Join Us On Social Media!

Canada

Recent Posts

💬 Re: Superstructure

20 days ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 21 Views · 4 Likes

Flag

💬 Add Comment

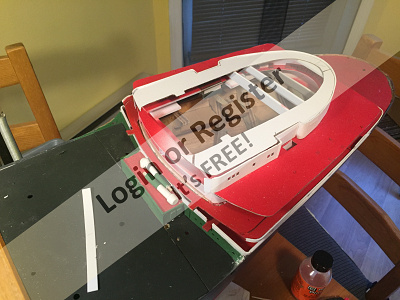

Thank you all for your comments and compliments. Alessandro, I find your project with your quest for authenticity, sparing no efforts and pain to reproduce according to the original most inspiring and in line with my own endeavours. This is not to diminish the excellent work portrayed by others here on this forum, but your attention to detail is outstanding. Unfortunately my experience is limited and other than a Billings 'Blue Nose', started in the '70's never finished due to career and family and moving across the continent, beyond rigging and sails, I have never attempted a project in this magnitude. As I run into issues and dissatisfaction with my shortcomings I do wonder if I may have cut off too much at this stage in my life. I am 4 years into the 10 years I was giving myself to start and while I am quasi happy with what I have accomplished and willing to live with the warts and inaccuracies, I had hoped for a bit better but unless I start over, it will not correct. Maybe nobody will ever see those but it bugs me what I know. Maybe I need counselling when I am done. I have reserved finishing the 'Blue Nose' when and if I get utterly frustrated.

Today I am picking up my RC set from a local hobby shop as I hope to initiate maiden voyage in early Spring before I tackle the monumental task of replicating fittings and few meters of tubing. I thought of buying a small metal lathe for making what I need but still hoping I can save myself by finding some sources for getting it done or maybe somebody local with 3-D printing capability.

Today I am picking up my RC set from a local hobby shop as I hope to initiate maiden voyage in early Spring before I tackle the monumental task of replicating fittings and few meters of tubing. I thought of buying a small metal lathe for making what I need but still hoping I can save myself by finding some sources for getting it done or maybe somebody local with 3-D printing capability.

▲

⟩⟩

hermank

premecekcz

RodC

AlessandroSPQR

Login To

Remove Ads

Remove Ads

💬 Re: Superstructure

21 days ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 30 Views · 2 Likes

Flag

💬 Add Comment

sorry for the duplication in some of the pictures

▲

⟩⟩

hermank

AlessandroSPQR

💬 Re: Superstructure

21 days ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 30 Views · 2 Likes

Flag

💬 Add Comment

why is half my original text left from the posting?

▲

⟩⟩

hermank

AlessandroSPQR

📝 Superstructure

21 days ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 30 Views · 11 Likes · 8 Comments

Flag

💬 Add Comment

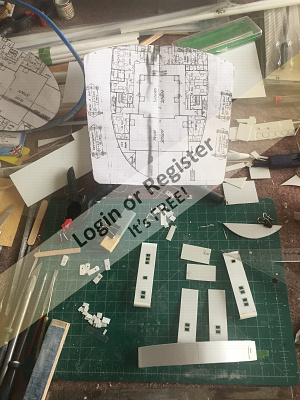

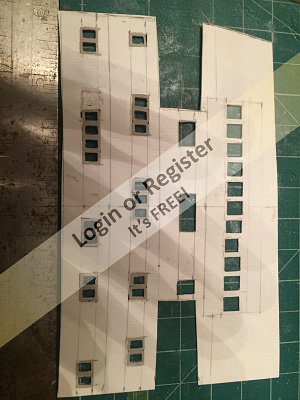

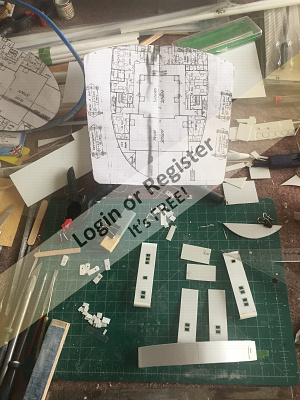

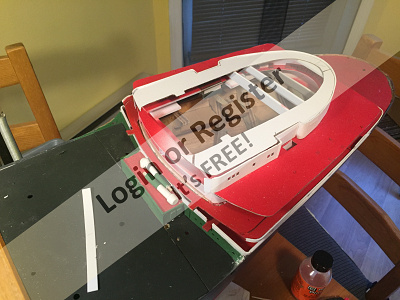

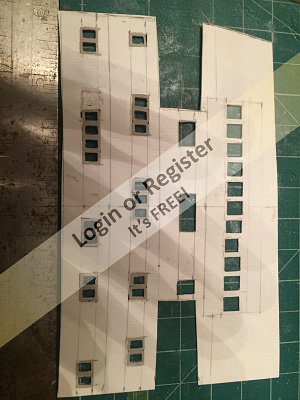

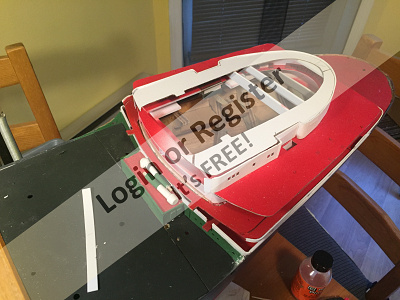

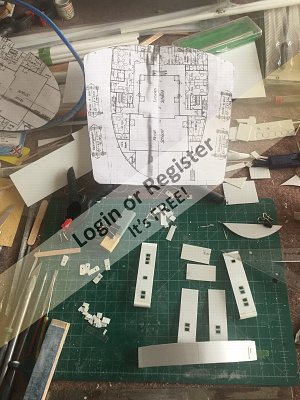

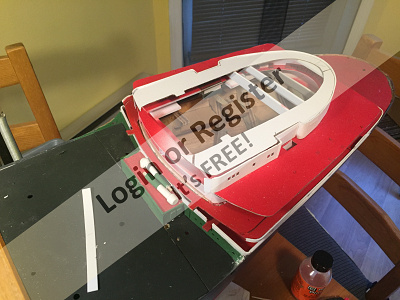

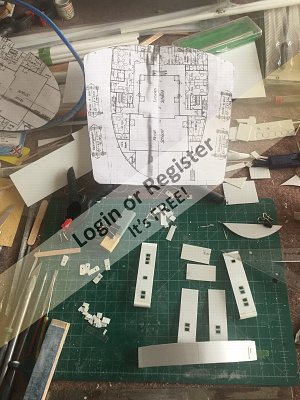

I had hoped to finish the superstructure by Christmas but far from it. I finally managed to cut out the front wall and with adjustments and fine tuning finally felt comfortable to glue it in place. I had to do a lot of filling small spaces on the existing structure. As already mention previously the deck walls are styrene. I went for .5mm material for the outside. I wanted to achieve a (almost) flush appearance for the windows, gave it a few coat of white paint and followed with clear material where the windows are and laminated another layer of material to strengthen the structure. BTW the windows are inserts cut from 6.5x5.5mm tubular material and individual sanded to

▲

⟩⟩

premecekcz

JOHN

Mike Stoney

RodC

Commodore-H

hermank

AlessandroSPQR

GaryLC

EdW

SimpleSailor

jumpugly

📝 And Now For Something Completely Different

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 61 Views · 2 Likes

Flag

📝 Reply

Interesting, Bob. Something new to know. Thanks for sharing

▲

⟩⟩

hermank

zooma

📝 And Now For Something Completely Different

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 75 Views · 2 Likes

Flag

📝 Reply

Very impressive.... the Tiger. I use something similar, veggie boxes from the grocer but with holes on the side for more air flow.

But what are the dots on the tank for. Never seen anything like it in the WWII photos.

But what are the dots on the tank for. Never seen anything like it in the WWII photos.

▲

⟩⟩

hermank

zooma

📝 Modello RC scala 1/60, di piroscafo armato a goletta, liberamente ispirato alle cannoniere classe US

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 25 Views · 6 Likes

Flag

📝 Reply

I only know what I believe it is in German "Scheuerleiste". In English it translates to

"skirting board". But not sure if it properly translates what you are referring to.

"skirting board". But not sure if it properly translates what you are referring to.

▲

⟩⟩

stevedownunder

hermank

RodC

jumpugly

RNinMunich

AlessandroSPQR

💬 Re: And...... another Titanic

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 7 Views · 0 Likes

Flag

💬 Add Comment

deleted wrong thread

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Modello RC scala 1/60, di piroscafo armato a goletta, liberamente ispirato alle cannoniere classe US

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 25 Views · 5 Likes

Flag

📝 Reply

As I understand the problem (the boom extension) I would have done the same. This way you preserve authenticity to the Original. For that I admire your endeavours and share your enthusiasm.👍

▲

⟩⟩

hermank

RodC

jumpugly

stevedownunder

AlessandroSPQR

📝 CONSTRUCTION OF A CASE FOR DISPLAYING A SCALE MODEL SHIP

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 33 Views · 3 Likes

Flag

📝 Reply

Beautiful craftsmanship Alessandro. Truly museum grade quality.

▲

⟩⟩

hermank

Mike Stoney

AlessandroSPQR

📝 CONSTRUCTION OF A CASE FOR DISPLAYING A SCALE MODEL SHIP

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 31 Views · 3 Likes

Flag

📝 Reply

Kay. What method of securing the joints to each other while the glue is curing keeping a true 90deg.?

▲

⟩⟩

Mike Stoney

hermank

AlessandroSPQR

Login To

Remove Ads

Remove Ads

📝 CONSTRUCTION OF A CASE FOR DISPLAYING A SCALE MODEL SHIP

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 34 Views · 1 Like

Flag

📝 Reply

Thank you Alessandro. The perfect fit of the joints is critical and with no experience and proper machines/tools may be difficult to achieve.

▲

⟩⟩

AlessandroSPQR

📝 CONSTRUCTION OF A CASE FOR DISPLAYING A SCALE MODEL SHIP

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 36 Views · 1 Like

Flag

📝 Reply

As far as the glueing part is concerned, I was wondering if the case would be strong enough without the wood frame (as in the example of an aquarium) and what your research concluded.

▲

⟩⟩

AlessandroSPQR

📝 CONSTRUCTION OF A CASE FOR DISPLAYING A SCALE MODEL SHIP

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 39 Views · 2 Likes

Flag

📝 Reply

Aquariums are glued with (I think) a silicone based component and considering the pressure a sizeable tank will hold, it should suffice for holding the joints by itself. Part from covering uneven cuts, would still be necessary for the wood frame?

▲

⟩⟩

zooma

AlessandroSPQR

📝 CONSTRUCTION OF A CASE FOR DISPLAYING A SCALE MODEL SHIP

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 61 Views · 1 Like

Flag

📝 Reply

I am faced with the same task but from what I understand in your description, the PMMA is joined by the wooden frame. How will you secure the PMMA to the wooden frame? How thick is the PMMA? How do you cut the PMMA? Circular Table saw? What kind of saw blade and what challenges did you encounter to achieve a 100% true 90degree on the corners?😊

▲

⟩⟩

AlessandroSPQR

📝 Superstructure

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 40 Views · 3 Likes

Flag

💬 Add Comment

Thank you Jumpugly for the kind words. I will try to add more pictures as things are getting a bit easier. I had never done anything in this magnitude, so it is a steep learning curve.

▲

⟩⟩

hermank

AlessandroSPQR

jumpugly

📝 Superstructure coming together

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 41 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

Made some progress with the superstructure having completed the transition of the removable Bootsdeck. This turned out to be more difficult than thought but with a lot of adjustments and 'building on the fly' so to speak, I think I found the workable solution.

Issues I have found were the different materials. Since I have selected to arbourite for deck material but side walls are styrene. I found some issues with the styrene as it will somewhat deform when too much solvent for the glue is applied. Also I am using .5mm material as I attempting to make the windows appear as in the original (no frame and very small margin in thickness). Fortunately I had some styrene rectangular tubing with the exact inside dimensions to be inserted flush to the wall and paint before applying the window acrylic from the back.

Issues I have found were the different materials. Since I have selected to arbourite for deck material but side walls are styrene. I found some issues with the styrene as it will somewhat deform when too much solvent for the glue is applied. Also I am using .5mm material as I attempting to make the windows appear as in the original (no frame and very small margin in thickness). Fortunately I had some styrene rectangular tubing with the exact inside dimensions to be inserted flush to the wall and paint before applying the window acrylic from the back.

▲

⟩⟩

JOHN

RodC

hermank

jumpugly

EdW

AlessandroSPQR

📝 ...some progress

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 51 Views · 13 Likes · 3 Comments

Flag

💬 Add Comment

Since the last time posting I was at it almost daily but despite my best efforts had very little to show for. However I managed to tackle the inside fo'c's'le bulwark and prepared to openings for the fairleads I did over year ago. In the attempt to achieve a higher degree of an accuracy I keep going back to make adjustments and corrections. I managed to install the aft bridgedeck super structure and glue in next deck level. The sidewalls took some time to paint (still having problems with white paint and required a lot of sanding and redoing). Meanwhile I experimented with building the Anchor chain guide ways. I had to cut individiual supports and glue into the centreline. But eventually I succeeded. I may have to redo some of them as they deformed after glueing and the long guide way from the anchor spill develops a bow not intended. Hope this even itself out once glued to the deck. Although I made up some anchor spills, I tried to replicate the notched grove to fit the chain, I may just redo them again to improve on the appearance. The picture shows them in its raw condition and unpainted.

I have enclosed a few pics to illustrate my story and hope you enjoy reading about my trials and tribulation.

I need to mention that I spent a few weeks in Germany with stays in Hamburg (obligatory visit at the IMM) Berlin, Prag and Dortmund to attend the Inter Modellbau in April. Interesting but I was disappointed about the ships model segment being a bit sparse. Lots of Model rail and R/C trucks.

I have enclosed a few pics to illustrate my story and hope you enjoy reading about my trials and tribulation.

I need to mention that I spent a few weeks in Germany with stays in Hamburg (obligatory visit at the IMM) Berlin, Prag and Dortmund to attend the Inter Modellbau in April. Interesting but I was disappointed about the ships model segment being a bit sparse. Lots of Model rail and R/C trucks.

▲

⟩⟩

premecekcz

JOHN

Mike Stoney

RodC

SimpleSailor

LeeA

Len1

EdW

hermank

AlessandroSPQR

Wolle

RNinMunich

jumpugly

📝 Building from plans

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 49 Views · 4 Likes

Flag

📝 Reply

What ChrisF said. I also would tape it around a dowel or anything fitting the intended bend when drying.

▲

⟩⟩

Len1

hermank

AlessandroSPQR

cheddarman

📝 Question for Pat and the others as an alternative to AI.

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 21 Views · 2 Likes

Flag

📝 Reply

I have known about sacraficial Zinc Anodes be used on parts of vessels around the vicinity of the propeller as the slow process of electrolyse develops between 2 different metals (steel of the hull and bronze of the propeller). Over time they will be eaten away and have to be replaced to prevent deterioration of the propeller. Somebody with the knowledge of chemical galvanization processes would be better capable of explaining it in detail.

Placing copper sheathing on the wooden hull is a different matter and helps keeping mussels and algae attaching itself to the hull.

Placing copper sheathing on the wooden hull is a different matter and helps keeping mussels and algae attaching itself to the hull.

▲

⟩⟩

SouthportPat

AlessandroSPQR

📝 Pats QOD 16/07/25

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 11 Views · 2 Likes

Flag

📝 Reply

Sorry Pat I have to correct you on the description of the Alexander von Humboldt. Your original picture shows the first AvH which was decommissioned around 2014 and with its masts removed converted into a Hotel and Restaurant vessel. Your description however describes its replacement the AvH II which was built as you stated in 2011 but has a different hull design without the extended aft to midships superstructure.

▲

⟩⟩

AlessandroSPQR

jumpugly

Login To

Remove Ads

Remove Ads

💬 Re: Orion

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 24 Views · 1 Like

Flag

💬 Add Comment

Very nice job. It has a distinct 60's look with the turquoise deck. The burgee looks like Swedish flag. Is that because of the Scandinavian heritage of Prince Rupert immigrants?

▲

⟩⟩

Len1

📝 Pats QOD 16/07/25

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 19 Views · 4 Likes

Flag

📝 Reply

I would agree with Alessandro on his choices for 2. - 4.

1. I would speculate is the Dar Mlodziezy Polish Flag

1. I would speculate is the Dar Mlodziezy Polish Flag

▲

⟩⟩

jumpugly

AlessandroSPQR

hermank

SouthportPat

📝 For Those That Have Served

8 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 26 Views · 7 Likes

Flag

📝 Reply

Although I did not have a sea-faring career I spent my working life in Ship chartering and shipping project management. As such I had extensive exposure to travel to many parts, some quite exotic, in the world.

My choice of favourable ports/destinations:

Lulea, Sweden - as an apprentice taking the 3 year program for Shipbroker and owner

with a Hamburg Ship Owner we had the opportunity to take a trip on one of our vessels.

I took a round trip from Kiel-Canal to Lulea, Skelefteahamn and Gavle. I loved the Swedish ports and the natural beauty of the Swedish coast line just south of the polar circle.

London - I had many stays in London, the historic buildings and sites and enjoyed visiting the Baltic Exchange, its culture and had the chance to have Lunch there a few times.

Rio de Janeiro - got a bit of a sunburn on Ipanema Beach the morning arriving on an overnight flight from Europe after spending some unexpected delays and travel re-bookings in snow-bound Poland. Had an afternoon of watching a football game at the old Maracana Stadium.

Jeddah - In the late 70's spend a fair amount in Saudi Arabia, operating out of Damman

but travel by plane and car to Riyadh and Jeddah. The old architecture in those early days was straight out of a National Geographic magazine and up the coast to Yenbo gave someone the sense what it probably looked like for the last 1000 years.

Iquitos - Peru. Being only accessible by plane or boat, some of the sites are historically milestones as it went through a very prosperous period during the height of the rubber

boom. A building by Eiffel being the most renowned. On my first visit there we had to fly by float plane to meet the M/V Yacu Wayo (formerly a Horn Line Vsl) at the joint

border of Peru/Columbia and Brazil. Ended up staying in a small hotel on the banks of the Amazon in Benjamin Constant. On a later trip and a different project I had to attend the barge transport from Iquitos (transfer from oceangoing vessel to barges) going up river the Rio Napo into the Amazon forest to the foothills east of the Andes into Ecuador at abt 3knots/hr. Quite the experience without A/C or fresh water.

Aqaba, Jordan - At the height of the Iran/Iraq war in the 80's I had to baby sit a cargo of Ambulances from Canada to Iraq with implication of getting a berth with over 100 ships waiting in the roads for discharge with most cargoes diverted from War bound ports in the Persian Gulf and having the company from Germans being there looking after their companies interests. We even managed to find a friendly restaurant which would make Sauerbraten with Rotkohl for our group. Having to sit around days we took a taxi from there one day to visit Petra. Amazing site.

I could add more but than we are getting less unusual destinations in South America, North Africa, Middle East or Hongkong

My choice of favourable ports/destinations:

Lulea, Sweden - as an apprentice taking the 3 year program for Shipbroker and owner

with a Hamburg Ship Owner we had the opportunity to take a trip on one of our vessels.

I took a round trip from Kiel-Canal to Lulea, Skelefteahamn and Gavle. I loved the Swedish ports and the natural beauty of the Swedish coast line just south of the polar circle.

London - I had many stays in London, the historic buildings and sites and enjoyed visiting the Baltic Exchange, its culture and had the chance to have Lunch there a few times.

Rio de Janeiro - got a bit of a sunburn on Ipanema Beach the morning arriving on an overnight flight from Europe after spending some unexpected delays and travel re-bookings in snow-bound Poland. Had an afternoon of watching a football game at the old Maracana Stadium.

Jeddah - In the late 70's spend a fair amount in Saudi Arabia, operating out of Damman

but travel by plane and car to Riyadh and Jeddah. The old architecture in those early days was straight out of a National Geographic magazine and up the coast to Yenbo gave someone the sense what it probably looked like for the last 1000 years.

Iquitos - Peru. Being only accessible by plane or boat, some of the sites are historically milestones as it went through a very prosperous period during the height of the rubber

boom. A building by Eiffel being the most renowned. On my first visit there we had to fly by float plane to meet the M/V Yacu Wayo (formerly a Horn Line Vsl) at the joint

border of Peru/Columbia and Brazil. Ended up staying in a small hotel on the banks of the Amazon in Benjamin Constant. On a later trip and a different project I had to attend the barge transport from Iquitos (transfer from oceangoing vessel to barges) going up river the Rio Napo into the Amazon forest to the foothills east of the Andes into Ecuador at abt 3knots/hr. Quite the experience without A/C or fresh water.

Aqaba, Jordan - At the height of the Iran/Iraq war in the 80's I had to baby sit a cargo of Ambulances from Canada to Iraq with implication of getting a berth with over 100 ships waiting in the roads for discharge with most cargoes diverted from War bound ports in the Persian Gulf and having the company from Germans being there looking after their companies interests. We even managed to find a friendly restaurant which would make Sauerbraten with Rotkohl for our group. Having to sit around days we took a taxi from there one day to visit Petra. Amazing site.

I could add more but than we are getting less unusual destinations in South America, North Africa, Middle East or Hongkong

▲

⟩⟩

Peejay

RNinMunich

Doogle

hermank

Len1

AlessandroSPQR

SouthportPat

📝 trawler Toirette

10 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 38 Views · 5 Likes

Flag

📝 Reply

Too bad it didn't have a function for the decks boy to clean up the mess on the deck....

No serious, this is an incredible and amazing job. The detail is just out of this world.

No serious, this is an incredible and amazing job. The detail is just out of this world.

▲

⟩⟩

AlessandroSPQR

alexandre

Len1

hermank

RNinMunich

📝 Modello RC scala 1/60, di piroscafo armato a goletta, liberamente ispirato alle cannoniere classe US

10 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 35 Views · 6 Likes

Flag

📝 Reply

beautiful work Alessandro. They are a piece of art all by themselves.

▲

⟩⟩

RossM

Len1

AlessandroSPQR

stevedownunder

hermank

jumpugly

📝 Can Anyone ID this one for me?

10 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 62 Views · 7 Likes

Flag

📝 Reply

Doesn't look like the Bugsier 3. Again, I find there are quite a few, what looks like to me, fantacy models floating around.

▲

⟩⟩

Len1

hermank

Commodore-H

AlessandroSPQR

jumpugly

Wolle

Nickthesteam

📝 Marriage

11 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 30 Views · 5 Likes

Flag

📝 Reply

Ich gratuliere und meine besten Glückwünsche und viel Spass auf Helgoland.

▲

⟩⟩

jumpugly

hermank

RNinMunich

Mike Stoney

Wolle

📝 Modello RC scala 1/60, di piroscafo armato a goletta, liberamente ispirato alle cannoniere classe US

11 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 37 Views · 3 Likes

Flag

📝 Reply

Your explanations make very much sense. Just make sure the outboard boats are secured safely to the davits if there is a chance they dip into the water when the boat is listing.

▲

⟩⟩

stevedownunder

hermank

AlessandroSPQR

📝 Modello RC scala 1/60, di piroscafo armato a goletta, liberamente ispirato alle cannoniere classe US

11 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 34 Views · 5 Likes

Flag

📝 Reply

Fantastic work Alessandro. Do I understand you right that after all that great detail work on the interior of the boats you will leave them covered up for no one to see?

▲

⟩⟩

AlessandroSPQR

Wolle

hermank

Len1

RNinMunich

Rear Admiral)

Rear Admiral)

Fleet Admiral)

Fleet Admiral)

Liked Why do we still use Knots Go Question for todays Question 4 days ago

Liked Why do we still use Knots Go Question for todays Question 4 days ago

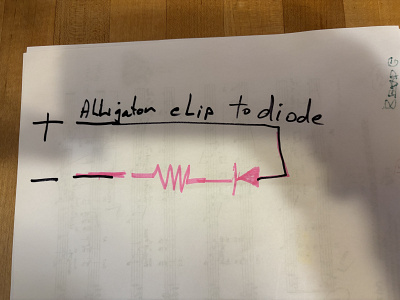

Liked Testing LED diodes 8 days ago

Liked Testing LED diodes 8 days ago

Liked My Saint Pierre Dory has improved lights 11 days ago

Liked My Saint Pierre Dory has improved lights 11 days ago

Liked Prostates! Get a blood test. 12 days ago

Liked Prostates! Get a blood test. 12 days ago