Join Us On Social Media!

Australia

Recent Posts

📝 Vosper Rescue -target towing launch

8 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 15 Views · 1 Like · 3 Comments

Flag

💬 Add Comment

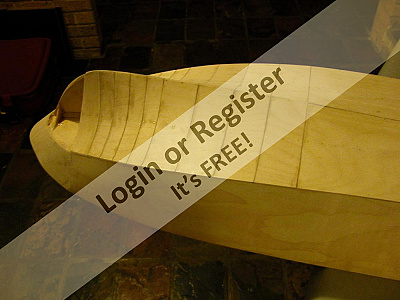

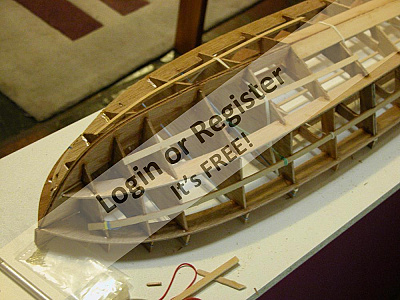

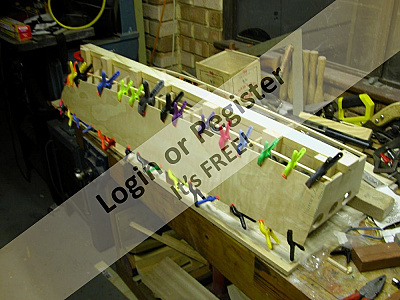

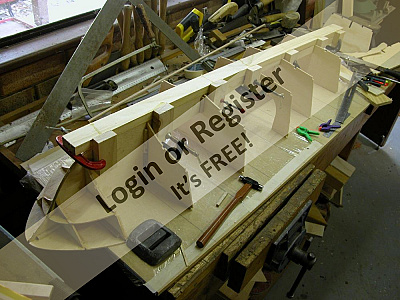

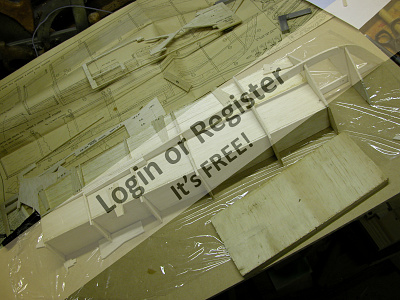

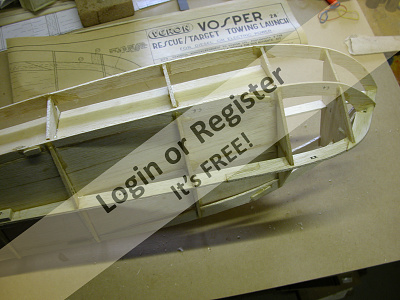

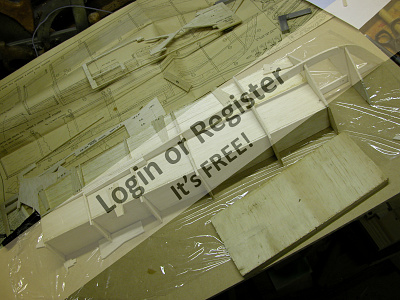

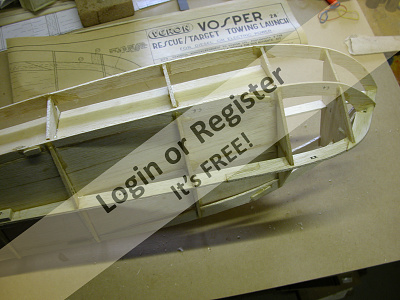

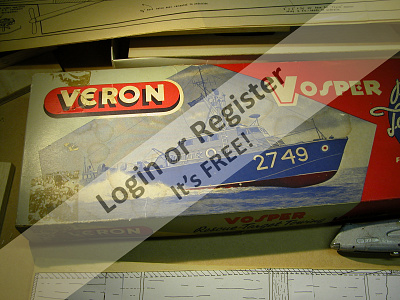

I'm starting to build a Veron kit of the Vosper Rescue-target towing launch, which I bought on Ebay. This boat seems quite rare - well to me anyway - although Belair sell one currently which is similar but slightly larger (34in long - mine is 28in). The kit is obviously old and if anyone knows when these were sold then please let me know.

The structure is balsa - not my favourite wood - and ply for the exterior. Balsa does not hold temporary or permanent pins well, and holding things in position while the glue dries is made more difficult.

The balsa has been pre-cut to shape and several of the curved pieces are weak in places where the grain is inevitably across the length of the piece. I broke several parts and needed ply backing to repair. Glue used is 5 min epoxy.

The keel is made up of several pieces and to get the right shape I photocopied part of the plan and laid the parts on that to set while gluing.

The structure is balsa - not my favourite wood - and ply for the exterior. Balsa does not hold temporary or permanent pins well, and holding things in position while the glue dries is made more difficult.

The balsa has been pre-cut to shape and several of the curved pieces are weak in places where the grain is inevitably across the length of the piece. I broke several parts and needed ply backing to repair. Glue used is 5 min epoxy.

The keel is made up of several pieces and to get the right shape I photocopied part of the plan and laid the parts on that to set while gluing.

▲

⟩⟩

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Perkasa

8 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 23 Views · 6 Likes · 4 Comments

Flag

💬 Add Comment

This is a 49" Perkasa built from a ply Precedent kit - the build blog is on this site. Videoed from a 46" Fireboat on a lake in Western Australia. Neither boat is running at top speed, which is spectacular but overscale! Both boats have identical brushless motors. Apologies for the video being a bit long, and for the water on the lens, but this is a first attempt and I hope you enjoy the music.

▲

⟩⟩

Brightwork

Sakibian

jfstoker

ollie

Scratchbuilder

John2

💬 Naval pinnace or Picket boat completed

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 17 Views · 1 Like

Flag

💬 Add Comment

Thanks for the compliments - a long time coming but eventually worth it. And now for something different......

▲

⟩⟩

Novice

📝 Naval Pinnace (or Royal Navy steam picket boat)

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 17 Views · 2 Likes · 6 Comments

Flag

💬 Add Comment

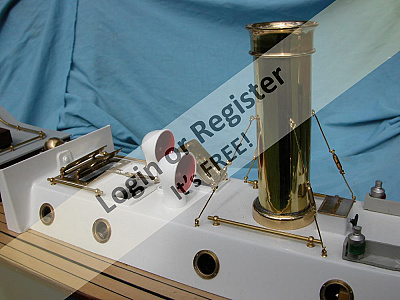

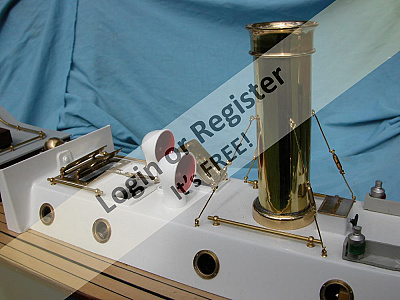

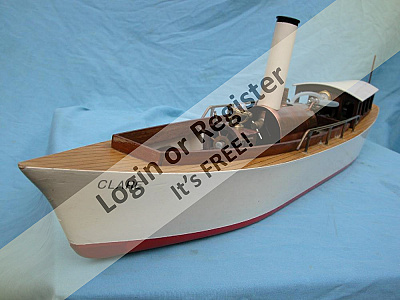

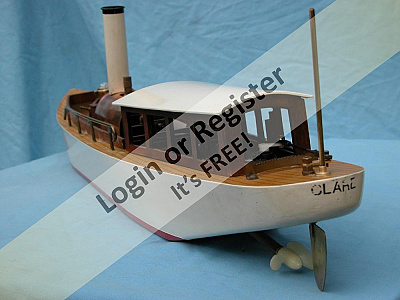

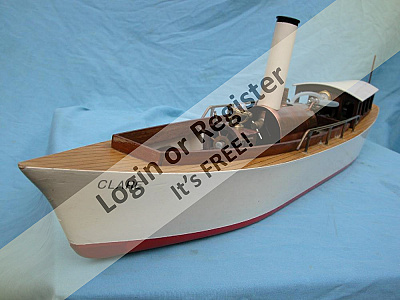

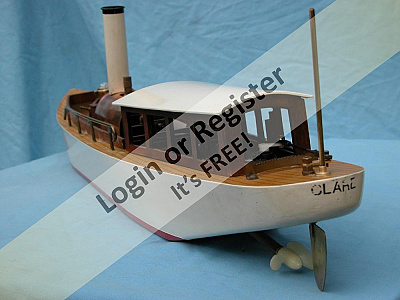

Finally completed after 35 years, must be a record! Boiler clad in balsa insulation and then mahogany strips. Four channel radio, throttle, steering, reverser and gas isolation valve - in case the prop gets stuck on something out on the water.

Hotchkiss 3 pounder made by 3D printing and forward cabin made in fiberglass on a 3D printed mould. All superstructure held down by magnets. Manual gas shut off valve under the gun.

Funnel is rolled brass and hatches scratch built from brass sheet. Very nice looking boat and it's a shame that the 'innards' aren't visible when its working.

Hotchkiss 3 pounder made by 3D printing and forward cabin made in fiberglass on a 3D printed mould. All superstructure held down by magnets. Manual gas shut off valve under the gun.

Funnel is rolled brass and hatches scratch built from brass sheet. Very nice looking boat and it's a shame that the 'innards' aren't visible when its working.

▲

⟩⟩

RNinMunich

ianed57

💬 Clare

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 17 Views · 0 Likes

Flag

💬 Add Comment

HI Roger,

hadn't thought of a tube, and it's a lot simpler than my yacht keel idea!

Laurie

hadn't thought of a tube, and it's a lot simpler than my yacht keel idea!

Laurie

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Clare

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 17 Views · 0 Likes

Flag

💬 Add Comment

Hi Roger,

I have put a couple of bits of flat lead sheet in it but not very much. With a flat bottom hull it really isn't very stable, with little of the hull in the water and no real 'self centering' influence. Having a high centre of gravity (almost all the weight is in a boiler full of water) doesn't help either. My boat does not like a windy day since the keel-less hull has no bite in the water and its easily blown windward. I have considered adding a lightly weighted keel like a yacht (removable?) which would solve all these problems but have as yet ignored it and gone on and built three other boats since that one.

regards,

Laurie

I have put a couple of bits of flat lead sheet in it but not very much. With a flat bottom hull it really isn't very stable, with little of the hull in the water and no real 'self centering' influence. Having a high centre of gravity (almost all the weight is in a boiler full of water) doesn't help either. My boat does not like a windy day since the keel-less hull has no bite in the water and its easily blown windward. I have considered adding a lightly weighted keel like a yacht (removable?) which would solve all these problems but have as yet ignored it and gone on and built three other boats since that one.

regards,

Laurie

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Clare

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 18 Views · 1 Like

Flag

💬 Add Comment

Thanks Roger

▲

⟩⟩

Novice

💬 PT109

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 18 Views · 2 Likes

Flag

💬 Add Comment

HI blucher,

I'm a bit late in replying but even if I had started straight away and Concorde was still flying I doubt I could have got there in time. I live about 14000km away in Perth, Western Australia....... 😓 😎

I'm a bit late in replying but even if I had started straight away and Concorde was still flying I doubt I could have got there in time. I live about 14000km away in Perth, Western Australia....... 😓 😎

▲

⟩⟩

RNinMunich

Novice

💬 PT109

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 18 Views · 1 Like

Flag

💬 Add Comment

Hi,

I bought my Perkasa fittings from

I bought my Perkasa fittings from

▲

⟩⟩

Novice

💬 PT109

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 18 Views · 1 Like

Flag

💬 Add Comment

HI blucher,

The PT109 was built from a Dumas Boats plywood kit which is reasonably heavy, very strong and quite rigid. it has a quite shallow prop shaft angle which allows the motor to sit very low in the boat, and it sits just above the keel. There is not much else in terms of weight other than the batteries, and I have experimented to the extent of fitting four smaller batteries connected in parallel, all sitting on the bottom skin of the boat. They can't get any lower and still be inside the boat! The boat still wants to roll.....

The Perkasa I built was from a Precedent kit with the plywood hull and it was relatively straightforward and very satisfying to build. it isn't plank on frame thank goodness but just uses plywood and a small amount of balsa. I covered mine with fibreglass cloth. My build blog showing the Perkasa and some pictures of the PT109 frames is on this website, and if you go to this link it will take you there directly:

The PT109 was built from a Dumas Boats plywood kit which is reasonably heavy, very strong and quite rigid. it has a quite shallow prop shaft angle which allows the motor to sit very low in the boat, and it sits just above the keel. There is not much else in terms of weight other than the batteries, and I have experimented to the extent of fitting four smaller batteries connected in parallel, all sitting on the bottom skin of the boat. They can't get any lower and still be inside the boat! The boat still wants to roll.....

The Perkasa I built was from a Precedent kit with the plywood hull and it was relatively straightforward and very satisfying to build. it isn't plank on frame thank goodness but just uses plywood and a small amount of balsa. I covered mine with fibreglass cloth. My build blog showing the Perkasa and some pictures of the PT109 frames is on this website, and if you go to this link it will take you there directly:

▲

⟩⟩

Novice

💬 PT109

10 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 18 Views · 1 Like

Flag

💬 Add Comment

HI Seaman Blucher - shouldn't that be Admiral? Are you named after Gebhard Leberecht von Blücher of WW1 warship fame?

Anyway, thanks for your comments, although my intention was never to put anyone off building these boats. I have looked at other peoples PT109s and seem to recognised the same stability problems that mine exhibits. Mine can look quite alarming when turning to starboard - I can't help thinking it's going to 'dig in' and submarine, even after the turn signal is cancelled.

I have to admit that I probably installed the rudder a few degees off vertical - not much really, about 3-4 degrees - and wondered if it was that. I should get around to straightening it up one day. I have tried multiples of lower batteries and more ballast up front or at the stern but nothing has improved it. The boat isn't plastic, it's plywood and you can see its very robust construction on the build blog I did for it on this site.

Your idea of a false keel or keels might work but seems very drastic when you think how many of these kits have been made, and presumably they don't suffer from the same stability problems that mine does. At least I haven't heard of it if they do.

I have also thought about fitting trim tabs which I expect will fight any tendency to roll the boat at speed. Obviously more work is needed but my Perkasa works so well the PT109 is on the shelf for the moment!

Anyway, thanks for your comments, although my intention was never to put anyone off building these boats. I have looked at other peoples PT109s and seem to recognised the same stability problems that mine exhibits. Mine can look quite alarming when turning to starboard - I can't help thinking it's going to 'dig in' and submarine, even after the turn signal is cancelled.

I have to admit that I probably installed the rudder a few degees off vertical - not much really, about 3-4 degrees - and wondered if it was that. I should get around to straightening it up one day. I have tried multiples of lower batteries and more ballast up front or at the stern but nothing has improved it. The boat isn't plastic, it's plywood and you can see its very robust construction on the build blog I did for it on this site.

Your idea of a false keel or keels might work but seems very drastic when you think how many of these kits have been made, and presumably they don't suffer from the same stability problems that mine does. At least I haven't heard of it if they do.

I have also thought about fitting trim tabs which I expect will fight any tendency to roll the boat at speed. Obviously more work is needed but my Perkasa works so well the PT109 is on the shelf for the moment!

▲

⟩⟩

Novice

Login To

Remove Ads

Remove Ads

📝 brushless motor

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 12 Views · 2 Likes

Flag

📝 Reply

Hi,

I use the same motor on both my 46" Fireboat and on my slightly bigger Perkasa. it is the Turnigy AquaStar 4084-620KV, run with two 5000mAh 4 cell (14.8V) LiPo batteries in parallel, and this gives both boats a brilliant and potentially slightly overscale speed and a long run time.

Go to

I use the same motor on both my 46" Fireboat and on my slightly bigger Perkasa. it is the Turnigy AquaStar 4084-620KV, run with two 5000mAh 4 cell (14.8V) LiPo batteries in parallel, and this gives both boats a brilliant and potentially slightly overscale speed and a long run time.

Go to

▲

⟩⟩

Novice

dawnthreader

💬 Re: Swol progress

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 30 Views · 2 Likes

Flag

💬 Add Comment

Hi, and thanks for the complement. With a powerful motor this boat is very impressive to run and I don't see much point in two motors/shafts/props when one will do the job extremely well. Good luck with your build.

▲

⟩⟩

Sakibian

Novice

📝 Boiler and steam engine.

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 19 Views · 3 Likes

Flag

💬 Add Comment

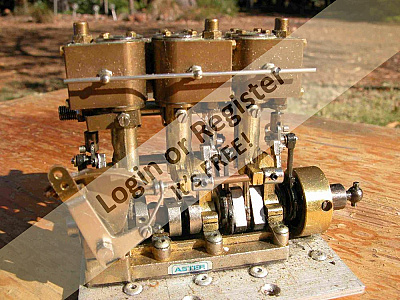

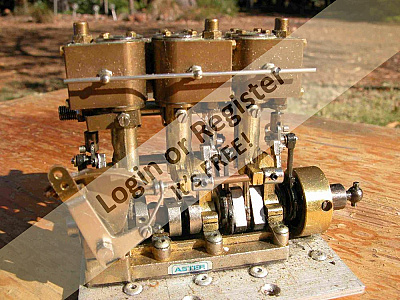

The power for this boat comes from a three cylinder steam engine and boiler made by the Japanese company Aster, better known for their Gauge 1 locomotives. The engine is double acting but it's 'simple' not compound, and is identical to the engine they fitted to the three cylinder 'Shay' type geared logging locomotive. The boiler, which I will eventually lag and clad with timber, was originally fired by an Aster metholated spirit burner which relied on the heat from its own flame to heat and pressurise the meths tank and push meths vapour out of a tiny jet, and make a 'blowlamp' type flame which entered the flue. I found this extemely touchy and difficult to use and despite years of experimenting (I bought this in the early '80's too!) I gave up and bought a ceramic burner from Maccsteam which works well.

▲

⟩⟩

Novice

sandkb

robtroi

📝 Naval Pinnace (or Royal Navy steam picket boat)

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 19 Views · 3 Likes

Flag

💬 Add Comment

I bought the fibreglass moulding for this hull in 1981 and clearly it has taken a long time to get round to building it... I bought it from Aero Nautical Models in Camden Town and have long thought it was a Kingston Mouldings Hull. Since their hull is 40" long and the Aero Nautical Models one which I have is only 36", I was wrong. The plan is MW/1328 from the Model Boats plan service - or at least it was then!

It got a bit flattened in my suitcase on its way to Australia, and 34 years later it took some fiddling to get the internal ply frames the right shape and in the right place to straighten it out. I bought the 'Heat Resistant' version - at £16.80 it was £3 more than the standard one - but I have already managed to scorch the inside where a burner flame touched it, so how heat resistant it is, I have yet to find out. I doubt it is very resistant at all!

The photographs show that a lot of aluminium sheet has been added below and around the boiler area to shield the hull from heat,and aluminium is also used to support the engine and other essentials.

The deck is 2mm x 10mm lime strips glued to a ply floor, with thick black card glued between the strips to denote the caulking - very effective. Two removable sections are fitted, one over the rudder servo and the other over the boiler area.

It got a bit flattened in my suitcase on its way to Australia, and 34 years later it took some fiddling to get the internal ply frames the right shape and in the right place to straighten it out. I bought the 'Heat Resistant' version - at £16.80 it was £3 more than the standard one - but I have already managed to scorch the inside where a burner flame touched it, so how heat resistant it is, I have yet to find out. I doubt it is very resistant at all!

The photographs show that a lot of aluminium sheet has been added below and around the boiler area to shield the hull from heat,and aluminium is also used to support the engine and other essentials.

The deck is 2mm x 10mm lime strips glued to a ply floor, with thick black card glued between the strips to denote the caulking - very effective. Two removable sections are fitted, one over the rudder servo and the other over the boiler area.

▲

⟩⟩

Novice

sandkb

robtroi

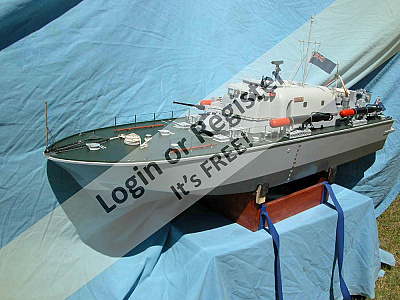

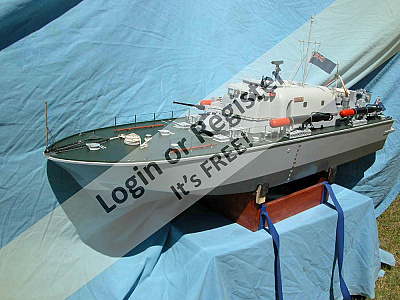

📝 1:24 scale KD Perkasa from an older Precedent kit

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 28 Views · 0 Likes

Flag

💬 Add Comment

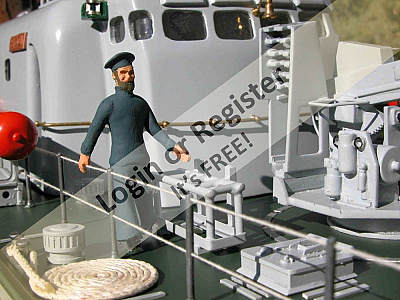

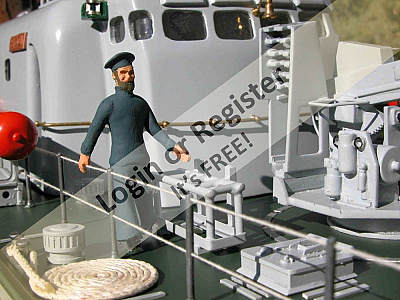

Nothing completes a model like adding some crew to drive It, so at last I have added five scale figures from the Battle Crafts range and painted them a tasteful navy blue.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Clare

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 21 Views · 4 Likes · 6 Comments

Flag

💬 Add Comment

Built from a plan in 'Model Boats' in the 80's with a balsa hull and ply decking. Powered by a single cylinder 'Unit Steam Engine' from the same era, and a meths fired boiler. Only recently has radio control been added.

▲

⟩⟩

Novice

Brightwork

shavings

mehmetalialtas

📝 PT109

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 21 Views · 4 Likes · 11 Comments

Flag

💬 Add Comment

33" Dumas kit of the PT109. Not very stable boat with little freeboard it doesn't inspire confidence at speed. 😭

▲

⟩⟩

Novice

petercbrown

johnfastboat

Northumbrian

📝 (Naval Ship) PT109

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 10 Views · 2 Likes · 2 Comments

Flag

💬 Add Comment

Recently completed, this DUMAS kit is a bit of a disappointment in that its stability - or lack of it - looks quite frightening sometimes. it can take on an alarming list even in a straight line although it takes up a quite satisfactory 'lean into the corner ' when making a turn. Adding and moving weight around has yet to solve this awkward looking performance and I have yet to buy two batteries so the battery weight can be moved lower and possible more to the rear. Speed is not a problem but there is no way that anything like full throttle can be attempted. There is little freeboard and a list looks very alarming at speed! Any ideas? (Motor: Turnigy Aquastar 3660-1460kV) (ESC: Birdie) (4/10)

▲

⟩⟩

RNinMunich

Novice

📝 (Pleasure Craft) Clare (a Basil Harley 'Mabel')

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 11 Views · 2 Likes

Flag

💬 Add Comment

Made in the 1980's from a simple, balsa hulled design in 'Model Boats' magazine. Powered by a purchased 'USE' single cylinder oscillating engine with a solid fuel fired boiler - converted by me to meths firing. No good on a windy day because the flat bottom has little hold on the water and the breeze affects the fire. (Motor: Unit Steam Engines (USE)) (6/10)

▲

⟩⟩

ianed57

Novice

📝 (Working Vessel) Le Marignan

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 10 Views · 2 Likes

Flag

💬 Add Comment

Built from a 'New Maquettes' kit in 1984 and it was quite a difficult kit being plank on frame. Some repair work required now due to planks springing - should have covered the hull in fibreglass and it wouldn't be doing it now probably, but back then it wasn't the 'done thing'. Kit was lot cheaper than the £260 it costs now! (Motor: Graupner Speed 600) (ESC: Inverter FET - from a car.) (8/10)

▲

⟩⟩

RNinMunich

Novice

Login To

Remove Ads

Remove Ads

📝 Wanted - Instructions for Dumas Boats PT109 kit

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 12 Views · 1 Like

Flag

📝 Reply

Thanks jgs43 - I should probably have thought of that first!!! must have been brain fade.

I have just ordered a set of instructions (which includes the drawings) from their website at what seemed a reasonable price.

I have just ordered a set of instructions (which includes the drawings) from their website at what seemed a reasonable price.

▲

⟩⟩

Novice

📝 Wanted - Instructions for Dumas Boats PT109 kit

11 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 11 Views · 0 Likes

Flag

📝 Reply

HI everyone,

I'm building the 33 Inch PT-109 from an old Dumas Boats kit bought online, which unfortunately came with drawings but without the Instruction booklet.

Does anyone have one they could scan and email to me - or photocopy and post? All reasonable expenses reimbursed,

Lauriem

😭

I'm building the 33 Inch PT-109 from an old Dumas Boats kit bought online, which unfortunately came with drawings but without the Instruction booklet.

Does anyone have one they could scan and email to me - or photocopy and post? All reasonable expenses reimbursed,

Lauriem

😭

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 (Naval Ship) K D Perkasa

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 10 Views · 1 Like

Flag

💬 Add Comment

Build was covered in build blog on this website (Motor: Turnigy 4084 - 620KV) (ESC: Turnigy) (10/10)

▲

⟩⟩

Novice

📝 Completed

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 34 Views · 7 Likes · 3 Comments

Flag

💬 Add Comment

Perkasa now finished and maiden voyage completed, build time a bit over five months. Radar rotates and lights work, and Bofors rotates under radio control. initial trials showed that the prop shaft inner had been made out of some bent stainless and it whirled alarmingly at speed, making a horrendous noise. The shaft is quite long and with bearings around 18 inches apart it is very flexible, and the bend when it was stationary just got worse as revs increased. Straightening was found to be Impossible but some Improvement was obtained with a mid-position, pressed in, Teflon bearing, and the terrible rattling/vibration noise was reduced by replacing the rear brass bearing with Teflon. A new inner shaft has however been ordered.

With the same motor and batteries as my 46 inch Fireboat and no extra ballast, the Perkasa weighs about 600g more, but its performance seemed to be slightly faster. This boat does have a 5mm larger propeller but still it only drew around 55A maximum. At high speed it lifted noticeably at the front so after the first run I have added some 300g of leaded vinyl - taken from an old X-ray gown - placed under the Bofors. The hull shape at the front is much more successful than the fireboat in keeping water off the deck at slower speeds, but the hull becomes dead flat at the rear making this a real planing boat capable of high speed. With a single motor and a fairly big prop I found considerable torque reaction, and on the first run I couldn't trim the boat to run straight, it just wanted to turn right. The rudder was adjusted quite a bit to overcome this, but I suppose that's not much of a price to pay if the alternative was contra-rotating motors and props, or three props like the original!

😎

With the same motor and batteries as my 46 inch Fireboat and no extra ballast, the Perkasa weighs about 600g more, but its performance seemed to be slightly faster. This boat does have a 5mm larger propeller but still it only drew around 55A maximum. At high speed it lifted noticeably at the front so after the first run I have added some 300g of leaded vinyl - taken from an old X-ray gown - placed under the Bofors. The hull shape at the front is much more successful than the fireboat in keeping water off the deck at slower speeds, but the hull becomes dead flat at the rear making this a real planing boat capable of high speed. With a single motor and a fairly big prop I found considerable torque reaction, and on the first run I couldn't trim the boat to run straight, it just wanted to turn right. The rudder was adjusted quite a bit to overcome this, but I suppose that's not much of a price to pay if the alternative was contra-rotating motors and props, or three props like the original!

😎

▲

⟩⟩

donkshophorse

rikster67

Novice

sandkb

robtroi

llareggub9568

Mallory

📝 Getting closer...

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 33 Views · 5 Likes

Flag

💬 Add Comment

Most of the painting completed and down to fitting out. The transom flap has been added - not hydraulically operated as in the real thing, but angle adjustable anyway. The transom shelf was originally made removeable - a ply back behind the balsa curvature allowing it to bolted on through the two stay anchor points. it was however bolted and glued in place because it would probably be used as a handle to pick the boat up out of the water... The exhaust flaps are fixed in the open position so at least the turbine exhausts will be open in operation.

Some fiddly bits are now taking my time, like fixing a servo under the Bofors for rotation, and another, modified to continuously rotate, attached beneath the radar scanner. I purchased an electronic servo slowing device which was a disappointment since its operation was slow but jerky in one direction, then rapid on the return! Most unrealistic unless you were to apply it to a plane's undercarriage retract - which is what it was meant for. The continuously rotating radar can be slowed to a stop or speed adjusted simply by using the trim on its R C channel.

Paint was simply aerosol cans from a hardware store, which unfortunately were only available in gloss. However, the same paint supplier sold satin finish clear acrylic spray in aerosols too and his has done a good job.

Some fiddly bits are now taking my time, like fixing a servo under the Bofors for rotation, and another, modified to continuously rotate, attached beneath the radar scanner. I purchased an electronic servo slowing device which was a disappointment since its operation was slow but jerky in one direction, then rapid on the return! Most unrealistic unless you were to apply it to a plane's undercarriage retract - which is what it was meant for. The continuously rotating radar can be slowed to a stop or speed adjusted simply by using the trim on its R C channel.

Paint was simply aerosol cans from a hardware store, which unfortunately were only available in gloss. However, the same paint supplier sold satin finish clear acrylic spray in aerosols too and his has done a good job.

▲

⟩⟩

rikster67

Novice

sandkb

robtroi

taffy

📝 More progress

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 34 Views · 7 Likes

Flag

💬 Add Comment

The hull ended up with a single layer of fibreglass cloth and epoxy over the whole thing, and three layers over the balsa at the front. I don't want the balsa end grain showing through in the future. The superstructure received two layers over the balsa bits also. I have never fibre glassed a model before but I found ¾ oz fibreglass cloth is very forgiving and will readily accept being fitted to quite complex surfaces. if it is too complex a shape and you end up with it folded up or overlapping itself, don't worry because when it's all hard it sands flat very easily.

I used Z-Poxy finishing resin (www.zapadhesives.com) instead of fibreglass resin and found it very nice to use, even if thinned with meths it certainly went hard enough to sand after leaving overnight. On the flatter surfaces of the hull I spread the epoxy with discarded playing cards to leave little excess on the cloth. if you sand too hard you can easily go through the cloth so it's best to lightly sand and fill any open weave with filler.

The superstructure parts really didn't fit that well but after adding some packing and opening out some slots it all went together. I really don't want to see any evidence of balsa or balsa to ply joins in the future, hence the attention to covering it with fibreglass, which left a nice hard surface.

Motor was aligned and installed as shown, and the boat now has a home-made rudder and water scoop installed. I bought an 18 inch prop shaft but cut 1.25 inches off it before it was epoxied in place to get the motor near the centre of the hull.

I used Z-Poxy finishing resin (www.zapadhesives.com) instead of fibreglass resin and found it very nice to use, even if thinned with meths it certainly went hard enough to sand after leaving overnight. On the flatter surfaces of the hull I spread the epoxy with discarded playing cards to leave little excess on the cloth. if you sand too hard you can easily go through the cloth so it's best to lightly sand and fill any open weave with filler.

The superstructure parts really didn't fit that well but after adding some packing and opening out some slots it all went together. I really don't want to see any evidence of balsa or balsa to ply joins in the future, hence the attention to covering it with fibreglass, which left a nice hard surface.

Motor was aligned and installed as shown, and the boat now has a home-made rudder and water scoop installed. I bought an 18 inch prop shaft but cut 1.25 inches off it before it was epoxied in place to get the motor near the centre of the hull.

▲

⟩⟩

rikster67

Novice

sandkb

robtroi

taffy

Lauriem

Colin H

📝 More on the front end

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 34 Views · 6 Likes

Flag

💬 Add Comment

The photo's show my slow progress. The balsa blocks have been added, carved and sanded to shape and then the whole front underside coated with body filler and sanded smooth.

The balsa is in a very vulnerable position and very likely to suffer dings in use, so I am coating the whole front end with two layers of 3/4 oz fibreglass cloth and epoxy resin. This process is new to me, although I've repaired fiberglass canoes in the past but not then worried too much about the finish. This time I used finishing epoxy which was made more 'spreadable' by adding metholated spirit to the emixture. it evaporates before the epoxy hardens but makes it more 'runny' and easy to spread.

It was a relief that it hardened well and sanded easily to remove any drips. The excess fibreglass cloth also sanded off easily.

The balsa is in a very vulnerable position and very likely to suffer dings in use, so I am coating the whole front end with two layers of 3/4 oz fibreglass cloth and epoxy resin. This process is new to me, although I've repaired fiberglass canoes in the past but not then worried too much about the finish. This time I used finishing epoxy which was made more 'spreadable' by adding metholated spirit to the emixture. it evaporates before the epoxy hardens but makes it more 'runny' and easy to spread.

It was a relief that it hardened well and sanded easily to remove any drips. The excess fibreglass cloth also sanded off easily.

▲

⟩⟩

rikster67

Novice

sandkb

robtroi

taffy

Colin H

💬 Ply added

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 29 Views · 1 Like

Flag

💬 Add Comment

Hi,

my boat details are listed in the boat harbour under the name 'Scimitar',but the basic details are:

Power Source: LiPoly (14.8v) 10 Amp.h batteries x2

Speed control: Turnigy Marine TR-M-180A

Motor: Turnigy Aqastar4084-620kV

Type: Brushless watercooled

Drive: Direct Drive

Props: Single Propellor

Type: 3 Blade

Size: 50mm

regards,

Laurie

my boat details are listed in the boat harbour under the name 'Scimitar',but the basic details are:

Power Source: LiPoly (14.8v) 10 Amp.h batteries x2

Speed control: Turnigy Marine TR-M-180A

Motor: Turnigy Aqastar4084-620kV

Type: Brushless watercooled

Drive: Direct Drive

Props: Single Propellor

Type: 3 Blade

Size: 50mm

regards,

Laurie

▲

⟩⟩

Novice

💬 Ply added

12 years ago by 🇦🇺 Lauriem ( Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)

Petty Officer 1st Class)✧ 29 Views · 1 Like

Flag

💬 Add Comment

Thanks Dave,

I really don't think weight will be a problem at all with this boat - well I hope not anyway. My reinforcing will add very little to what is a very big boat indeed. My 46" Fireboat has two hard case 5000 mAh batteries alongside its brushless motor, and weighing in at 8.8kg total it has a very fast performance without the 'nervous' pitch and roll you see in lighter boats on choppy water. My guess is that this boat will end up at around the same weight even though it's bigger, and I'm putting the same motor in it as the Fireboat, but with a slighly larger prop. The Fireboat motor is currently only running at 50% of rated current - and less than 30% of the controller rating, so the same hardware in Perkasa should do very well.

I really don't think weight will be a problem at all with this boat - well I hope not anyway. My reinforcing will add very little to what is a very big boat indeed. My 46" Fireboat has two hard case 5000 mAh batteries alongside its brushless motor, and weighing in at 8.8kg total it has a very fast performance without the 'nervous' pitch and roll you see in lighter boats on choppy water. My guess is that this boat will end up at around the same weight even though it's bigger, and I'm putting the same motor in it as the Fireboat, but with a slighly larger prop. The Fireboat motor is currently only running at 50% of rated current - and less than 30% of the controller rating, so the same hardware in Perkasa should do very well.

▲

⟩⟩

Novice

Recruit)

Recruit)

Liked Re: Precedent 49" Perkasa 3 years ago

Liked Re: Precedent 49" Perkasa 3 years ago

Liked WMBC BREAK-UP. 5 years ago

Liked WMBC BREAK-UP. 5 years ago

Liked FOR SALE Veron Vosper Target Towing Launch 28" 7 years ago

Liked FOR SALE Veron Vosper Target Towing Launch 28" 7 years ago

Liked More progress 12 years ago

Liked More progress 12 years ago

Liked HS93's MinI RAF Crash tender seen at Deans Marine 12 years ago

Liked HS93's MinI RAF Crash tender seen at Deans Marine 12 years ago