Join Us On Social Media!

New Zealand

Recent Posts

📝 AIRBOAT No 2

11 hours ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 1 View · 2 Likes

Flag

💬 Add Comment

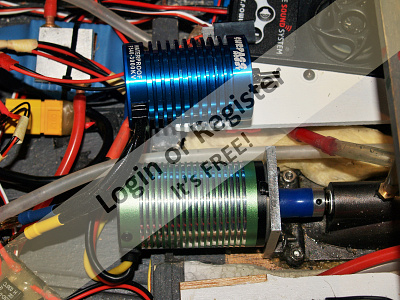

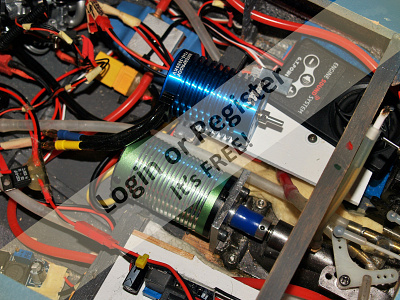

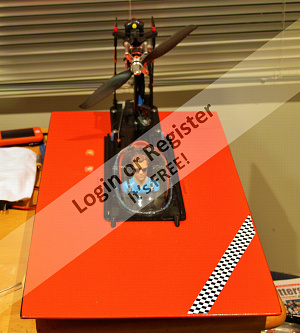

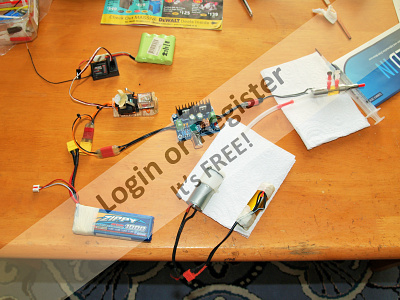

Another airboat, this time made from a 33" x 18" foam body board, and powered by a 3648 1450kv 50A outrunner with a pusher prop, and 3s 4000mah LiPo

▲

⟩⟩

stevedownunder

chugalone100

Login To

Remove Ads

Remove Ads

📝 SEMI SCALE 1953 EDSON SCHOCK 15FT DAY SAILER

12 hours ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 1 View · 6 Likes · 3 Comments

Flag

💬 Add Comment

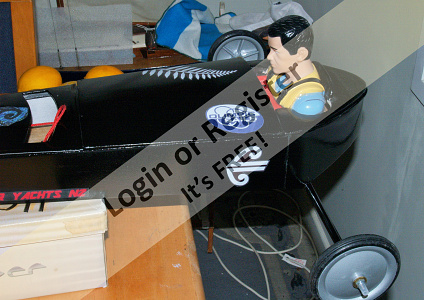

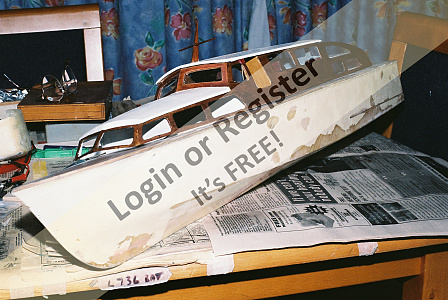

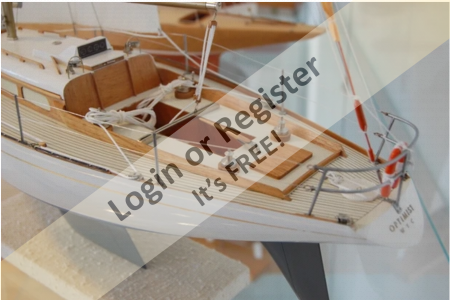

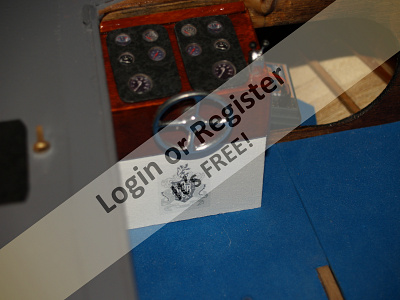

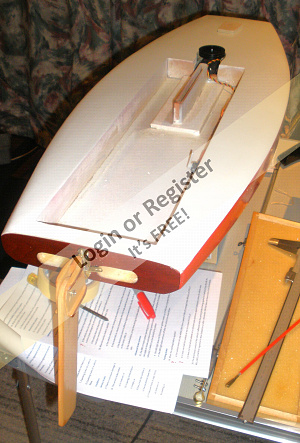

A 1/5 semi scale model of my 15ft day sailer,- designed by US naval architect Edson I Schock in 1953. The original was built in NZ in the late 80s and I bought and restored it in 2008. Thought it would be nice to have an RC model of it, so measured the boat and made the model 1/5 scale.

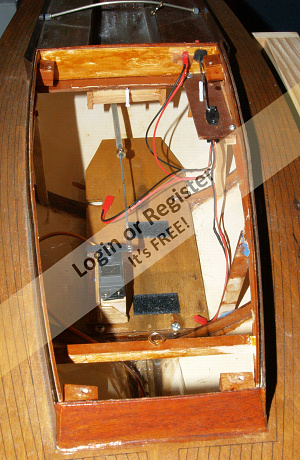

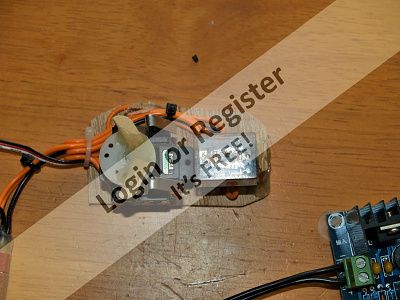

Model is made from polystyrene foam, shaped and f/glassed with a ply deck and ply lined cockpit and ply transom. Uses a HiTec winch with a floor mounted sheet hauler pulley system.

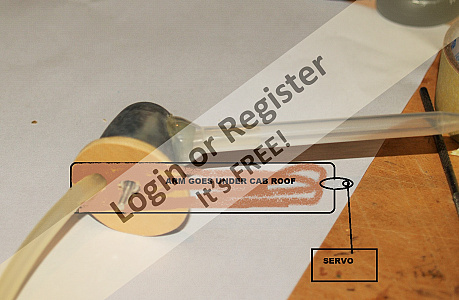

The skipper is servo powered and ducks under the boom when tacking

Model is made from polystyrene foam, shaped and f/glassed with a ply deck and ply lined cockpit and ply transom. Uses a HiTec winch with a floor mounted sheet hauler pulley system.

The skipper is servo powered and ducks under the boom when tacking

▲

⟩⟩

cjanik001

stevedownunder

hermank

ColinJ2

Ronald

chugalone100

💬 Re: New Moth MKII semi scale yacht

12 hours ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 8 Views · 1 Like

Flag

💬 Add Comment

Hi Ron,- using rip stop nylon

JB

JB

▲

⟩⟩

stevedownunder

📝 New Moth MKII semi scale yacht

3 days ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 23 Views · 8 Likes · 3 Comments

Flag

💬 Add Comment

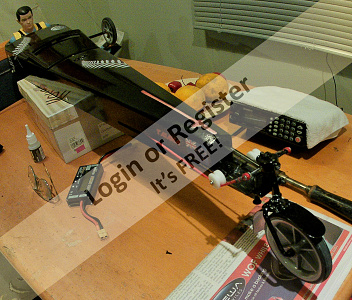

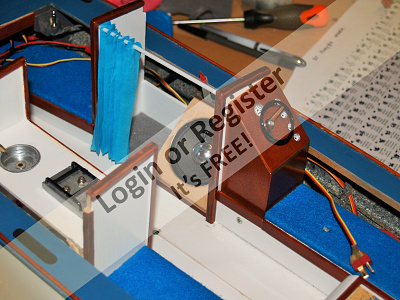

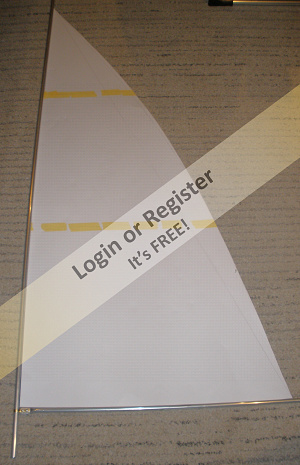

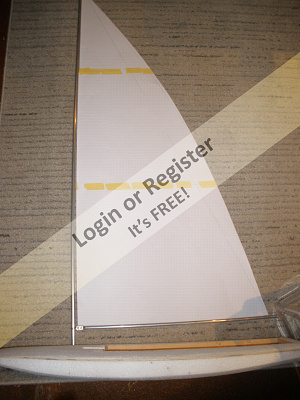

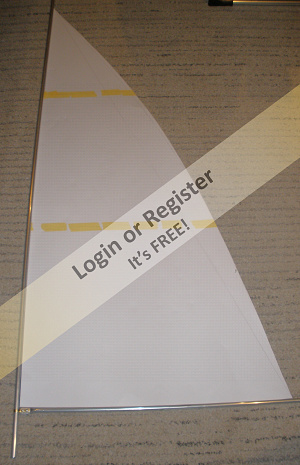

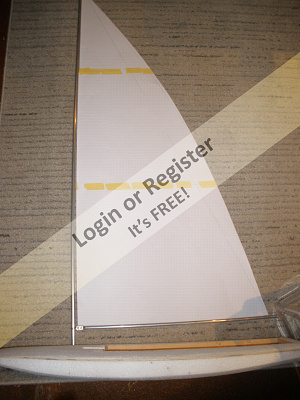

Cut the sail last night using a Weller soldering gun, and managed to get the luff and foot taped ready to sew. Rather than make a mess with my sewing, I decided to take it to the experts a few houses down the road, where a couple of ladies do alterations in a well set up workshop. I'm getting them to sew the foot and luff, and sail batten pockets (which I made a wrinkly mess of on the first catamaran sail) . There is a special folded hemming? tape the lady showed me which looked ideal for those. Hopefully it will all come out nice and flat.

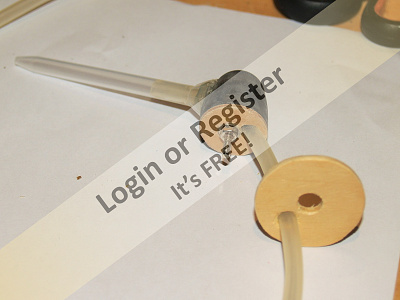

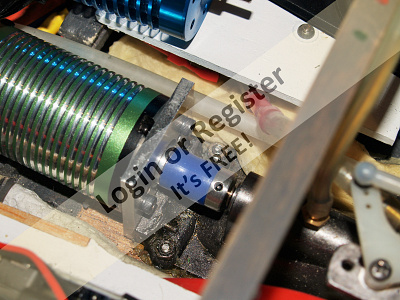

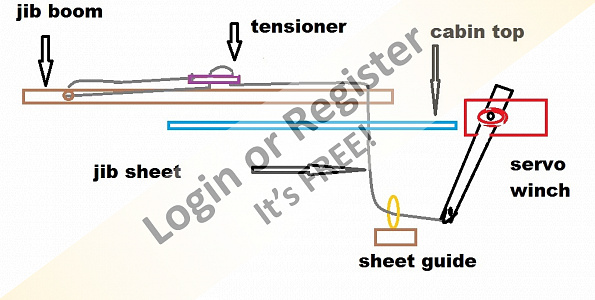

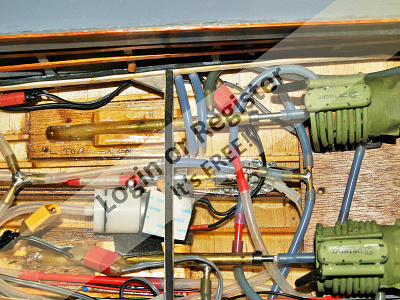

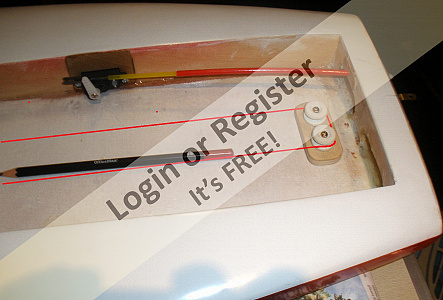

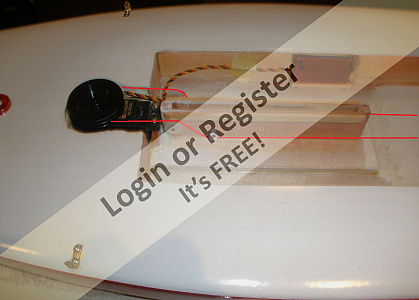

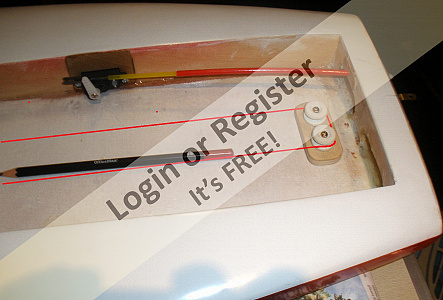

Also worked out the sheet hauler pulley system which is similar to the last day-sailer yacht I built. Comes off the winch one side lower than the other, so the initial pulley for the top of the drum, is slightly higher than the lower drum side pulley. The line goes over that and under a guide at the bottom of the c/board case, and back around the 2 rear pulleys in a continuous loop, as per normal. The dropper idea gets the lines down near the floor and less obvious. A bit harder to do than a yacht where the lines are all internal and out of sight.

The rear 2 pulleys are made from tuned down bungy tie down buttons used on utes or trailers, drilled out for a brass tube insert, and bolted to a ply plate with 3mm machine screws with nuts pressed and cyano'd into the bottom.

Sail will need fitting when it's done, and cockpit needs painting before everything is screwed on permanently. Still have to figure out how I'm going to fit the battery.

JB

Also worked out the sheet hauler pulley system which is similar to the last day-sailer yacht I built. Comes off the winch one side lower than the other, so the initial pulley for the top of the drum, is slightly higher than the lower drum side pulley. The line goes over that and under a guide at the bottom of the c/board case, and back around the 2 rear pulleys in a continuous loop, as per normal. The dropper idea gets the lines down near the floor and less obvious. A bit harder to do than a yacht where the lines are all internal and out of sight.

The rear 2 pulleys are made from tuned down bungy tie down buttons used on utes or trailers, drilled out for a brass tube insert, and bolted to a ply plate with 3mm machine screws with nuts pressed and cyano'd into the bottom.

Sail will need fitting when it's done, and cockpit needs painting before everything is screwed on permanently. Still have to figure out how I'm going to fit the battery.

JB

▲

⟩⟩

GaryLC

chugalone100

stevedownunder

hermank

luckyduck

DWBrinkman

Ronald

jumpugly

📝 RESTORING MODELS

3 days ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 47 Views · 6 Likes

Flag

📝 Reply

Excellent restoration of a complicated model!

JB

JB

▲

⟩⟩

hermank

DWBrinkman

AlessandroSPQR

jumpugly

Wolle

chugalone100

💬 Re: New Moth MKII semi scale yacht

7 days ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 34 Views · 6 Likes

Flag

💬 Add Comment

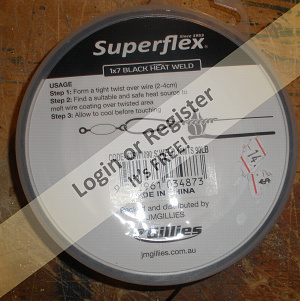

Hi guys, thanks for the kind comments. Re crimps Chris, they are just pieces of 3mm copper tube, cut to length from some K&S precision metals (USA) stock, and crimped with Bonito pliers (for making fishing traces). The plastic coated stainless trace wire I used was able to be twisted and fused with heat, but crimping was easier.

JB

JB

▲

⟩⟩

philcaretaker

chugalone100

ChrisF

stevedownunder

premecekcz

hermank

📝 New Moth MKII semi scale yacht

8 days ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 37 Views · 10 Likes · 4 Comments

Flag

💬 Add Comment

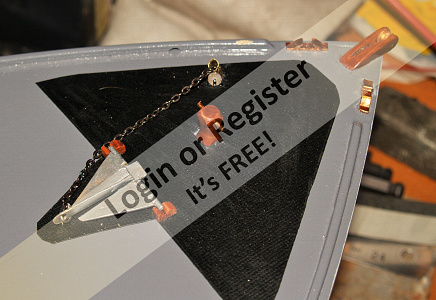

Have poured the lead into the c/board mould and it came out well. I've filed the good side (wooden mould side) to a curved shape, and filed the top side flush with the aluminium center. I used a Surform file which I have found to be the best for lead, (a slightly used one is best as it won't grab). The filings and a few other bits will be used in the mould to make an identical side to be attached to the flat side, which will be filed to match the other side.

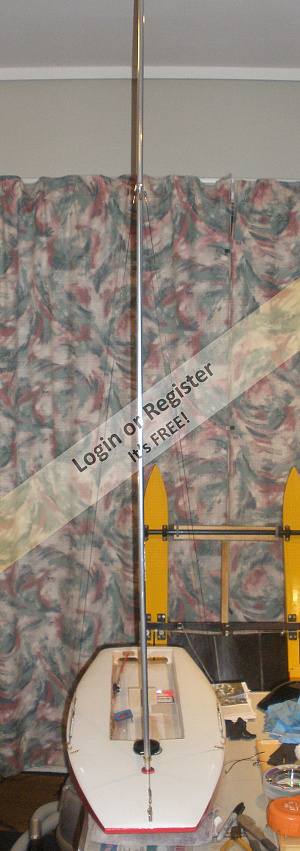

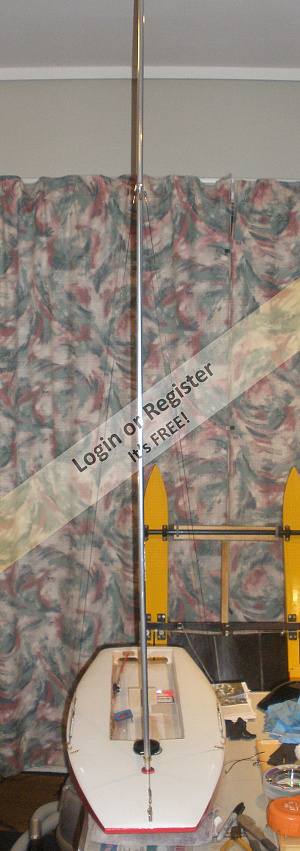

I've also rigged the mast, and made a pair of turnbuckles for the side stays. They were made from 5mm aluminium rod, drilled and tapped for 3 x 30mm machine screws. The screw heads were peened flat and a 2mm hole drilled through them. One end of each the aluminium rod was carved with the tip of the lathe tool by turning the chuck by hand and making a knurled effect for grip.

The top end of the rod was cross drilled 2mm, then cross cut at 90deg to the holes with a hacksaw. 2 small fishing swivels had one end loop peened flat on each to fit into the slots, then held in place with brass pins with soldered ends to keep them in place. Brass wire hooks were bent and soldered through the drilled screw heads for the chainplate ends.

Mast had a center drilled dowel inserted in the bottom for a locating pin, which was cyano'd in.

Stays were made from plastic coated stainless fishing trace, the trace was fed through a brass ferrule, through the attachments on the turnbuckles, back through the ferrules, adjusted and then crimped in place (leaving half the thread on the turnbuckles for final adjustment.)

Brass chainplates were made, and screwed through the deck f/glass into the ply sub deck below. Sail template needs some adjustment, then I'll be having a look at making the sail. The template is pretty close to scale, so sailing is going to be 'interesting" !

JB

I've also rigged the mast, and made a pair of turnbuckles for the side stays. They were made from 5mm aluminium rod, drilled and tapped for 3 x 30mm machine screws. The screw heads were peened flat and a 2mm hole drilled through them. One end of each the aluminium rod was carved with the tip of the lathe tool by turning the chuck by hand and making a knurled effect for grip.

The top end of the rod was cross drilled 2mm, then cross cut at 90deg to the holes with a hacksaw. 2 small fishing swivels had one end loop peened flat on each to fit into the slots, then held in place with brass pins with soldered ends to keep them in place. Brass wire hooks were bent and soldered through the drilled screw heads for the chainplate ends.

Mast had a center drilled dowel inserted in the bottom for a locating pin, which was cyano'd in.

Stays were made from plastic coated stainless fishing trace, the trace was fed through a brass ferrule, through the attachments on the turnbuckles, back through the ferrules, adjusted and then crimped in place (leaving half the thread on the turnbuckles for final adjustment.)

Brass chainplates were made, and screwed through the deck f/glass into the ply sub deck below. Sail template needs some adjustment, then I'll be having a look at making the sail. The template is pretty close to scale, so sailing is going to be 'interesting" !

JB

▲

⟩⟩

luckyduck

RossM

philcaretaker

GaryLC

chugalone100

stevedownunder

premecekcz

hermank

ChrisF

jumpugly

📝 New Moth MKII semi scale yacht

13 days ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 42 Views · 7 Likes

Flag

💬 Add Comment

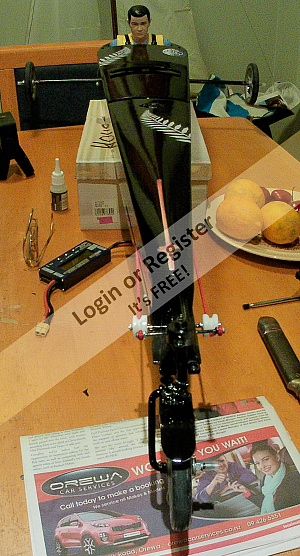

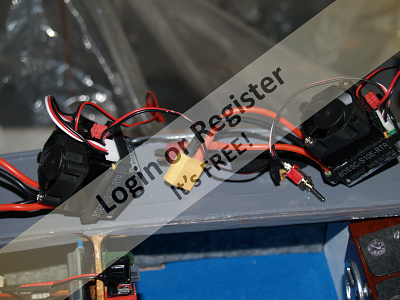

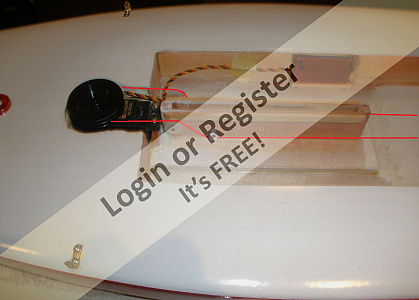

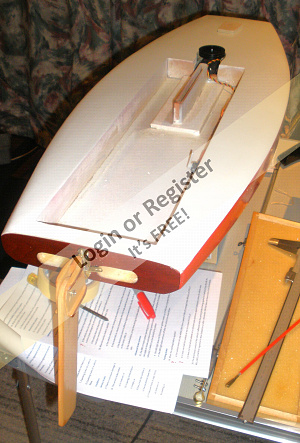

Deck has been painted now, and the walnut transom veneer epoxied on, stained and varnished. The winch has been fitted and the pocket it fits in has had all the foam surfaces (from cutting the pocket) epoxied to prevent any water getting in. Managed to get the ESC hidden in a side 'pocket, and the rudder servo mounted and working. A tunnel was bored through the foam between the rudder servo and the ESC, so as to keep the servo lead (fitted with a servo extender) out of sight and dry. Rudder servo will be waterproofed with Vaseline in the casing joints and round the output shaft, will also have a splash cover to keep anything major off it, and will be sealed into the cockpit side with some silicone. Self draining cockpit should let most of the water out.

The side pocket for the ESC, has a waterproof cover which will be screwed on once everything is finally installed and set up, after the cockpit is painted. The glass covering the bottom of the c/board slot, has been cut out, with the balsa plug (previously fitted before glassing) doing its' job stopping any resin intruding into the case.

The centerboard is something I've been working at,- thinking of ways to avoid having a large bulb, which would not suit a small c/board racing dinghy. Here's what I'm going to try as a way round it. If this works, it should end up with a slightly fat fin, rather than a big blob on the end. I'm only after good self righting from horizontal, but not a 'stick to the water upright' sort of weight, as the whole idea is for the boat to plane easily.

Re c/board. -- milled out the aluminium centerboard last night for the lead infill. I bolted the 2 50mmx3mm halves together with 3mm drilled and tapped machine screws, and they will be clamped over the block which has the same profile routered out of it, then filled with lead (hopefully it won't pour out everywhere!) The block itself will have another lot of lead poured in after that, to make the other side of the c/board, well that's the theory ! If it looks good, it will be glassed and painted.

At the same time as this, I've been knocking up a new improved beach trolley for my restored 11ft 70s vintage Cherokee racing dinghy, which is going on display with many other small yachts at our next Auckland Wooden Boat Festival in March, plus- putting a new roof on my bathroom,- so modeling progress is a bit slow at the moment. Hopefully pouring some lead today.

JB

The side pocket for the ESC, has a waterproof cover which will be screwed on once everything is finally installed and set up, after the cockpit is painted. The glass covering the bottom of the c/board slot, has been cut out, with the balsa plug (previously fitted before glassing) doing its' job stopping any resin intruding into the case.

The centerboard is something I've been working at,- thinking of ways to avoid having a large bulb, which would not suit a small c/board racing dinghy. Here's what I'm going to try as a way round it. If this works, it should end up with a slightly fat fin, rather than a big blob on the end. I'm only after good self righting from horizontal, but not a 'stick to the water upright' sort of weight, as the whole idea is for the boat to plane easily.

Re c/board. -- milled out the aluminium centerboard last night for the lead infill. I bolted the 2 50mmx3mm halves together with 3mm drilled and tapped machine screws, and they will be clamped over the block which has the same profile routered out of it, then filled with lead (hopefully it won't pour out everywhere!) The block itself will have another lot of lead poured in after that, to make the other side of the c/board, well that's the theory ! If it looks good, it will be glassed and painted.

At the same time as this, I've been knocking up a new improved beach trolley for my restored 11ft 70s vintage Cherokee racing dinghy, which is going on display with many other small yachts at our next Auckland Wooden Boat Festival in March, plus- putting a new roof on my bathroom,- so modeling progress is a bit slow at the moment. Hopefully pouring some lead today.

JB

▲

⟩⟩

philcaretaker

GaryLC

chugalone100

stevedownunder

premecekcz

hermank

jumpugly

📝 New Moth MKII semi scale yacht

30 days ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 45 Views · 8 Likes

Flag

💬 Add Comment

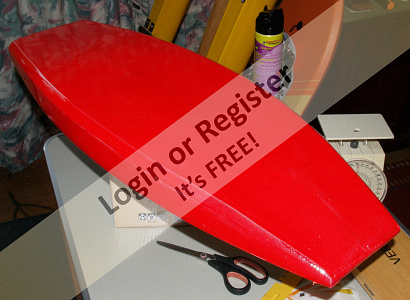

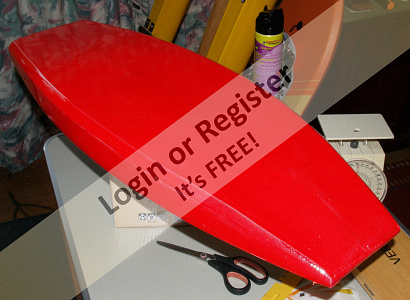

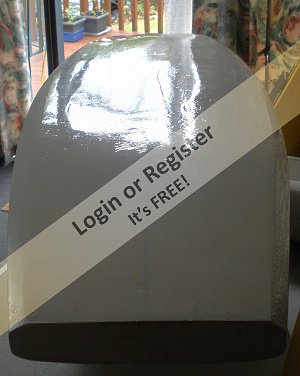

Hull's back to red paint now after the Zinsser coat which fixed the fisheyes. Added some mahogany trim to the rudder stock, and have now cut out the self draining slots in the transom, (i think it's going to need them) The foam between the cockpit ply and transom will need filling and coating round the inside of the drains. Still have the deck to paint (over the white resin) and a veneer to go on the transom (varnished). After that,- fittings. Decided to leave the rudder unpainted, looks ok as is I think.

Rough weather slowing things down at the moment, heavy rain, landslides (unfortunately people missing,) slips everywhere, flooding etc . It's supposed to be summer !

JB

Rough weather slowing things down at the moment, heavy rain, landslides (unfortunately people missing,) slips everywhere, flooding etc . It's supposed to be summer !

JB

▲

⟩⟩

philcaretaker

chugalone100

premecekcz

stevedownunder

luckyduck

jumpugly

ChrisF

hermank

📝 How much is too much? (If it ain't free and I need to volunteer then I ain't joining.)

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 50 Views · 6 Likes

Flag

📝 Reply

Hi Lew,

same everywhere, I think. Some of it is because of pressures at home, looking after kids with all the after school activities and sports these days kids demand. We used to amuse ourselves as kids, and didn't need to have our parents cart us everywhere, maybe bike for miles to watch model planes etc. The way work is these days with staggered hours, working weekends etc, cuts peoples time down, whereas in the 60s and 70s it was 9 to5 or 8 to 5, everybody had holidays at the same time,- hardly anyone worked on weekends- one late night a week, now it's all over the place.

Don't know about the US, but here in NZ, parents may not be able to have holidays together due to different work schedules, may have to arrange holidays a month or 2 ahead. Now there are virtually no model club or car club activities advertised in papers etc, all on facebook now, and if you don't use facebook, you miss out. Seems to be the way things are going now, organisers just send out a post to members on where and when.

I found a massive Jap car get together at our local bus station park and ride by sheer luck,- looked everywhere, not a mention, seemed to be a random get together by phone. many 'clubs' don't even have a website these days, but have hundreds of 'members' floating around.

JB

same everywhere, I think. Some of it is because of pressures at home, looking after kids with all the after school activities and sports these days kids demand. We used to amuse ourselves as kids, and didn't need to have our parents cart us everywhere, maybe bike for miles to watch model planes etc. The way work is these days with staggered hours, working weekends etc, cuts peoples time down, whereas in the 60s and 70s it was 9 to5 or 8 to 5, everybody had holidays at the same time,- hardly anyone worked on weekends- one late night a week, now it's all over the place.

Don't know about the US, but here in NZ, parents may not be able to have holidays together due to different work schedules, may have to arrange holidays a month or 2 ahead. Now there are virtually no model club or car club activities advertised in papers etc, all on facebook now, and if you don't use facebook, you miss out. Seems to be the way things are going now, organisers just send out a post to members on where and when.

I found a massive Jap car get together at our local bus station park and ride by sheer luck,- looked everywhere, not a mention, seemed to be a random get together by phone. many 'clubs' don't even have a website these days, but have hundreds of 'members' floating around.

JB

▲

⟩⟩

DWBrinkman

stevedownunder

Madwelshman

premecekcz

Mike Stoney

hermank

📝 New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 47 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

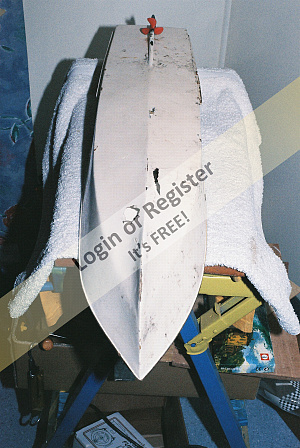

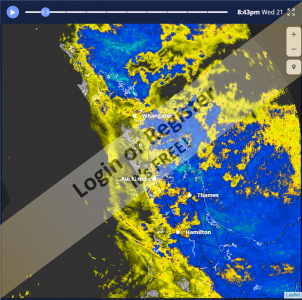

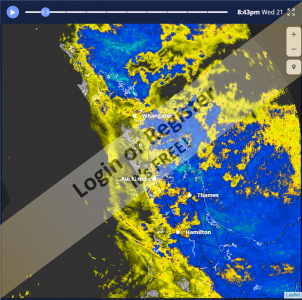

More sanding and fairing on the hull lately, (not so much the last week, as it's been raining non stop the whole week, (big storm, see todays' rain radar pic,- NZ's under there somewhere 😐) - floods everywhere,- workshop downstairs has a tiny stream running through due to a retaining wall leak and water coming from underground,- happens whenever we get torrential persistent rain, eventually most drains out, then its mop time. Does no damage, just a nuisance. Just got my new bathroom roof on in time,- and no leaks,- good test though.

Re-resin coated the hull and tried using red tinted resin as a final coat. Looked good from a distance, super shiny, but was a bit opaque over the previous white and for some reason had a number of small 'fish eyes' from some wax bleeding through. I'd super degreased it, but it still happened. Sanded that back and tried again,-scrubbed it with degreaser and isopropyl alcohol,- same thing, same spots !*%^

Gave up, sanded it back and coated it with Zinsser stain blocker, which usually fixes most problems. Have to wait till the sun comes back to paint it with epoxy enamel.

Just finished building the rudder, stock and gudgeon and pintle setup. Rudder laminated with 3 pieces of basswood, then glassed using polyester aircraft cloth. Another resin coat after that. Stock was from basswood, coated with resin. Will be painted eventually.

Slowly progressing.

JB

Re-resin coated the hull and tried using red tinted resin as a final coat. Looked good from a distance, super shiny, but was a bit opaque over the previous white and for some reason had a number of small 'fish eyes' from some wax bleeding through. I'd super degreased it, but it still happened. Sanded that back and tried again,-scrubbed it with degreaser and isopropyl alcohol,- same thing, same spots !*%^

Gave up, sanded it back and coated it with Zinsser stain blocker, which usually fixes most problems. Have to wait till the sun comes back to paint it with epoxy enamel.

Just finished building the rudder, stock and gudgeon and pintle setup. Rudder laminated with 3 pieces of basswood, then glassed using polyester aircraft cloth. Another resin coat after that. Stock was from basswood, coated with resin. Will be painted eventually.

Slowly progressing.

JB

▲

⟩⟩

philcaretaker

chugalone100

stevedownunder

jumpugly

premecekcz

luckyduck

hermank

Login To

Remove Ads

Remove Ads

💬 Re: New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 53 Views · 2 Likes

Flag

💬 Add Comment

Hi Dave, are you in Minnesota or or Florida? You guys are getting a thrashing with the weather lately. Summer is a bit late starting here, but the temps are warmer than usual (usually round 25-28C-ish in Auckland, (I'm 33miles Nth of the city center) but been over 30 at times. Raining here at the moment, but still 27.8C (82F) and a bit humid. We are still nowhere near places where 45C is common luckily, don't think that would be pleasant.

Our temp averages look to be very similar to Arizona (surprised me, I thought we would be much lower) At least we don't have snow in Auckland in winter ! only in the central North Island plateau and South island.

JB

Our temp averages look to be very similar to Arizona (surprised me, I thought we would be much lower) At least we don't have snow in Auckland in winter ! only in the central North Island plateau and South island.

JB

▲

⟩⟩

stevedownunder

hermank

💬 Re: New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 54 Views · 1 Like

Flag

💬 Add Comment

Hi Steve,

a few showers today, and back to 25C at 10pm this evening. Mostly an even 21 in the city the entire day today, (1am to 10pm) but we are always warmer up here on the coast for some reason.

JB

a few showers today, and back to 25C at 10pm this evening. Mostly an even 21 in the city the entire day today, (1am to 10pm) but we are always warmer up here on the coast for some reason.

JB

▲

⟩⟩

hermank

📝 New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 54 Views · 7 Likes

Flag

💬 Add Comment

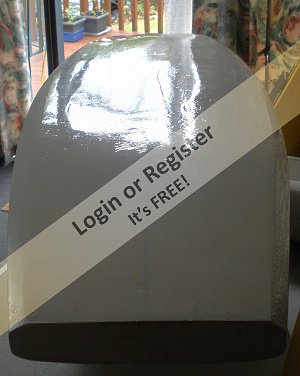

More sanding and fairing done. Tried tinting one of the resin coats, and it turned out well,- another coat and I wouldn't have needed to paint it !. But- it showed up bits I wasn't happy with, so mixed up some more resin and fairing powder and gave it another coat. Sanded that back today, and gave the deck another white tinted resin coat.

Not getting too carried away at this stage,- just getting it to a stage worth undercoating, as I want to see if it sails before spending money on paint. I'll be tinting a colour for the bottom as well, as that's not looking too bad at the moment, fairing wise.

JB

Not getting too carried away at this stage,- just getting it to a stage worth undercoating, as I want to see if it sails before spending money on paint. I'll be tinting a colour for the bottom as well, as that's not looking too bad at the moment, fairing wise.

JB

▲

⟩⟩

chugalone100

philcaretaker

AndyB2

stevedownunder

hermank

jumpugly

luckyduck

📝 New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 56 Views · 8 Likes · 7 Comments

Flag

💬 Add Comment

Even hotter day today, (37C in the shed) so added some more f/glass. The bottom was trimmed and sanded back, then some glass tissue was laid over (the previous night) to help with fairing. When that was set, it was sanded back. The deck was then glassed with 200gsm cloth. After that set, it was sanded back, and a coat of thick resin and filler was squeegeed over the deck and bottom to get rid of a few imperfections.

That will all be sanded smooth, and if satisfactory, will be painted with a thick acrylic primer, with more sanding to go. getting closer to the fun part of making the fittings and installing the gear. Hull now weighs 1.4kg,- (was 1.3kg before deck glass) hoping it will end up around 1.5kg when painted

JB

That will all be sanded smooth, and if satisfactory, will be painted with a thick acrylic primer, with more sanding to go. getting closer to the fun part of making the fittings and installing the gear. Hull now weighs 1.4kg,- (was 1.3kg before deck glass) hoping it will end up around 1.5kg when painted

JB

▲

⟩⟩

chugalone100

philcaretaker

Madwelshman

stevedownunder

jumpugly

oefranz

hermank

luckyduck

💬 Re: New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 56 Views · 2 Likes

Flag

💬 Add Comment

Hi Steve, even toaster today !

33.5 inside today,- shed 37, grass 40?! deck temp 69, Highest temp ever since I've been on the coast here in Orewa, (16yrs) good for the glass again though! No aircon, every window and door open and still 31 inside with a breeze blowing through. I think someone's cut our anchor cable and we've drifted over the ditch towards you guys 😀

With your last big fires a few years back, our sky went red, and the smoke here was like something was on fire locally, and it was like dusk at 3pm. Amazing it can travel over 1000 miles and still be so strong. Same thing happened back in the 70s during a huge fire there, when Skippys' place burnt down in the Ku-Ring-Gai Chase park. I was living in Sydney, and I'd been right up to the end of the chase about 2 months before I came back- and the fire happened not long after. The whole place was 6ft thick bracken and bush, and went up like a match. Being a dead end, there's no escape from there if there's a fire.

We also get plagues of your Xmas/ golden nectar beetles which get everywhere in the house. Hope there are no fires near you, sounds a bit rough at the moment ! What area are you in?

JB

33.5 inside today,- shed 37, grass 40?! deck temp 69, Highest temp ever since I've been on the coast here in Orewa, (16yrs) good for the glass again though! No aircon, every window and door open and still 31 inside with a breeze blowing through. I think someone's cut our anchor cable and we've drifted over the ditch towards you guys 😀

With your last big fires a few years back, our sky went red, and the smoke here was like something was on fire locally, and it was like dusk at 3pm. Amazing it can travel over 1000 miles and still be so strong. Same thing happened back in the 70s during a huge fire there, when Skippys' place burnt down in the Ku-Ring-Gai Chase park. I was living in Sydney, and I'd been right up to the end of the chase about 2 months before I came back- and the fire happened not long after. The whole place was 6ft thick bracken and bush, and went up like a match. Being a dead end, there's no escape from there if there's a fire.

We also get plagues of your Xmas/ golden nectar beetles which get everywhere in the house. Hope there are no fires near you, sounds a bit rough at the moment ! What area are you in?

JB

▲

⟩⟩

stevedownunder

hermank

💬 Re: New Moth MKII semi scale yacht

1 month ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 58 Views · 3 Likes

Flag

💬 Add Comment

Hi Steve,

35C in my shed yesterday, while I was adding the deck f/glass,- 30C in the house. F/glass was setting in around 2 hrs ! I try and stay out of the sun here, as we have very high UV due to a hole in the ozone layer over Antarctica. We have the highest skin cancer rate in the world, but still have all the idiots sun bathing all day on the beaches.

JB

35C in my shed yesterday, while I was adding the deck f/glass,- 30C in the house. F/glass was setting in around 2 hrs ! I try and stay out of the sun here, as we have very high UV due to a hole in the ozone layer over Antarctica. We have the highest skin cancer rate in the world, but still have all the idiots sun bathing all day on the beaches.

JB

▲

⟩⟩

AlessandroSPQR

stevedownunder

hermank

📝 New Moth MKII semi scale yacht

2 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 60 Views · 5 Likes · 1 Comment

Flag

💬 Add Comment

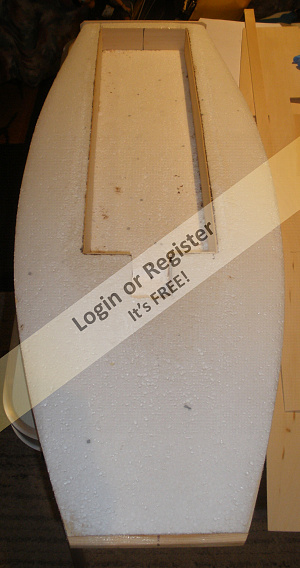

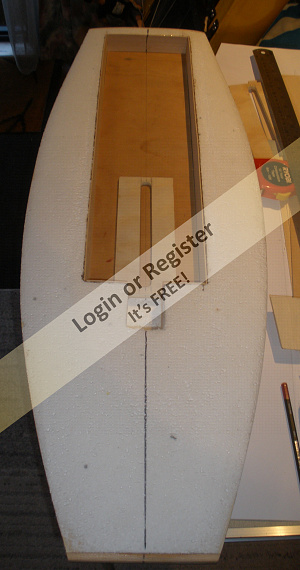

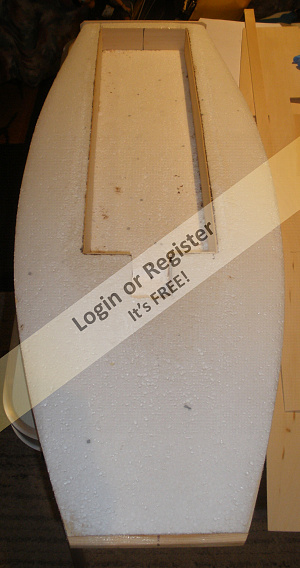

Decent hot day today, so decided to f/glass the bottom of the hull. All the c/board case parts were epoxied in the night before and set well. The bottom of the c/board slot was filled with a tight fitting balsa square, and planed flush, to keep any epoxy from entering. When the glassing is finished, this will be easy to remove and sand back.

I put a coat of epoxy mixed with filler powder on before the 6oz cloth, and troweled it into the pores of the foam as a filler, then straight away laid the cloth on and rolled the normal epoxy through the cloth. This should help with fairing the hull later.

My Hitec winch arrived from a surviving model shop 80 miles south, and that will be eventually fitted in front of the c/board case, in the cutout. Lots more to do yet.

JB

I put a coat of epoxy mixed with filler powder on before the 6oz cloth, and troweled it into the pores of the foam as a filler, then straight away laid the cloth on and rolled the normal epoxy through the cloth. This should help with fairing the hull later.

My Hitec winch arrived from a surviving model shop 80 miles south, and that will be eventually fitted in front of the c/board case, in the cutout. Lots more to do yet.

JB

▲

⟩⟩

ChrisF

luckyduck

stevedownunder

jumpugly

hermank

💬 Re: New Moth MKII semi scale yacht

2 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 60 Views · 3 Likes

Flag

💬 Add Comment

Hi Steve,

not jealous at all, bet your aircon's working overtime ! Only 28 inside here today. Putting a new roof on my bathroom on Tues, you could have fried eggs on the roof, - you'd set fire to them on your roof at 42! Saw the fire risk was not looking good at the moment, hope there are no more big fires. The weather has gone weird here, with fruit trees doing odd things and producing more than ever before with the climate change.

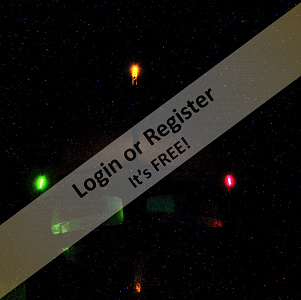

We just finished a round of big thunderstorms sweeping over Auckland and up north where I live. Next day it's back to blazing hot and humid (Auckland city is on the left of the windscreen in pic 1,- the small spikes on the horizon- 25km away - pic 2 it's on its' way up) Bit of an odd summer this year,

rains, a big storm, wind etc, all round Xmas time not like it used to be.

JB

not jealous at all, bet your aircon's working overtime ! Only 28 inside here today. Putting a new roof on my bathroom on Tues, you could have fried eggs on the roof, - you'd set fire to them on your roof at 42! Saw the fire risk was not looking good at the moment, hope there are no more big fires. The weather has gone weird here, with fruit trees doing odd things and producing more than ever before with the climate change.

We just finished a round of big thunderstorms sweeping over Auckland and up north where I live. Next day it's back to blazing hot and humid (Auckland city is on the left of the windscreen in pic 1,- the small spikes on the horizon- 25km away - pic 2 it's on its' way up) Bit of an odd summer this year,

rains, a big storm, wind etc, all round Xmas time not like it used to be.

JB

▲

⟩⟩

GaryLC

stevedownunder

hermank

📝 New Moth MKII semi scale yacht

2 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 65 Views · 8 Likes · 6 Comments

Flag

💬 Add Comment

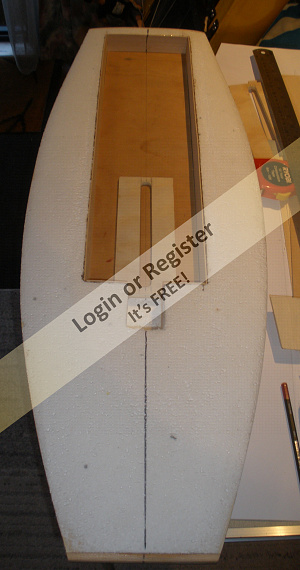

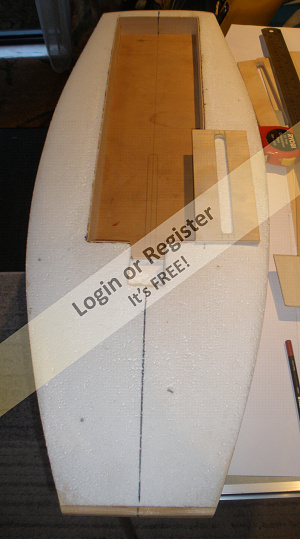

Cockpit floor is now epoxied in. The centerboard case is also epoxied into the lower reinforcing pad, ready for the unit to be epoxied into the bottom hull rebate. - (Pics added to show the centerboard case parts with the assembly method.) Once that's set, the upper centerboard case reinforcing pad, which is a firm push fit over the case will be epoxied in.

JB

JB

▲

⟩⟩

oefranz

DuncanP

GaryLC

EdW

stevedownunder

jumpugly

hermank

luckyduck

📝 HAPPY NEW YEAR

2 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 46 Views · 5 Likes

Flag

📝 Reply

Same from down here in NZ,- wishing everyone a happy and safe new year.

JB

JB

▲

⟩⟩

GARTH

Mike Stoney

jumpugly

hermank

AlessandroSPQR

Login To

Remove Ads

Remove Ads

📝 New Moth MKII semi scale yacht

2 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 100 Views · 18 Likes · 7 Comments

Flag

💬 Add Comment

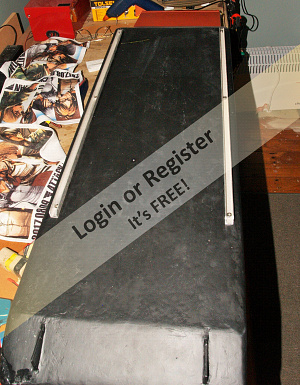

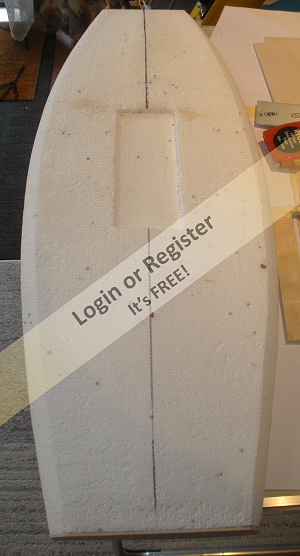

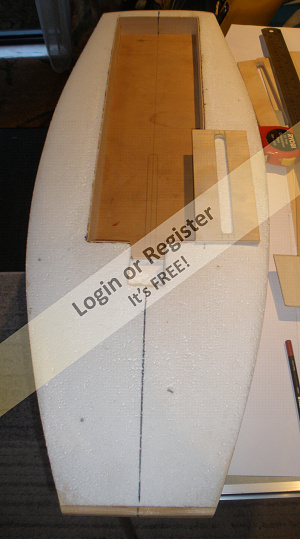

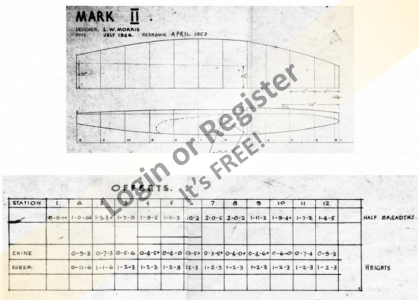

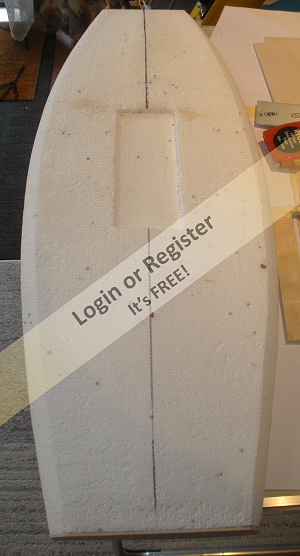

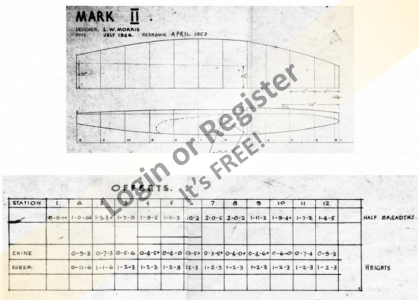

Haven't built anything for a while due to lack of space (too many models) but the urge to build something was too great. After looking at many options, I decided to go with something 'easy' to build. I found some full size plans for an Australian MkI Moth which I'm building to a MKII (double chine) style.

I'm building in foam and glass again to make things easier. It's 850mm long and 310 wide which is roughly 1/4 scale (original is 11 ft)

Started by converting all the lofting measurements on the redrawn 1953 plan to metric and dividing them by 4 to get the scale.

Next was creating the ply deck, then contact gluing onto it a piece of dense 50mm building polystyrene. This was then shaped with a surform file and the chines shaped afterwards using eyeometry. Then the 10mm deck foam was glued on so the deck sheer could be shaped.

Next the cockpit foam was routered out, and basswood sides and inner transom piece epoxied in. After that, the ply outer transom piece and hardwood nose block was epoxied on.

The centerboard case upper and lower ply braces were routered out (using the mill and a 1/2" slotting bit) large enough to accept the case sides, leaving enough room for the 6mm aluminium keel (can't use a centerboard for obvious reasons) which will have to have a bulb fitted.

A rebate in the bottom of the hull was routered out for the lower c/board brace. These braces are needed to form part of a box structure with the floor and cockpit sides which the c/board can lever on. Once everything is eventually glassed in, it will make it very strong unit, so the foam will just be the shape surrounding the box, and not having any strain put on it. The ply deck will take the strain of the stays/mast.

The cockpit floor was cut, and will be slotted the same as the braces, then the c/board case will be built.

The mast on this is 1.486m tall, - sail is -luff -11.295, foot 609mm, so quite large for a small boat. The full sized boat is a lot of fun to sail, so this model will be interesting to sail. Unfortunately, without the human input required, and being a performance boat, it may assume the attributes of a submarine in a stiff breeze, - time and testing will tell.

The basic mast was made from 12mm ally tube, boom from 10mm. Sail pattern was cut from art card to the plan. All laid out on the floor to get an idea of what it will look like.

PDF is the history of the Moth. There were a number of versions round the world as it went along,- scow, international moth (dinghy type) and todays high speed foiling moth.

Lots more to do yet

JB

2025 world champs, off the Whangaparaoa peninsula, just up from where I live.

I'm building in foam and glass again to make things easier. It's 850mm long and 310 wide which is roughly 1/4 scale (original is 11 ft)

Started by converting all the lofting measurements on the redrawn 1953 plan to metric and dividing them by 4 to get the scale.

Next was creating the ply deck, then contact gluing onto it a piece of dense 50mm building polystyrene. This was then shaped with a surform file and the chines shaped afterwards using eyeometry. Then the 10mm deck foam was glued on so the deck sheer could be shaped.

Next the cockpit foam was routered out, and basswood sides and inner transom piece epoxied in. After that, the ply outer transom piece and hardwood nose block was epoxied on.

The centerboard case upper and lower ply braces were routered out (using the mill and a 1/2" slotting bit) large enough to accept the case sides, leaving enough room for the 6mm aluminium keel (can't use a centerboard for obvious reasons) which will have to have a bulb fitted.

A rebate in the bottom of the hull was routered out for the lower c/board brace. These braces are needed to form part of a box structure with the floor and cockpit sides which the c/board can lever on. Once everything is eventually glassed in, it will make it very strong unit, so the foam will just be the shape surrounding the box, and not having any strain put on it. The ply deck will take the strain of the stays/mast.

The cockpit floor was cut, and will be slotted the same as the braces, then the c/board case will be built.

The mast on this is 1.486m tall, - sail is -luff -11.295, foot 609mm, so quite large for a small boat. The full sized boat is a lot of fun to sail, so this model will be interesting to sail. Unfortunately, without the human input required, and being a performance boat, it may assume the attributes of a submarine in a stiff breeze, - time and testing will tell.

The basic mast was made from 12mm ally tube, boom from 10mm. Sail pattern was cut from art card to the plan. All laid out on the floor to get an idea of what it will look like.

PDF is the history of the Moth. There were a number of versions round the world as it went along,- scow, international moth (dinghy type) and todays high speed foiling moth.

Lots more to do yet

JB

2025 world champs, off the Whangaparaoa peninsula, just up from where I live.

▲

⟩⟩

AndyB2

Mike W

Cashrc

EdW

Doogle

SimpleSailor

GaryLC

AlessandroSPQR

stevedownunder

Madwelshman

RossM

luckyduck

Ronald

jumpugly

ChrisF

Newby7

premecekcz

hermank

💬 Re: Classic Model Power Boats

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 158 Views · 7 Likes

Flag

💬 Add Comment

Hi Bob, your rapier runs very well and mine runs pretty much exactly the same. I haven't needed any ballast to make it run level (laterally) which surprised me, given the deep V and how lightly it sits on the water. Mine dosn't turn as tightly as yours, but my rudder is a lot smaller and we have a large pond to play on. I can easily change the rudder, but it's fine for now.

Here's a vid of it running. It's limited to around 70% throttle on a 4000mah 3s at the moment which is more than enough for normal use. (think I've put this up in the build blog)

JB

Here's a vid of it running. It's limited to around 70% throttle on a 4000mah 3s at the moment which is more than enough for normal use. (think I've put this up in the build blog)

JB

▲

⟩⟩

RodC

stevedownunder

DWBrinkman

SimpleSailor

hermank

ColinJ2

EdW

💬 Re: 'Fairacre', Broads Cruiser

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 23 Views · 4 Likes

Flag

💬 Add Comment

Hi Bob,

from memory I used either meths or isopropyl alcohol, then detergent then hosed it out and let it dry for a few weeks. I know i had to be a bit 'severe' with it, but the hull needed a major rebuild, and f/glassing, so I wasn't too worried.

If you use Zinsser stain blocker undercoat, it will cover what remains no problem. You can then overcoat it with an enamel.

JB

from memory I used either meths or isopropyl alcohol, then detergent then hosed it out and let it dry for a few weeks. I know i had to be a bit 'severe' with it, but the hull needed a major rebuild, and f/glassing, so I wasn't too worried.

If you use Zinsser stain blocker undercoat, it will cover what remains no problem. You can then overcoat it with an enamel.

JB

▲

⟩⟩

stevedownunder

hermank

Madwelshman

zooma

💬 Re: Classic Model Power Boats

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 158 Views · 4 Likes

Flag

💬 Add Comment

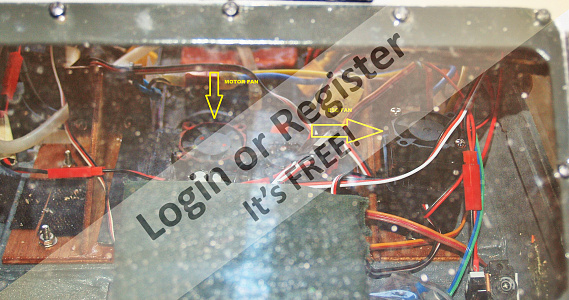

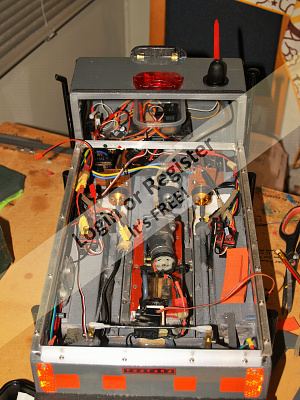

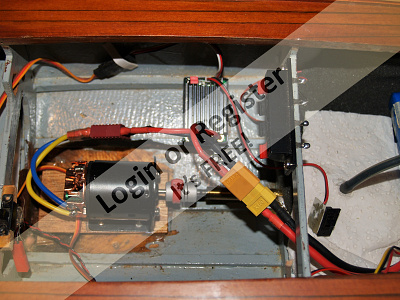

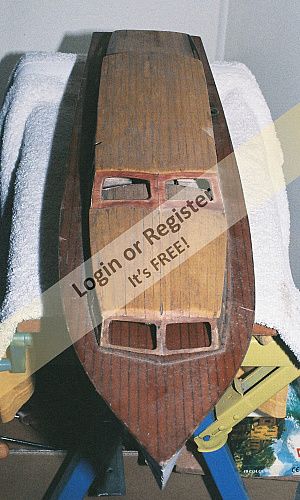

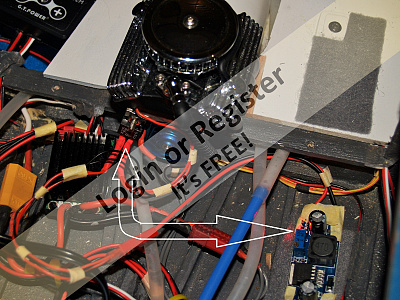

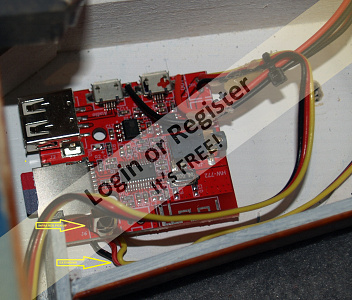

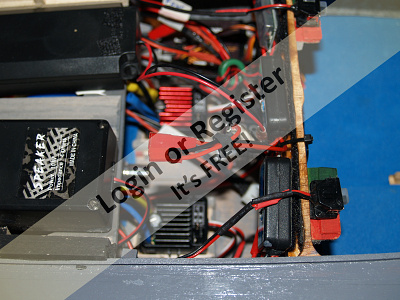

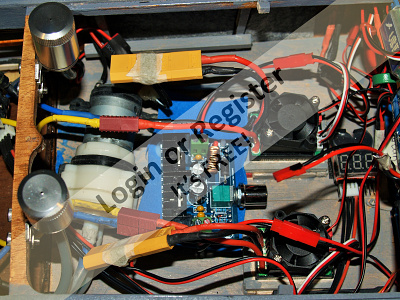

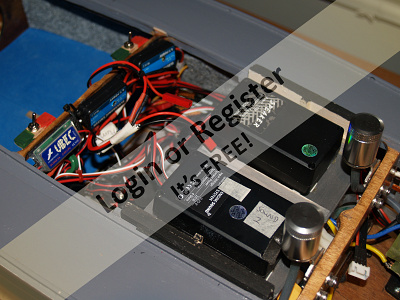

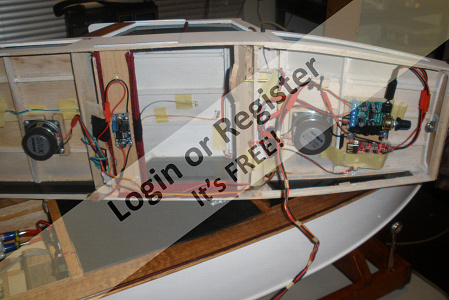

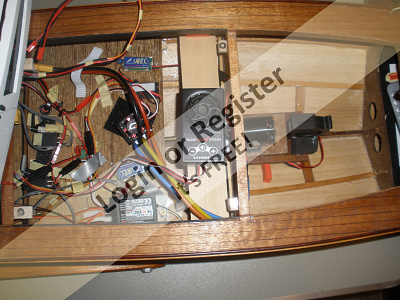

Hi Bob,

prop is just an old Graupner 35mm racing prop from the 70s, which works well.

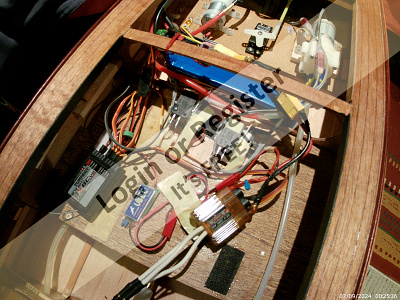

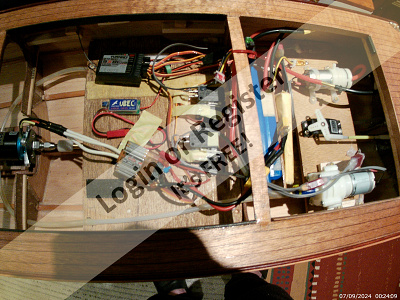

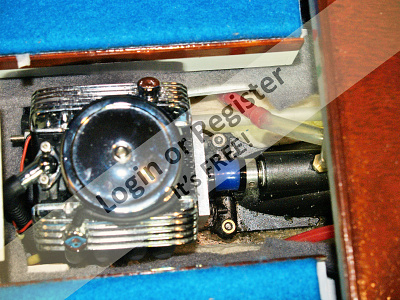

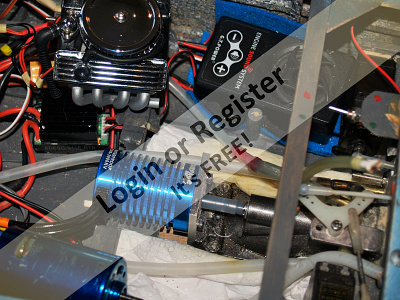

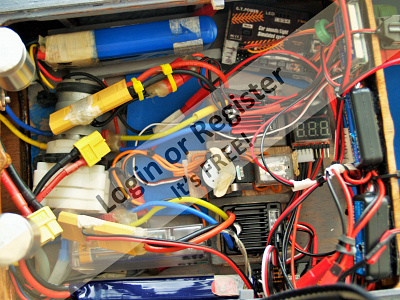

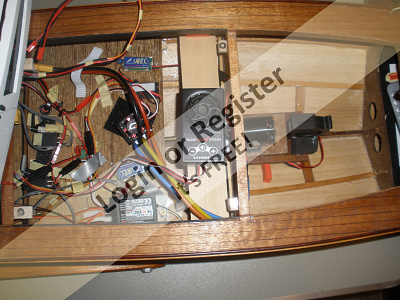

A few pics of added 'extras' which may be of interest, - removable cabin has a stereo fitted, which runs from a 5v multi player board (BT, Micro SD card, Aux in) to a 5v amp then to the speakers mounted in the roof under the skylights. There is a voltage regulator for the LED lights also. On the cabin roof next to the radar is a small metal box which is the IR sensor for the stereo remote.

I have a small media player which can also plug into the board for the FM radio, or music from a micro SD card, or via BT from a phone etc. Just a bit of fun and very cheap to do with parts from Ali Express.

There is a removable false floor under the cabin to hide the internals. At the stern there is an air/water pump system to simulate exhaust. The 1500 KV outrunner heli motor has a built in fan, plus I've added an extra fan in front of it, (doesn't need water cooling). The fairleads, (plus anchor fairlead) are all resin moulded, using imprinted modelling clay, other fittings are brass, (rails, cleats etc)

By modernising the cabin and adding some 'bling' you can make a lot of improvements to the original look, while retaining a good running hull.

JB

prop is just an old Graupner 35mm racing prop from the 70s, which works well.

A few pics of added 'extras' which may be of interest, - removable cabin has a stereo fitted, which runs from a 5v multi player board (BT, Micro SD card, Aux in) to a 5v amp then to the speakers mounted in the roof under the skylights. There is a voltage regulator for the LED lights also. On the cabin roof next to the radar is a small metal box which is the IR sensor for the stereo remote.

I have a small media player which can also plug into the board for the FM radio, or music from a micro SD card, or via BT from a phone etc. Just a bit of fun and very cheap to do with parts from Ali Express.

There is a removable false floor under the cabin to hide the internals. At the stern there is an air/water pump system to simulate exhaust. The 1500 KV outrunner heli motor has a built in fan, plus I've added an extra fan in front of it, (doesn't need water cooling). The fairleads, (plus anchor fairlead) are all resin moulded, using imprinted modelling clay, other fittings are brass, (rails, cleats etc)

By modernising the cabin and adding some 'bling' you can make a lot of improvements to the original look, while retaining a good running hull.

JB

▲

⟩⟩

hermank

Madwelshman

EdW

zooma

💬 Re: Classic Model Power Boats

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 160 Views · 4 Likes

Flag

💬 Add Comment

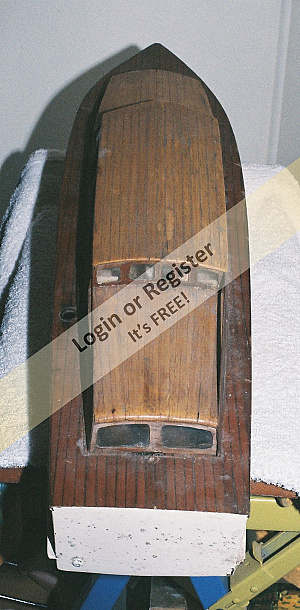

Hi Bob,

re the Stiletto, the plan was just used as a reference, but the whole boat has been changed. The deck sheer is different, construction method is different, cabin position is about 50mm forward and lifts off in one piece (did away with the box build structure inside, now fits over a coaming) drive is cable, which makes it ride spot on and dead level (laterally). As you can see, the boat sits with the chines out of the water due to it being a lot lighter.

I was worried it might have affected the handling, and contemplated making the V shallower, but thought I'd leave it as is and use trim tabs if it had a problem. It worked out perfectly straight off which was a bonus. The rocker in the bottom makes it automatically sit up at the bow when running, especially with the cable drive.

Your cabin mods should look good once finished. The original cabin didn't look right to me, the boat looked unbalanced. Your new windows are a big improvement.👍

JB

re the Stiletto, the plan was just used as a reference, but the whole boat has been changed. The deck sheer is different, construction method is different, cabin position is about 50mm forward and lifts off in one piece (did away with the box build structure inside, now fits over a coaming) drive is cable, which makes it ride spot on and dead level (laterally). As you can see, the boat sits with the chines out of the water due to it being a lot lighter.

I was worried it might have affected the handling, and contemplated making the V shallower, but thought I'd leave it as is and use trim tabs if it had a problem. It worked out perfectly straight off which was a bonus. The rocker in the bottom makes it automatically sit up at the bow when running, especially with the cable drive.

Your cabin mods should look good once finished. The original cabin didn't look right to me, the boat looked unbalanced. Your new windows are a big improvement.👍

JB

▲

⟩⟩

Madwelshman

hermank

premecekcz

zooma

💬 Re: Cheap unsinkable airboat

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 65 Views · 3 Likes

Flag

💬 Add Comment

Thanks Steve, just a quick build, no hull to make, only took about a week all up, - still has a way to go to find its' max performance before 'V1'😀. The first one was pretty uncontrollable till I put the strakes on, and this one is no exception. It's like steering water on a hot pan, just breathe on the rudder stick and it spins. I deliberately reduced the motor power on the new one, (max 660W) as it's a lot lighter than the first glassed ply job, and would probably take off using the the other max 1600W motor. The first boat is only running a 3s LiPo for 30kph, but can take a 6s. It would be faster but the noise would be ear splitting with the smaller prop required - bad enough now!

JB

JB

▲

⟩⟩

hermank

LazyFerret

stevedownunder

💬 Re: Classic Model Power Boats

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 160 Views · 5 Likes

Flag

💬 Add Comment

Hi Bob,

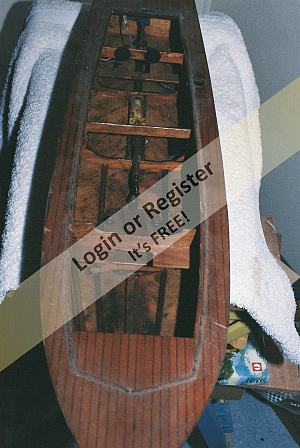

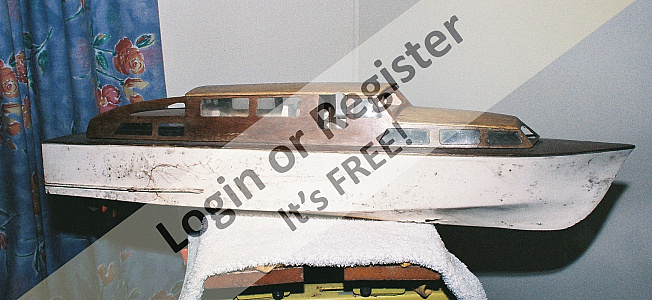

here are a few oldies (and new old builds, restos)

first 2 are my own designs from the early 70s (OS MAX .40 powered)

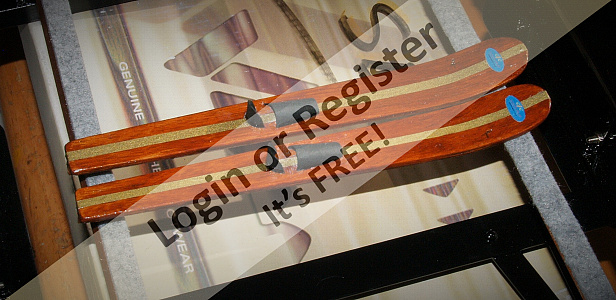

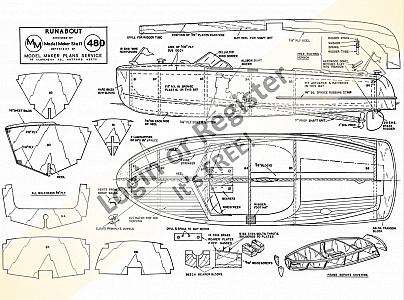

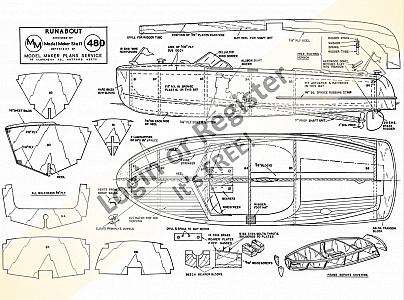

Runabout is from a MM plan from the early 60s,- scaled up from from 18" to 32" and gas to twin HV electrics, with engine sound and stereo etc. Uses 2 -2200mah 2s Lipos, (for motors) 1 -1800mah LiPo (for water and smoke systems) and a 1s Li-ion for the stereo. Also tows a skiier

Stiletto is from a modified original plan from a S.A friend, and scaled up to 39" and bult using conventional glassed balsa on frames, rather than ply sheets and box construction. Also has a modified cabin, cable drive, stereo and engine sound unit, Uses a 1500KV heli outrunner and a 3s 3000MAh LiPo.

Fairacre is from a 60s MM plan. Ex IC powered. Rescued from a farm rubbish bin and restored. Uses 550 brushed motor and 2s LiPo.

JB

here are a few oldies (and new old builds, restos)

first 2 are my own designs from the early 70s (OS MAX .40 powered)

Runabout is from a MM plan from the early 60s,- scaled up from from 18" to 32" and gas to twin HV electrics, with engine sound and stereo etc. Uses 2 -2200mah 2s Lipos, (for motors) 1 -1800mah LiPo (for water and smoke systems) and a 1s Li-ion for the stereo. Also tows a skiier

Stiletto is from a modified original plan from a S.A friend, and scaled up to 39" and bult using conventional glassed balsa on frames, rather than ply sheets and box construction. Also has a modified cabin, cable drive, stereo and engine sound unit, Uses a 1500KV heli outrunner and a 3s 3000MAh LiPo.

Fairacre is from a 60s MM plan. Ex IC powered. Rescued from a farm rubbish bin and restored. Uses 550 brushed motor and 2s LiPo.

JB

▲

⟩⟩

Madwelshman

hermank

stevedownunder

ChrisF

zooma

📝 Cheap unsinkable airboat

3 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 77 Views · 8 Likes · 4 Comments

Flag

💬 Add Comment

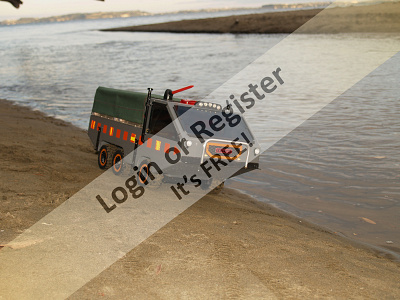

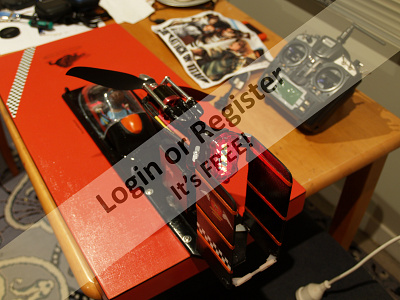

For a bit of fun i decided to knock up another airboat for rescue and camera work. made from a $19 body board with a 3542 1000kv TGY outrunner running on a 4s Lipo, with a 10x6 pusher prop. Went fairly well on it's first test using only about 30% power, but needed some up thrust and rudder trim for much more throttle. Probably needs some small bottom strakes to limit the drifting tendency and make it easier to control, (did this with the first airboat which manages 30kph)

Could quite easily run on 3s for more economy, as it planes very easily. I got 20mins almost continuous running at the speed in the video, (on 30%) which is more than adequate, as it would be just idling around for videos. Quick to make and lots of fun. Motor mount screws onto 4 -30mm dowels epoxied into the body board.

JB

Could quite easily run on 3s for more economy, as it planes very easily. I got 20mins almost continuous running at the speed in the video, (on 30%) which is more than adequate, as it would be just idling around for videos. Quick to make and lots of fun. Motor mount screws onto 4 -30mm dowels epoxied into the body board.

JB

▲

⟩⟩

jumpugly

zooma

LazyFerret

EdW

hermank

stevedownunder

GaryLC

ChrisF

💬 Re: SEMI SCALE FOAM AND GLASS MODEL OF MY 15FT 1953 SCHOCK US DESIGN DAY SAILER. CREW ADDED

5 months ago by 🇳🇿 jbkiwi ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 35 Views · 4 Likes

Flag

💬 Add Comment

Hi Bob, in case you thought otherwise, the tiller moves the arm, the arm doesn't move the tiller.

JB

JB

▲

⟩⟩

Madwelshman

hermank

zooma

stevedownunder

Captain)

Captain)

Lieutenant Commander)

Lieutenant Commander)

Commodore)

Commodore)

Recruit)

Recruit)

Rear Admiral)

Rear Admiral)

Admiral)

Admiral)

Lieutenant)

Lieutenant)