Join Us On Social Media!

United Kingdom

Recent Posts

💬 Re: Fitting the Rudder

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 165 Views · 6 Likes

Flag

💬 Add Comment

Superb!

I used to build Airfix kits in the '50s (two shillings each) and the advertising was "just like the real thing!"

What more can I say.

Steve

I used to build Airfix kits in the '50s (two shillings each) and the advertising was "just like the real thing!"

What more can I say.

Steve

▲

⟩⟩

stevedownunder

Colin H

pressonreguardless

Ronald

GaryLC

Graham93

Login To

Remove Ads

Remove Ads

📝 Very sad news Martin555

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 145 Views · 18 Likes

Flag

📝 Reply

Martin

You will be very sadly missed, not only on this site, but both as a good friend and a stalwart member of out Skype group.

Rest in Peace

Steve

You will be very sadly missed, not only on this site, but both as a good friend and a stalwart member of out Skype group.

Rest in Peace

Steve

▲

⟩⟩

Mike Stoney

RNinMunich

philcaretaker

hermank

Cashrc

ChrisG

GaryLC

Black Shoe

pressonreguardless

MouldBuilder

fireboat

Nerys

jbkiwi

River Rat

Newby7

stevedownunder

Colin H

Scratchbuilder

💬 Re: Finishing the hatch

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 168 Views · 5 Likes

Flag

💬 Add Comment

Hi Graham

What a superb build. Very well done indeed!

I must admit to not following the build very closely. I was not set up for receiving updates, which I now am.

Did you ever sort out a name for the paddler?

I think we decided Eskimo Nell was a non-starter for gender reasons?

Regards

Steve

What a superb build. Very well done indeed!

I must admit to not following the build very closely. I was not set up for receiving updates, which I now am.

Did you ever sort out a name for the paddler?

I think we decided Eskimo Nell was a non-starter for gender reasons?

Regards

Steve

▲

⟩⟩

HappyHaggis

MouldBuilder

stevedownunder

Colin H

Graham93

💬 Re: First Planking

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 52 Views · 4 Likes

Flag

💬 Add Comment

Hi Colin

A plank bender is similar to a pair of anvil head secateurs and you use them to cut into the grain of the wood to create a bend. The more cuts you make and the deeper you go the tighter the curve.

Practice is required on a scrap plank and one of the main problems is being overambitious and cutting right through.

Good bit of kit though.

A plank bender is similar to a pair of anvil head secateurs and you use them to cut into the grain of the wood to create a bend. The more cuts you make and the deeper you go the tighter the curve.

Practice is required on a scrap plank and one of the main problems is being overambitious and cutting right through.

Good bit of kit though.

▲

⟩⟩

DWBrinkman

Len1

MouldBuilder

stevedownunder

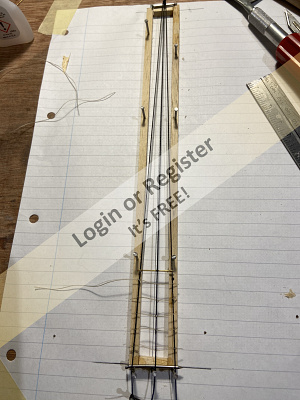

📝 First Planking

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 58 Views · 10 Likes · 4 Comments

Flag

💬 Add Comment

It has taken me two months to complete the first planking! Holidays, illness (over Christmas), major flooding (at the mother-in-laws house), have all played their part, not to mention using the wrong grade of sandpaper.

However, with help and advice from Martin555, and a final sanding, my task is complete.

Once again, the instructions couldn't decide on whether to use 1.5 x 6mm or 1.5 x 5mm lime wood strip, but apart from being annoying, there was only 6mm strip to choose from.

Previously, I have been soaking the planks in warm water, as instructed, but following a demo by Martin555, I have been converted to a plank bender, which has been very successful and a lot less fiddly.

I should have spent more time bevelling and sanding the bulkheads, which caused me some grief during planking, but with the use of polyfilla, I think I have just about got it right.

I had proposed to use proprietary wood filler, but once again, was advised that polyfilla was just as good, and cheaper, in this instance.

The laying of the planks went quite well, but I should have taken more time in shaping, as much filling and sanding was required. Sanding is done with coarse grit, followed by medium. It didn't help that it was only towards the end of the process did I realise that I was using coarse instead of medium for the first pass! The acquisition of the correct grade made life so much easier.

However, with help and advice from Martin555, and a final sanding, my task is complete.

Once again, the instructions couldn't decide on whether to use 1.5 x 6mm or 1.5 x 5mm lime wood strip, but apart from being annoying, there was only 6mm strip to choose from.

Previously, I have been soaking the planks in warm water, as instructed, but following a demo by Martin555, I have been converted to a plank bender, which has been very successful and a lot less fiddly.

I should have spent more time bevelling and sanding the bulkheads, which caused me some grief during planking, but with the use of polyfilla, I think I have just about got it right.

I had proposed to use proprietary wood filler, but once again, was advised that polyfilla was just as good, and cheaper, in this instance.

The laying of the planks went quite well, but I should have taken more time in shaping, as much filling and sanding was required. Sanding is done with coarse grit, followed by medium. It didn't help that it was only towards the end of the process did I realise that I was using coarse instead of medium for the first pass! The acquisition of the correct grade made life so much easier.

▲

⟩⟩

Scratchbuilder

Len1

bombero

stevedownunder

Graham93

pressonreguardless

MouldBuilder

jbkiwi

AndyN

Colin H

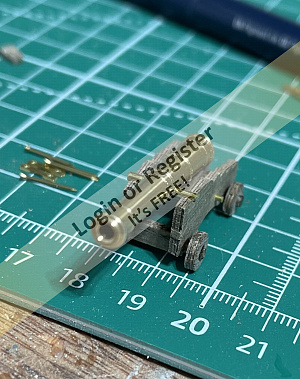

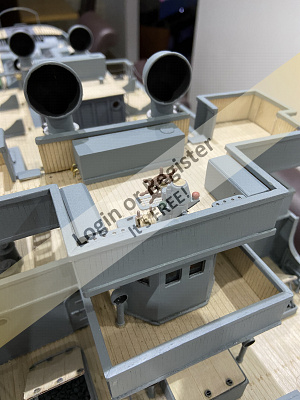

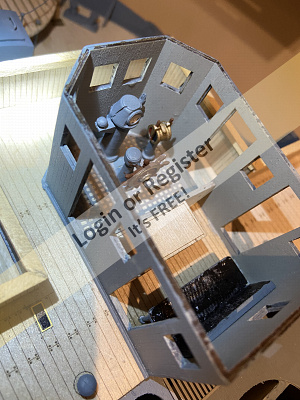

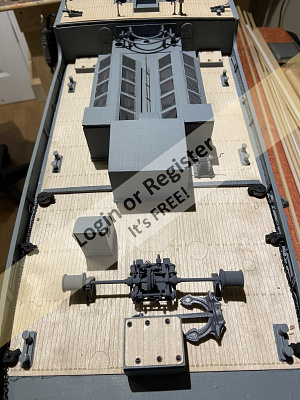

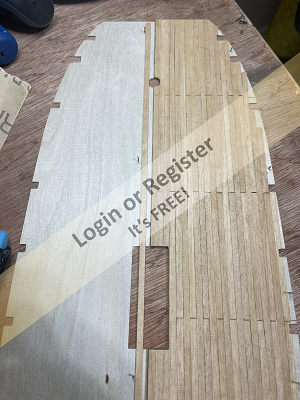

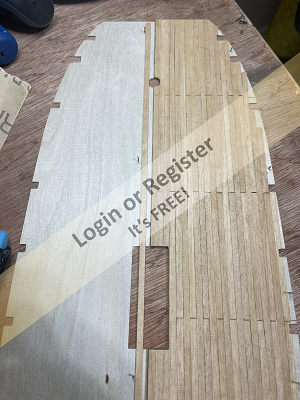

📝 Gun Deck and Gun Deck Walls

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 67 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

Instructions give me two choices as to when to plank the 0.8mm false gun deck.

'It can be pinned and glued into place, then planked, or planked prior to fixing. The easiest way is the latter but the deck will have much less spring to get it past the top deck supports on the bulkheads.'

I was unable to get the deck anywhere near past the supports prior to planking, without fear of breakage, so I had no choice but to choose the latter. This involved cutting the deck in half along the centre line, then planking each half, starting at the centre line and working outwards

To get the two centre planks butted up as close as possible, I pinned both halves of the deck on the workbench prior to gluing.

However, as you can see in the photo, I was not careful enough when gluing the two halves in the hull and the join is visible, particularly at each end.

The jury is still out as the whether I should fit a 'centreline' plank, or leave well alone, as the top deck and ship's boats will hide most of poor workmanship.

Any views?

Prior to fixing and matt varnishing, I used a fine pencil and ruler to represent the caulking.

Planking of the inner gun deck walls was quite straightforward, using 1.5x6mm lime wood. Another anomaly in the instructions variously describes it as 5mm and 6mm. It is in fact 6mm, so another note for Jotika.

Although the width would have made no difference, 6mm brought the planks just under the top deck supports, which is where they should be. I had to cut them to size between the middle bulkheads, to attain the correct level, but found no difficulty with a sharp Stanley knife and a straight edge.

Once finished, I was instructed to "paint the outer side of the wall with watered down pva where they are glued to the bulkheads. This will reduce the chance of the planks splitting when cutting out the gun ports."

Then sand the inner side smooth.

The next job is to prepare for first planking.

'It can be pinned and glued into place, then planked, or planked prior to fixing. The easiest way is the latter but the deck will have much less spring to get it past the top deck supports on the bulkheads.'

I was unable to get the deck anywhere near past the supports prior to planking, without fear of breakage, so I had no choice but to choose the latter. This involved cutting the deck in half along the centre line, then planking each half, starting at the centre line and working outwards

To get the two centre planks butted up as close as possible, I pinned both halves of the deck on the workbench prior to gluing.

However, as you can see in the photo, I was not careful enough when gluing the two halves in the hull and the join is visible, particularly at each end.

The jury is still out as the whether I should fit a 'centreline' plank, or leave well alone, as the top deck and ship's boats will hide most of poor workmanship.

Any views?

Prior to fixing and matt varnishing, I used a fine pencil and ruler to represent the caulking.

Planking of the inner gun deck walls was quite straightforward, using 1.5x6mm lime wood. Another anomaly in the instructions variously describes it as 5mm and 6mm. It is in fact 6mm, so another note for Jotika.

Although the width would have made no difference, 6mm brought the planks just under the top deck supports, which is where they should be. I had to cut them to size between the middle bulkheads, to attain the correct level, but found no difficulty with a sharp Stanley knife and a straight edge.

Once finished, I was instructed to "paint the outer side of the wall with watered down pva where they are glued to the bulkheads. This will reduce the chance of the planks splitting when cutting out the gun ports."

Then sand the inner side smooth.

The next job is to prepare for first planking.

▲

⟩⟩

MouldBuilder

AndyN

jbkiwi

Colin H

Martin555

stevedownunder

💬 Re: HMS Diana(38) Heavy Frigate

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 87 Views · 5 Likes

Flag

💬 Add Comment

Thanks Graham. Yes, I do intend to feed back any issues to Jotika.

I have just come back onto the site with the intention, (as you have already suggested), to copy and paste the YouTube link:-

I have just come back onto the site with the intention, (as you have already suggested), to copy and paste the YouTube link:-

▲

⟩⟩

Colin H

Martin555

jbkiwi

Graham93

stevedownunder

📝 HMS Diana(38) Heavy Frigate

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 109 Views · 8 Likes · 2 Comments

Flag

💬 Add Comment

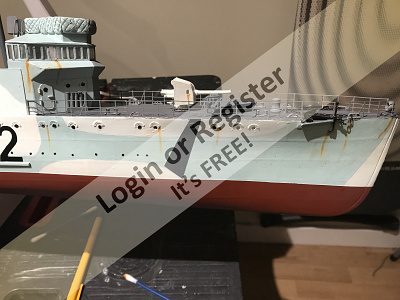

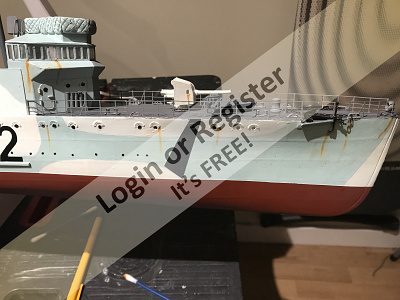

Some two years ago I built HMS Cruizer, a 1/64 scale brig sloop from the Nelson's Navy series made by Caldercraft, aka JoTiKa. Some of you may have followed the build blog.

This was my first attempt at this type of model and I was so satisfied and pleased with the result, that I decided to up the ante and have a go at HMS Diana, a 38 gun heavy frigate, also from Caldercraft's Nelson's Navy.

My plan is to learn from the experience (and mistakes) from Cruizer and put it to good use in the building of Diana.

I found the kit to be of the usual high standard in both materials and CNC plywood parts (I have made a video uploaded to YouTube which I can't seem to upload to this site ).

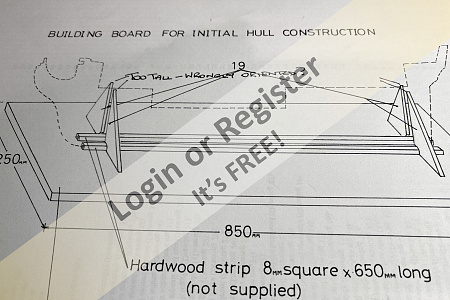

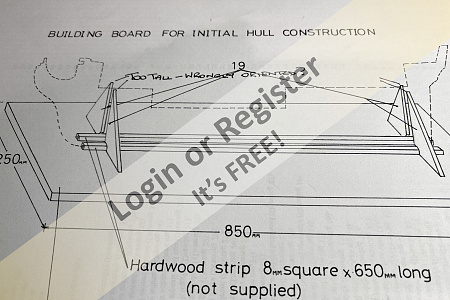

The first stage was to make a building board for initial hull construction.

I first of all found that the 8mm square hardwood strips were too high and some of the bukheads would not fit down far enough onto the keel. A more realistic height for the strips would be 5mm.

I also found that parts 19 appeared to have been wrongly orientated on the drawing, not allowing the lower deck to fit down far enough. I needed to cut then down accordingly. However, having looked a the drawings again, perhaps it was me?

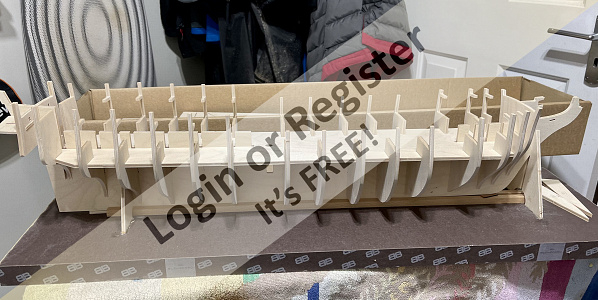

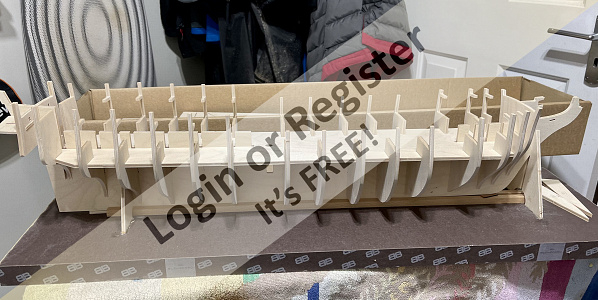

Once sorted I was able to dry fit the 15 bulkheads, deck, and various templates prior to gluing in position.

This was my first attempt at this type of model and I was so satisfied and pleased with the result, that I decided to up the ante and have a go at HMS Diana, a 38 gun heavy frigate, also from Caldercraft's Nelson's Navy.

My plan is to learn from the experience (and mistakes) from Cruizer and put it to good use in the building of Diana.

I found the kit to be of the usual high standard in both materials and CNC plywood parts (I have made a video uploaded to YouTube which I can't seem to upload to this site ).

The first stage was to make a building board for initial hull construction.

I first of all found that the 8mm square hardwood strips were too high and some of the bukheads would not fit down far enough onto the keel. A more realistic height for the strips would be 5mm.

I also found that parts 19 appeared to have been wrongly orientated on the drawing, not allowing the lower deck to fit down far enough. I needed to cut then down accordingly. However, having looked a the drawings again, perhaps it was me?

Once sorted I was able to dry fit the 15 bulkheads, deck, and various templates prior to gluing in position.

▲

⟩⟩

MouldBuilder

AndyN

Martin555

jbkiwi

pressonreguardless

stevedownunder

Graham93

Colin H

📝 Gaff rigged cutter Antares by Krick

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 35 Views · 0 Likes

Flag

📝 Reply

That's how I initially envisaged my set up. Two sheets on one winch which was divided into two. I set the sheets up so one turned clockwise and the other anti clockwise so as one wound in the other wound out.

However, as one wound out and released the sail, the other sheet was winding back in and tightening the sail, unless I was missing something.....?

I will let you know how it goes and hopefully get some video footage.

However, as one wound out and released the sail, the other sheet was winding back in and tightening the sail, unless I was missing something.....?

I will let you know how it goes and hopefully get some video footage.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Gaff rigged cutter Antares by Krick

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 37 Views · 3 Likes

Flag

📝 Reply

I have solved the problem, I hope!

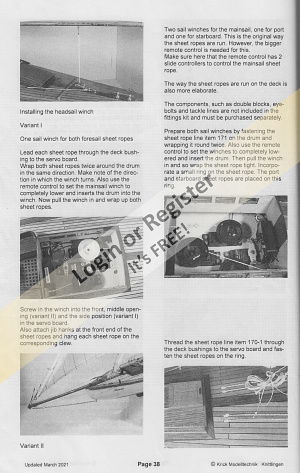

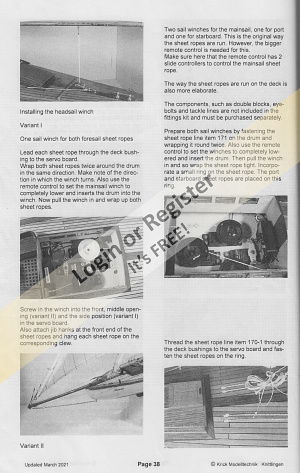

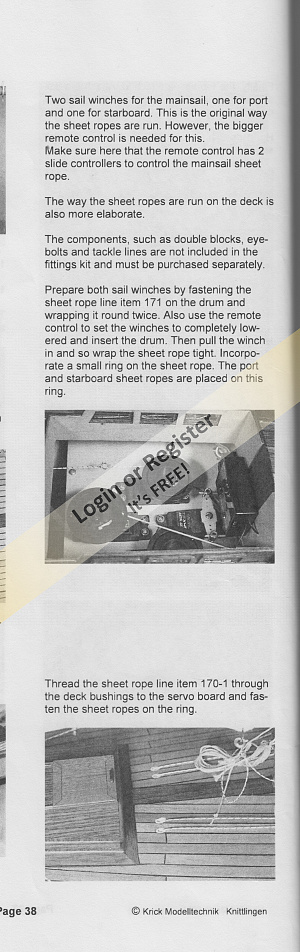

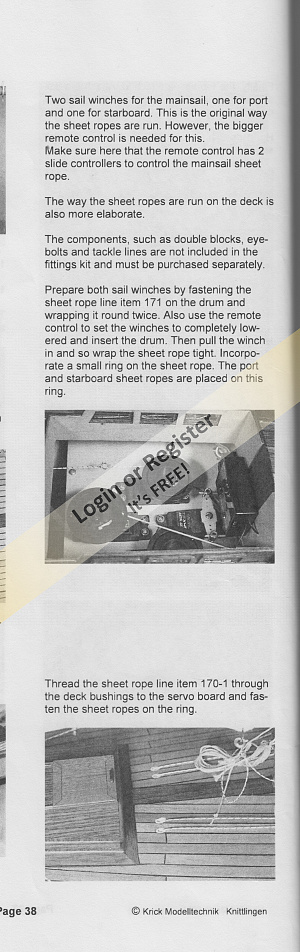

I have read read the instructions many times and disregarded the opening gambit "Two sail winches for the mainsail, one for port and one for starboard."

Fourth paragraph reads "Prepare both sail winches (one for foresail and one for jib), by fastening the sheet rope on the drum and wrapping it round twice. Also use the remote control to set the winches to completely lowered and insert the drum. Then pull the winch in and so wrap the sheet rope tight. Incorporate a small ring on the sheet rope. The port and starboard sheet ropes are placed on this ring."

I understand this to read 'One winch controls the jib, in and out, and one controls the foresail, in and out.'

All will be revealed on Wednesday when I propose to launch.

I have read read the instructions many times and disregarded the opening gambit "Two sail winches for the mainsail, one for port and one for starboard."

Fourth paragraph reads "Prepare both sail winches (one for foresail and one for jib), by fastening the sheet rope on the drum and wrapping it round twice. Also use the remote control to set the winches to completely lowered and insert the drum. Then pull the winch in and so wrap the sheet rope tight. Incorporate a small ring on the sheet rope. The port and starboard sheet ropes are placed on this ring."

I understand this to read 'One winch controls the jib, in and out, and one controls the foresail, in and out.'

All will be revealed on Wednesday when I propose to launch.

▲

⟩⟩

Martin555

Graham93

pressonreguardless

📝 Gaff rigged cutter Antares by Krick

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 77 Views · 0 Likes

Flag

📝 Reply

A very easy to follow video. The deck layout of the sheets is very similar to mine. However, very different below decks.

Oh that I had seen this before getting the stage of the build that I am at!

Oh that I had seen this before getting the stage of the build that I am at!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Gaff rigged cutter Antares by Krick

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 72 Views · 0 Likes

Flag

📝 Reply

Roy

Thank you for that, I may very well copy you.

Having read Variant 1, which I have attached (left hand side of the page) for your info.

Though I have mounted all three servos as per instructions I am still at a loss.

Thank you for that, I may very well copy you.

Having read Variant 1, which I have attached (left hand side of the page) for your info.

Though I have mounted all three servos as per instructions I am still at a loss.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Gaff rigged cutter Antares by Krick

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 72 Views · 0 Likes

Flag

📝 Reply

Thanks Dave. I too have come across this series of videos (after much searching), but it really doesn't help with the connection of the three servos.

The first line of the instructions (translated from German),

"Variant II.Two sail winches for the mainsail, one for port and one for starboard."

I have attached the rest of the page.

Is it me.....?

The first line of the instructions (translated from German),

"Variant II.Two sail winches for the mainsail, one for port and one for starboard."

I have attached the rest of the page.

Is it me.....?

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Gaff rigged cutter Antares by Krick

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 76 Views · 3 Likes

Flag

📝 Reply

I am coming to the end of a most enjoyable build but, cannot get my head round the set up of Variant 2 of the running rigging which involves 3 sail winches. The instructions and photographs are not very good (unless it is me?).

Has anyone built this kit and able to give me some pointers?

Has anyone built this kit and able to give me some pointers?

▲

⟩⟩

Martin555

stevedownunder

Colin H

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 71 Views · 1 Like

Flag

📝 Reply

Have you tried here ?

▲

⟩⟩

Colin H

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 95 Views · 1 Like

Flag

📝 Reply

Received my Quicrun 1060s this morning from Modelsport in Yorkshire. They gave the most competitive price and only took 2 days to arrive.

I have spent the afternoon fitting them after cutting one of the red wires. I have 8 channels working and so far so good!

Thanks for all your help and advice.

Ps When taking out the old Vipermarines I found I had in fact disconnected one of the red wires, so it couldn't have been that problem

I have spent the afternoon fitting them after cutting one of the red wires. I have 8 channels working and so far so good!

Thanks for all your help and advice.

Ps When taking out the old Vipermarines I found I had in fact disconnected one of the red wires, so it couldn't have been that problem

▲

⟩⟩

Colin H

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 101 Views · 1 Like

Flag

📝 Reply

Thanks for the suggestion but problem is shipping and taxes from the States almost amount to the cost of the item.

▲

⟩⟩

Rowen

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 100 Views · 0 Likes

Flag

📝 Reply

Once again chaps, thank you for all your help.

I have looked at the Quicrun 1060 and 1625. As I am using 3s lipos the 1060 is the one I have ordered - I notice that the 1625 is only good for 2s.

I am using the Hobbywing brushless esc s in other boats with no trouble, so hopefully no more burn outs - and no more Mtronics!.

I have looked at the Quicrun 1060 and 1625. As I am using 3s lipos the 1060 is the one I have ordered - I notice that the 1625 is only good for 2s.

I am using the Hobbywing brushless esc s in other boats with no trouble, so hopefully no more burn outs - and no more Mtronics!.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 103 Views · 0 Likes

Flag

📝 Reply

Hi Rowen

I can only find 'Hobbywing 30A Brushed Speed Controller Eagle-30A'. Is this the one you mean?

The Hobbywing I am thinking about only seems to make brushless esc s.

Thanks

Steve

I can only find 'Hobbywing 30A Brushed Speed Controller Eagle-30A'. Is this the one you mean?

The Hobbywing I am thinking about only seems to make brushless esc s.

Thanks

Steve

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 103 Views · 2 Likes

Flag

📝 Reply

Thanks for your observations chaps.

All was wired according to manufacturers instructions.

I had thought of removing one one of the red wires but considered it unnecessary - perhaps I should have done.

I didn't know that Mtronics were not lipo safe so it seems the solution is to change to the T10 range - thank you for the tip Rowen!

Any suggestion as to how to get rid of the most unpleasant stink?😀

All was wired according to manufacturers instructions.

I had thought of removing one one of the red wires but considered it unnecessary - perhaps I should have done.

I didn't know that Mtronics were not lipo safe so it seems the solution is to change to the T10 range - thank you for the tip Rowen!

Any suggestion as to how to get rid of the most unpleasant stink?😀

▲

⟩⟩

Martin555

Rowen

📝 Mtronics Viper Marine 20 esc for brushed motors

3 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 112 Views · 3 Likes

Flag

📝 Reply

One of my builds has two 600 brushed motors, each connected to the above esc and to separate 3s lipos.

The batteries were connected and the system switched on as was the Tx. The Rx was showing a green light indicating it was bound and the esc s were showing the correct lights.

Neither of the motors were turning.

Suddenly one of the esc s starting hissing and then produced clouds of white smoke. I was only able to stop this by disconnecting the battery (the on/off switch had no effect).

When the smoke had cleared I saw that the wiring and part of the case had melted.

I had exactly the same thing happen to another boat with 500 motors, wired in the same way and with the same esc s, about two years ago. I have since replaced the esc in this boat and it has been working ok ever since.

Has anyone had any similar problems?

The batteries were connected and the system switched on as was the Tx. The Rx was showing a green light indicating it was bound and the esc s were showing the correct lights.

Neither of the motors were turning.

Suddenly one of the esc s starting hissing and then produced clouds of white smoke. I was only able to stop this by disconnecting the battery (the on/off switch had no effect).

When the smoke had cleared I saw that the wiring and part of the case had melted.

I had exactly the same thing happen to another boat with 500 motors, wired in the same way and with the same esc s, about two years ago. I have since replaced the esc in this boat and it has been working ok ever since.

Has anyone had any similar problems?

▲

⟩⟩

Martin555

Rookysailor

stevedownunder

Login To

Remove Ads

Remove Ads

📝 Batteries

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 109 Views · 2 Likes

Flag

📝 Reply

This, and the 'Watercooling' forum, has just about done it for me. I don't want to read insulting and offensive remarks on a hobby site!

With no moderators to calm things down (even Fireboat, the site owner not bothering), adverts popping up all over the place, it's time to put my ticket in.

Thank you to all members who have given me help, advice and encouragement in the past.

Mind how you go.

Steve

With no moderators to calm things down (even Fireboat, the site owner not bothering), adverts popping up all over the place, it's time to put my ticket in.

Thank you to all members who have given me help, advice and encouragement in the past.

Mind how you go.

Steve

▲

⟩⟩

Martin555

Scratchbuilder

📝 "paint" What paint to use rattle can?

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 68 Views · 0 Likes

Flag

📝 Reply

Thirty two years in the job, mainly Traffic, retired in 1997.

The vehicle is a VW Porsche sports car which the Dutch police used to patrol their motorways. You can just make out their red crash helmets on the rear parcel shelf.

Happy days!

The vehicle is a VW Porsche sports car which the Dutch police used to patrol their motorways. You can just make out their red crash helmets on the rear parcel shelf.

Happy days!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 "paint" What paint to use rattle can?

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 75 Views · 4 Likes

Flag

📝 Reply

I also have used Halfords paint with great success.

particularly red or black primer below the waterline then oversprayed with matt varnish to prevent chipping and allow any marks to be wiped off.

I have used gloss black and got a superb deep shine and also Volkswagen orange on an Aeronaut Pilot Boat

particularly red or black primer below the waterline then oversprayed with matt varnish to prevent chipping and allow any marks to be wiped off.

I have used gloss black and got a superb deep shine and also Volkswagen orange on an Aeronaut Pilot Boat

▲

⟩⟩

Martin555

DamonH

bruce1946

dave976

📝 Boat Stand

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 58 Views · 3 Likes

Flag

📝 Reply

▲

⟩⟩

Martin555

RNinMunich

Mike Stoney

📝 Boat Stand

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 58 Views · 2 Likes

Flag

📝 Reply

Hi Michel-Cl.

I am a 3D printer and use stl files of a design to convert to g.codes for the printer.

I have little knowledge of the CAD side of things. Where does a DXF fit into this please?

Steve

I am a 3D printer and use stl files of a design to convert to g.codes for the printer.

I have little knowledge of the CAD side of things. Where does a DXF fit into this please?

Steve

▲

⟩⟩

Martin555

RNinMunich

💬 Re: Rigging.

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 64 Views · 2 Likes

Flag

💬 Add Comment

Patience running very thin at times. Good job the door to my workshop is soundproof!

▲

⟩⟩

Scratchbuilder

Martin555

💬 Re: Rigging.

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 65 Views · 2 Likes

Flag

💬 Add Comment

Hi Nerys.

You are quite correct, of course. Having tied so many clove hitch knots, how could I forget the name?

I have made the necessary amendment.

I found that I was able to tie the knots securely, with practice, and a blob of glue was only required at each end.

I considered building HMS Victory next, but its size makes it too big to display anywhere in the house.

I am waiting for Caldercraft to release HMS Surprise, being a fan of Jack Aubrey, but I am told that it will not be any time soon.

Steve

You are quite correct, of course. Having tied so many clove hitch knots, how could I forget the name?

I have made the necessary amendment.

I found that I was able to tie the knots securely, with practice, and a blob of glue was only required at each end.

I considered building HMS Victory next, but its size makes it too big to display anywhere in the house.

I am waiting for Caldercraft to release HMS Surprise, being a fan of Jack Aubrey, but I am told that it will not be any time soon.

Steve

▲

⟩⟩

Scratchbuilder

Martin555

💬 Re: Rigging.

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 69 Views · 2 Likes

Flag

💬 Add Comment

Thank you Bill. Your comments are much appreciated.

Steve

Steve

▲

⟩⟩

Scratchbuilder

Martin555

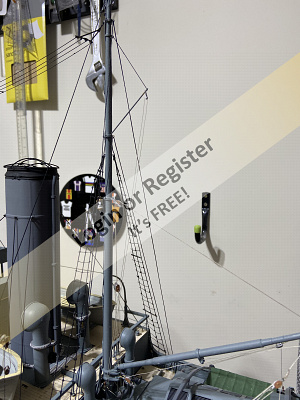

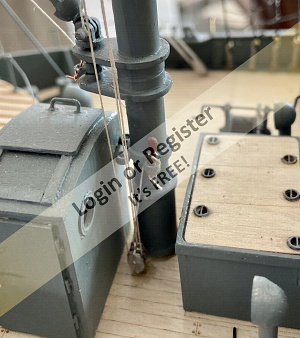

📝 Rigging.

4 years ago by 🇬🇧 cormorant ( Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)

Lieutenant Commander)✧ 71 Views · 8 Likes · 10 Comments

Flag

💬 Add Comment

I am sure those of you who have built this type of model before will understand the frustrations, but more importantly, the satisfaction of watching the rigging come together.

Instructions say to rig the shrouds first, then tie the ratlines.

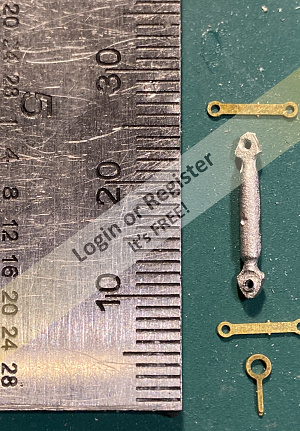

First job, lace the deadeyes. This was quite straightforward, having beeswaxed the rigging thread first (to prevent the ends fraying), then using tweezers to thread through the very small holes.

To get the deadeyes a uniform distance apart, I used a piece of brass wire, cut to the appropriate length and bent at right angles at each end. The wire was pushed into a hole in the upper and lower deadeye until lacing had commenced, then removed, to finish the lacing and tie off.

Let us now pretend that I followed the instructions and completed tying the ratlines.They are tied to the shrouds using a clove hitch, which is quite straightforward, once you have done one or two, using tweezers. Just as well, as I estimated that I tied 920. A dab of superglue at each end then clipping them, finished the job.

It is worth taking time to get the ratlines a regular distance apart and also making sure the tension is right. Too loose and they look too slack and too tight can pull the shrouds inward from the vertical.

A word of warning! I decided that I needed a change from ratlines, so I rigged other things - backstays and forestays to name just a few. This made life so much more difficult when I returned to the task in hand, trying to manoeuvre tweezers, fingers and clippers.

The remainder of the rigging was reasonably straightforward, once I had translated it into three dimensions from the two dimensional plans.

One of my main concerns was to ensure that none of the rigging became slack, by over tightening some of the other elements.

Also, the overzealous use of clippers, resulting in a stay being cut when the trimming of a loose end was the objective.

I have now finished my first model of this type. It is by no means perfect, but I must say, I am really chuffed with the end result.

For one who is used to building in fibreglass and plastic, this has been a learning curve, but I am so pleased with the help and advice I have received. Thank you!

Steve

Instructions say to rig the shrouds first, then tie the ratlines.

First job, lace the deadeyes. This was quite straightforward, having beeswaxed the rigging thread first (to prevent the ends fraying), then using tweezers to thread through the very small holes.

To get the deadeyes a uniform distance apart, I used a piece of brass wire, cut to the appropriate length and bent at right angles at each end. The wire was pushed into a hole in the upper and lower deadeye until lacing had commenced, then removed, to finish the lacing and tie off.

Let us now pretend that I followed the instructions and completed tying the ratlines.They are tied to the shrouds using a clove hitch, which is quite straightforward, once you have done one or two, using tweezers. Just as well, as I estimated that I tied 920. A dab of superglue at each end then clipping them, finished the job.

It is worth taking time to get the ratlines a regular distance apart and also making sure the tension is right. Too loose and they look too slack and too tight can pull the shrouds inward from the vertical.

A word of warning! I decided that I needed a change from ratlines, so I rigged other things - backstays and forestays to name just a few. This made life so much more difficult when I returned to the task in hand, trying to manoeuvre tweezers, fingers and clippers.

The remainder of the rigging was reasonably straightforward, once I had translated it into three dimensions from the two dimensional plans.

One of my main concerns was to ensure that none of the rigging became slack, by over tightening some of the other elements.

Also, the overzealous use of clippers, resulting in a stay being cut when the trimming of a loose end was the objective.

I have now finished my first model of this type. It is by no means perfect, but I must say, I am really chuffed with the end result.

For one who is used to building in fibreglass and plastic, this has been a learning curve, but I am so pleased with the help and advice I have received. Thank you!

Steve

▲

⟩⟩

Newby7

Ygagnon

Graham93

dave976

Scratchbuilder

Colin H

Martin555

Nonsuch

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Admiral)

Admiral)

Liked Very sad news Martin555 3 years ago

Liked Very sad news Martin555 3 years ago

Liked Very sad news Martin555 3 years ago

Liked Very sad news Martin555 3 years ago

Liked Very sad news Martin555 3 years ago

Liked Very sad news Martin555 3 years ago

Liked Maiden voyage 3 years ago

Liked Maiden voyage 3 years ago