Join Us On Social Media!

Hungary

Recent Posts

📝 Question of the Day?

5 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 49 Views · 4 Likes

Flag

📝 Reply

I thought that HMS Hood damaged Bismarck’s fuel tanks during the sea battle which led to the sinking of Hood. Didn’t that lead to the final sinking of Bismarck? She had to slow down to dog for repairs, or so I thought. 😳

▲

⟩⟩

SouthportPat

hermank

luckyduck

DuncanP

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

5 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 49 Views · 2 Likes

Flag

📝 Reply

Must put the drain plug back in. I am sinking fast.

These awkward questions have often had a clue in the question. A red herring today. Bah!!! Another 3 years and seven months before I get to 100%.

These awkward questions have often had a clue in the question. A red herring today. Bah!!! Another 3 years and seven months before I get to 100%.

▲

⟩⟩

SouthportPat

hermank

📝 Question of the Day?

5 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 2 Likes

Flag

📝 Reply

That was lucky. I just picked the longest one.😀

▲

⟩⟩

hermank

AndyN

📝 Question of the Day?

5 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 50 Views · 3 Likes

Flag

📝 Reply

Titanic must still be the theme as I really am getting that sinking feeling.🐙

▲

⟩⟩

hermank

RNinMunich

jumpugly

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 56 Views · 2 Likes

Flag

📝 Reply

Like me, 30 days Doug?🥹

▲

⟩⟩

hermank

RNinMunich

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 2 Likes

Flag

📝 Reply

I had no idea but the answer was pointed to by the question, at least in my warped head it was.😃

▲

⟩⟩

hermank

cenbeth

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 56 Views · 1 Like

Flag

📝 Reply

Oh dear, Doug.🤡

▲

⟩⟩

hermank

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 49 Views · 4 Likes

Flag

📝 Reply

No idea on this one. Loaded finger stab failed today. Oh well, that’s 100% aspirations gone for at least another 30 days.🤨

▲

⟩⟩

hermank

Mike Stoney

fireboat

Nickthesteam

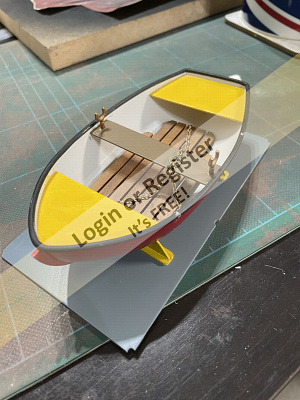

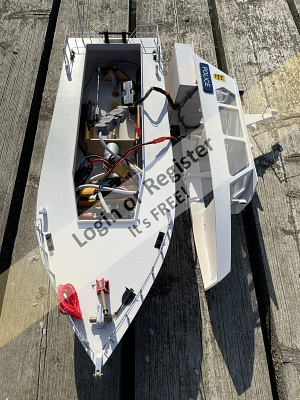

📝 RNLI LIFEGUARDS inspired jet ski

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 22 Views · 1 Like

Flag

📝 Reply

Looks super. Runs well as well. Good job.😃

▲

⟩⟩

Len1

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 38 Views · 7 Likes

Flag

📝 Reply

Well, all I can say is that if AI performs as it has on the question of the day, let’s hope that nobody puts it in charge of any nuclear arsenal. I have bought a hard hat just in case.😬

▲

⟩⟩

DuncanP

AlessandroSPQR

jumpugly

Mike Stoney

hermank

RNinMunich

fireboat

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 31 Views · 2 Likes

Flag

📝 Reply

Good grief Doug. I have enough trouble reading the clear text on my IPhone early in the morning. I think it would drive me mad to try to read the blurred writing.😳😬😬

▲

⟩⟩

hermank

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 30 Views · 2 Likes

Flag

📝 Reply

Thanks for your picture Alessandro. It is a very good way to remember the assignments of the triangles on the tops of Cardinal buoys.

▲

⟩⟩

AlessandroSPQR

hermank

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 31 Views · 2 Likes

Flag

📝 Reply

The description told me that it was a cardinal buoy. I have forgotten which is which so is about time that I brushed up on my CEVNI.😳

▲

⟩⟩

jumpugly

hermank

📝 Easter greetings

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 39 Views · 13 Likes

Flag

📝 Reply

Thanks to all and a Happy Easter to you all too from here in Hungary.😃😃

▲

⟩⟩

Wolle

Len1

Ronald

RNinMunich

DWBrinkman

Peejay

DuncanP

ColinJ2

IanL1

roycv

Doogle

hermank

AlessandroSPQR

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 53 Views · 4 Likes

Flag

📝 Reply

Quite right Doug. I must confess, I did panic for a second after reading the question.😃

▲

⟩⟩

RNinMunich

Peejay

fireboat

hermank

📝 Question of the Day?

6 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 4 Likes

Flag

📝 Reply

Every day is a new 30 days. It rolls on.

▲

⟩⟩

Peejay

RNinMunich

fireboat

hermank

📝 Question of the Day?

7 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 49 Views · 4 Likes

Flag

📝 Reply

I would assume that the reason you lose percentage when absent is so that you do not get an advantage by answering only the questions you know the answers to. This might keep somebody on 100% having only answered one question per 30 days.

▲

⟩⟩

RNinMunich

hermank

DuncanP

fireboat

📝 Question of the Day?

7 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 41 Views · 2 Likes

Flag

📝 Reply

I had no idea at all. Lucky finger stab today.

▲

⟩⟩

Nickthesteam

hermank

📝 Question of the Day?

7 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 40 Views · 3 Likes

Flag

📝 Reply

It’s a good job that three of today’s answers can be eliminated fairly safely leaving only one. Never heard of that one.

▲

⟩⟩

hermank

RNinMunich

Peejay

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 44 Views · 3 Likes

Flag

📝 Reply

In Budapest City Centre today. I am looking for a Sunstone so that I can find my way home.😳

▲

⟩⟩

hermank

DWBrinkman

DuncanP

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 2 Likes

Flag

📝 Reply

Thinking about it a little deeper, it is a good job that the Vikings didn’t transit the Northwest Passage using a Sunstone or we might be in a never ending loop of questions.🤔

▲

⟩⟩

RNinMunich

hermank

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 49 Views · 2 Likes

Flag

📝 Reply

Well, we know what AI wants for Christmas. A Sunstone extracted from the Northwest Passage.😳

▲

⟩⟩

RNinMunich

hermank

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 48 Views · 2 Likes

Flag

📝 Reply

Do you think that this version of AI has a serious disease of its Northwest Passage?😳

▲

⟩⟩

hermank

jumpugly

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 40 Views · 3 Likes

Flag

📝 Reply

Well, this new format and new questions are refreshing but I don’t think it will be long before I am sitting in the corner with a dunces cap on.

▲

⟩⟩

Mike Stoney

SimpleSailor

hermank

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 47 Views · 2 Likes

Flag

📝 Reply

Yes. And I repeated again and got it wrong.😳

▲

⟩⟩

hermank

SimpleSailor

📝 Question of the Day?

8 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 47 Views · 3 Likes

Flag

📝 Reply

The questions are much better in my view. It was a lucky break that the answer is in the question today or I would not have had a clue.😃

▲

⟩⟩

hermank

fireboat

RossM

📝 Question of the Day?

9 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 53 Views · 3 Likes

Flag

📝 Reply

Hi Stephen.

It will be very interesting to see how these changes go. Thanks for taking the time to try something different.

On another note, I know that we here in Hungary are quite a small country in Central Europe but I am reasonably confident that there has not been a revolution or been taken over by another state recently. Please can we be put back on the world leader board for the question of the day.

Thanks.

Peter.

It will be very interesting to see how these changes go. Thanks for taking the time to try something different.

On another note, I know that we here in Hungary are quite a small country in Central Europe but I am reasonably confident that there has not been a revolution or been taken over by another state recently. Please can we be put back on the world leader board for the question of the day.

Thanks.

Peter.

▲

⟩⟩

DuncanP

SimpleSailor

hermank

📝 Question of the Day?

9 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 55 Views · 2 Likes

Flag

📝 Reply

This question must have been asked 3 times now. How can I get it wrong every time! By the way, Hungary is still here as far aes I know but still missing from the list above. This happened last time there was a score process change.🤗

▲

⟩⟩

Peejay

hermank

📝 Question of the Day?

9 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 55 Views · 3 Likes

Flag

📝 Reply

I hear complaints that scores have gone down since the change, but has Hungary 🇭🇺 left the planet!😐🤔

▲

⟩⟩

Peejay

jumpugly

hermank

📝 In Memorium - Martin555

10 months ago by 🇭🇺 MouldBuilder ( Admiral)

Admiral)

Admiral)

Admiral)✧ 45 Views · 7 Likes

Flag

📝 Reply

I think it is a great idea to pay this tribute to Martin. I did not meet him personally either but was fortunate enough to have had numerous Skype sessions with him, the last only days before he left us. I can say that he was much more than a good bloke. He was the best bloke. He would never turn down a request for help. His humour, well, spend a couple of hours with him on Skype and you were made up for the week. A thoroughly great bloke. RIP Martin.

▲

⟩⟩

Doogle

jbkiwi

Mike Stoney

Wolle

Cashrc

RNinMunich

Colin H

Rear Admiral)

Rear Admiral)

Petty Officer 1st Class)

Petty Officer 1st Class)

Warrant Officer)

Warrant Officer)

Vice Admiral)

Vice Admiral)

Fleet Admiral)

Fleet Admiral)

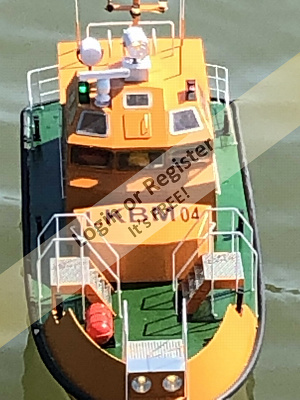

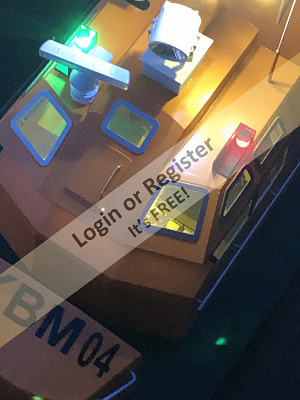

Liked Re: Camera Boat No.7 2 months ago

Liked Re: Camera Boat No.7 2 months ago