Join Us On Social Media!

United Kingdom

Recent Posts

📝 Re-start.

23 days ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 15 Views · 5 Likes

Flag

💬 Add Comment

Ooh look, 9 years later I'm doing a bit more, it's sat on the top of various wardrobes over the years but now it's back. There's a 2mm deck and some superstructure and even some possible Sterodent torpedo tubes....the hull was done, motor mounts and propshaft all in. I'll nick the radio out of my MK2 Fireboat, it rarely runs anyway. I did find an Iranian Navy gun/missile boat the other day, add a torpedo or two and perhaps this isn't such an OTT concept after all!

▲

⟩⟩

ChrisF

EdW

hermank

HappyHaggis

Wolle

Login To

Remove Ads

Remove Ads

💬 Slowly does it.

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

That's interesting, didn't know that! Always thought it only became a cardan when a short shaft had a UJ at each end to to change the drive plane. Live and learn!😁

▲

⟩⟩

hermank

💬 Slowly does it.

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

All getting involved now! I suspect it looks worse in the pictures because the prop thrust will definitely pass over the rudder although perhaps not ideally. And I don't have a cardan shaft, just a uj because as I said, simple appealled for a part time hobby as this is to me. My aim was to see if I could form the wooden hull like my Dad did on the fireboat cos I always admired the shape but of course I would like to finish the job eventually 😀

▲

⟩⟩

hermank

💬 Slowly does it.

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

Ah well, thanks for that! I think you and Sonar are quite right, and no doubt better qualified to comment. Certainly the motor could be lower but I hesitated about moving it forward because of the weight distribution which I thought would be better at least halfway or more aft. As for prop sizes, again I am largely guessing what might work, on the fireboat I have a fifty mm z two blade which seems to work well without the motor getting hot but that has a slower, torquey motor, so smaller will probably be appropriate with the 750s. in truth I'll leave it as it is until I can trial it, probably a few years away, and if it is a disaster then I can still change it then😉

▲

⟩⟩

hermank

💬 Slowly does it.

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

Mines a bit more than that! in all truth I am no a boat designer so I just look at things in a practical way and while I absolutely agree with what you are saying I also know the old fireboat works ok for me. The other thing I wonder is with a short, light at the bow boat and all the weight aft of the centre could the prop thrust tend to lift the whole boat as much as push the front down? Like I say, just thinking aloud rather than speaking from experience!

▲

⟩⟩

hermank

💬 Slowly does it.

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

I would tend to agree! The more it pushes forward the better of course. But I largely copied my 36" fireboat and to get the prop dia options up to about 50mm it needs quite a angle. I didn't want to complicate the drive line either as my main interest was in forming the hull, just to see if I could really. I suppose the proof will be in the sailing!

▲

⟩⟩

hermank

📝 MTGMB

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 4 Likes

Flag

💬 Add Comment

▲

⟩⟩

ChrisF

EdW

hermank

Wolle

📝 Slowly does it.

9 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 20 Views · 2 Likes · 12 Comments

Flag

💬 Add Comment

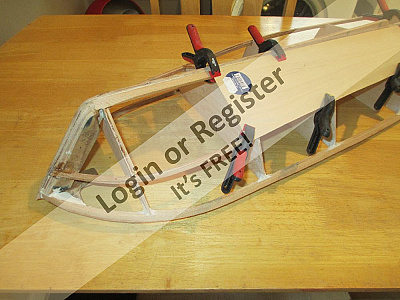

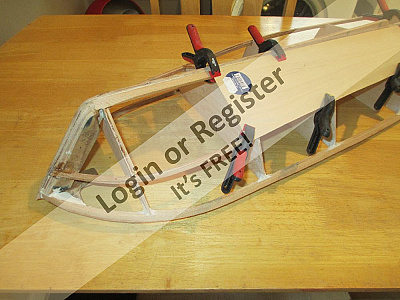

After a long pause I am as far as propshaft, motor and rudder installation. I need a servo next but spent all my pocket money climbing a mountain in Wales this month. it was good but wet.

The motor lives on the usual alloy bracket, screwed to two wooden plinths made from strip laminated with araldite. it's all standard stuff but making it this way allowed me to shim the height correctly, the strip being about 1.5mm thick. I'll post some pics if I can work out the Google drive thing but you will also see that the lower skins are on and after the servo installation I can think about the upper hull skins and then the superstructure. All good stuff😀.

The motor lives on the usual alloy bracket, screwed to two wooden plinths made from strip laminated with araldite. it's all standard stuff but making it this way allowed me to shim the height correctly, the strip being about 1.5mm thick. I'll post some pics if I can work out the Google drive thing but you will also see that the lower skins are on and after the servo installation I can think about the upper hull skins and then the superstructure. All good stuff😀.

▲

⟩⟩

hermank

Inkoust

💬 I have done something, honest...

10 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

HI thanks for the advice, I have been keeping it clamped down during any work and I agree totally, as the skins go on the risk gets worse! My double skins are going to be one on the outside and doublers between the bulkheads on the inside so should avoid some tension issues there. I am happy to see it coming together though!

▲

⟩⟩

hermank

📝 I have done something, honest...

10 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 21 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

Ought to say the skin here is just trial fitting, not gluing on, see comments below! Couple of pictures just to prove it really does exist! I am about to start on the lower skins but here you can see the stringers and bulkheads etc. The second to last one definitely did not get drawn wrong and need a modification, oh no. it isn't on the kitchen table when my wife was at work either.

Bit concerned at the change of profile at the forward keel, not looking forward to that bit but will be able to re-profile it if need be as there is a lot of spare material there. I'm using 0.032" ply for the skins and will laminate to strengthen as required, not having done this before I am as usual guessing a bit. it seems to me easier to go with the more flexible materials rather that struggle with the thicker- how thick does the skin need to be? How does 2 plies of .032" with a layer of epoxy between them sound, I don't know, well stiff enough I would have thought on the high seas but generally abuse proof enough I am not so sure.

Bit concerned at the change of profile at the forward keel, not looking forward to that bit but will be able to re-profile it if need be as there is a lot of spare material there. I'm using 0.032" ply for the skins and will laminate to strengthen as required, not having done this before I am as usual guessing a bit. it seems to me easier to go with the more flexible materials rather that struggle with the thicker- how thick does the skin need to be? How does 2 plies of .032" with a layer of epoxy between them sound, I don't know, well stiff enough I would have thought on the high seas but generally abuse proof enough I am not so sure.

▲

⟩⟩

hermank

Wolle

sandkb

Deswelham

💬 First steps

10 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

Slowest reply ever? Sorry,just noticed this, perhaps by now you have the order?

▲

⟩⟩

hermank

Login To

Remove Ads

Remove Ads

💬 MTGMB

10 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 19 Views · 1 Like

Flag

💬 Add Comment

I've no doubt he'd love it! if it goes bang, explodes or otherwise creates mayhem it's good for him...

▲

⟩⟩

hermank

📝 Merry Christmas

10 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 20 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

I bet this was written off as another idea that got no further! I will pop some photos up soon but I have completed the main part of the hull minus skins, once I glue the last stringer on I will clean up what I have done and get the camera out. I have learned that bending 3/8" sq spruce around the deck profile is easier said than done and laminating in 1/8" strips is easy! I also found that warming said 1/8" sq strip is easy with a heat gun and less messy than steaming which is how I did the 3/8...said I hadn't built a boat before.

▲

⟩⟩

hermank

sandkb

📝 First steps

11 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 23 Views · 6 Likes · 2 Comments

Flag

💬 Add Comment

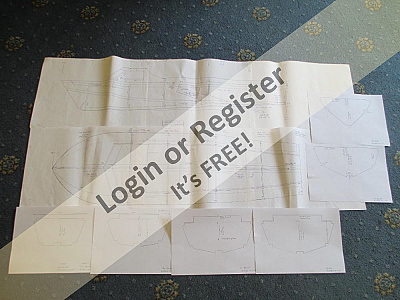

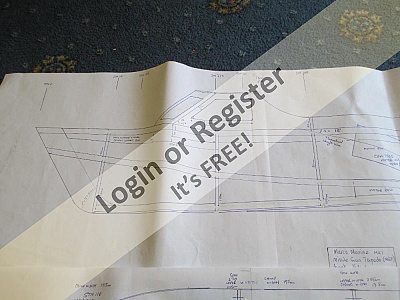

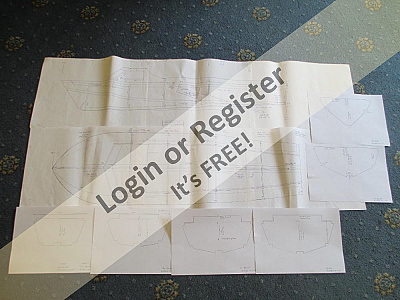

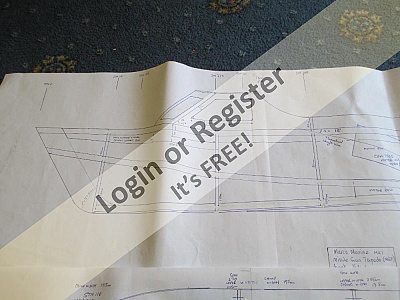

Been looking for a hobby for a while now to fill in the small amount of spare time I get and having (mostly) finished my Dads Aerokit 36" (detailed in another blog somewhere here) fire tender a mere 40 odd years after he began it, I decided to see if I could do the hard bit and build a hull myself rather than fitting out what he had already done. I do like to do things my own way though so decided to go from scratch rather than a kit. I can't list marine architect on my CV so I used the Aerokit hull to get a start for the dimensions then altered it all to suit what I thought would be best, especially the spacing between the bulkheads to allow for batteries and radio etc. The superstructure will be different to reflect the er, interesting weapons specification demanded by the 'customer'. Hopefully we will end up with a wooden hull around 880mm long by 255mm beam, powered by a Caldercraft CEM750S at 12v driving a single prop. I did want to go for a twin motor set-up but the extra cost didn't really justify itself to me.

I have drawn full scale the plan and side elevation and the bulkheads which have now been photocopied full size. I cut the main keel section from 5mm ply and laminated it with two 9x9mm spruce sections using polyurethane adhesive. Despite clamping to a flat surface during the cure it still ended up a banana which is why I like to work with metal but never mind, I clamped it to a long radiator in the lounge (understanding wife required here) for a few days and it is now straight. I have pasted the plan views of the bulkheads to 3mm ply and will be fret sawing them over the next few days if time allows. That's about it so far.

I have drawn full scale the plan and side elevation and the bulkheads which have now been photocopied full size. I cut the main keel section from 5mm ply and laminated it with two 9x9mm spruce sections using polyurethane adhesive. Despite clamping to a flat surface during the cure it still ended up a banana which is why I like to work with metal but never mind, I clamped it to a long radiator in the lounge (understanding wife required here) for a few days and it is now straight. I have pasted the plan views of the bulkheads to 3mm ply and will be fret sawing them over the next few days if time allows. That's about it so far.

▲

⟩⟩

hermank

Wolle

sandkb

Deswelham

petercbrown

Pav403

📝 MTGMB

11 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 22 Views · 4 Likes · 4 Comments

Flag

💬 Add Comment

This the story, possibly to be a long drawn out one, of a scratch built wooden boat. Nominally for my six year old son, he has provided the spec for the armament, and as no amount of firepower is too much for a boy, he has asked for torpedoes, guns and missiles, hence the name!

▲

⟩⟩

hermank

sandkb

Deswelham

petercbrown

📝 Glenn Aerokit 36" Mk2

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 10 Views · 1 Like

Flag

💬 Add Comment

Painting went quite well, the only snag was the red which kept bleeding through the black. The white line was I think successful, although a bit of a fiddle to get flat over the chine line, doing It on a hot day helped. The grey primer upper deck looks OK too, but the first coat of acrylic laquer was a bit flat. I then used poly-urethane laquer for alloy wheels, miles better, the hull especially Is like glass. It Is slow to dry but well worth the wait. Usual stickers from Cornwall model boats, used 94 as most people seem to favour the more photographed 93! I just need a bit of time to fit the deck out with the model slipway stuff In the winter, but the latest test post re-assembly was fine, too much rudder travel was easy to remedy and everything else was good for me. This was finally at my local pond, Norwich and I had the place to myself, probably because It was raining! It seemed very big after Sheringham but as I say It was empty, I will have to join the club and visit on a Sunday morning actually with a boat rather than as a spectator.

▲

⟩⟩

Sakibian

📝 Paint your wagon

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

OK, been a while since I could do much but I am a little surprised to find how much I have missed not having the chance to take her for a turn around a pond- other things get in the way. I removed all the internals except the prop shaft which is unaccountably stuck to the aft U/J, might as well leave it there for now, and started sanding, which was a fairly painless process. Then a little P45 and more sanding, you know how it goes. Then came the paint choice- no-one really seems to be able to say 'these boats were this colour' and to be honest I am not worried about the perfect shade, all the photos of the originals look slightly different anyway. I first put a coat of car acrylic primer over everything then used an epoxy two part light grey for the interior, very hard and waterproof. I liked it so much I carried on above decks as it seemed to be going so well. A couple of days later I did the hatch tops white and hmm, not much contrast with that grey so it has to be over coated- makes a good solid base though. The hull is traditional red and black with white stripe to split them, car paint again and a self-adhesive pinstripe, we'll see how well it stays on after a few coats of laquer. The grey above the deck will be plain car primer, it seems the right shade and will be shiny once laquered also. So there I am, half painted and not in the least laquered but that should change in the next week, then a while for it all to harden fully and I will fit the old girl out again, and post a photo and maybe video if I make it to a pond- I am keen to try my local pond at Norwich where I might get more than 2 seconds at full chat!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Overview

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Motor

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 10 Views · 1 Like

Flag

💬 Add Comment

▲

⟩⟩

Sakibian

📝 Electronics.

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Steering gear and water pick-up

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

Might need a little fettling on the rather rough servo bracket. And I need to make a permanent link rod now I know the length although I might try a longer arm on the servo yet.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 rudder and prop

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Final test

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

OK, last post for a bit, did another run today at Sheringham with a 45mm X prop- blimey, how fast (to me at least). Bows and all the mid section out of the water and spray everywhere- too fast really as very windy and into the wind I really thought we would be right out of the water 😱 . I think the 45mm S is best for most times but if I want the speed I know she has it in there!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 getting wet

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 10 Views · 1 Like

Flag

💬 Add Comment

OK, end of March 13 finaly saw the beast on the water at Gorleston pond, where it last ran about 30 years ago!

It was a 50/50 first test, and on the plus side she didn't leak or capsize, didn't crash into the submerged hazard the local council call a fountain and it trimmed OK. in the neutral camp we had fairly sedate performance with only 7.2V available on the 40mm/3 prop. I swapped that for the only spare I had, a 35mm/2, and she went a little better. At which point the negatives need a mention, like the rudder not having enough travel, turning circle of a real supertanker, and worse, the propshaft seized. End of test.

Once home I found the stuck shaft was down to my choice of lubrication. I went for a dry lubricant which seems to turn into glue with a little water and rpm so a poor choice. I replaced it with a very thin ultra low temp grease designed for aircraft which is another odd choice I suppose but it has good load bearing and will not drag the shaft too much. The rudder links got adjusted for more sweep at the business end and finally I looked at the volts issue.

I had two 7.2v Nimh 6 cell batteries. Had I realised the limitation of my speed cotroller I would have bought two 5 cell but there you go. Not having the funds for replacement I pulled one apart and removed two cells, soldered a new link and re-insulated it. Then I made up a series link with a couple of new Tamiya type connectors and had 12v at last. I also changed to a 45mm/2 prop.

Test run 2 was at Sheringham pond. Very nice venue. A much livelier boat, she was getting her bow out of the water a bit and accelerated well. Gentle turns at low speed OK, tried a bit more speed in the turn and oops, bit unstable. I moved the batteries back to about 6" aft of the middle of the boat and that sorted it, much better, nose up more at speed and stable at a sensible speed in the turns, which were now as tight as I would want. I was quite chuffed, she looked good despite the scruffy paint and no deck fittings, with the bow up and stern below the water line. I can't claim a rooster tail (it's not a speed boat) but the water had a sort of coming to the boil look! The next test run is just for experimenting with prop sizes when I have a couple more to try then it will be time for a proper battery mount and paint.

It was a 50/50 first test, and on the plus side she didn't leak or capsize, didn't crash into the submerged hazard the local council call a fountain and it trimmed OK. in the neutral camp we had fairly sedate performance with only 7.2V available on the 40mm/3 prop. I swapped that for the only spare I had, a 35mm/2, and she went a little better. At which point the negatives need a mention, like the rudder not having enough travel, turning circle of a real supertanker, and worse, the propshaft seized. End of test.

Once home I found the stuck shaft was down to my choice of lubrication. I went for a dry lubricant which seems to turn into glue with a little water and rpm so a poor choice. I replaced it with a very thin ultra low temp grease designed for aircraft which is another odd choice I suppose but it has good load bearing and will not drag the shaft too much. The rudder links got adjusted for more sweep at the business end and finally I looked at the volts issue.

I had two 7.2v Nimh 6 cell batteries. Had I realised the limitation of my speed cotroller I would have bought two 5 cell but there you go. Not having the funds for replacement I pulled one apart and removed two cells, soldered a new link and re-insulated it. Then I made up a series link with a couple of new Tamiya type connectors and had 12v at last. I also changed to a 45mm/2 prop.

Test run 2 was at Sheringham pond. Very nice venue. A much livelier boat, she was getting her bow out of the water a bit and accelerated well. Gentle turns at low speed OK, tried a bit more speed in the turn and oops, bit unstable. I moved the batteries back to about 6" aft of the middle of the boat and that sorted it, much better, nose up more at speed and stable at a sensible speed in the turns, which were now as tight as I would want. I was quite chuffed, she looked good despite the scruffy paint and no deck fittings, with the bow up and stern below the water line. I can't claim a rooster tail (it's not a speed boat) but the water had a sort of coming to the boil look! The next test run is just for experimenting with prop sizes when I have a couple more to try then it will be time for a proper battery mount and paint.

▲

⟩⟩

Will-I-Am

📝 2 steps forward...

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 9 Views · 0 Likes

Flag

💬 Add Comment

Thought I might be doing some gentle turns around the pond by start of March but didn't get further than the bath! The job was going well, a new frame for the aft end and a cover/deck to sit on it, a frame and tray for the electronics to sit on. The water pick-up for the jacket on the diesel engine now runs water around in a loop and out the back of the boat without actually doing anything but I thought it might look a bit more interesting to retain it. All electronics mounted and working, batteries in situ alongside the motor. Bit of a bother with the receiver/ESC/servo connections in so far as the instructions that came with the (cheap) 2CH 2.4Ghz set gave no real clue as to what went where. There were 4 sockets, marked /- then Ch1,2 and 3(?). The instructions showed the ESC on Ch1 and the servo on 2. The leads from the ESC and servo have no key/spline to ensure they only fit one way around so I crossed fingers and plugged in. Various combinations later, mostly resulting in the throttle lever on the Tx operating the rudder and nothing else, I ended up with the ESC in /- and the servo on Ch1 which seems to work fine. I think I am lucky not to have let the smoke out of the circuits really but being an RC virgin I had no idea of what the set up should have been. I also noticed that the motor runs a higher rpm in reverse, is this an internal ESC resistance thing, the higher rated amps for fwd causing the resistance increase? Haven't checked it with a meter so can't comment on the voltage actually being delivered as yet.

Anyway, I put everything in and gave it a spin on the stocks- god, what a row. The motor is quiet enough on its own but with the shaft and UJ in it is awful. I did know the original brass shaft was a bit loose to be honest but hoped to get away with it just for a test run or two but no, it has to go. Most of the noise seemed to be from the UJ though which I thought a bit odd as it has almost no angle to run at. Solutions, replace known problem of shaft and try a different UJ. I didn't fancy getting a 50 year old hull too upset removing the old tube so have gone for a 4mm stainless shaft/tube which will fit inside the old 1/4" ID tube and save disturbances. I don't think the motor will produce enough torque to twist the shaft. This is the next job along with making another motor mount as the thing needs to be in a different place now.But I couldn't resist a quick if noisy test so into the bath just to see what we had- at 7.2V it is moving a fair bit of water with its 35mm 3 blade prop and revs don't drop much under the load so nothing seems to be stressed there but I am sure we could go a bit bigger on the prop and of course when I resolve my battery issues (see below) we will have about 12v anyway. No idea what this all might translate to in terms of forward speed but that doesn't really matter that much anyway. Tune in for the next exiting episode soon...

Anyway, I put everything in and gave it a spin on the stocks- god, what a row. The motor is quiet enough on its own but with the shaft and UJ in it is awful. I did know the original brass shaft was a bit loose to be honest but hoped to get away with it just for a test run or two but no, it has to go. Most of the noise seemed to be from the UJ though which I thought a bit odd as it has almost no angle to run at. Solutions, replace known problem of shaft and try a different UJ. I didn't fancy getting a 50 year old hull too upset removing the old tube so have gone for a 4mm stainless shaft/tube which will fit inside the old 1/4" ID tube and save disturbances. I don't think the motor will produce enough torque to twist the shaft. This is the next job along with making another motor mount as the thing needs to be in a different place now.But I couldn't resist a quick if noisy test so into the bath just to see what we had- at 7.2V it is moving a fair bit of water with its 35mm 3 blade prop and revs don't drop much under the load so nothing seems to be stressed there but I am sure we could go a bit bigger on the prop and of course when I resolve my battery issues (see below) we will have about 12v anyway. No idea what this all might translate to in terms of forward speed but that doesn't really matter that much anyway. Tune in for the next exiting episode soon...

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 ESC help

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 1 View · 0 Likes

Flag

📝 Reply

hmm, interesting, I had assumed with the motors rated range I would be OK at 14.4v but I have no experience to go by and others do so point noted. I guess at the moment (or soon as she is ready to take to the water) I am not going to be looking at more than pottering around to get used to the thing so 7.2v is enough. When I get confident I will look at more options if I need to and yes, those two NiMh's are heavy! This whole matter of prop size/pitch/blades, motor rating/rpm and voltage is confusing, there must be some sort of formula for arriving at the optimum but everyone seems to use a different set-up, mostly found by what a technical manual I once read described as the 'emperical technique', or trial and error to the rest of us! Cheers anyway.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 ESC help

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 1 View · 0 Likes

Flag

📝 Reply

HI all, being a newbie to this hobby I need a little help. I have a 34" Aerokits Mk2, It Is to be run with a Graupner 700BB turbo. I planned on 7.2v NiMh and bought an HM-50 ESC (think the makers are Himark, whoever they may be). Anyway this has a rated Input voltage of 12v max. A bit later I decided that It would be good to be able to run a second 7.2v battery In series If the performance needed a boost, assuming I have learned to steer It properly at some point.So question Is, can I safely exceed the rated Input voltage, or do I look at a new ESC or 12v battery arrangement (obviously the better choices but funds are tight)- could I even remove one cell from each NiMh 7.2v which would then give me 2x 6v, or Is this deemed naughty?

Thanks.

Thanks.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 learning points

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 7 Views · 0 Likes

Flag

💬 Add Comment

OK finally got going for real at start of Feb. in Jan all I did was reinforce some of the old joints on the hull that looked a bit dry and dubious, used Araldite resin AW106, not the lightest way of doing it but it will work OK and I could run it up under the deck/hull joints as well as the bits I could reach. I didn't fancy taking the deck off, what with my woodworking skills...The motor mount is more my area and this was quickly folded up and drilled from .071" aluminium alloy, slotted holes allow a good alignment to the shaft. The rudder was always a problem, a very short tube (I'm sure there is a tech name for it) allowed water to get in with the boat at speed so I changed that for a longer one and new rudder, which is far too big at the moment I suspect but I will wait and see before I cut it down. The servo is mounted in the aft bay on a galvanised steel bracket, there should be enough room for a link and again I slotted the holes to help set up the correct ratio. I am currently doing a bit of framing to sit the new aft hatch and electronics tray on, the latter is going just aft of the motor in what might be called the 2nd to last bay (are the divided areas in a boat called bays???). The learning point is the speed controller, I bought two 7.2v batteries thinking to run at either 7.2 or 14.4 depending on how I found the performance/my RC skill (none) ratio. Then I bought a 12v ESC... 😯 I don't know, can I push my luck and see if it will take 2.4v extra without setting things alight or do I buy a new ESC or 2 6v batteries?

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 first steps

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 7 Views · 0 Likes

Flag

💬 Add Comment

OK, went out and spent MONEY, not nice but as Dad is financing the final build of his boat it wasn't as bad as usual! Played with the new toys for a while than decided the motor mount was first up for attention. Problem one, motor is a bit longer than expected as I hadn't allowed for the connector lugs sticking out the back and the UJ, a Graupner 5-6mm, is much longer than it needs to be so I had a bit of a clearance issue, I.e. I didn't have any between the motor and the bulkhead, in fact it is all about 10mm too long. So I have edited a bit out of said bulkhead and will be bonding on a stiffer to what remains (only a 2" diameter cut out so not too weakened). That done the next job is to make the motor mount itself, could have bought one but around £13 for a bit of ally bent wrongly (with the grain) and a couple of holes in it sounds too much to an aircraft sheet metal herbert like me. While I am borrowing company time making that I will turn the old prop shaft down from 1/4" to 6mm at the motor end then we shouldn't be far off installation of these bits. Photo's soon.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Glenn Aerokit 36" Mk2

13 years ago by 🇬🇧 fid2b ( Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Petty Officer 2nd Class)✧ 7 Views · 0 Likes

Flag

💬 Add Comment

OK, usual story so far. Dad started a build in about '62 and by about '66 had a complete running ED diesel powered boat that did some trips across ponds in S London. He did a nice job too, odd because while he is a great mechanic and a passable metal worker you wouldn't ask him to put shelves up or do anything with wood as a rule. All steamed in the kitchen with an overworked kettle apparently. it never got a top coat of paint or radio, the latter as it was too expensive at the time for him. There it rested until the early 80's when a 14 year old me painted it the wrong colours (but not far out), put the fittings on and replaced the coolant pipes etc. Radio still too pricey on a paper round salary so it did some more trips over Gorleston pond. Finally it made it's way out of Dads loft in October this year to be finished off.

So here we are in 2012. The 2.46 ED diesel was being run on the bench, spraying a gentle rain of castor oil and kerosine over everything within 3 feet when disaster struck. All went quiet except for the still spinning flywheel. The crank output end has loosened from the rest of it. it could no doubt be repaired and I would love to run the boat as intended but an electric conversion makes sense of course. The sight and sound of a diesel Mk2 screaming across the pond, trailing a rainbow of unburnt fuel on the wake behind is set to be denied to Norwich. Better news, the boat is sound structurally, all well protected with primer and interior paint at build although there are two small delaminated bits on the upper structure to fix. Many of the fittings are damaged and need replacing and the upper deck paint needs freshening after 25 years in a loft, the rest is OK though. Colours on the hull are wrong, it is all dark blue but I did that all those years ago and it is still shiny and waterproof so I'll leave it for now. Plan then is for a Graupner 700BB turbo 12v running either 7.2 or 8.4V (depends what will fit), fit radio a basic 2.4Ghz 2 channel and ESC and see what happens. I will leave the 40mm 3 blade prop at the moment and the original shaft which means a custom coupling. I should say I know next to nothing about RC or model boats in general and am on a limited budget so it may all go horribly wrong! Having said that I am an engineer by trade so should manage to muddle through...time will tell. I am off shopping for bits this week so hopefully will start work on it soon.

So here we are in 2012. The 2.46 ED diesel was being run on the bench, spraying a gentle rain of castor oil and kerosine over everything within 3 feet when disaster struck. All went quiet except for the still spinning flywheel. The crank output end has loosened from the rest of it. it could no doubt be repaired and I would love to run the boat as intended but an electric conversion makes sense of course. The sight and sound of a diesel Mk2 screaming across the pond, trailing a rainbow of unburnt fuel on the wake behind is set to be denied to Norwich. Better news, the boat is sound structurally, all well protected with primer and interior paint at build although there are two small delaminated bits on the upper structure to fix. Many of the fittings are damaged and need replacing and the upper deck paint needs freshening after 25 years in a loft, the rest is OK though. Colours on the hull are wrong, it is all dark blue but I did that all those years ago and it is still shiny and waterproof so I'll leave it for now. Plan then is for a Graupner 700BB turbo 12v running either 7.2 or 8.4V (depends what will fit), fit radio a basic 2.4Ghz 2 channel and ESC and see what happens. I will leave the 40mm 3 blade prop at the moment and the original shaft which means a custom coupling. I should say I know next to nothing about RC or model boats in general and am on a limited budget so it may all go horribly wrong! Having said that I am an engineer by trade so should manage to muddle through...time will tell. I am off shopping for bits this week so hopefully will start work on it soon.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Liked Slowly does it. 9 years ago

Liked Slowly does it. 9 years ago