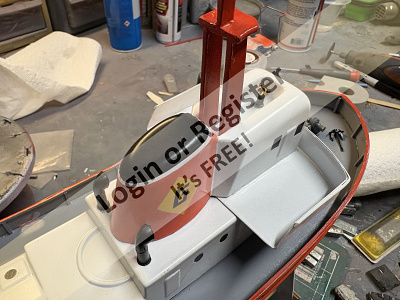

Hi y’all. Did some railing and the door locks? Wheel? Thingy? The wheel on the door that secures it. Y’all have to understand, I come from an aviation and automotive background, not a nautical one, so there’s some things on a boat that I have no clue what to call it. Anyway, I did the lower wheelhouse side railings,most of them are easy enough, the forward lower railings that wrap around the front of the house took a little bit of finagling, not to mention that the boat came with a glued on life preserver right where the rail wraps around. I took it off, scraped and sanded the glue ring down to the paint, touched it up and sanded gently with 1000 grit sandpaper. The door securing device took a little thought. I found a dowel the right size and wrapped brass wire around it, then cut off what I needed, put it in a vise to lay flat, soldered the brass together and glued that assembly to aluminum tube, painted and installed.

That’s it for now. I’m doing this in stages…the wheel house, that mast and then the rest of the deck.

Cash

That’s it for now. I’m doing this in stages…the wheel house, that mast and then the rest of the deck.

Cash

▲

⟩⟩

premecekcz

jumpugly

pressonreguardless

chugalone100

GaryLC

Chum444

hermank

📝 Need help, I can't identify this beauty.

9 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 31 Views · 4 Likes

Flag

📝 Reply

Probably not Robbe or Graupner, most of their kits use ABS for the hulls, if you look closely you can see the fiberglass weave of the hull. I think she’s a one off, a boat built for a client like Jump said, or it’s an older kit from a boutique manufacturer that may no longer be around, but the kit was built recently and modern equipment installed. That’s my best guess

▲

⟩⟩

DWBrinkman

hermank

Wolle

jumpugly

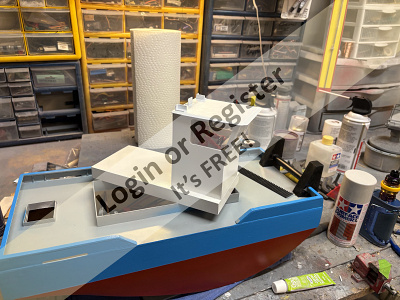

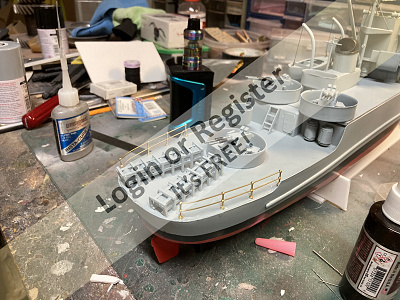

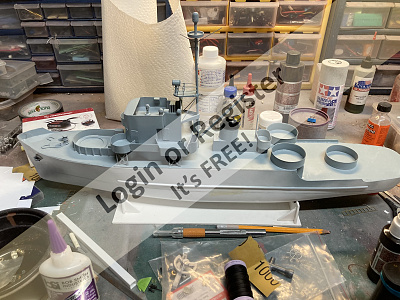

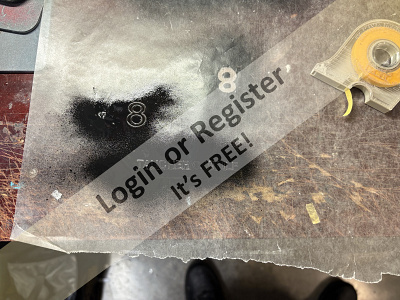

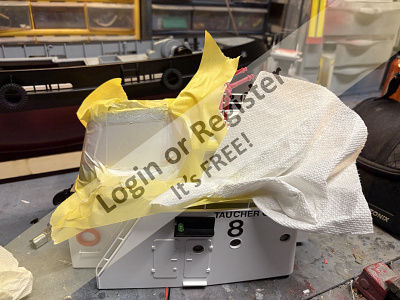

📝 After the maiden, a name change and a little paint

14 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 35 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

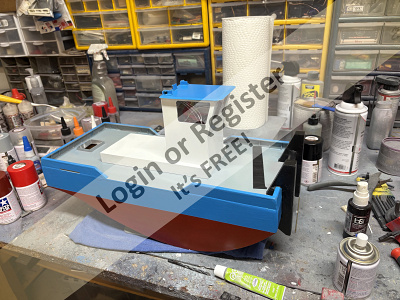

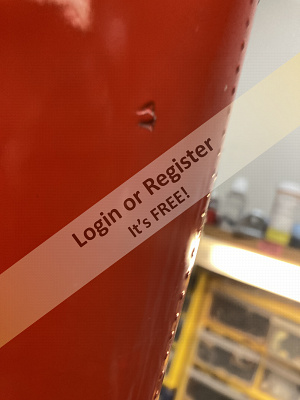

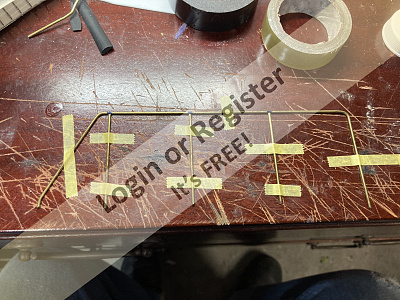

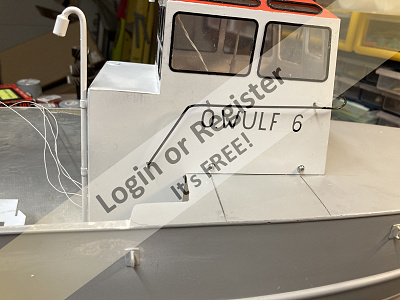

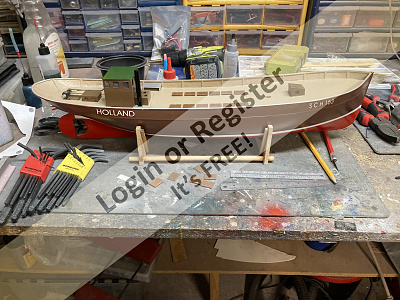

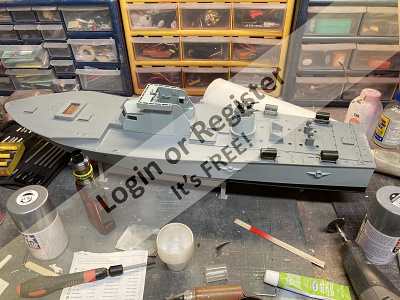

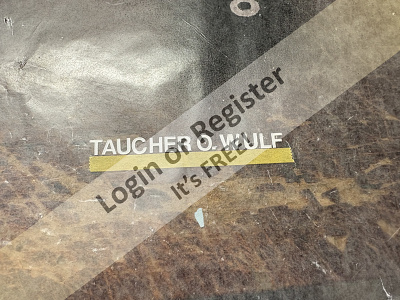

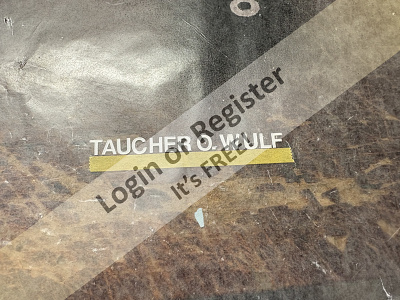

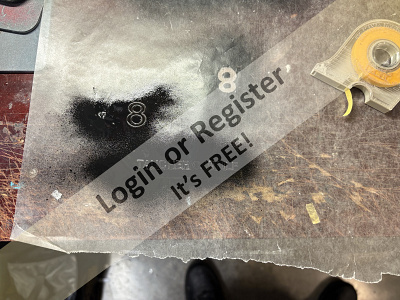

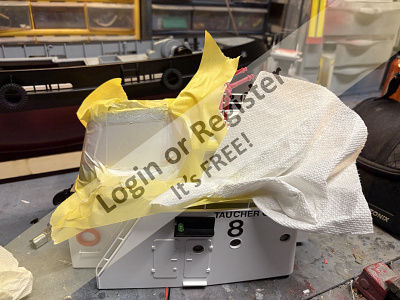

Hi y’all. I maidened the Harbor Tug 2 weekends ago, and she performed well above my expectations. Ran dry, power looked good, everything worked as advertised and looked good on the water. So I’ve spent a few days changing her livery to the Taucher O.Wulf 8. This is the first step to her conversion to a stand off sport scale model.

Now, a heads up. The lettering isn’t perfect, but it looks good. My first try was to use 1/4 inch die cut Chartpak lettering that I had to paint black. I’ll post a pic of that. It looked good, but the font on the real boat is much thinner. A new member of the NTMS, Richard Johnston, has a vinyl cutter, and he produced a much nicer font that’s much closer to the font on the O Wulf, and I looks really good! Only problem we had is the lettering is so small and thin, it did not want to release from the backing paper. So, I just used a piece of 6mm Tamiya masking tape over the letters, carefully peeled and prodded a bit with the very tip of an Xacto knife and once they released, it was a simple job to burnish in place.

The “W” on the funnel is standard Chartpak in black. The font isn’t as thick as the real thing, but looks the part so I’m satisfied. Only issue I had was getting the adhesive off the funnel, as the remover I had just wasn’t cutting it, so I carefully used lacquer thinner. I rubbed a bit too hard on the starboard side and rubbed thru the paint!! So, I had to clean that up, masked it, painted with Tamiya base white, sanded then semigloss over that. Unless you look really close you can’t tell what happened. Dodged a bullet there yall.

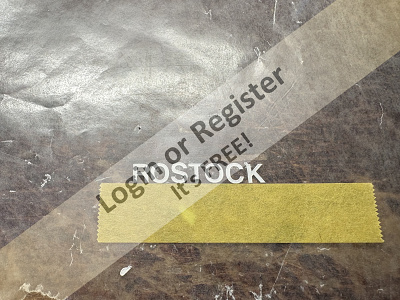

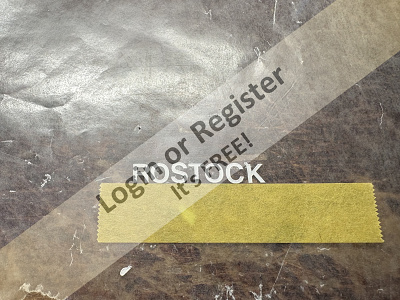

The real boat has the Cuxhaven crest on the front of the superstructure, and the port of Rostock is on the aft bulwarks both sides. I used the stick on letters for that, lining them up on wax paper then using a thin piece of tape to lift off and then apply to the boat like a decal.

The rails on this boat are all painted white. On the real boat, and some models I’ve seen, the hand rails either side of both companionways are painted black, the abruptly change to white at the top of the lower superstructure. I don’t know why but that’s the way it is. I carefully painted them with a small brush and acrylic paint, as I knew I was going to make a mistake and acrylic is easier to clean up than lacquer or enamel. Also, the rails on this boat are on forever, so I had to paint in situ. So much fun!! Anyway, first coat is on but I need to get a better brush to touch up.

Next up is the fun stuff. The real boat has several railings this model doesn’t have, a zodiac boat on a mount aft of the superstructure, some life raft containers, and quite a few other details. I’m not doing them all, but enough to make her recognizable as the O Wulf 8. That’s my goal.

Next couple of posts will be what details I’m doing and how I’m accomplishing them.

Cash

Now, a heads up. The lettering isn’t perfect, but it looks good. My first try was to use 1/4 inch die cut Chartpak lettering that I had to paint black. I’ll post a pic of that. It looked good, but the font on the real boat is much thinner. A new member of the NTMS, Richard Johnston, has a vinyl cutter, and he produced a much nicer font that’s much closer to the font on the O Wulf, and I looks really good! Only problem we had is the lettering is so small and thin, it did not want to release from the backing paper. So, I just used a piece of 6mm Tamiya masking tape over the letters, carefully peeled and prodded a bit with the very tip of an Xacto knife and once they released, it was a simple job to burnish in place.

The “W” on the funnel is standard Chartpak in black. The font isn’t as thick as the real thing, but looks the part so I’m satisfied. Only issue I had was getting the adhesive off the funnel, as the remover I had just wasn’t cutting it, so I carefully used lacquer thinner. I rubbed a bit too hard on the starboard side and rubbed thru the paint!! So, I had to clean that up, masked it, painted with Tamiya base white, sanded then semigloss over that. Unless you look really close you can’t tell what happened. Dodged a bullet there yall.

The real boat has the Cuxhaven crest on the front of the superstructure, and the port of Rostock is on the aft bulwarks both sides. I used the stick on letters for that, lining them up on wax paper then using a thin piece of tape to lift off and then apply to the boat like a decal.

The rails on this boat are all painted white. On the real boat, and some models I’ve seen, the hand rails either side of both companionways are painted black, the abruptly change to white at the top of the lower superstructure. I don’t know why but that’s the way it is. I carefully painted them with a small brush and acrylic paint, as I knew I was going to make a mistake and acrylic is easier to clean up than lacquer or enamel. Also, the rails on this boat are on forever, so I had to paint in situ. So much fun!! Anyway, first coat is on but I need to get a better brush to touch up.

Next up is the fun stuff. The real boat has several railings this model doesn’t have, a zodiac boat on a mount aft of the superstructure, some life raft containers, and quite a few other details. I’m not doing them all, but enough to make her recognizable as the O Wulf 8. That’s my goal.

Next couple of posts will be what details I’m doing and how I’m accomplishing them.

Cash

▲

⟩⟩

pressonreguardless

Chum444

hermank

DWBrinkman

chugalone100

jumpugly

Wolle

Ronald

💬 Re: JUANITA STERN WHEELER

21 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 56 Views · 2 Likes

Flag

💬 Add Comment

Dude!! This is gonna be nice. Really want to see her in the water.

▲

⟩⟩

hermank

chugalone100

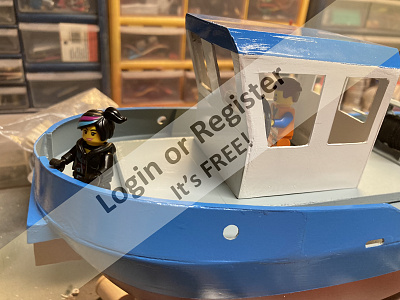

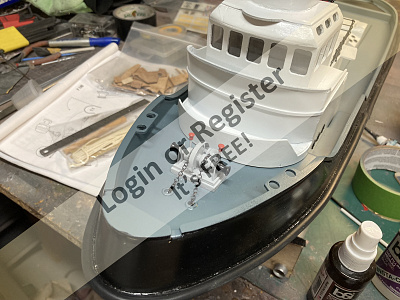

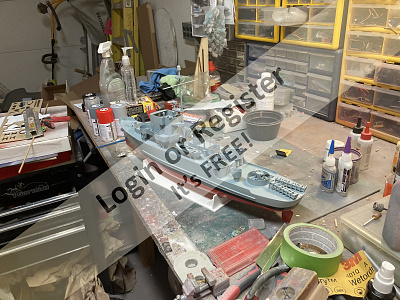

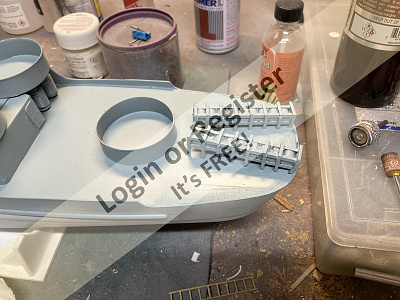

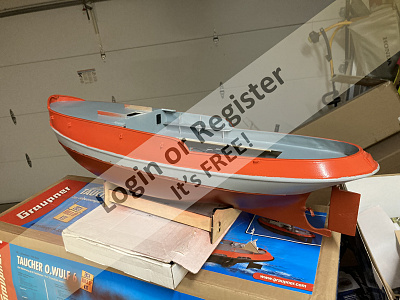

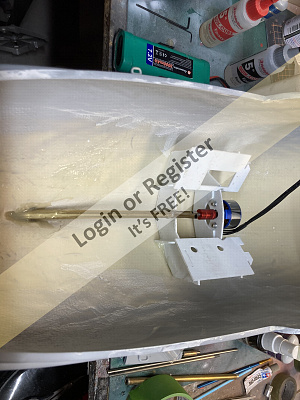

📝 Something a little different-Horizon Harbor Tug

22 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 73 Views · 12 Likes · 2 Comments

Flag

💬 Add Comment

Hi y’all. I turned 65 last month, and in preparation for celebrating making it this far without getting myself seriously injured or spending time in jail I sold a few boats and cashed out some excess pto so I could do something I normally don’t do…spend more than usual for my birthday.

So, I had a budget, and my goal was to use as much as possible from my savings from boat sales without disturbing the family Kitty much if at all. I was successful, came in under budget, my wife got me two kits and I picked up this-the Horizon Harbor Tug.

Now, I’m not usually a RTR or RTF kind of person. The few times I’ve purchased a hobby grade ready to run or fly model I’m usually disappointed. But…this boat has been praised by modelers of all stripes, and Horizon has kept it in production for 4 years, which I think is some sort of record, as usually Horizons scale offerings last maybe a year, 2 years tops. Also, we have 2 members who are dedicated builders of tugs and submarines that love them to death. So here goes…

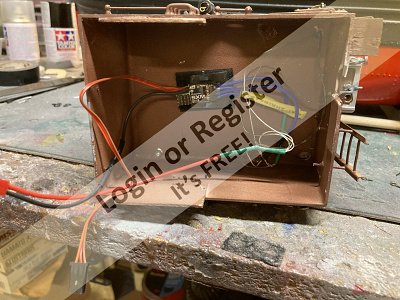

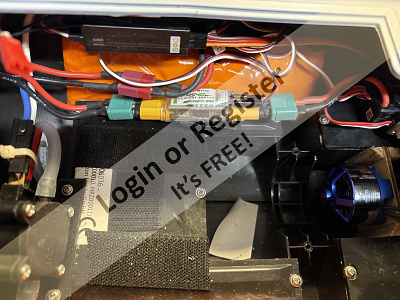

I was not allowed to touch my birthday presents until my birthday, so I had time to figure out what I wanted to do with the Harbor. Once I got her on the bench, I gutted her like a fish.🤣

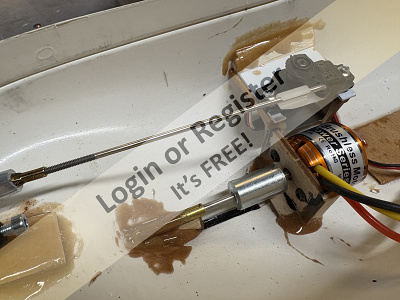

The Harbor Tug comes with a barely hobby grade pistol grip radio capable of 4 channels, a combo brushed esc/receiver, an esc for the fire monitor pump, and a radio controlled electronic on off switch for the led lights. Power is a 700 size motor, this is all supposed to be powered by 3 cells. It does NOT come with the water pump, that’s 60 dollars more, and from what I’ve seen it’s not as strong as I like.

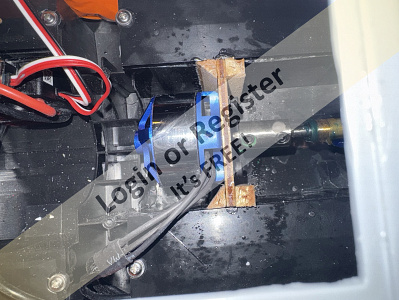

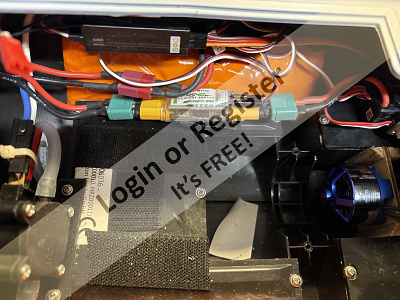

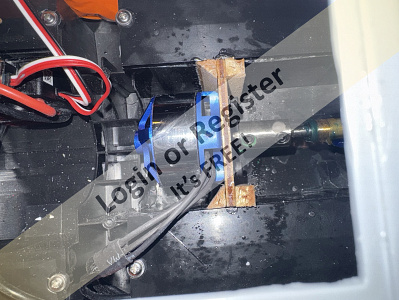

So, I had to make a mount for my preferred motor, the Zippkits 650 brushless outrunner, that’s coupled to the shaft with a good solid coupler. Esc is a HobbyWing 16BL30 30 amp unit. I had to do some modifications to mount my preferred Amazon sourced pump, which included drilling out the molded in water pickup and epoxying in a brass pickup, and changing the mounting location of the pump. Pump is powered by a 10 amp brushed aircraft esc-the original that came with the boat works well, but is set up for 3 cells, and doesn’t give me enough voltage at the pump. Originally I was going to use a FrSky 7 channel receiver, but I wanted to try my hand at telemetry. So I used a FrSky X8R so I could run the FrSky FAS40 module, which gives my real Tim battery voltage and current draw. I also added ballast to bring her up to 12 pounds, as the stock weight of 9.5 or so is seriously under ballasted.

Now, the first production runs of this boat had some issues, leaks near the stern and along the bulwarks were common. It seems to me that Horizon did what Joysway did with the DF65, and listened to feedback, as my boat ran dry. There was a bit of water in the hull before the maiden as I was checking ballast and leaks the day before, and there was no appreciable water in the hull after. All systems worked well, and the boat exceeded my expectations.

Now, y’all know me. You’ve seen my build logs. Probably wondering why I’m loving a boat that I don’t have much time at the bench with. You see, the story doesn’t stop here, oh no, I have more work to do. The real boat this was modeled after is the Taucher O Wulf 8. Horizon put just enough detail to please the average boat modeler, and decaled it with an H on the funnel. My goal is to get her recognizable as the Taucher. I have to do some detail work, add some things that’s missing, do some lettering, etc. The end game is a stand off scale model of the Taucher. So stay tuned, we’re going for a ride!

Cash

So, I had a budget, and my goal was to use as much as possible from my savings from boat sales without disturbing the family Kitty much if at all. I was successful, came in under budget, my wife got me two kits and I picked up this-the Horizon Harbor Tug.

Now, I’m not usually a RTR or RTF kind of person. The few times I’ve purchased a hobby grade ready to run or fly model I’m usually disappointed. But…this boat has been praised by modelers of all stripes, and Horizon has kept it in production for 4 years, which I think is some sort of record, as usually Horizons scale offerings last maybe a year, 2 years tops. Also, we have 2 members who are dedicated builders of tugs and submarines that love them to death. So here goes…

I was not allowed to touch my birthday presents until my birthday, so I had time to figure out what I wanted to do with the Harbor. Once I got her on the bench, I gutted her like a fish.🤣

The Harbor Tug comes with a barely hobby grade pistol grip radio capable of 4 channels, a combo brushed esc/receiver, an esc for the fire monitor pump, and a radio controlled electronic on off switch for the led lights. Power is a 700 size motor, this is all supposed to be powered by 3 cells. It does NOT come with the water pump, that’s 60 dollars more, and from what I’ve seen it’s not as strong as I like.

So, I had to make a mount for my preferred motor, the Zippkits 650 brushless outrunner, that’s coupled to the shaft with a good solid coupler. Esc is a HobbyWing 16BL30 30 amp unit. I had to do some modifications to mount my preferred Amazon sourced pump, which included drilling out the molded in water pickup and epoxying in a brass pickup, and changing the mounting location of the pump. Pump is powered by a 10 amp brushed aircraft esc-the original that came with the boat works well, but is set up for 3 cells, and doesn’t give me enough voltage at the pump. Originally I was going to use a FrSky 7 channel receiver, but I wanted to try my hand at telemetry. So I used a FrSky X8R so I could run the FrSky FAS40 module, which gives my real Tim battery voltage and current draw. I also added ballast to bring her up to 12 pounds, as the stock weight of 9.5 or so is seriously under ballasted.

Now, the first production runs of this boat had some issues, leaks near the stern and along the bulwarks were common. It seems to me that Horizon did what Joysway did with the DF65, and listened to feedback, as my boat ran dry. There was a bit of water in the hull before the maiden as I was checking ballast and leaks the day before, and there was no appreciable water in the hull after. All systems worked well, and the boat exceeded my expectations.

Now, y’all know me. You’ve seen my build logs. Probably wondering why I’m loving a boat that I don’t have much time at the bench with. You see, the story doesn’t stop here, oh no, I have more work to do. The real boat this was modeled after is the Taucher O Wulf 8. Horizon put just enough detail to please the average boat modeler, and decaled it with an H on the funnel. My goal is to get her recognizable as the Taucher. I have to do some detail work, add some things that’s missing, do some lettering, etc. The end game is a stand off scale model of the Taucher. So stay tuned, we’re going for a ride!

Cash

▲

⟩⟩

zooma

ColinJ2

algon

Ray

jumpugly

DWBrinkman

premecekcz

EdW

chugalone100

hermank

Wolle

ChrisF

Login To

Remove Ads

Remove Ads

💬 Re: Midwest/ Model Expo The Fireboat

24 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 25 Views · 5 Likes

Flag

💬 Add Comment

I’m so glad to see Model Expo picking up the old Midwest line of boats. Chug, next time you go to see them tell them a lot of modelers say thanks.

Cash

Cash

▲

⟩⟩

jumpugly

hermank

DWBrinkman

chugalone100

Ronald

💬 Re: Midwest/Model Expo Fireboat

24 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 25 Views · 0 Likes

Flag

💬 Add Comment

Zippkits 650 for the win!! Good Choice!!

Cash

Cash

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Midwest/Model Expo Fireboat

24 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 25 Views · 1 Like

Flag

💬 Add Comment

Chug, I’ve been using little 10 amp aircraft brushed speed controls to power my pumps in boats that have a fire monitor. On some you have to arm them, off-on-off and then they’re good. I use a y harness in parallel between the battery and both the main esc and the pump to power both units from one battery. However, your micro switch is done right and obviously works well too.

Cash

Cash

▲

⟩⟩

hermank

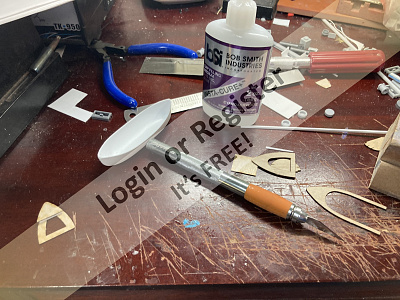

📝 The tools/equipment of the ship modeler.

26 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 37 Views · 5 Likes

Flag

📝 Reply

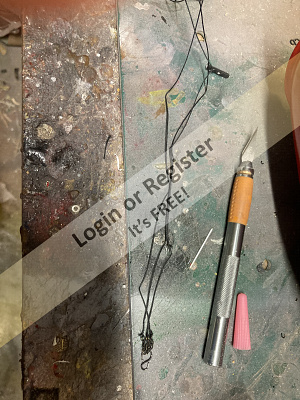

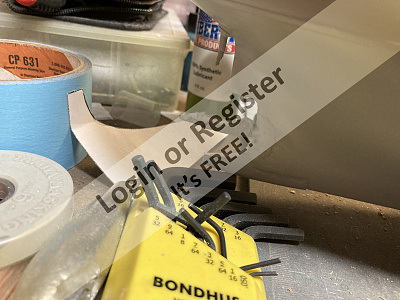

Okay y’all, here’s my list. I’ve built a lot of models but I usually build from kits, or so times I’ll use the hull and build up from there. Most of my boats have plastic or wood hulls, but I have one or two that are fiberglass, so my list is rather old fashioned.

A good, quality XActo knife and spare blades, preferably 2 knives

Zona/XActo saw

Allen wrenches with bondhus tips

A sanding block and a good sanding bar

2-3 different types of pliers, mainly needle nose

Clamps, including clothespins

Rulers in different sizes

Right angle

Screwdrivers

A Dremel

Power drill and bits

Heat gun

A good soldering station that can do some light brass work as well as electrical

Paintbrushes

Plastic nippers

Wire cutter

Vise

If you can afford it a good small scroll saw

Hacksaw

Small hammer

Pencils

An RC car tool set, with interchangeable small nut drivers, Allen drivers and screwdrivers that go into a handle

The 4 way metric wrench that comes with Tamiya rc car kits

Above all, a good, large solid workbench that you don’t mind getting glue and paint on, and it needs to be straight and true as much as possible.

Cutting mat

Servo tester

Lipo battery tester

Voltmeter

If you can find one, an AstroFlight Whatmeter-plug it in between esc and battery, you can run the boat on the bench and see how many watts and amps you’re pulling and battery voltage all at once

A good charger. If, like me the majority of your models are electric, you’ll need a good one. And not a proprietary “smart charger” that only does a decent job of one manufacturer’s product, but a good 2-4 channel charger that can charge multiple battery chemistries at the same time. If you are, however, the type of person that likes staying with one brand then the smart charger might be for you, but I’d at least have a backup charger for some things you may come across later.

A connector holder for soldering bullet, deans, etc.

Extendable magnet

Flashlight

Not really needed but nice to have:tap and die set in small SAE and metric threads.

Nice to have if you have the money, space and knowledge: 3D printer, small drill press and a lathe. As of now I have none of those.

Oh-I consider this a supply and a tool, good quality masking tape. Sometimes, depending on the boat and the shape and attachment of the deck, I use masking tape to hold the deck down while the glue sets, as I gives me the ability ro put tension on the deck and hull to make a good bond, and allows me to make adjustments on the fly depending on cure time.

That’s about it for me.

Cash

A good, quality XActo knife and spare blades, preferably 2 knives

Zona/XActo saw

Allen wrenches with bondhus tips

A sanding block and a good sanding bar

2-3 different types of pliers, mainly needle nose

Clamps, including clothespins

Rulers in different sizes

Right angle

Screwdrivers

A Dremel

Power drill and bits

Heat gun

A good soldering station that can do some light brass work as well as electrical

Paintbrushes

Plastic nippers

Wire cutter

Vise

If you can afford it a good small scroll saw

Hacksaw

Small hammer

Pencils

An RC car tool set, with interchangeable small nut drivers, Allen drivers and screwdrivers that go into a handle

The 4 way metric wrench that comes with Tamiya rc car kits

Above all, a good, large solid workbench that you don’t mind getting glue and paint on, and it needs to be straight and true as much as possible.

Cutting mat

Servo tester

Lipo battery tester

Voltmeter

If you can find one, an AstroFlight Whatmeter-plug it in between esc and battery, you can run the boat on the bench and see how many watts and amps you’re pulling and battery voltage all at once

A good charger. If, like me the majority of your models are electric, you’ll need a good one. And not a proprietary “smart charger” that only does a decent job of one manufacturer’s product, but a good 2-4 channel charger that can charge multiple battery chemistries at the same time. If you are, however, the type of person that likes staying with one brand then the smart charger might be for you, but I’d at least have a backup charger for some things you may come across later.

A connector holder for soldering bullet, deans, etc.

Extendable magnet

Flashlight

Not really needed but nice to have:tap and die set in small SAE and metric threads.

Nice to have if you have the money, space and knowledge: 3D printer, small drill press and a lathe. As of now I have none of those.

Oh-I consider this a supply and a tool, good quality masking tape. Sometimes, depending on the boat and the shape and attachment of the deck, I use masking tape to hold the deck down while the glue sets, as I gives me the ability ro put tension on the deck and hull to make a good bond, and allows me to make adjustments on the fly depending on cure time.

That’s about it for me.

Cash

▲

⟩⟩

DWBrinkman

RodC

hermank

AlessandroSPQR

Wolle

💬 Re: Seaway tug boat

30 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 39 Views · 5 Likes

Flag

💬 Add Comment

▲

⟩⟩

Ronald

Mike Stoney

jumpugly

EdW

hermank

💬 Re: 3 day running knife fight

30 days ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 35 Views · 2 Likes

Flag

💬 Add Comment

Jump!!! The Pay n’Pak is so COOL! Looks good already sir, very nice. Are you gonna glass it? What power you looking at? I like old hydroplanes, especially shovelnose and early pickleforks. Keep at it, you’ll make a winner of her I’m sure.

Cash

Cash

▲

⟩⟩

jumpugly

hermank

💬 Re: Converting a toy semi tractor trailer into a decent RC model Unit

1 month ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 63 Views · 3 Likes

Flag

💬 Add Comment

My co-worker, who occasionally gives me a little flak for messing about with model boats, just confided to me today that he’s looking into getting back to racing HO scale slot cars! So that surprised me. Then I start thinking about it. I used to race 1/24 scale drag cars and messed about with group 12 1/24 cars and Eurotoy 1/32 scale cars. Never been into HO but a buddy of mine in our boat group has a lot of experience with them…then I started to think about checking out what’s out there if we get a little slow at work…then I hear Captain Jack Aubrey’s voice paraphrasing in my head…..”you don’t have time for anymore damnable hobbies sir!!!”

🤣

🤣

▲

⟩⟩

jumpugly

LewZ

hermank

📝 Esc failure, explore and rescue by REAL Pilot boat

1 month ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 55 Views · 4 Likes

Flag

📝 Reply

That is very cool!! Glad you got Froggy back, and made a few friends along the way!!

Cash

Cash

▲

⟩⟩

algon

cdnfurball

Mike Stoney

hermank

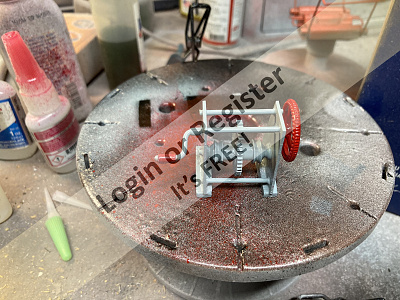

📝 She’s done

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 31 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

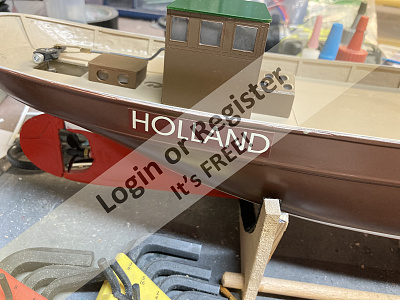

Hi y’all. The Pollux is ready for her maiden. I was originally going to use a 2200 2 cell lipo for power but I would have had to add a LOT more ballast to get her to 21 ounces, so I’m using a 2 cell hard case shorty 5000 mah pack, still had to add about 3 oz ballast.

I had an altercation with the paint. I used some ca kicker to finish assembly of the superstructure. Usually I use Bob Smiths brand, never had it attack paint before, but I had some off brand and it acted like thinner. Ticke me off, had to spot sand and fix it best I could. I’ll keep it for emergencies, but I’ll use the Bob Smith for the most part.

Anyway, once she maidens I’ll post pics of the splash, till then y’all have a good week.

Cash

I had an altercation with the paint. I used some ca kicker to finish assembly of the superstructure. Usually I use Bob Smiths brand, never had it attack paint before, but I had some off brand and it acted like thinner. Ticke me off, had to spot sand and fix it best I could. I’ll keep it for emergencies, but I’ll use the Bob Smith for the most part.

Anyway, once she maidens I’ll post pics of the splash, till then y’all have a good week.

Cash

▲

⟩⟩

GARTH

chugalone100

premecekcz

hermank

jumpugly

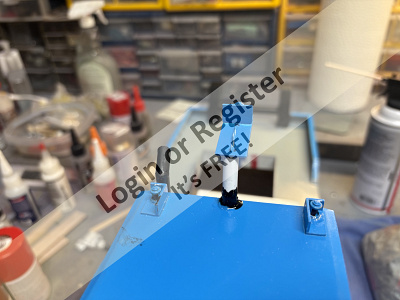

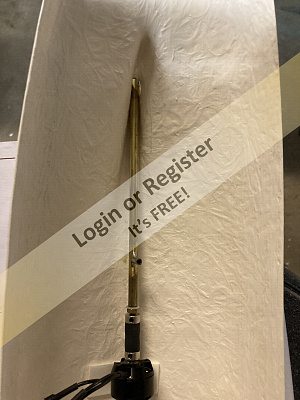

📝 Superstructure painted and decaled, some fittings and the mast

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 42 Views · 6 Likes · 2 Comments

Flag

💬 Add Comment

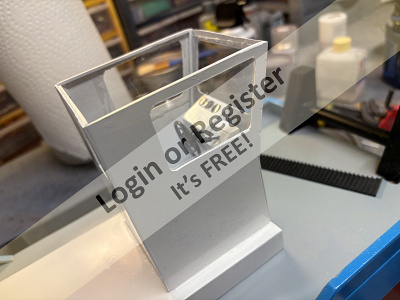

Hi y’all. Feeling a sight better, however this virus hangs on a bit after the initial onset of symptoms. My energy is coming up, so I did a bit more on the Pollux.

I got the superstructure painted and the decals for windows and portholes applied. Took a piece of 1/8th pinstripe and cut it down to about 1/16 wide, apples that to the funnel between the orange body and the black top. The kit came with fittings, so I painted up the bollards and installed those.

Then came the mast. The mast is a vacuformed part that had already been cut out. The kit was never actually started, but some parts were already cut out from their sheets. The mast was a little rough, and it’s hollow, and fragile. So I cleaned up a bit and filled the back side with abs sheet scraps, and sanded the heck out of it, then primered. Next time I’m at the bench I can see any thing that needs to be cleaned up, then I’ll re-primer and gin from there.

Once this boat is finished, I’ll run it a few times, see how she handles, but I’m thinking I’ll put a different receiver in her and set her up on my pistol grip DX4C, and let her be a pass around boat.

Cash

I got the superstructure painted and the decals for windows and portholes applied. Took a piece of 1/8th pinstripe and cut it down to about 1/16 wide, apples that to the funnel between the orange body and the black top. The kit came with fittings, so I painted up the bollards and installed those.

Then came the mast. The mast is a vacuformed part that had already been cut out. The kit was never actually started, but some parts were already cut out from their sheets. The mast was a little rough, and it’s hollow, and fragile. So I cleaned up a bit and filled the back side with abs sheet scraps, and sanded the heck out of it, then primered. Next time I’m at the bench I can see any thing that needs to be cleaned up, then I’ll re-primer and gin from there.

Once this boat is finished, I’ll run it a few times, see how she handles, but I’m thinking I’ll put a different receiver in her and set her up on my pistol grip DX4C, and let her be a pass around boat.

Cash

▲

⟩⟩

chugalone100

premecekcz

Rookysailor

Chum444

jumpugly

hermank

Login To

Remove Ads

Remove Ads

💬 Re: Hull and deck paint, prop installed and a ##&&!! virus!

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 47 Views · 4 Likes

Flag

💬 Add Comment

Years ago I saw a gloss black toilet at Home Depot. I told my wife I wanted to install one in our master bathroom then rig it up to play "The Imperial March" from Star Wars when one sat down. Darth Vaders toilet!!

Teresa nixed the idea.....☹️🤣

Teresa nixed the idea.....☹️🤣

▲

⟩⟩

RossM

RNinMunich

Ronald

hermank

💬 Re: Hull and deck paint, prop installed and a ##&&!! virus!

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 47 Views · 1 Like

Flag

💬 Add Comment

I got a respiratory infection. No flu, fever, nothing. had what felt like a bit of bad allergies and then I got torpedoed Friday night. On the mend now.

▲

⟩⟩

hermank

💬 Re: New Moth MKII semi scale yacht

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 72 Views · 4 Likes

Flag

💬 Add Comment

You have mad skills sir, cant wait to see her on the water!!

Cash

Cash

▲

⟩⟩

jumpugly

jbkiwi

stevedownunder

hermank

💬 Re: AND FINALLY...

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 25 Views · 2 Likes

Flag

💬 Add Comment

I have Mr Guests book with this tug in it. I have a lot of projects ahead of me, but I just might have to add this to the list. You did a grand job on her!!

Cash

Cash

▲

⟩⟩

Mike Stoney

hermank

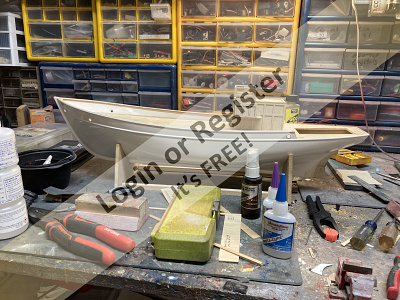

📝 Hull and deck paint, prop installed and a ##&&!! virus!

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 52 Views · 10 Likes · 3 Comments

Flag

💬 Add Comment

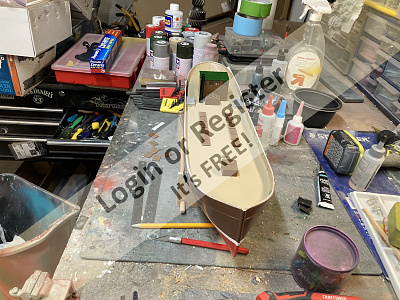

Hi y’all. The last couple of weeks, actually well before Christmas, a couple of bugs have been circulating in North Texas. One of my fellow countermen goat flu B, another a viral infection. I’ve felt it taking passes at me for two weeks, but never had any major symptoms, till Friday night..the virus took residence in my chest. So, went to the doc in a box, it’s a virus, no flu, just started my first course of steroids this morning, already feel a sight better and the congestion is loosening and becoming more manageable. However, this made me miss my outing with my club mates today, so😠

Anyway, I felt good enough to do a little painting this week, and finished the painting today. Might do a semigloss clear, might not. Decided on black below waterline, orange up to the railing, gray deck, will do the superstructure white trimmed in orange and maybe a dark blue band around the funnel top. The superstructure main parts are primered ready to paint. I also took some thin brass and made a rudder shoe, got lucky and lined everything up properly so the rudder works as advertised with no binding.

That’s all I could do this time. Since I had already painted the deck I had to do a lot of masking to get this where I wanted it, but it came out pretty good. However I sill have some touch up to do on the railing. I’ll get more done this week and weekend as I mend.

Cash

Anyway, I felt good enough to do a little painting this week, and finished the painting today. Might do a semigloss clear, might not. Decided on black below waterline, orange up to the railing, gray deck, will do the superstructure white trimmed in orange and maybe a dark blue band around the funnel top. The superstructure main parts are primered ready to paint. I also took some thin brass and made a rudder shoe, got lucky and lined everything up properly so the rudder works as advertised with no binding.

That’s all I could do this time. Since I had already painted the deck I had to do a lot of masking to get this where I wanted it, but it came out pretty good. However I sill have some touch up to do on the railing. I’ll get more done this week and weekend as I mend.

Cash

▲

⟩⟩

EdW

jbkiwi

Rookysailor

Wolle

robbob

Chum444

jumpugly

AlessandroSPQR

hermank

RNinMunich

📝 Radio in deck installed bulwarks beefed up

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 69 Views · 10 Likes

Flag

💬 Add Comment

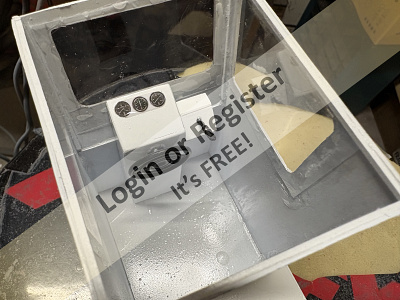

Hi y’all. The radio is installed in the hull, and the deck is installed. I built up the rudder access hatch from 2 pieces of plasticard, the inner piece is a press fit into the access hole, the upper piece has an overlap of roughly 3/16 inch all round. Once I was satisfied with the rudder linkage and installation I tack glued it at the corners. Once primed and painted it will be sealed, if I have to get it loose and can pry it up to effect any repairs. The deck has a one piece coaming that is glued under the deck via a molded flange.

I drilled and cut out the freeing ports, one was a little bigger than the others as cutting out freeing ports is not my strong suit, so I trimmed the rest to match. The hull is very thin abs, the bulwarks is almost a knife edge topside, so I added a strip of 1/16 plastic inboard flush with the top edge, then added supports between the added lip and deck of the same material. I have to do some cleaning op and light sanding the the hull is ready for primer and paint.

Cash

I drilled and cut out the freeing ports, one was a little bigger than the others as cutting out freeing ports is not my strong suit, so I trimmed the rest to match. The hull is very thin abs, the bulwarks is almost a knife edge topside, so I added a strip of 1/16 plastic inboard flush with the top edge, then added supports between the added lip and deck of the same material. I have to do some cleaning op and light sanding the the hull is ready for primer and paint.

Cash

▲

⟩⟩

Wolle

thadlietz

Rookysailor

SimonB2

jumpugly

ChrisF

SimpleSailor

Mike Stoney

hermank

Chum444

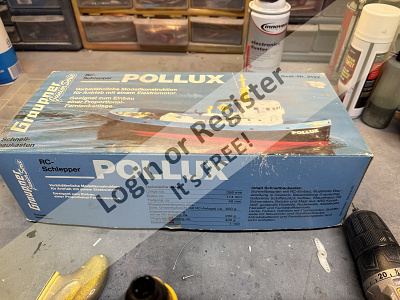

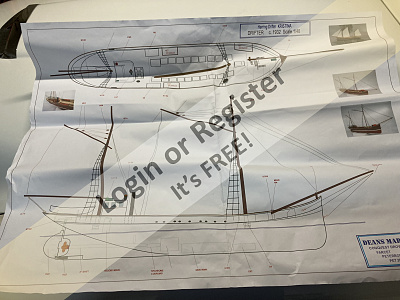

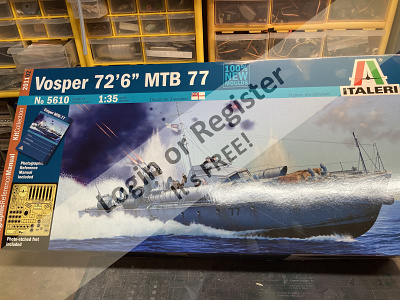

📝 Next project

2 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 46 Views · 7 Likes

Flag

📝 Reply

Merry Christmas y’all. Hope everyone of you find peace and happiness now and in the future, and maybe a new boat kit or two also😀. G’nite.

Cash

Cash

▲

⟩⟩

pressonreguardless

BOATSHED

DWBrinkman

Newby7

jumpugly

PhilH

hermank

💬 Re: Tower

3 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 92 Views · 3 Likes

Flag

💬 Add Comment

Hi Bill…maybe drill, pin and epoxy or CA? Or maybe a thin wall brass tubing if you can find it in the right size. Plastic rod might work as well, or a combo of different materials.

Cash

Cash

▲

⟩⟩

RodC

hermank

Chum444

💬 Re: Graupner Pollux

3 months ago by 🇺🇸 Cashrc ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 78 Views · 4 Likes

Flag

💬 Add Comment

Yessir Jump, good old microballoons. I’ve also used baby powder as a filler too. I really wish we could get Stabilit-Express in the US…that stuff works great!!

Cash

Cash

▲

⟩⟩

thadlietz

Beemerboy

jumpugly

hermank

Commodore)

Commodore)

Rear Admiral)

Rear Admiral)

Sub-Lieutenant)

Sub-Lieutenant)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Leading Seaman)

Leading Seaman)

Recruit)

Recruit)