Join Us On Social Media!

United Kingdom

Recent Posts

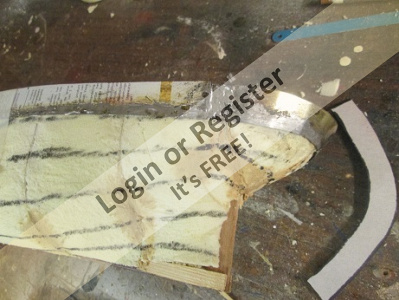

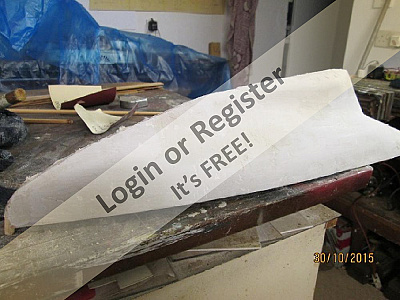

📝 Creating Realistic Mast Hoops

3 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 32 Views · 7 Likes

Flag

📝 Reply

Thick shavings rapped around a tube. Four or five layers. Stick with wood glue. Cut off size required. Oil tube so it can be removed, after cutting. Yes very strong

▲

⟩⟩

boatmam

dave976

Doogle

chugalone100

Scratchbuilder

Colin H

Ronald

Login To

Remove Ads

Remove Ads

📝 Rowing Dinghy 1/24 scale

3 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 45 Views · 4 Likes

Flag

📝 Reply

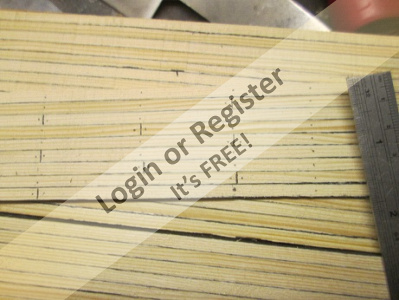

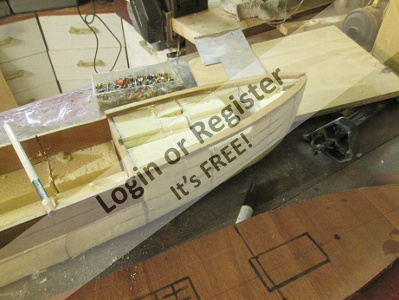

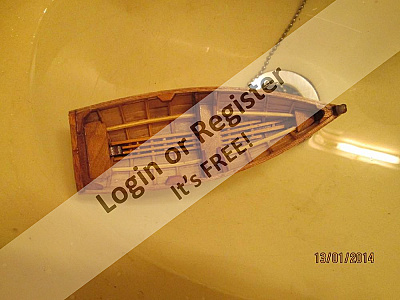

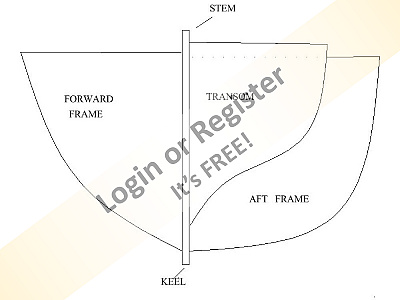

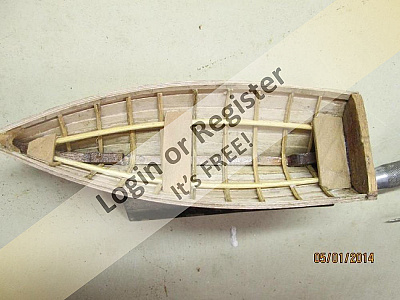

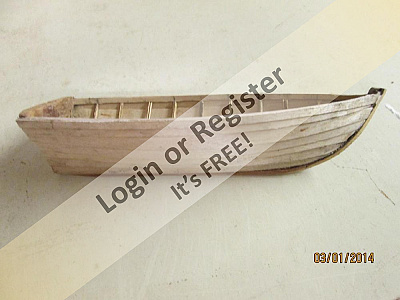

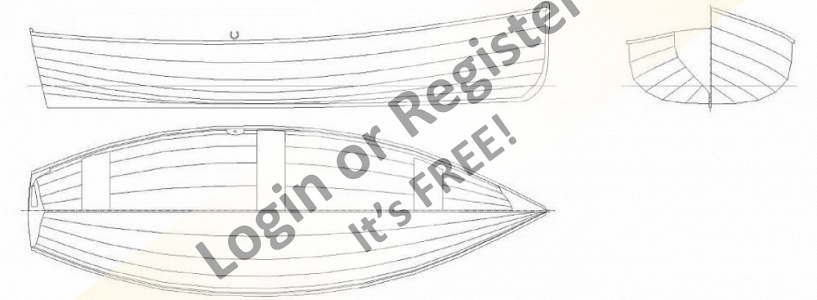

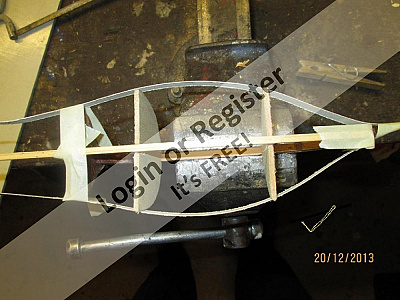

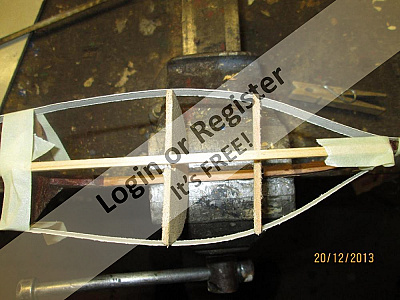

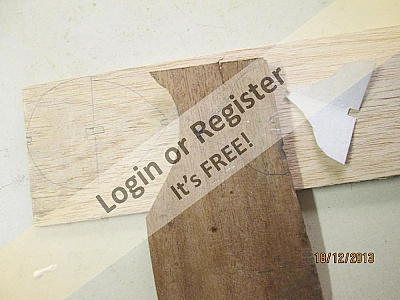

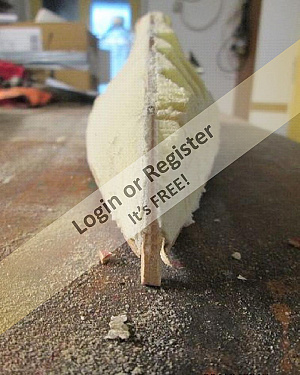

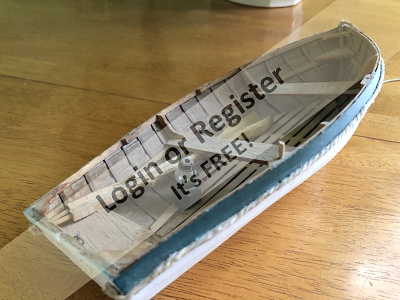

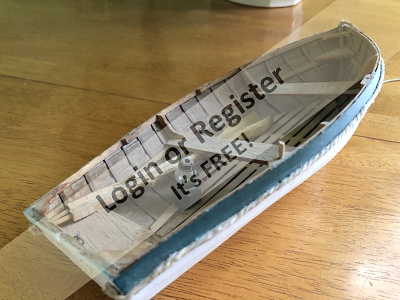

I use 1mm ply or even card for planks. I do cheat with the rebates in the keel & stem I stick a backing piece each side back about half way

▲

⟩⟩

Nickthesteam

Colin H

ChrisG

peterd

📝 Rowing Dinghy 1/24 scale

3 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 47 Views · 3 Likes

Flag

📝 Reply

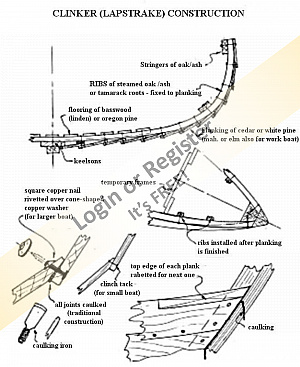

Ron. It is not to difficult to build a clinker boat. I have made 12 in scales from 3/4 -1ft down to 1/4 - 1ft. Just build as in full size. Most important only the first & last planks are straight all others are shaped.

▲

⟩⟩

Colin H

Ronald

ChrisG

📝 Blocks

3 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 44 Views · 1 Like

Flag

📝 Reply

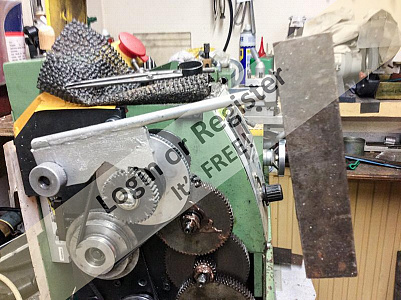

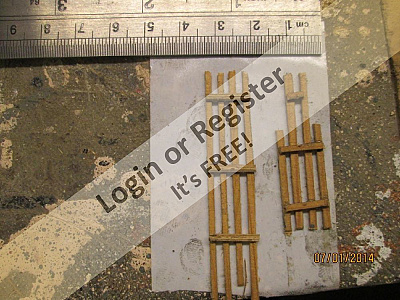

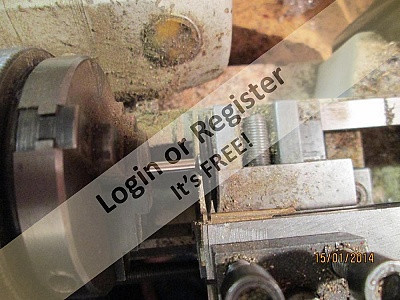

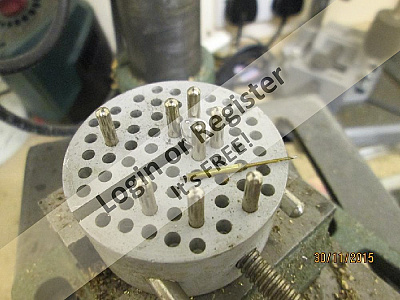

A dead bush from the garden supplied a closed grain timber. Cut to size on bandsaw & smoothed on belt sander. Slots cut on mill with a 2mm end mill. Could have used a drill. Cleaned the slots with home made chisel & small file. Shaping with a large file & sandpaper. Cut off & drive a brass pin through the centre. That was the most difficult.

▲

⟩⟩

Graham93

📝 Blocks

3 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 44 Views · 0 Likes

Flag

📝 Reply

Needed small working blocks for my model Irene. It sits in the window of our bedroom. I see it every morning & a few things worry me. Two sails need recutting. I can cut the stay sail out of the main. So will make a better main. The blocks are to big way out of scale. But they do have to operate. As I alter the rig to suit the weather.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Coal Bunker Lids Continued.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 147 Views · 2 Likes

Flag

💬 Add Comment

Cross hatching definitely

▲

⟩⟩

Martin555

stevedownunder

💬 Re: The dinghy

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 138 Views · 1 Like

Flag

💬 Add Comment

I made a westerman from balsa. Hand fixed to tiller spring for arms. Other arms spring has string when pulled it waves.

▲

⟩⟩

AndyB

💬 Re: "Mods"

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 156 Views · 0 Likes

Flag

💬 Add Comment

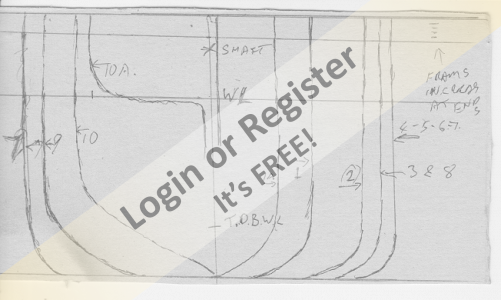

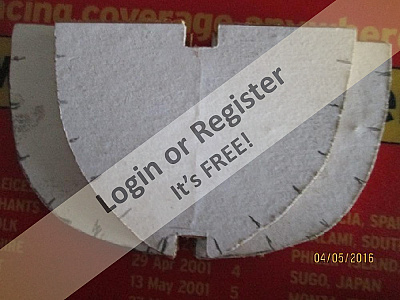

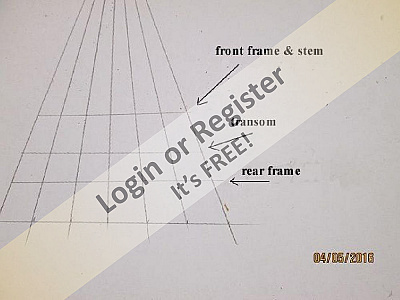

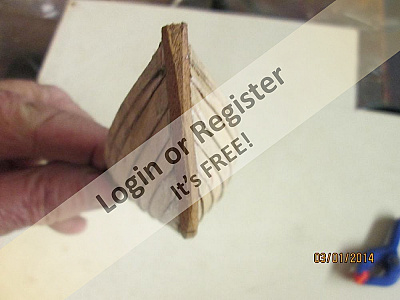

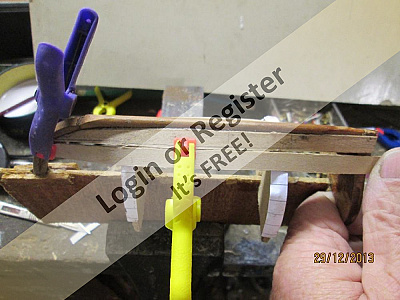

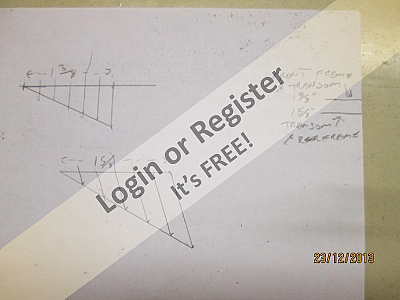

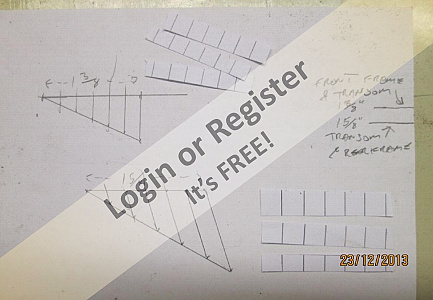

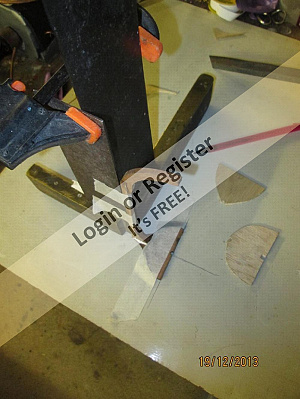

No drawings I build them as full size practice. Upside down on a frame. I use 1or2mm ply depending on size. The secret to remember is only the first and last planks are straight. All others are shaped against the previous plank. After removing off frame the inside is fitted out. Photo of old frame for a 4.5” boat. Clamp just holding rule. The hole in frame is to hold model down. As full size use props off the shed roof.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: "Mods"

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 171 Views · 0 Likes

Flag

💬 Add Comment

Adjusting the sails to suit the conditions, the right idea. I am disappointed that you are using a plastic punt. With your skill I am sure you would have made a superb job. I did a demo on here somewhere. Phone of my smallest.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

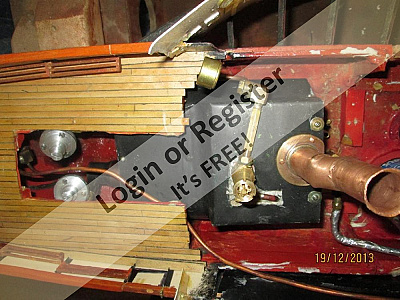

💬 Re: At Last Deck Planking is Done (well nearly).

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 170 Views · 0 Likes

Flag

💬 Add Comment

Well I am happy to have convinced you the ends should be jogged into the cover board. Teds method has to reduce the width of the plank. With a short grain nib the original width. 2 men a day is what I have been told. It is surprising what can be done with organisation. I was a carpenter & with a labourer cut & fixed 10 sets of floor joists a day. Only small houses true.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: At Last Deck Planking is Done (well nearly).

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 175 Views · 1 Like

Flag

💬 Add Comment

I can not fault your workmanship. How ever your mentor Ted must be more used to yacht deck planking than work boats. I think I said before a man and boy expected to lay a trawler deck in a day. They did not waste wood. The boards are notch into the cover board. See photo. Not notched into the next plank. Glad to you show any pointed ends. Sorry to be pedantic.

▲

⟩⟩

stevedownunder

Login To

Remove Ads

Remove Ads

💬 Re: Making a Start, Deck Planking.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 210 Views · 1 Like

Flag

💬 Add Comment

K I S is always best.

▲

⟩⟩

stevedownunder

💬 Re: Bilge & Circulating Pump Outflow.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 219 Views · 1 Like

Flag

💬 Add Comment

I would turn up outlets not drill the metal stake. The out let is best just below cockpit floor. Just my thoughts 😎

▲

⟩⟩

stevedownunder

💬 Re: Get the Glue Out + Look at Deck Planking.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 217 Views · 1 Like

Flag

💬 Add Comment

Your in charge. I will say one days work for man & a boy. Lay the deck of a Brixham trawler. When men were men⚡

▲

⟩⟩

stevedownunder

💬 Re: Get the Glue Out + Look at Deck Planking.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 226 Views · 1 Like

Flag

💬 Add Comment

The way I read it they use the line of the engine hatch sides. In your case the hold edges would be used. This would ensure the line of planks would be straight. Bending the line would require a tapered plank down the centre. I always lay the central plank first, cutting out openings after fixing. I also use random length boards. Do not want a zigzag pattern with the butt ends. Just my way.

▲

⟩⟩

stevedownunder

💬 Re: Finished Deck

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 201 Views · 1 Like

Flag

💬 Add Comment

I think red oxide is more for iron hull. Wooden hulls of this period would be pitched. Could be painted above W/L. Anywhere near navy dock grey favoured. Ask no questions 😂

▲

⟩⟩

AndyB

💬 Re: Modified Stern, etc

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 84 Views · 1 Like

Flag

💬 Add Comment

With few opportunities to cover openings on my pilot cutter. Had to make cutout in deck. Rubber seal & screwed down. Screws covered by lose plank, well not that lose a press fit holding them in place. Rubber I have used, window draft seal, also split worn out windscreen wipers.

▲

⟩⟩

Colin H

💬 Re: The Gooseneck

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 227 Views · 2 Likes

Flag

💬 Add Comment

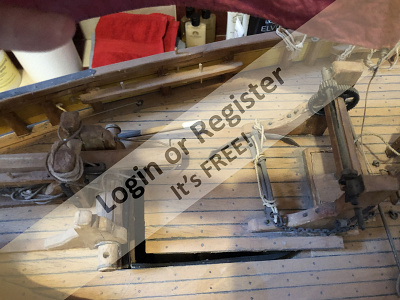

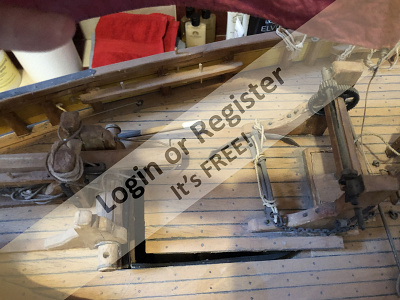

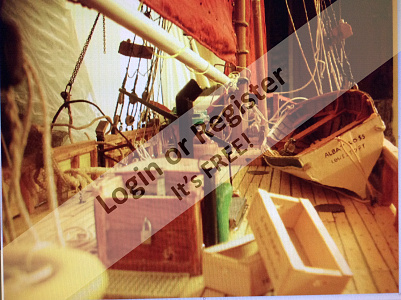

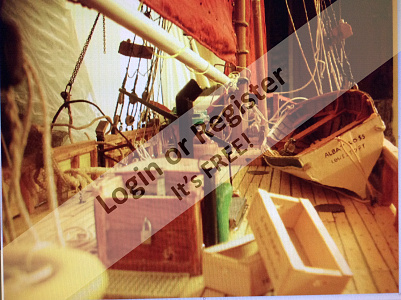

Where the end of the boom fits in the upright. drill out the pivot pin replace with a screw. This can be removed roll up sail & replace screw. That’s what I do. Photos best I can as packed down for winter. A 10BA screw is pivot.

▲

⟩⟩

Colin H

AndyB

💬 Re: Planking progress

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 121 Views · 1 Like

Flag

💬 Add Comment

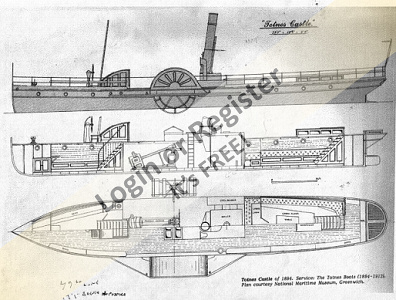

Looking good. I always plank on frames even my steam ships. 5ft model planked with 1/16 balsa Impregnated with resin. Built 2001 still going. Even dropped it twice so did have to repair. 1/16 is to thin use 1/8 now as I have a large supply. Bought 40 years ago when aero modelling. Boats don’t crash had 2 sink though 😂

▲

⟩⟩

Hillro

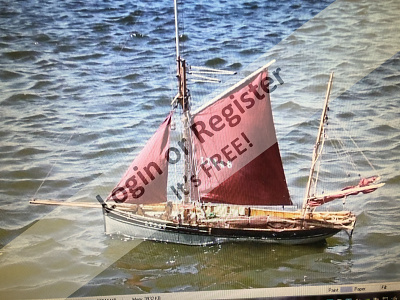

📝 Up for sale..

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 57 Views · 1 Like

Flag

📝 Reply

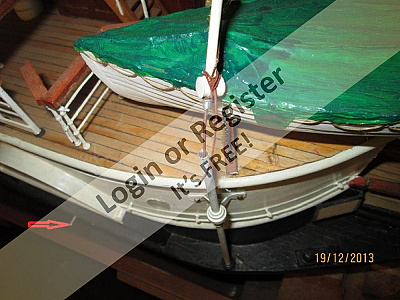

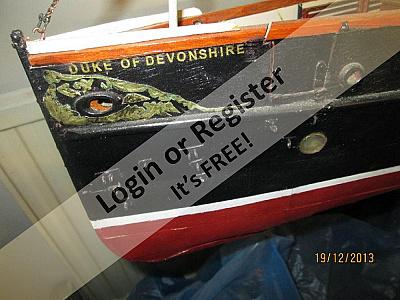

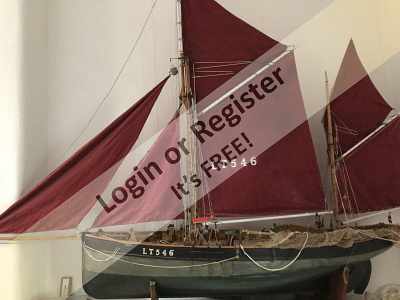

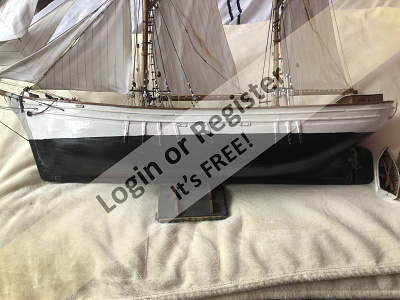

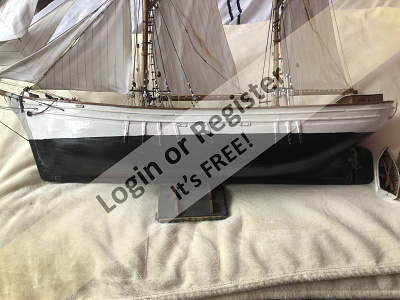

She sails on internal ballast only. But there are 2 sailing aids. Expanding rudder & drop centre plate. ( only half way down). Both by radio control.

▲

⟩⟩

Colin H

📝 Up for sale..

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 57 Views · 1 Like

Flag

📝 Reply

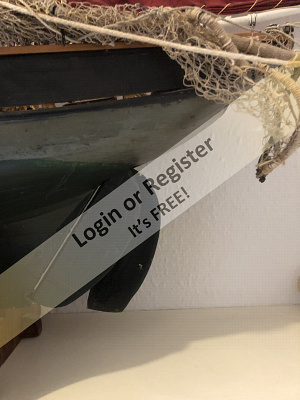

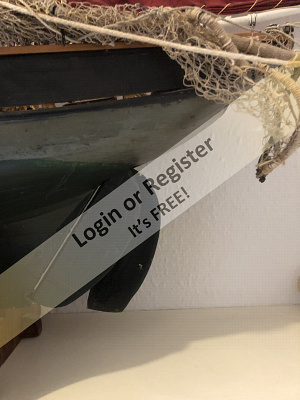

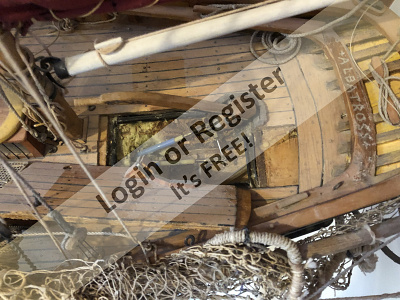

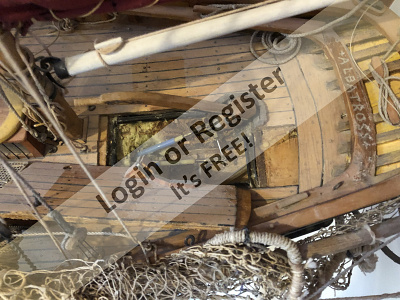

Dave all the money is your side. 😂🤣. Pictures of the 3 hatch hard to see if you don’t know where to look. The punt is a model on its own & floats. Also the net is correct, although the mesh is over scale.

▲

⟩⟩

Colin H

Login To

Remove Ads

Remove Ads

📝 Up for sale..

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 89 Views · 4 Likes

Flag

📝 Reply

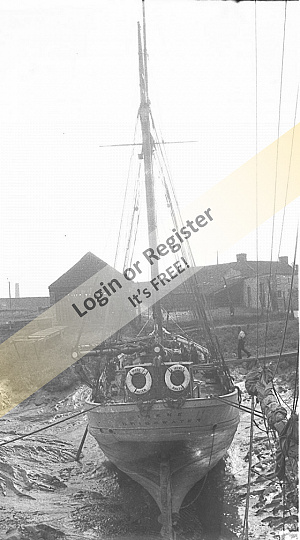

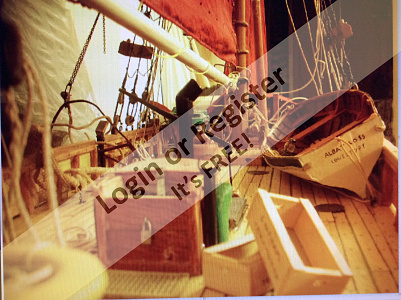

Albatross LT546. Large accurate model of Lowestoft trawler. Built by Mansfield in Teignmouth. Double planked hull, from my own plans. Very good sailer in all weathers. I will be sad to see it go, but it is to big & heavy for me to manage on my own. As I am over 80 & my legs don’t work properly any more. Collection only from west county. Offers £400. Only selling here.

Geoff

Geoff

▲

⟩⟩

Colin H

dave976

DWBrinkman

Peejay

📝 Up for sale..

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 90 Views · 4 Likes

Flag

📝 Reply

▲

⟩⟩

TonyAsh

Peejay

Ronald

Colin H

📝 Beginners Question

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 66 Views · 0 Likes

Flag

📝 Reply

I am not replying. It’s just stuck here

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Covering Boards continued. 6.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 270 Views · 3 Likes

Flag

💬 Add Comment

Good idea, come back to a job another day. It sorts it’s self out usually.

▲

⟩⟩

Martin555

GaryLC

stevedownunder

💬 Re: Covering Boards continued. 4.

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 270 Views · 2 Likes

Flag

💬 Add Comment

I must say you method called for extreme accurate work. Which you can do. For lessers mortals cheat.

In 4 jaw turn a spigot on stanchions. Cut & fix cover board. With a jig mark centre of stanchions + thickness of planks. Drill holes to fit spigots. Glue rail to tops.

In 4 jaw turn a spigot on stanchions. Cut & fix cover board. With a jig mark centre of stanchions + thickness of planks. Drill holes to fit spigots. Glue rail to tops.

▲

⟩⟩

Martin555

stevedownunder

📝 Arlington Court (North Devon)

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 46 Views · 0 Likes

Flag

📝 Reply

Yes plenty of lakes in Devon. But all fishing only. The boating lake in Goodrington has hire boats on it can be used out of season.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Arlington Court (North Devon)

4 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 57 Views · 0 Likes

Flag

📝 Reply

South Devon has no suitable sailing water ether. Very sad. Exeter MBC has a lake at Cannonteign Falls. Only really good for power, but very good for subs. Not good for sail to many trees & water lilies.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Scratch built, Working Steam powered Drifter trawler LT100, to 1:24th scale.

5 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 262 Views · 0 Likes

Flag

💬 Add Comment

I live in Devon near Brixham. A man & boy would lay a deck on a sailing trawler in a day. That would be 9 hours. So you can tell how rough it would be. This did not include calking Of course.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Fin and Keel

5 years ago by 🇬🇧 hammer ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 233 Views · 3 Likes

Flag

💬 Add Comment

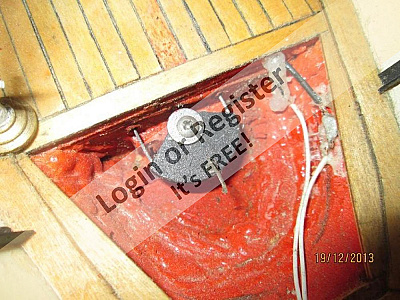

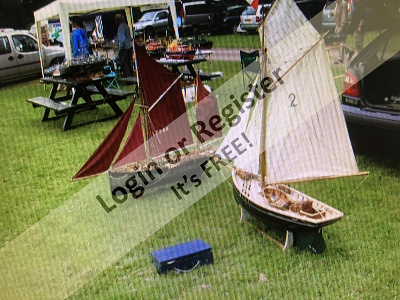

Well if the plan shows a fin & weight. That’s that I always draw my own plans so I do what I want😀. I have found the biggest problem, for good sailing is the size of the rudder. I cheat with my schooners. Photo tells all. In first photo the square is the hatch to stop model rolling upright.

▲

⟩⟩

Colin H

Martin555

Ronald

Fleet Admiral)

Fleet Admiral)

Admiral)

Admiral)

Liked Shackles 5 years ago

Liked Shackles 5 years ago

Liked Re: (Working Vessel) spray 5 years ago

Liked Re: (Working Vessel) spray 5 years ago

Liked Binnacle 5 years ago

Liked Binnacle 5 years ago

Liked Fairleads 5 years ago

Liked Fairleads 5 years ago

Liked Cruise Ships 5 years ago

Liked Cruise Ships 5 years ago