Join Us On Social Media!

United States

Recent Posts

📝 Sprite

7 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 5 Views · 1 Like

Flag

📝 Reply

Wow, it’s coming alone beautifully.

Great job.

😎

Great job.

😎

▲

⟩⟩

zooma

Login To

Remove Ads

Remove Ads

💬 Re: Trim tabs removed

10 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 7 Views · 0 Likes

Flag

💬 Add Comment

Another excellent eBay find. You’re truly a skilled hunter.

The finished result clearly reflects your expertise with this type of model.

Congratulations.

😎

The finished result clearly reflects your expertise with this type of model.

Congratulations.

😎

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

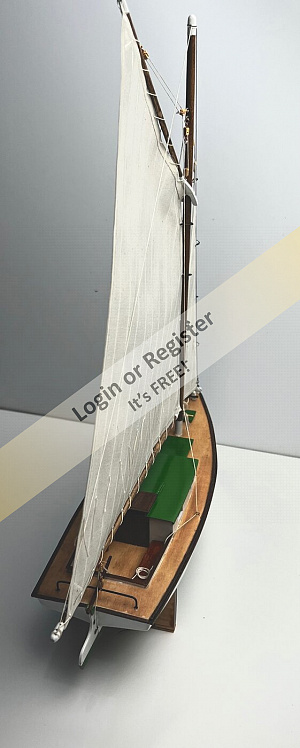

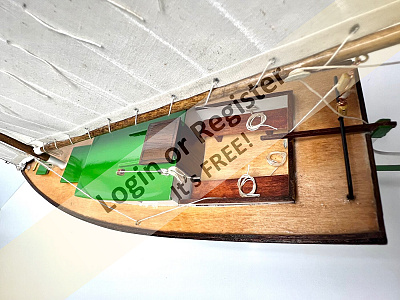

📝 LesRo Javelin (2).

10 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 11 Views · 2 Likes

Flag

📝 Reply

Zooma,

That was some great eBay hunting...you really scored with her.

I check my eBay listings several times a day hoping to catch a good deal like yours.

Nevertheless, you definitely have your hands full restoring your newly acquired LesRo Javelin.

I’d honestly be afraid to take on a project like that myself, so credit where credit is due.

I sincerely admire the dedication and skill it takes to tackle a restoration of that caliber.

😎

That was some great eBay hunting...you really scored with her.

I check my eBay listings several times a day hoping to catch a good deal like yours.

Nevertheless, you definitely have your hands full restoring your newly acquired LesRo Javelin.

I’d honestly be afraid to take on a project like that myself, so credit where credit is due.

I sincerely admire the dedication and skill it takes to tackle a restoration of that caliber.

😎

▲

⟩⟩

Madwelshman

zooma

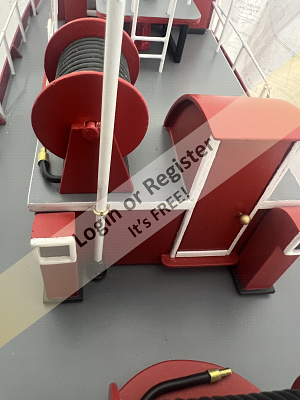

📝 JUANITA STERN WHEELER

14 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 2 Likes

Flag

💬 Add Comment

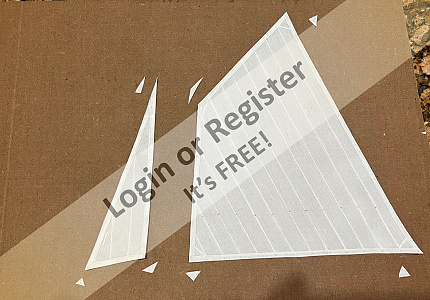

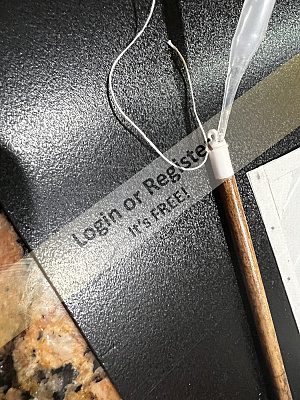

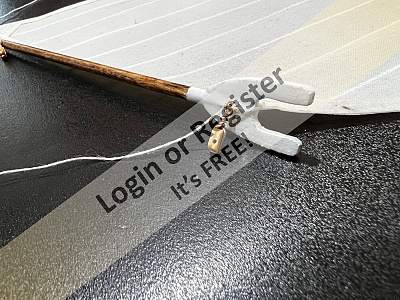

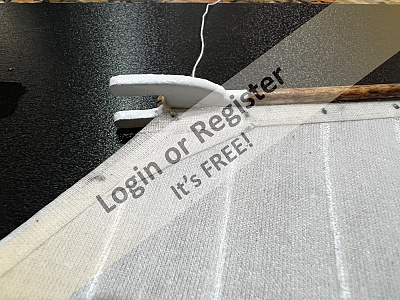

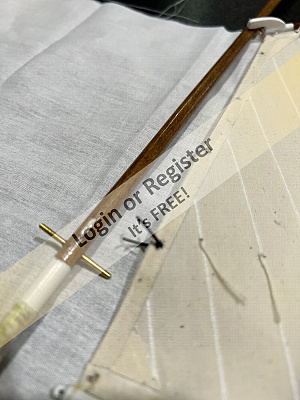

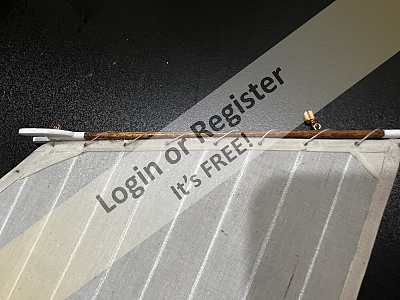

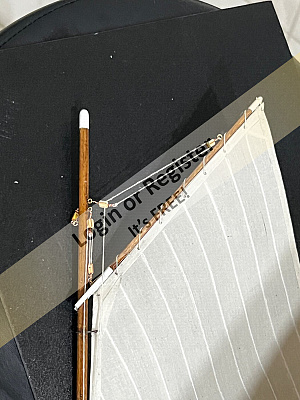

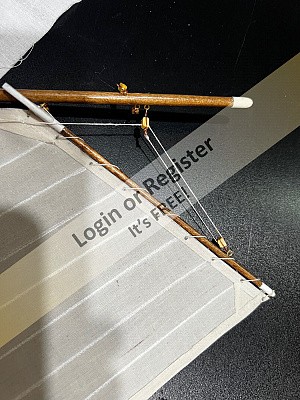

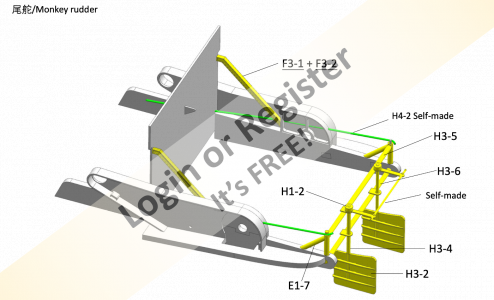

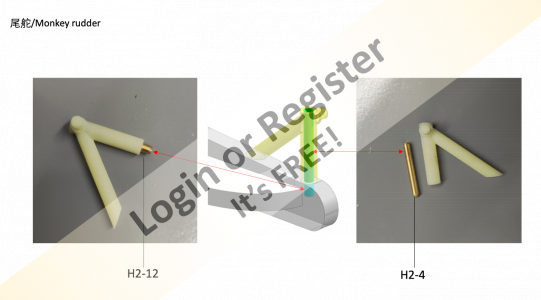

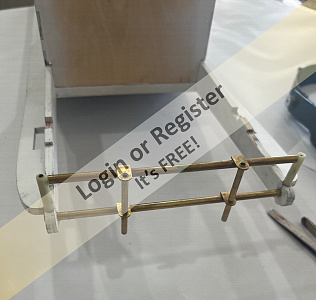

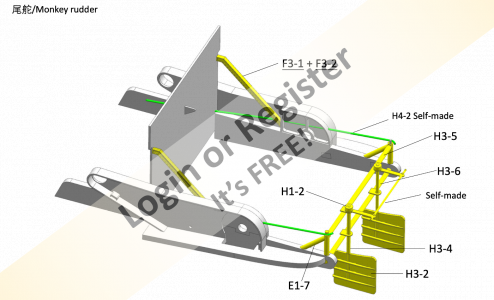

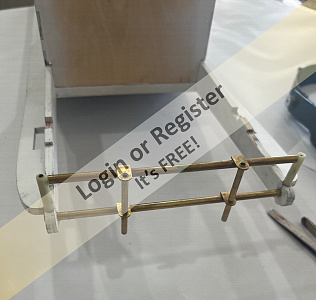

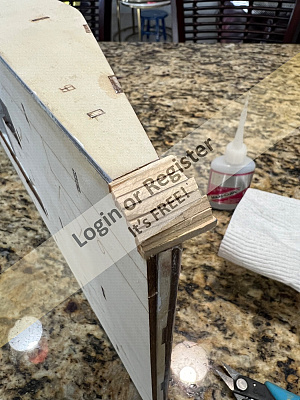

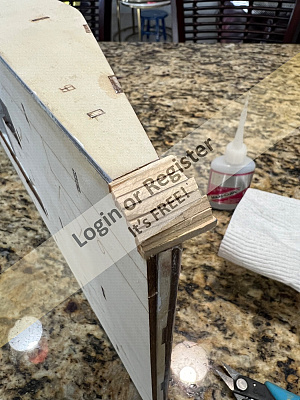

Assembling the Monkey Rudders and Components

After having a good time assembling the window panes, I moved on the next day to assembling the Monkey Rudders and their components.

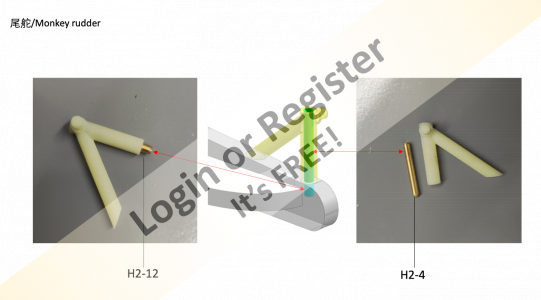

Before assembling anything, the first and most important step is to locate, mark, and drill a small pilot hole on top of the paddle horns A18, as shown. This is where part E1-7 will later be glued.

Be careful with E1-7, as there is a right and a left piece. Also, be very gentle when drilling the final hole that will accept the brass tube from E1-7—these parts are small and easy to damage.

Now assemble all the components and perform a full dry fit.

Your kit includes two pieces: one measuring 154 mm (top) and one 161 mm (bottom).

Once you are satisfied that everything fits correctly, disassemble the parts and epoxy only the bottom piece H3-6. Make sure the holes that accept H3-4 (the monkey rudder stock) are properly aligned and match the position of K3-5.

After the bottom piece has fully cured, epoxy the remaining components in place.

😎

After having a good time assembling the window panes, I moved on the next day to assembling the Monkey Rudders and their components.

Before assembling anything, the first and most important step is to locate, mark, and drill a small pilot hole on top of the paddle horns A18, as shown. This is where part E1-7 will later be glued.

Be careful with E1-7, as there is a right and a left piece. Also, be very gentle when drilling the final hole that will accept the brass tube from E1-7—these parts are small and easy to damage.

Now assemble all the components and perform a full dry fit.

Your kit includes two pieces: one measuring 154 mm (top) and one 161 mm (bottom).

Once you are satisfied that everything fits correctly, disassemble the parts and epoxy only the bottom piece H3-6. Make sure the holes that accept H3-4 (the monkey rudder stock) are properly aligned and match the position of K3-5.

After the bottom piece has fully cured, epoxy the remaining components in place.

😎

▲

⟩⟩

hermank

pressonreguardless

📝 JUANITA STERN WHEELER

14 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

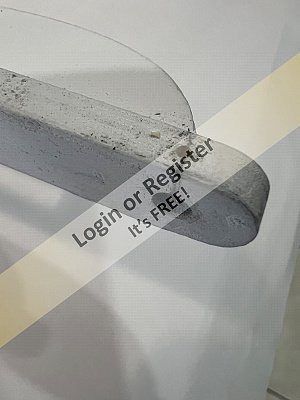

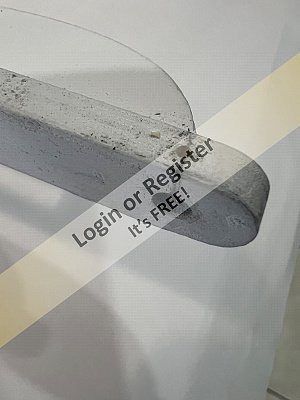

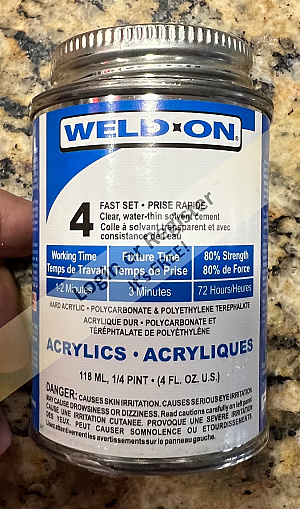

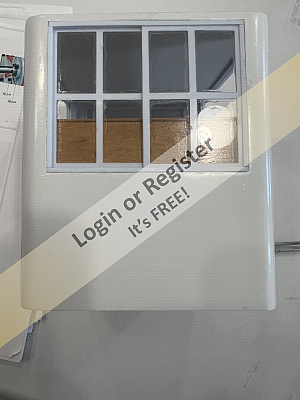

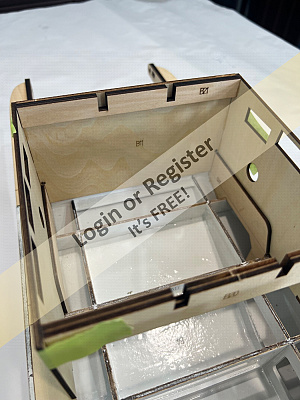

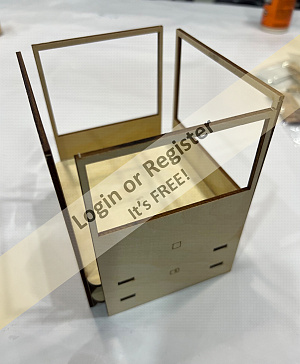

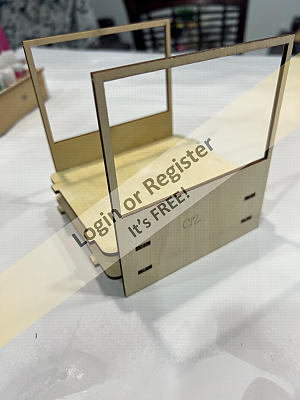

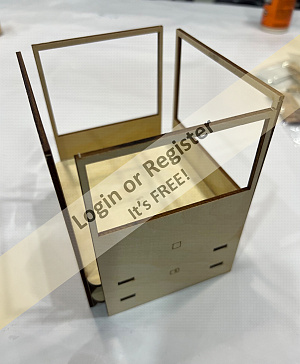

Gluing Window Panes to the Window Frames

This was my first attempt at assembling the pilothouse window panes into their corresponding frames.

I initially used canopy glue, but I wasn’t satisfied with the final result. Too much dried glue was visible, and trying to remove it from the clear window panes turned into a tedious and honestly horrifying experience.

A fellow modeler then recommended Micro Metal Foil Adhesive. Unfortunately, after a few days of frustration—and more than a few nightmares—working with something that looks simple but is extremely difficult to execute cleanly, I knew I needed a different approach.

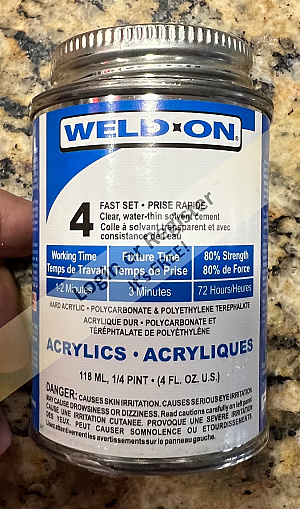

That’s when the light bulb went on. Since I work for a display company, I remembered that we regularly use Weld-On for many of our projects. I decided to give it a try—this time knowing I had to be completely calm and in full control. I applied it using a syringe fitted with a very fine needle, placing just a couple of drops at a time. The precision required was definitely nerve-racking.

For that, I relied on a proven nerve-calming formula: Glenlivet 18-Year-Old Scotch 🍷 😁 a very effective solution used by many modelers.

This was my first attempt at assembling the pilothouse window panes into their corresponding frames.

I initially used canopy glue, but I wasn’t satisfied with the final result. Too much dried glue was visible, and trying to remove it from the clear window panes turned into a tedious and honestly horrifying experience.

A fellow modeler then recommended Micro Metal Foil Adhesive. Unfortunately, after a few days of frustration—and more than a few nightmares—working with something that looks simple but is extremely difficult to execute cleanly, I knew I needed a different approach.

That’s when the light bulb went on. Since I work for a display company, I remembered that we regularly use Weld-On for many of our projects. I decided to give it a try—this time knowing I had to be completely calm and in full control. I applied it using a syringe fitted with a very fine needle, placing just a couple of drops at a time. The precision required was definitely nerve-racking.

For that, I relied on a proven nerve-calming formula: Glenlivet 18-Year-Old Scotch 🍷 😁 a very effective solution used by many modelers.

▲

⟩⟩

Rookysailor

hermank

pressonreguardless

📝 JUANITA STERN WHEELER

14 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 3 Likes

Flag

💬 Add Comment

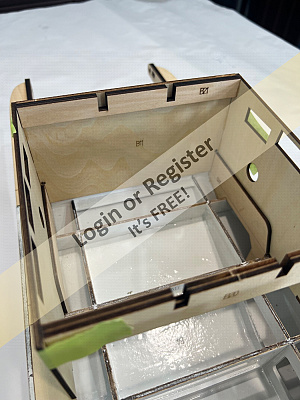

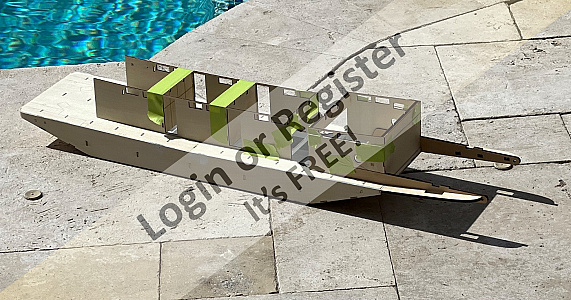

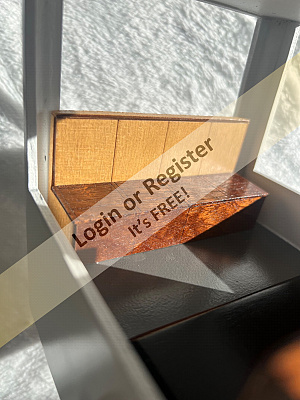

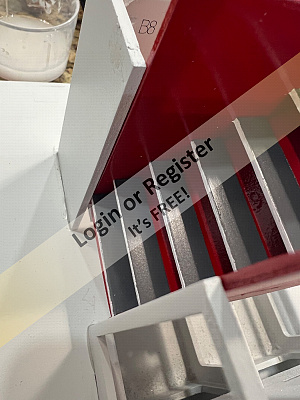

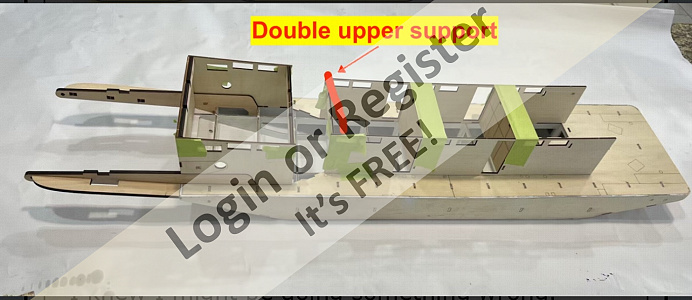

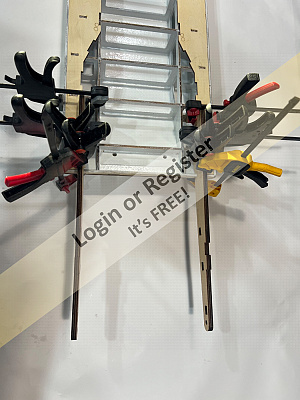

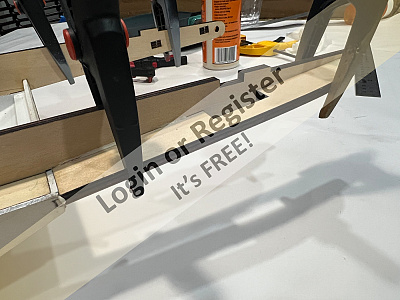

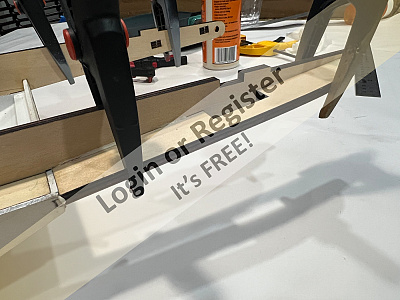

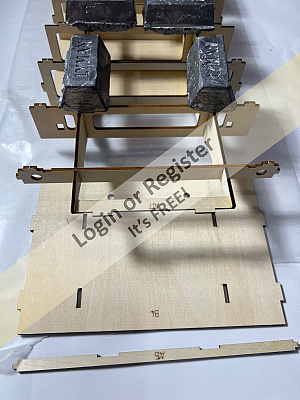

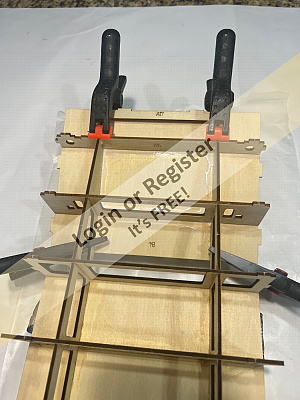

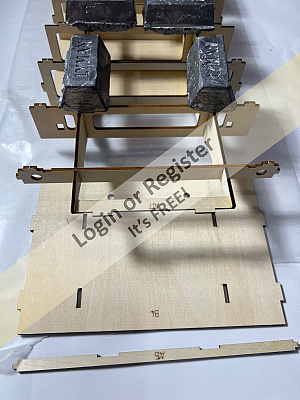

Attaching the Superstructure to the Hull

After sanding and priming to my satisfaction, I permanently glued the superstructure to the deck.

I used a few spare wooden wedges to ensure the structure made full contact with all sides of the hull while the glue cured.

As you can see in many of the photos, I use Lyman lead weights whenever I have the opportunity. Their flat shape and weight make them ideal for holding parts firmly in place without shifting during glue-up.

😎

After sanding and priming to my satisfaction, I permanently glued the superstructure to the deck.

I used a few spare wooden wedges to ensure the structure made full contact with all sides of the hull while the glue cured.

As you can see in many of the photos, I use Lyman lead weights whenever I have the opportunity. Their flat shape and weight make them ideal for holding parts firmly in place without shifting during glue-up.

😎

▲

⟩⟩

Rookysailor

hermank

pressonreguardless

📝 JUANITA STERN WHEELER

15 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 3 Likes

Flag

💬 Add Comment

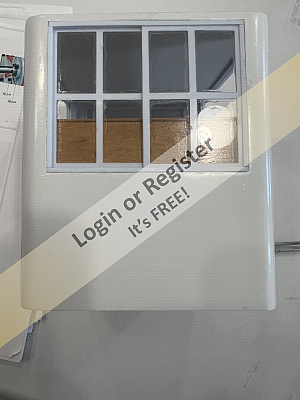

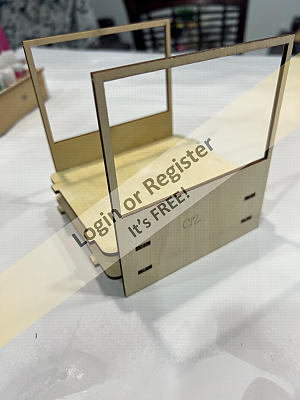

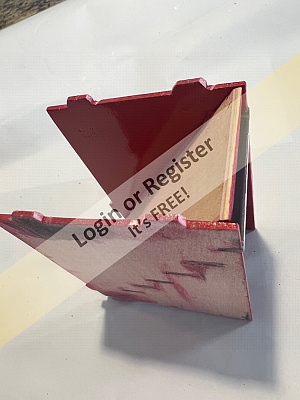

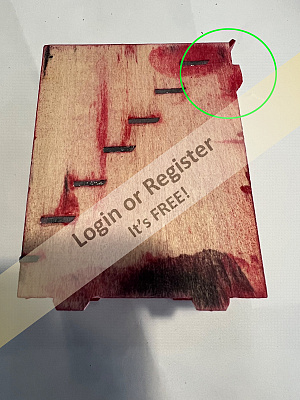

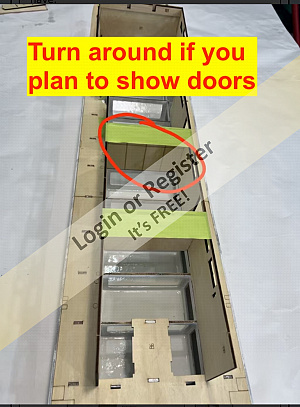

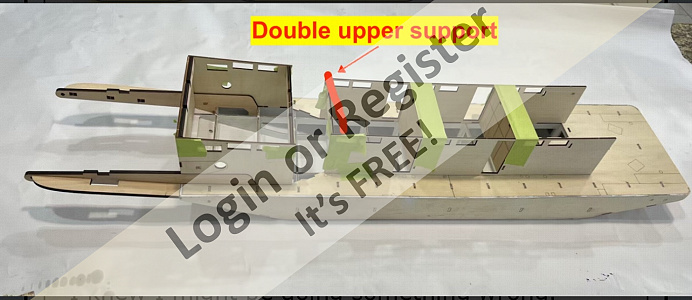

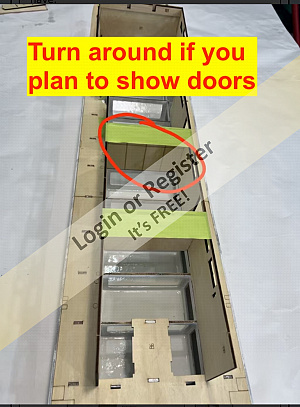

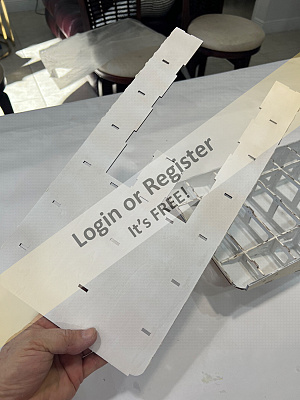

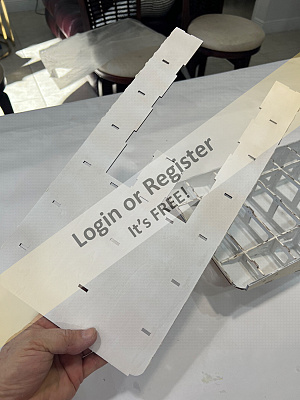

Superstructure Crossbeams – Continued

1. At this stage, I felt the structure needed additional support between B19 and B20+20, so I added a reinforcing bridge. This piece was carefully sized to sit perfectly flush on top, since any excess height would interfere with the sundeck above.

2. Before mounting the doors, I decided it would be a good idea to add rear backing support. As shown in one of the photos, this extra reinforcement helps keep everything rigid and prevents movement later on.

3. Next, I positioned the doors and windows. I made reference markings directly on the structure to ensure the correct orientation, especially to keep the door handles facing the proper direction.

4. When installing the window frames, I used a strip as a guide so all frames would be aligned and consistent. Later in the build, some of the very thin upper sections broke, so I reinforced them by adding a 1/16" square strip to the inside of each window opening. This greatly improved their strength without affecting appearance.

5.

The final photo shows the completed superstructure with primer applied. I never glue this assembly to the deck at this stage, as I prefer to paint it separately before permanently attaching it.

Note: You can also see the corner supports glued to the front of the structure. These are in place to receive the companionway unit later on, once the entire vessel has received its final finish.

😎

1. At this stage, I felt the structure needed additional support between B19 and B20+20, so I added a reinforcing bridge. This piece was carefully sized to sit perfectly flush on top, since any excess height would interfere with the sundeck above.

2. Before mounting the doors, I decided it would be a good idea to add rear backing support. As shown in one of the photos, this extra reinforcement helps keep everything rigid and prevents movement later on.

3. Next, I positioned the doors and windows. I made reference markings directly on the structure to ensure the correct orientation, especially to keep the door handles facing the proper direction.

4. When installing the window frames, I used a strip as a guide so all frames would be aligned and consistent. Later in the build, some of the very thin upper sections broke, so I reinforced them by adding a 1/16" square strip to the inside of each window opening. This greatly improved their strength without affecting appearance.

5.

The final photo shows the completed superstructure with primer applied. I never glue this assembly to the deck at this stage, as I prefer to paint it separately before permanently attaching it.

Note: You can also see the corner supports glued to the front of the structure. These are in place to receive the companionway unit later on, once the entire vessel has received its final finish.

😎

▲

⟩⟩

Rookysailor

hermank

pressonreguardless

📝 JUANITAS STERN WHEELER

16 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 3 Likes

Flag

💬 Add Comment

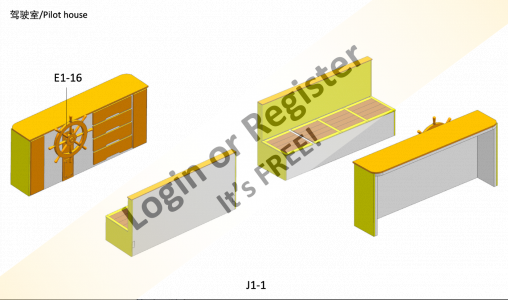

Pilothouse Control Console

The next step was the construction of the pilothouse control console and bench.

At this stage of the build, I had to make a decision: whether to build the kit-supplied console or attempt to replicate the actual console found on the real Juanita.

In the interest of simplicity and progress, I chose the more straightforward route and proceeded with the kit-provided control console.

In the last photo, you can also notice what appears to be a black anti-fatigue mat on the floor in front of the console—this is a small detail I added for authenticity.

😎

The next step was the construction of the pilothouse control console and bench.

At this stage of the build, I had to make a decision: whether to build the kit-supplied console or attempt to replicate the actual console found on the real Juanita.

In the interest of simplicity and progress, I chose the more straightforward route and proceeded with the kit-provided control console.

In the last photo, you can also notice what appears to be a black anti-fatigue mat on the floor in front of the console—this is a small detail I added for authenticity.

😎

▲

⟩⟩

Rookysailor

hermank

pressonreguardless

📝 JUANITA STERN WHEELER

16 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 3 Likes

Flag

💬 Add Comment

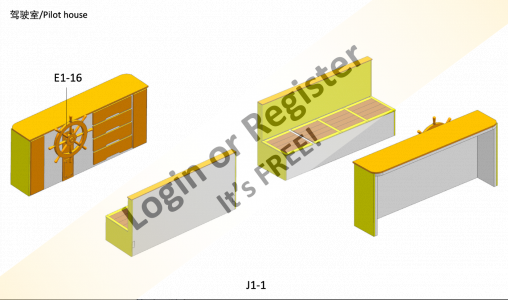

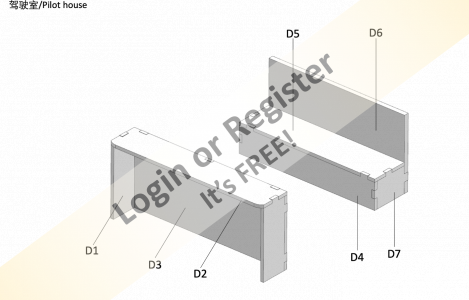

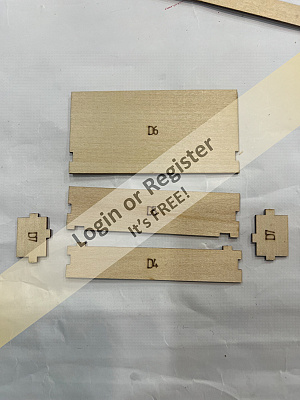

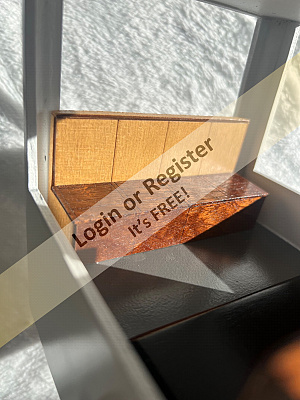

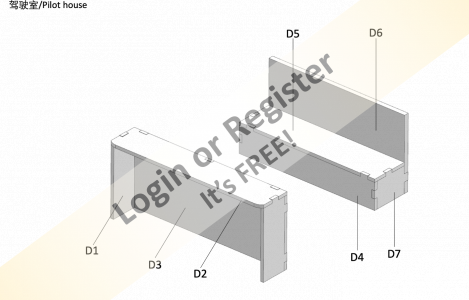

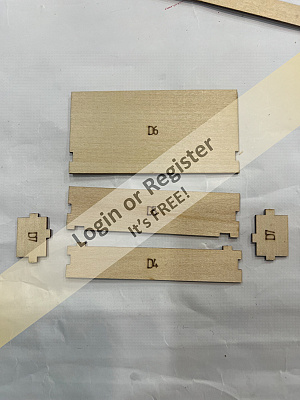

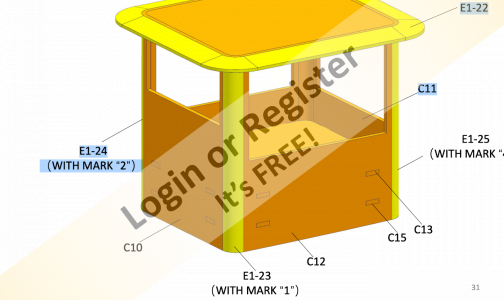

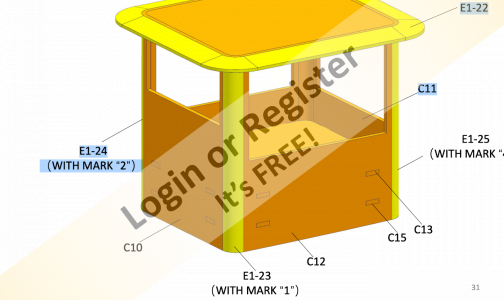

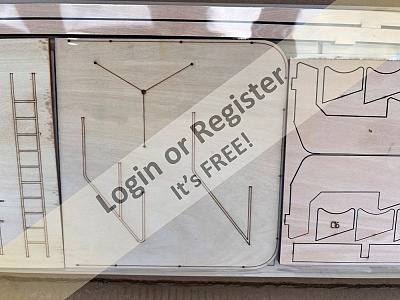

Pilothouse Assembly

While allowing the superstructure to dry, I used the time to begin construction of the pilothouse.

First, I’ll show the instruction drawings.

When it comes time to install the rounded corner pieces, keep in mind that the plastic corner parts are numbered on the inside and must be installed in their corresponding corners. Be sure to match them correctly before gluing.

The final photo shows the kit-provided markings on the pilothouse roof, which are intended to help position the items that will be added later in the building.

Great detail that the maker to in consideration.

😎

While allowing the superstructure to dry, I used the time to begin construction of the pilothouse.

First, I’ll show the instruction drawings.

When it comes time to install the rounded corner pieces, keep in mind that the plastic corner parts are numbered on the inside and must be installed in their corresponding corners. Be sure to match them correctly before gluing.

The final photo shows the kit-provided markings on the pilothouse roof, which are intended to help position the items that will be added later in the building.

Great detail that the maker to in consideration.

😎

▲

⟩⟩

Rookysailor

pressonreguardless

hermank

📝 JUANITA STERN WHEELER

16 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 24 Views · 3 Likes

Flag

💬 Add Comment

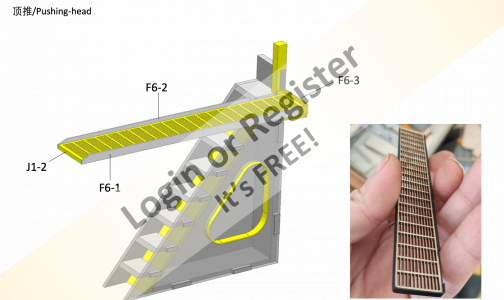

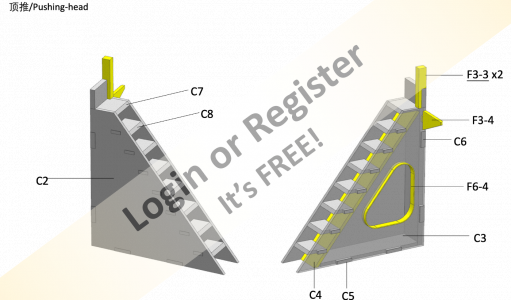

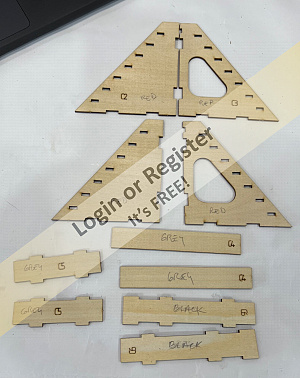

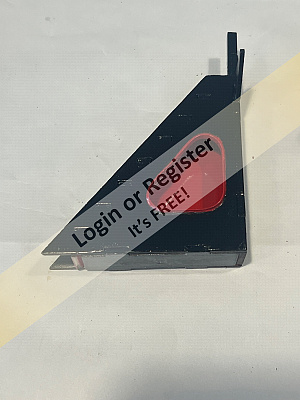

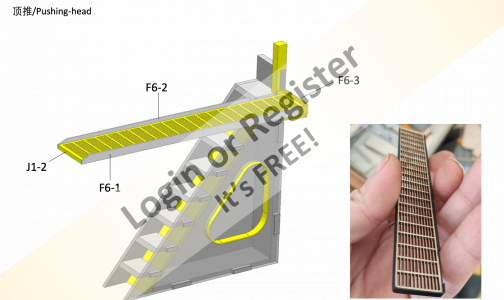

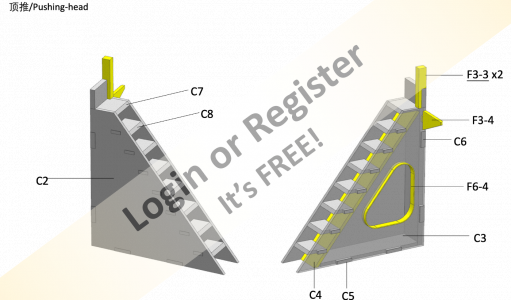

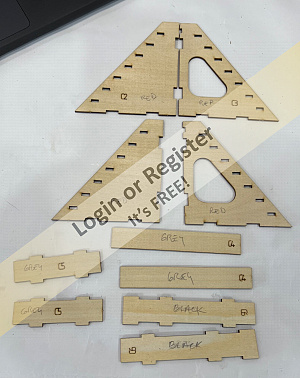

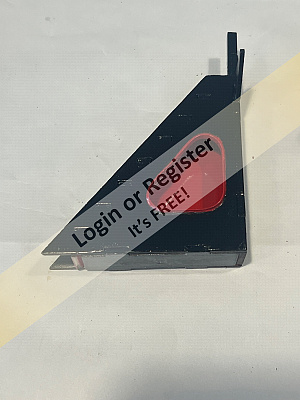

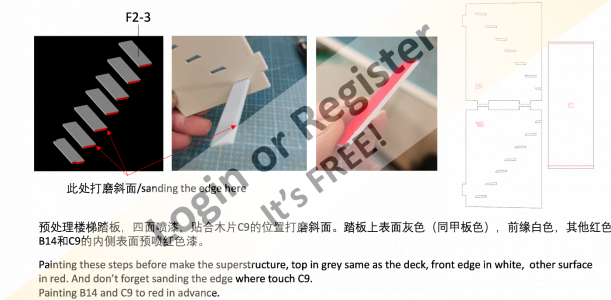

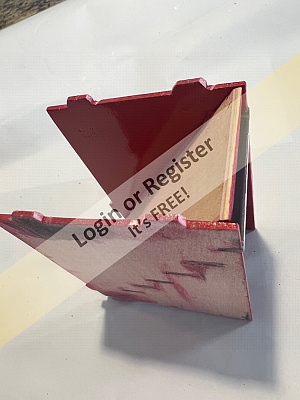

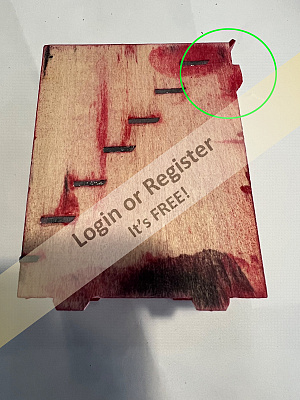

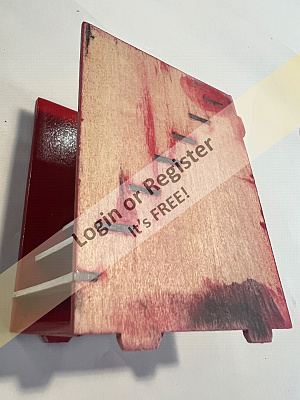

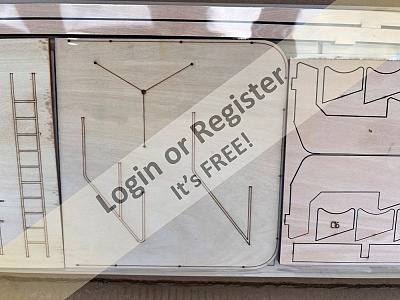

Pushing Heads / Knees Assembly

Another component that should be assembled separately is the set of 17 pieces that make up the pushing heads (knees). I recommend approaching this task in a relaxed manner, as it is time-consuming and requires patience.

First, I’ll show what is provided in the instruction drawings.

1. The treads include lasered markings that indicate the areas which must be sanded at an angle to achieve the correct fit.

2. All 17 individual pieces need to be painted separately. This is a very tedious and, at times, frustrating process, but it’s necessary to achieve a clean final result.

3. The final two photos show the completed, assembled units—those little buggers once they’re finally done. 😎

Another component that should be assembled separately is the set of 17 pieces that make up the pushing heads (knees). I recommend approaching this task in a relaxed manner, as it is time-consuming and requires patience.

First, I’ll show what is provided in the instruction drawings.

1. The treads include lasered markings that indicate the areas which must be sanded at an angle to achieve the correct fit.

2. All 17 individual pieces need to be painted separately. This is a very tedious and, at times, frustrating process, but it’s necessary to achieve a clean final result.

3. The final two photos show the completed, assembled units—those little buggers once they’re finally done. 😎

▲

⟩⟩

Rookysailor

pressonreguardless

hermank

📝 JUANITA STERN WHEELER

17 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 25 Views · 3 Likes

Flag

💬 Add Comment

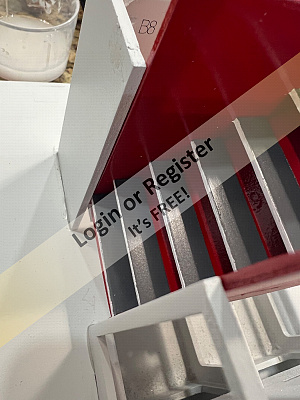

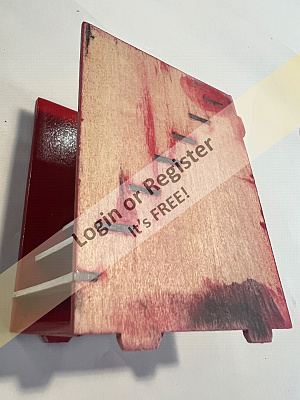

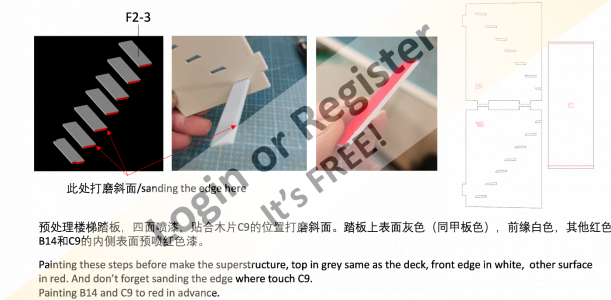

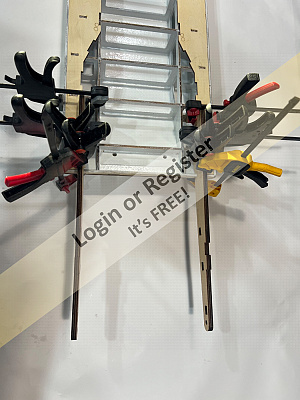

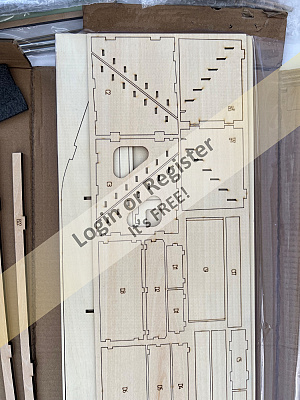

Stairs: Lower Deck to Sundeck”Companionway”

Another component of the superstructure is the companionway stairs assembly connecting the lower deck to the sundeck. All of the stair components need to be painted prior to assembly. This is a three-color part and not an easy one to finish cleanly, especially along the edges of the treads

This stairway section also requires some trimming of the interlocking tabs in order to fit properly into the upper section of the superstructure.

1. First, let me show what is provided in the instruction drawings. I then added the back panel of the treads, setting it at the correct angle so it would mate properly with the upper deck. I assembled the treads on a flat surface to ensure they were all even and aligned.

2. This side represents the top portion that meets the sundeck. During dry fitting, the stairway assembly will slide into position, but the upper tabs require a slight angle in order to engage properly.

3. When dry fitting the stairway, I noticed that at the front—where the stairway assembly meets the forward structure—the rear tabs that interlock with the crossbeam prevented the stairs from sliding fully into place. The only solution I found was to carefully sand a small angle into the rear tabs so the assembly could be eased down into position.

4. The final photo shows the upper tabs sanded at a slight angle to facilitate insertion into the upper part of the structure. I’m not entirely sure how the designer intended this to be done, but this method works well and allows the stairs to seat correctly.

After I was satisfied with how the entire stair unit fit and how all of the tabs engaged, I set it aside for final gluing at a later stage.

😎

Another component of the superstructure is the companionway stairs assembly connecting the lower deck to the sundeck. All of the stair components need to be painted prior to assembly. This is a three-color part and not an easy one to finish cleanly, especially along the edges of the treads

This stairway section also requires some trimming of the interlocking tabs in order to fit properly into the upper section of the superstructure.

1. First, let me show what is provided in the instruction drawings. I then added the back panel of the treads, setting it at the correct angle so it would mate properly with the upper deck. I assembled the treads on a flat surface to ensure they were all even and aligned.

2. This side represents the top portion that meets the sundeck. During dry fitting, the stairway assembly will slide into position, but the upper tabs require a slight angle in order to engage properly.

3. When dry fitting the stairway, I noticed that at the front—where the stairway assembly meets the forward structure—the rear tabs that interlock with the crossbeam prevented the stairs from sliding fully into place. The only solution I found was to carefully sand a small angle into the rear tabs so the assembly could be eased down into position.

4. The final photo shows the upper tabs sanded at a slight angle to facilitate insertion into the upper part of the structure. I’m not entirely sure how the designer intended this to be done, but this method works well and allows the stairs to seat correctly.

After I was satisfied with how the entire stair unit fit and how all of the tabs engaged, I set it aside for final gluing at a later stage.

😎

▲

⟩⟩

Rookysailor

pressonreguardless

hermank

Login To

Remove Ads

Remove Ads

📝 JUANITA STERN WHEELER

17 hours ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 26 Views · 3 Likes

Flag

💬 Add Comment

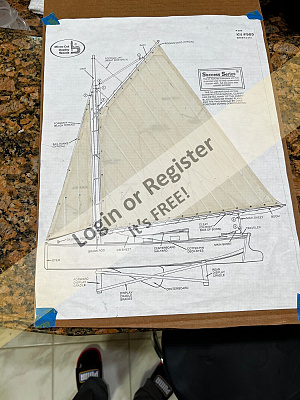

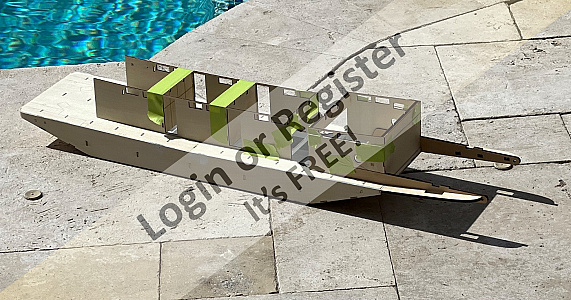

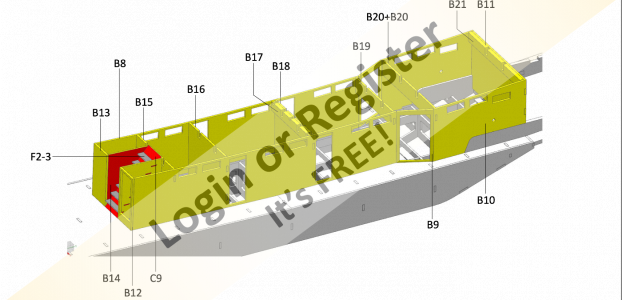

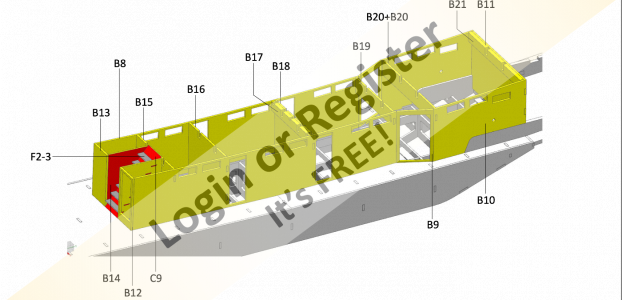

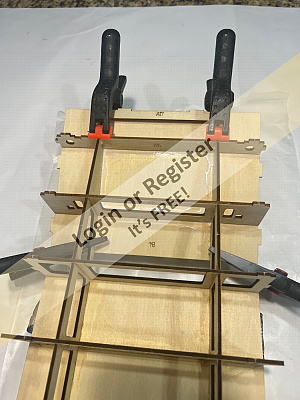

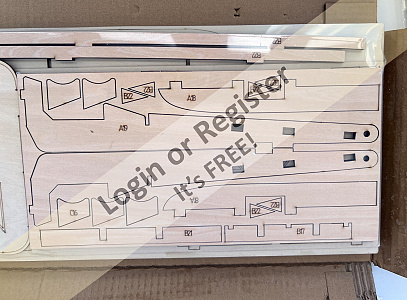

Superstructure Assembly

For the superstructure assembly, I received a great deal of guidance from Chuck, who was very helpful in putting this section together, as he was with many others, until communication was unfortunately interrupted due to internet restrictions in China.

The instruction drawings do not specify an assembly sequence, so after giving it some careful thought, this is the approach I followed. I began the assembly from the stern forward, starting with parts B10, B11, and B21.

I made an error when installing B20, as I initially did not laminate (double) the part. I later corrected this by tracing the original, cutting a replacement, and installing it afterward.

Part B16 should be reversed if you intend to open the door and display the interior. I chose not to show the interior and installed it as supplied, although opening the door would have been a nice added detail.

The yellow copy shown was marked by Chuck.

😎

For the superstructure assembly, I received a great deal of guidance from Chuck, who was very helpful in putting this section together, as he was with many others, until communication was unfortunately interrupted due to internet restrictions in China.

The instruction drawings do not specify an assembly sequence, so after giving it some careful thought, this is the approach I followed. I began the assembly from the stern forward, starting with parts B10, B11, and B21.

I made an error when installing B20, as I initially did not laminate (double) the part. I later corrected this by tracing the original, cutting a replacement, and installing it afterward.

Part B16 should be reversed if you intend to open the door and display the interior. I chose not to show the interior and installed it as supplied, although opening the door would have been a nice added detail.

The yellow copy shown was marked by Chuck.

😎

▲

⟩⟩

Rookysailor

pressonreguardless

hermank

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 30 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

Cash;

Yes, that’s my goal with this build.

i actually started working on it the very first day I received the kit in the mail, but other commitments kept putting it on the back burner.

Now I’m finally free from building for someone else, and I can focus on building just for myself…at least until Juanita is paddling in the water.

😎

Yes, that’s my goal with this build.

i actually started working on it the very first day I received the kit in the mail, but other commitments kept putting it on the back burner.

Now I’m finally free from building for someone else, and I can focus on building just for myself…at least until Juanita is paddling in the water.

😎

▲

⟩⟩

hermank

DWBrinkman

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 5 Likes

Flag

💬 Add Comment

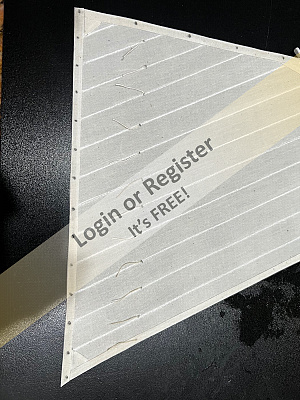

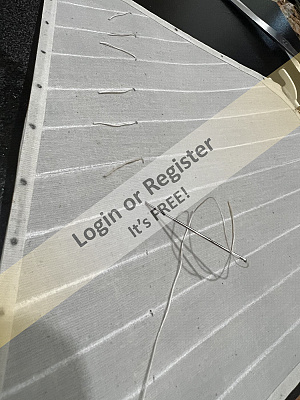

Stern Wheel Arms Assembly

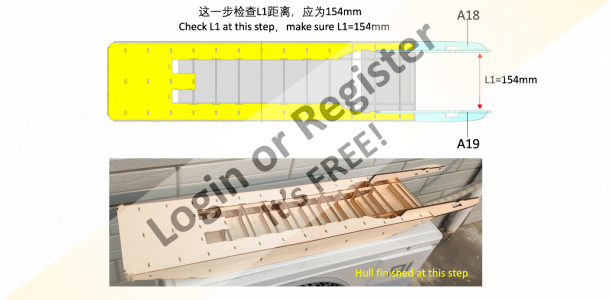

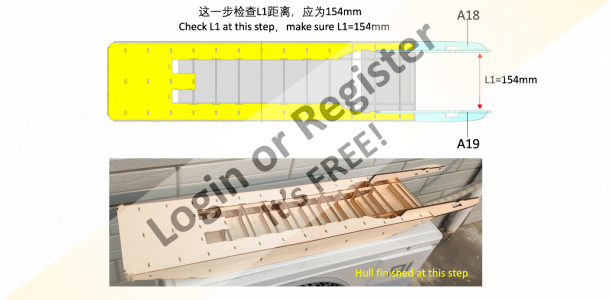

1. The next step is to assemble the stern wheel arms A18 and A19.

2. Before gluing A18 to A19, ensure that the opening between the two A19 arms measures exactly 154 mm.

3. Once the correct spacing is confirmed, glue A18 in place.

😎

1. The next step is to assemble the stern wheel arms A18 and A19.

2. Before gluing A18 to A19, ensure that the opening between the two A19 arms measures exactly 154 mm.

3. Once the correct spacing is confirmed, glue A18 in place.

😎

▲

⟩⟩

Rookysailor

hermank

premecekcz

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

Once again, I’d like to emphasize that all of the parts shown so far interlock perfectly, with no adjustment required. In this particular case, I did have to apply slight pressure during installation because some paint had entered the slots. Even so, the part snapped into place cleanly, much like a precision-fit kit component. Overall, this is a very well-engineered and accurately manufactured kit.

You can also see the reference marks on the deck indicating where each component is intended to be installed. With the deck now in place, the rounded bow corners can be filled using leftover scrap material to complete the area cleanly.

😎

You can also see the reference marks on the deck indicating where each component is intended to be installed. With the deck now in place, the rounded bow corners can be filled using leftover scrap material to complete the area cleanly.

😎

▲

⟩⟩

Rookysailor

hermank

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

Hull Interior Sealing and Deck Preparation

1. The entire hull interior was sealed with epoxy. The products I used were purchased from Amazon.

2. After the epoxy had fully cured, I sprayed the interior with primer, followed by paint.

3. Once the paint dried, I scraped the mating edges that will receive the deck to ensure proper glue adhesion.

4. The forward deck was sealed and primed prior to being glued to the hull.

😎

1. The entire hull interior was sealed with epoxy. The products I used were purchased from Amazon.

2. After the epoxy had fully cured, I sprayed the interior with primer, followed by paint.

3. Once the paint dried, I scraped the mating edges that will receive the deck to ensure proper glue adhesion.

4. The forward deck was sealed and primed prior to being glued to the hull.

😎

▲

⟩⟩

Rookysailor

hermank

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 4 Likes

Flag

💬 Add Comment

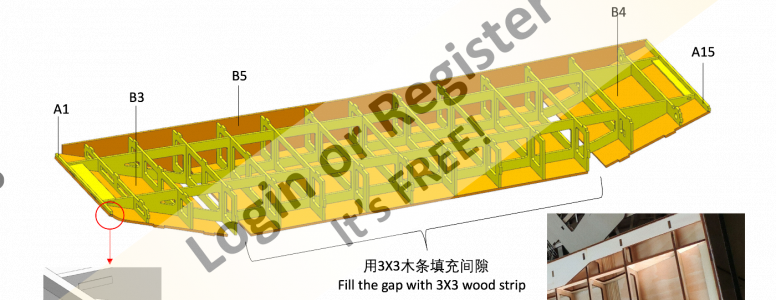

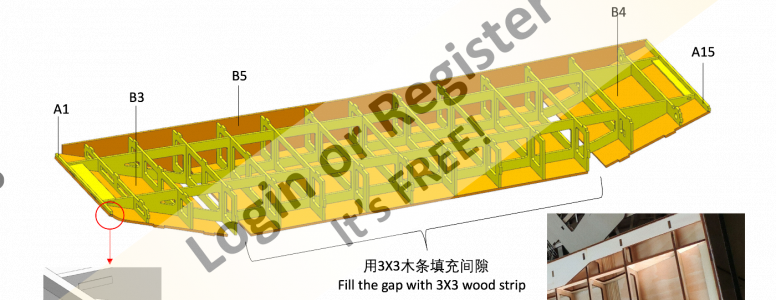

Once all the frames had fully dried, the next step was to install the bow bottom B3 and bow tip A1, followed by the stern bottom B4 and stern tip A15.

The bow tip A1 is a thin piece and requires sanding at a slight angle. Care should be taken during this process, as the part is fragile—I broke mine while sanding, as shown in the drawing.

The final photo shows how I filled the curved bottom joints using thin leftover material to improve continuity and support.

😎

The bow tip A1 is a thin piece and requires sanding at a slight angle. Care should be taken during this process, as the part is fragile—I broke mine while sanding, as shown in the drawing.

The final photo shows how I filled the curved bottom joints using thin leftover material to improve continuity and support.

😎

▲

⟩⟩

Rookysailor

hermank

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

Once all the frames had fully dried, the next step was to install the bow bottom B3 and bow tip A1, followed by the stern bottom B4 and stern tip A15.

The bow tip A1 is a thin piece and requires sanding at a slight angle. Care should be taken during this process, as the part is fragile...I broke mine while sanding, as shown in the drawing.

😎

The bow tip A1 is a thin piece and requires sanding at a slight angle. Care should be taken during this process, as the part is fragile...I broke mine while sanding, as shown in the drawing.

😎

▲

⟩⟩

Rookysailor

hermank

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

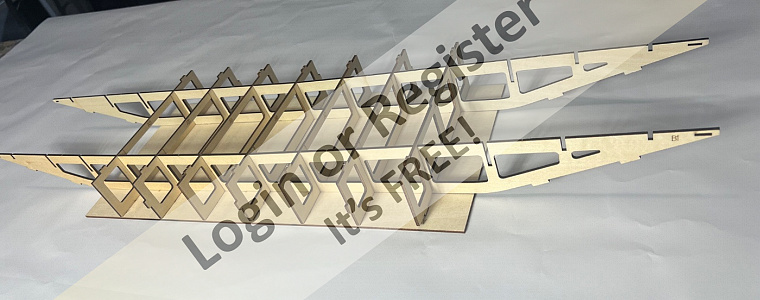

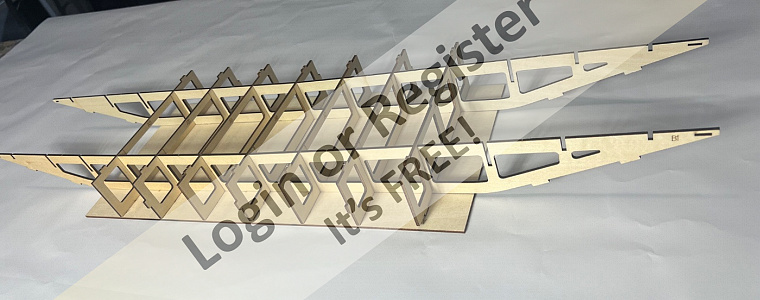

First Step

I began with a dry fit of several frames to the hull bottom. The fit is almost snap-together in nature, with the parts aligning perfectly. However, there is a specific assembly sequence that must be followed when gluing the frames to the hull bottom to ensure proper alignment.

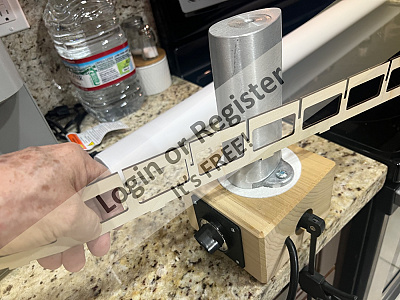

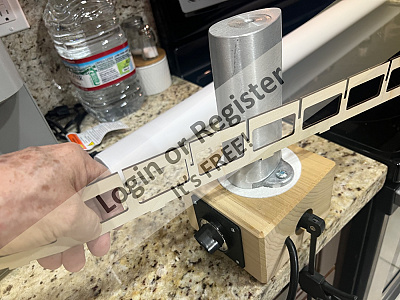

One side of the hull bottom had a slight bend, which I corrected using my guitar wood bender. In retrospect, this may not have been strictly necessary, as the frames would likely have pulled the structure straight during assembly. Nevertheless, I preferred to correct it beforehand to ensure everything was properly aligned before gluing.

😎

I began with a dry fit of several frames to the hull bottom. The fit is almost snap-together in nature, with the parts aligning perfectly. However, there is a specific assembly sequence that must be followed when gluing the frames to the hull bottom to ensure proper alignment.

One side of the hull bottom had a slight bend, which I corrected using my guitar wood bender. In retrospect, this may not have been strictly necessary, as the frames would likely have pulled the structure straight during assembly. Nevertheless, I preferred to correct it beforehand to ensure everything was properly aligned before gluing.

😎

▲

⟩⟩

Rookysailor

hermank

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 2 Likes

Flag

💬 Add Comment

When ordering the kit, you can choose between plastic or brass rudders. I elected to use the brass rudders for this build, as their accuracy and level of detail are truly exceptional.

😎

😎

▲

⟩⟩

hermank

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 31 Views · 2 Likes

Flag

💬 Add Comment

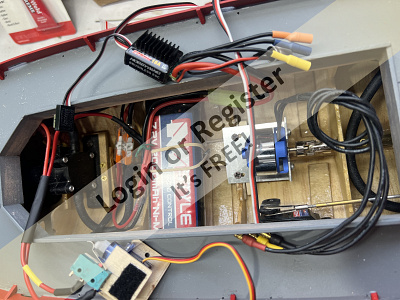

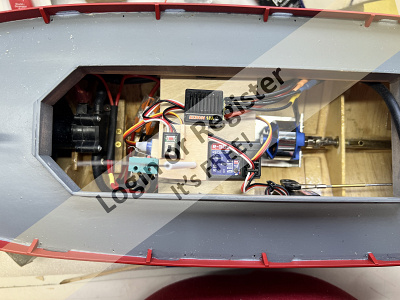

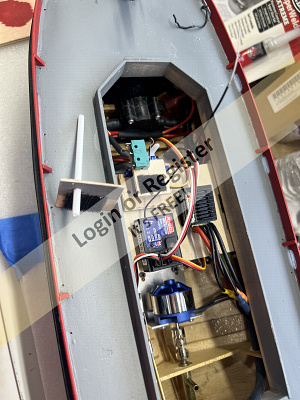

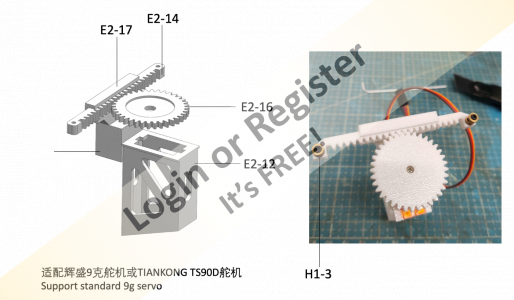

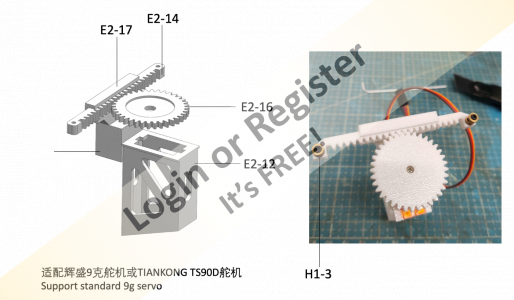

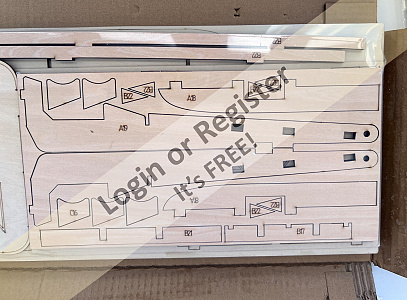

Also included are two very practical 9 g servo trays, intended for the steering and speed control mechanisms.

😎

😎

▲

⟩⟩

hermank

pressonreguardless

Login To

Remove Ads

Remove Ads

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 30 Views · 3 Likes

Flag

💬 Add Comment

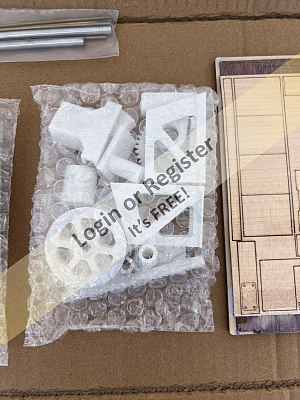

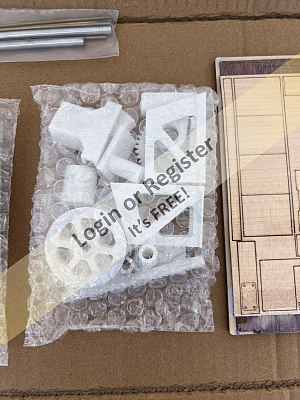

The kit includes a jig to assist with soldering all required brass components. In addition, the 3D-printed parts are accurately produced and show a high level of detail. The kit also includes a motor.

😎

😎

▲

⟩⟩

hermank

EdW

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 29 Views · 4 Likes

Flag

💬 Add Comment

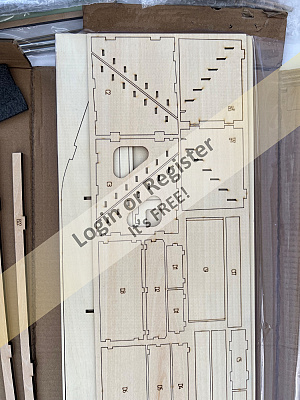

Considering that the kit came from China, it was very well packaged. And the wood is excellent with very clean laser cuts.

▲

⟩⟩

jumpugly

Nickthesteam

hermank

pressonreguardless

📝 JUANITA STERN WHEELER

1 day ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 26 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

A good hello to all members.

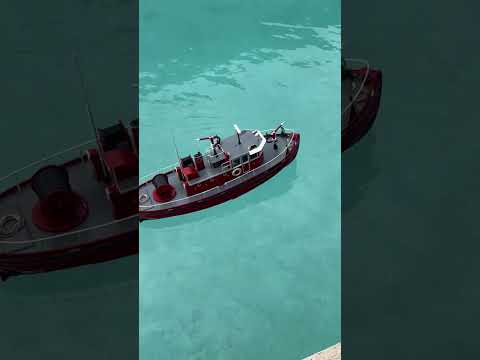

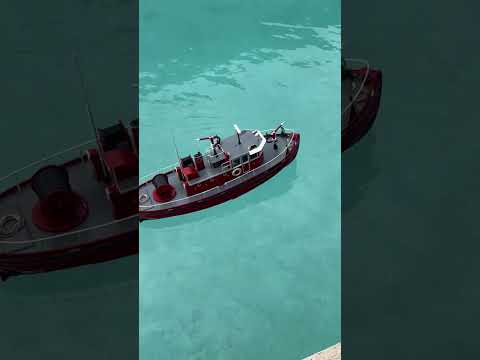

Now that I finished The Fireboat, I would like to add to the forum my favorite build, one you are all familiar with.Hello fellow members.

The Juanita Stern Wheeler.

This an amazing, high end kit that that when finished will be 40" LOA & should weigh under 10lbs ballasted.

According to online sources the JUANITA was built in 1954 by O. F. Shearer & Sons at Cedar Grove, West Virginia. Another source on the internet says that the JUANITA has been "in operation since 1977."

The present owner of the JUANITA is Tom Cook of Dunbar, West Virginia on the Kanawha River.

I was lucky enough to be a part of the first clients that purchase the first run of this fantastic model and I got it for a very reasonable price.

With that being said, I would like to show you guys a building log for this model but buy no means I will say that this is the best way to build the Juanita but this is how Im building it with my limited knowledge and the help of the instructions emailed to me by the designer.

I also like to say that this kit does not have written instructions since this kit was produced in a rush job before kits had to be sent out; the only instructions is a PDF file containing drawings showing the main steps of building process, but the designer himself is very helpful in answering all of my emails about specific needed details in the build.

So, lets get started.

I will start by showing the real Juanita.

😎

Now that I finished The Fireboat, I would like to add to the forum my favorite build, one you are all familiar with.Hello fellow members.

The Juanita Stern Wheeler.

This an amazing, high end kit that that when finished will be 40" LOA & should weigh under 10lbs ballasted.

According to online sources the JUANITA was built in 1954 by O. F. Shearer & Sons at Cedar Grove, West Virginia. Another source on the internet says that the JUANITA has been "in operation since 1977."

The present owner of the JUANITA is Tom Cook of Dunbar, West Virginia on the Kanawha River.

I was lucky enough to be a part of the first clients that purchase the first run of this fantastic model and I got it for a very reasonable price.

With that being said, I would like to show you guys a building log for this model but buy no means I will say that this is the best way to build the Juanita but this is how Im building it with my limited knowledge and the help of the instructions emailed to me by the designer.

I also like to say that this kit does not have written instructions since this kit was produced in a rush job before kits had to be sent out; the only instructions is a PDF file containing drawings showing the main steps of building process, but the designer himself is very helpful in answering all of my emails about specific needed details in the build.

So, lets get started.

I will start by showing the real Juanita.

😎

▲

⟩⟩

Nickthesteam

hermank

pressonreguardless

📝 Lobster Smack

3 days ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 14 Views · 1 Like

Flag

💬 Add Comment

Jumpugly:

Your father’s model is truly outstanding…more than craftsmanship, it feels like a piece of his spirit lives in it.

I think many of us are quietly looking forward to the day your own skill and care bring it back to full glory, as a beautiful tribute to his memory.

Model Expo also offers a Lobster Smack kit, though it isn’t quite as large as your father’s. I thought you might enjoy seeing it:

Your father’s model is truly outstanding…more than craftsmanship, it feels like a piece of his spirit lives in it.

I think many of us are quietly looking forward to the day your own skill and care bring it back to full glory, as a beautiful tribute to his memory.

Model Expo also offers a Lobster Smack kit, though it isn’t quite as large as your father’s. I thought you might enjoy seeing it:

▲

⟩⟩

jumpugly

📝 Midwest/ Model Expo The Fireboat

3 days ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 20 Views · 2 Likes

Flag

💬 Add Comment

Hi Chris:

That was actually one of the questions I asked the Production Manager. According to him, they have already started setting up parts of the model. Now that all of the upgrades are finalized, his estimate is that it may take about two months for the kit to appear in their catalog as soon as possible.

Both of the videos you’ve seen here were shown to Mark, the owner, and he approved moving forward with production of the kit.

The next time I stop by, I’ll be more specific in asking about the release date. I’ll keep everyone posted as soon as possible.

😎

That was actually one of the questions I asked the Production Manager. According to him, they have already started setting up parts of the model. Now that all of the upgrades are finalized, his estimate is that it may take about two months for the kit to appear in their catalog as soon as possible.

Both of the videos you’ve seen here were shown to Mark, the owner, and he approved moving forward with production of the kit.

The next time I stop by, I’ll be more specific in asking about the release date. I’ll keep everyone posted as soon as possible.

😎

▲

⟩⟩

jumpugly

cjanik001

💬 Re: Midwest/ Model Expo The Fireboat

4 days ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 25 Views · 4 Likes

Flag

💬 Add Comment

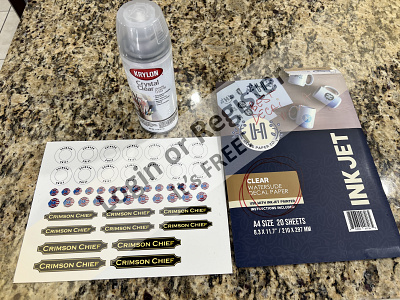

I’ll tell them cash. As a matter of fact, I need to stop by anyway to give them the decal file I created with the help of a coworker.

😎

😎

▲

⟩⟩

jumpugly

Cashrc

hermank

DWBrinkman

📝 Midwest/ Model Expo The Fireboat

4 days ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 27 Views · 8 Likes · 5 Comments

Flag

💬 Add Comment

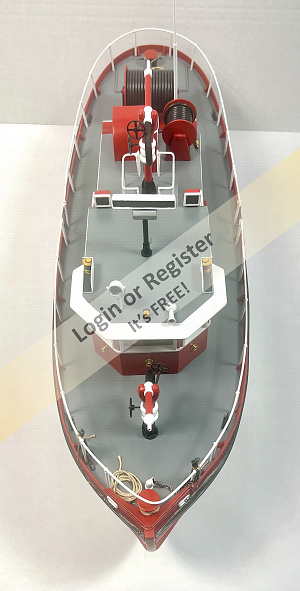

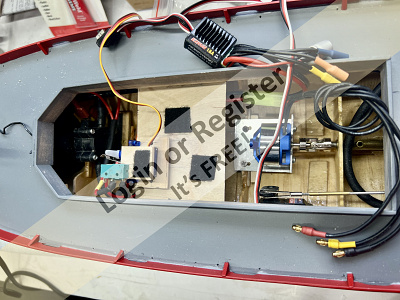

I just returned from Model Expo today, where I had an extended discussion with both the production manager and the designer. At the conclusion of that meeting, I left the model in their care.

After many months of designing, assembling, painting, and refining every detail, the final result was extremely satisfying.

Letting go of a freshly completed model does bring an unexpected sense of detachment.

However, knowing that this improved version will benefit both new and experienced model builders makes the experience a positive one. It’s gratifying to know that my contribution will ultimately serve the greater modeling community.

😎

After many months of designing, assembling, painting, and refining every detail, the final result was extremely satisfying.

Letting go of a freshly completed model does bring an unexpected sense of detachment.

However, knowing that this improved version will benefit both new and experienced model builders makes the experience a positive one. It’s gratifying to know that my contribution will ultimately serve the greater modeling community.

😎

▲

⟩⟩

ChrisF

LeeA

cjanik001

hermank

DWBrinkman

RodC

Ronald

jumpugly

📝 Midwest/ Model Expo Fireboat

4 days ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 28 Views · 5 Likes · 3 Comments

Flag

💬 Add Comment

Finally the youtube videos are ready.

THE PHOTO SHOOT.

THE PHOTO SHOOT.

▲

⟩⟩

GARTH

Ronald

hermank

jumpugly

DWBrinkman

💬 Re: Finishing the Decks with Epoxy Resin.

5 days ago by 🇺🇸 chugalone100 ( Commander)

Commander)

Commander)

Commander)✧ 37 Views · 2 Likes

Flag

💬 Add Comment

That is one super sharp looking deck.

Great work.

😎

Great work.

😎

▲

⟩⟩

robbob

hermank

Rear Admiral)

Rear Admiral)

Fleet Admiral)

Fleet Admiral)

Commodore)

Commodore)

Lieutenant Commander)

Lieutenant Commander)

Vice Admiral)

Vice Admiral)

Liked Sprite 7 hours ago

Liked Sprite 7 hours ago