Join Us On Social Media!

Canada

Recent Posts

📝 My Absence From Model Boats Website

2 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 26 Views · 6 Likes · 2 Comments

Flag

💬 Add Comment

Hello

Sorry about my absence From Model Boats Website and my builds, but once again, my health had other plans for me. Now I am feeling much better so will try to pick up the pieces - starting with NAXOS. So that I am reasonably comfortable that I am stroking with both oars, it will be a little time before I donany posting here. I have to assess what has to be done and how much $$ is available to do it and then go from there. With the economy what it is and the exorbitant grocery and other costs its a lot harder to justify casual or hobby spending than a couple of years ago.

Hope to see you soon

Sorry about my absence From Model Boats Website and my builds, but once again, my health had other plans for me. Now I am feeling much better so will try to pick up the pieces - starting with NAXOS. So that I am reasonably comfortable that I am stroking with both oars, it will be a little time before I donany posting here. I have to assess what has to be done and how much $$ is available to do it and then go from there. With the economy what it is and the exorbitant grocery and other costs its a lot harder to justify casual or hobby spending than a couple of years ago.

Hope to see you soon

▲

⟩⟩

jbkiwi

LewZ

Scratchbuilder

Len1

AlessandroSPQR

Wolle

Login To

Remove Ads

Remove Ads

📝 bluenose build - on hold

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 47 Views · 1 Like

Flag

💬 Add Comment

I have put the build for the ship on hold because I found that building with foamboard is not the best option....at least thats my opinion. It was not a complete waste of time because I learned a few things along the way. Therefore I will not proceed with that medium. If I am going to put the time and effort into this model, it will be plank on frame construction.

at this time I will devote my time to learning a 3D modeling software (Sketchup) so that I can come up with reasonable plans which is the foundation for any model.

hopefully I will be back soon with progress.

thank you to my followers

at this time I will devote my time to learning a 3D modeling software (Sketchup) so that I can come up with reasonable plans which is the foundation for any model.

hopefully I will be back soon with progress.

thank you to my followers

▲

⟩⟩

pressonreguardless

📝 Bluenose - The build

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 56 Views · 2 Likes

Flag

💬 Add Comment

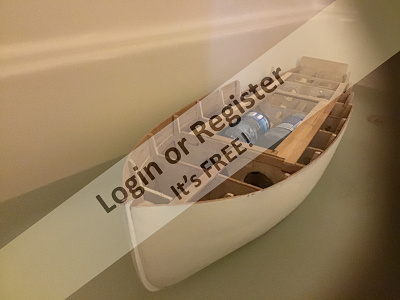

Well, started the actual build this morning. Cut the deck outline and the bulkheads and stuck together with Gorilla glue. The boat is built upside down and the pictures show her laying deck side down.

A bit of fairing on the bulkhead sides is needed, then will add the waterline sheet and finally the hull left and right hull sides. Once everything looks ok, I will cut the deck opening and bulkhead openings.

Looking at her now, she seems a bit small so if worse comes to worse, she will become a static ship and I will say she is a "learning model" and will go for a larger model once I find out what,I did wrong on this build. It's a bit early yet to say all is ok, but so far, so good and I will add the below waterline details later on in the build process.

I am kind of wondering about how I will accomplish the flair of the bow area between bulkheads 1 to 3. It is a compound curve and they are not liked by solid and mostly unyeilding covering material. I may have to use solid foam between bulkheads 1 & 2 as well as 2 & 3 and shape it as needed...we shall see.

Forward of bulkhead 1 to the stem will be solid foam shaped as necessary. I don't see (as of yet) any issue with the stern curve as that is pretty much a foam block shaped as necessary.

Here's a few pics of what I got so far.

A bit of fairing on the bulkhead sides is needed, then will add the waterline sheet and finally the hull left and right hull sides. Once everything looks ok, I will cut the deck opening and bulkhead openings.

Looking at her now, she seems a bit small so if worse comes to worse, she will become a static ship and I will say she is a "learning model" and will go for a larger model once I find out what,I did wrong on this build. It's a bit early yet to say all is ok, but so far, so good and I will add the below waterline details later on in the build process.

I am kind of wondering about how I will accomplish the flair of the bow area between bulkheads 1 to 3. It is a compound curve and they are not liked by solid and mostly unyeilding covering material. I may have to use solid foam between bulkheads 1 & 2 as well as 2 & 3 and shape it as needed...we shall see.

Forward of bulkhead 1 to the stem will be solid foam shaped as necessary. I don't see (as of yet) any issue with the stern curve as that is pretty much a foam block shaped as necessary.

Here's a few pics of what I got so far.

▲

⟩⟩

pressonreguardless

Colin H

📝 MV Bluenose

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 3 Likes

Flag

💬 Add Comment

▲

⟩⟩

Forrest E

Crawldad

Colin H

📝 NAXOS

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 2 Likes

Flag

💬 Add Comment

1st RC BOAT

▲

⟩⟩

Forrest E

Crawldad

💬 Re: MV Bluenose -Plans

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 70 Views · 3 Likes

Flag

💬 Add Comment

Stations

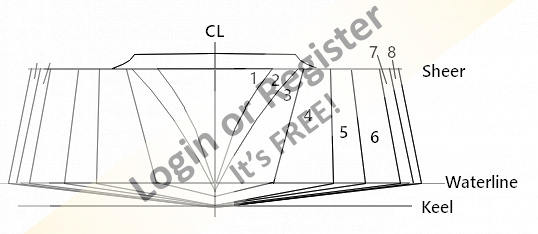

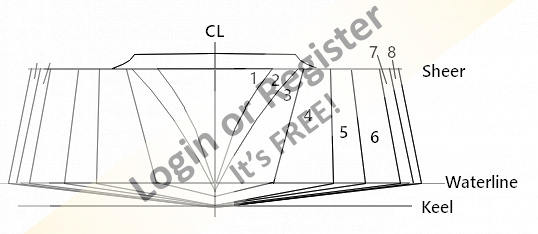

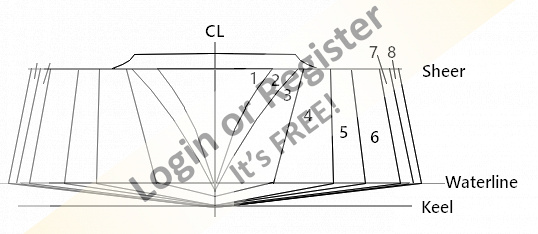

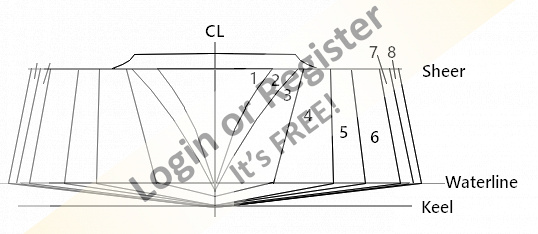

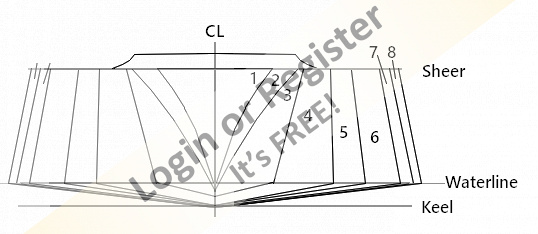

I am thinking that the station profiles would look something like this. Rough sketch only - no measurements

I am thinking that the station profiles would look something like this. Rough sketch only - no measurements

▲

⟩⟩

Colin H

Mike Stoney

ToraDog

💬 Re: Getting back into the project

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 26 Views · 1 Like

Flag

💬 Add Comment

I am Thinking that the station profiles would look something like this: Only a drawing not to any scale or dimensioin

▲

⟩⟩

Colin H

📝 MV Bluenose -Plans

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 71 Views · 2 Likes · 3 Comments

Flag

💬 Add Comment

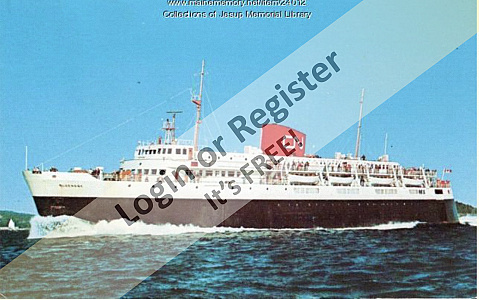

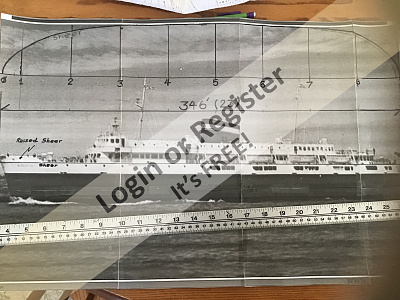

Began the job of drawing plans tonight. From the image I have to work from, the sheer line appears to be level. That illusion may be caused by the fact that the image is not exactly perpendiculat to the camera.

Somehow I am betting that the sheer height offset is a bit shorter at the stern than the sheer height at the bow. Anyway that will be figured out as Inprogress.

I am finding out one thing for cure - at 80, my hand doesnt draw curves like it did when I was 40!

Somehow I am betting that the sheer height offset is a bit shorter at the stern than the sheer height at the bow. Anyway that will be figured out as Inprogress.

I am finding out one thing for cure - at 80, my hand doesnt draw curves like it did when I was 40!

▲

⟩⟩

Colin H

Mike Stoney

💬 Re: MV Bluenose - Plans started

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 75 Views · 0 Likes

Flag

💬 Add Comment

Hi ToraDog

Thank you for the info - all info is very important and so very much appreciated. As far as I can remember there were several captains for her - 11 or so I think, two of them being Capt Davies and Captain Crump.

Just had a brainwave - i know one of the radio ops (Sparks) that worked on her for years. He is a fellow radio ham op living in Yarmouth, and I know him quite well. Will see what he can come up with as far as possible plan sources.

Info for this ship is basically non-existant which is too bad seeing that info is available for most of the previous and later ferries…my luck. I did hear bk from Lloyds Register and they are looking, so all hope is not gone.

Thank you for the info - all info is very important and so very much appreciated. As far as I can remember there were several captains for her - 11 or so I think, two of them being Capt Davies and Captain Crump.

Just had a brainwave - i know one of the radio ops (Sparks) that worked on her for years. He is a fellow radio ham op living in Yarmouth, and I know him quite well. Will see what he can come up with as far as possible plan sources.

Info for this ship is basically non-existant which is too bad seeing that info is available for most of the previous and later ferries…my luck. I did hear bk from Lloyds Register and they are looking, so all hope is not gone.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 MV Bluenose - Plans started

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 75 Views · 1 Like · 3 Comments

Flag

💬 Add Comment

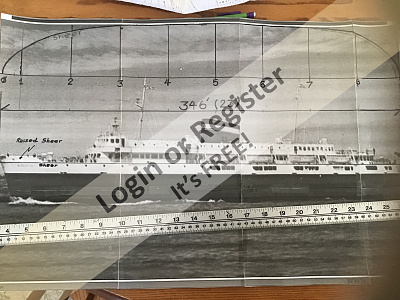

Sent my broadside image to rasterbator.com and processed it tiled to four 8.5” X 11” sheets. Printed them off and trimmed to the margin lines. Finally with the help of my Scotch tape dispenser, stuck ‘em all together. The final outcome produced a hull with overall hull length of 23” which suits me just fine. The scale calculator tells me she will be a 1:180 model.

Drawing of the top view of her is basically a guess and going by what I can recall of her lines tells me that the stem at the waterline was quite pointed and flared at the sheer to produce a top view of a rounded “nose”. This part will be made with balsa or basswood blocking.

According to her specs she had a 17’ draft which wheen scaled comes out to only a little under 2”. I will build her as a flat bottom at the waterline and build the underwater as a self emptying ballast tank because being mostly foam, she will be quite light. I have heard of this before and aparently it works quite well.

Power for her is planned to be dual brushless motors/ESC’s with reverse. All this will be fed with high capacity LiPo battery. Someone should advise me - considering she will have two props - how many rudders (single or dual) I should give her.

Thats about it for this post - will be adding more as progress happens.

Drawing of the top view of her is basically a guess and going by what I can recall of her lines tells me that the stem at the waterline was quite pointed and flared at the sheer to produce a top view of a rounded “nose”. This part will be made with balsa or basswood blocking.

According to her specs she had a 17’ draft which wheen scaled comes out to only a little under 2”. I will build her as a flat bottom at the waterline and build the underwater as a self emptying ballast tank because being mostly foam, she will be quite light. I have heard of this before and aparently it works quite well.

Power for her is planned to be dual brushless motors/ESC’s with reverse. All this will be fed with high capacity LiPo battery. Someone should advise me - considering she will have two props - how many rudders (single or dual) I should give her.

Thats about it for this post - will be adding more as progress happens.

▲

⟩⟩

Colin H

📝 Building Materials

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 89 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

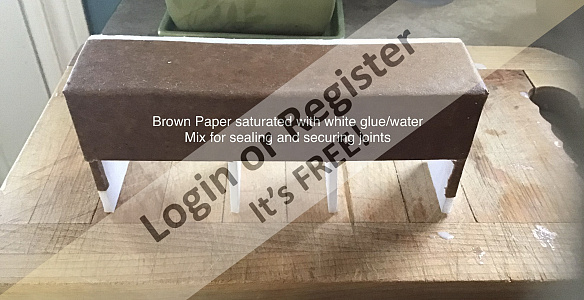

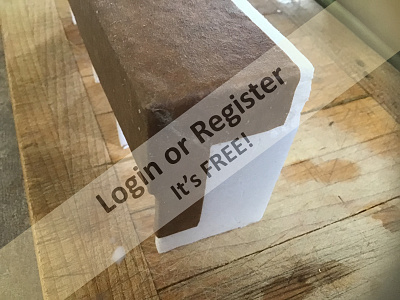

Quite likely, most builders that read this already know what I am presenting here, but just to put forward what I have experimented with seems to work - so far. I welcome any comments and the subject of building materials and putting them together as a usable model is open. I am very new to modeling - especially watercraft, and therefore am very receptive to advice.

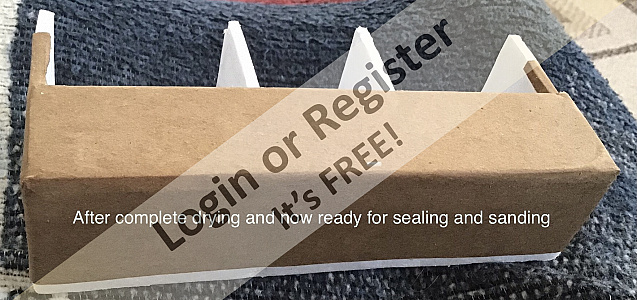

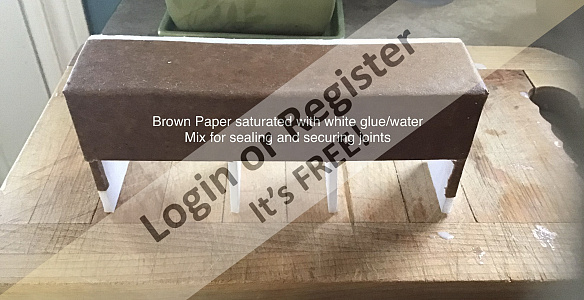

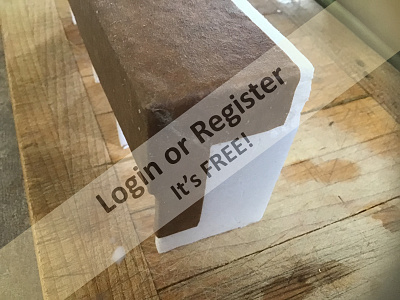

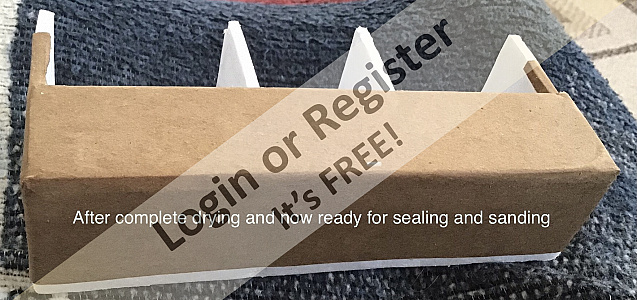

After carrying out some experiments with materials such as wood, Elmers foam board and after a lot of reading, pro and con for both types of material, I have come to the following conclusion: I will be using 1/4” [6mm] foamboard. Joints will be glued with Gorilla Instant Glue. Joints inside and outside will be sealed with brown paper soaked with an Elmers waterproof Glue-All/water mix. Final sealing will be with several coats of an exterior water based polyurethane. Final painting will be with a spray enamel.

Some of my experimenting with foam.

OK, NOW OFF TO THE DRAWING BOARD.

*****************💡💡 UPDATE - UPDATE 💡💡 Wed Jan 28 2022************

This morning, the brown paper experiment to seal and strengthen the joints and seams looks very promising. Upon drying, sure enough, the shrinkage has produced an absolutely smoothe surface with no wrinkles or bumps. When tapped with a fingernail, one would swear that the mockup structure was made from 1/8” plywood.

After carrying out some experiments with materials such as wood, Elmers foam board and after a lot of reading, pro and con for both types of material, I have come to the following conclusion: I will be using 1/4” [6mm] foamboard. Joints will be glued with Gorilla Instant Glue. Joints inside and outside will be sealed with brown paper soaked with an Elmers waterproof Glue-All/water mix. Final sealing will be with several coats of an exterior water based polyurethane. Final painting will be with a spray enamel.

Some of my experimenting with foam.

OK, NOW OFF TO THE DRAWING BOARD.

*****************💡💡 UPDATE - UPDATE 💡💡 Wed Jan 28 2022************

This morning, the brown paper experiment to seal and strengthen the joints and seams looks very promising. Upon drying, sure enough, the shrinkage has produced an absolutely smoothe surface with no wrinkles or bumps. When tapped with a fingernail, one would swear that the mockup structure was made from 1/8” plywood.

▲

⟩⟩

ChrisG

pressonreguardless

Colin H

Login To

Remove Ads

Remove Ads

💬 Re: MV Bluenose

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 90 Views · 1 Like

Flag

💬 Add Comment

Rowen

Thanks so much for the info on possible sources for drawing info..will try both of those leads.

You are absolutely correct about info from Davie. The company had been re purchased by another concern and drawings no longer exist.

As a last resort, I am fortunate enough to be somewhat skilled in drawing so may have to rely on myself. Its all part of a great hobby and if nothing else will be able to say “shes all mine.”

Thanks so much for the info on possible sources for drawing info..will try both of those leads.

You are absolutely correct about info from Davie. The company had been re purchased by another concern and drawings no longer exist.

As a last resort, I am fortunate enough to be somewhat skilled in drawing so may have to rely on myself. Its all part of a great hobby and if nothing else will be able to say “shes all mine.”

▲

⟩⟩

Colin H

📝 MV Bluenose

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 106 Views · 2 Likes · 3 Comments

Flag

💬 Add Comment

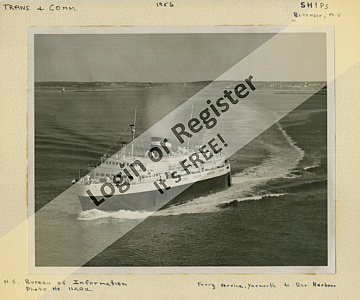

Ok, ok…I know…I havent quite completed the Pole Dancer (ne NAXOS) yet, but it is quite difficult getting the items I need to finish up. Shipment times seem quite long.

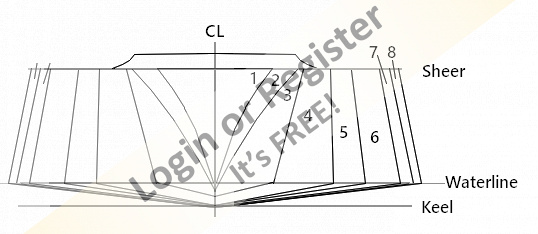

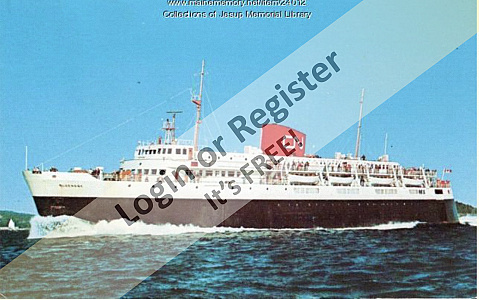

So, to take up the slack, I am pondering a 2nd project, the MV Bluenose - not to be confused with the sailing vessel Bluenose and Bluenose ll.

The MV Bluenose provided ferry passenger and vehicle service between my home town Yarmouth, Nova Scotia and Bar Harbour, Maine from 1955 till 1982. I am seeking drawings for her from Davie Shipbuilding, Quebec but have not received any return mail from them as of yet. I have her dimensions on hand from her wikki and. if I have to will make my own drawings from many online images that I have obtained from the internet

I have thought about several possibilities as far as construction material and will include that info on my DIY “Blueprints”.

Scale? I am aiming for semiscale and her overall length will be between 32” and 36” and breadth approximately 8”.

Wish me luck

So, to take up the slack, I am pondering a 2nd project, the MV Bluenose - not to be confused with the sailing vessel Bluenose and Bluenose ll.

The MV Bluenose provided ferry passenger and vehicle service between my home town Yarmouth, Nova Scotia and Bar Harbour, Maine from 1955 till 1982. I am seeking drawings for her from Davie Shipbuilding, Quebec but have not received any return mail from them as of yet. I have her dimensions on hand from her wikki and. if I have to will make my own drawings from many online images that I have obtained from the internet

I have thought about several possibilities as far as construction material and will include that info on my DIY “Blueprints”.

Scale? I am aiming for semiscale and her overall length will be between 32” and 36” and breadth approximately 8”.

Wish me luck

▲

⟩⟩

Peejay

Colin H

📝 Naxos

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 58 Views · 5 Likes · 1 Comment

Flag

💬 Add Comment

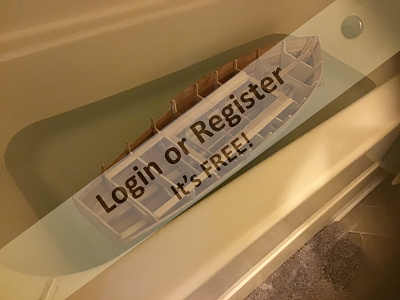

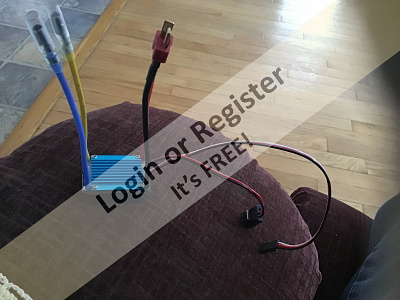

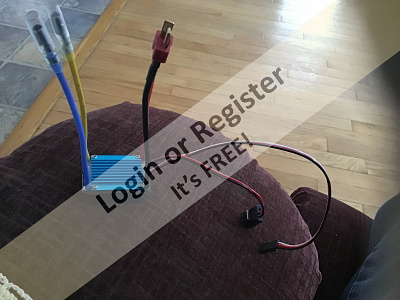

Finally - something to show and tell for my Naxos Project. After a very long delay and a lot of communication with my supplier, I received my Speed controller, and this morning, I received my main batteries - two 6v units each with 4.5Ah rating. It is my plan to parallel them.

The pictures show the placement of batteries, motor, Receiver, Speed controller and rudder servo. Bathtub float test indicates that she lies pretty fair in the H2o with possibility of a few oz of weight in the stern.

Somewhere I think I remember reading something about not placing the Rx neas an esc or the drive motor due to possibility noise pickup, so I may need to rethink that placement. I wonder how many of you boat captains wrapped the Rx in a few layers of plastic followed by a wrap or two of aluminum foil?

So, until the next time, thats all I got.

The pictures show the placement of batteries, motor, Receiver, Speed controller and rudder servo. Bathtub float test indicates that she lies pretty fair in the H2o with possibility of a few oz of weight in the stern.

Somewhere I think I remember reading something about not placing the Rx neas an esc or the drive motor due to possibility noise pickup, so I may need to rethink that placement. I wonder how many of you boat captains wrapped the Rx in a few layers of plastic followed by a wrap or two of aluminum foil?

So, until the next time, thats all I got.

▲

⟩⟩

Colin H

Mike Stoney

mturpin013

stevedownunder

Ronald

📝 Not much progress on the Naxos

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 69 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

Since covid seems to have consumed most of my activities, there has not been a lot of progress on my project. This is not because I have been sick with the virus, it has just been a chore getting parts that I have ordered.

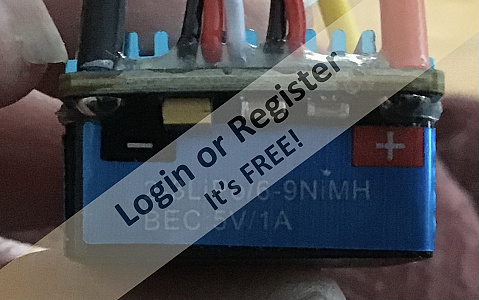

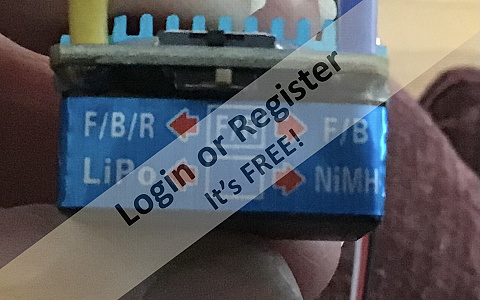

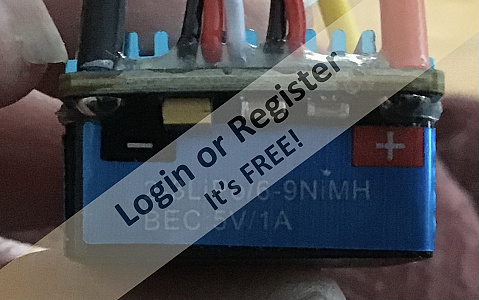

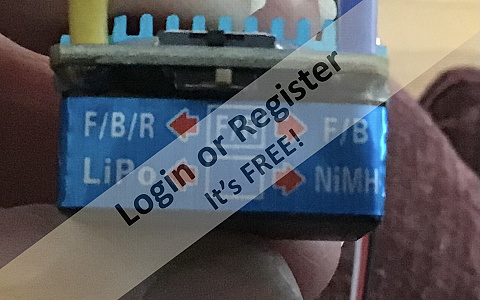

Today, I finally received the speed controller which is a New Rain 160A controller for a brushed motor (which I am using).

Now I face another issue for which I have very little knowledge...what battery to use for my boat. With this, I need advice.

The speed controller contains a switch which allows one to use a LiPo or NI-MH. Battery. Can I use a SLA battery in the NI-MH position? I have the room and reasonable weight (2-3kg) should not be a problem.

The ESC also has a braking switch, but I would operate the controller in the F/R mode only.

IF SLA battery is not my best choice, I would appreciate suggestions from you that know a whole lot more than I do.

Today, I finally received the speed controller which is a New Rain 160A controller for a brushed motor (which I am using).

Now I face another issue for which I have very little knowledge...what battery to use for my boat. With this, I need advice.

The speed controller contains a switch which allows one to use a LiPo or NI-MH. Battery. Can I use a SLA battery in the NI-MH position? I have the room and reasonable weight (2-3kg) should not be a problem.

The ESC also has a braking switch, but I would operate the controller in the F/R mode only.

IF SLA battery is not my best choice, I would appreciate suggestions from you that know a whole lot more than I do.

▲

⟩⟩

Colin H

Mike Stoney

stevedownunder

📝 WHAT IS THIS BOAT ? - Any ideas ??

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 61 Views · 0 Likes

Flag

📝 Reply

Its my boat, lol

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 WHAT IS THIS BOAT ? - Any ideas ??

4 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 61 Views · 0 Likes

Flag

📝 Reply

Hmmmm………….

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Remus is in pretty bad shape

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 44 Views · 3 Likes

Flag

📝 Reply

Hi Ron

If you don’t mind me adding my two cents worth, you might want to consider adding a bit more slope to the stem for your Remus. From the pictures I have seen, there appears to be quite a slope at the stem compared to NAXOS. This would be quite easy to do.

Just my opinion.

HC

If you don’t mind me adding my two cents worth, you might want to consider adding a bit more slope to the stem for your Remus. From the pictures I have seen, there appears to be quite a slope at the stem compared to NAXOS. This would be quite easy to do.

Just my opinion.

HC

▲

⟩⟩

Martin555

Scratchbuilder

Colin H

📝 Getting back into the project

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 90 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

The winter here seemed long. The constant threat of a dreaded virus for the past 1-1/2 years have made the winter seem even much longer. The workshop in my unheated basement means that no projects that require prolonged work get tended to, thus I am out of business from the late fall until mid Spring - which is now.

I need to take a bit of a look at placement for the electronics and get the various electrical connectors that I need. I also need to revamp access to the innards as simply removing the cabin doesn’t really leave an opening large enough to accommodate my large paws. Will post some shots on how I will do that. Hopefully by the end of June the maiden cruise will take place.

Now, on top of it all, my sister wants me to build a static Cape Island fishing boat for her. Our dear dad carved one out of a pine block for her years ago when she was about 6 or 7. Somehow in the years of moving here and there she lost it. By the way - do any of the members have a set of plans that they would like to share? (Wink, wink, hint, hint)😉😉

I need to take a bit of a look at placement for the electronics and get the various electrical connectors that I need. I also need to revamp access to the innards as simply removing the cabin doesn’t really leave an opening large enough to accommodate my large paws. Will post some shots on how I will do that. Hopefully by the end of June the maiden cruise will take place.

Now, on top of it all, my sister wants me to build a static Cape Island fishing boat for her. Our dear dad carved one out of a pine block for her years ago when she was about 6 or 7. Somehow in the years of moving here and there she lost it. By the way - do any of the members have a set of plans that they would like to share? (Wink, wink, hint, hint)😉😉

▲

⟩⟩

stevedownunder

Peejay

Martin555

jbkiwi

📝 Pole Dancer - holdup

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 94 Views · 2 Likes · 2 Comments

Flag

💬 Add Comment

The ESC I used is a fwd only, so had to order one that is reservable. Likely a couple of weeks before I get it.

Siiiiiggggggghhhhhhh.

Siiiiiggggggghhhhhhh.

▲

⟩⟩

MouldBuilder

Martin555

💬 Re: Naxos (Now “Pole Dancer”)

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 94 Views · 0 Likes

Flag

💬 Add Comment

Hi Doug

The one in Nfld is “St. John’s” while the one in NB (where I Live) is “Saint John”.

Mixups happen a lot in pretty well every service thats available.

Certainly hope you got to kiss the Cod and Drink the Screech when you got there.

The one in Nfld is “St. John’s” while the one in NB (where I Live) is “Saint John”.

Mixups happen a lot in pretty well every service thats available.

Certainly hope you got to kiss the Cod and Drink the Screech when you got there.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Naxos (Now “Pole Dancer”)

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 97 Views · 9 Likes · 5 Comments

Flag

💬 Add Comment

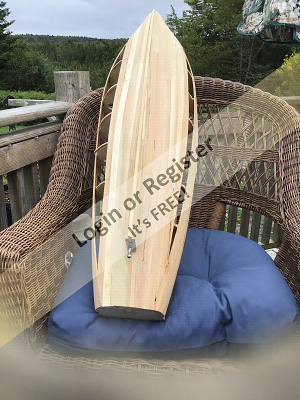

Here is the Pole Dancer (ex Naxos) as she is this date - Oct 09/2020

With not much work on her left, She is getting very close to her maiden voyage. Mostly electronics and testing to finish up. Hoping for mid November.

With not much work on her left, She is getting very close to her maiden voyage. Mostly electronics and testing to finish up. Hoping for mid November.

▲

⟩⟩

Mike Stoney

Peejay

Joe727

figtree7nts

stevedownunder

Colin H

MouldBuilder

Martin555

RNinMunich

📝 NAXOS - Equipment panel

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 95 Views · 5 Likes · 1 Comment

Flag

💬 Add Comment

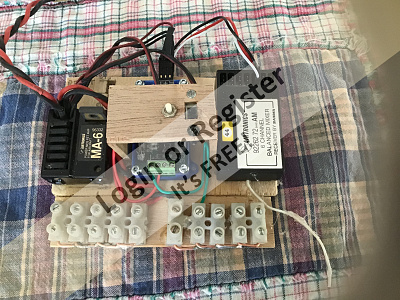

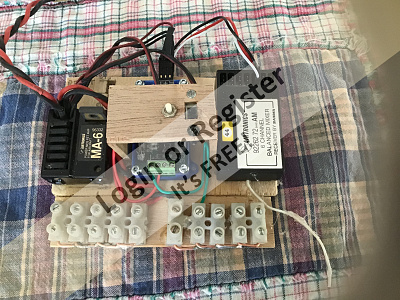

Here is my equipment panel. It is about 5 inches wide and 4 inches high.

Extreme left - Airtronics ESC - 20A

Center - on/off switch for the ESC. Small white button is the ESC reset.

Center - (below the ESC panel is the sound module

Right - the Receiver - Airtronics 6 ch

Along the bottom is the +Bat bus and -Bat bus.

Extreme left - Airtronics ESC - 20A

Center - on/off switch for the ESC. Small white button is the ESC reset.

Center - (below the ESC panel is the sound module

Right - the Receiver - Airtronics 6 ch

Along the bottom is the +Bat bus and -Bat bus.

▲

⟩⟩

jbkiwi

stevedownunder

MouldBuilder

Martin555

RNinMunich

📝 Naxos - Main Battery

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 94 Views · 4 Likes · 3 Comments

Flag

💬 Add Comment

I am up against it here and seeking advice on the main battery type to use. I have read lots on lithium ion and lipo polymir and hazards associated with charging and storing them. I know absolutely nothing about this battery technology and don’t relish turning my hard work nor my home into a pile of smouldering cinders. For this reason, I am leaning toward the SLA battery of 2 to 4ah rating. The weight and physical size of these smaller units will work well for fitting into the allocated space of the battery compartment. I could even parallel them for approximately twice the ah rating.

Some advice on this please!

Some advice on this please!

▲

⟩⟩

stevedownunder

billmcl61

Colin H

Martin555

💬 Re: Naxos - Paint Shop

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 94 Views · 1 Like

Flag

💬 Add Comment

Hey Ken

Thanks for the comment on the paint. AllI can tell you is good old Rustoleum spray paint, calm winds and a nice dry sunshine day, and outhouse luck. Hope it don’t look too good though or I will have to convert her to a yacht, har! har!

Thanks for the comment on the paint. AllI can tell you is good old Rustoleum spray paint, calm winds and a nice dry sunshine day, and outhouse luck. Hope it don’t look too good though or I will have to convert her to a yacht, har! har!

▲

⟩⟩

Martin555

💬 Re: Naxos - latest progress

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 94 Views · 1 Like

Flag

💬 Add Comment

Hey - Martin

i tend to agree with you 100% on the WL looking low. It is very close to where it shows on the plan. Maybe I didn’t weight her enough during the float test and I marked it with pencil during the float test at the stem and stern.

Anyway, will have another look at it with radio gear and batteries. Maybe I will have to mix lead shot and glue to get her to sit so she looks good and mark the WL from that.

Anyway, thanks for your input...appreciated.

i tend to agree with you 100% on the WL looking low. It is very close to where it shows on the plan. Maybe I didn’t weight her enough during the float test and I marked it with pencil during the float test at the stem and stern.

Anyway, will have another look at it with radio gear and batteries. Maybe I will have to mix lead shot and glue to get her to sit so she looks good and mark the WL from that.

Anyway, thanks for your input...appreciated.

▲

⟩⟩

Martin555

📝 Naxos - latest progress

5 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 95 Views · 6 Likes · 3 Comments

Flag

💬 Add Comment

Well,gave the old girl a waterline. Levelled her up and used my cheapir lazer level. Even though it checks level, it looks like it swoops down 1/4” to 3/8” about a quarter of the way back from th stem...just doesnt look quite right sideview.

Next I finished the decking. All straight runs were easy, but cutting, trimming and fitting the pieces between the uprights was slow work, and a real pain. If I had to do it again, I would have added them after. Hindsight!

Next, the prop arrived so now she has propulsion. Should have rethought the stuffing box a bit more and got a 30cm unit instead of the 25cm because it is nearly impossible to get at the set screw for the U joint. It would be reachable with a “t” handle Allen key or at least a long Allen key down through the hole in the deck for the mast. Will put a collar at the bottom of the mast to prevent the mast from slipping down through the deck. The sidestays and forestay are used for holding the mast upright.

So, that’s it for this post.

Next I finished the decking. All straight runs were easy, but cutting, trimming and fitting the pieces between the uprights was slow work, and a real pain. If I had to do it again, I would have added them after. Hindsight!

Next, the prop arrived so now she has propulsion. Should have rethought the stuffing box a bit more and got a 30cm unit instead of the 25cm because it is nearly impossible to get at the set screw for the U joint. It would be reachable with a “t” handle Allen key or at least a long Allen key down through the hole in the deck for the mast. Will put a collar at the bottom of the mast to prevent the mast from slipping down through the deck. The sidestays and forestay are used for holding the mast upright.

So, that’s it for this post.

▲

⟩⟩

mturpin013

MouldBuilder

ianed57

stevedownunder

Colin H

Martin555

📝 Naxos - Paint Shop

6 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 96 Views · 7 Likes · 6 Comments

Flag

💬 Add Comment

Took the old girl into the paint shop today. Hull is a tan colour with teal roof and white superstructure

Now waiting for the portholes to come in then Will do the window glazing (plastic, of course) And paint the interior.

So far, so good, and I am actually quite proud of my “girl”

Now waiting for the portholes to come in then Will do the window glazing (plastic, of course) And paint the interior.

So far, so good, and I am actually quite proud of my “girl”

▲

⟩⟩

MouldBuilder

RNinMunich

jbkiwi

ianed57

Martin555

stevedownunder

Ronald

📝 NAXOS - 20/11/14

6 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 96 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

Was a busy day for real life things so just put the top rail and tidied up a few other things. Also, removed the decking experiment - didn’t like it. Will get some 1/8 x 3/8 basswood For decking.

The coffee is to give you guys the impression that I don’t just work on my boat ..... I do other things as awll, haw, haw, haw!

The coffee is to give you guys the impression that I don’t just work on my boat ..... I do other things as awll, haw, haw, haw!

▲

⟩⟩

Joe727

jbkiwi

ianed57

Martin555

stevedownunder

MouldBuilder

Colin H

📝 NAXOS - Decking

6 years ago by 🇨🇦 hecrowell ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 81 Views · 5 Likes · 4 Comments

Flag

💬 Add Comment

This is more or less an experiment for me. Using the same width decking as I used for planking. Laid most of the fwd decking and sanded it nice and flat. Dressed the joints with lead pencil to make it look somewhat like deck caulking. As one member reminded me - its only a fishing boat, not a yacht. Br fussy, but don't worry too much if a planking seam is showing a bit or a little dent.

▲

⟩⟩

Colin H

jbkiwi

stevedownunder

Martin555

Peejay

Fleet Admiral)

Fleet Admiral)

Liked WHAT IS THIS BOAT ? - Any ideas ?? 4 years ago

Liked WHAT IS THIS BOAT ? - Any ideas ?? 4 years ago