Join Us On Social Media!

🎂 LewZ turns 82 this week! 🎂

United States

Recent Posts

💬 Re: Trawler

1 hour ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 1 View · 0 Likes

Flag

💬 Add Comment

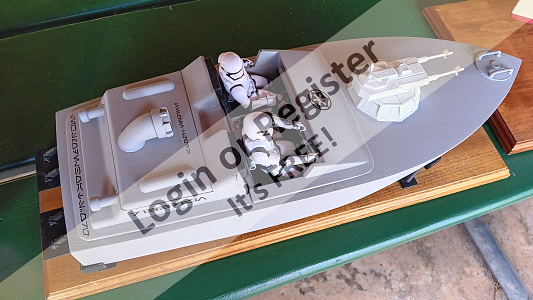

Funny you mentioning guns. I haven't been to the range in a long time. The range is too busy, everyone is shooting! Probably one of the reasons RC model boats are suffering a downturn in people interested in that.

Lew

The free state of Florida (U.S.A.)

Lew

The free state of Florida (U.S.A.)

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Dumas Closing

21 hours ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 16 Views · 3 Likes

Flag

📝 Reply

One would think a good number of Florida residents would have model boats. We have plenty of ponds, lakes, and saltwater canals, etc., along the coast. But no. Third largest state in the US but I know of only a half dozen clubs here. We tend not to be like the old world and take up hobbies like this.

Being we run in a public park we do get people stopping by to look. Not many, but a few. There is just no interest.

I'll be 82 next week and keep my mind occupied with scale model RC boats, armor, other RC vehicles, photography, web site maintenance, and of course 3d printing (just about anything). In between I try to fit in my family. This year I think I will be giving up yard maintenance. Too hot in the summer. No bingo or trivia nights for me (yet).

Lew

Being we run in a public park we do get people stopping by to look. Not many, but a few. There is just no interest.

I'll be 82 next week and keep my mind occupied with scale model RC boats, armor, other RC vehicles, photography, web site maintenance, and of course 3d printing (just about anything). In between I try to fit in my family. This year I think I will be giving up yard maintenance. Too hot in the summer. No bingo or trivia nights for me (yet).

Lew

▲

⟩⟩

chugalone100

hermank

jumpugly

📝 Dumas Closing

2 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 28 Views · 2 Likes

Flag

📝 Reply

I wonder what type and how large their manufacturing department is. They said they were just closing. Don't know if they tried selling the business to anyone else. I believe that Loyalhanna Dockyard (New York, USA) had taken over some other bussinesses.

Lew

Lew

▲

⟩⟩

jumpugly

hermank

📝 Dumas Closing

2 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 29 Views · 3 Likes

Flag

📝 Reply

... especially when trying to sell an already built Dumas kit, regardless of quality, they just don't seem to sell very well. Pretty much goes for all model boats, including scratch builds, there's not much of a market for them here (Florida).

Lew

Lew

▲

⟩⟩

hermank

jumpugly

chugalone100

📝 Dumas Closing

3 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 43 Views · 7 Likes

Flag

📝 Reply

Loosing the art of building model kits. Dumas' fate and others seem to prove that. On the other hand, Motion-RC (here in the U.S.) seems to indicate that build skills are giving way to buying pre-built models, a.ka., RTR and ARTR. Sad!

Lew

Lew

▲

⟩⟩

chugalone100

hermank

DWBrinkman

LeeA

GARTH

jumpugly

pressonreguardless

💬 Re: Suncoast Scale Model Boat Club - March 1, 2026 meet

3 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 14 Views · 2 Likes

Flag

💬 Add Comment

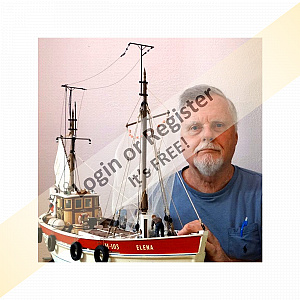

Yes Dave, is was the Helen kit. I bought it (2016?) partially built (up to the deck) but had to rip it apart to get the big dead battery out.

Worst part was the entire hull was covered in masking tape for many years. What a pain it was to remove it. In the long run it worked out.

I renamed it "Elena" after my wife. It sits in our front room and is the first model one sees in our home. Still uses the old FM radio. Runs perfect as I have alluded to.

Lew

Worst part was the entire hull was covered in masking tape for many years. What a pain it was to remove it. In the long run it worked out.

I renamed it "Elena" after my wife. It sits in our front room and is the first model one sees in our home. Still uses the old FM radio. Runs perfect as I have alluded to.

Lew

▲

⟩⟩

DWBrinkman

hermank

💬 Re: Painted paddle wheels

3 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 32 Views · 2 Likes

Flag

💬 Add Comment

Kevin55, the drives setup kind of look like what is in most rc 1/16 tanks except that they are geared instead of belts. I wonder if anyone tried using the RC tank drives in side wheel paddle boats.

Lew

Lew

▲

⟩⟩

Ronald

hermank

💬 Re: Suncoast Scale Model Boat Club - March 1, 2026 meet

4 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 23 Views · 5 Likes

Flag

💬 Add Comment

Ronald, the reason I built this boat with the nets up is I wanted it to show it in action. The net is loaded with fish and two men are working to bring the catch aboard. See photos.

Lew

Lew

▲

⟩⟩

GARTH

DWBrinkman

hermank

LeeA

Ronald

📝 Suncoast Scale Model Boat Club - March 1, 2026 meet

6 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 60 Views · 17 Likes · 5 Comments

Flag

💬 Add Comment

SSMBC - although a little windy, only four members showed up. The wonderful temperature and no rain was great. I decide to run my trawler, "Elena", which has not seen the pond in over five years. It handled the wind quite well and is perhaps my best operating boat for rough conditions. I know there is a limit with that much above the deck to catch the wind, but I must admit this was a very good run with a little challenge!

I hope you all enjoy the short video.

Lew

I hope you all enjoy the short video.

Lew

▲

⟩⟩

philcaretaker

Kevin55

LeeA

IanL1

algon

Wolle

PhilH

Doogle

ColinJ2

chugalone100

DWBrinkman

Ray

jumpugly

RossM

roycv

LIBERTY CAPTAIN

hermank

📝 decals

11 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 14 Views · 3 Likes

Flag

📝 Reply

I use Paint Shop Pro to design my decals. If you want white or any light color in the decal you have to use white decal paper. This does not allow the background to show through, requiring some trimming if necessary.

Black and dark colors you can use clear that also lets the background show through.

Lew

Black and dark colors you can use clear that also lets the background show through.

Lew

▲

⟩⟩

Steves-s

hermank

chugalone100

💬 Re: Port Area

12 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 33 Views · 3 Likes

Flag

💬 Add Comment

Looking really good Mike. Looks like you beat us to the punch. Ours is still needs finishing up and painting. The weather here in Florida has not been too kind to us this year. Got so many things to do, hopefully your photos will motivate me to get moving on finishing up our docking system. Thanks for the good photos!

Lew

Lew

▲

⟩⟩

chugalone100

Mike Stoney

hermank

Login To

Remove Ads

Remove Ads

📝 two or one

15 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 45 Views · 6 Likes

Flag

📝 Reply

VictorC,

Now that is a good looking model! How about a few more pics and inf?

Lew

Now that is a good looking model! How about a few more pics and inf?

Lew

▲

⟩⟩

hermank

Doogle

chugalone100

pressonreguardless

xtramaths

jumpugly

📝 two or one

17 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 68 Views · 6 Likes

Flag

📝 Reply

This depends on how maneuverable you want your boat to be. Operating shafts independently is the option I would take. This makes an amazing difference in turning the boat, especially when docking. You can use as many motors as you want on one ESC, you just have to change the ESC so you will be able to supply the motors with sufficient amperage

Lew

Lew

▲

⟩⟩

Doogle

jumpugly

DWBrinkman

chugalone100

DuncanP

hermank

💬 Re: 3D printed tugboat

18 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 51 Views · 5 Likes

Flag

💬 Add Comment

Always great to see more 3D printing used for model boats. Thanks for posting this. Also, do you print with 100,% fill? If so, drop it down to get the parts to float.

Lew

Lew

▲

⟩⟩

DWBrinkman

jumpugly

chugalone100

HappyHaggis

hermank

💬 Re: Suncoast Scale Model Boat Club

19 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 77 Views · 1 Like

Flag

💬 Add Comment

In case anyone missed it, that bridge to the floating dock is the one in the video (recently posted) of my towboat pushing the barge under it.

Lew

Lew

▲

⟩⟩

hermank

📝 Suncoast Scale Model Boat Club

21 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 81 Views · 14 Likes · 2 Comments

Flag

💬 Add Comment

Finally our first meet of 2026! Very unusual weather for us, like the rest of the country. Normally we might miss 1 or 2 weekends during the winter season but this was our first meet since December.

This would have been a great perfect day was hampered by wind, a little much for many smaller boats. Also a lot of dead fish around the pond, probably caused by a lack of oxygen because of a lack of rain. We are in the middle of a drought, but it is supposed to rain tonight.

Lew

This would have been a great perfect day was hampered by wind, a little much for many smaller boats. Also a lot of dead fish around the pond, probably caused by a lack of oxygen because of a lack of rain. We are in the middle of a drought, but it is supposed to rain tonight.

Lew

▲

⟩⟩

GARTH

RodC

jbkiwi

HappyHaggis

philcaretaker

Wolle

xtramaths

jumpugly

LeeA

ColinJ2

PhilH

EdW

hermank

chugalone100

📝 RC Semi update (Segment 4)

22 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 23 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

Still working on this truck chassis. Making changes to the suspension as I go. Big issue is how much weight can it handle and how should the ABS suspension parts be designed. I think the last of several itineration's will work. Want the axles (all spring loaded) to move up and down.

New sound an lighting system arrived. Getting anxious to see this thing run.

Lew

New sound an lighting system arrived. Getting anxious to see this thing run.

Lew

▲

⟩⟩

GaryLC

jumpugly

hermank

📝 The tools/equipment of the ship modeler.

24 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 49 Views · 3 Likes

Flag

📝 Reply

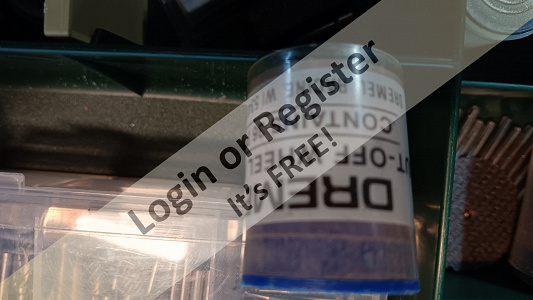

Duncan, there are so many different types of blades and cutting tools for Dremel tools for various materials. It depends on what material you want to cut, brass, copper, aluminum, steel, wood, plastic, etc. I don't think anyone has a cross reference chart that will show you what tool goes with what material.

The only thing that would make sense is when you buy the tool bit it should say on the box what the bit is good for.

There are many third-party suppliers for bits for Dremel tools, available. I even got some little bits from a dentist for cutting whatever I want. This is why a variable check works much better than the 1/8 inch collet.

And the photos you will see that I put most of my Dremel tool bits in one box. A pretty good accessory are the grinding disc which you can see in the upper left corner of the tool box bottom which has the Dremel EZ lock cutting discs for metal (2nd photo).

I have so much stuff it would take quite a bit of time to make an inventory list. The best bet is if you are trying to do something, look and see if they make a tool that helps you do it better and faster. Just common sense.

Lew

The only thing that would make sense is when you buy the tool bit it should say on the box what the bit is good for.

There are many third-party suppliers for bits for Dremel tools, available. I even got some little bits from a dentist for cutting whatever I want. This is why a variable check works much better than the 1/8 inch collet.

And the photos you will see that I put most of my Dremel tool bits in one box. A pretty good accessory are the grinding disc which you can see in the upper left corner of the tool box bottom which has the Dremel EZ lock cutting discs for metal (2nd photo).

I have so much stuff it would take quite a bit of time to make an inventory list. The best bet is if you are trying to do something, look and see if they make a tool that helps you do it better and faster. Just common sense.

Lew

▲

⟩⟩

DWBrinkman

hermank

chugalone100

💬 Re: South Florida Boatyard re-opens

25 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 32 Views · 2 Likes

Flag

💬 Add Comment

Chum... you are a little south of me. Been a little too cool up here (Tampa Bay area) especially for MB meets. Had a few tank meets though. Glad you first run was a success. Where do you sail?

Lew

Lew

▲

⟩⟩

Chum444

hermank

💬 Re: Towboat pushing a large barge.

25 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 92 Views · 6 Likes

Flag

💬 Add Comment

Did the giant foot on the dock give it a way?

I enjoy watching the real towboats pushing their "tow" LIVE (hence "towboats in the US) through the locks, especially Lock 19 on the old Mississippi River.

Towboats straining to push 1,000's of tons with the turbos screaming . Too bad I live so far away.

The video link show one of the towboats pushing 42 barges on the river. Each barge is 200 feet long. (Copy and paste the link in your browser.)

Lew

I enjoy watching the real towboats pushing their "tow" LIVE (hence "towboats in the US) through the locks, especially Lock 19 on the old Mississippi River.

Towboats straining to push 1,000's of tons with the turbos screaming . Too bad I live so far away.

The video link show one of the towboats pushing 42 barges on the river. Each barge is 200 feet long. (Copy and paste the link in your browser.)

Lew

▲

⟩⟩

LeeA

roycv

HappyHaggis

EdW

chugalone100

hermank

📝 Towboat pushing a large barge.

26 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 112 Views · 15 Likes · 3 Comments

Flag

💬 Add Comment

Got a new tablet and when I placed my SD card in it I found this old video (~8 years ago) video of my towboat pushing a barge under the bridge between the dock and shore.

Lew

Lew

▲

⟩⟩

LeeA

jbkiwi

HappyHaggis

MartyV

Mike Stoney

IanL1

luckyduck

DWBrinkman

ScouterChil

BOATSHED

EdW

hermank

Wolle

chugalone100

RodC

Login To

Remove Ads

Remove Ads

💬 Re: Re: RC Semi (Segment 3 "The Drive")

29 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 11 Views · 0 Likes

Flag

💬 Add Comment

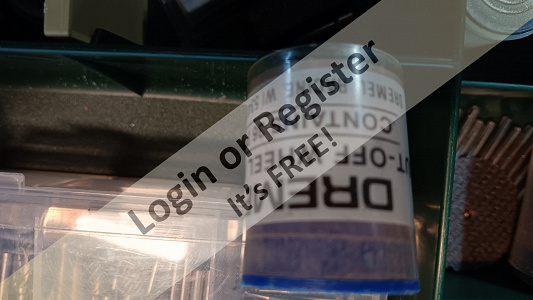

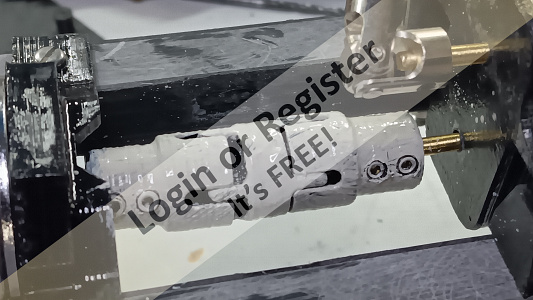

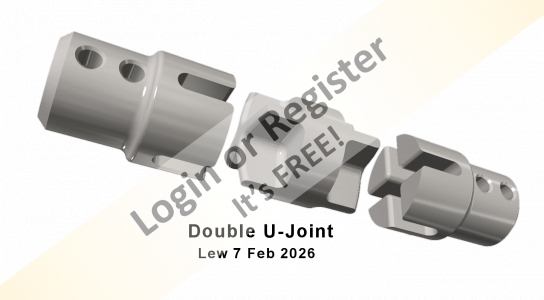

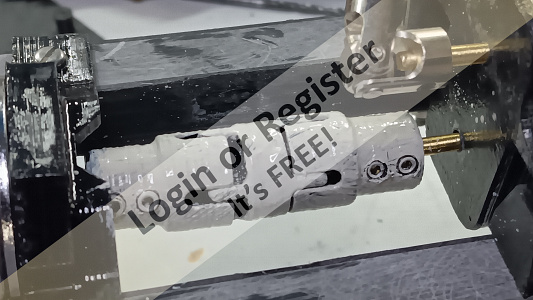

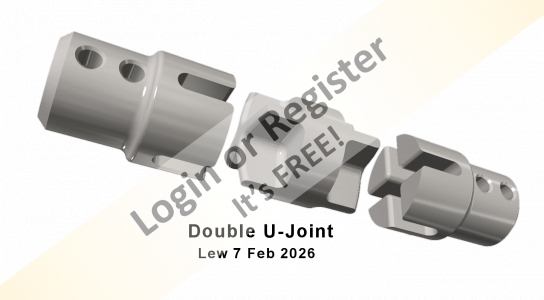

ChrisF, the three pieces slide together but not completely tight (about .05 inch each). Between that and the fact that the "+" shapes (positive and negative) have some clearance in them allows the center piece to wobble or float. The center piece can't fall out. This allows some misalignment both radially and axially.

Not sure how long it will last. Just an experiment for now. I'm sure the setscrews will not hold in the ABS very long.

Lew

Not sure how long it will last. Just an experiment for now. I'm sure the setscrews will not hold in the ABS very long.

Lew

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: RC Semi (Segment 3 "The Drive")

29 days ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 35 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

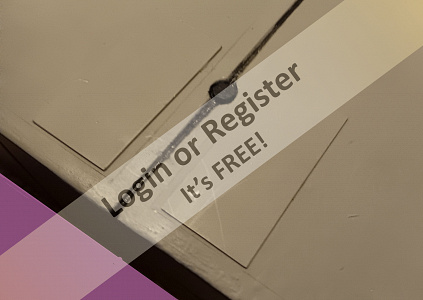

U-Joint test and status update:

I have plenty of u-joints but with a short space between the motor and the transfer case I decided to make my own u-joint. (A 3D printed prototype to be remade stronger later.) Not a new idea, might of seen it somewhere before, looks ideal for that short space. Photo looks crummy, I painted the print as it was shiny black and hard to see. The center piece is floating and held captive by the two ends that are on stationary shafts.

Working on the truck's frame. Ran into some problems with the steel square tubing (approx .40 inch sq.) encased in the ABS 3D print. It has a thin wall but the steel is harder than I thought it would be. Slow, but making progress.

Thinking about sound... The sound units for a diesel truck at an "affordable price" are really bad. They start to get better at about $40 US. However, I ordered a GT Power Truck and Light Container system for about $60 US. More than I wanted to spend but for a little more money I get a lot more "bells and whistles". Should be fun.

Lew

I have plenty of u-joints but with a short space between the motor and the transfer case I decided to make my own u-joint. (A 3D printed prototype to be remade stronger later.) Not a new idea, might of seen it somewhere before, looks ideal for that short space. Photo looks crummy, I painted the print as it was shiny black and hard to see. The center piece is floating and held captive by the two ends that are on stationary shafts.

Working on the truck's frame. Ran into some problems with the steel square tubing (approx .40 inch sq.) encased in the ABS 3D print. It has a thin wall but the steel is harder than I thought it would be. Slow, but making progress.

Thinking about sound... The sound units for a diesel truck at an "affordable price" are really bad. They start to get better at about $40 US. However, I ordered a GT Power Truck and Light Container system for about $60 US. More than I wanted to spend but for a little more money I get a lot more "bells and whistles". Should be fun.

Lew

▲

⟩⟩

chugalone100

hermank

EdW

💬 Re: RC Semi (Comment)

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 51 Views · 1 Like

Flag

💬 Add Comment

I just checked on train controllers, apparently they still use DCC. Check out the cost. A couple of low cost RC Trans/Rec with speed controllers and batteries (or still use the track) looks like a workable inexpensive solution.

Lew

Lew

▲

⟩⟩

hermank

💬 Re: RC Semi (Segment 3 "The Drive")

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 51 Views · 1 Like

Flag

💬 Add Comment

Thanks HH,

If I can't do it with my 6-channel Futaba's (I have 2) I can go to my Specktrum 8 or one of my Flysky's (I have a spare 10-ch rec.). I don't think I will need past 10. If I ever get back to my fireboat rebuild I will look into this. I guess all those years as a test equipment designer paid off in preparing me for my retirement hobbies!

Lew

If I can't do it with my 6-channel Futaba's (I have 2) I can go to my Specktrum 8 or one of my Flysky's (I have a spare 10-ch rec.). I don't think I will need past 10. If I ever get back to my fireboat rebuild I will look into this. I guess all those years as a test equipment designer paid off in preparing me for my retirement hobbies!

Lew

▲

⟩⟩

hermank

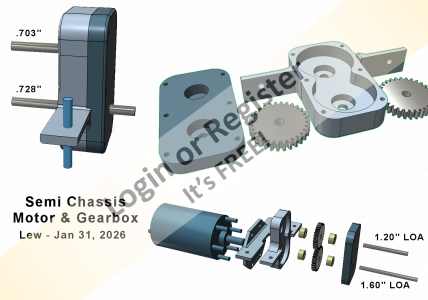

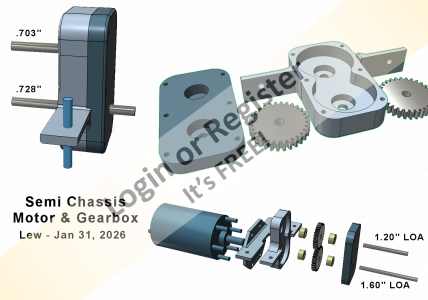

📝 RC Semi (Segment 3 "The Drive")

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 54 Views · 6 Likes · 4 Comments

Flag

💬 Add Comment

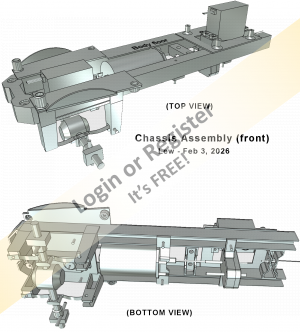

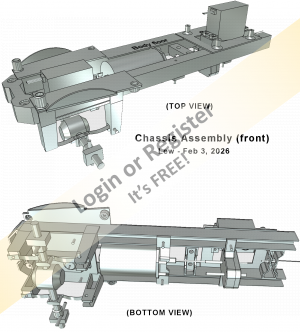

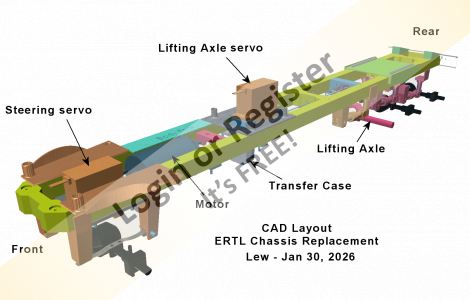

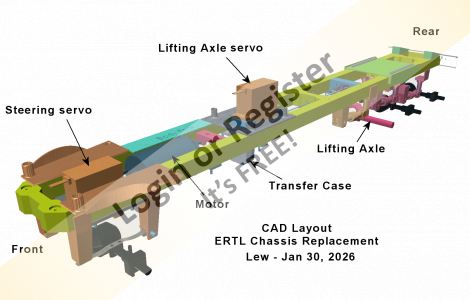

Going to take a look at the power train parts I am accumulating for this project. (Trying to use what I have rather than buy new items.) So here is what I am looking at:

Geared Motor: Zheng ZYDT520, 550 RPM @ 12VDC.

Transfer Case: My 3D build + bearings 1:1

Axle #1 (front): Steerable (source unknown) 1/16 scale

Axle #2 (retractable): My 3D build

Axle #3 (through-put): (source unknown) 1/16 scale

Axle # 4 (end): (source unknown) 1/16 scale

Suspension Front: My 3D build, leaf spring

Suspensions Rear mains: My 3D build Coiled springs

Support plates and brackets: My 3D build

Servos: Futaba S3005 (2)

Having build the transfer case and gears with a 1:1 ratio, I can change the speed OR tractive power of the vehicle simply by making a new transfer case. This case takes the output from the motor and has two output shafts, one to the front and the other to the rear.

My concern right now is if six channels are enough?

Now back to 3D printing.

Lew

Geared Motor: Zheng ZYDT520, 550 RPM @ 12VDC.

Transfer Case: My 3D build + bearings 1:1

Axle #1 (front): Steerable (source unknown) 1/16 scale

Axle #2 (retractable): My 3D build

Axle #3 (through-put): (source unknown) 1/16 scale

Axle # 4 (end): (source unknown) 1/16 scale

Suspension Front: My 3D build, leaf spring

Suspensions Rear mains: My 3D build Coiled springs

Support plates and brackets: My 3D build

Servos: Futaba S3005 (2)

Having build the transfer case and gears with a 1:1 ratio, I can change the speed OR tractive power of the vehicle simply by making a new transfer case. This case takes the output from the motor and has two output shafts, one to the front and the other to the rear.

My concern right now is if six channels are enough?

Now back to 3D printing.

Lew

▲

⟩⟩

chugalone100

GaryLC

PhilH

EdW

hermank

HappyHaggis

📝 RC Semi (Segment 2)

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 58 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

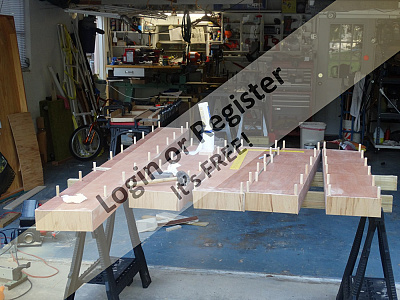

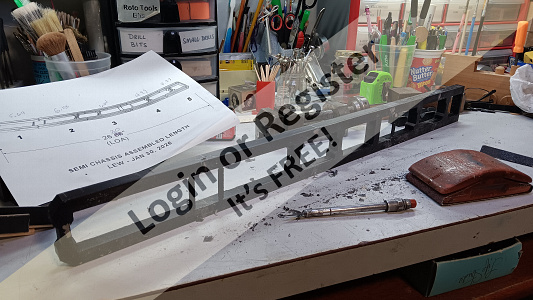

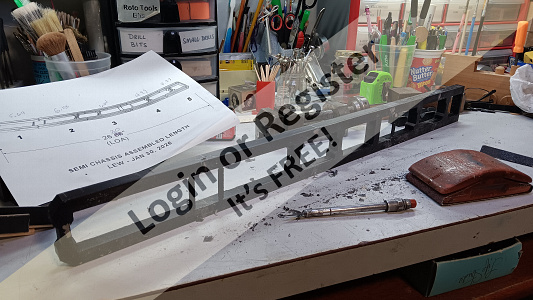

As I had decided to lengthen the chassis/frame by almost 8 inches (200mm), I decided to make a new frame (as previously shown). The new frame incorporated the mounting of items from the original truck now includes the mounting of the new items (servo mounts, motor and transfer case, axles, sleep cabin, etc.

The layout was done in my 3D CAD app (see photo). This also includes a suspension system as the toy truck had nothing but oblong holes to simulate up-down movement of the wheels.

Current Status:

The frame was printed in five pieces due to the limitations of my 3D printer's build plate. The cross-section is "U" shaped as I had some square soft steel tubing that would fit inside the "U". That was placed inside using JB-Kwick epoxy. Clean-up is currently in progress.

Lew

The layout was done in my 3D CAD app (see photo). This also includes a suspension system as the toy truck had nothing but oblong holes to simulate up-down movement of the wheels.

Current Status:

The frame was printed in five pieces due to the limitations of my 3D printer's build plate. The cross-section is "U" shaped as I had some square soft steel tubing that would fit inside the "U". That was placed inside using JB-Kwick epoxy. Clean-up is currently in progress.

Lew

▲

⟩⟩

chugalone100

RodC

EdW

hermank

📝 RC Semi (Comment)

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 59 Views · 3 Likes · 1 Comment

Flag

💬 Add Comment

HO scale? That's on the horizon for me as well. What I have is old, control by transformers via the tracks. Then it went to DCC where the tracks had constant DC and control by radio signal. I was thinking that a better setup would be total RC, no power to the tracks. Batteries are small and powerful. Any thoughts?

Lew

Lew

▲

⟩⟩

RodC

jumpugly

hermank

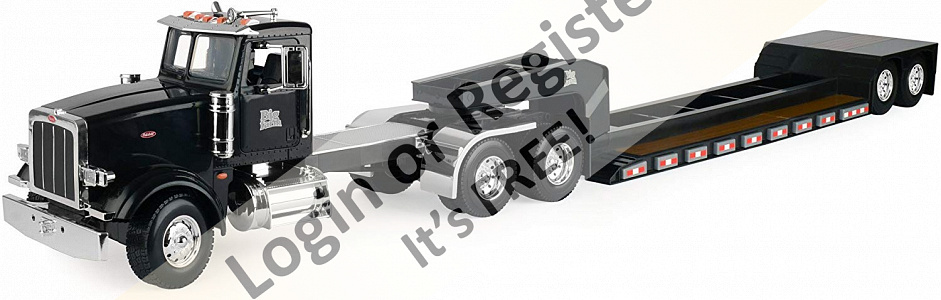

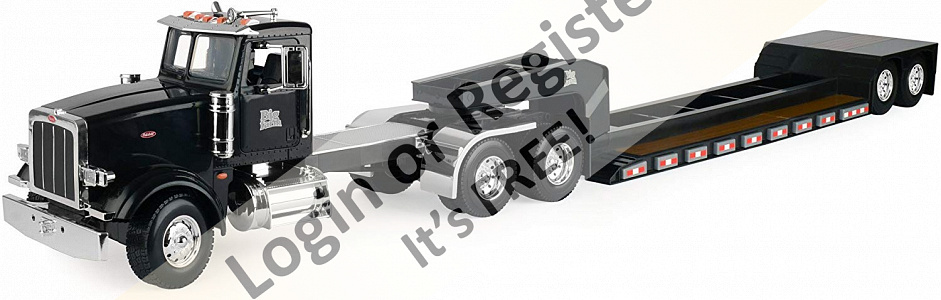

📝 Converting a toy semi tractor trailer into a decent RC model Unit

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 71 Views · 14 Likes · 6 Comments

Flag

💬 Add Comment

Another RC hobby? I'm already into RC scale model boats (since the early 1970's) and RC armor (since 2015) I am branching out to RC scale vehicles (but not too many). Notice the word scale in each of these three segments of RC hobbies.

This topic is for a RC semi tractor and lowboy trailer being converted from an inexpensive toy. It is already in 1/16 scale and should be compatible with my Springer ("truckable") tugs and Armor (tanks, etc.). I plan to use it at both Model Boat and Armor meets.

This first segment involves the selections I have made and my plan to make the necessary modifications to the toy.

I bought two ERTL about three years ago with the intent to convert them into RC. I paid about $70 (US) for the pair of them on sale. They are currently in the $70-80 range (each). They look good enough to use although not to exact scale. The project goal is to keep the cost down and have a fun functional vehicle.

Why buy two units? When done, I will be using parts from the second vehicle for the first, like wheels for extra axles and other parts.

Right now I am working on the semi-tractor. The new unit will have another axle, this one to lift by RC. It will also have the extra sleeper cabin and other accessories. I am planning to make the "gooseneck" (the part that connects to the trailer) RC controlled. Unfortunately the model's lowboy trailer suffers problems like the real trailers do. Too close to the ground. I will need to elevate the trailer sufficiently so it will not get stuck. I do not have to contend with railroad tracks which makes the vehicles good targets for fast moving trains.

The latest:

This evening I am cementing the chassis frame together. I had to print it in five pieces due to the limitations of my 3D printer. There will be rectangular steel tubing epoxied inside the frame for extra strength.

Lew

This topic is for a RC semi tractor and lowboy trailer being converted from an inexpensive toy. It is already in 1/16 scale and should be compatible with my Springer ("truckable") tugs and Armor (tanks, etc.). I plan to use it at both Model Boat and Armor meets.

This first segment involves the selections I have made and my plan to make the necessary modifications to the toy.

I bought two ERTL about three years ago with the intent to convert them into RC. I paid about $70 (US) for the pair of them on sale. They are currently in the $70-80 range (each). They look good enough to use although not to exact scale. The project goal is to keep the cost down and have a fun functional vehicle.

Why buy two units? When done, I will be using parts from the second vehicle for the first, like wheels for extra axles and other parts.

Right now I am working on the semi-tractor. The new unit will have another axle, this one to lift by RC. It will also have the extra sleeper cabin and other accessories. I am planning to make the "gooseneck" (the part that connects to the trailer) RC controlled. Unfortunately the model's lowboy trailer suffers problems like the real trailers do. Too close to the ground. I will need to elevate the trailer sufficiently so it will not get stuck. I do not have to contend with railroad tracks which makes the vehicles good targets for fast moving trains.

The latest:

This evening I am cementing the chassis frame together. I had to print it in five pieces due to the limitations of my 3D printer. There will be rectangular steel tubing epoxied inside the frame for extra strength.

Lew

▲

⟩⟩

chugalone100

LIBERTY CAPTAIN

RodC

BarryS

xtramaths

jumpugly

Newby7

EdW

Cashrc

DWBrinkman

ChrisF

hermank

GaryLC

JSS4

📝 Animal and nature photos to enjoy.

1 month ago by 🇺🇸 LewZ ( Vice Admiral)

Vice Admiral)

Vice Admiral)

Vice Admiral)✧ 39 Views · 3 Likes

Flag

📝 Reply

Jump, et al.,

As not everyone is interested in model truck building I will create a build blog for the semi tractor - lowboy trailer and post info there.

Building this rig involves a lot of practices similar to those used in RC model boat building, direction, speed, sound, lights, and operational accessories.

Look for it soon as I am going to try to get the semi tractor done while the "cool" weather is upon us.

Lew

As not everyone is interested in model truck building I will create a build blog for the semi tractor - lowboy trailer and post info there.

Building this rig involves a lot of practices similar to those used in RC model boat building, direction, speed, sound, lights, and operational accessories.

Look for it soon as I am going to try to get the semi tractor done while the "cool" weather is upon us.

Lew

▲

⟩⟩

Wolle

jumpugly

hermank

Recruit)

Recruit)

Captain)

Captain)

Lieutenant Commander)

Lieutenant Commander)

Rear Admiral)

Rear Admiral)

Warrant Officer)

Warrant Officer)

Fleet Admiral)

Fleet Admiral)

Leading Seaman)

Leading Seaman)