Join Us On Social Media!

United Kingdom

Recent Posts

📝 Decent quality BRASS FITTINGS.

2 days ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 38 Views · 5 Likes

Flag

📝 Reply

Can anyone out there in the ether help me to find some decent quality brass fittings, as in fairleads and bollards for my current open launch. It would appear that all my current sources are no longer trading, and everything available appears to be plastic. If anyone out there can help me out I shall be forever grateful. Regards, Gary.

▲

⟩⟩

LeeA

Commodore-H

Newby7

hermank

chugalone100

Login To

Remove Ads

Remove Ads

📝 prop question

18 days ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 63 Views · 4 Likes

Flag

📝 Reply

If you would care to enlarge the photo will find a grub-screw through the prop and into the prop shaft, as well as the vice jaw marks on the rudder brass sheet. Regards. Gary.

▲

⟩⟩

RodC

Wolle

hermank

AlessandroSPQR

📝 prop question

18 days ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 63 Views · 6 Likes

Flag

📝 Reply

Having just given you my opinion on your prop shaft problem I thought I should back it up with the following photo, it might not look very pretty but it will be both effective and manoeuvrable, hopefully and as it turns to ninety degrees it will act as a brake. Regards. Gary.

▲

⟩⟩

BOATSHED

RodC

Wolle

hermank

AlessandroSPQR

Ronald

📝 prop question

18 days ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 63 Views · 5 Likes

Flag

📝 Reply

My humble opinion on this propeller problem is, the prop is to large for the recess it is housed in. one doesn't normally fit a prop which leaves hardly any clearance room. Also, I should like to add that the rudder looks nice but is far to small to be affective and responsive, especially considering the oversized propeller. For the record I have been designing and building model boats for the last FIFTY years.

▲

⟩⟩

RodC

Wolle

hermank

AlessandroSPQR

Ronald

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 33 Views · 8 Likes

Flag

📝 Reply

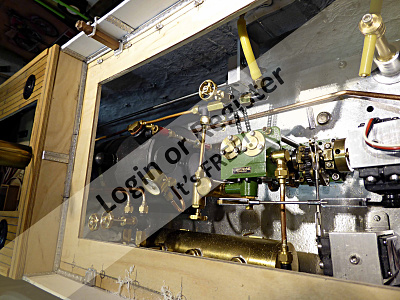

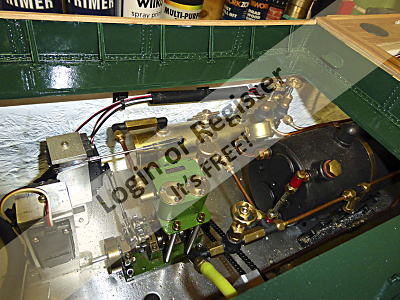

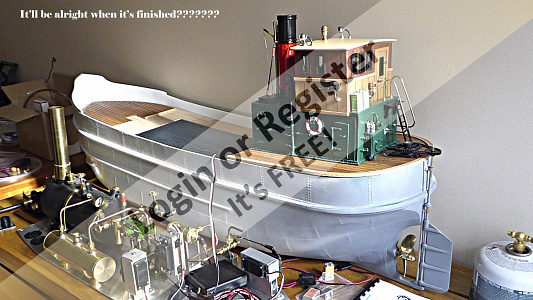

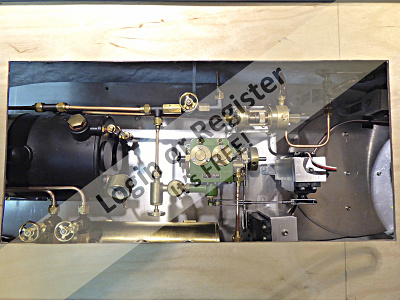

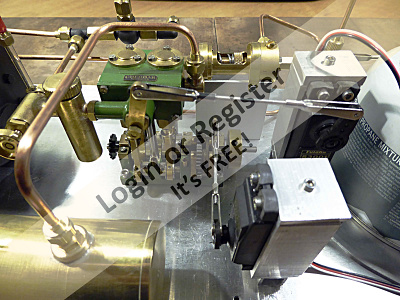

A little more progress on the building front, and a few more decisions made with regards to exactly what I am trying to accomplish. So we now have planked decks front and rear of the engine, and maybe timber box grating around the engine. I have decided to cover up the servo at the side of the engine, so the full metal jacket now has a wooden over coat. I have also made a start on the pipe work and some serious silver soldering. Fluxed rods or easy-flow, that is the question? I have made a Windemere steam kettle, which will be fed from the bottom of the sight glass fitting, and it will be moved from its temporary location on the servo cover. Regards, Gary.

▲

⟩⟩

pressonreguardless

MartyV

BarryS

mturpin013

stevedownunder

Newby7

Northernflotsam

AlessandroSPQR

💬 Re: Marian Belle' Empire class tug (Mobile Marine.)

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 29 Views · 0 Likes

Flag

💬 Add Comment

Thanks Doug, very much appreciated. Regards, Gary.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Marian Belle' Empire class tug (Mobile Marine.)

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 29 Views · 0 Likes

Flag

💬 Add Comment

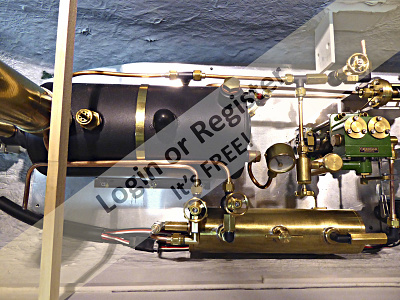

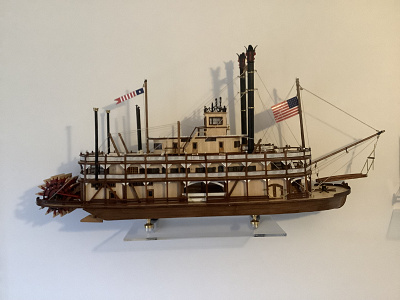

I have just found this post by accident, as I was trying to find Mobile marine tug boats. This was completed some seven years ago, and still looks every bit as good as on completion. This was down to the current posts on tugs. this one was ideal because the huge lengthy super structure gives excellent access to the steam plant. Mobile marine does have a really good selection of model tugs, although one needs to be a touch physic, to figure out the instructions. The best kit ever has to be the ANTEO from Panart, a double skinned plank on frame kit.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Marian Belle' Empire class tug (Mobile Marine.)

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 37 Views · 7 Likes

Flag

💬 Add Comment

I have just found this post by accident, as I was trying to find Mobile marine tug boats. This was completed some seven years ago, and still looks every bit as good as on completion. This was down to the current posts on tugs. this one was ideal because the huge lengthy super structure gives excellent access to the steam plant. Mobile marine does have a really good selection of model tugs, although one needs to be a touch physic, to figure out the instructions. The best kit ever has to be the ANTEO from Panart, a double skinned plank on frame kit.

▲

⟩⟩

MartyV

EdW

chugalone100

hermank

premecekcz

stevedownunder

AlessandroSPQR

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 44 Views · 7 Likes

Flag

📝 Reply

I decided to plank the rear section of aluminium plate, in the hope it would look better, and I think it is an improvement. The next step will be to plank the section under the boiler to match. My tip of the day is do not use super glue to stick plywood onto aluminium plate, it does not work, use Evo-stik contact. Regards, Gary.

▲

⟩⟩

mturpin013

AlessandroSPQR

stevedownunder

premecekcz

Newby7

hermank

chugalone100

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 51 Views · 8 Likes

Flag

📝 Reply

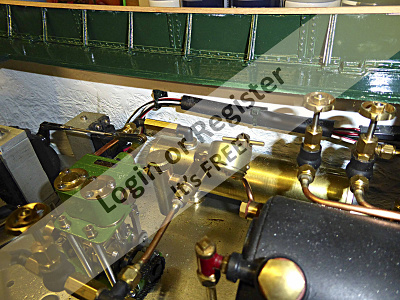

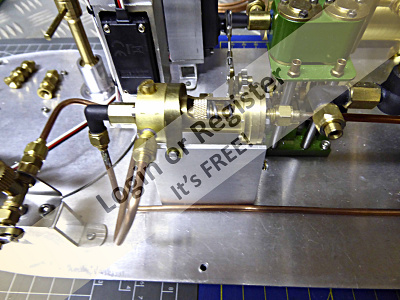

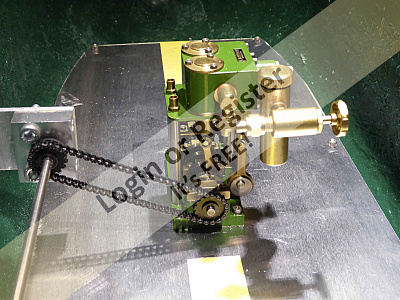

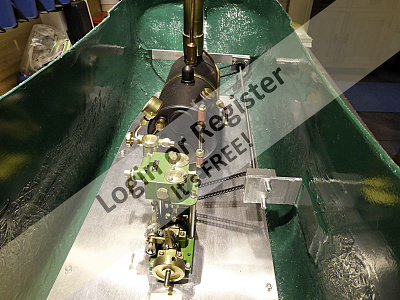

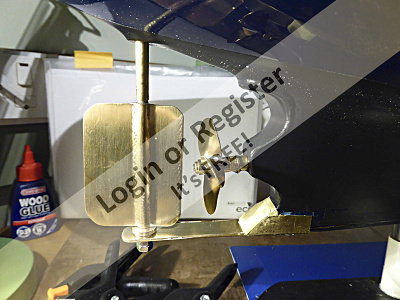

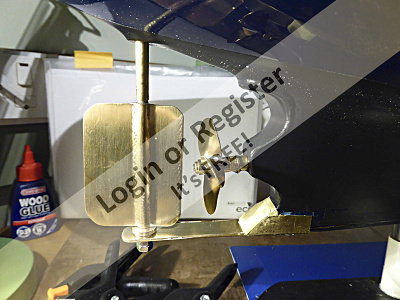

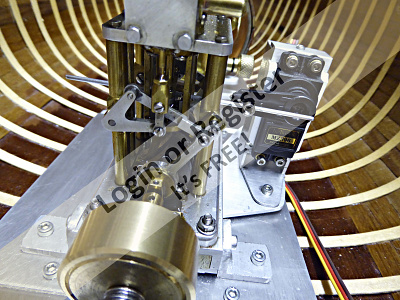

Hi Mike, I have tried to take a couple of photos of the widening of the transmission tunnel come keel, to suit the drive chain and prop shaft sprocket. Please be warned that the hull is very thin, and it is a fibre glass repair job, good luck with that, it is worth the effort in the end, and I couldn't see any other way of sorting this problem. Regards, Gary.

▲

⟩⟩

pressonreguardless

mturpin013

premecekcz

chugalone100

Northernflotsam

stevedownunder

hermank

AlessandroSPQR

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 52 Views · 4 Likes

Flag

📝 Reply

Hi Mike, and good to see you back on here, and wow you certainly have been busy. The wooden hull you have built is exceptional and to an incredibly high standard. Definitely worth all the effort it looks bloody fantastic. With regards to the lady Jane hull, what a struggle to try and sort that out, I am talking about the transmission keel tunnel. A lot of thought went into exactly how to get around this problem and in the end it had to be a chain and sprockets. I used a 6" prop tube so as to try and keep the engine reasonably central. I also used a very small sanding wheel to widen the tunnel, and ended up with two holes through the keel. This was then redesigned to be a bit more user friendly and to take a 9 tooth sprocket about 19 mm wide. Yes, my engine is hinged at the front and jacked up at the back, this matches the prop shaft angle, and helps with chain tension. (I have spare chain and split links going spare, yours for the asking.) This has been an ongoing struggle but the end is now in sight. A couple more photos of your wooden hull engine bay would not go amiss, you are going to need some sort of a sump around your steam engine to catch the oil spray when running. Going to send you a PM. Regards, Gary.

▲

⟩⟩

pressonreguardless

AlessandroSPQR

hermank

stevedownunder

Login To

Remove Ads

Remove Ads

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 54 Views · 7 Likes

Flag

📝 Reply

Hi Alessandro, I have been off the air for a while as I managed to empty a full cup of coffee on to my keyboard, and everything went to hell, (my new one is spill proof?) To answer your question, I would say that yes the majority of steam boat users, are using gas and some have converted to gas, mind the majority of Saito engine users seem quite happy with their spirit fired blow lamp burners, this could easily be because the spirit used is cheaper than gas. Mind there is a few die-hards that use coal despite the fact this is very expensive, as it needs to be smokeless, and comes from Wales. I was also pleasantly surprised by the 3 1/2" diameter boiler, first by how much water it can hold, and secondly by the fact it ran for more than thirty minutes. Have a look at Martin Baylis Engineering and you will be pleasantly surprised and even more so when you mind out the prices. Regards, Gary. (Nature Photo.)

▲

⟩⟩

pressonreguardless

chugalone100

zooma

AlessandroSPQR

stevedownunder

hermank

Newby7

📝 No motor coupling

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 39 Views · 9 Likes

Flag

📝 Reply

thanks Bob, I really appreciate that comment and find it quite strange that when I was at your place for some strange reason model boats was never mention, mind I was somewhat engaged loading that very heavy lathe on to its coming home transport. I am not quite sure what I have sent you, anyway it is an Ariel Huntmaster FH 650, completely altered in its appearance, and completely rebuilt. Regards, Gary.

▲

⟩⟩

AustinG

Mike Stoney

EdW

cjanik001

zooma

AlessandroSPQR

stevedownunder

hermank

chugalone100

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 72 Views · 11 Likes

Flag

📝 Reply

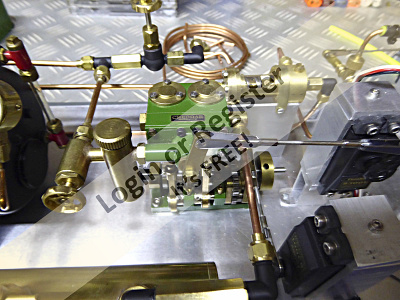

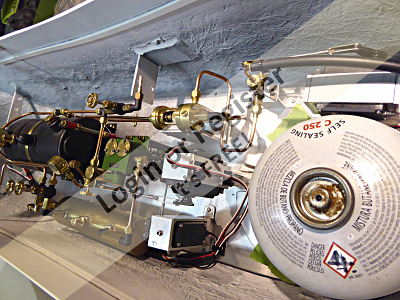

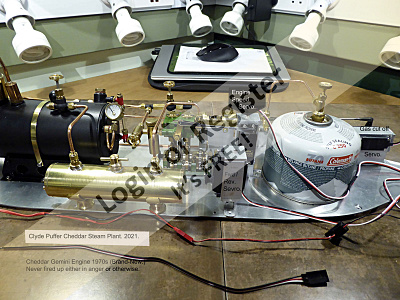

Hi Alessandro, just a couple of photos to hopefully explain what an attenuator, the pressure operated gas valve, and a home made condenser come separator with prices. Regards, Gary.

▲

⟩⟩

pressonreguardless

premecekcz

chugalone100

zooma

EdW

Newby7

stevedownunder

jumpugly

PhilH

hermank

AlessandroSPQR

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 62 Views · 7 Likes

Flag

📝 Reply

Hi Alessandro, that is quite a complex question to answer, but I will give it a go baring in mind that this is in reference to my latest build the open launch. This is a Pendle boiler and it measures 3 1/2" x 6" and it will hold 1 pint of water, the engine is a TVR 1A twin cylinder, double acting side valve which is extremely efficient slide valve. The boiler is canister gas fired using a mix of 70% butane and 30% propane, this produces more heat than butane alone. The object of the exercise is to maintain a reasonable speed and also maintain a decent head of steam in the boiler. As you are going to run out of water before you run out of gas, it is a good idea to fit a gas cut off valve. To help you save water you fit an attenuator valve, this will switch to a pilot flame when the valve reaches its setting, this is an adjustable valve, to save you gas and water and prolong your time on the water. A 3 1/2" diameter boiler will give you a thirty minutes guaranteed sailing session. I will also mention that a 3" diameter boiler will give you twenty minutes sailing. The main factor here is boiler size, although of course you could carry a water tank and top up using either a mechanical or electric pump. I am quite happy to accept thirty minutes as being enough for one session, and with extra gas canisters and water, that is distilled water not tap water, not forgetting steam oil and normal engine oil, you can have as many sessions as you like. The condenser come separator will need to be emptied after a thirty minute session. (and you will not need a battery charger in any one of these operations.) Regards, Gary.

▲

⟩⟩

pressonreguardless

Newby7

stevedownunder

jumpugly

PhilH

hermank

AlessandroSPQR

📝 No motor coupling

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 38 Views · 5 Likes

Flag

📝 Reply

Hi Bob, and if the truth beknown I could not have done this without you, after all it was on your lathe I turned the necessary bit and pieces on. The only thing holding be back at the moment is the bloody cold weather and the fact my workshop is freezing. Plus a crying shame that the schools and colleges that used to teach fitting and turning no longer exist as they did in the GOOD old days. Regards, Gary. ( Mind I suppose there is YouTube but it is not quite the same as hands on.)

▲

⟩⟩

hermank

stevedownunder

chugalone100

zooma

AlessandroSPQR

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 58 Views · 6 Likes

Flag

📝 Reply

Hi Alessandro, working model steam is quite addictive, and once smitten there is no going back, although I will admit to the fact it is very expensive, although I did manage to buy both the engine and boiler from eBay at reasonable prices. I have both open launches and working boats, (Puffer, Tug, Drifter. etc.) Working boats take much longer to get onto the water, as you have a superstructure and rigging to remove and then replace, prior to oiling and firing up the boiler. With an open launch there is nothing to remove, plus you can have lots of shiny brass and copper on display. Plus I don't have any plans for this boat, so I will incorporate numerous features from several Edwardian Victorian type open launches which I like, as per the steam kettle feature. Regards, Gary.

▲

⟩⟩

pressonreguardless

Newby7

jumpugly

PhilH

hermank

AlessandroSPQR

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 57 Views · 12 Likes

Flag

📝 Reply

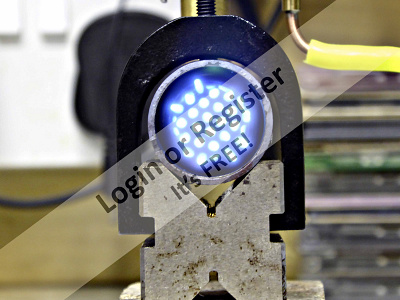

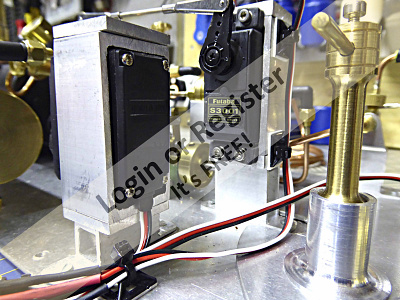

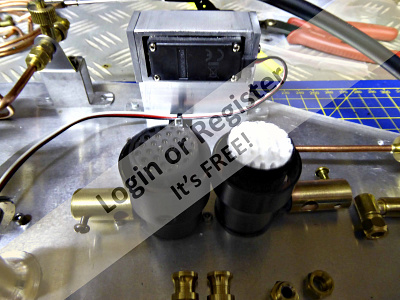

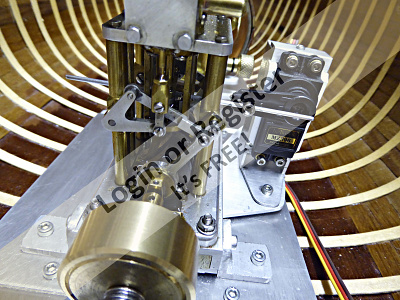

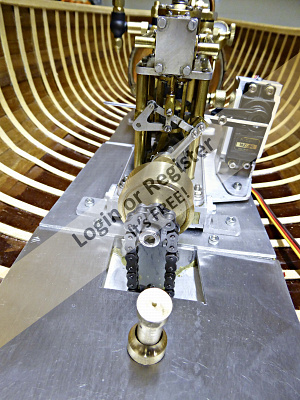

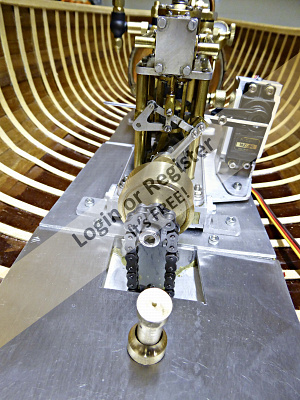

I have finally managed to make a little progress on the building front, of what eventually will be an open steam launch. If anyone out there in the ether is struggling with the problem of fitting the forward and reverse servo. This set up works really well, mind it did take a little while to perfect, using a standard size servo wrapped in a full metal jacket of aluminium. As per the photos, which also show the 6mm steel chain, as the prop-shaft and crank-shaft are on different levels.

▲

⟩⟩

pressonreguardless

premecekcz

Ray

jumpugly

zooma

PhilH

Northernflotsam

hermank

EdW

stevedownunder

Newby7

AlessandroSPQR

📝 Need help identifying

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 32 Views · 5 Likes

Flag

📝 Reply

I wonder if the guy that put this together was short sighted, hence the size of the pressure gauge. I agree that copper is the norm when it comes to boiler building, but on the other hand Saito have been using brass for every thing boilers, spirit burners and engines since the 1950s.

▲

⟩⟩

hermank

AlessandroSPQR

stevedownunder

Nickthesteam

algon

📝 No motor coupling

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 43 Views · 7 Likes

Flag

📝 Reply

Having read all of the posted answers to this some what strange proposal it does beg the question why. Stick to the the tried and proven method and use some sort of a coupling. My personal proffered method is to use an uncoupled coupling as per the photos. Or in some cases where prop shaft and engine are on different levels a steel chain and sprockets. Regards, Gary.

▲

⟩⟩

EdW

chugalone100

zooma

stevedownunder

LewZ

AlessandroSPQR

hermank

📝 Nigel Trafford-Jones

3 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 73 Views · 1 Like

Flag

📝 Reply

Hi Zippy, I have read your message on here and sent you a private message which hopefully might help. Regards, Gary.

▲

⟩⟩

hermank

Login To

Remove Ads

Remove Ads

📝 Building the Rapier

4 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 49 Views · 1 Like

Flag

📝 Reply

Try:- metals4U -: Aluminium mouldings, they have a reasonable selection to choose from.

▲

⟩⟩

hermank

📝 Model Boat Builders in the Redcar area.

4 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 29 Views · 5 Likes

Flag

📝 Reply

Yes, at least I was a member way back in the days when it had the use of the building at the lake side,(a club-house come meeting point.) Which was then reclaimed by the council and fitted out as a café. These days it seems to have somehow resurrected itself from the ashes, and has a few members who tend to gather on Saturday and Sunday afternoons, especially if the weather is decent and the lake has water in it. To the uninitiated non locals, the lake uses sea water and can be pumped in at high tide, or out as required. I believe at this moment of time ongoing repairs are finally complete and it is all sorted and ready to go.

▲

⟩⟩

stevedownunder

AlessandroSPQR

Northernflotsam

Ronald

hermank

📝 Model Boat Builders in the Redcar area.

4 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 32 Views · 3 Likes

Flag

📝 Reply

I love the Cobble a very authentic, build especially for this corner of the county, and the Whitby kipper boxes add the realistic touch.

▲

⟩⟩

AlessandroSPQR

Ronald

hermank

📝 Model Boat Builders in the Redcar area.

4 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 34 Views · 2 Likes

Flag

📝 Reply

Thanks for that, appreciated, and Saltburn by-the-sea is a much nicer place than Redcar, mind it does not have a boating lake. Regards, Gary.

▲

⟩⟩

hermank

Northernflotsam

📝 Model Boat Builders in the Redcar area.

4 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 35 Views · 1 Like

Flag

📝 Reply

As a model boat builder living in Redcar, I felt the need to reply to your post, and out of curiosity I gave your profile a quick looking at to find out where you live, and the answer came up as, "By- the -Sea, which you have to admit is different, and this brings a song to mind. Oh I do love to be by the Sea-Side. Would you care to elaborate on that, or is it a secret? Regards, Gary.

▲

⟩⟩

hermank

📝 Ron in Scotland

6 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 59 Views · 13 Likes

Flag

📝 Reply

Hi, Ron in Scotland, I don't know if you are interested in Clyde Puffers or not, if you are interested in seeing and maybe a trip out on the water, the last two remaining puffers are at Crinan, on the Crinan Canal which links the Sound of Jura to Lock Fyne. Crinan is a rather remote area in the middle of no where. Mind, definitely worth while, or at least I thought so. Plus they do trips out around the Western Iles. Enjoy your holiday. Regards Gary.

▲

⟩⟩

SimpleSailor

Cashrc

BarryS

Madwelshman

roycv

hermank

stevedownunder

EdW

Ronald

Wolle

Steves-s

RNinMunich

GARTH

💬 Re: History of boating

6 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 34 Views · 0 Likes

Flag

💬 Add Comment

check your private messages, who knows you could get lucky?

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Animal and nature photos to enjoy.

6 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 47 Views · 6 Likes

Flag

📝 Reply

My idea of a really great day out, and a nice bit of photography.

▲

⟩⟩

stevedownunder

jumpugly

hermank

AlessandroSPQR

Wolle

Nickthesteam

📝 Steam launch stability dilemma..

6 months ago by 🇬🇧 GaryLC ( Captain)

Captain)

Captain)

Captain)✧ 37 Views · 3 Likes

Flag

📝 Reply

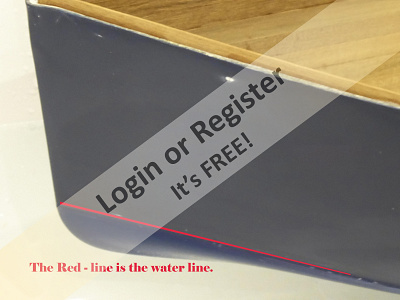

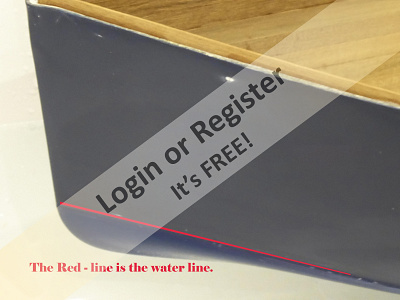

As mentioned in my last post on here, that a sensible starting point would be to place the steam plant and other hardware, into the hull which is then placed into a bath full of water. then shuffle the hardware round to suit until it looks right, and then mark the positions of where the fixing beams, brackets, or what ever need to go. Having just done that today I was somewhat surprised at the results, which I will share with you. I honestly thought that the boiler 3 &1/2" x 6" which will carry 1 pint of water, might cause a bit of a problem, as the weight is quite considerable at 3lb (that's 3 not 31)and 2.5 oz. (for the metricated types) that is 1477 grams, the boiler contained 1 pint of water. The engine was a mere 373 grams, which is 13oz. I expected the hull to submerge a little and it hardly moved. I was very surprised bordering on shocked at the results, mind on the other hand I don't have seek out weight saving solutions to complete the launch. I did manage a couple of photos which leave a little to be desired, but better than nothing. note the red line on the hull front end that is the water line. Regards, Gary.

▲

⟩⟩

Nickthesteam

stevedownunder

AlessandroSPQR

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Commodore)

Commodore)

Lieutenant Commander)

Lieutenant Commander)

Admiral)

Admiral)

Fleet Admiral)

Fleet Admiral)

Rear Admiral)

Rear Admiral)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Recruit)

Recruit)