Join Us On Social Media!

United States

Recent Posts

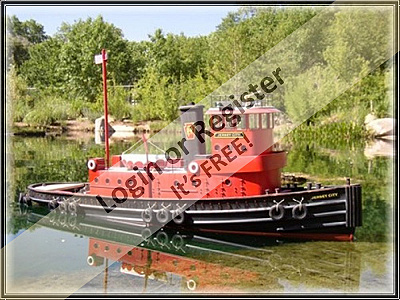

💬 Re: Testing results sofar of the SMIT harber tug

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 187 Views · 1 Like

Flag

💬 Add Comment

Hi Albert90,

Your Smit Nederland is superbly built, and I love the sound system!

Pity we're so far away from each other?

As, I'd love to do some tug boating competition with you?

Also, Thanks for pointing out the wrong lighting on my mast!

Regards,

Ed-

Your Smit Nederland is superbly built, and I love the sound system!

Pity we're so far away from each other?

As, I'd love to do some tug boating competition with you?

Also, Thanks for pointing out the wrong lighting on my mast!

Regards,

Ed-

▲

⟩⟩

Albert90

Login To

Remove Ads

Remove Ads

📝 Very sad news about Nerys plus update on her final boat project

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 48 Views · 7 Likes

Flag

📝 Reply

Hello, Alice

I've been away from the website for a while doing other hobbies!

And, I have just read such devastating news.

I'd like to give my Sincerest Condolences on your loss of Nerys!

I can remember many times reading her post and the way she spoke about you showed true Love!

Nerys, will be truly missed by all of us!

With Kind Regards,

Ed & Jenn-

U.S.A.

I've been away from the website for a while doing other hobbies!

And, I have just read such devastating news.

I'd like to give my Sincerest Condolences on your loss of Nerys!

I can remember many times reading her post and the way she spoke about you showed true Love!

Nerys, will be truly missed by all of us!

With Kind Regards,

Ed & Jenn-

U.S.A.

▲

⟩⟩

RNinMunich

Newby7

GaryLC

Rookysailor

Scratchbuilder

hermank

Colin H

💬 Re: Dusseldorf

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 91 Views · 5 Likes

Flag

💬 Add Comment

Hi Peter,

What can I say?

Absolutely a Fantastic Build 👍👍👍

Cheers, Ed

What can I say?

Absolutely a Fantastic Build 👍👍👍

Cheers, Ed

▲

⟩⟩

pressonreguardless

stevedownunder

MouldBuilder

Colin H

River Rat

📝 Very sad news Martin555

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 157 Views · 20 Likes

Flag

📝 Reply

"RIP" Martin555-

I've known Martin for over 5 years now!

A true friend and an awesome model builder!

I will miss his wealth of information and techniques.

He'll truly be missed by us all!

Ed-

I've known Martin for over 5 years now!

A true friend and an awesome model builder!

I will miss his wealth of information and techniques.

He'll truly be missed by us all!

Ed-

▲

⟩⟩

Rookysailor

Mike Stoney

RNinMunich

philcaretaker

hermank

Black Shoe

pressonreguardless

ChrisG

MouldBuilder

Nerys

jbkiwi

HappyHaggis

Colin H

stevedownunder

Scratchbuilder

dave976

GaryLC

River Rat

Newby7

fireboat

💬 Re: Scuppers Oh My!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 43 Views · 0 Likes

Flag

💬 Add Comment

Hi Doug,

Thank you, I try!

Cheers,

Ed-

Thank you, I try!

Cheers,

Ed-

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

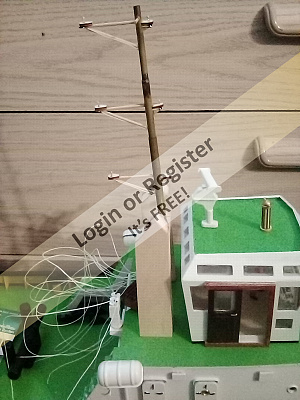

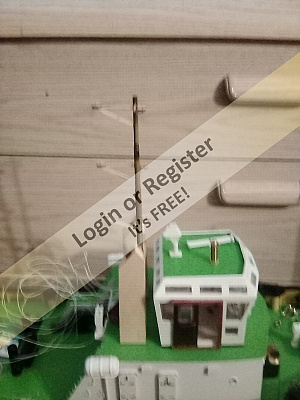

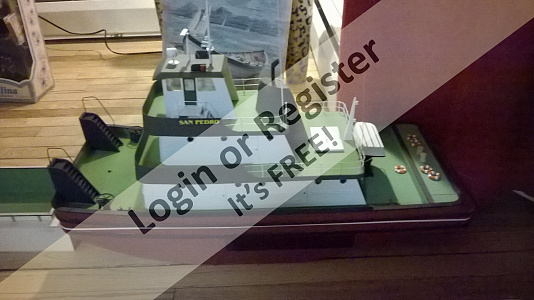

📝 Not much to Report!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 46 Views · 6 Likes · 2 Comments

Flag

💬 Add Comment

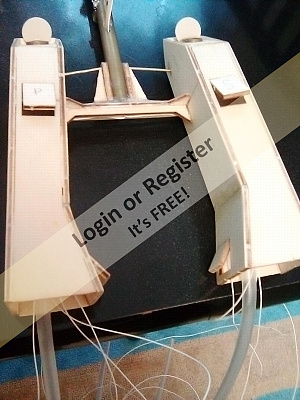

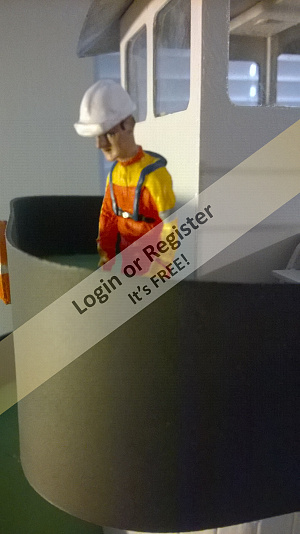

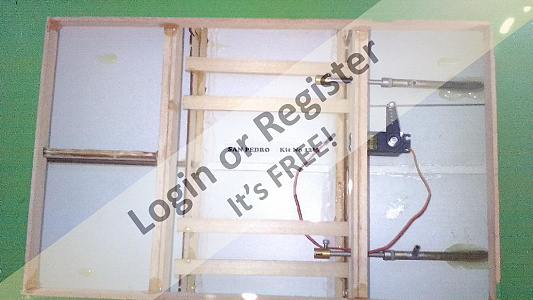

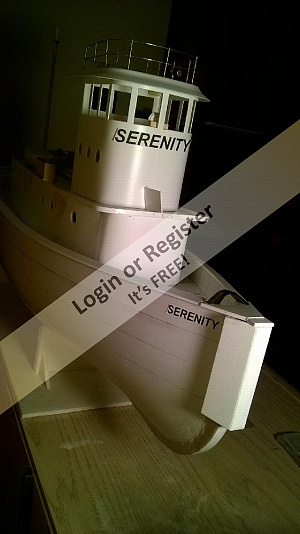

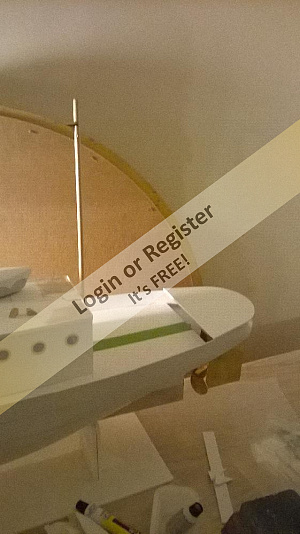

I'm in the process of placing the support ribs around the bulwark!

But I stopped working on the Happy Hunter temporarily to work on the Smit Nederland!

See I botched up the light colours on the Aft of the Mast!

So, I had to correct my mistake which I did!

It took 2 days of swearing, But I did it!

As you can see in the picture the Aft Mast lights are now correct!

Cheers,

Ed-

But I stopped working on the Happy Hunter temporarily to work on the Smit Nederland!

See I botched up the light colours on the Aft of the Mast!

So, I had to correct my mistake which I did!

It took 2 days of swearing, But I did it!

As you can see in the picture the Aft Mast lights are now correct!

Cheers,

Ed-

▲

⟩⟩

RNinMunich

Colin H

jbkiwi

Albert90

pressonreguardless

MouldBuilder

📝 Frozen Pond

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 77 Views · 3 Likes

Flag

📝 Reply

Hi Ron,

Its -7C here and will go lower tonight! ❄️

Tomorrow morning it'll be -20C! ⛄

There's no boating any time soon! LOL! 🚤

Cheers,

Ed-

Its -7C here and will go lower tonight! ❄️

Tomorrow morning it'll be -20C! ⛄

There's no boating any time soon! LOL! 🚤

Cheers,

Ed-

▲

⟩⟩

River Rat

pressonreguardless

MouldBuilder

💬 Re: STEAM LAUNCH VULCANIA WITH CALLIOPE

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 290 Views · 1 Like

Flag

💬 Add Comment

Outstanding!!! I've never seen anything like it!

It would be an awesome model steamboat!

Cheers,

Ed-

It would be an awesome model steamboat!

Cheers,

Ed-

▲

⟩⟩

jbkiwi

📝 Wanted Brushed outboard

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 33 Views · 1 Like

Flag

📝 Reply

Hi Scott,

Take a look here:

Take a look here:

▲

⟩⟩

MouldBuilder

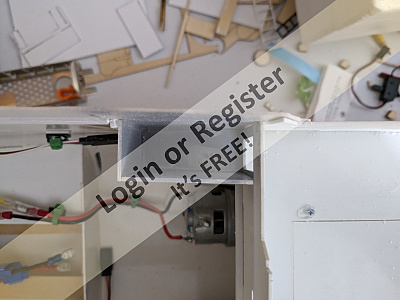

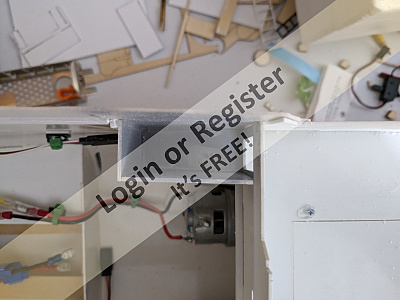

💬 Re: Smit Nederland Tugboat

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 38 Views · 0 Likes

Flag

💬 Add Comment

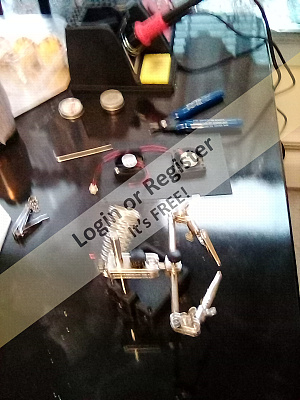

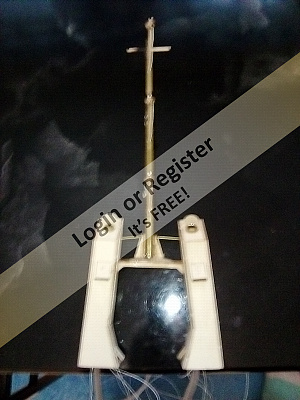

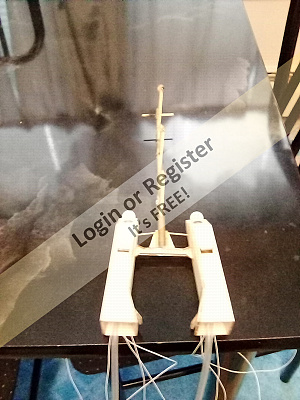

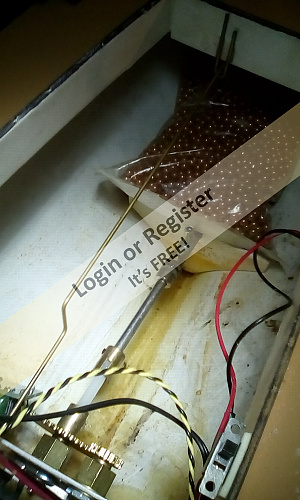

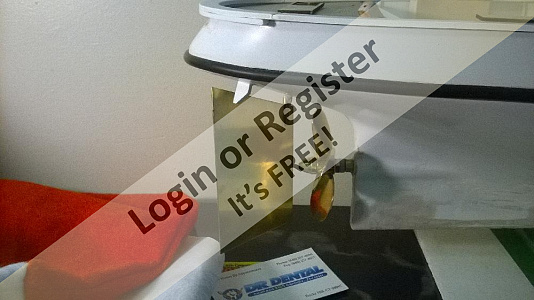

I spent a few days trying to figure out how to fix my botched-up Mast!

As the lighting wasn't correct and Albert90 was kind enough to let me know it was Botched up!

Thanks, Albert90 it's now fixed!

Anyway,

I ended up pulling the old led's from the aft of the Mast!

I then had to somehow drill tiny little holes to run the wires from the new led's!

I carefully did everything without breaking the Mast!

It was a real challenge to do this repair!

This is what I ended up with!

Repairs all done- 👍

As the lighting wasn't correct and Albert90 was kind enough to let me know it was Botched up!

Thanks, Albert90 it's now fixed!

Anyway,

I ended up pulling the old led's from the aft of the Mast!

I then had to somehow drill tiny little holes to run the wires from the new led's!

I carefully did everything without breaking the Mast!

It was a real challenge to do this repair!

This is what I ended up with!

Repairs all done- 👍

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Scuppers Oh My!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 70 Views · 4 Likes

Flag

💬 Add Comment

Hi Peter,

Thank You,

I tried as best as I could to cut them out the same size!

I do have to tidy up the ends of the Scuppers though!

Cheers,

Ed-

Thank You,

I tried as best as I could to cut them out the same size!

I do have to tidy up the ends of the Scuppers though!

Cheers,

Ed-

▲

⟩⟩

MouldBuilder

RNinMunich

Colin H

Martin555

Login To

Remove Ads

Remove Ads

📝 Lead strip alternatives?

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 60 Views · 4 Likes

Flag

📝 Reply

Hi Scott,

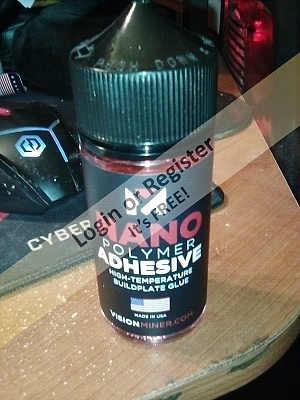

Give a look on Amazon or your local pound shop or maybe even a local hobby shop too!

Also, when you add the Ballast place it as close to the center Of the Model as possible!

Add Ballast torwards the Aft end of the Model!

Bring her down till the Black is barely touching the water!

See if that helps!

Cheers,

Ed-

Give a look on Amazon or your local pound shop or maybe even a local hobby shop too!

Also, when you add the Ballast place it as close to the center Of the Model as possible!

Add Ballast torwards the Aft end of the Model!

Bring her down till the Black is barely touching the water!

See if that helps!

Cheers,

Ed-

▲

⟩⟩

dave976

Len1

Colin H

HappyHaggis

📝 Lead strip alternatives?

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 60 Views · 5 Likes

Flag

📝 Reply

Hi Scott,

Peejay's recommendation is right!

I would use these:

Peejay's recommendation is right!

I would use these:

▲

⟩⟩

dave976

Colin H

Nickthesteam

MouldBuilder

HappyHaggis

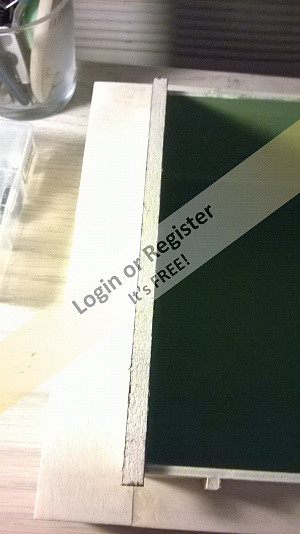

📝 Scuppers Oh My!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 75 Views · 12 Likes · 5 Comments

Flag

💬 Add Comment

You know the saying?

"There's a first time for everything?"

Well, it's true!

I've never cutout Scuppers!

I looked all over the internet looking for ideas on how such a task should be handled!

Everywhere I looked they spoke about real scuppers on real ships.

So, after thing about it?

And I did this for days!

I then looked at the way the scuppers are on the Happy Hunter Model versus the Real Happy Hunter.

The Happy Hunter Model has Scuppers on the Aft deck and upper deck!

But, I looked at a picture of the real Happy Hunter and there are no Scuppers on the Aft Deck!

So, I decided to cutout the Scuppers on my Happy Hunter!

As this adds more details to her aft deck!

Each Scupper is 35mm wide by 5mm high!

On the Model you have to laminate a preshaped piece to the inside of the bulwark!

This piece has the Scuppers and scribed lines of where the Bulwark supports are placed!

Now you can then see where the Scuppers are placed!

So, what I did was use a light to see where the Scupper would be?

I then saw the center of the Scupper.

I then made holes to drill out the Scupper!

Then cut away the center after having drilled about 5 to 6 holes where the scupper is located!

Then I used my trusty rattail and a small flat file as well!

I did 10 Scuppers in 2 days.

I have to cutout 12 Scupper on her upper deck as soon as I get there!

Oh, I also drilled out her Portholes too!

Lots of fun with this Build!

Cheers for now,

Ed-

"There's a first time for everything?"

Well, it's true!

I've never cutout Scuppers!

I looked all over the internet looking for ideas on how such a task should be handled!

Everywhere I looked they spoke about real scuppers on real ships.

So, after thing about it?

And I did this for days!

I then looked at the way the scuppers are on the Happy Hunter Model versus the Real Happy Hunter.

The Happy Hunter Model has Scuppers on the Aft deck and upper deck!

But, I looked at a picture of the real Happy Hunter and there are no Scuppers on the Aft Deck!

So, I decided to cutout the Scuppers on my Happy Hunter!

As this adds more details to her aft deck!

Each Scupper is 35mm wide by 5mm high!

On the Model you have to laminate a preshaped piece to the inside of the bulwark!

This piece has the Scuppers and scribed lines of where the Bulwark supports are placed!

Now you can then see where the Scuppers are placed!

So, what I did was use a light to see where the Scupper would be?

I then saw the center of the Scupper.

I then made holes to drill out the Scupper!

Then cut away the center after having drilled about 5 to 6 holes where the scupper is located!

Then I used my trusty rattail and a small flat file as well!

I did 10 Scuppers in 2 days.

I have to cutout 12 Scupper on her upper deck as soon as I get there!

Oh, I also drilled out her Portholes too!

Lots of fun with this Build!

Cheers for now,

Ed-

▲

⟩⟩

dave976

Ronald

marky

Rookysailor

Colin H

RNinMunich

Martin555

Len1

pressonreguardless

jbkiwi

MouldBuilder

River Rat

💬 Re: Hull Completion 2

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 171 Views · 5 Likes

Flag

💬 Add Comment

Hi Peter,

Fantastic workmanship! 👍

Cheers,

Ed-

Fantastic workmanship! 👍

Cheers,

Ed-

▲

⟩⟩

PemyslJ

Peejay

Martin555

stevedownunder

MouldBuilder

💬 Re: Hull completion 1 of ?

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 171 Views · 4 Likes

Flag

💬 Add Comment

Hi Peter,

Just tell everybody to shake their head up and down?

That'll make the waterline even! LOL!

Cheers,

Ed-

Just tell everybody to shake their head up and down?

That'll make the waterline even! LOL!

Cheers,

Ed-

▲

⟩⟩

Peejay

Martin555

MouldBuilder

RNinMunich

💬 Re: Final assembly part 1 of ?

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 183 Views · 6 Likes

Flag

💬 Add Comment

Hi Peter,

Your Düsseldorf looks fantastic she has awesome details too.

Very nice lines!

Cheers,

Ed-

Your Düsseldorf looks fantastic she has awesome details too.

Very nice lines!

Cheers,

Ed-

▲

⟩⟩

Peejay

Cashrc

pressonreguardless

Martin555

Colin H

MouldBuilder

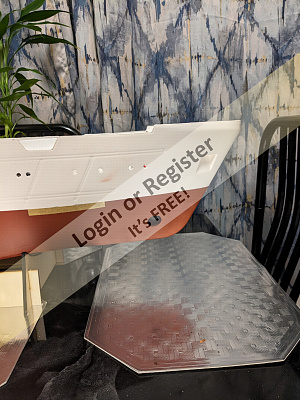

📝 Aft Deck in Place!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 85 Views · 4 Likes

Flag

💬 Add Comment

Hi, All

I've laid the Aft Deck!

Which was a straightforward process!

Next, I'll have to place the ribs.

They're just in place they don't do anything but look good!

Oh, if you look at the pic that shows the entrance that goes up to the forecastle!

Anyway, its late here and I'm tired!

It's been a long day as I did a lot of grinding.

Cheers,

Ed-

PS, I have to cut out the scuppers also!

I'll do that tomorrow!

I've laid the Aft Deck!

Which was a straightforward process!

Next, I'll have to place the ribs.

They're just in place they don't do anything but look good!

Oh, if you look at the pic that shows the entrance that goes up to the forecastle!

Anyway, its late here and I'm tired!

It's been a long day as I did a lot of grinding.

Cheers,

Ed-

PS, I have to cut out the scuppers also!

I'll do that tomorrow!

▲

⟩⟩

Colin H

Martin555

MouldBuilder

HappyHaggis

💬 Re: Happy Hunter Ballast!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 85 Views · 1 Like

Flag

💬 Add Comment

Hi Martin,

No, I haven't but as I add weight, I'll compensate by taking out ballast.

But my WTL is about 7mm I hope it's alright.

If not? I'll subtract weight as needed!

Cheers,

Ed-

No, I haven't but as I add weight, I'll compensate by taking out ballast.

But my WTL is about 7mm I hope it's alright.

If not? I'll subtract weight as needed!

Cheers,

Ed-

▲

⟩⟩

Martin555

💬 Re: Happy Hunter Ballast!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 85 Views · 2 Likes

Flag

💬 Add Comment

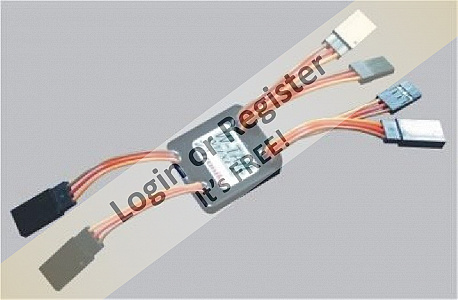

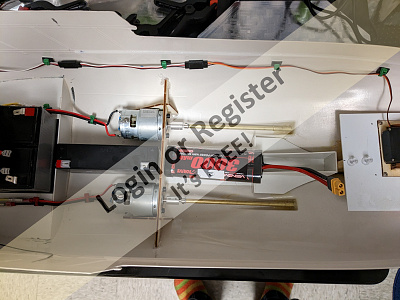

Hi Peter,

I do!

I'm using the BEC from the Bow Thruster!

And Port Starboard engines have their red wire disconnected!

And I didn't see any magic smoke! LOL!

Everything tested and it works just fine!

Oh, I had to order a replacement clutch for the port engine.

As I notice its off alignment and vibrates terribly!

Cheers,

Ed-

I do!

I'm using the BEC from the Bow Thruster!

And Port Starboard engines have their red wire disconnected!

And I didn't see any magic smoke! LOL!

Everything tested and it works just fine!

Oh, I had to order a replacement clutch for the port engine.

As I notice its off alignment and vibrates terribly!

Cheers,

Ed-

▲

⟩⟩

Martin555

MouldBuilder

📝 Coloured Sticky Tape For Coach Lining

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 57 Views · 3 Likes

Flag

📝 Reply

Hi,

Have you tried looking in your local auto parts store?

Or do a search on Amazon?

Cheers,

Ed-

Have you tried looking in your local auto parts store?

Or do a search on Amazon?

Cheers,

Ed-

▲

⟩⟩

Martin555

firefighter

River Rat

Login To

Remove Ads

Remove Ads

💬 Re: Aeronaut "Diva"

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 65 Views · 3 Likes

Flag

💬 Add Comment

Hi ChrisG,

Your Aeronaut "Diva" looks very well made!

She looks great!

Cheers,

Ed-

Your Aeronaut "Diva" looks very well made!

She looks great!

Cheers,

Ed-

▲

⟩⟩

fireboat

ChrisG

Martin555

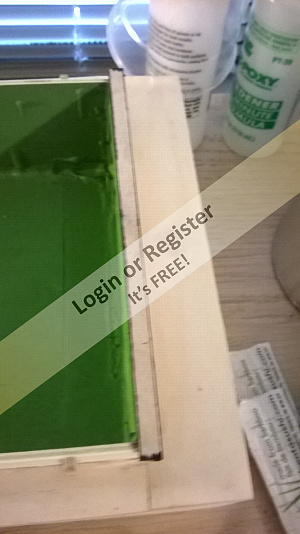

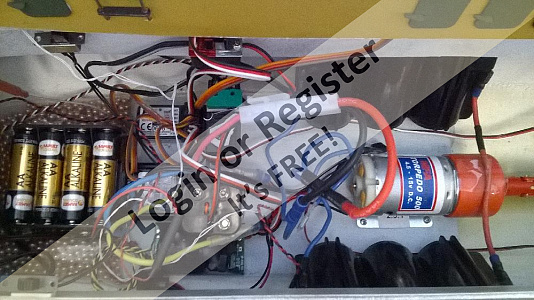

📝 Happy Hunter Ballast!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 93 Views · 5 Likes · 4 Comments

Flag

💬 Add Comment

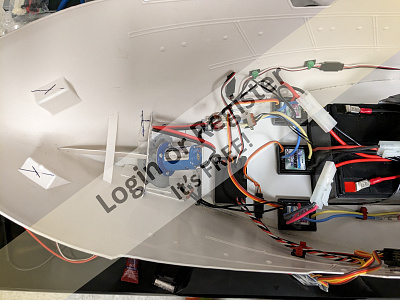

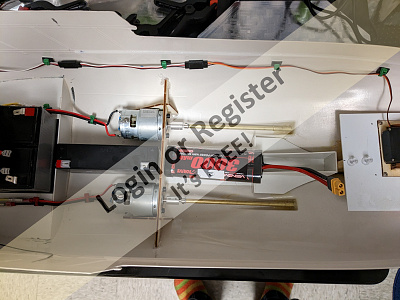

My Happy Hunter has about 20.5 lbs. of Ballast in her to bring her down to her Waterline.

There's are about 10.5 lbs. aft and 2.3 lbs. forward under the fiddly deck!

And another .6 Onces aft of the tillers

Oh, there's about .6 Onces at the Bow!

If you look very carefully, you'll see a red strip going from port to starboard in pic 1.

I had to carefully place the Ballast under the ESC's!

So, with the Ballast forward and Aft Ballast and the weight of the SLA's

I have a total of 20.6 Lbs.

I'm missing about a few Onces but that's ok no one will know! LOL!

Opp's now you know----

Cheers,

Ed-

There's are about 10.5 lbs. aft and 2.3 lbs. forward under the fiddly deck!

And another .6 Onces aft of the tillers

Oh, there's about .6 Onces at the Bow!

If you look very carefully, you'll see a red strip going from port to starboard in pic 1.

I had to carefully place the Ballast under the ESC's!

So, with the Ballast forward and Aft Ballast and the weight of the SLA's

I have a total of 20.6 Lbs.

I'm missing about a few Onces but that's ok no one will know! LOL!

Opp's now you know----

Cheers,

Ed-

▲

⟩⟩

jbkiwi

MouldBuilder

Peejay

Colin H

Martin555

💬 Re: 1930 Chris craft runabout ( Driftwood)

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 45 Views · 3 Likes

Flag

💬 Add Comment

Hi River Rat,

Fantastic build and Fantastic Details!

Very good!

Cheers,

Ed-

Fantastic build and Fantastic Details!

Very good!

Cheers,

Ed-

▲

⟩⟩

AlessandroSPQR

Martin555

River Rat

💬 Re: My Engine Room!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 102 Views · 4 Likes

Flag

💬 Add Comment

Hi Peter,

No, I haven't given up on LiPo's!

I use the SLA's as part of the Ballast for my Tugs!

I use my LiPo's for my Yacht!

The Happy Hunter needs about 18.4 lbs. of Ballast!

So, the SLA's come in handy! LOL! 👍

Cheers,

Ed-

PS, did you finish the Dusseldorf?

How'd it come out?

Ed-

No, I haven't given up on LiPo's!

I use the SLA's as part of the Ballast for my Tugs!

I use my LiPo's for my Yacht!

The Happy Hunter needs about 18.4 lbs. of Ballast!

So, the SLA's come in handy! LOL! 👍

Cheers,

Ed-

PS, did you finish the Dusseldorf?

How'd it come out?

Ed-

▲

⟩⟩

Colin H

MouldBuilder

Len1

Martin555

💬 Re: My Engine Room!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 102 Views · 1 Like

Flag

💬 Add Comment

Hi Martin,

I'm trying my best,

Thank you!

Cheers,

Ed-

I'm trying my best,

Thank you!

Cheers,

Ed-

▲

⟩⟩

Martin555

💬 Re: Smit Nederland Tugboat

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 58 Views · 1 Like

Flag

💬 Add Comment

Hi Marky,

Thank you, it's good to be back!

And building a nice big boat!

Cheers,

Ed-

Thank you, it's good to be back!

And building a nice big boat!

Cheers,

Ed-

▲

⟩⟩

Martin555

💬 Re: Smit Nederland Tugboat

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 58 Views · 2 Likes

Flag

💬 Add Comment

Hi Albert90,

I see what you mean about the lights!

As I was building the Mast, I didn't have any reference to her lights!

Someday I'll fix that mistake!

But, for now all I can say is Oop's! LOL!

Thanks for noticing!

Cheers,

Ed-

I see what you mean about the lights!

As I was building the Mast, I didn't have any reference to her lights!

Someday I'll fix that mistake!

But, for now all I can say is Oop's! LOL!

Thanks for noticing!

Cheers,

Ed-

▲

⟩⟩

Martin555

Albert90

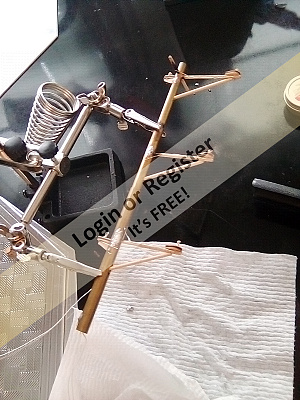

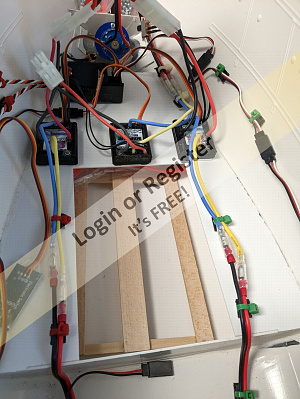

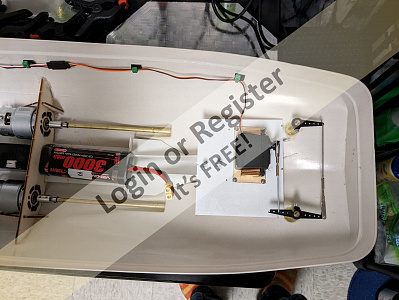

📝 My Engine Room!

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 104 Views · 9 Likes · 6 Comments

Flag

💬 Add Comment

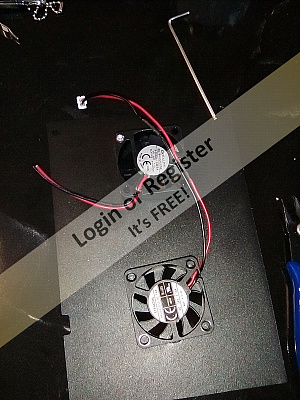

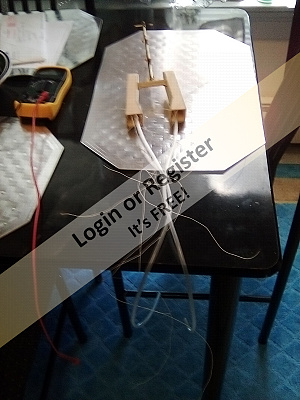

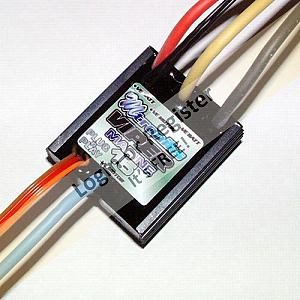

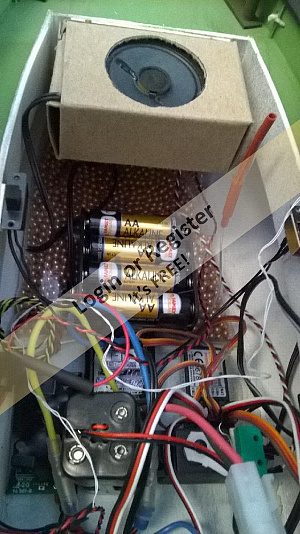

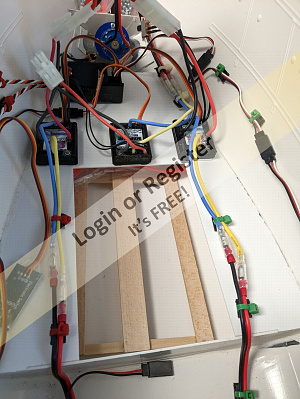

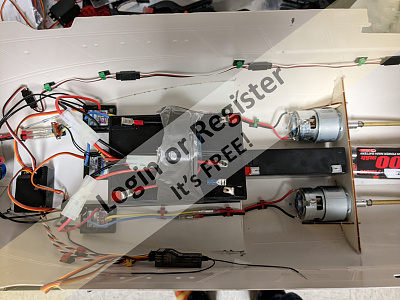

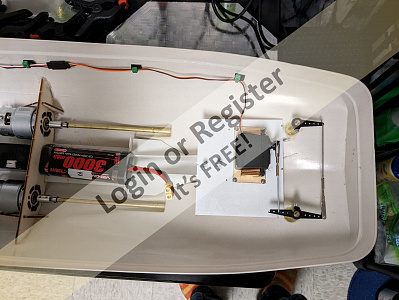

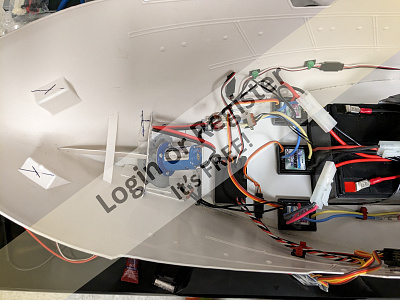

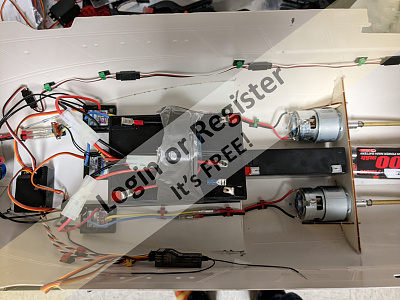

This is my first time setting up an Engine Room using 3 ESC's

My Happy Hunter will use 12 volts at 25 Amp's for her Main Engines!

And my Bow Thruster will use 6 volts at 3.2 Amp's!

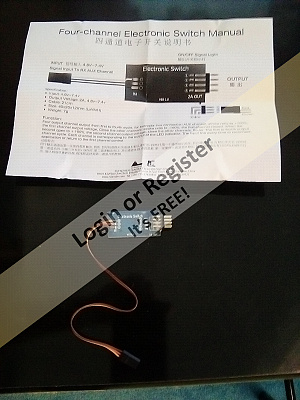

Oh, I am also incorporating a P40-E which will come in handy on some monoverses!

I know where are my fuses?

I'll place the fuses before I lay the main deck!

I'm just taking my time with her!

If anybody has any suggestions, please by all means make your recommendations?

That's it for now!

Cheers,

Ed-

My Happy Hunter will use 12 volts at 25 Amp's for her Main Engines!

And my Bow Thruster will use 6 volts at 3.2 Amp's!

Oh, I am also incorporating a P40-E which will come in handy on some monoverses!

I know where are my fuses?

I'll place the fuses before I lay the main deck!

I'm just taking my time with her!

If anybody has any suggestions, please by all means make your recommendations?

That's it for now!

Cheers,

Ed-

▲

⟩⟩

HappyHaggis

Colin H

jbkiwi

peterd

mturpin013

RNinMunich

Len1

Martin555

MouldBuilder

💬 Re: Smit Nederland Tugboat

3 years ago by 🇺🇸 figtree7nts ( Admiral)

Admiral)

Admiral)

Admiral)✧ 74 Views · 3 Likes

Flag

💬 Add Comment

Hi Peter,

It's 5 volts for all my LEDs with a resister that was supplied by the Manufacturer!

I haven't a clue as to its rating! LOL!

But I believe I did it correctly because I haven't blown myself up! TeHe😂🤣👍

But these LEDs are bright!

My port is a bit dimmer than my starboard side!

Cheers,

Ed-

It's 5 volts for all my LEDs with a resister that was supplied by the Manufacturer!

I haven't a clue as to its rating! LOL!

But I believe I did it correctly because I haven't blown myself up! TeHe😂🤣👍

But these LEDs are bright!

My port is a bit dimmer than my starboard side!

Cheers,

Ed-

▲

⟩⟩

Martin555

Colin H

MouldBuilder

Rear Admiral)

Rear Admiral)

Sub-Lieutenant)

Sub-Lieutenant)

Fleet Admiral)

Fleet Admiral)

Recruit)

Recruit)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Liked Dusseldorf Function Test 3 years ago

Liked Dusseldorf Function Test 3 years ago