Join Us On Social Media!

United Kingdom

Recent Posts

💬 Re: 3 day running knife fight

14 days ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 15 Views · 1 Like

Flag

💬 Add Comment

hi there Jumpugly

I like your hydroplane build; food for thought - I wonder if I can fit a build in somewhere - maybe next future build.

Couple of questions for you my friend, regarding your Bluebird build. Is there any evidence or photographs of this particular kit of Bluebird being run on a ducted fan - I have read reports from the makers that it can be run this way with a ducted fan, but, I cannot find any evidence anywhere.

There is someone from UK on Facebook who is building a Bluebird and I think he may be going to try and put a ducted fan in. The weight he is quoting of the hull is 6 lbs and this is a little bit too heavy because by the time you put the batteries and fan in the hull, it would be something like 8 lbs - 9 lbs. I believe the maximum thrust you can obtain is about 7 lbs from a 90 mm ducted fan on 6s batteries.

What are you thoughts my friend and your answers? As you have opted for the prop driven way....

John

I like your hydroplane build; food for thought - I wonder if I can fit a build in somewhere - maybe next future build.

Couple of questions for you my friend, regarding your Bluebird build. Is there any evidence or photographs of this particular kit of Bluebird being run on a ducted fan - I have read reports from the makers that it can be run this way with a ducted fan, but, I cannot find any evidence anywhere.

There is someone from UK on Facebook who is building a Bluebird and I think he may be going to try and put a ducted fan in. The weight he is quoting of the hull is 6 lbs and this is a little bit too heavy because by the time you put the batteries and fan in the hull, it would be something like 8 lbs - 9 lbs. I believe the maximum thrust you can obtain is about 7 lbs from a 90 mm ducted fan on 6s batteries.

What are you thoughts my friend and your answers? As you have opted for the prop driven way....

John

▲

⟩⟩

jumpugly

Login To

Remove Ads

Remove Ads

💬 Re: Donald returns...

1 month ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 75 Views · 2 Likes

Flag

💬 Add Comment

hi there,

Thank you for the kind comments.

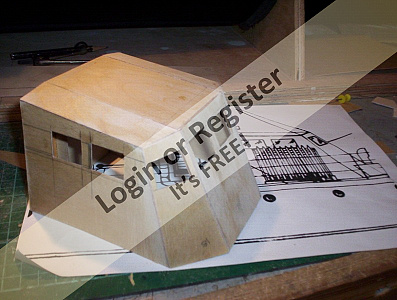

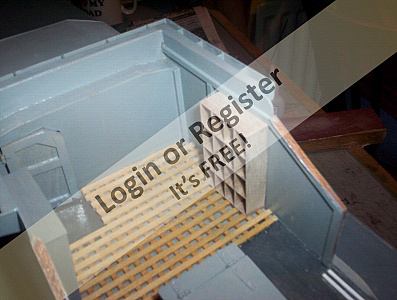

The Crusader of mine 'mark II' comes in at just under 6 lb all up weight - that is including the fan and 2 batteries plus speed controller. The hull, itself, with nothing inside, comes in at just a tadge over 4 lb. About 4 lb 3 oz to be exact. (That is in Uk/English lbs ) She is built from 2mm lite ply, frames in the bottom of the hull with balsa wood framing; covered with Obechi planks. Just 3 coats of pure epoxy finishing resin over the top of the hull.

Mark I, which is, at this present time retired to the garage came in at 6 1/2 lbs - that is without any internal propulsion systems, e.g. power plant and batteries and it was way too heavy. When I was running this on 12 s batteries, it was liking running a house brick through the water - plenty of spray but nothing else.

My initial hopes on Mark I i.e. getting her to work on the water just dissipated and I was going to give up on the model. Until, just before Christmas I was clearing stuff out and I came across some of the drawings again of the Crusader and my mind began to work again....so, Mark II was put on the drawing board.

John

Thank you for the kind comments.

The Crusader of mine 'mark II' comes in at just under 6 lb all up weight - that is including the fan and 2 batteries plus speed controller. The hull, itself, with nothing inside, comes in at just a tadge over 4 lb. About 4 lb 3 oz to be exact. (That is in Uk/English lbs ) She is built from 2mm lite ply, frames in the bottom of the hull with balsa wood framing; covered with Obechi planks. Just 3 coats of pure epoxy finishing resin over the top of the hull.

Mark I, which is, at this present time retired to the garage came in at 6 1/2 lbs - that is without any internal propulsion systems, e.g. power plant and batteries and it was way too heavy. When I was running this on 12 s batteries, it was liking running a house brick through the water - plenty of spray but nothing else.

My initial hopes on Mark I i.e. getting her to work on the water just dissipated and I was going to give up on the model. Until, just before Christmas I was clearing stuff out and I came across some of the drawings again of the Crusader and my mind began to work again....so, Mark II was put on the drawing board.

John

▲

⟩⟩

hermank

jumpugly

💬 Re: Donald returns...

1 month ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 80 Views · 6 Likes

Flag

💬 Add Comment

hi there, not long before sea trials - your progress is coming along well. Yes, don't forget to add some form of floatation because, some things tend to happen when you don't expect them.

Take for instances sea trials last Sunday for the Crusader - I was running her on 6s batteries, driving a 90mm fan - near enough right and not far off getting her on the plane. So, I upgraded her to 8s batteries and I just flicked the rudder to correct her as she was running a bit off and she flipped right over. The camera man, my son, managed to take a pic just as model was about to flip - the camera was put away awfully quick and everyone tried to retrieve the model before sinking, Lucky she stayed afloat. When I got home and checked the model, dried everything out and started the fan up - the fan blades had shredded a little bit of the casing and sheared a few bits off the blades. So, obviously the impact with the water had done some unseen damage and now I am waiting for a brand new fan to arrive.

John

Take for instances sea trials last Sunday for the Crusader - I was running her on 6s batteries, driving a 90mm fan - near enough right and not far off getting her on the plane. So, I upgraded her to 8s batteries and I just flicked the rudder to correct her as she was running a bit off and she flipped right over. The camera man, my son, managed to take a pic just as model was about to flip - the camera was put away awfully quick and everyone tried to retrieve the model before sinking, Lucky she stayed afloat. When I got home and checked the model, dried everything out and started the fan up - the fan blades had shredded a little bit of the casing and sheared a few bits off the blades. So, obviously the impact with the water had done some unseen damage and now I am waiting for a brand new fan to arrive.

John

▲

⟩⟩

Razor1955

xtramaths

chugalone100

hermank

EdW

jumpugly

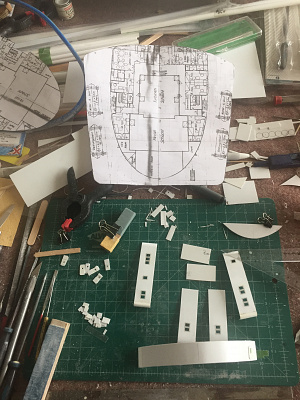

📝 Glynn Guest models

2 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 54 Views · 5 Likes

Flag

📝 Reply

hi there, this is my contribution to the Glynn Guest builds :-)

MTB

The American PT boat

HMS Penelope

Lifeboat

I have one or two more on my 'to build list' of Glynn's plans to build.

John

MTB

The American PT boat

HMS Penelope

Lifeboat

I have one or two more on my 'to build list' of Glynn's plans to build.

John

▲

⟩⟩

chugalone100

EdW

hermank

Steves-s

Doogle

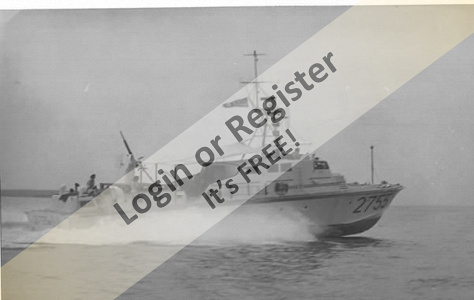

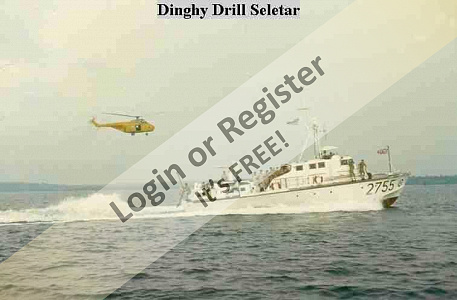

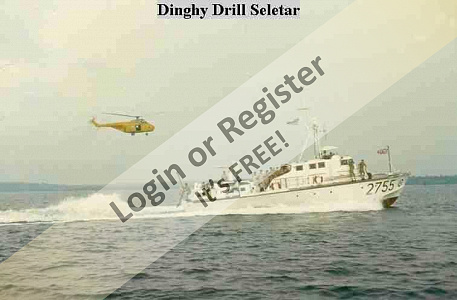

📝 RTTL2755 having a run out

3 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 44 Views · 2 Likes

Flag

📝 Reply

Hi the video is in slow mo but it will give you some idea of speed

john

john

▲

⟩⟩

hermank

Rogal118

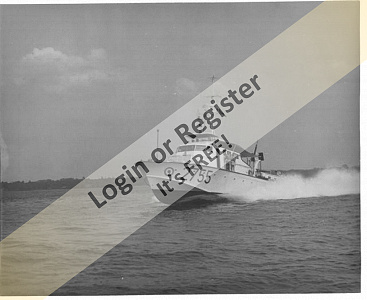

📝 RTTL2755 having a run out

3 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 46 Views · 5 Likes

Flag

📝 Reply

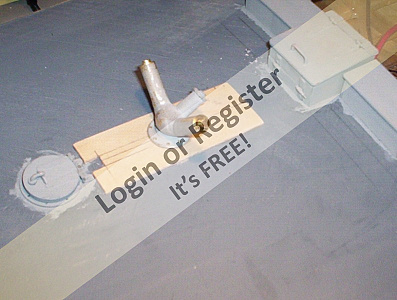

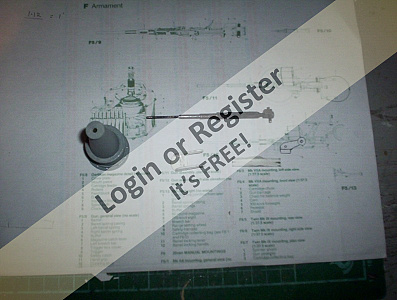

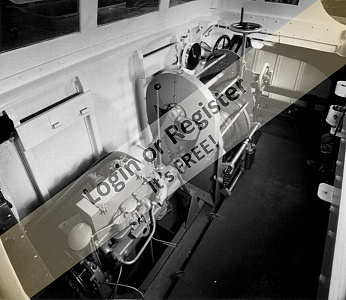

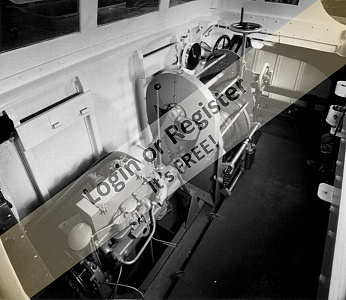

Hi there, not trying to deviate too much, however, the aforesaid motors, I believe are a stock motor from China. They are manufactured and sometimes come into the modelling stream under the name of Mabuchi and Companies buy them in and rebrand them under the Companies name who have bought them. I say this because I have some MFA motors which are identical to the one in this listing and also the ones in my Launch come from MTroniks and they are branded as Vision 600s or something like that. MTroniks seem to have the same specs. I run mine on 2 x 500 amp 7.2 volt NiCads. There is obviously a bit more weight in the Launch which I built - that is because there is a sound module an amplifier and speaker; plus there is one of the very first ACTion twin speed controllers and mixer. I will put some photographs on of the layout to give you some idea. The first photograph is the rear bay of the craft which houses the speed controller, sound module and 6 channel receiver. The 2nd photograph shows the installation of the motors. The 3rd pic shows the amplifier and the speaker and this is in the forward compartment of the boat and also there are the battery trays for the 2 NiCads and there is a 9 volt stick batter which sits between the battery trays, which supplies the power for the sound system and amplifier. I still get about 30 minutes run at a good turn of speed.

The propellers on my model are 30 mm brass x 3 blades and they both turn in the same direction as in the real launch.

The propellers on my model are 30 mm brass x 3 blades and they both turn in the same direction as in the real launch.

▲

⟩⟩

PeteJev

hermank

GaryLC

cumbrae

Rogal118

📝 RTTL2755 having a run out

3 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 52 Views · 8 Likes

Flag

📝 Reply

▲

⟩⟩

GaryLC

cumbrae

hermank

jumpugly

Rogal118

chugalone100

Ronald

AlessandroSPQR

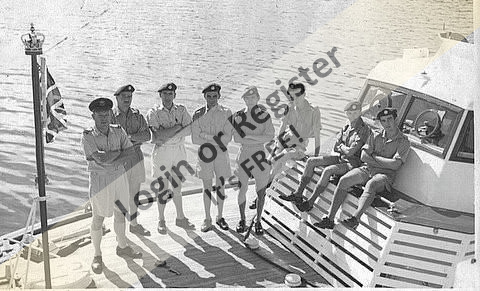

📝 RTTL2755 having a run out

3 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 31 Views · 6 Likes

Flag

📝 Reply

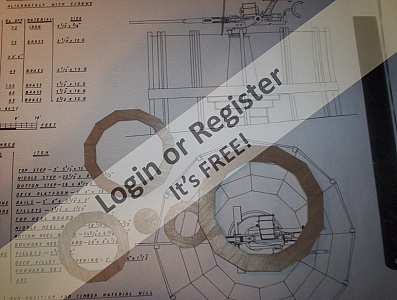

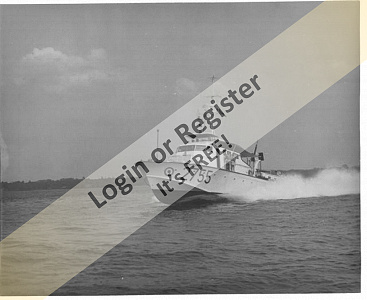

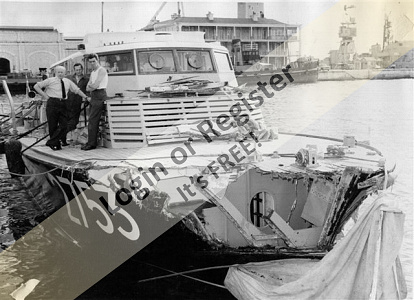

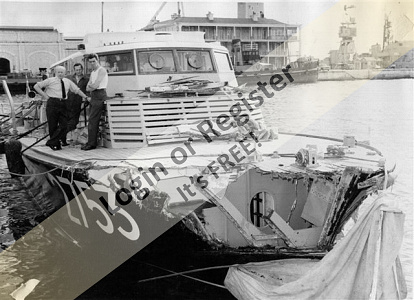

Hi there, I know its a bit too late now....but a few images from the RTTL file of mine. These may be of interest to you.

John

John

▲

⟩⟩

cumbrae

hermank

jumpugly

Rogal118

roycv

AlessandroSPQR

📝 Bluebird

3 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 40 Views · 4 Likes

Flag

📝 Reply

Hi zooma

Have you had a look at the link which I put on here (on my last posting) regarding Thrust WSH - its quite enlightening. Although, you may already know about this. Wouldnt you think all of the money they spent to rebuild Bluebird could have been put towards this.

This would have been a better tribute to Donald Campbell and his family.

John

Have you had a look at the link which I put on here (on my last posting) regarding Thrust WSH - its quite enlightening. Although, you may already know about this. Wouldnt you think all of the money they spent to rebuild Bluebird could have been put towards this.

This would have been a better tribute to Donald Campbell and his family.

John

▲

⟩⟩

hermank

GaryLC

jumpugly

zooma

📝 Bluebird

3 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 40 Views · 5 Likes

Flag

📝 Reply

hi there, before we all start taking sides and saying who is to blame and try to point the finger. We need to have the full story, right from when Gina Campbell first gave the go-ahead for the wreck to be salvaged. What I will say is that Bill Smith is a business man and his prime aim in anything is to gain profits. I do not think there was much if any respect given by him towards Donald Campbell or his family.

What was evident to me and a big eye-opener as well was when a statement was made that Bluebird was heavily over engineered and it could have been made lighter. Did the person who made that statement not know that when Bluebird was first constructed - all calculations regarding the construction were done with a slide ruler and paper.

I have followed the full scenario of this - even to the televised Court Case, because I have a great interest in this.

My personal feelings is that Bluebird should have been left as was when found and stabilised and put on show. Because there are a few mock ups of Bluebird which were used for the film Across the Lake with the actor Anthony Hopkins. Before Donald Campbell made his fatal run, he did know Bluebird was at its limits, because he said if he had achieved 300 mph; he would have been in a better position for financing and developing a faster boat.

Each to his own thoughts, but, we do have to be careful what we believe.

What was evident to me and a big eye-opener as well was when a statement was made that Bluebird was heavily over engineered and it could have been made lighter. Did the person who made that statement not know that when Bluebird was first constructed - all calculations regarding the construction were done with a slide ruler and paper.

I have followed the full scenario of this - even to the televised Court Case, because I have a great interest in this.

My personal feelings is that Bluebird should have been left as was when found and stabilised and put on show. Because there are a few mock ups of Bluebird which were used for the film Across the Lake with the actor Anthony Hopkins. Before Donald Campbell made his fatal run, he did know Bluebird was at its limits, because he said if he had achieved 300 mph; he would have been in a better position for financing and developing a faster boat.

Each to his own thoughts, but, we do have to be careful what we believe.

▲

⟩⟩

Rookysailor

hermank

GaryLC

AlessandroSPQR

jumpugly

📝 What tug is this?

6 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 63 Views · 3 Likes

Flag

📝 Reply

hi there, I dont know if this is of any help to yourself however, there is a plan available of the steam tug F C Sturrock Plan is numbered MM1480 - from sarik hobbies. There was a build of this particular tug which was printed in Model Boats Magazine - I am unsure of what year it was - but we can try and find that out for you.

I do have this particular plan myself - and - it is on my 'to do list'

I have just found this on the Model Boats website and this does give the issues etc if you are interested. I do know that these magazines become available on Ebay and also in Magazine Exchange.

"Part 1 was the June 1997 issue of MB and then parts 2, 3, 4 and 5 were in July, Aug, Sept and Oct 1997. They were MB issues 558 to 562 inclusive".

John

I do have this particular plan myself - and - it is on my 'to do list'

I have just found this on the Model Boats website and this does give the issues etc if you are interested. I do know that these magazines become available on Ebay and also in Magazine Exchange.

"Part 1 was the June 1997 issue of MB and then parts 2, 3, 4 and 5 were in July, Aug, Sept and Oct 1997. They were MB issues 558 to 562 inclusive".

John

▲

⟩⟩

hermank

EdW

Wolle

Login To

Remove Ads

Remove Ads

📝 Propulsion; three props or other systems

7 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 25 Views · 3 Likes

Flag

📝 Reply

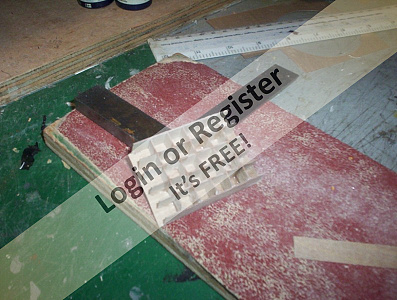

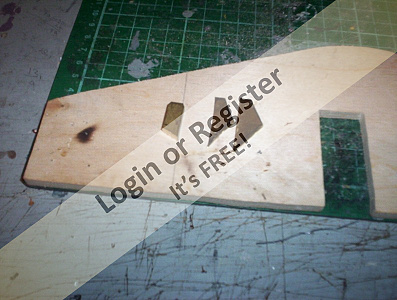

building the Kort nozzle and it presented me with a bit of a problem – because of its awkward size in diameter. Normally, I would have used a bit of 3” plastic drainpipe machined to the correct shape and size. This one has an outside diameter/dimension of 68 mm. So, I ended up laminating the Kort from plywood and the procedure I used for this was:

I used a cardboard tube which came from the centre of some knitting yarn which the Mrs is using at the moment. This tube had correct internal dimension required which corresponded with the outside diameter of the Kort nozzle so – this tube became the former for me to build up laminates of 1 mm thick plywood by 30 mm wide by roughly 200 mm long to begin with. The first laminate I applied some cellotape to one side of it to prevent it bonding to the inside of the cardboard tube.

This laminate was placed inside the tube first with no glue on ensuring that the side which had the cellotape on was against the inside of the cardboard tube. The second piece of plywood of similar dimensions, only slightly shorter had the glued to the inner piece of plywood already in the cardboard tube ensuring that the butt joints were opposite each other. Then an assortment of clamps clamping the laminates together – when this had dried, I applied 4 more laminates building up the required wall thickness of the Korts nozzle. This was then allowed to dry out completely and then the cardboard tubing was removed.

I have the facility of a lathe to which I machined the outside/inside angle and polished. This was then given 2 coats of epoxy resin.

For those not having the facility of a lathe – you could make a mandrel up to hold the nozzle and then machine it in an electric drill. From plasticard I also made a double jig up for aligning the nozzle with the prop shaft. Then I located and fixed the nozzle in place using 2 brass pins.

aye

john

I used a cardboard tube which came from the centre of some knitting yarn which the Mrs is using at the moment. This tube had correct internal dimension required which corresponded with the outside diameter of the Kort nozzle so – this tube became the former for me to build up laminates of 1 mm thick plywood by 30 mm wide by roughly 200 mm long to begin with. The first laminate I applied some cellotape to one side of it to prevent it bonding to the inside of the cardboard tube.

This laminate was placed inside the tube first with no glue on ensuring that the side which had the cellotape on was against the inside of the cardboard tube. The second piece of plywood of similar dimensions, only slightly shorter had the glued to the inner piece of plywood already in the cardboard tube ensuring that the butt joints were opposite each other. Then an assortment of clamps clamping the laminates together – when this had dried, I applied 4 more laminates building up the required wall thickness of the Korts nozzle. This was then allowed to dry out completely and then the cardboard tubing was removed.

I have the facility of a lathe to which I machined the outside/inside angle and polished. This was then given 2 coats of epoxy resin.

For those not having the facility of a lathe – you could make a mandrel up to hold the nozzle and then machine it in an electric drill. From plasticard I also made a double jig up for aligning the nozzle with the prop shaft. Then I located and fixed the nozzle in place using 2 brass pins.

aye

john

▲

⟩⟩

Len1

EdW

hermank

📝 Propulsion; three props or other systems

7 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 43 Views · 6 Likes

Flag

📝 Reply

just a quick note, whilst doing a lot of research on the Vosper RTTL Launch; it was discovered that, originally the boats were triple screw all driving in the same direction. Vosper did experiment on these and it was found that there was a slight increase in speed over the prop formation of 2 outboard props turning inboard and the centre prop was turning inboard or outboard and that it made no difference to the speed. It was also found, later on, that with the props all turning in the same direction the boat did have a tendency to corkscrew when going on the plane and the boat would dive into the next wave in front. Consequently breaking planking on the bottom of the hull at the bow. So, Vosper strengthened the hull by adding a 3rd layer of planking to the bottom of these boats. The other thing which has been mentioned is that during the War the shortage of materials for making reverse drive gear boxes was one of the main reasons for all of the MTBs and PT boats shafts driving in the same direction .

▲

⟩⟩

Len1

hermank

AlessandroSPQR

Ray

Ronald

Chum444

📝 Prop selection for triple (3) props

7 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 61 Views · 3 Likes

Flag

📝 Reply

hi there

I believe this question may have been asked on Mayhem Forum and to which I posted several photographs of fast plaining vessels, to show which way the props turn. But, having said that, we will try this way .... normally you would have your 2 outboard props turning inwards; and, depending on the design of the vessel, the centre prop will either rotate port or starboard. However, on lifesized vessels, they have the ability to control the speeds of the props whilst the vessel is turning. Slow the inboard prop down and speed the outside prop up, depending on which way the vessel is turning. Normally whilst performing manouvres like this the centre prop is slowed down, so, it doesnt influence any turning. In model ways, we can assimilate this as there are mixers on the market which we incorporate with our speed controllers which allow us to do this. One of them is from ACTion which has the speed controllers and the mixer combined. This allows you to add a 3rd speed controller for your centre prop. There are obviously other mixers on the market.

As far as prop walk - it would be very negligable on our scale models unless all the props are turning in the same direction when it does have affect.

John

I believe this question may have been asked on Mayhem Forum and to which I posted several photographs of fast plaining vessels, to show which way the props turn. But, having said that, we will try this way .... normally you would have your 2 outboard props turning inwards; and, depending on the design of the vessel, the centre prop will either rotate port or starboard. However, on lifesized vessels, they have the ability to control the speeds of the props whilst the vessel is turning. Slow the inboard prop down and speed the outside prop up, depending on which way the vessel is turning. Normally whilst performing manouvres like this the centre prop is slowed down, so, it doesnt influence any turning. In model ways, we can assimilate this as there are mixers on the market which we incorporate with our speed controllers which allow us to do this. One of them is from ACTion which has the speed controllers and the mixer combined. This allows you to add a 3rd speed controller for your centre prop. There are obviously other mixers on the market.

As far as prop walk - it would be very negligable on our scale models unless all the props are turning in the same direction when it does have affect.

John

▲

⟩⟩

Len1

SimpleSailor

hermank

📝 Warships Only

7 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 47 Views · 2 Likes

Flag

📝 Reply

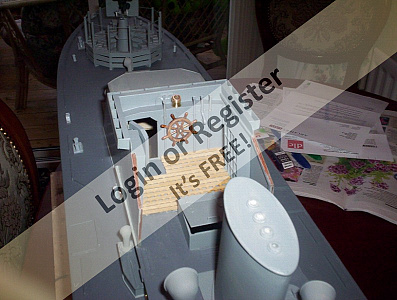

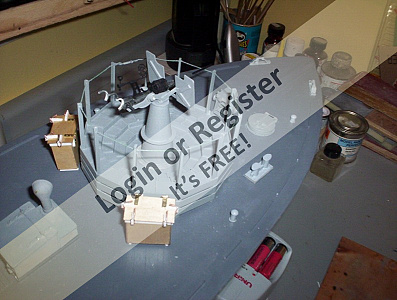

here are a couple of pics of half my Naval fleet. HMS Exeter at 1:96 scale; HMS York 1:96 scale; Fairmile B 1:12 scale - all of them plank on frame, scratch built.

▲

⟩⟩

hermank

LewZ

📝 Building from plans

7 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 56 Views · 8 Likes

Flag

📝 Reply

hi

I am in the camp of tracing paper for transferring from plans to building materials. The main reason for this is once you have traced all your building frames along with water lines and verticals, you can lay the tracing paper one on top of the other to ensure that they all align up correctly and you can make sure you don't have any mis shaped /out of line frames.

The other bonus is when you draw the internals of the frames i.e. where you are going to cut the centres out. If you trace this as well, you can flick the tracing paper over so that they are identical both sides. The third and final bonus to this system is you can place all your tracings onto the building materials and move them around so you can obtain the most economical spacings for your frames from the building materials sheet.

Just as a side note about lite ply - an old dear friend Dave Milbourn used to swear by it - but you must ensure it is water proofed well. I normally give mine a couple of coats of HMG Paints Sanding Sealer. It does stink, but it does the job great.

John

I am in the camp of tracing paper for transferring from plans to building materials. The main reason for this is once you have traced all your building frames along with water lines and verticals, you can lay the tracing paper one on top of the other to ensure that they all align up correctly and you can make sure you don't have any mis shaped /out of line frames.

The other bonus is when you draw the internals of the frames i.e. where you are going to cut the centres out. If you trace this as well, you can flick the tracing paper over so that they are identical both sides. The third and final bonus to this system is you can place all your tracings onto the building materials and move them around so you can obtain the most economical spacings for your frames from the building materials sheet.

Just as a side note about lite ply - an old dear friend Dave Milbourn used to swear by it - but you must ensure it is water proofed well. I normally give mine a couple of coats of HMG Paints Sanding Sealer. It does stink, but it does the job great.

John

▲

⟩⟩

Madwelshman

Waiting2Retire

RodC

EdW

cheddarman

ChrisF

Len1

roycv

💬 Re: Propeller Shafts and Propellers to Complete the Drive Train

8 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 54 Views · 8 Likes

Flag

💬 Add Comment

hi there,

As has already been mentioned, adding electrician tape to the outside of the hull, whilst epoxying your propeller shafts in place, is one of the best methods.

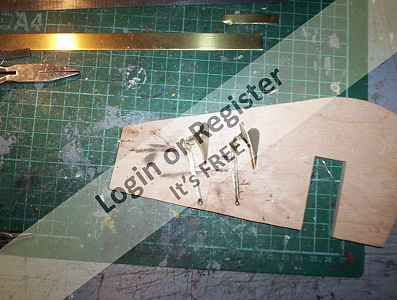

Also, one of the tips which I learned was to make 2 plywood templates up with the correct distance between your prop shafts and the hull & this is placed over the end of the prop shafts to keep them in line. One plywood jig on the outside and one identical plywood jig on the inside over the prop shafts. This helps keep the shafts parallel whilst the epoxy sets.

John

As has already been mentioned, adding electrician tape to the outside of the hull, whilst epoxying your propeller shafts in place, is one of the best methods.

Also, one of the tips which I learned was to make 2 plywood templates up with the correct distance between your prop shafts and the hull & this is placed over the end of the prop shafts to keep them in line. One plywood jig on the outside and one identical plywood jig on the inside over the prop shafts. This helps keep the shafts parallel whilst the epoxy sets.

John

▲

⟩⟩

chugalone100

premecekcz

AlessandroSPQR

hermank

thadlietz

peterbro

SimpleSailor

ChrisF

💬 Re: Rudders Fitted

8 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 92 Views · 5 Likes

Flag

💬 Add Comment

hi there

I made my servo horns for my RTTL from an old 3-pin plug and 2 strips of brass. Also, I use what is known as a closed circuit system for the push rods to the rudder servo whereas the 2 rudder horns are joined together.

John

I made my servo horns for my RTTL from an old 3-pin plug and 2 strips of brass. Also, I use what is known as a closed circuit system for the push rods to the rudder servo whereas the 2 rudder horns are joined together.

John

▲

⟩⟩

hermank

peterd

EdW

premecekcz

SimpleSailor

💬 Re: Bluebird k-7

9 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 94 Views · 7 Likes

Flag

💬 Add Comment

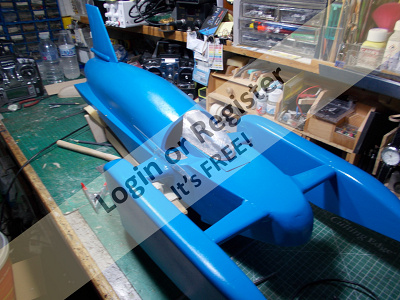

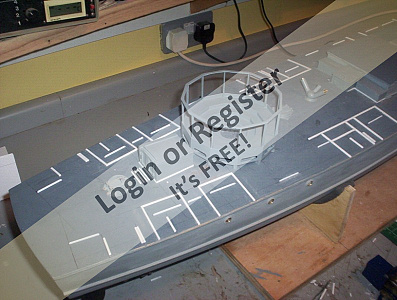

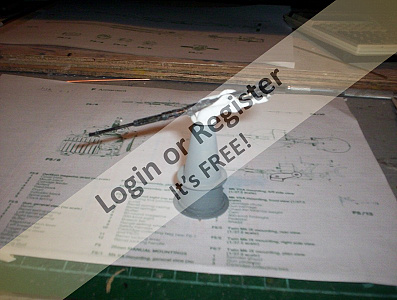

hi ya there my friend, when I first built Bluebird, I worked to the formulae of the surface area of Bluebirds air intakes must equal the surface area of the fan face. Don't forget, or as you may already know, any obstructions in the front of the fan will decrease the efficiency drastically. So, that was why I suggested removing Donald and the plastic canopy. The model I built, I used a wire mesh to represent the canopy and it is hard to tell the difference when she is on the lake. Also, you are right about making a funnel to channel the air from the air ducts to the fan. A lot of failures of Bluebird and ducted fans is because many people miss this out. What actually happens, is, you cannot supply sufficient air through the ducts and it creates a vacuum between the ducts and the fan.

Here are a couple of pics of the build of mine showing the air funnel from the ducts to the fan.

John

Here are a couple of pics of the build of mine showing the air funnel from the ducts to the fan.

John

▲

⟩⟩

jbkiwi

Peejay

SouthportPat

Ray

RodC

hermank

jumpugly

💬 Re: Bluebird k-7

9 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 94 Views · 4 Likes

Flag

💬 Add Comment

Hi, I like that mind, it is as smart as a dart that one is.

Here is food for thought - if you lose Donald & the perspex canopy to increase air flow into the ducted fan; an 80 mm 12 bladed fan running on 22 volts should give you in the region of about 6 - 6.5 lb thrust which should just get her on the plane.

It all really depends on the size and weight of your batteries.

If you want to go down the route of the old brushless motor and propeller there is a good topic which ran on model boat mayhem, where a few people actually converted Bluebird to being prop driven & had pretty good results. If you aren't already a member of the Mayhem forum you could join just to see photographs & etc.

All good stuff my friend.

Here is a link:

Here is food for thought - if you lose Donald & the perspex canopy to increase air flow into the ducted fan; an 80 mm 12 bladed fan running on 22 volts should give you in the region of about 6 - 6.5 lb thrust which should just get her on the plane.

It all really depends on the size and weight of your batteries.

If you want to go down the route of the old brushless motor and propeller there is a good topic which ran on model boat mayhem, where a few people actually converted Bluebird to being prop driven & had pretty good results. If you aren't already a member of the Mayhem forum you could join just to see photographs & etc.

All good stuff my friend.

Here is a link:

▲

⟩⟩

Peejay

SouthportPat

hermank

jumpugly

📝 Help identify a part completed project

11 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 40 Views · 6 Likes

Flag

📝 Reply

Hi there

Just to give you some idea of what can be achieved with the internals of the boat, without removing the deck - these models require a small amount of power to push them along at quite a speed. So, in this model that I built there was a 385/400 MFA motor driving a 35mm 4 bladed brass prop. I used (I think it was a 7.2 NiCad battery). Bear in mind this model was built in the 90s - the weird looking circuitry either side of the motor on the strip board is an actual home made speed controller. As you can see, there is a standard servo which I fitted and a miniature receiver. There is also room for a power supply of 4.5 volt for the radio gear.

With today's new technology and cheaper speed controllers from China - which we will all have to buy awfully quickly - so we have plenty in stock for future projects - I can see no problems with fitting out this little model.

One thing to note with the model I built, it was plank on frame and not balsa wood.

The funnel was made from a 'Haliborange vitamin C tube'.

John

Just to give you some idea of what can be achieved with the internals of the boat, without removing the deck - these models require a small amount of power to push them along at quite a speed. So, in this model that I built there was a 385/400 MFA motor driving a 35mm 4 bladed brass prop. I used (I think it was a 7.2 NiCad battery). Bear in mind this model was built in the 90s - the weird looking circuitry either side of the motor on the strip board is an actual home made speed controller. As you can see, there is a standard servo which I fitted and a miniature receiver. There is also room for a power supply of 4.5 volt for the radio gear.

With today's new technology and cheaper speed controllers from China - which we will all have to buy awfully quickly - so we have plenty in stock for future projects - I can see no problems with fitting out this little model.

One thing to note with the model I built, it was plank on frame and not balsa wood.

The funnel was made from a 'Haliborange vitamin C tube'.

John

▲

⟩⟩

Isaac

Len1

RNinMunich

BillA

Mike Stoney

chugalone100

Login To

Remove Ads

Remove Ads

📝 Help identify a part completed project

11 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 63 Views · 5 Likes

Flag

📝 Reply

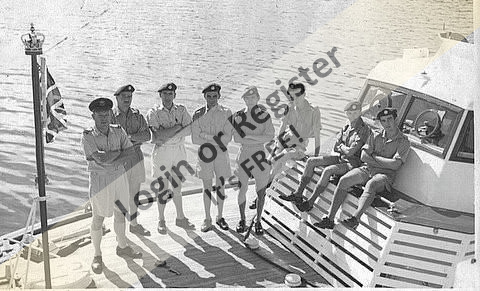

Hi ya there,

Thank you for your kind comments. The model has been made for a while now - something like 20 0dd years - the figures are 1:35 Tamiya make and I think they are the loading crew off the flack gun (if I remember rightly). I think the figure standing at the side with a blue suit on, came from Deans Marine, because he is made from white metal. I have been on the Deans site - but - I cannot find any at 1:35 scale, only at 1:24 and some smaller - as in 1:96 scale.

I have heard reports that the figures you receive, you may have to do a good bit of work on them to make them look respectable. I Hope this helps.

John

Thank you for your kind comments. The model has been made for a while now - something like 20 0dd years - the figures are 1:35 Tamiya make and I think they are the loading crew off the flack gun (if I remember rightly). I think the figure standing at the side with a blue suit on, came from Deans Marine, because he is made from white metal. I have been on the Deans site - but - I cannot find any at 1:35 scale, only at 1:24 and some smaller - as in 1:96 scale.

I have heard reports that the figures you receive, you may have to do a good bit of work on them to make them look respectable. I Hope this helps.

John

▲

⟩⟩

Len1

RodC

hermank

Wolle

chugalone100

📝 Help identify a part completed project

11 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 63 Views · 12 Likes

Flag

📝 Reply

hi there

That model looks remarkably like a Vic Smeed design of a Customs Launch - which was a free plan many moons ago in Model Boats Magazine. There is also a very similar design / model which is slightly larger but I believe it is based on a vac formed hull. Similar style customs launch - give me time to wake up 🙄 and I will look for some photographs and plan references.

The plan was first published in the Model boats mag in Jan 1982 👍

That model looks remarkably like a Vic Smeed design of a Customs Launch - which was a free plan many moons ago in Model Boats Magazine. There is also a very similar design / model which is slightly larger but I believe it is based on a vac formed hull. Similar style customs launch - give me time to wake up 🙄 and I will look for some photographs and plan references.

The plan was first published in the Model boats mag in Jan 1982 👍

▲

⟩⟩

SimpleSailor

RodC

DWBrinkman

RNinMunich

AlessandroSPQR

Len1

chugalone100

hermank

Wolle

Ronald

peterd

BillA

📝 Bluebird K-7 Obsession

11 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 34 Views · 2 Likes

Flag

📝 Reply

hi there

A Plan for a Jet X powered semi scale Bluebird is available from a Company located in Canada who may be producing the plans.

Next picture Don Walkenshaw's gas turbine driven Bluebird K7 - early version.

john

A Plan for a Jet X powered semi scale Bluebird is available from a Company located in Canada who may be producing the plans.

Next picture Don Walkenshaw's gas turbine driven Bluebird K7 - early version.

john

▲

⟩⟩

RPLedm

jumpugly

📝 Bluebird K-7 Obsession

12 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 78 Views · 8 Likes

Flag

📝 Reply

Hi there

I think the maximum speed I would be able to achieve with this model of Bluebird would be possibly 45 to 50 mph that would really be stretching it.

Long story - but I don't fancy the idea of taking more yachts out at the lakeside 😊😮

For the novice; the basic principal of a ducted fan is a propeller in a tube - what volume of air & speed is pushed out at the back end. It is not increased in volume - it is just whatever goes in the front - comes out at the back - at the same volume and speed.

Unlike a jet engine - where the air is expanded in a gas form and accelerated at a greater speed.

Therefore, with a ducted fan, your critical factor is the power to weight ratio, so, the all up weight of my model Bluebird is just over 4 llb and that is with the batteries in the model. The thrust of the ducted fan is roughly about 6 - 7 llb. Giving a ratio of about 1.75 llb.

To get more speed, I would somehow have to drop the weight of the vessel, or, increase the thrust.

If you want a good headache, my next model which I am in the process of testing further is John Cobb's Crusader (1955). This has 100 mm ducted fan and is a running on 44 volts. It refuses to plane properly - when she starts off she creates such a spray it sucks a lot of water into the fan and therefore flooding the model.

I have sent off for lighter batteries and I am thinking about repositioning the centre of gravity & all sorts. Later this year I think for retesting.

John

I think the maximum speed I would be able to achieve with this model of Bluebird would be possibly 45 to 50 mph that would really be stretching it.

Long story - but I don't fancy the idea of taking more yachts out at the lakeside 😊😮

For the novice; the basic principal of a ducted fan is a propeller in a tube - what volume of air & speed is pushed out at the back end. It is not increased in volume - it is just whatever goes in the front - comes out at the back - at the same volume and speed.

Unlike a jet engine - where the air is expanded in a gas form and accelerated at a greater speed.

Therefore, with a ducted fan, your critical factor is the power to weight ratio, so, the all up weight of my model Bluebird is just over 4 llb and that is with the batteries in the model. The thrust of the ducted fan is roughly about 6 - 7 llb. Giving a ratio of about 1.75 llb.

To get more speed, I would somehow have to drop the weight of the vessel, or, increase the thrust.

If you want a good headache, my next model which I am in the process of testing further is John Cobb's Crusader (1955). This has 100 mm ducted fan and is a running on 44 volts. It refuses to plane properly - when she starts off she creates such a spray it sucks a lot of water into the fan and therefore flooding the model.

I have sent off for lighter batteries and I am thinking about repositioning the centre of gravity & all sorts. Later this year I think for retesting.

John

▲

⟩⟩

Commodore-H

AlessandroSPQR

Ray

Chuck

RPLedm

hermank

jumpugly

Mike Stoney

📝 Bluebird K-7 Obsession

12 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 78 Views · 4 Likes

Flag

📝 Reply

My model is 1/8 scale - and the ducted fan is 80 diameter - with 12 blades. Running on 2 voltages for testing - the first was run on 14.8 batteries just to find out the characteristics of how she handled. Then when I was happy and ironed out a few faults, I upgraded the batteries up to 11.1 giving a total voltage of 22.2 volts. Now all I need is a BIGGER lake, to allow the model to achieve its top speed. As I was having to throttle it down 1/3 of the way down the length of the lake cos she ran on 'no power' for a good distance.

▲

⟩⟩

Chuck

hermank

Mike Stoney

jumpugly

📝 Bluebird K-7 Obsession

12 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 71 Views · 12 Likes

Flag

📝 Reply

new vid of Bluebird K7

JOHN

JOHN

▲

⟩⟩

xtramaths

Commodore-H

Ray

Chuck

Cashrc

ScouterChil

hermank

Mike Stoney

GaryLC

AlessandroSPQR

luckyduck

jumpugly

📝 Bluebird K-7 Obsession

12 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 73 Views · 10 Likes

Flag

📝 Reply

hi there

a ducted fan driven Bluebird is not a simple matter - I myself spent a good few years doing a lot of research -collecting plans and data from all over the place. Any person who is confessing to have built or is building an exact scale of Bluebird K7 to be driven by a ducted fan - I myself would be very sceptical. The reason I come up with this statement is I have done it myself and built the model. My model is pretty successful. My model is driven by a 80 mm ducted fan and I think it was 2 x 6S lipo batteries. The model is made basically from very lite ply and balsa wood. I had to think of a way to increase the flow of air into the ducted fan as on the model the canopy (if it is solid) will restrict airflow (only on a ducted fan and not gas turbine).

The way I worked around it, the canopy is of a mesh, and under the canopy is a hollow tube which runs to the fan and either side of the canopy there is an opening in the deck to allow more airflow.

The model I built achieved approximately 37 - 38 mph. However, the size of the lake restricted me from keeping the power on. I do have a couple of photographs which I will put on.

Also, if you go onto my 'harbour' have a look at the short video and couple of pictures of the build which I put on Mayhem.

There are a set of plans for her which are available on the web also, you may be able to obtain a set of plans from the Bluebird Society which is in the Lake District (Ruskin museum).

john

a ducted fan driven Bluebird is not a simple matter - I myself spent a good few years doing a lot of research -collecting plans and data from all over the place. Any person who is confessing to have built or is building an exact scale of Bluebird K7 to be driven by a ducted fan - I myself would be very sceptical. The reason I come up with this statement is I have done it myself and built the model. My model is pretty successful. My model is driven by a 80 mm ducted fan and I think it was 2 x 6S lipo batteries. The model is made basically from very lite ply and balsa wood. I had to think of a way to increase the flow of air into the ducted fan as on the model the canopy (if it is solid) will restrict airflow (only on a ducted fan and not gas turbine).

The way I worked around it, the canopy is of a mesh, and under the canopy is a hollow tube which runs to the fan and either side of the canopy there is an opening in the deck to allow more airflow.

The model I built achieved approximately 37 - 38 mph. However, the size of the lake restricted me from keeping the power on. I do have a couple of photographs which I will put on.

Also, if you go onto my 'harbour' have a look at the short video and couple of pictures of the build which I put on Mayhem.

There are a set of plans for her which are available on the web also, you may be able to obtain a set of plans from the Bluebird Society which is in the Lake District (Ruskin museum).

john

▲

⟩⟩

xtramaths

Ray

Chuck

ScouterChil

hermank

JohnJ1

Mike Stoney

AlessandroSPQR

jumpugly

DWBrinkman

💬 Re: Starting to plank the hull

12 months ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 114 Views · 11 Likes

Flag

💬 Add Comment

hi there

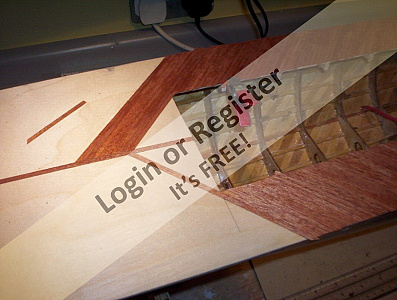

One thing about diagonal planking - you do seem to be going on forevermore putting planks on - getting no where and all of a sudden it is done.

I myself have diagonally planked several hulls; even the one you are building the RTTL hull - and I tend to add stringers from bow to stern - maybe 2 on the side and 2 on the top - of each side of the hull. This serves 3 purposes; 1 it aides a bit more strength to the hull, 2 you can follow the true shape of the hull as in concave of the bottom and on the sides, 3 it gives you an extra place to clamp your planks to.

If you have a look at my photographs in my profile, you will see the RTTL model which I built there.

Are you making it twin prop? or, some of these vessels were triple props if you want a bit more excitement.

Good luck with the planking and the model. It is a lovely model to sail.

John

One thing about diagonal planking - you do seem to be going on forevermore putting planks on - getting no where and all of a sudden it is done.

I myself have diagonally planked several hulls; even the one you are building the RTTL hull - and I tend to add stringers from bow to stern - maybe 2 on the side and 2 on the top - of each side of the hull. This serves 3 purposes; 1 it aides a bit more strength to the hull, 2 you can follow the true shape of the hull as in concave of the bottom and on the sides, 3 it gives you an extra place to clamp your planks to.

If you have a look at my photographs in my profile, you will see the RTTL model which I built there.

Are you making it twin prop? or, some of these vessels were triple props if you want a bit more excitement.

Good luck with the planking and the model. It is a lovely model to sail.

John

▲

⟩⟩

Waiting2Retire

EdW

Wolle

premecekcz

SimpleSailor

jbkiwi

hermank

RNinMunich

Mike Stoney

cenbeth

Ronald

📝 Kitshack Vosper 28” RTTL

1 year ago by 🇬🇧 JOHN ( Midshipman)

Midshipman)

Midshipman)

Midshipman)✧ 45 Views · 6 Likes

Flag

📝 Reply

hi there

Nice project to start on. I am unsure if you are aware of the history of these boats. I found the more you delve into the history of them, the more complicated (shall we say) they become. Some of the boats began life as a Hants and Dorset hull with 3 motors and shafts and ended up having only 2 motors as they were converted. One I do know was fitted with an Oerlikon gun on the rear cabin. They were a bit notorious for splitting the hull open, as they were prone to diving off waves; this was due to the fact that both props and shafts turned in the same direction giving the hull a corkscrew movement. Some hulls were fitted with a wedge shape right at the rear to try and help with this effect. I built a model of the RTTL a good while ago; and I believe it is in my profile dockyard. Here are a couple of photographs which I have managed to find on my computer. I know my build of my model was originally on Mayhem - but after a few crashes of Mayhem a good few pictures have gone missing of the build.

There is also one here of the towing target which the RTTL used to tow.

John

Nice project to start on. I am unsure if you are aware of the history of these boats. I found the more you delve into the history of them, the more complicated (shall we say) they become. Some of the boats began life as a Hants and Dorset hull with 3 motors and shafts and ended up having only 2 motors as they were converted. One I do know was fitted with an Oerlikon gun on the rear cabin. They were a bit notorious for splitting the hull open, as they were prone to diving off waves; this was due to the fact that both props and shafts turned in the same direction giving the hull a corkscrew movement. Some hulls were fitted with a wedge shape right at the rear to try and help with this effect. I built a model of the RTTL a good while ago; and I believe it is in my profile dockyard. Here are a couple of photographs which I have managed to find on my computer. I know my build of my model was originally on Mayhem - but after a few crashes of Mayhem a good few pictures have gone missing of the build.

There is also one here of the towing target which the RTTL used to tow.

John

▲

⟩⟩

Razor1955

SimpleSailor

Len1

EdW

Peejay

DaveWhittaker

Commodore)

Commodore)

Able Seaman)

Able Seaman)

Fleet Admiral)

Fleet Admiral)

Liked Why do we still use Knots Go Question for todays Question 5 days ago

Liked Why do we still use Knots Go Question for todays Question 5 days ago

Liked 3 day running knife fight 19 days ago

Liked 3 day running knife fight 19 days ago

Liked Superstructure 20 days ago

Liked Superstructure 20 days ago