Join Us On Social Media!

United States

Recent Posts

💬 Re: Midwest/ Model Expo The Fireboat

13 days ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 16 Views · 2 Likes

Flag

💬 Add Comment

Is there a timeline as to when this redesigned version will be released?

Chris

Chris

▲

⟩⟩

jumpugly

chugalone100

Login To

Remove Ads

Remove Ads

📝 Dole Aztec cont. (Answers to comments)

1 month ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 12 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

Rod...

I use a metal oven baking sheet or cookie sheet as I call it.

Works good !!!

Chum444...

The Cricut Machine is the called the Cricut Maker. This machine is several years old, and there may be a newer out now.

For CAD design software I use Autosketch ver. 10. I don't think this is available anymore. I have an old program CD from years back and as long as I can load it on new Window versions, I will keep using as it does what I need.

The Cricut Machine has its own type of design software that it uses called Design Space. I can import the files from Autosketch in a .PNG format and go from there.

jumpugly...

I use the polycrylic so the Admiral (Wife) won't throw me out of the house because of the smell!! she is very sensitive to VOC fumes, and I found that this is acceptable. Yes, I did read that this product may not be acceptable for outdoor use, but since my boats rarely get in the water anyway I figured its a good compromise. Once painted, I do spray several coats of Krylon clear coat to protect as well.

Chris

I use a metal oven baking sheet or cookie sheet as I call it.

Works good !!!

Chum444...

The Cricut Machine is the called the Cricut Maker. This machine is several years old, and there may be a newer out now.

For CAD design software I use Autosketch ver. 10. I don't think this is available anymore. I have an old program CD from years back and as long as I can load it on new Window versions, I will keep using as it does what I need.

The Cricut Machine has its own type of design software that it uses called Design Space. I can import the files from Autosketch in a .PNG format and go from there.

jumpugly...

I use the polycrylic so the Admiral (Wife) won't throw me out of the house because of the smell!! she is very sensitive to VOC fumes, and I found that this is acceptable. Yes, I did read that this product may not be acceptable for outdoor use, but since my boats rarely get in the water anyway I figured its a good compromise. Once painted, I do spray several coats of Krylon clear coat to protect as well.

Chris

▲

⟩⟩

hermank

Chum444

📝 Dole Aztec cont.

1 month ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 24 Views · 3 Likes · 3 Comments

Flag

💬 Add Comment

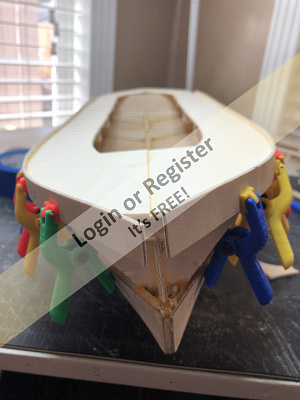

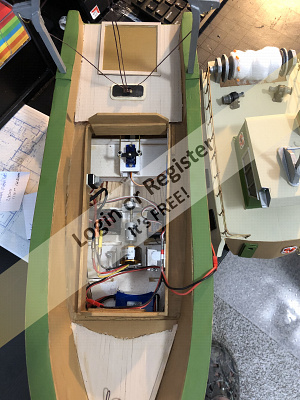

Happy New Year everyone! I thought I would take some time out to finish the build blog for the Dole Aztec. I actually finished the model in September, but haven't had the time to get the blog in. So as the ole saying goes, "the job ain't finished till the paperwork is done!"

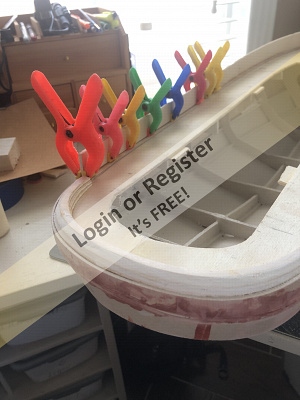

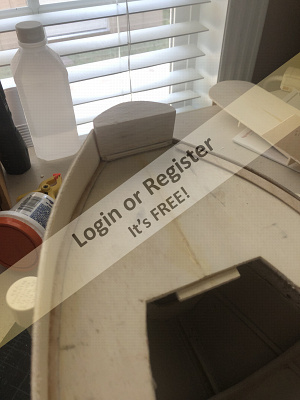

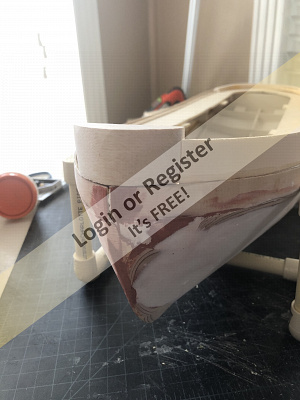

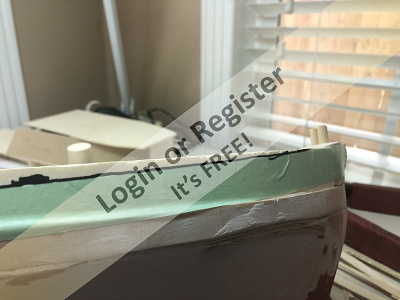

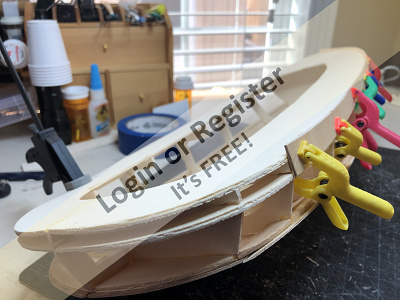

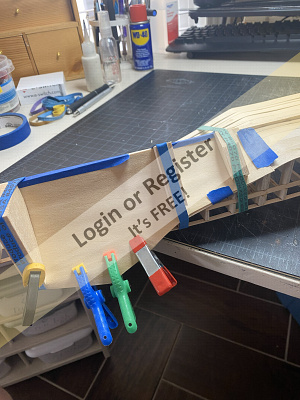

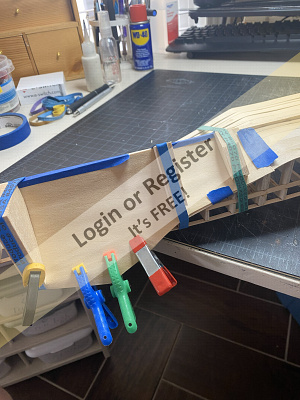

My previous post showed the first layer of hull planking. This was done only on the bottom so that the 1/32 bass wood sheet skins had ample surface area to adhere to. After making card stock templates of each side of the bow bottom, I cut this template into 6 sections, 3 on each side of the keel so that it would be easier to attach to the hull. The bass wood sheet was then cut from the templates for each side. I made some gluing blocks that matched the curvature of the hull at the bow end from some scrap balsa to aid in holding the sheet in place once it was glued. Rubber bands, clamps, and painters tape using to fix the pieces.

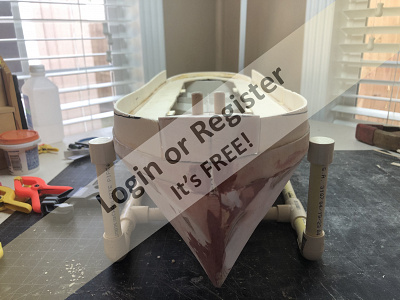

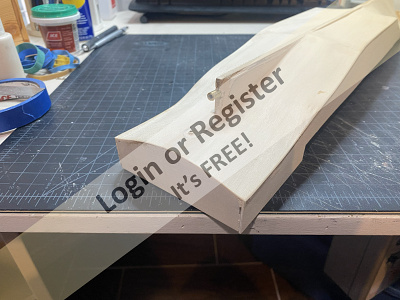

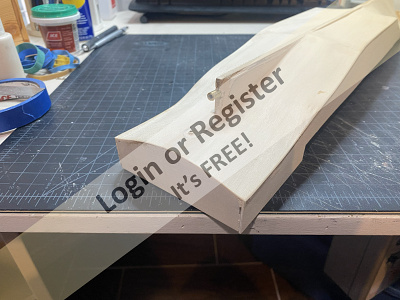

The first two bulkhead sections of the bow were filled with cut pieces of balsa and then sanded to form the curvature of the bow. Side skins made from 3/32" bass wood ply were then added to the sides to finish it off.

Once filled and sanded, the fore deck was cut from 3/32" bass wood ply. The gunnels were made from some .046"x .5" bass wood strip and attached to the edge of the fore deck. This assembly was then glued to the bow of the hull.

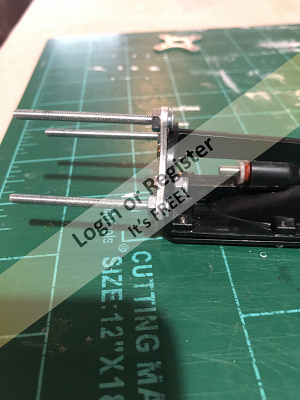

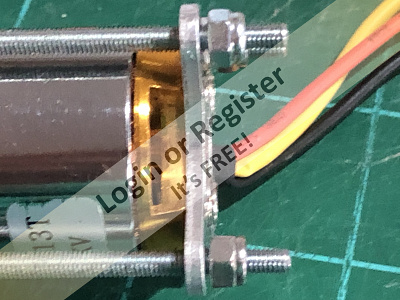

I also made mounting provisions for the rudder servo shown in one of the photos, as well as a removable motor mount. This mount slides in between bulkhead #10 and #11 and attaches to #10 by two 3mm screw hardware.

The inside of the hull was given several liberal coats of Minwax Polycrylic, an acrylic based "polyurathane" to waterproof the hull. I applied this to the outside of the hull as well also adding some very fine fiberglass cloth to the application for added strength.

I will probably have two more installments to finish. I promise it will not be 9mos in between. 🤞

Chris

My previous post showed the first layer of hull planking. This was done only on the bottom so that the 1/32 bass wood sheet skins had ample surface area to adhere to. After making card stock templates of each side of the bow bottom, I cut this template into 6 sections, 3 on each side of the keel so that it would be easier to attach to the hull. The bass wood sheet was then cut from the templates for each side. I made some gluing blocks that matched the curvature of the hull at the bow end from some scrap balsa to aid in holding the sheet in place once it was glued. Rubber bands, clamps, and painters tape using to fix the pieces.

The first two bulkhead sections of the bow were filled with cut pieces of balsa and then sanded to form the curvature of the bow. Side skins made from 3/32" bass wood ply were then added to the sides to finish it off.

Once filled and sanded, the fore deck was cut from 3/32" bass wood ply. The gunnels were made from some .046"x .5" bass wood strip and attached to the edge of the fore deck. This assembly was then glued to the bow of the hull.

I also made mounting provisions for the rudder servo shown in one of the photos, as well as a removable motor mount. This mount slides in between bulkhead #10 and #11 and attaches to #10 by two 3mm screw hardware.

The inside of the hull was given several liberal coats of Minwax Polycrylic, an acrylic based "polyurathane" to waterproof the hull. I applied this to the outside of the hull as well also adding some very fine fiberglass cloth to the application for added strength.

I will probably have two more installments to finish. I promise it will not be 9mos in between. 🤞

Chris

▲

⟩⟩

hermank

Chum444

jumpugly

📝 Glynn Guest models

2 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 58 Views · 2 Likes

Flag

📝 Reply

Thanks Steve’s-s,

I’ll give that website a try.

Chris

I’ll give that website a try.

Chris

▲

⟩⟩

Steves-s

hermank

📝 Glynn Guest models

2 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 67 Views · 3 Likes

Flag

📝 Reply

Where or how do you obtain these plans from Glynn Guest. I googled his name and got an Amazon hit for a book! Are the plans within his books?

Thanks

Chris

Thanks

Chris

▲

⟩⟩

hermank

Steves-s

Doogle

📝 Round Bumpers

3 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 44 Views · 2 Likes

Flag

📝 Reply

Here is the link to harbormodels.com

▲

⟩⟩

hermank

SimpleSailor

📝 Round Bumpers

3 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 44 Views · 1 Like

Flag

📝 Reply

Check out Harbor Models. I have purchased several times from them.

Chris

Chris

▲

⟩⟩

hermank

📝 On my roof top this morning

10 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 64 Views · 8 Likes

Flag

📝 Reply

Looking over the scene!

From this point the closest tree is about 30 feet away. He better be aware of the red tail hawks. 😮

Chris

From this point the closest tree is about 30 feet away. He better be aware of the red tail hawks. 😮

Chris

▲

⟩⟩

IanL1

Len1

hermank

Mike Stoney

jumpugly

GARTH

Peejay

Wolle

💬 Re: Continuing on with the Aztec build

11 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 37 Views · 3 Likes

Flag

💬 Add Comment

sorry about the picture quality.

I was sending the pictures from my phone to my email, then saving them to my computer file. This creates a very low resolution image of the picture, and when zoomed in results in poor quality.

In the future, I won't be lazy and actually download with a cable.😔

This should result in very crisp and zoomable pictures.

Chris 😊

I was sending the pictures from my phone to my email, then saving them to my computer file. This creates a very low resolution image of the picture, and when zoomed in results in poor quality.

In the future, I won't be lazy and actually download with a cable.😔

This should result in very crisp and zoomable pictures.

Chris 😊

▲

⟩⟩

hermank

RodC

RNinMunich

📝 Continuing on with the Aztec build

11 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 46 Views · 12 Likes · 5 Comments

Flag

💬 Add Comment

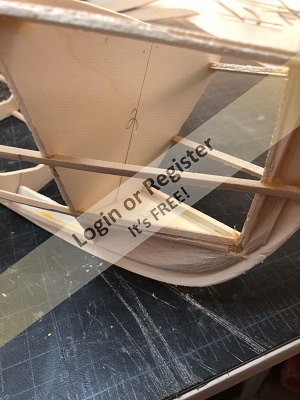

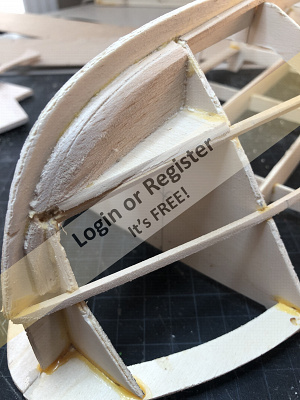

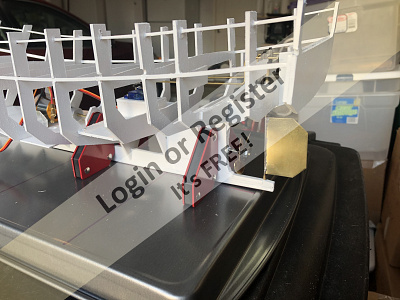

Ahoy fellow model boaters,

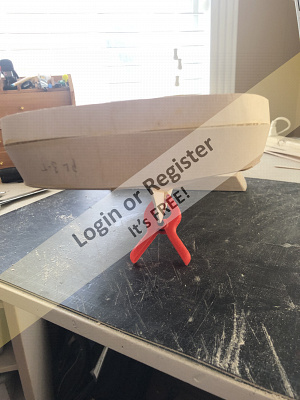

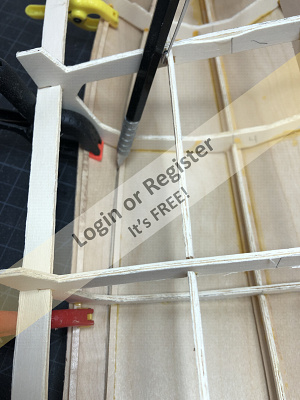

The Aztec is shaping up nicely. I was able to get all of the bulkheads cut and glued to the keel, but not without incident. I started noticing that the bulkheads were not landing straight, causing the deck to appear as if it was slanted up, not level. I corrected this by cutting #11 - 18 back off of the keel and remaking them. This time, when securing, I carefully used levels to make sure that the keel remained in the correct position when the bulkheads were glued. This resulted in a very flat deck surface.

However, all was not well, once all were placed, I could tell that the stern curvature was not going to be correct. I had to add some 1/8" balsa to #18 - 22 to get the correct curvature. If you look at the .pdf drawing in the initial post, these bulkheads have an inward curvature, what I realized is that it needed an outward curve to the hull. Once I made the corrections to the existing bulkheads, I was able to measure and make corrections to the cad design.

Once all the bulkheads were in place, I added the thin strips to the bow and sides of the hull for strength.

I have started to plank the hull using 1/16" basswood strips which were cut from a sheet of 1/16" x 24" basswood on the Cricut.

I will add a second 1/16" skin over the initial planking.

all for now,

Chris

The Aztec is shaping up nicely. I was able to get all of the bulkheads cut and glued to the keel, but not without incident. I started noticing that the bulkheads were not landing straight, causing the deck to appear as if it was slanted up, not level. I corrected this by cutting #11 - 18 back off of the keel and remaking them. This time, when securing, I carefully used levels to make sure that the keel remained in the correct position when the bulkheads were glued. This resulted in a very flat deck surface.

However, all was not well, once all were placed, I could tell that the stern curvature was not going to be correct. I had to add some 1/8" balsa to #18 - 22 to get the correct curvature. If you look at the .pdf drawing in the initial post, these bulkheads have an inward curvature, what I realized is that it needed an outward curve to the hull. Once I made the corrections to the existing bulkheads, I was able to measure and make corrections to the cad design.

Once all the bulkheads were in place, I added the thin strips to the bow and sides of the hull for strength.

I have started to plank the hull using 1/16" basswood strips which were cut from a sheet of 1/16" x 24" basswood on the Cricut.

I will add a second 1/16" skin over the initial planking.

all for now,

Chris

▲

⟩⟩

tomarack

Ronald

RodC

IanL1

Mike Stoney

Eddielisa2000

chugalone100

ChrisF

hermank

fireboat

jumpugly

RNinMunich

💬 Re: Fairey Faun 17 - Planking Hull

11 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 139 Views · 2 Likes

Flag

💬 Add Comment

Great job so far!

Was looking for a way to do the bow on the Aztec (aka Banana Boat), I think I will try it like that as well.

Chris

Was looking for a way to do the bow on the Aztec (aka Banana Boat), I think I will try it like that as well.

Chris

▲

⟩⟩

hermank

ChrisF

Login To

Remove Ads

Remove Ads

📝 Driving update

12 months ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 65 Views · 1 Like

Flag

📝 Reply

That’s great. Congratulations on your success.

Chris

Chris

▲

⟩⟩

Doogle

📝 Solder

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 72 Views · 5 Likes

Flag

📝 Reply

Sticker Shock!!!! The price of solder is out of this world.

So maybe finding some liquid rosin flux may be the answer.

Also the newer lead free, no clean, or water clean type solders may require a higher temperature soldering iron.

Good luck,

Chris

So maybe finding some liquid rosin flux may be the answer.

Also the newer lead free, no clean, or water clean type solders may require a higher temperature soldering iron.

Good luck,

Chris

▲

⟩⟩

Len1

xtramaths

GregHiltz

Doogle

AlessandroSPQR

📝 Solder

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 71 Views · 6 Likes

Flag

📝 Reply

Yes, the flux in solder can get old and not have the wetting action which makes the solder ball up and yield cold solder joints.

Throw your old stuff away, and get some new fresh solder.

You can purchase rosin solder flux on its own, but it is probably more expensive that route, then just investing in new rosin core solder.

Chris

Throw your old stuff away, and get some new fresh solder.

You can purchase rosin solder flux on its own, but it is probably more expensive that route, then just investing in new rosin core solder.

Chris

▲

⟩⟩

Len1

GregHiltz

Doogle

LewZ

RogerA1

DuncanP

📝 The Aztec Construction begins

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 55 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

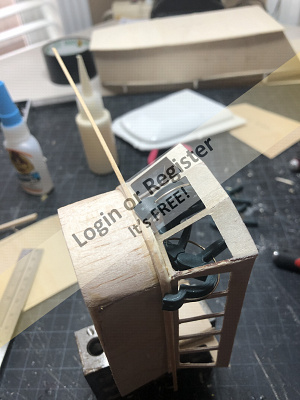

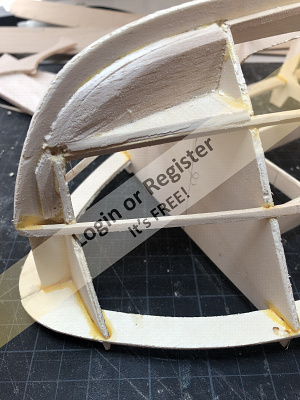

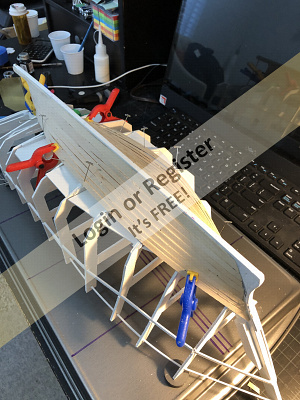

First off, I appreciate all for the likes, follows and suggestions sent in so far about the build.

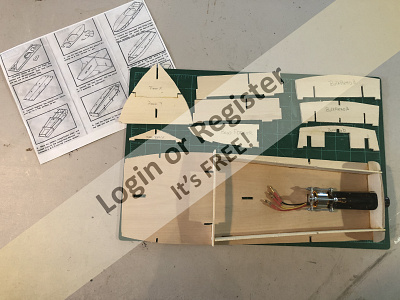

With the design now in a CAD, I am able to print out a 1:1 pattern of the keel and cut out the 3/16" basswood using my bandsaw. The bulkheads are constructed using the Cricut cutting machine. I can download the cutting files directly from the cad software saving a lot of time with tedious cuts on the band saw. The Cricut has limitations to the thickness of material which it can cut, so I purchased some 1/16" Basswood ply and cut duplicates of each bulkhead with the grain of the wood at a 90 degree angle, then glued the two together to get the 1/8" requirement. I am able to put multiple patterns on a sheet of plywood to be cut by the machine.

I created the bulbous nose of the keel by making item "0". (see pdf from initial blog) and placing it on the keel, then fill the remainder with balsa wood, and then sand to fit.

Two pictures show the sheets cut with the different grain direction. Once cut the two matching pairs are glued together, sanded and then glued to the keel.

The Cricut machine does take time to do the cuts. The cut time varies between 2 and 3 hours depending upon how many items are on the pattern, but once started, there is very little that needs to be done until finished. There is a picture of how clean the machine cuts, and a short video of the machine in action.

Chris

With the design now in a CAD, I am able to print out a 1:1 pattern of the keel and cut out the 3/16" basswood using my bandsaw. The bulkheads are constructed using the Cricut cutting machine. I can download the cutting files directly from the cad software saving a lot of time with tedious cuts on the band saw. The Cricut has limitations to the thickness of material which it can cut, so I purchased some 1/16" Basswood ply and cut duplicates of each bulkhead with the grain of the wood at a 90 degree angle, then glued the two together to get the 1/8" requirement. I am able to put multiple patterns on a sheet of plywood to be cut by the machine.

I created the bulbous nose of the keel by making item "0". (see pdf from initial blog) and placing it on the keel, then fill the remainder with balsa wood, and then sand to fit.

Two pictures show the sheets cut with the different grain direction. Once cut the two matching pairs are glued together, sanded and then glued to the keel.

The Cricut machine does take time to do the cuts. The cut time varies between 2 and 3 hours depending upon how many items are on the pattern, but once started, there is very little that needs to be done until finished. There is a picture of how clean the machine cuts, and a short video of the machine in action.

Chris

▲

⟩⟩

IanL1

hermank

RNinMunich

AlessandroSPQR

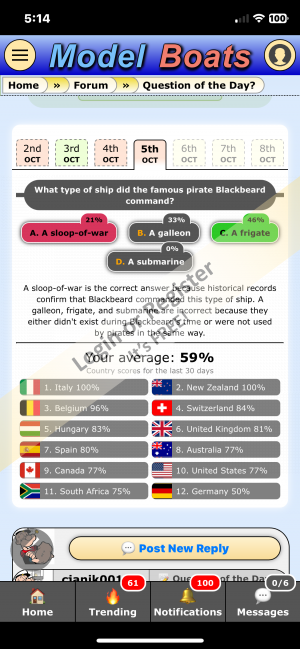

📝 Question of the Day?

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 59 Views · 4 Likes

Flag

📝 Reply

I have to agree with this comment. I never understood how not answering a question did not count against your score. If I knew this in high school I would have been a straight "A" student. Not the average Joe I truly am.

Scrap the overall, and have an all-time average based on number of correct answers to total number of questions.

Just my 2cents worth.

Chris

Scrap the overall, and have an all-time average based on number of correct answers to total number of questions.

Just my 2cents worth.

Chris

▲

⟩⟩

AlessandroSPQR

fireboat

hermank

RNinMunich

📝 A Banana Boat??!

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 92 Views · 12 Likes · 5 Comments

Flag

💬 Add Comment

Happy Groundhog Day fellow model boaters. Seemed like a good day to start a build blog after the weather we have been having here in SE Texas. From hurricanes to snow fall, now nice sunny temps in the 70's.

I asked my grandson earlier this summer what boat would he want me to build next. Without hesitation, he said a cargo ship showing me a picture of a Maresk Lines container ship in a children's picture book. I thought about this one for several weeks wondering how to build a realistic replica of something that large. My dry dock isn't very big, and the Admiral frowns on large models. One morning at breakfast I was peeling my banana, and I realize the perfect boat. A quick google search verified my thinking of the perfect cargo ship.

I have lived in this area all my life, and my first job was in the small gulf port town of Freeport, Texas. In the early 80's it basically only served the shrimp boat operators and commercial fishermen as well as a few cargo ships for Dow Chemical and the like. The size does not compare to the Port of Houston or even Galveston. However, in the 90's the Dole Fruit Company started operations delivering containers of tropical fruit for distribution to the US.

At that time I was commuting to Houston for work, and would see the Dole container trucks on the road and would chuckle to myself "must be a banana boat in port!

The Dole company just celebrated 30 years of service in Freeport, and in 2023 launched two sister container ships, the Aztec and Maya, specifically for the Gulf of Mexico deliveries. These are smaller ships which I estimate carry only about 500 containers.

Since I could not find any plans on the internet for a smaller container ship, I decided to make my own. From pictures of the Aztec, I free handed a graph paper drawing of what I intended to build, and when satisfied, I produced a CAD version in Autosketch.

The attached pictures are of the Aztec in port at Gulfport MS.. The Maya being built in drydock. My hand drawn rendering on graph paper, and a .PDF of the cad version with bulkhead detail.

The model ship will be about 26.5 inches long with a width of about 4.5". I plan to have a brushless motor driving a 1 inch 5 bladed brass prop.

Chris

I asked my grandson earlier this summer what boat would he want me to build next. Without hesitation, he said a cargo ship showing me a picture of a Maresk Lines container ship in a children's picture book. I thought about this one for several weeks wondering how to build a realistic replica of something that large. My dry dock isn't very big, and the Admiral frowns on large models. One morning at breakfast I was peeling my banana, and I realize the perfect boat. A quick google search verified my thinking of the perfect cargo ship.

I have lived in this area all my life, and my first job was in the small gulf port town of Freeport, Texas. In the early 80's it basically only served the shrimp boat operators and commercial fishermen as well as a few cargo ships for Dow Chemical and the like. The size does not compare to the Port of Houston or even Galveston. However, in the 90's the Dole Fruit Company started operations delivering containers of tropical fruit for distribution to the US.

At that time I was commuting to Houston for work, and would see the Dole container trucks on the road and would chuckle to myself "must be a banana boat in port!

The Dole company just celebrated 30 years of service in Freeport, and in 2023 launched two sister container ships, the Aztec and Maya, specifically for the Gulf of Mexico deliveries. These are smaller ships which I estimate carry only about 500 containers.

Since I could not find any plans on the internet for a smaller container ship, I decided to make my own. From pictures of the Aztec, I free handed a graph paper drawing of what I intended to build, and when satisfied, I produced a CAD version in Autosketch.

The attached pictures are of the Aztec in port at Gulfport MS.. The Maya being built in drydock. My hand drawn rendering on graph paper, and a .PDF of the cad version with bulkhead detail.

The model ship will be about 26.5 inches long with a width of about 4.5". I plan to have a brushless motor driving a 1 inch 5 bladed brass prop.

Chris

▲

⟩⟩

Peejay

MartyV

IanL1

ToraDog

hermank

PhilH

RNinMunich

roycv

jumpugly

Doogle

Wolle

AlessandroSPQR

📝 Baby Bootlegger

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 65 Views · 5 Likes

Flag

📝 Reply

I just ordered balsa wood and bass wood from National Balsa. Good price and good delivery. Packaged in a way as to not get damaged in shipping. The only down side is the cost of shipping is not cheap. But if you purchase $100.00 US it’s free!

▲

⟩⟩

hermank

Len1

AlessandroSPQR

jumpugly

Wolle

📝 2025

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 19 Views · 6 Likes

Flag

📝 Reply

I just want to say to all the new members who have just signed up, I hope you find this group of model boating hobbyists as informative and genuine as I have the past few years.

Do not hesitate to ask any questions you may have. This site is very friendly and open.

Good luck with your hobby and take part in the conversations. We also like pictures and videos!

Have fun😀

Chris

Do not hesitate to ask any questions you may have. This site is very friendly and open.

Good luck with your hobby and take part in the conversations. We also like pictures and videos!

Have fun😀

Chris

▲

⟩⟩

AlessandroSPQR

hibbard

Doogle

Wolle

Mike Stoney

RNinMunich

📝 Merry Christmas!

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 49 Views · 13 Likes

Flag

📝 Reply

Merry Christmas from the greater Texas Gulf Coast. No sign of snow here, temps are in the 70’s!

Wishing all a very Merry Christmas, Happy Holidays and a wonderful and prosperous New Year.

Chris

Wishing all a very Merry Christmas, Happy Holidays and a wonderful and prosperous New Year.

Chris

▲

⟩⟩

MouldBuilder

roycv

Mike Stoney

Wolle

Doogle

RNinMunich

Peejay

Nickthesteam

bruce1946

Colin H

RodC

fireboat

jumpugly

📝 Fishing nets

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 76 Views · 8 Likes

Flag

📝 Reply

I’ve used cheese cloth in the past. Also, a gauze bandage may do as well.

▲

⟩⟩

Peejay

RodC

Mike Stoney

Doogle

Commodore-H

PhilH

jumpugly

Wolle

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 67 Views · 1 Like

Flag

📝 Reply

I also have items arriving on gmail. Funny thing is it’s only a subset of what is trending. I would also like to remove myself from Gmail if possible.

▲

⟩⟩

Peejay

📝 Happy Thanksgiving

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 41 Views · 5 Likes

Flag

📝 Reply

Lew,

Yes it has been a trying year, and I too living on the Texas Gulf Coast am aware of what damage hurricanes can do. I wish you, your family, and all Model Boaters a Happy Thanksgiving as well.

Chris

Yes it has been a trying year, and I too living on the Texas Gulf Coast am aware of what damage hurricanes can do. I wish you, your family, and all Model Boaters a Happy Thanksgiving as well.

Chris

▲

⟩⟩

hermank

Mike Stoney

jumpugly

LewZ

Len1

📝 I no longer receive notification emails.

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 36 Views · 2 Likes

Flag

📝 Reply

Apparently, this did not work either! 😒

▲

⟩⟩

Mike Stoney

hermank

📝 I no longer receive notification emails.

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 35 Views · 3 Likes

Flag

📝 Reply

I am experiencing the same. I logged in and went to the support tab. There is a selection for “not receiving emails”. I followed the directions and will see if this helps.

Chris

Chris

▲

⟩⟩

Len1

Mike Stoney

hermank

📝 Minature action camera

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 79 Views · 3 Likes

Flag

📝 Reply

I found a “cheap” about $10 camera off of Amazon. Camera will record on a memory card, however I also would like to view and record to my phone while sailing. With limited success I have gotten this to work, but the wireless connection is limited in distance to about 20’ from the phone.

▲

⟩⟩

RodC

Len1

hermank

📝 Question of the Day?

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 78 Views · 3 Likes

Flag

📝 Reply

▲

⟩⟩

Harwind

Peejay

GARTH

📝 Question of the Day?

1 year ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 76 Views · 2 Likes

Flag

📝 Reply

Well AI did me in today!! I chose sloop of war, and AI indicated frigret was the correct answer, but the verbiage read sloop of war is the correct answer! How can anyone win with AI like this!!!

May just have to let the QofD go and stick to my solitaire card games.

May just have to let the QofD go and stick to my solitaire card games.

▲

⟩⟩

GARTH

hermank

📝 battery

2 years ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 53 Views · 3 Likes

Flag

📝 Reply

Good morning Fulmic,

If the 6v lead acid battery is giving a low battery signal, then the additional 6v battery is probably not going to solve the issue.

Check your receiver specifications for voltage input range!

You may need to power the receiver with a separate higher voltage battery, and wire the motor independent with the 6v lead acid.

Good luck

If the 6v lead acid battery is giving a low battery signal, then the additional 6v battery is probably not going to solve the issue.

Check your receiver specifications for voltage input range!

You may need to power the receiver with a separate higher voltage battery, and wire the motor independent with the 6v lead acid.

Good luck

▲

⟩⟩

fulmic

Len1

hermank

📝 Motor burn out?

2 years ago by 🇺🇸 cjanik001 ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 75 Views · 5 Likes

Flag

📝 Reply

I don’t know if this post has any previous posts, but it sounds like it may be a motor over voltage situation.

Double check the motor specifications and adjust the battery voltage accordingly.

Good luck

Double check the motor specifications and adjust the battery voltage accordingly.

Good luck

▲

⟩⟩

Doogle

Spence

Len1

hermank

Peejay

Captain)

Captain)

Fleet Admiral)

Fleet Admiral)

Rear Admiral)

Rear Admiral)

Liked SEMI SCALE 1953 EDSON SCHOCK 15FT DAY SAILER 3 days ago

Liked SEMI SCALE 1953 EDSON SCHOCK 15FT DAY SAILER 3 days ago

Liked 3D printed tugboat 8 days ago

Liked 3D printed tugboat 8 days ago

Liked Keilcraft ; Thornycroft Range Safety boat 7112 11 days ago

Liked Keilcraft ; Thornycroft Range Safety boat 7112 11 days ago

Liked My Saint Pierre Dory has improved lights 12 days ago

Liked My Saint Pierre Dory has improved lights 12 days ago