Join Us On Social Media!

United Kingdom

Recent Posts

📝 Submarines

7 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 14 Views · 2 Likes

Flag

📝 Reply

I have a hull of HMS Thetis at 1:48 scale. However it has stalled in its construction, mainly due to not being able to get a water-tight compartment made and trying to make the forward planes fold. Like most of my models, I’ve moved on to other projects!

▲

⟩⟩

hermank

SouthportPat

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

8 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 57 Views · 2 Likes

Flag

📝 Reply

If they want to compensate surely it should be shorter as in B? No, AI is wrong.

▲

⟩⟩

hermank

roycv

📝 Question of the Day?

8 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 51 Views · 2 Likes

Flag

📝 Reply

This required an educated guess which in my case was correct. Yes, they are getting more obscure.

▲

⟩⟩

DuncanP

hermank

📝 Games Chest Vanished

8 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 48 Views · 4 Likes

Flag

📝 Reply

I use an iPad. Question of the Day has vanished from my iPad. It has as much relevance to model boats as the questions. Plainly it is still there because people are commenting on it.

▲

⟩⟩

hermank

Len1

AlessandroSPQR

RNinMunich

📝 Games Chest Vanished

8 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 65 Views · 2 Likes

Flag

📝 Reply

Hi,

As part of my morning routine I open this site and go to Games Chest to find Question of the Day. Today I go and it’s empty, no QofD. What’s happening?

Best wishes

Edward

As part of my morning routine I open this site and go to Games Chest to find Question of the Day. Today I go and it’s empty, no QofD. What’s happening?

Best wishes

Edward

▲

⟩⟩

hermank

Len1

📝 Question of the Day?

9 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 49 Views · 3 Likes

Flag

📝 Reply

Hi Doug,

I just think that there should be some relationship to model boats rather than obscure (and inaccurate) historical facts. And duplications but they have already been commented on.

Having said that I continue to enjoy this site!

Best wishes

Edward

I just think that there should be some relationship to model boats rather than obscure (and inaccurate) historical facts. And duplications but they have already been commented on.

Having said that I continue to enjoy this site!

Best wishes

Edward

▲

⟩⟩

Nickthesteam

AustinG

hermank

📝 Question of the Day?

9 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 50 Views · 1 Like

Flag

📝 Reply

Are these model boating questions???

▲

⟩⟩

hermank

📝 Question of the Day?

10 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 48 Views · 3 Likes

Flag

📝 Reply

This is crazy. No British submarines were scuttled near Java as far as I can ascertain. I’m stopping doing this game.

▲

⟩⟩

Peejay

SimpleSailor

RNinMunich

📝 Question of the Day?

10 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 55 Views · 3 Likes

Flag

📝 Reply

It could have been C or D as really they are the same thing. I chose C and was lucky.

▲

⟩⟩

DuncanP

hermank

AndyN

📝 Question of the Day?

10 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 53 Views · 3 Likes

Flag

📝 Reply

Triton was not commissioned until 27 September 1959. I don’t know how she could have gone through the strait in February.

▲

⟩⟩

RonH

RossM

Nickthesteam

📝 Prop shaft lubricant

12 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 45 Views · 0 Likes

Flag

📝 Reply

Many of you seem to be using marine grease, at least according to the responses. How do you apply it?

I use an oiling tube fixed to the prop shaft casing but to get grease down could be problematical. Presumably you have to remove the prop shaft and inject it, or am I missing something?

I use an oiling tube fixed to the prop shaft casing but to get grease down could be problematical. Presumably you have to remove the prop shaft and inject it, or am I missing something?

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Prop shaft lubricant

12 months ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 91 Views · 1 Like

Flag

📝 Reply

How do you tell whether fibres are in it? What sort of fibres are they?

▲

⟩⟩

Mike Stoney

📝 Question of the Day?

1 year ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 70 Views · 1 Like

Flag

📝 Reply

Hi Cash,

Sorry about that. I’ve tried the menu button and it works! Thank you for your help.

I wonder why the layout changed?

Edward

Sorry about that. I’ve tried the menu button and it works! Thank you for your help.

I wonder why the layout changed?

Edward

▲

⟩⟩

hermank

📝 Question of the Day?

1 year ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 67 Views · 1 Like

Flag

📝 Reply

Hi Cash,

Thank you for that. I have tried rotating my iPad but it doesn’t do anything to my display.

Edward

Thank you for that. I have tried rotating my iPad but it doesn’t do anything to my display.

Edward

▲

⟩⟩

hermank

📝 Question of the Day?

1 year ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 69 Views · 2 Likes

Flag

📝 Reply

Hi Garth,

As I said, I use an iPad. There are no option on the left.

Thank you for trying.

As I said, I use an iPad. There are no option on the left.

Thank you for trying.

▲

⟩⟩

Peejay

hermank

📝 Question of the Day?

1 year ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 65 Views · 2 Likes

Flag

📝 Reply

I use an iPad to look at these posts. Question of the Day used to appear at the top of the Home page but recently it has vanished. What has happened?

I can get it via some else’s post but it isn’t very convenient. Currently I’m up to 88%!

I can get it via some else’s post but it isn’t very convenient. Currently I’m up to 88%!

▲

⟩⟩

Peejay

DWBrinkman

💬 Re: Rigging-Screws

2 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 100 Views · 1 Like

Flag

💬 Add Comment

Try eBay. There are numerous left hand taps and dies.

▲

⟩⟩

AlessandroSPQR

💬 Re: my workshop

3 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 282 Views · 2 Likes

Flag

💬 Add Comment

Looks interesting. What are the floor dimensions and do you have any plans?

▲

⟩⟩

AlessandroSPQR

Wolle

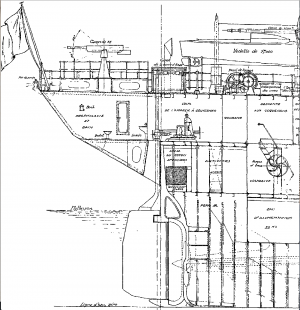

💬 Re: Bilge & Circulating Pump Outflow.

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 231 Views · 2 Likes

Flag

💬 Add Comment

I would have thught that they would be lower so as not necessitate cutting the irons. But hey, what do I know!

▲

⟩⟩

AlessandroSPQR

stevedownunder

📝 sail control ????

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 108 Views · 3 Likes

Flag

📝 Reply

Hi,

On the weight of the keel, may I suggest that you place it in a filled bath and add weight to it until it floats to the waterline? Then remove the weight and weigh them. I take a small amount of the resultant weight to allow for trimming.

I hope this makes sense.

Best of luck

Edward

On the weight of the keel, may I suggest that you place it in a filled bath and add weight to it until it floats to the waterline? Then remove the weight and weigh them. I take a small amount of the resultant weight to allow for trimming.

I hope this makes sense.

Best of luck

Edward

▲

⟩⟩

AlessandroSPQR

david41

Colin H

📝 Servo issues etc

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 40 Views · 1 Like

Flag

📝 Reply

Hi Dave

I've stripped the main sail servos out and I've mislead you all. The arm servo is HiTec HS-765HB and the main sail is a Futaba S5801.

Cheers

Edward

I've stripped the main sail servos out and I've mislead you all. The arm servo is HiTec HS-765HB and the main sail is a Futaba S5801.

Cheers

Edward

▲

⟩⟩

AlessandroSPQR

Login To

Remove Ads

Remove Ads

📝 Servo issues etc

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 48 Views · 2 Likes

Flag

📝 Reply

Hi Stephen

I've just measured the model; its 4 foot long pus 15.5 inch bowsprit. It has a 14 inch beam and the draft is about 6 inches plis 4 inches for the bulb keel (detachable)

Cheers

Edward

I've just measured the model; its 4 foot long pus 15.5 inch bowsprit. It has a 14 inch beam and the draft is about 6 inches plis 4 inches for the bulb keel (detachable)

Cheers

Edward

▲

⟩⟩

AlessandroSPQR

stevedownunder

📝 Servo issues etc

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 48 Views · 2 Likes

Flag

📝 Reply

Hi Dave

I'll try and answer your questions.

Ch1 Jib (arm) & Foresail (drum)via Y adapter

Ch 2 Speed controller; Mtronics Viper Marine 15

Ch 3 Main Sail - Drum

Ch 4 rudder - normal high power servo.

The battery splits via a Y lead to the Mtronics and a bus bar that serves the two drum winches.

All servos are Futaba. I am not aware that Futaba make different drum winches and I've thrown away the boxes. I would have bought the strongest they do at the time.

The tests done so far have been under a No Load state so the current draw should be minimal.

Does this help?

Edward

I'll try and answer your questions.

Ch1 Jib (arm) & Foresail (drum)via Y adapter

Ch 2 Speed controller; Mtronics Viper Marine 15

Ch 3 Main Sail - Drum

Ch 4 rudder - normal high power servo.

The battery splits via a Y lead to the Mtronics and a bus bar that serves the two drum winches.

All servos are Futaba. I am not aware that Futaba make different drum winches and I've thrown away the boxes. I would have bought the strongest they do at the time.

The tests done so far have been under a No Load state so the current draw should be minimal.

Does this help?

Edward

▲

⟩⟩

AlessandroSPQR

dave976

📝 Servo issues etc

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 48 Views · 3 Likes

Flag

📝 Reply

Hi Stephen,

The model is about 4 feet long, plus a bow sprit. It has a beam of about 12 inches. The ballast is about 12Kg. Sorry about the range of units - put it down to my age!

Yes, it is an auxiliary motor; a monoperm special if I remember correctly. The speed controller is a Milltronics. I can do some pictures but not now; its bed time here!

The Servomorph P96 is currently unavailable and I'm waiting to hear from Components Shop when they hop to have them.

Edward

The model is about 4 feet long, plus a bow sprit. It has a beam of about 12 inches. The ballast is about 12Kg. Sorry about the range of units - put it down to my age!

Yes, it is an auxiliary motor; a monoperm special if I remember correctly. The speed controller is a Milltronics. I can do some pictures but not now; its bed time here!

The Servomorph P96 is currently unavailable and I'm waiting to hear from Components Shop when they hop to have them.

Edward

▲

⟩⟩

AlessandroSPQR

stevedownunder

GaryLC

📝 Servo issues etc

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 48 Views · 3 Likes

Flag

📝 Reply

Thanks Garry, I'll give it a try. Will they work with the speed controller too? Edward

▲

⟩⟩

AlessandroSPQR

GaryLC

stevedownunder

📝 Servo issues etc

4 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 47 Views · 2 Likes

Flag

📝 Reply

I am building a twice scale Cariad Bristol Pilot Cutter. I have a Futaba servos for the rudder, main sail (drum), Jib (arm servo) and fore sail (Drum), a Miltronics speed controller and BEC. The Receiver is a FrSky while the Transmitter is a Futaba 6EX-2.4GHz. I have been told that the Transmitter will not work with a FrSky receiver, but it has binded together fine and works on the bench.

The problem I have is the throw of the servos is not sufficient and the speed controller is either on or off and will not go in reverse. There is no graduation of speed.

Last time I used R/C was in the early 1980s and that was with 27MHz. I am currently at a loss how I could improve the servos and any advice would be gratefully received.

The boat is almost ready to go into the water but I need the servos to work correctly.

The problem I have is the throw of the servos is not sufficient and the speed controller is either on or off and will not go in reverse. There is no graduation of speed.

Last time I used R/C was in the early 1980s and that was with 27MHz. I am currently at a loss how I could improve the servos and any advice would be gratefully received.

The boat is almost ready to go into the water but I need the servos to work correctly.

▲

⟩⟩

AlessandroSPQR

stevedownunder

💬 Re: Scratch built, Working Steam powered Drifter trawler LT100, to 1:24th scale.

5 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 284 Views · 2 Likes

Flag

💬 Add Comment

Hi,

I know that steam locos have a bypass valve on the water feed pipework to allow the partial return of the feedwater. Would one help with your system?

I'm enjoying your blog!

Keep it up

Edward

I know that steam locos have a bypass valve on the water feed pipework to allow the partial return of the feedwater. Would one help with your system?

I'm enjoying your blog!

Keep it up

Edward

▲

⟩⟩

stevedownunder

Martin555

📝 HMS Dido

6 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 38 Views · 0 Likes

Flag

📝 Reply

HMS Dido did indeed start off life with two twin forward turrets but was soon fitted out with three.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 HMS Dido

6 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 38 Views · 0 Likes

Flag

📝 Reply

White Ensign do a 1/700 kit. This could be a bit fiddly but the cost would be relatively modest. Deans Marine used to do a 1/96 semi kit and Fleetscale Marine do a 1/128 semi kit too. Personally, I like the Fleetscale one.

The main difference in HMS Dido to the other ships is the cross-bracing on the foremast and degaussing wires around the hull being exposed. The armorment changed over time too so select the right date!

Good luck with the build and let us know how you are progressing!

The main difference in HMS Dido to the other ships is the cross-bracing on the foremast and degaussing wires around the hull being exposed. The armorment changed over time too so select the right date!

Good luck with the build and let us know how you are progressing!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Casting a lead bulb keel

6 years ago by 🇬🇧 cenbeth ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 40 Views · 0 Likes

Flag

📝 Reply

Useful information. I'm not sure where I'd get these powders from though. When I designed the plugs I avoided undercuts and had no need to use the mould more than once but if anybody did need to your advice seems more than sound.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Commodore)

Commodore)

Liked M. N. Golo, 1300 Tonne Coastal Freighter 21 days ago

Liked M. N. Golo, 1300 Tonne Coastal Freighter 21 days ago

Liked Bluebird of Chelsea 25 days ago

Liked Bluebird of Chelsea 25 days ago

Liked Spray Rails. 1 month ago

Liked Spray Rails. 1 month ago

Liked Double Jointed Universal Couplings 1 month ago

Liked Double Jointed Universal Couplings 1 month ago

Liked Tools 2 months ago

Liked Tools 2 months ago

Liked Re: Aerokits Sea Commander. Strange Handling ? 2 months ago

Liked Re: Aerokits Sea Commander. Strange Handling ? 2 months ago