Join Us On Social Media!

United Kingdom

Recent Posts

💬 Re: Decking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 36 Views · 2 Likes

Flag

💬 Add Comment

Hi Alessandro,

The space for the polystyrene is small, but it’s the only option to hide some buoyancy. I’m going to have to be careful when sailing this!

The space for the polystyrene is small, but it’s the only option to hide some buoyancy. I’m going to have to be careful when sailing this!

▲

⟩⟩

Len1

stevedownunder

Login To

Remove Ads

Remove Ads

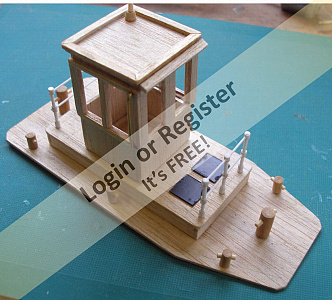

📝 Decking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 50 Views · 18 Likes · 4 Comments

Flag

💬 Add Comment

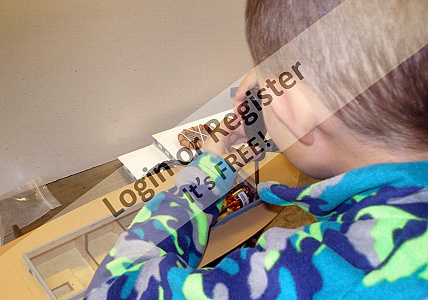

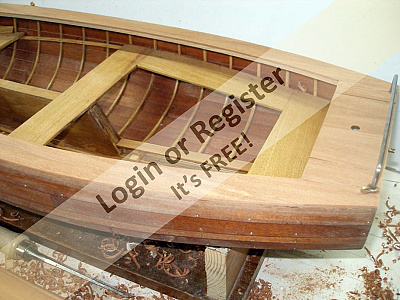

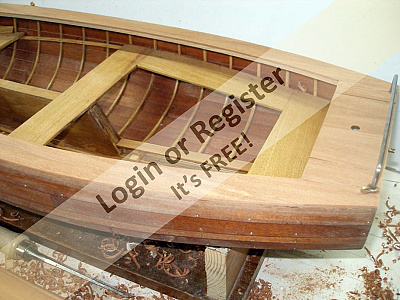

Time to get back to the build!

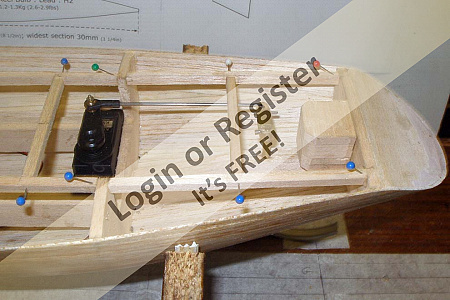

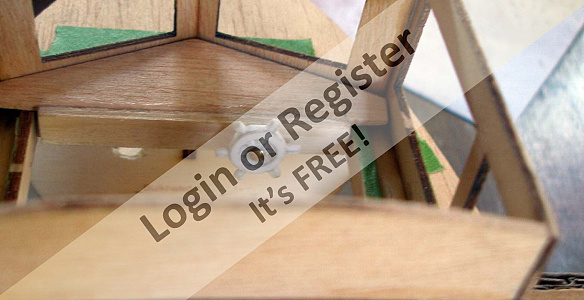

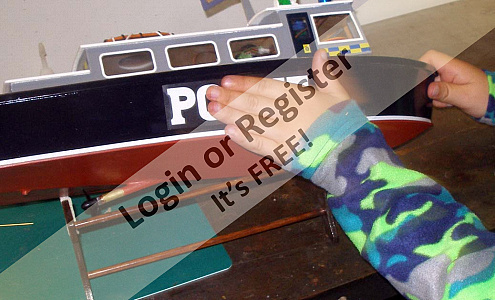

A support framework for the decking was glued in place. As the timber sections are quite small, this framework is not very strong, but it should be sufficient to support the deck planks. The strength will come from the glued on planking.

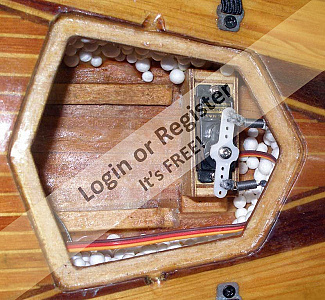

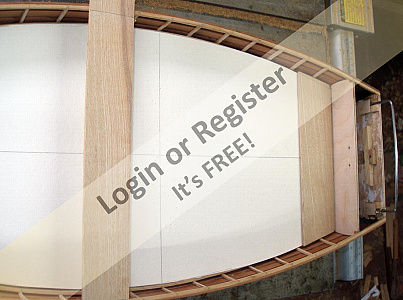

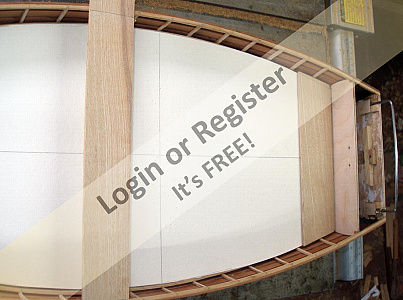

Before fitting the decking, the space between the forward bulkheads was filled with polystyrene beads coated with PVA glue. This is to provide some bouyancy in case of a capsize! The space between the bulkheads at the stern was filled in a similar way. Holes at the bottom of the bulkheads ensure that any water which does get into this space will be able to drain out.

The decking is constructed from offcuts of the mahogany hull planking. At the stern, a piece of the decking can be removed to provide access to the rudder servo.

A support framework for the decking was glued in place. As the timber sections are quite small, this framework is not very strong, but it should be sufficient to support the deck planks. The strength will come from the glued on planking.

Before fitting the decking, the space between the forward bulkheads was filled with polystyrene beads coated with PVA glue. This is to provide some bouyancy in case of a capsize! The space between the bulkheads at the stern was filled in a similar way. Holes at the bottom of the bulkheads ensure that any water which does get into this space will be able to drain out.

The decking is constructed from offcuts of the mahogany hull planking. At the stern, a piece of the decking can be removed to provide access to the rudder servo.

▲

⟩⟩

philcaretaker

MartinH2

Commodore-H

PeterL3

Rockbag

MouldBuilder

EdW

stevedownunder

jbkiwi

River Rat

Peejay

AlessandroSPQR

flaxbybuck

Razor1955

Len1

GARTH

hermank

MartinW

📝 Thwarts

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 71 Views · 13 Likes · 1 Comment

Flag

💬 Add Comment

Two 4mm square oak risers were fitted along the length of the hull, one each side. These are to support the thwarts. They had to be fitted at the same height as the keel box. This took a lot of time measuring and adjusting the position before finally glueing and pinning them into position. In the end, they turned out to be slightly higher than they should have been, but that's much better than being too low resulting in the thwarts fouling the keel box!

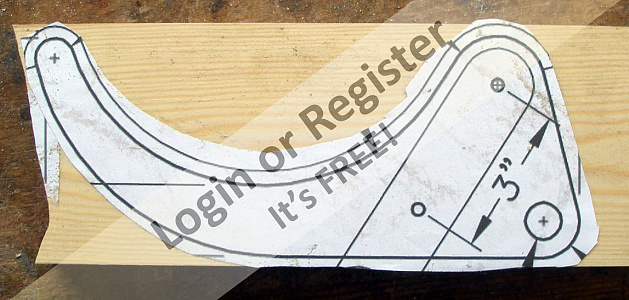

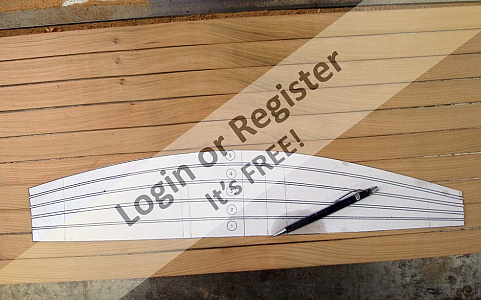

A cardboard template was traced from the plan and then adjusted slightly to fit in place sitting on the risers. The template was then used to mark out the thwarts which were cut from more of the salvaged oak tabletop.

Finally the thwarts were glued together and then glued and pinned onto the risers. The forward thwart has a hole for the mast to pass through. As this thwart will take some strain from the mast it was glued and pinned to the risers and the keel box. Additional reinforcing oak blocks were added to strengthen the joints. The hull hadn't been varnished at the position of the thwart ends so the reinforcement block could be glued in position. Once the glue was set, the varnish was touched up.

A cardboard template was traced from the plan and then adjusted slightly to fit in place sitting on the risers. The template was then used to mark out the thwarts which were cut from more of the salvaged oak tabletop.

Finally the thwarts were glued together and then glued and pinned onto the risers. The forward thwart has a hole for the mast to pass through. As this thwart will take some strain from the mast it was glued and pinned to the risers and the keel box. Additional reinforcing oak blocks were added to strengthen the joints. The hull hadn't been varnished at the position of the thwart ends so the reinforcement block could be glued in position. Once the glue was set, the varnish was touched up.

▲

⟩⟩

MartinH2

PeterL3

EdW

jbkiwi

hermank

cenbeth

luckyduck

Peejay

mturpin013

AndyB2

River Rat

Len1

stevedownunder

💬 Re: Mast Step

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 71 Views · 3 Likes

Flag

💬 Add Comment

Hi flaxbybuck,

You are probably right, I'll set it up for one position, and never change it, but it's nice to have the option just in case 😉 Not planning to enter any races with this build 😂

You are probably right, I'll set it up for one position, and never change it, but it's nice to have the option just in case 😉 Not planning to enter any races with this build 😂

▲

⟩⟩

hermank

Peejay

Len1

💬 Re: Mast Step

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 71 Views · 3 Likes

Flag

💬 Add Comment

Hi Ron,

Thanks for the contact details for Paul. It's good to know there's someone I can get help from if I need it.

I enjoy scratch building like this as it gives me plenty of challenges to solve which is a large part of the enjoyment with the build. By making the mast step adjustable, I'll be able to change the mast rake to try out the effect of different angles. If I had fixed it, I expect it would sail OK, but I'd never know if a different angle would have been better.

Thanks for the contact details for Paul. It's good to know there's someone I can get help from if I need it.

I enjoy scratch building like this as it gives me plenty of challenges to solve which is a large part of the enjoyment with the build. By making the mast step adjustable, I'll be able to change the mast rake to try out the effect of different angles. If I had fixed it, I expect it would sail OK, but I'd never know if a different angle would have been better.

▲

⟩⟩

hermank

Peejay

Len1

📝 Mast Step

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 78 Views · 13 Likes · 4 Comments

Flag

💬 Add Comment

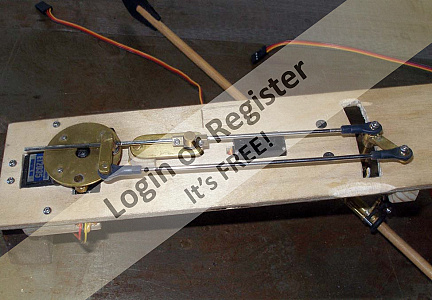

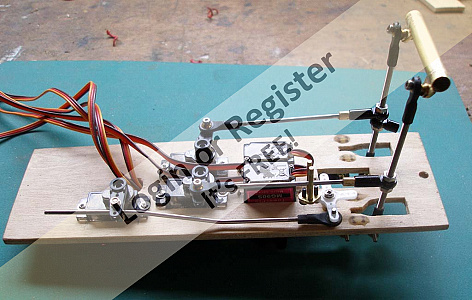

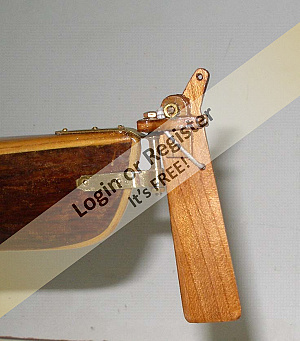

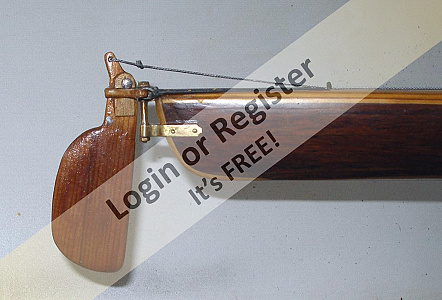

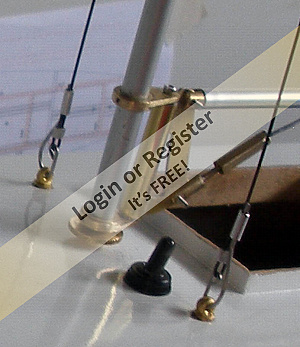

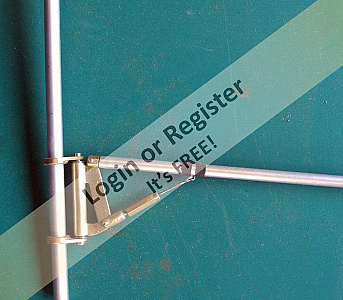

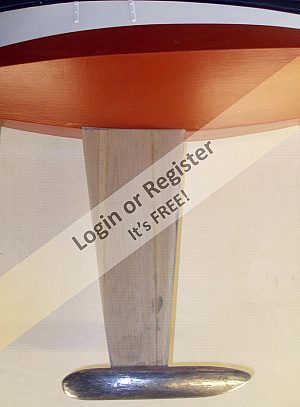

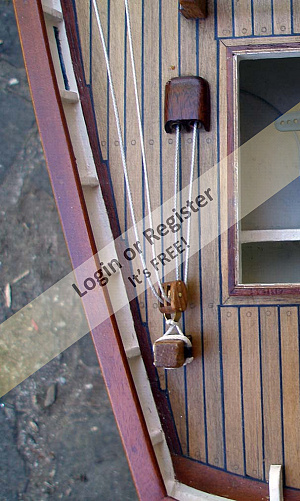

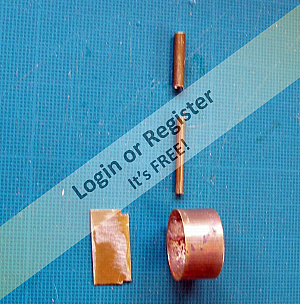

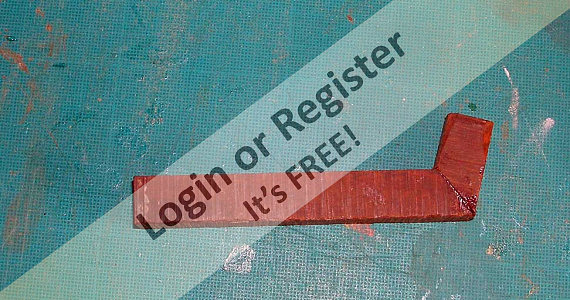

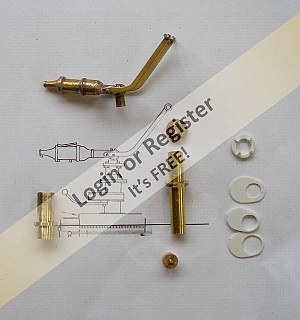

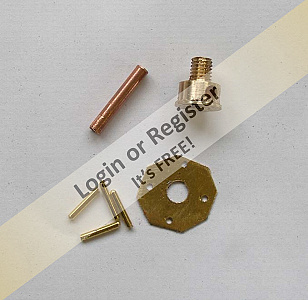

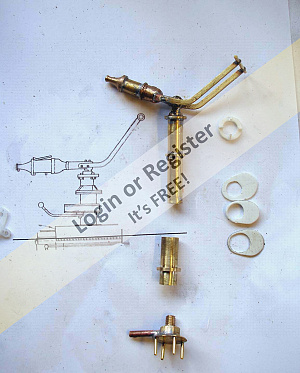

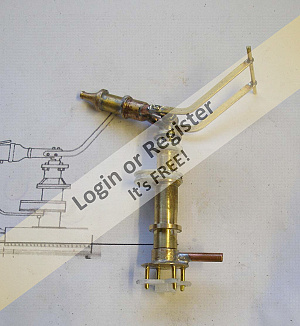

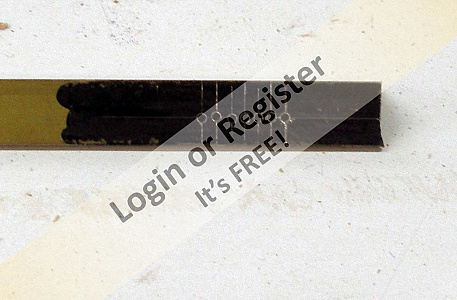

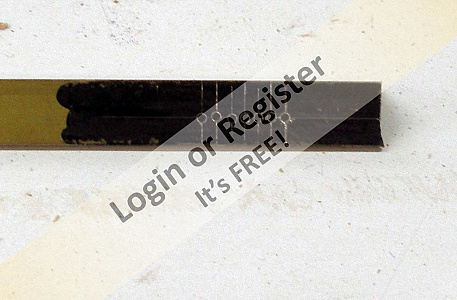

The mast passes through the forward thwart with the foot of the mast resting on the keel. There is no information on the plan detailing where exactly the mast rests on the keel so I decided to make an adjustable mast step so the position can be adjusted.

A short length of brass angle was marked and drilled with 1.5mm holes. The spacings are not as even as I would have liked, but the best I could do, and near enough. The angle was then cut down to leave a row of notches. An additional length of brass was silver soldered to the angle to produce a 'T' section.

For the foot of the mast, a fitting was made to push on to the end of the mast, with a slot which fits over the brass T section. A pin fixed across the slot (difficult to see in photo 3) engages with one of the notches in the T section.

Finally, the T section was glued and pinned in position on the keel.

A short length of brass angle was marked and drilled with 1.5mm holes. The spacings are not as even as I would have liked, but the best I could do, and near enough. The angle was then cut down to leave a row of notches. An additional length of brass was silver soldered to the angle to produce a 'T' section.

For the foot of the mast, a fitting was made to push on to the end of the mast, with a slot which fits over the brass T section. A pin fixed across the slot (difficult to see in photo 3) engages with one of the notches in the T section.

Finally, the T section was glued and pinned in position on the keel.

▲

⟩⟩

MartinH2

EdW

hermank

cenbeth

Peejay

mturpin013

River Rat

stevedownunder

roycv

flaxbybuck

jbkiwi

Len1

RNinMunich

💬 Re: Floorboards

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 82 Views · 1 Like

Flag

💬 Add Comment

Thanks Mike,

While I am in awe with what can be achieved with laser cutters and 3D printers these days, nothing beats the satisfaction of hand crafting something IMHO 😆

While I am in awe with what can be achieved with laser cutters and 3D printers these days, nothing beats the satisfaction of hand crafting something IMHO 😆

▲

⟩⟩

Mike Stoney

📝 Radio Installation

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 101 Views · 17 Likes · 2 Comments

Flag

💬 Add Comment

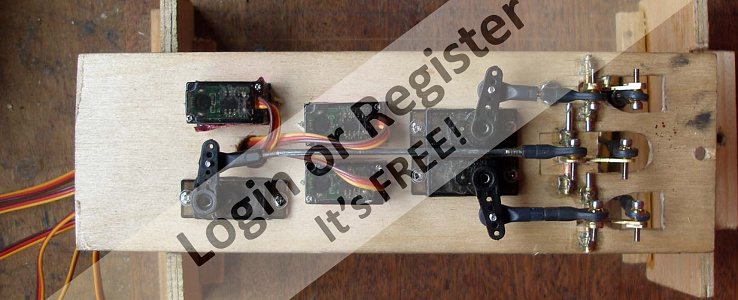

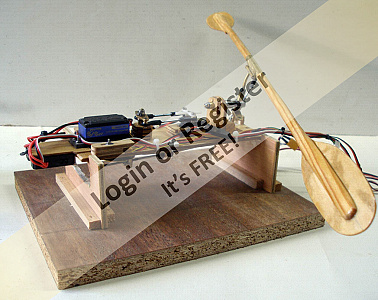

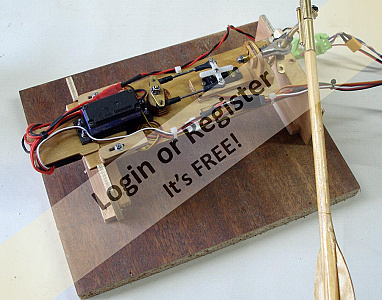

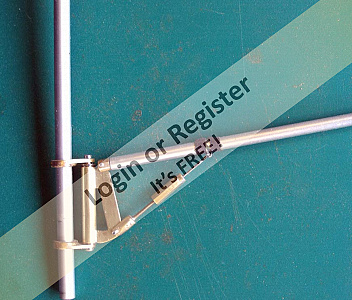

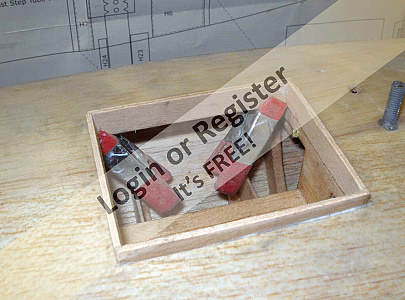

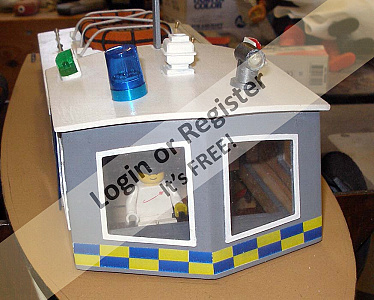

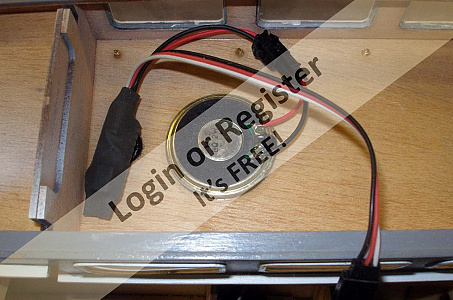

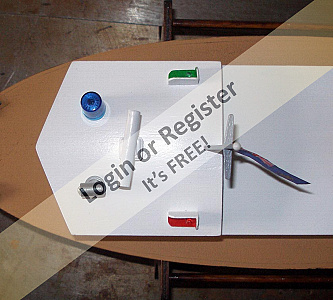

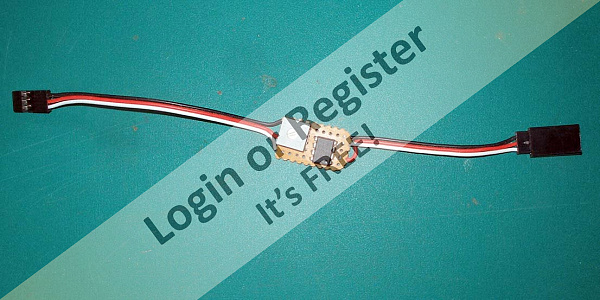

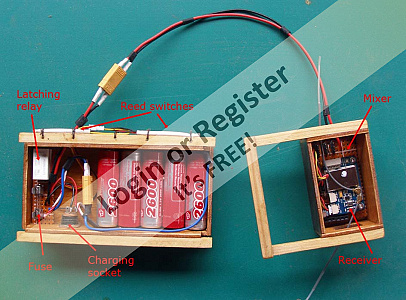

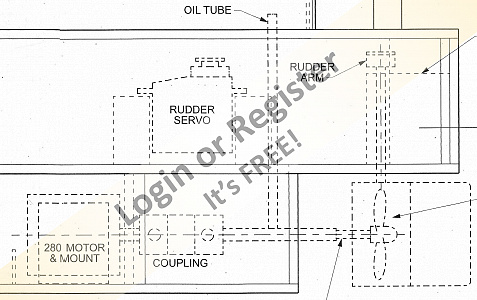

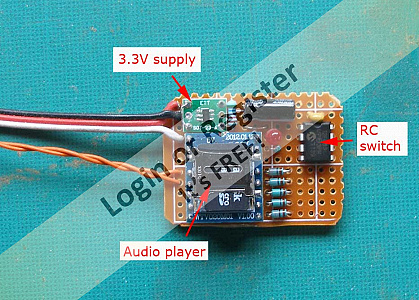

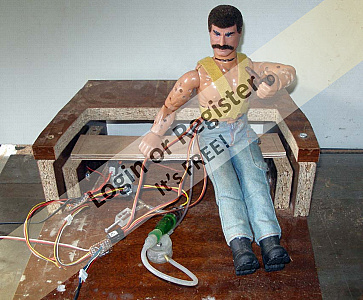

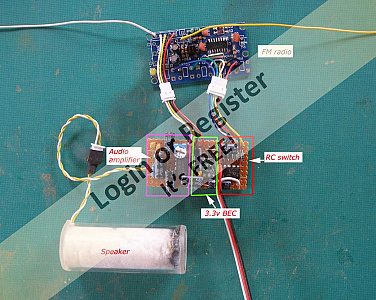

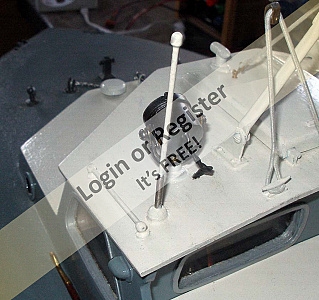

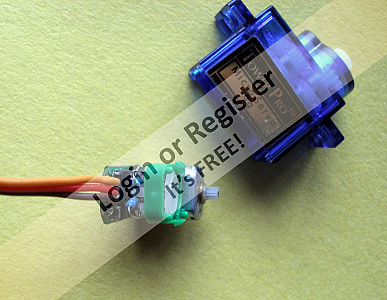

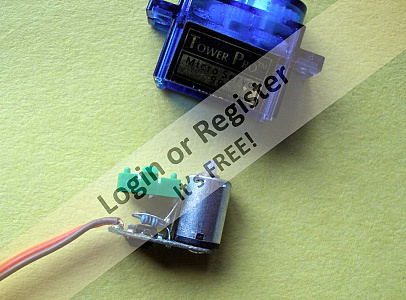

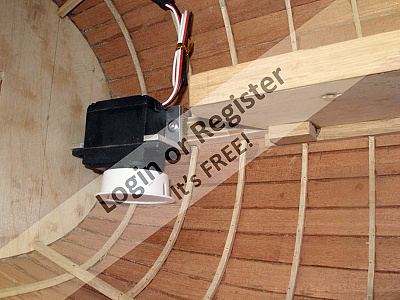

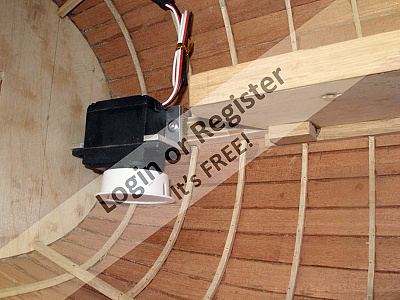

I want to hide the radio gear as far as is possible. Not easy with an open dinghy. There are two enclosed spaces, one at the bow, and one at the stern.

A wooden tray and support were added behind the forward bulkhead for the receiver. The tray slides out through the bulkhead and is held in the closed position with a magnet. This position keeps the receiver as high as possible for better reception and hopefully will avoid any water that might get into the boat.

The rudder servo is mounted between the rear bulkhead and the transom. Once the rear deck is in place only the servo shaft will be visible. The deck will need to be removable to allow access for servo maintenance.

There isn't anywhere to hide the sail winch so it is mounted as low as possible at the forward end, just behind the forward bulkhead. This will hide it from view when the boat is out on the water. A mounting bracket was made from a short length of aluminium angle.

A wooden tray and support were added behind the forward bulkhead for the receiver. The tray slides out through the bulkhead and is held in the closed position with a magnet. This position keeps the receiver as high as possible for better reception and hopefully will avoid any water that might get into the boat.

The rudder servo is mounted between the rear bulkhead and the transom. Once the rear deck is in place only the servo shaft will be visible. The deck will need to be removable to allow access for servo maintenance.

There isn't anywhere to hide the sail winch so it is mounted as low as possible at the forward end, just behind the forward bulkhead. This will hide it from view when the boat is out on the water. A mounting bracket was made from a short length of aluminium angle.

▲

⟩⟩

MartinH2

PeterL3

EdW

hermank

cenbeth

Peejay

AndyB2

roycv

Mike Stoney

philcaretaker

stevedownunder

RNinMunich

mturpin013

Len1

jbkiwi

flaxbybuck

Wolle

💬 Re: Floorboards

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 104 Views · 3 Likes

Flag

💬 Add Comment

Hi Ronald,

I haven’t nailed the floorboards as I’ve run out of nails! Thanks for the link - interesting information. I’ve used cherry for the floorboards as I happened to have a few boards in my stock. It is very fine grained and looks ‘right’ for this application. Photo 4 shows it with it’s first coat of varnish.

I haven’t nailed the floorboards as I’ve run out of nails! Thanks for the link - interesting information. I’ve used cherry for the floorboards as I happened to have a few boards in my stock. It is very fine grained and looks ‘right’ for this application. Photo 4 shows it with it’s first coat of varnish.

▲

⟩⟩

Len1

BOATSHED

Peejay

📝 Floorboards

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 106 Views · 25 Likes · 5 Comments

Flag

💬 Add Comment

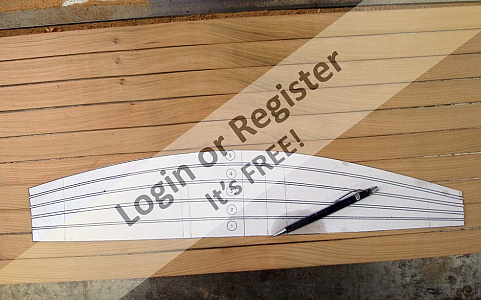

The plan includes templates for the floor boards. I decided to split the boards in half lengthways to make the completed floor easier to remove.

The templates were glued to some 3mm thick cherry planks, cut out with the bandsaw and then glued to support beams.

The completed floor panels fitted into the hull with very little adjustment needed. Much easier than the hull planking where the increase in model scale resulted in the templates becoming distorted.

At this stage, the hull was given several coats of yacht varnish inside and out because it will become more difficult to apply any finish to the inside as construction continues.

The templates were glued to some 3mm thick cherry planks, cut out with the bandsaw and then glued to support beams.

The completed floor panels fitted into the hull with very little adjustment needed. Much easier than the hull planking where the increase in model scale resulted in the templates becoming distorted.

At this stage, the hull was given several coats of yacht varnish inside and out because it will become more difficult to apply any finish to the inside as construction continues.

▲

⟩⟩

MartinH2

PeterL3

cenbeth

ARL58

Mike Stoney

sirscapa

RNinMunich

Len1

AndyN

flaxbybuck

BOATSHED

stevedownunder

philcaretaker

Peejay

EdW

mturpin013

roycv

Black Shoe

peterd

hermank

Ronald

GaryLC

BarryS

jbkiwi

robbob

📝 Death of a member.

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 100 Views · 10 Likes

Flag

📝 Reply

Colin,

So sad to hear your terrible news. As a parent, I can only imagine how you must be feeling. My thoughts are with you and your family.

Graham

So sad to hear your terrible news. As a parent, I can only imagine how you must be feeling. My thoughts are with you and your family.

Graham

▲

⟩⟩

RNinMunich

Rookysailor

Scratchbuilder

BOATSHED

Colin H

stevedownunder

Doogle

Peejay

Len1

hermank

Login To

Remove Ads

Remove Ads

📝 Nailing the Planks

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 118 Views · 22 Likes · 3 Comments

Flag

💬 Add Comment

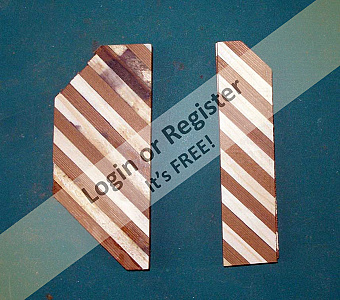

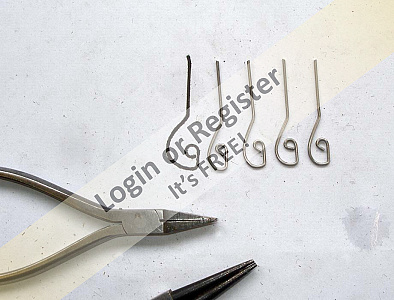

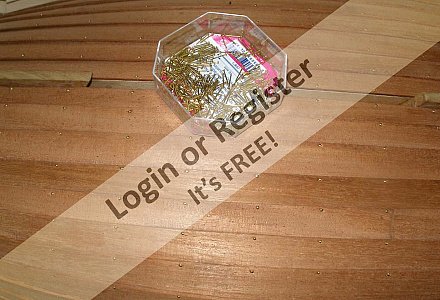

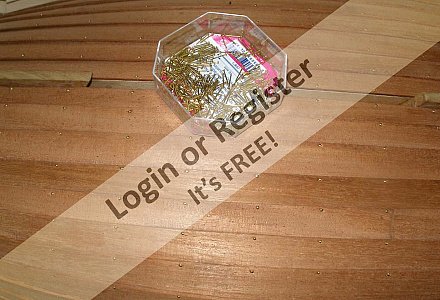

In traditional clinker built boats the planks are nailed together with square shank copper nails. These are clenched on rooves or copper washers in the inside. At 1/6th scale, this would be difficult to achieve (!) so I opted for a sipler approach of using 0.6mm dia brass pins.

The pins for the first rib were fitted by drilling 0.4mm holes from the inside of the hull, through the ribs and planks. Once that datum had been established a compass was used to measure the distance between ribs on the inside of the hull. This dimension was then transferred to the outside so that the holes for the pins could be predrilled in the correct position at the edge of the planks. The occasional hole in the wrong position was redrilled. Those in the wrong position are not noticeable and will be sealed when the hull is varnished.

In total 550 nails were fitted!

The pins for the first rib were fitted by drilling 0.4mm holes from the inside of the hull, through the ribs and planks. Once that datum had been established a compass was used to measure the distance between ribs on the inside of the hull. This dimension was then transferred to the outside so that the holes for the pins could be predrilled in the correct position at the edge of the planks. The occasional hole in the wrong position was redrilled. Those in the wrong position are not noticeable and will be sealed when the hull is varnished.

In total 550 nails were fitted!

▲

⟩⟩

MartinH2

PeterL3

cenbeth

ARL58

Mike Stoney

flaxbybuck

BOATSHED

Peejay

mturpin013

hermank

robbob

philcaretaker

roycv

Len1

River Rat

stevedownunder

RNinMunich

jbkiwi

Colin H

Ronald

EdW

JOHN

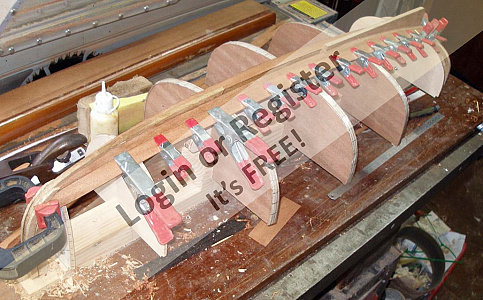

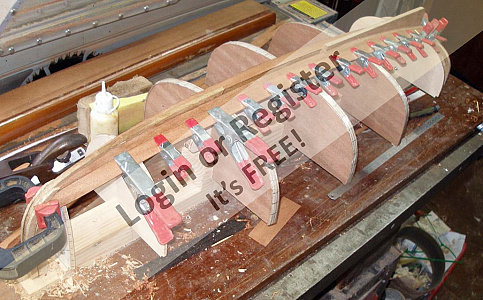

📝 Ribs

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 123 Views · 15 Likes

Flag

💬 Add Comment

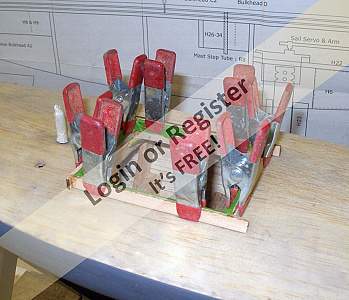

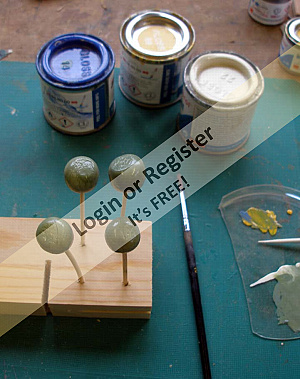

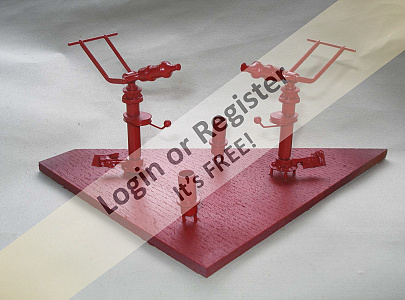

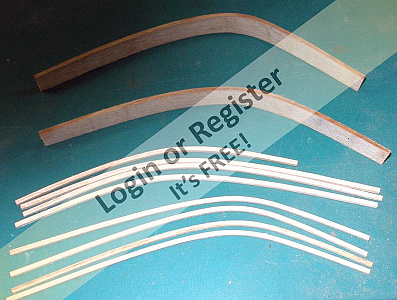

Before fitting the ribs, I cut gunwales from oak and glued and clamped them in position. These were flexible enough to bend into shape and clamp in position without steaming. Unfortunately, the ribs have a sharper bend and could not be bent dry without splitting.

A steamer was constructed using offcuts of plastic drainpipe (I knew it would come in one day!). Steam was generated using an electric wallpaper stripper. Strips of oak with a cross section of 25 x 4mm were steamed for 30 minutes and then clamped in a jig overnight. The bent strips were then cut using a bandsaw into 4 x 4 mm ribs.

While I have a good collection of clamps, I didn't have any of a suitable size to allow the ribs to be clamped in place along the keel. So more of the oak (recycled tabletop) was used to make a couple of long reach clamps using 8mm threaded rod for the clamp screws and to reinforce the frame.

Finally, the ribs were glued into position, two at a time.

A steamer was constructed using offcuts of plastic drainpipe (I knew it would come in one day!). Steam was generated using an electric wallpaper stripper. Strips of oak with a cross section of 25 x 4mm were steamed for 30 minutes and then clamped in a jig overnight. The bent strips were then cut using a bandsaw into 4 x 4 mm ribs.

While I have a good collection of clamps, I didn't have any of a suitable size to allow the ribs to be clamped in place along the keel. So more of the oak (recycled tabletop) was used to make a couple of long reach clamps using 8mm threaded rod for the clamp screws and to reinforce the frame.

Finally, the ribs were glued into position, two at a time.

▲

⟩⟩

MartinH2

cenbeth

Mike Stoney

flaxbybuck

BOATSHED

mturpin013

hermank

philcaretaker

EdW

jbkiwi

stevedownunder

RNinMunich

Len1

luckyduck

Colin H

📝 Lipo vs Li-ion

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 62 Views · 1 Like

Flag

📝 Reply

JBkiwi and I did quite a bit of development on smokers using vapes 3-4 years ago. No dark smoke though! Try searching the blogs and Media Gallery. Unfortunately many of the videos have been deleted from the site but I found one here:

▲

⟩⟩

Len1

💬 Re: More Planking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 131 Views · 2 Likes

Flag

💬 Add Comment

Stotty,

Very nice build.👍 It looks to be based on the same plans I'm using. I like the way you have hidden the radio gear, that's something I'm currently thinking about a solution for.

Very nice build.👍 It looks to be based on the same plans I'm using. I like the way you have hidden the radio gear, that's something I'm currently thinking about a solution for.

▲

⟩⟩

BOATSHED

Colin H

💬 Re: More Planking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 131 Views · 2 Likes

Flag

💬 Add Comment

Doug,

Roll on Feb 30th 😂🤣

Roll on Feb 30th 😂🤣

▲

⟩⟩

BOATSHED

RNinMunich

💬 Re: More Planking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 131 Views · 5 Likes

Flag

💬 Add Comment

Hi Ross,

I didn't have to soak or steam the planks. I was surprised that they would bend easily to shape 'cold'. As you can see, I used plenty of clamps, but that was to ensure that the overlapping seams were tight while the glue dried.

Very pleased with it so far, although there are always bits that could have been done better!

I didn't have to soak or steam the planks. I was surprised that they would bend easily to shape 'cold'. As you can see, I used plenty of clamps, but that was to ensure that the overlapping seams were tight while the glue dried.

Very pleased with it so far, although there are always bits that could have been done better!

▲

⟩⟩

cenbeth

BOATSHED

Colin H

RNinMunich

RossM

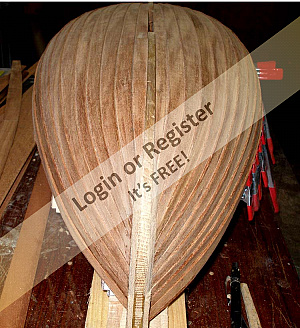

📝 More Planking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 138 Views · 26 Likes · 14 Comments

Flag

💬 Add Comment

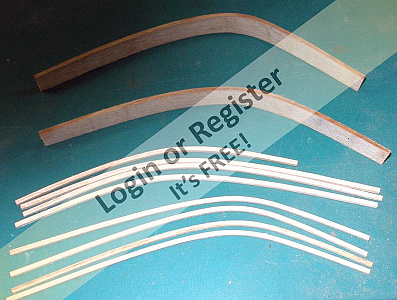

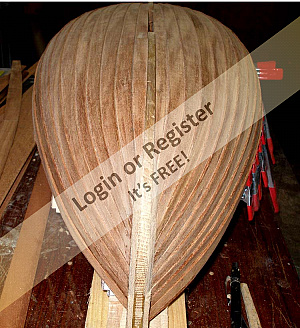

As the planking continues, the planks become more and more curved to the point where it is not possible to cut a plank from the 25mm wide mahogany strips. Curved blanks had to be made using two or even three pieces scarphed together. A curved plank, ready for fitting made from three pieces can be seen in the first photo.

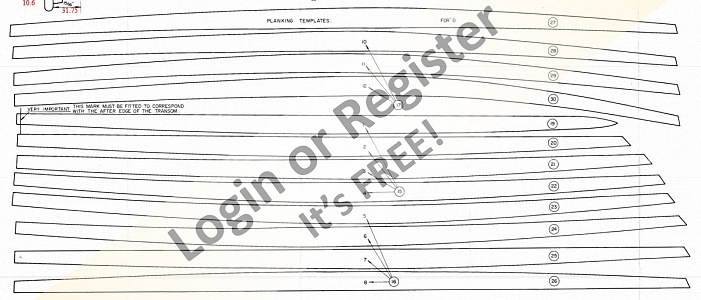

A second problem that became apparent was that the templates included as part of the plan were not the right shape for the enlarged scale being used. The planks required more curvature than shown on the plan. I think this was caused by the change in scale rather than an inherent error in the original plans. Changing the scale of a 2D drawing of a plank which is going to be bent into a 3D object doesn't work.

The templates had to be dispensed with, and each plank marked and shaped to fit by trying it in place on the hull over and over again. It took around 2 hours to shape each plank before it was ready to glue and clamp into position.

Finally, all the planks were in place and the completed hull could be removed from the strongback. The three central formers were removed giving a clear open interior.

A second problem that became apparent was that the templates included as part of the plan were not the right shape for the enlarged scale being used. The planks required more curvature than shown on the plan. I think this was caused by the change in scale rather than an inherent error in the original plans. Changing the scale of a 2D drawing of a plank which is going to be bent into a 3D object doesn't work.

The templates had to be dispensed with, and each plank marked and shaped to fit by trying it in place on the hull over and over again. It took around 2 hours to shape each plank before it was ready to glue and clamp into position.

Finally, all the planks were in place and the completed hull could be removed from the strongback. The three central formers were removed giving a clear open interior.

▲

⟩⟩

MartinH2

Mike Stoney

BOATSHED

mturpin013

philcaretaker

EdW

BarryS

Scratchbuilder

Trident73

JockScott

flaxbybuck

luckyduck

jbkiwi

Len1

AndyB2

hermank

Peejay

Ronald

stevedownunder

Rookysailor

RossM

GaryLC

River Rat

RNinMunich

Colin H

cenbeth

💬 Re: Sinking !!!

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 199 Views · 0 Likes

Flag

💬 Add Comment

Hi Cash,

The transmitter is home built 27MHz FM based on the design published in RCM&E in the 1970s. All of Paul's subs have a dedicated home made Tx.

On one occasion when Paul was sailing/sinking this boat in the park we had a passer by, in running kit, offer to jump in to rescue the boat! He was a bit embarrassed when it resurfaced 😂🤣

The transmitter is home built 27MHz FM based on the design published in RCM&E in the 1970s. All of Paul's subs have a dedicated home made Tx.

On one occasion when Paul was sailing/sinking this boat in the park we had a passer by, in running kit, offer to jump in to rescue the boat! He was a bit embarrassed when it resurfaced 😂🤣

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Sail winch, with metal gears and plastic spool.

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 46 Views · 3 Likes

Flag

📝 Reply

They are still available - you just need to know where to look 😀

Manufactured by Kingmax and available in two options 4 turn or 6 turn. I have used several of these in my sail boats.

Try:

Manufactured by Kingmax and available in two options 4 turn or 6 turn. I have used several of these in my sail boats.

Try:

▲

⟩⟩

Len1

stevedownunder

AlessandroSPQR

💬 Re: MAST HOOPS

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 97 Views · 1 Like

Flag

💬 Add Comment

Here's my attempt at mast hoops:

(when I click in the link it takes me to the right blog, but not the right post - you have to scroll down).

(when I click in the link it takes me to the right blog, but not the right post - you have to scroll down).

▲

⟩⟩

Peejay

Login To

Remove Ads

Remove Ads

📝 Crew, People, and Detailed Interiors

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 49 Views · 2 Likes

Flag

📝 Reply

and a recent video which includes "Katie the Kayaker"

▲

⟩⟩

stevedownunder

Len1

📝 Crew, People, and Detailed Interiors

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 49 Views · 3 Likes

Flag

📝 Reply

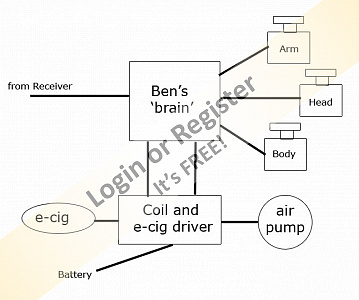

Hi Boatshed,

Here's a video of Bill and Ben in the rowing boat. You need to watch carefully to see Ben (the passenger) in action!

Here's a video of Bill and Ben in the rowing boat. You need to watch carefully to see Ben (the passenger) in action!

▲

⟩⟩

stevedownunder

Len1

jumpugly

📝 Planking

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 143 Views · 18 Likes · 1 Comment

Flag

💬 Add Comment

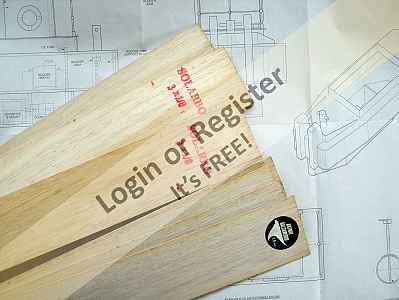

Before starting the planking, the location of the top edge of each plank was marked onto the edge of the bulkheads and forms. The edges of the three forms were also taped to avoid the risk of any of the planks sticking as the forms need to be removed once planking is complete.

The planks are 2mm thick mahogany strips cut from some salvaged 25mm thick boards. They were cut over thickness and then sanded both sides using my homemade thickness sander.

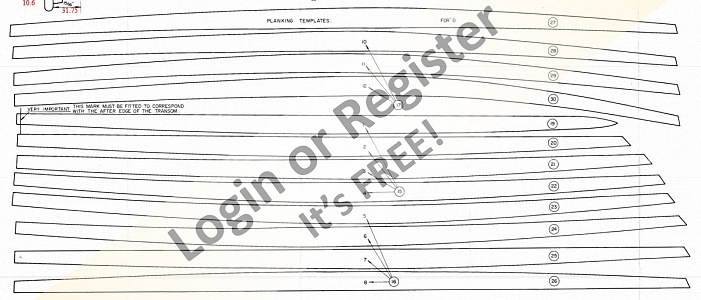

There are 24 planks required in total, 12 on each side. Each pair of planks (port and starboard) should be identical but are different from all the other 11 pairs. The plan includes full size templates for the planks so these were used to mark out the planks before cutting on the bandsaw. The ends of the planks need to have rebates planed along their edges (arrowed in photos 3 and 4) to overlap the previous plank. This gives a flush finish to the planking at the stem and transom.

Once shaped, each plank is glued into position along it's length and clamped until the glue has set. It is difficult to shape and fit more than one plank a day as the glue needs to set before the clamps can be removed for use with the next plank.

The planks are 2mm thick mahogany strips cut from some salvaged 25mm thick boards. They were cut over thickness and then sanded both sides using my homemade thickness sander.

There are 24 planks required in total, 12 on each side. Each pair of planks (port and starboard) should be identical but are different from all the other 11 pairs. The plan includes full size templates for the planks so these were used to mark out the planks before cutting on the bandsaw. The ends of the planks need to have rebates planed along their edges (arrowed in photos 3 and 4) to overlap the previous plank. This gives a flush finish to the planking at the stem and transom.

Once shaped, each plank is glued into position along it's length and clamped until the glue has set. It is difficult to shape and fit more than one plank a day as the glue needs to set before the clamps can be removed for use with the next plank.

▲

⟩⟩

BOATSHED

philcaretaker

jbkiwi

boatmam

Peejay

GaryLC

cenbeth

AndyB2

RossM

Len1

MartinH2

hermank

EdW

Colin H

stevedownunder

River Rat

MouldBuilder

RNinMunich

📝 Crew, People, and Detailed Interiors

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 67 Views · 9 Likes

Flag

📝 Reply

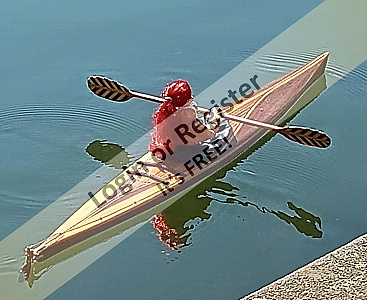

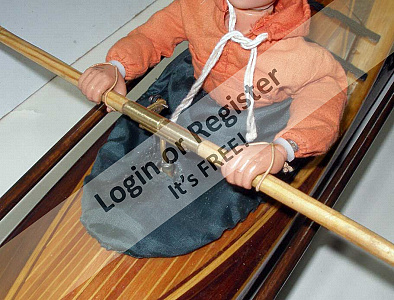

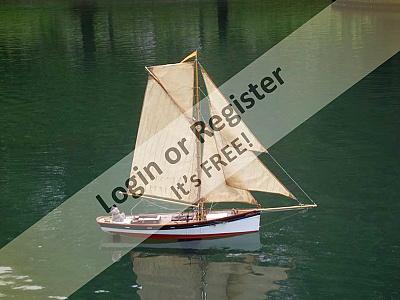

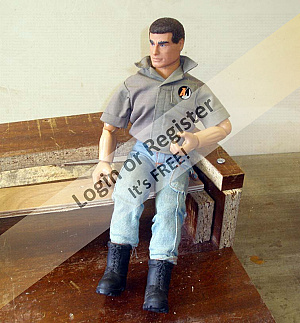

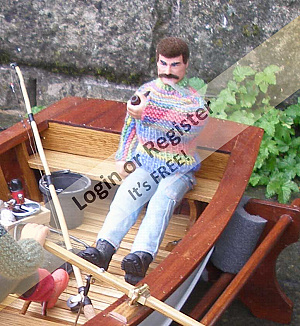

I have crew on some of my boats. They would look a little odd without!

These two boats were built at 1/6th scale. Part of the reason for choosing that scale was so that there would be suitable figures available. The two crew in the rowing boat are Action men, suitably aged. The kayaker is a Disney Ariel figure.

All the figures were sourced from eBay for just a couple of £.

These two boats were built at 1/6th scale. Part of the reason for choosing that scale was so that there would be suitable figures available. The two crew in the rowing boat are Action men, suitably aged. The kayaker is a Disney Ariel figure.

All the figures were sourced from eBay for just a couple of £.

▲

⟩⟩

Peejay

PeterL3

Len1

hermank

ChrisF

stevedownunder

River Rat

RNinMunich

jumpugly

📝 Admin

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 61 Views · 2 Likes

Flag

📝 Reply

Yes. Just search in the Members area of the site for ‘fireboat’. I’ve just done that and he is listed.

▲

⟩⟩

Mike Stoney

Len1

📝 Admin

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 61 Views · 1 Like

Flag

📝 Reply

Admin on the site is Stephen known as ‘Fireboat’ on the site. Try sending him a PM

▲

⟩⟩

Len1

💬 Re: Anchor and Chain

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 37 Views · 0 Likes

Flag

💬 Add Comment

Thanks Alain,

Interesting to know that the anchor is a 1950s design. I simply copied what I saw in the photo of the full sized Cutter. I usually follow the “if it looks right, it probably is right” approach 😀

Interesting to know that the anchor is a 1950s design. I simply copied what I saw in the photo of the full sized Cutter. I usually follow the “if it looks right, it probably is right” approach 😀

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Maiden voyage

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 80 Views · 1 Like

Flag

💬 Add Comment

Thanks Alain,

I’m glad you have enjoyed reading through the blog and hope you found it useful

Regards Graham

I’m glad you have enjoyed reading through the blog and hope you found it useful

Regards Graham

▲

⟩⟩

Len1

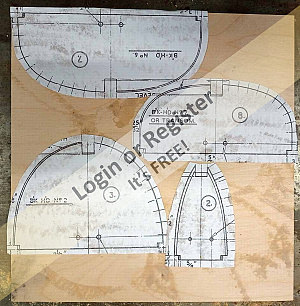

📝 Formwork

2 years ago by 🇬🇧 Graham93 ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 144 Views · 12 Likes

Flag

💬 Add Comment

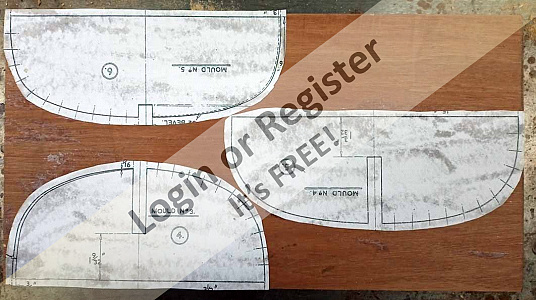

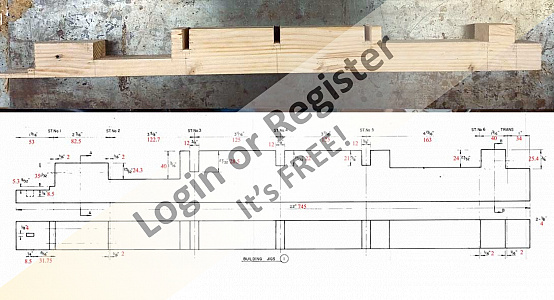

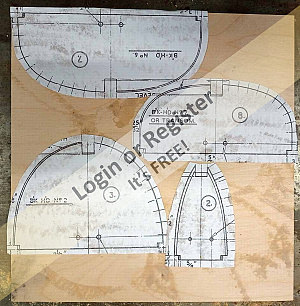

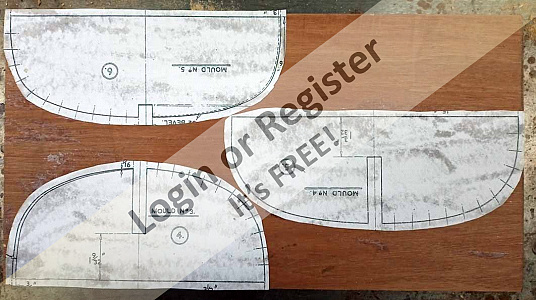

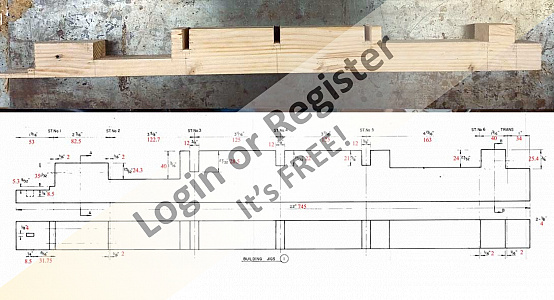

The hull is built inverted on a jig. There are four bulkheads which will form part of the completed hull, together with three temporary moulds which ensure that the planks are laid to the correct form.

The bulkhead shapes were printed and then glued to 4mm birch ply before cutting out. The same approach was used for the moulds although these were cut from 12mm construction ply.

The bulkheads and moulds all mount onto a timber strongback which was marked for cutting out using the scaled up dimensions from the plan.

The strongback was then screwed to a flat board and the bulkheads and moulds were fixed in position. The front pair of bulkheads are bolted together using two threaded rods which run through holes in the strongback. A similar arrangement is used to hold the rear pair of bulkheads in position.

Finally, the keel was fitted into the notches along the centreline of the bulkheads and moulds. It was glued to the bulkheads but not the three central moulds. Everything was checked for square before the glue dried. The complete assembly has turned out to be very rigid, which is probably going to be a good thing when it comes to fitting the planks.

The bulkhead shapes were printed and then glued to 4mm birch ply before cutting out. The same approach was used for the moulds although these were cut from 12mm construction ply.

The bulkheads and moulds all mount onto a timber strongback which was marked for cutting out using the scaled up dimensions from the plan.

The strongback was then screwed to a flat board and the bulkheads and moulds were fixed in position. The front pair of bulkheads are bolted together using two threaded rods which run through holes in the strongback. A similar arrangement is used to hold the rear pair of bulkheads in position.

Finally, the keel was fitted into the notches along the centreline of the bulkheads and moulds. It was glued to the bulkheads but not the three central moulds. Everything was checked for square before the glue dried. The complete assembly has turned out to be very rigid, which is probably going to be a good thing when it comes to fitting the planks.

▲

⟩⟩

BOATSHED

Peejay

cenbeth

philcaretaker

Len1

MartinH2

hermank

EdW

Colin H

RNinMunich

jbkiwi

stevedownunder

Commodore)

Commodore)

Rear Admiral)

Rear Admiral)

Recruit)

Recruit)

Admiral)

Admiral)

Fleet Admiral)

Fleet Admiral)

Sub-Lieutenant)

Sub-Lieutenant)

Lieutenant)

Lieutenant)