Join Us On Social Media!

United States

Recent Posts

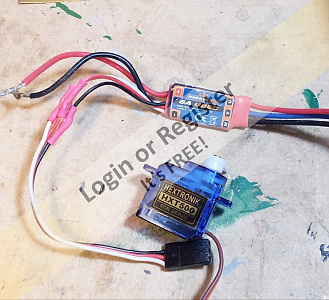

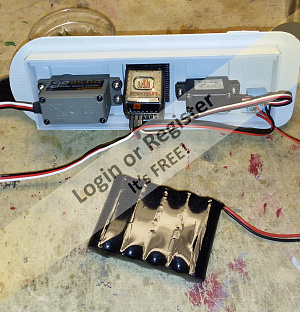

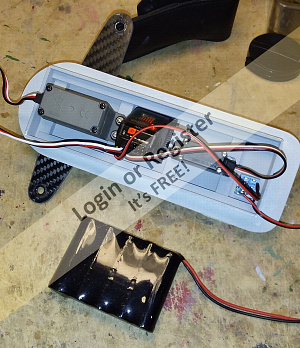

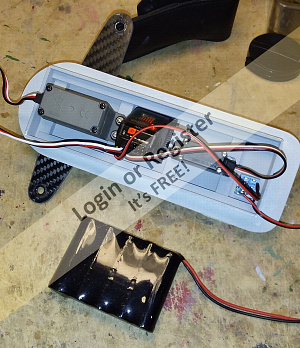

📝 US1 Hatch - servos, switch, battery hard wired

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 18 Views · 5 Likes

Flag

💬 Add Comment

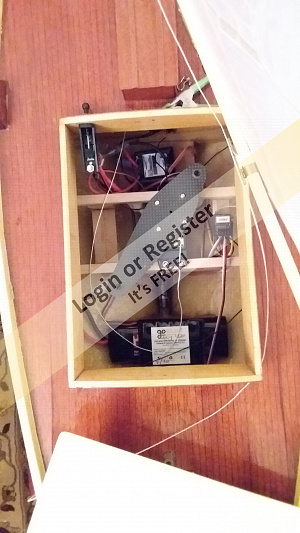

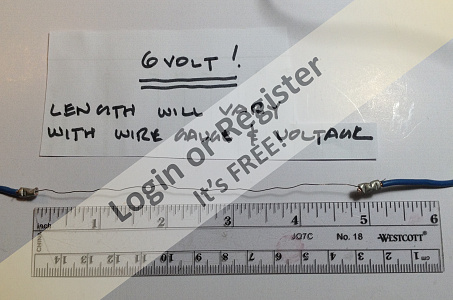

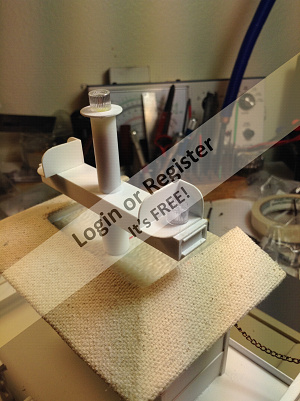

Mounted the recently fabricated sail arm on the high torque sail servo. Mounted RX with velcro and harded wired switch and battery port. Will use a 5 cell Nimh pack for 6 volt 2700mAh delivered.

Remaining work is painting the hull, making the sails and all rigging in place. Cooler weather has finally arrived here so my shop will be up and running at full speed ahead! 🤗

Joe 😎

Remaining work is painting the hull, making the sails and all rigging in place. Cooler weather has finally arrived here so my shop will be up and running at full speed ahead! 🤗

Joe 😎

▲

⟩⟩

MouldBuilder

mturpin013

Ianh

RNinMunich

Martin555

Login To

Remove Ads

Remove Ads

💬 Re: Keel build

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 19 Views · 3 Likes

Flag

💬 Add Comment

Rick,

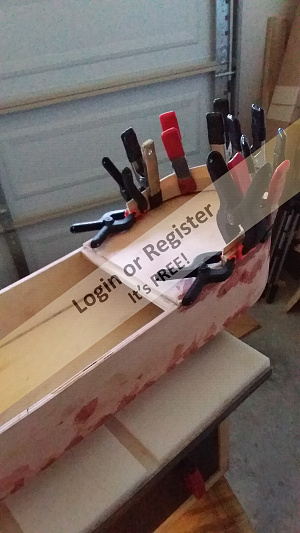

"Clamp clamp has anybody got a clamp"

What is it about clamps, no matter how many and how many different sizes and types, I can always use MORE! 😁

Joe 😎

"Clamp clamp has anybody got a clamp"

What is it about clamps, no matter how many and how many different sizes and types, I can always use MORE! 😁

Joe 😎

▲

⟩⟩

RNinMunich

Ianh

Martin555

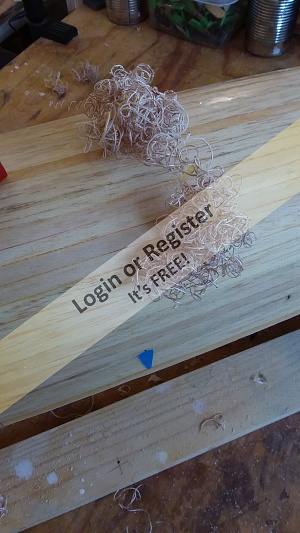

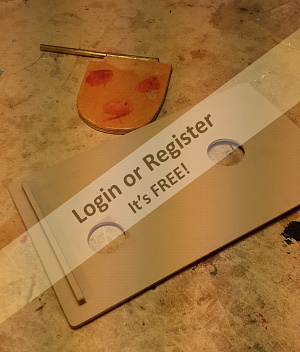

📝 Steel Bulb not lead experiment

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 20 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

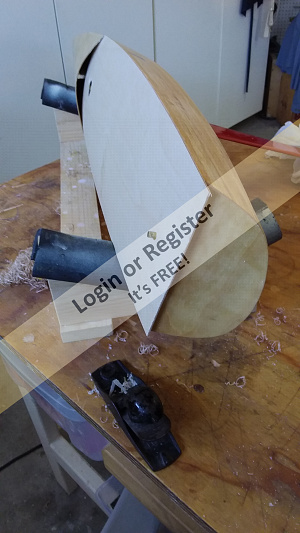

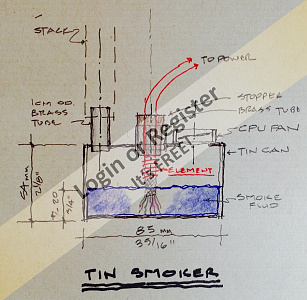

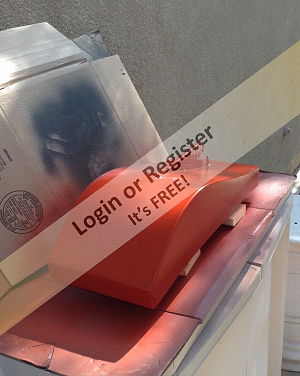

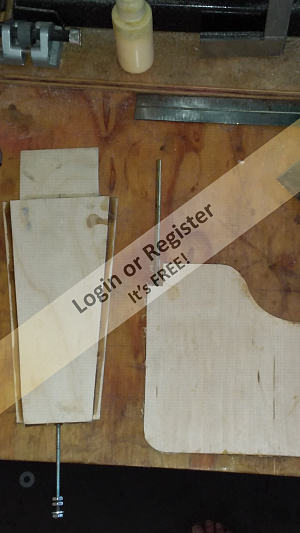

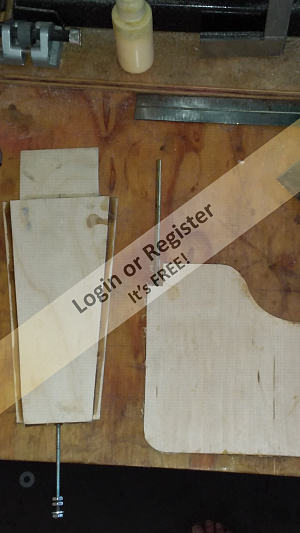

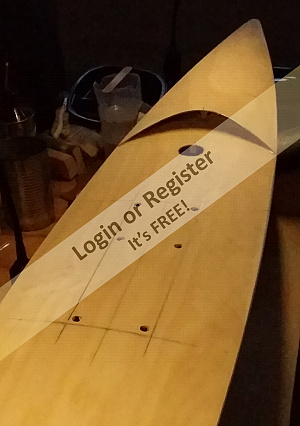

Right now I don't really have the setup to cast lead bulbs so I thought I would try something different. Since this is sailing barge and not a racing yacht I thought I could get away with a larger size and less sleek bulb, one made out of steel rather than lead.

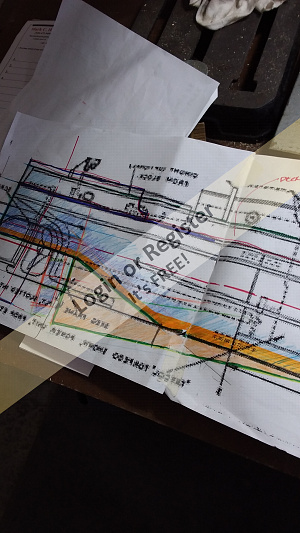

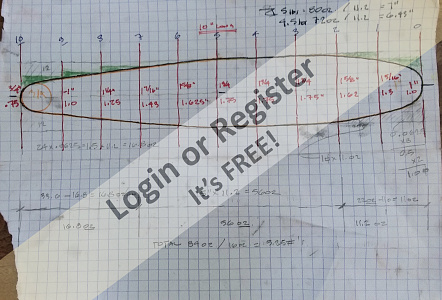

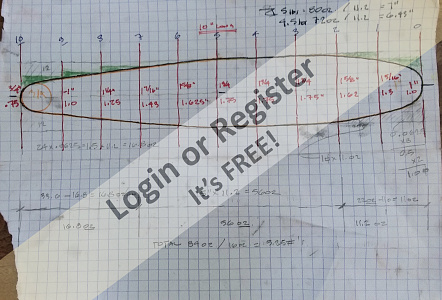

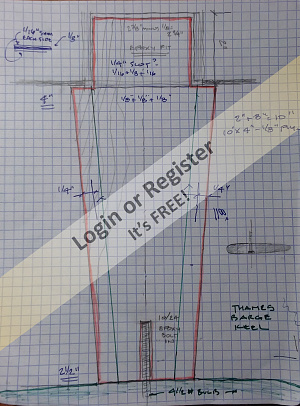

I sketched up a design based on the density of steel that would give me about 5 lbs. See sketch. I picked up a 1 3/4" x 12" steel bar from the local metal supply house. Intent was to turn it on my mini lathe which I did but was a lot of work. I had to freehand the curved shape so it's not perfect but will do the job for a barge. End result weighs in at 5.2 lbs!

I will drill a single hull for attachment to the keel and supplement with epoxy. Shown with the still rough shaped keel in photo. Plywood keel will be shaped today with hand planes and sanding. Rough rudder show as well.

More to come..... Joe 😎

I sketched up a design based on the density of steel that would give me about 5 lbs. See sketch. I picked up a 1 3/4" x 12" steel bar from the local metal supply house. Intent was to turn it on my mini lathe which I did but was a lot of work. I had to freehand the curved shape so it's not perfect but will do the job for a barge. End result weighs in at 5.2 lbs!

I will drill a single hull for attachment to the keel and supplement with epoxy. Shown with the still rough shaped keel in photo. Plywood keel will be shaped today with hand planes and sanding. Rough rudder show as well.

More to come..... Joe 😎

▲

⟩⟩

MouldBuilder

mturpin013

Ianh

jbkiwi

Martin555

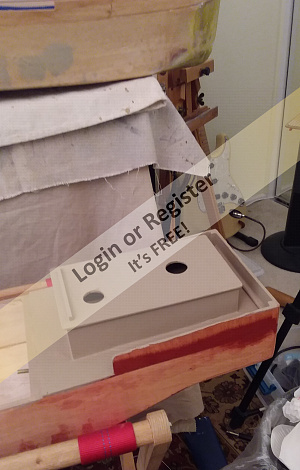

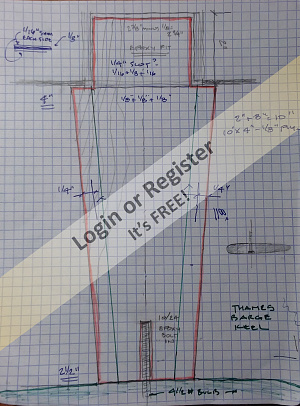

📝 Keel build

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 20 Views · 4 Likes · 3 Comments

Flag

💬 Add Comment

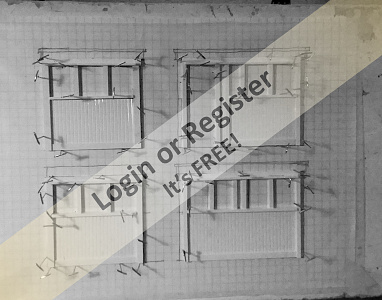

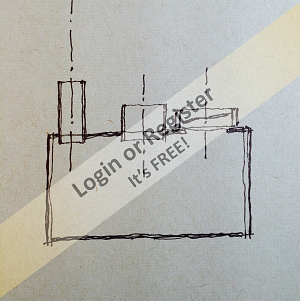

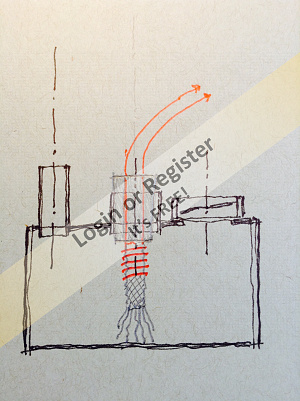

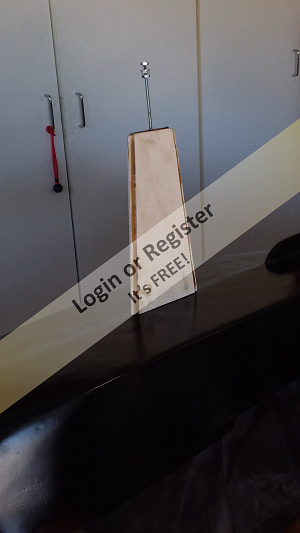

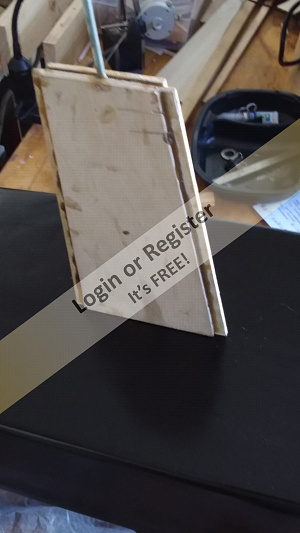

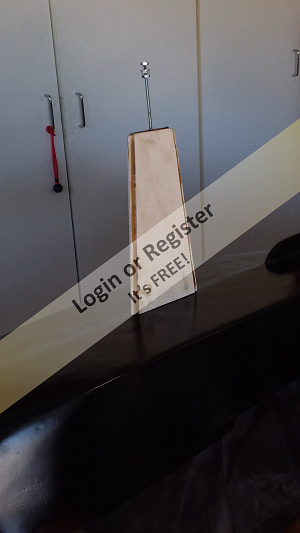

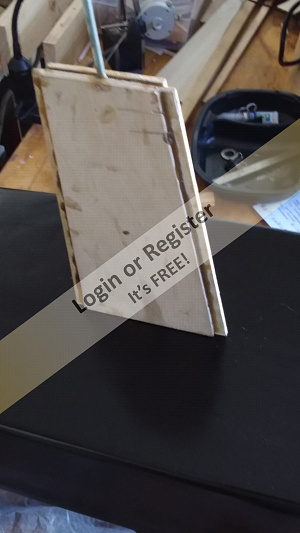

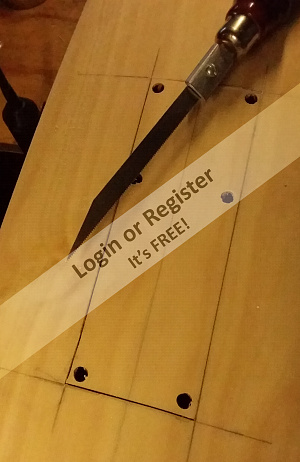

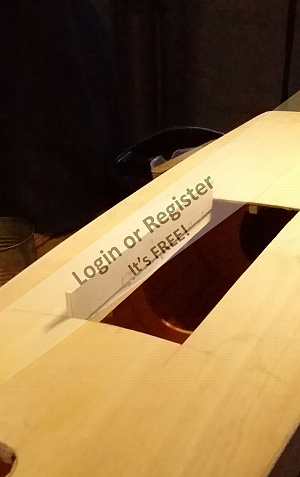

Designed first. Sketched out the keel design for the barge. Three layers of 1/8" plywood will be laminated together and shaped with a wood plane. Threaded rod will be inserted to allow for the metal bulb attachment. Keel will insert into the boats trunk that is already installed.

Now to let the glue dry for first side lamination.

Joe 😎

Now to let the glue dry for first side lamination.

Joe 😎

▲

⟩⟩

MouldBuilder

jbkiwi

Martin555

Nerys

📝 Additional photos

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 15 Views · 1 Like

Flag

💬 Add Comment

▲

⟩⟩

Martin555

💬 Re: Sail Servo Arm - How I build them....

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 15 Views · 1 Like

Flag

💬 Add Comment

Ron,

Each boat type has it's own design in terms of the hole spacing / arm length. I will try to explain it with some sketches when I can. Easy to do but hard to explain. Coming soon.....⛵

Joe 😎

Each boat type has it's own design in terms of the hole spacing / arm length. I will try to explain it with some sketches when I can. Easy to do but hard to explain. Coming soon.....⛵

Joe 😎

▲

⟩⟩

Martin555

💬 Re: Sail Servo Arm - How I build them....

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 15 Views · 1 Like

Flag

💬 Add Comment

Peter,

Wow, electrocution!

I was about to head out to the shop to build another but I will look this issue up first. Thanks for the heads up.

Joe 😎

Wow, electrocution!

I was about to head out to the shop to build another but I will look this issue up first. Thanks for the heads up.

Joe 😎

▲

⟩⟩

Martin555

💬 Re: Sail Servo Arm - How I build them....

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 15 Views · 1 Like

Flag

💬 Add Comment

Martin,

Thanks for the comment. I've built quite a few of these over the years, this one really went fast.

It's for my Sailing Barge that is in progress.

I am making another one today, one for my US1Meter build. Stay safe.

Joe 😎

Thanks for the comment. I've built quite a few of these over the years, this one really went fast.

It's for my Sailing Barge that is in progress.

I am making another one today, one for my US1Meter build. Stay safe.

Joe 😎

▲

⟩⟩

Martin555

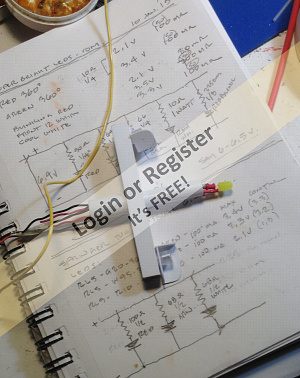

📝 Sail Servo Arm - How I build them....

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 20 Views · 8 Likes · 6 Comments

Flag

💬 Add Comment

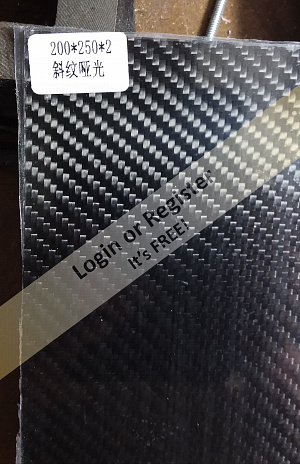

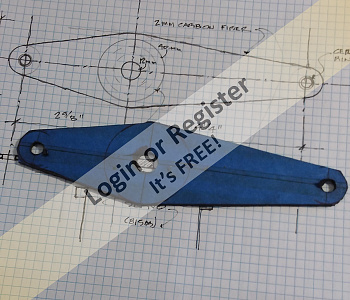

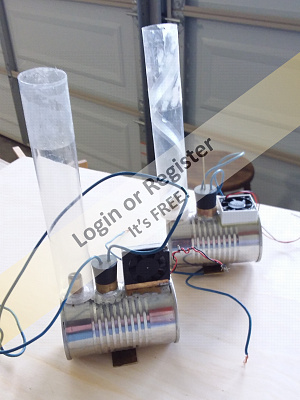

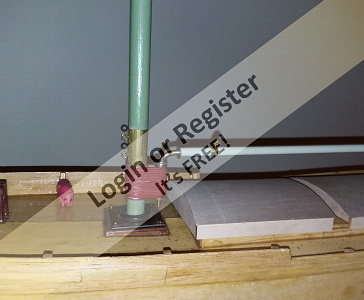

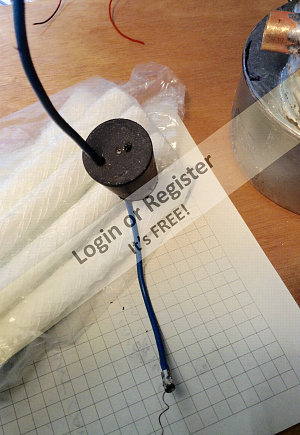

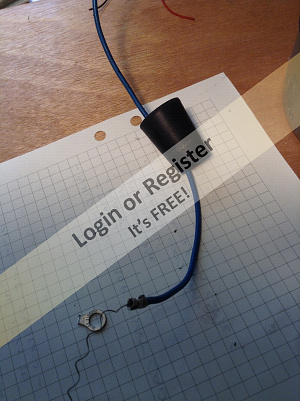

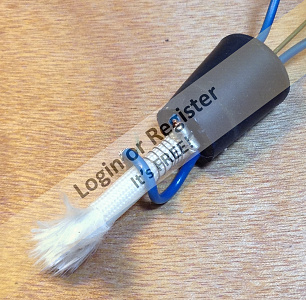

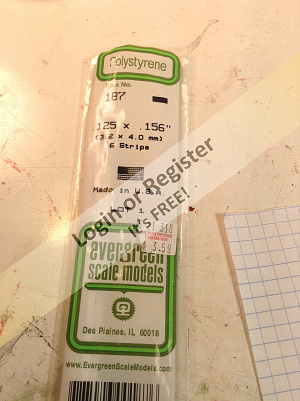

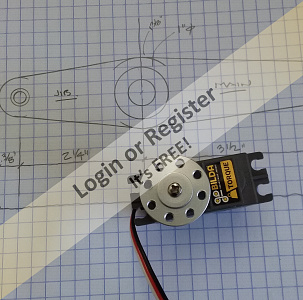

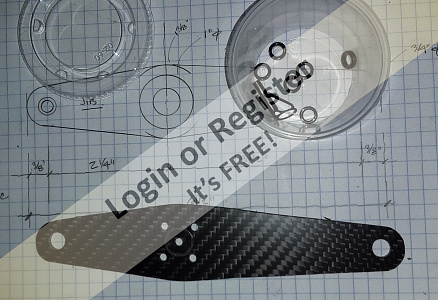

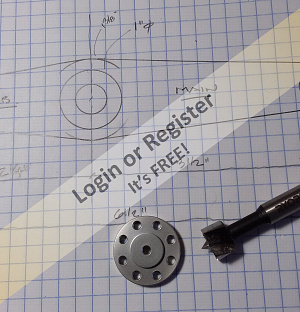

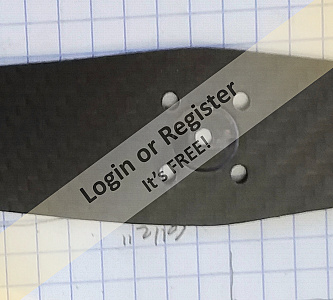

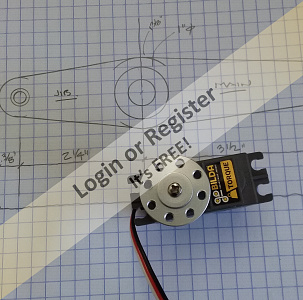

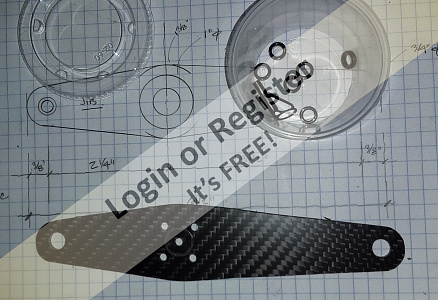

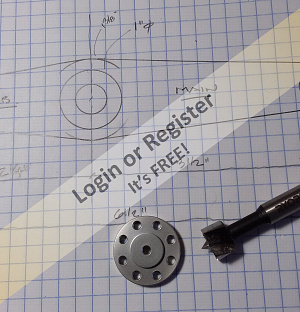

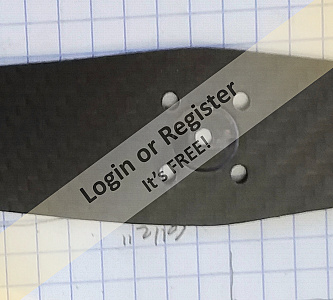

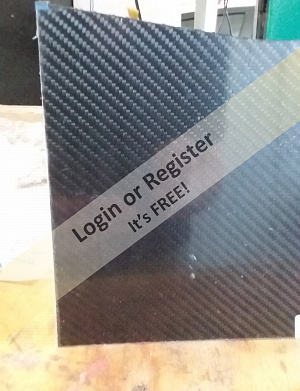

Sail Servo Arms are subjected to a great deal of stress and torque, particularly when handling 1,000 sq. inches of sail. The servos I use generate about 275 oz.in. of torque. (20kg.cm.), so a strong arm is necessary. There are commercially available arms that are typically plastic or aluminum, but I prefer to build my own out of carbon fiber 2.5mm sheet. I like to build everything anyways!

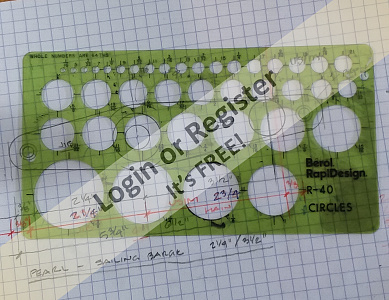

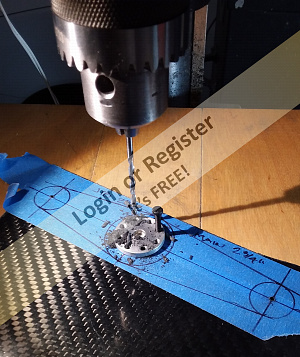

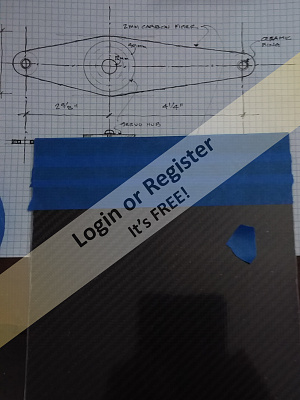

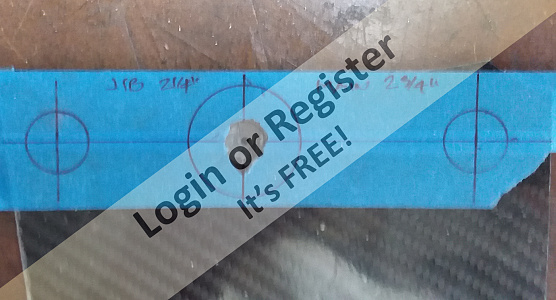

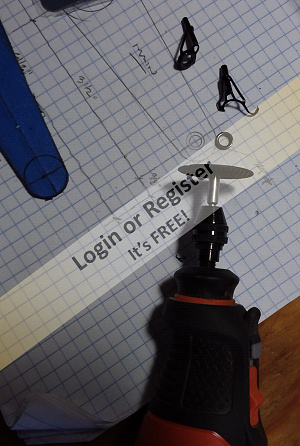

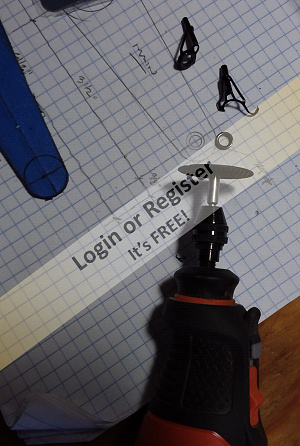

Starts out as with all of my designs, I sketch options and then creative final drawing to full size in graph paper. To transfer this design to the carbon sheet, I use some masking tape and cover an area of the cf sheet. Then I redraw on the masking tape with a thin sharpie. Then I cut out the arm on my bandsaw while wearing safety glasses and a mask. The carbon fiber dust and slivers are nasty, don't want to breath at all. Still trying to dig a sliver out of my finger so you might consider gloves as well.

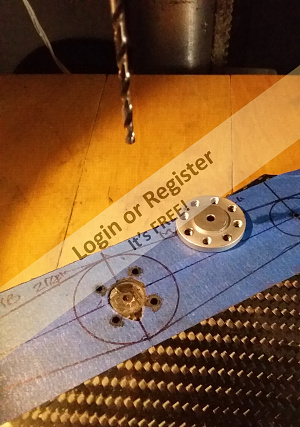

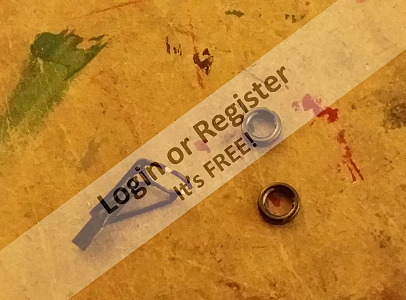

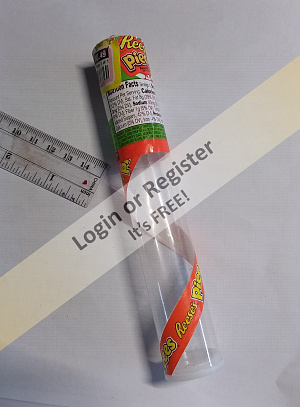

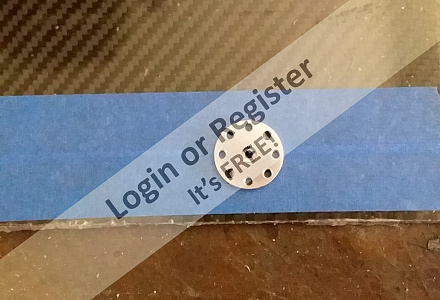

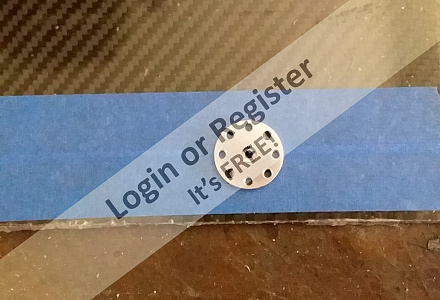

I recently found this nice aluminum servo hub which is low profile and has threaded holes - see photo for brand. The hub is secured with four screws and seem to be adequately strong.

The eyelets that the sail sheets (lines) will pass through need to be smooth to avoid snags and will have to take a lot of wear. I use glass rings that are used in fishing pole guides. I buy the replacement tip kit, see photos. Using a rotary tool with an abrasive wheel I gently cut through the metal ring holding the glass ring, it will just pop out.

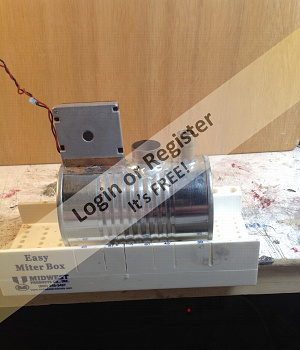

Finished arm shows the pressed in glass eyelets and hub mounted. Then, finally shown mocked up in a current build.

Please ask any questions that you may have as this is a pretty brief post. 😉

Joe 😎

Starts out as with all of my designs, I sketch options and then creative final drawing to full size in graph paper. To transfer this design to the carbon sheet, I use some masking tape and cover an area of the cf sheet. Then I redraw on the masking tape with a thin sharpie. Then I cut out the arm on my bandsaw while wearing safety glasses and a mask. The carbon fiber dust and slivers are nasty, don't want to breath at all. Still trying to dig a sliver out of my finger so you might consider gloves as well.

I recently found this nice aluminum servo hub which is low profile and has threaded holes - see photo for brand. The hub is secured with four screws and seem to be adequately strong.

The eyelets that the sail sheets (lines) will pass through need to be smooth to avoid snags and will have to take a lot of wear. I use glass rings that are used in fishing pole guides. I buy the replacement tip kit, see photos. Using a rotary tool with an abrasive wheel I gently cut through the metal ring holding the glass ring, it will just pop out.

Finished arm shows the pressed in glass eyelets and hub mounted. Then, finally shown mocked up in a current build.

Please ask any questions that you may have as this is a pretty brief post. 😉

Joe 😎

▲

⟩⟩

peterd

Rookysailor

jacko

Ronald

jbkiwi

RNinMunich

MouldBuilder

Martin555

💬 Re: US1Meter Build Aft Deck

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 16 Views · 1 Like

Flag

💬 Add Comment

Peter,

"Do you have an elastic band factory? "

Just noticed your amusing comment....I bought these rubber bands from the local Wally's mart. Good bargain, bags are pretty cheap.

Need to buy some more for my next build!

Joe 😎

"Do you have an elastic band factory? "

Just noticed your amusing comment....I bought these rubber bands from the local Wally's mart. Good bargain, bags are pretty cheap.

Need to buy some more for my next build!

Joe 😎

▲

⟩⟩

Martin555

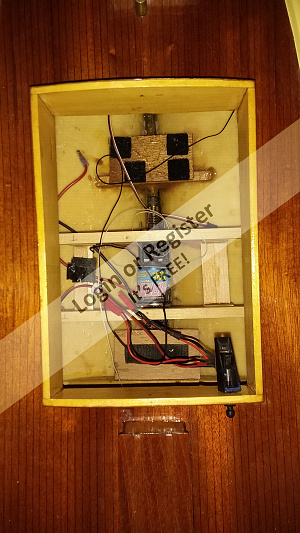

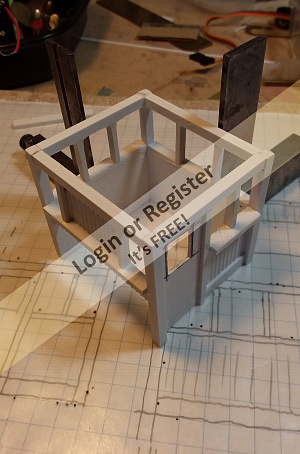

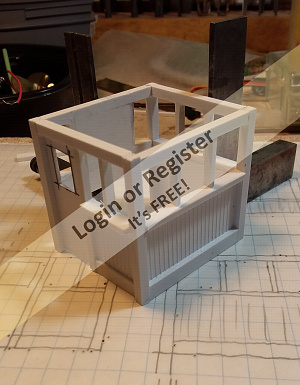

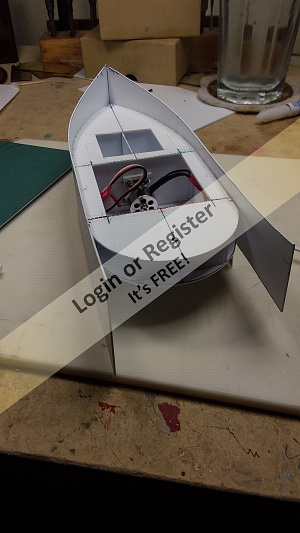

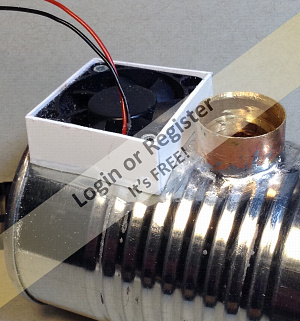

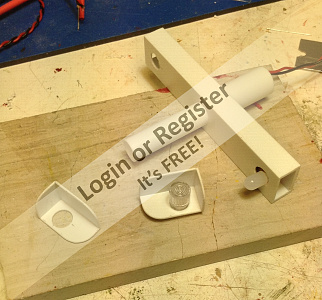

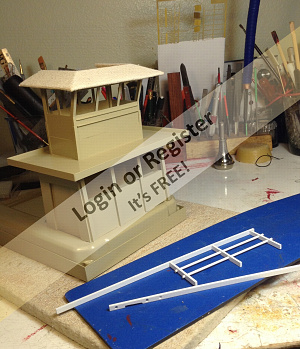

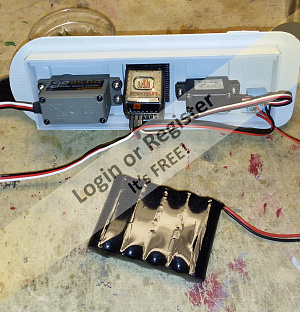

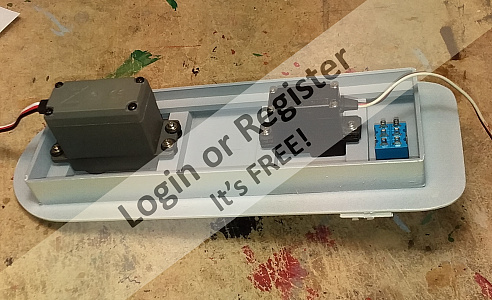

📝 Hatch with Servos mounted

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 16 Views · 4 Likes

Flag

💬 Add Comment

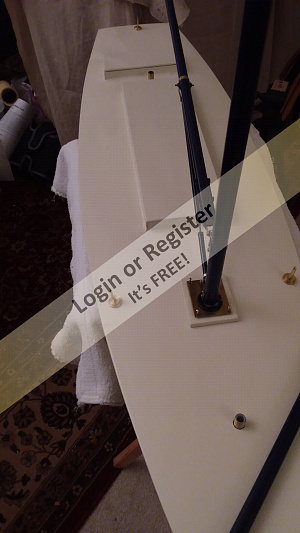

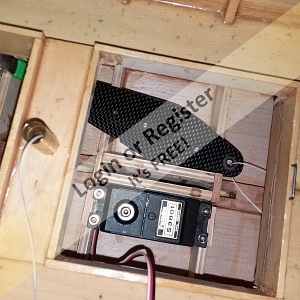

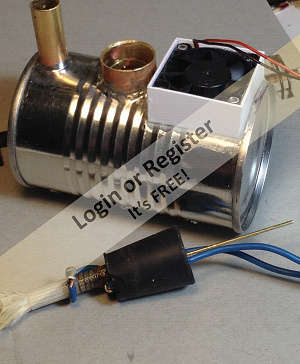

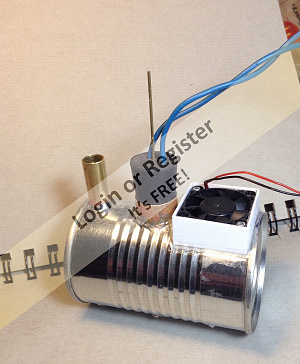

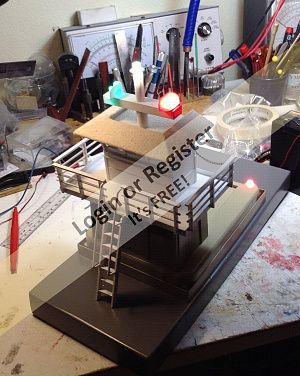

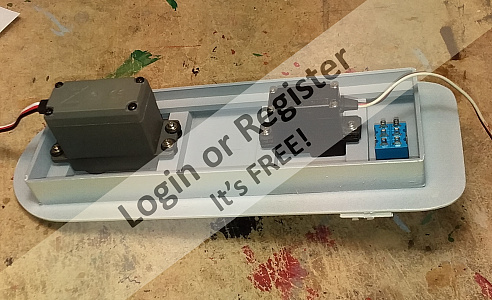

Photos show the sail and rudder servos mounted. Power switch as well. Sail Servo will get a 6" long servo arm which I will build next.

The RX will be mounted next between the servos, along with power leads that will connect to the battery. The battery will be placed in the bottom of the hull to keep center of gravity low.

More to come.

Joe 😎

The RX will be mounted next between the servos, along with power leads that will connect to the battery. The battery will be placed in the bottom of the hull to keep center of gravity low.

More to come.

Joe 😎

▲

⟩⟩

mturpin013

RNinMunich

Martin555

jbkiwi

Login To

Remove Ads

Remove Ads

💬 Re: Barge Ketch....back at it!

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 18 Views · 1 Like

Flag

💬 Add Comment

Martin,

Doing three builds at once, just my way of staying safe & sane in unusual times. 👍👍👍

Joe 😎

Doing three builds at once, just my way of staying safe & sane in unusual times. 👍👍👍

Joe 😎

▲

⟩⟩

Martin555

💬 Re: Barge Ketch....back at it!

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 18 Views · 1 Like

Flag

💬 Add Comment

Bill,

Thanks for the interest and comments, I appreciate it. 👍

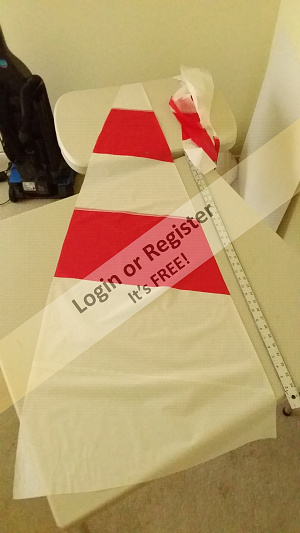

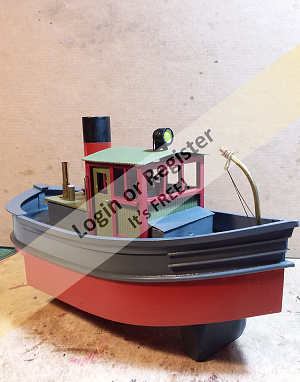

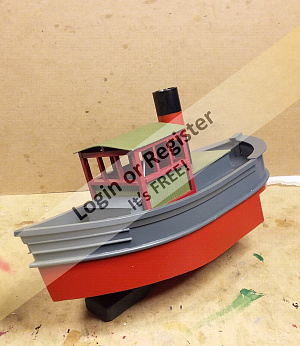

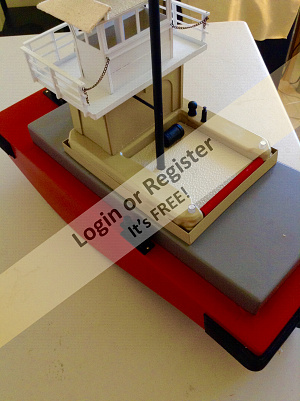

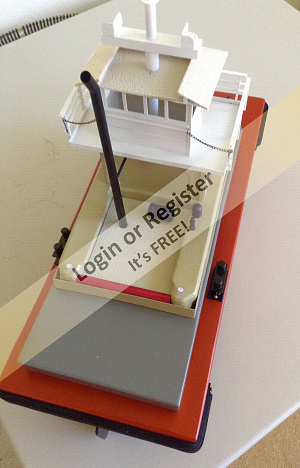

The red deck came from my search of a number of actual barges on the web, thought I give it a try, I like it too.

Took some time finding all the parts and pieces I had been working on. Luckily I take some notes and photos as I work. I am excited about getting back to it.

Joe 😎

Thanks for the interest and comments, I appreciate it. 👍

The red deck came from my search of a number of actual barges on the web, thought I give it a try, I like it too.

Took some time finding all the parts and pieces I had been working on. Luckily I take some notes and photos as I work. I am excited about getting back to it.

Joe 😎

▲

⟩⟩

Martin555

💬 Re: Barge Ketch....back at it!

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 18 Views · 1 Like

Flag

💬 Add Comment

Nerys,

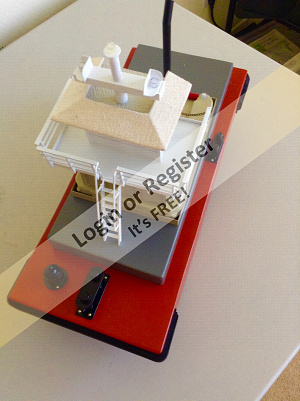

Thank you for your encouragement! The Pearl barge build stalled because I tend to be a perfectionist and the hull was a disappointment. Once I pulled the build back off the shelf, I realized how many hours I have into the boat. So out came the glazing compound and I have been busy correcting imperfections in the hull side and bottom. I am once again excited to complete her.

My other two boats in progress are also build blogs; "Star 45 Racing Yacht" and "US1Meter Lockdown".

My Covid19 lockdown continues as I, like many of us, am a high-risk type, so no trips to the pond yet. So I just continue to build boats and other projects which keeps me happy as I love to build.

Thanks for your interest.

Joe 😎

Thank you for your encouragement! The Pearl barge build stalled because I tend to be a perfectionist and the hull was a disappointment. Once I pulled the build back off the shelf, I realized how many hours I have into the boat. So out came the glazing compound and I have been busy correcting imperfections in the hull side and bottom. I am once again excited to complete her.

My other two boats in progress are also build blogs; "Star 45 Racing Yacht" and "US1Meter Lockdown".

My Covid19 lockdown continues as I, like many of us, am a high-risk type, so no trips to the pond yet. So I just continue to build boats and other projects which keeps me happy as I love to build.

Thanks for your interest.

Joe 😎

▲

⟩⟩

Martin555

📝 Barge Ketch....back at it!

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 21 Views · 4 Likes · 6 Comments

Flag

💬 Add Comment

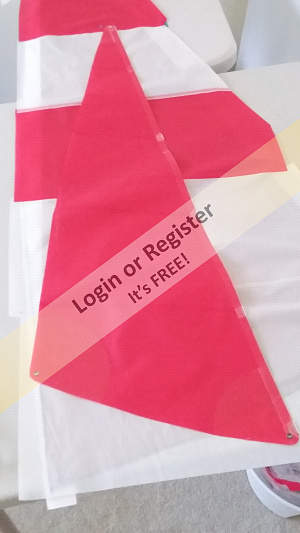

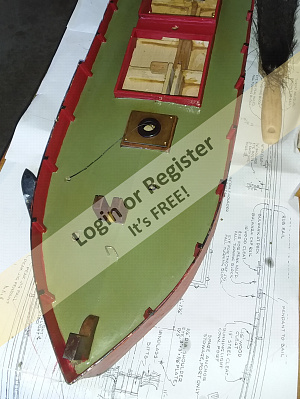

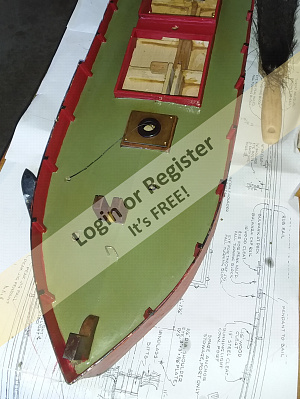

I started this barge build in early 2019, was not happy with the planking, so it went on the shelf for a year. I did some more work on the hull and continued the build in early 2020. Then back on the shelf while I was building two sailing yachts.

Pulled it back out last week and did some hand painting of the deck, etc. Varnished it today and will continue this build till she's ready to launch.

Yes, I have three sailboats going at once 🙄🙄😁

Joe 😎

Pulled it back out last week and did some hand painting of the deck, etc. Varnished it today and will continue this build till she's ready to launch.

Yes, I have three sailboats going at once 🙄🙄😁

Joe 😎

▲

⟩⟩

MouldBuilder

Martin555

billmcl61

Nerys

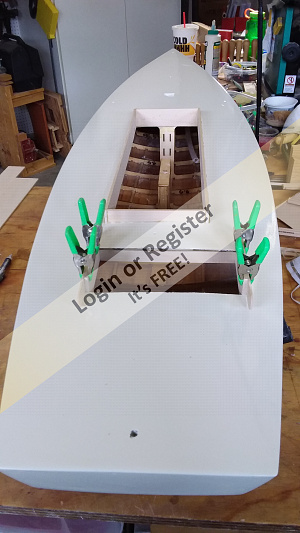

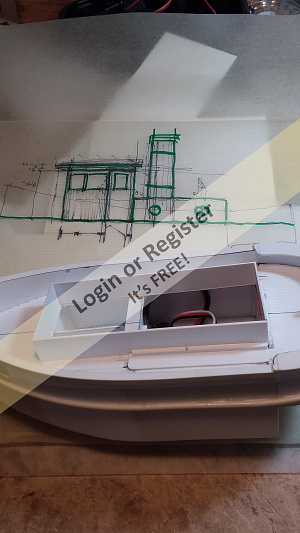

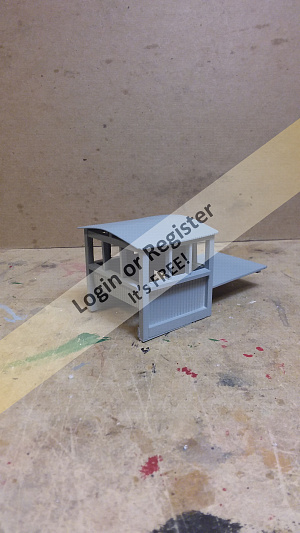

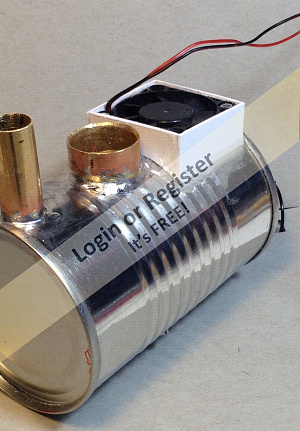

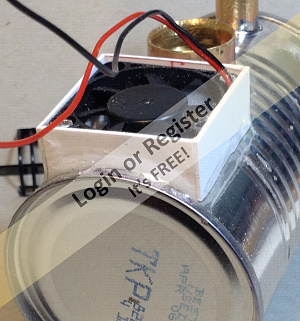

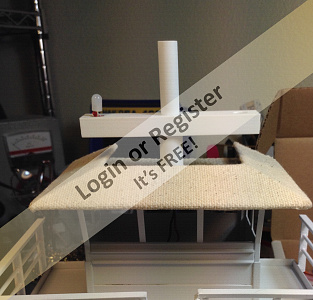

📝 US1Meter's only Hatch!

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 18 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

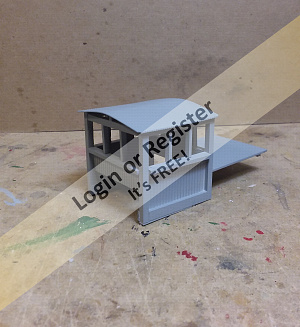

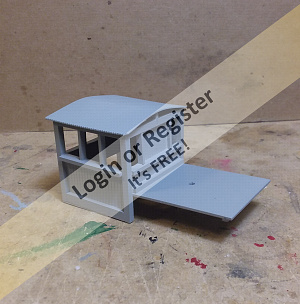

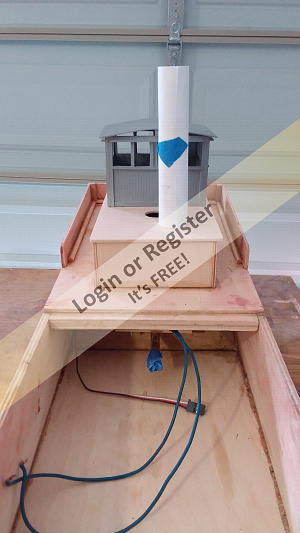

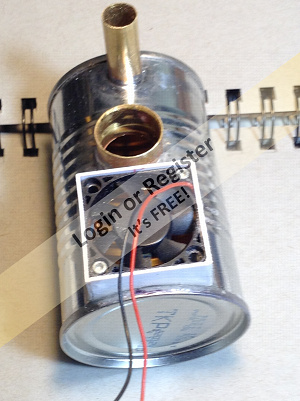

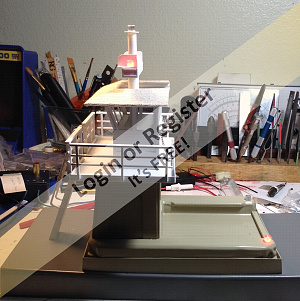

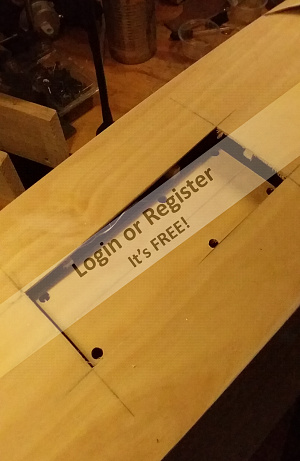

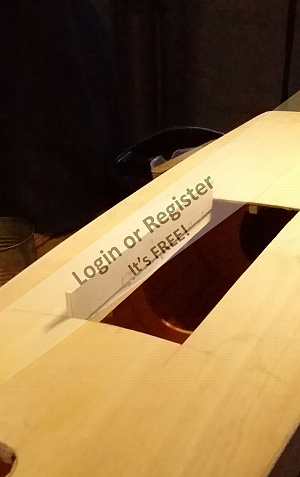

This is the freshly painted Hatch. It's designed to hold the Sail Servo, Rudder Servo, RX and Power Switch. The arched element on top with a hole in it is a sheet guide for the Main Sail.

Servo arms and all sheeting, rudder control arm will be above deck. Shown on hull which is soon to be prepped for paint! Still having fun....😉

Joe 😎

Servo arms and all sheeting, rudder control arm will be above deck. Shown on hull which is soon to be prepped for paint! Still having fun....😉

Joe 😎

▲

⟩⟩

mturpin013

RNinMunich

MouldBuilder

Martin555

jbkiwi

figtree7nts

💬 Re: One meter class yacht. Nimbus.

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 79 Views · 1 Like

Flag

💬 Add Comment

Chris,

Nice to see a 1 Meter build!

I've had a US1Meter in progress for a couple of months, I slowed up due to hot weather here. Starting to get back to it this week.

Good luck with your build, it looks good!

Joe 😎

Nice to see a 1 Meter build!

I've had a US1Meter in progress for a couple of months, I slowed up due to hot weather here. Starting to get back to it this week.

Good luck with your build, it looks good!

Joe 😎

▲

⟩⟩

Martin555

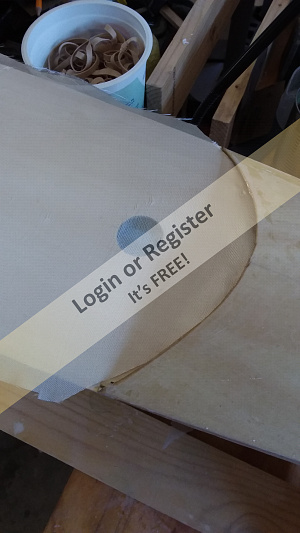

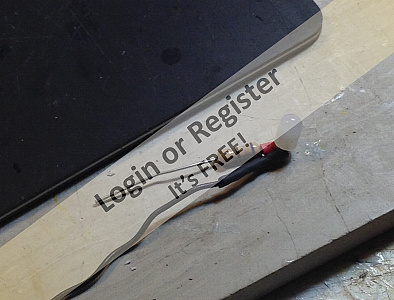

📝 Back in the shop.....

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 19 Views · 7 Likes

Flag

💬 Add Comment

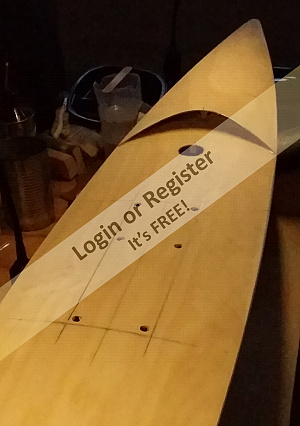

My two builds have been on hold due to a heat wave and poor air quality from our California Wildfires - keeping me out of my garage shop.

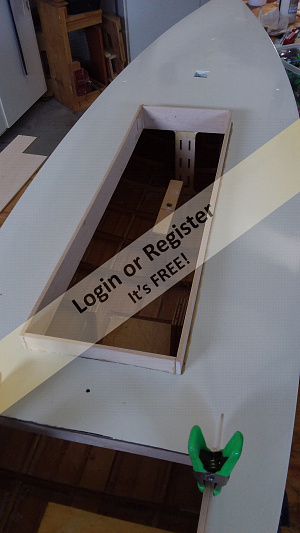

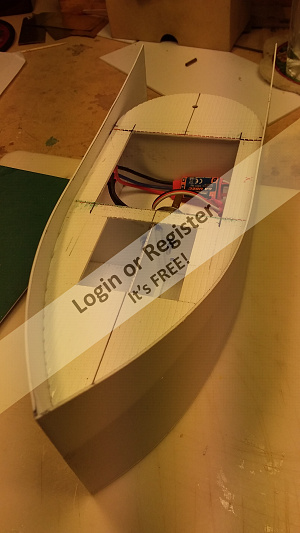

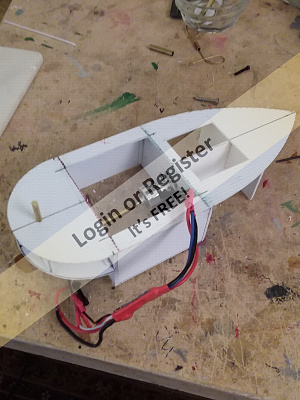

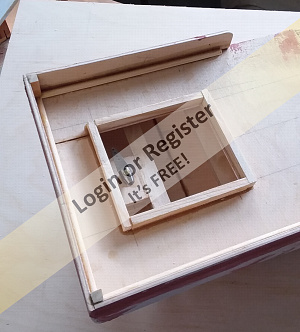

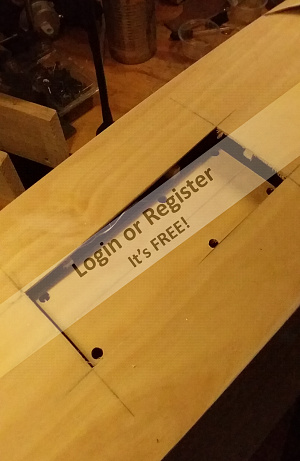

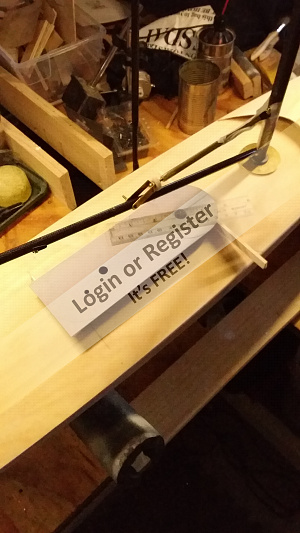

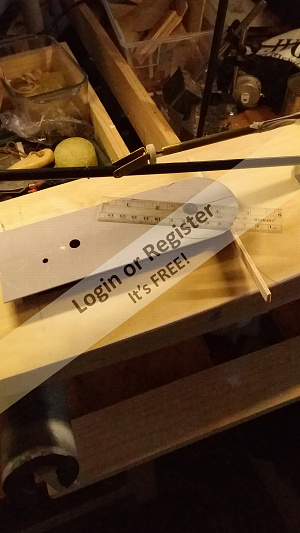

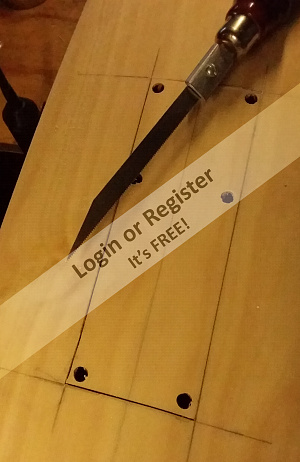

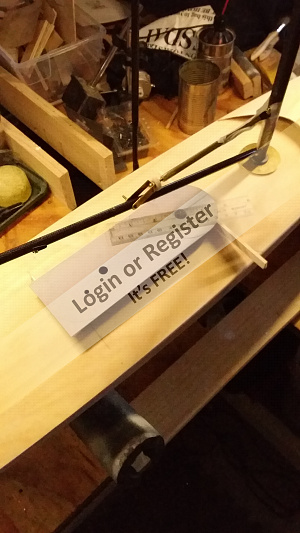

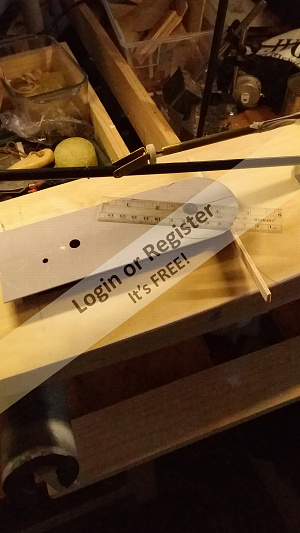

On the US1Meter boat, I sanded the fiberglassed deck and then laid out the main hatch opening on the deck. Using a thin razor saw I was able to make some clean cuts, cutting the opening turned out to be quick and simple. Started glueing up the opening sides and will fit the hatch cover to ensure a watertight seal.

Hopefully I can get some more work done on the boats before more heat is due next week.

Joe 😎

On the US1Meter boat, I sanded the fiberglassed deck and then laid out the main hatch opening on the deck. Using a thin razor saw I was able to make some clean cuts, cutting the opening turned out to be quick and simple. Started glueing up the opening sides and will fit the hatch cover to ensure a watertight seal.

Hopefully I can get some more work done on the boats before more heat is due next week.

Joe 😎

▲

⟩⟩

mturpin013

jbkiwi

RNinMunich

MouldBuilder

marky

robbob

Martin555

💬 Re: RC Sailing :- "Wee Nips" at the Goyt - Part 1

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 41 Views · 1 Like

Flag

💬 Add Comment

Thanks for posting the wee nip video. I've never sailed or built one of these, looks like it would be a fun little boat to have, certainly would be easier to transport than most of my sailboats!

Joe 😉

Joe 😉

▲

⟩⟩

Martin555

💬 Re: 📝 Cigarette hull (Kingston Mouldings)

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 40 Views · 1 Like

Flag

💬 Add Comment

Roy,

I like the use of the cd's! Great thinking....

Amazing how that foam expands, I've only used in in building construction. Tough to predict!

Joe 😎

I like the use of the cd's! Great thinking....

Amazing how that foam expands, I've only used in in building construction. Tough to predict!

Joe 😎

▲

⟩⟩

Martin555

💬 Re: Scratch built, Working Steam powered Drifter trawler LT100, to 1:24th scale.

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 228 Views · 2 Likes

Flag

💬 Add Comment

Stephen,

Your planking looks great!

Joe😎

Your planking looks great!

Joe😎

▲

⟩⟩

stevedownunder

Martin555

Login To

Remove Ads

Remove Ads

💬 Re: The Searchlights.

5 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 134 Views · 2 Likes

Flag

💬 Add Comment

Nicely done!

▲

⟩⟩

Martin555

robbob

💬 Re: NAXOS - Planking

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 55 Views · 1 Like

Flag

💬 Add Comment

"What a painstaking process this is! "

Yes, I agree, but I'll bet you'll be thinking about your next planking project soon!

That's what happened to me, I once dreaded planking but after some success I am beginning to really enjoy it.

Joe 😎

Yes, I agree, but I'll bet you'll be thinking about your next planking project soon!

That's what happened to me, I once dreaded planking but after some success I am beginning to really enjoy it.

Joe 😎

▲

⟩⟩

Martin555

📝 Promotion

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 13 Views · 1 Like

Flag

📝 Reply

Graham,

Thank you and congrats to you as well. Both of us made Commander the same day!

Joe

Thank you and congrats to you as well. Both of us made Commander the same day!

Joe

▲

⟩⟩

Martin555

💬 Re: RC Sailing - BMBC at Buxworth Basin

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 40 Views · 1 Like

Flag

💬 Add Comment

Very nice video, good to see so many boats. Now I can really appreciate the scale of bionic Bill's boat. Some nice sailboats as well.

▲

⟩⟩

Martin555

💬 Re: HARTLEY FLARELINE, NEW PROJECT

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 98 Views · 2 Likes

Flag

💬 Add Comment

JB,

Good tip on butt glueing balsa sheets, I'll remember that if i ever have the need.

Good tip on butt glueing balsa sheets, I'll remember that if i ever have the need.

▲

⟩⟩

jbkiwi

Martin555

💬 Re: Emma C Berry

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 15 Views · 1 Like

Flag

💬 Add Comment

Alan,

Looks like she sails well, I always like to see a Topsail as well. I looked in your harbor and saw that you scratch built her from plans....very good! Nice job on the sails and rigging. ⛵

Joe😎

Looks like she sails well, I always like to see a Topsail as well. I looked in your harbor and saw that you scratch built her from plans....very good! Nice job on the sails and rigging. ⛵

Joe😎

▲

⟩⟩

Martin555

📝 Racing dhows

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 13 Views · 1 Like

Flag

📝 Reply

Nerys,

That's interesting. I have seen these boats in photographs and thought they were unusual looking. Never would have thought they were capable of racing. Thanks for the post, I'll have to look up more about them.

Joe 😎

That's interesting. I have seen these boats in photographs and thought they were unusual looking. Never would have thought they were capable of racing. Thanks for the post, I'll have to look up more about them.

Joe 😎

▲

⟩⟩

Nerys

💬 Re: Amsterdam

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 21 Views · 2 Likes

Flag

💬 Add Comment

Your tug looks great, very nice detail and paint.

👍👍

👍👍

▲

⟩⟩

Ronald

Martin555

💬 Re: Build continues

6 years ago by 🇺🇸 Joe727 ( Commander)

Commander)

Commander)

Commander)✧ 27 Views · 1 Like

Flag

💬 Add Comment

Looking good, keep it up!

▲

⟩⟩

Martin555

Commodore)

Commodore)

Leading Seaman)

Leading Seaman)

Liked New top end of Zulu 5 years ago

Liked New top end of Zulu 5 years ago

Liked On Board the Loganville today 5 years ago

Liked On Board the Loganville today 5 years ago

Liked Boiler 5 years ago

Liked Boiler 5 years ago

Liked Boiler #3 with servos 5 years ago

Liked Boiler #3 with servos 5 years ago

Liked Red to White 5 years ago

Liked Red to White 5 years ago