Join Us On Social Media!

United Kingdom

Recent Posts

📝 Flysky Warning

1 month ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 23 Views · 2 Likes

Flag

📝 Reply

Totally agree bruce1946 I too have a separate set for each boat, I can buy a set with 6 channel receiver for £65 and don't have to pay postage as the model shop is just down the road form my house.

As you say when we have a regatta I take my grandson and some of his friends so they can all sail at the same time.

A great unit for the price.

As to the switch problem I haven't had any issues, however the solutions suggested seem to be a simple repair Thanks to all the solution pioneers

As you say when we have a regatta I take my grandson and some of his friends so they can all sail at the same time.

A great unit for the price.

As to the switch problem I haven't had any issues, however the solutions suggested seem to be a simple repair Thanks to all the solution pioneers

▲

⟩⟩

bruce1946

hermank

Login To

Remove Ads

Remove Ads

📝 TVR1A Steam Engine.

3 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 11 Likes

Flag

📝 Reply

Hi Gary Its a long time since I posted anything however I have a couple of question for you.

1) I see your latest launch is under construction, is it the Lady Jane hull ?

2) I see you current TVR1A unit is mounted horizontally above the prop shaft, presumably also horizontal, the question is -

Is it OK to mount the engine at an angle?, my Lady Jane prop shaft comes through at an angle of 15 degrees, I know I could use a couple of UJs but I'm not keen on this idea, Your thoughts would be appreciated.

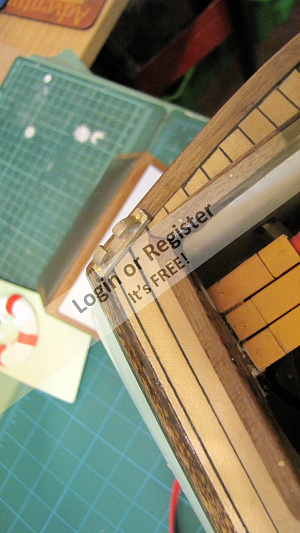

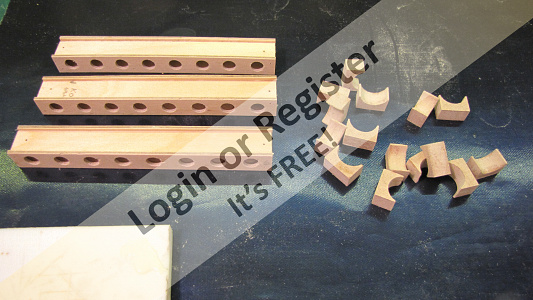

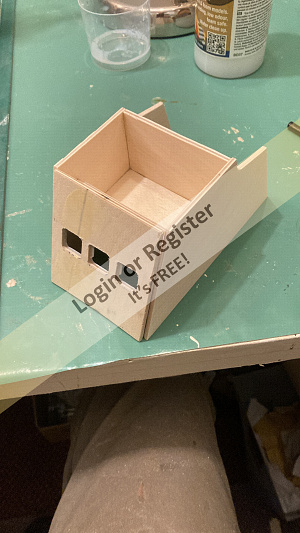

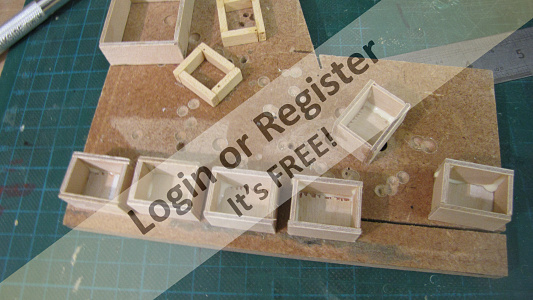

I have been working on my Plank on Frame Lady Jane, however its a very time consuming job. A year into construction and both halves of the hull have been planked, followed by the most time consuming job of all, drilling and inserting copper nails, 5000 in all. this is now complete and ready for its coat of 1oz fibreglass.

This may seem odd covering it in fibreglass but its the best way of maintaining the wood colour and its water integrity plus added strength.

The inner hull will then get a few coats of finishing resin to complete the hulls water proofing.

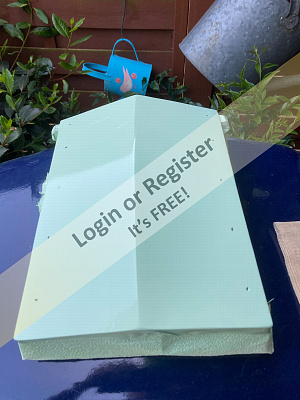

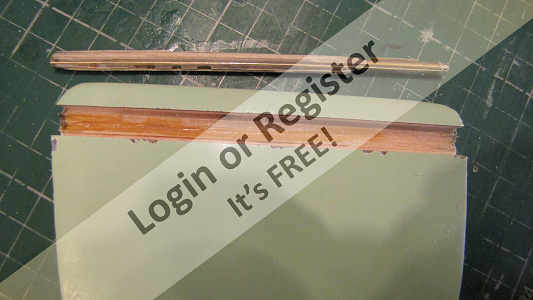

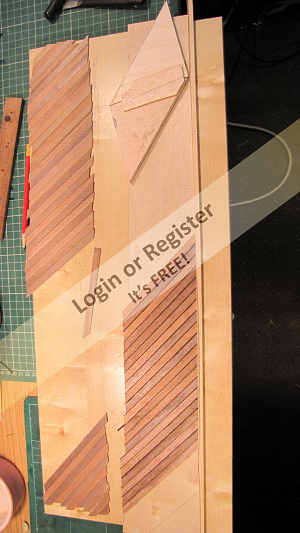

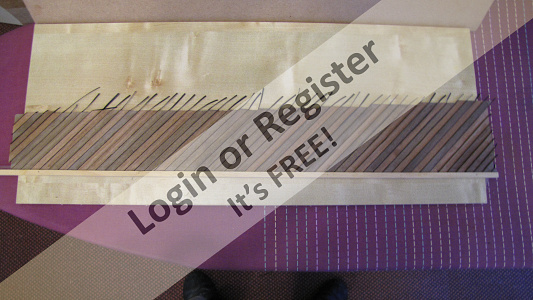

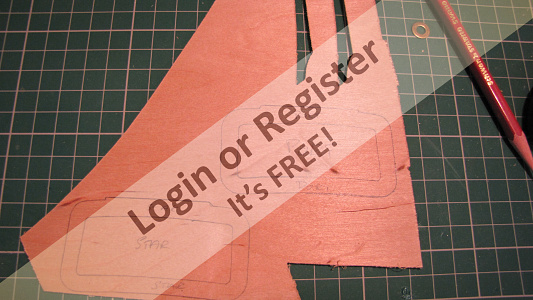

If you look at the sample piece picture (1) that has a 1oz matting applied followed by two further coats of epoxy finishing resin the wood colour is good and the copper nails are visible.

1) I see your latest launch is under construction, is it the Lady Jane hull ?

2) I see you current TVR1A unit is mounted horizontally above the prop shaft, presumably also horizontal, the question is -

Is it OK to mount the engine at an angle?, my Lady Jane prop shaft comes through at an angle of 15 degrees, I know I could use a couple of UJs but I'm not keen on this idea, Your thoughts would be appreciated.

I have been working on my Plank on Frame Lady Jane, however its a very time consuming job. A year into construction and both halves of the hull have been planked, followed by the most time consuming job of all, drilling and inserting copper nails, 5000 in all. this is now complete and ready for its coat of 1oz fibreglass.

This may seem odd covering it in fibreglass but its the best way of maintaining the wood colour and its water integrity plus added strength.

The inner hull will then get a few coats of finishing resin to complete the hulls water proofing.

If you look at the sample piece picture (1) that has a 1oz matting applied followed by two further coats of epoxy finishing resin the wood colour is good and the copper nails are visible.

▲

⟩⟩

pressonreguardless

MartyV

premecekcz

chugalone100

Northernflotsam

Ray

GaryLC

hermank

AlessandroSPQR

stevedownunder

EdW

📝 Still Can’t Believe

7 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 18 Views · 1 Like

Flag

📝 Reply

How about a picture?

Maybe a different hull could be modified have another look at the Maxwell Hemmens hulls for sale

Maybe a different hull could be modified have another look at the Maxwell Hemmens hulls for sale

▲

⟩⟩

hermank

💬 Re: Fitting the Keel, Formers & Bulkheads

8 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 115 Views · 4 Likes

Flag

💬 Add Comment

Good progress Rob keep going

▲

⟩⟩

Ace23

tonyb2

robbob

hermank

📝 Maxwell Hemmens GRP hulls

8 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 48 Views · 6 Likes

Flag

📝 Reply

Just a gentle reminder York Model Boat club has a number of GRP hulls for sale, theses hulls are good quality mostly coming from the estate of the late Maxwell Hemmens Steam Engineer.

Some are named EG “Formidable”, “BAT ?” and but there are pictures.

7 now sold

Its a once only chance - Please Email mturpin01@gmail.com if you want more detail Half Price £70, collection from Leeds or York area.

Some are named EG “Formidable”, “BAT ?” and but there are pictures.

7 now sold

Its a once only chance - Please Email mturpin01@gmail.com if you want more detail Half Price £70, collection from Leeds or York area.

▲

⟩⟩

Ray

Steves-s

jumpugly

stevedownunder

hermank

Wolle

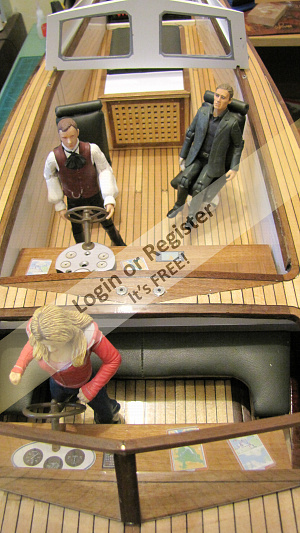

💬 Re: The Keel & Formers.

10 months ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 118 Views · 5 Likes

Flag

💬 Add Comment

Hi Rob, I don't follow much on the site now and don't post any blogs now as I felt that the amount of effort required to detail the blogs wasn't what the readers valued, anyway you may find that different now.

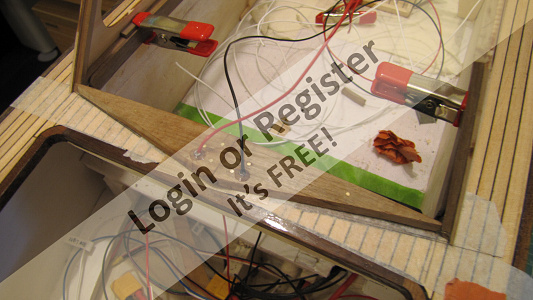

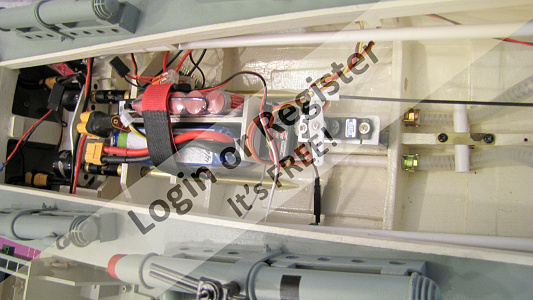

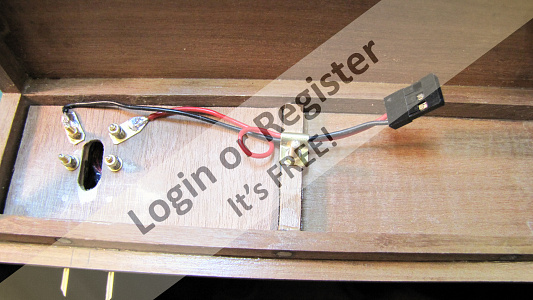

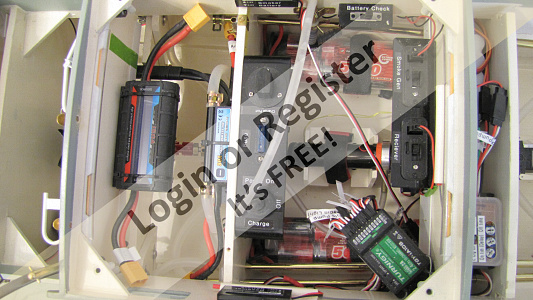

I remember putting the tubing under the floor of my Marlin to carry the wires and see you have followed my lead. I did mention it to Michael at VMW as a useful piece of information for new builders.

Do you know how both the Police tender and this Cabin Cruiser have done on the open market?

Ill keep an eye on your progress.

I remember putting the tubing under the floor of my Marlin to carry the wires and see you have followed my lead. I did mention it to Michael at VMW as a useful piece of information for new builders.

Do you know how both the Police tender and this Cabin Cruiser have done on the open market?

Ill keep an eye on your progress.

▲

⟩⟩

tonyb2

RNinMunich

hermank

robbob

DuncanP

📝 MYFORD ML10

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 50 Views · 1 Like

Flag

📝 Reply

Zooma please check your private messages

▲

⟩⟩

zooma

📝 Models being built

1 year ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 84 Views · 10 Likes

Flag

📝 Reply

Or is it "NOT" being built.

What has happened to all the build blogs that used to appear in the section headed "Build Blogs", all we seem to get are a few "during" the build and then the maiden voyage.

There were a lot of builders and just readers who relied on the assistance of detailed - (in text and picture) blogs.

It made this site so much more interesting.

I appreciate it takes a lot of time to produce a detailed blog but I'm sure it will be appreciated.

I just need to finish my Inga IV blog then there's an interesting steam project on

the horizon. So please put pen and pictures together to produce some interesting blogs, and don't forget to give some credit to the author's by making comment and suggestions rather than the easy option of a "like"

What has happened to all the build blogs that used to appear in the section headed "Build Blogs", all we seem to get are a few "during" the build and then the maiden voyage.

There were a lot of builders and just readers who relied on the assistance of detailed - (in text and picture) blogs.

It made this site so much more interesting.

I appreciate it takes a lot of time to produce a detailed blog but I'm sure it will be appreciated.

I just need to finish my Inga IV blog then there's an interesting steam project on

the horizon. So please put pen and pictures together to produce some interesting blogs, and don't forget to give some credit to the author's by making comment and suggestions rather than the easy option of a "like"

▲

⟩⟩

RNinMunich

Colin H

Doogle

Len1

jbkiwi

Peejay

ChrisF

hermank

DuncanP

RodC

💬 Re: A Fan for the Motor

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 163 Views · 11 Likes

Flag

💬 Add Comment

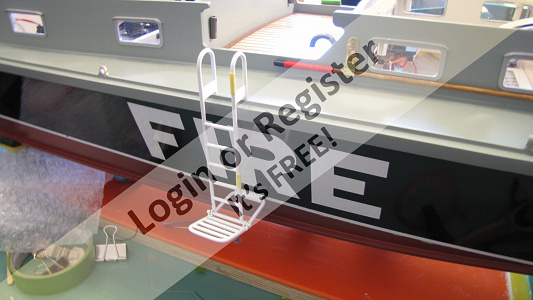

Hi Rob good to see you back, if you remember I did that mod on my Crash tender when I built mine (3 years ago now, doesn't time fly) mine was slightly different in that I used the prop adaptor but mounted the fan as a prop so a greater distance from the motor.

As for efficiency/power loss, when your powering from a 5s as I am as well it doesn't really matter as there's an abundance of power to spare

Those fire monitors look familiar too, I guess Stephen took the tip do his pump water?

As for efficiency/power loss, when your powering from a 5s as I am as well it doesn't really matter as there's an abundance of power to spare

Those fire monitors look familiar too, I guess Stephen took the tip do his pump water?

▲

⟩⟩

Mike Stoney

DaveWhittaker

Jay

Len1

EdW

RNinMunich

Peejay

PemyslJ

hermank

robbob

DuncanP

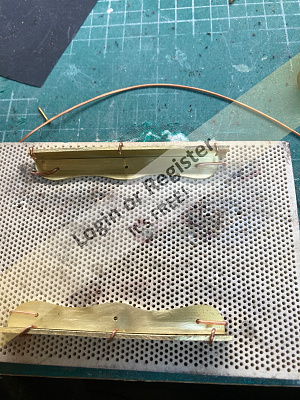

📝 Bending 7/32” tubing

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 85 Views · 7 Likes

Flag

📝 Reply

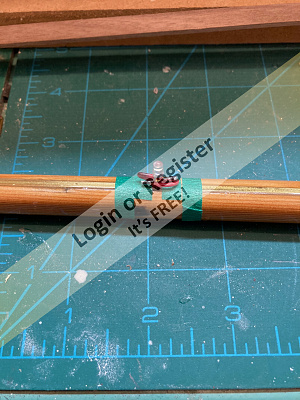

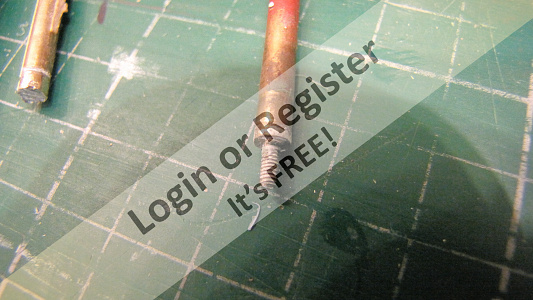

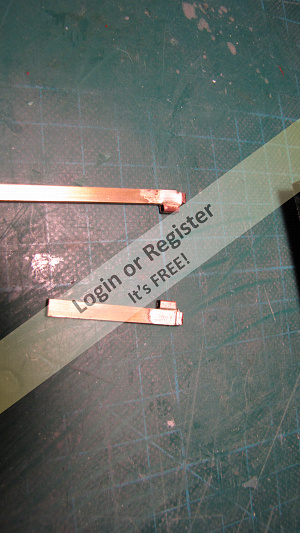

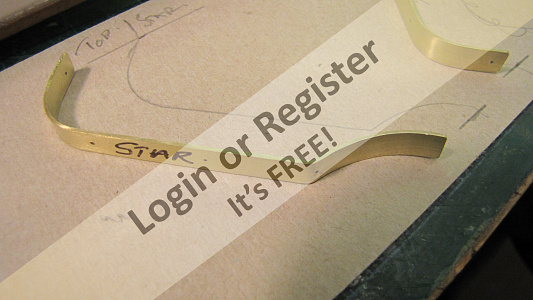

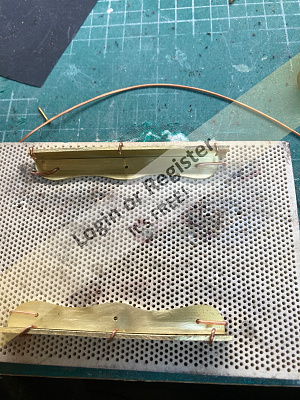

I usually block one end with a wooden plug then fill with molten solder let it cool, then bend to shape, finally heat up to melt solder

If your using brass or copper tube then its best to anneal it first

I've used this method up to 6mm brass tube. see picture solder still in 4mm tube

If your using brass or copper tube then its best to anneal it first

I've used this method up to 6mm brass tube. see picture solder still in 4mm tube

▲

⟩⟩

Peejay

Len1

stevedownunder

roycv

rmac

EdW

hermank

💬 Re: CGINGA1V

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 42 Views · 5 Likes

Flag

💬 Add Comment

Hi Chris I've not been modelling for some time so only just got back to the site and pleased to see your IngaIV sailing so well. I've just about finished mine but had some issues with sails trying various fixings and materials however I've made a set with a cotton material using the mast channels as fixings as designed and they seem to look correct and in keeping with the model. I will make a set from Ripstop material just to see the difference but I'm not keen on the square pattern in the material.

Anyway enough about my sails, so again congratulations on a successful completion of your build, I hope you are as pleased as the the rest of the members are with your build, you should be, well done.

Anyway enough about my sails, so again congratulations on a successful completion of your build, I hope you are as pleased as the the rest of the members are with your build, you should be, well done.

▲

⟩⟩

jbkiwi

stevedownunder

DuncanP

Len1

hermank

Login To

Remove Ads

Remove Ads

📝 Lady Jane

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 46 Views · 1 Like

Flag

📝 Reply

Hi Andy that sounds good I will PM you to discuss

▲

⟩⟩

Len1

📝 Lady Jane

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 78 Views · 8 Likes

Flag

📝 Reply

I have acquired some Maxwell Hemmens original GRP hulls, some are for sale but I need the build manual either for the GRP hull or the Plank on frame either will help me to make a start on a build

▲

⟩⟩

hermank

Len1

stevedownunder

flaxbybuck

IanL1

Peejay

jumpugly

Newby7

📝 Drifter Trawler Boat Formidable LT100

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 4 Likes

Flag

📝 Reply

Thanks for all your replies they are most helpful

▲

⟩⟩

Razor1955

Peejay

Len1

stevedownunder

📝 Drifter Trawler Boat Formidable LT100

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 82 Views · 6 Likes

Flag

📝 Reply

Has anybody built a Drifter Trawler Boat Formidable LT100

Im looking for plans and instruction manual and any pictures of a build

Im looking for plans and instruction manual and any pictures of a build

▲

⟩⟩

hermank

Frankiesays1953

Len1

stevedownunder

Peejay

GaryLC

💬 Re: CGINGA1V

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 122 Views · 5 Likes

Flag

💬 Add Comment

Hi Chis my method of holding the planks is a wooden clamp where the pin sticks in the sub deck slightly away from the plank and the wooden clamp pushes down on the plank holding it in place avoiding any marks to the new plank, but I do like your method and will give it a go next time.

▲

⟩⟩

ChrisG

Len1

stevedownunder

Peejay

hermank

📝 Deans Marine

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 99 Views · 4 Likes

Flag

📝 Reply

Unfortunately I had abusive language from Mr Dean some years ago when I queried a refund issue so I no longer use his services

▲

⟩⟩

Len1

EdW

hermank

tim morland

💬 Re: CGINGA1V

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 136 Views · 7 Likes

Flag

💬 Add Comment

Hi Chris I too haven't been on the site much myself so missed your post, anyway I hope your back on the road to recovery the progress looks good

▲

⟩⟩

Peejay

hermank

Rogal118

Mike Stoney

stevedownunder

Len1

ChrisG

📝 City of Sheffield Tyne lifeboat

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 7 Likes

Flag

📝 Reply

Hi Roger a great result a testament to your building skills.

A subject close to my heart, I look in despair sometimes at the flood of 3D printed parts that take away the traditional skill of model making from raw materials its nice to see your efforts.

A subject close to my heart, I look in despair sometimes at the flood of 3D printed parts that take away the traditional skill of model making from raw materials its nice to see your efforts.

▲

⟩⟩

Len1

Ronald

stevedownunder

RNinMunich

robbob

Rogal118

hermank

📝 Fibreglass hulls

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 91 Views · 0 Likes

Flag

📝 Reply

I'm looking for a Hull length of 40" / 42" would be ideal, to carry a pay-load of around 6 LBs

Does anybody have details of a seller?

Does anybody have details of a seller?

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Full Steam Ahead

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 52 Views · 4 Likes

Flag

📝 Reply

Gary , yes I think your right because I was surprised by the weight of the boiler alone when I unpack it ,so yes I will be making that check first.

Andi1 the blog on the Inga iv is already a long way through

Andi1 the blog on the Inga iv is already a long way through

▲

⟩⟩

Len1

GaryLC

Andi1

stevedownunder

Login To

Remove Ads

Remove Ads

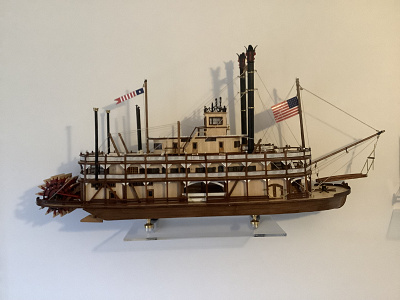

📝 Full Steam Ahead

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 91 Views · 16 Likes

Flag

📝 Reply

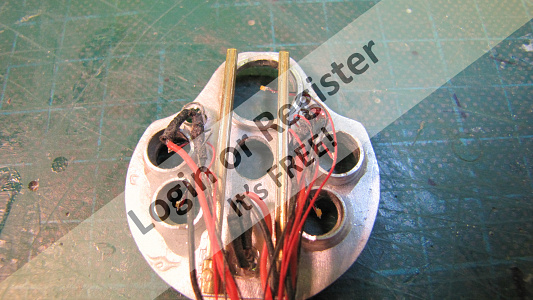

I placed an order last September for my Christmas present from my wife and it arrived today. The push that made me go for steam was after a visit to a fellow modeller who is a "master of steam" and he showed me around his most impressive workshop and the steam models he had made.

GaryLC (Captain) kindly gave me a twin cylinder oscillating steam engine and a hull to get me started in steam.

So Gary we are "Full Steam Ahead"

PS it may be a while before I start the new project as I have the Inga IV yacht to finish first.

GaryLC (Captain) kindly gave me a twin cylinder oscillating steam engine and a hull to get me started in steam.

So Gary we are "Full Steam Ahead"

PS it may be a while before I start the new project as I have the Inga IV yacht to finish first.

▲

⟩⟩

PeterL3

Commodore-H

boatmam

Len1

pressonreguardless

ChrisF

DuncanP

hermank

Andi1

stevedownunder

RodC

GaryLC

ARL58

roycv

Doogle

Nickthesteam

💬 Re: Winch setup finally decided

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 140 Views · 2 Likes

Flag

💬 Add Comment

Great winch layout

▲

⟩⟩

Len1

DuncanP

💬 Re: Wheelhouse Windows

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 62 Views · 3 Likes

Flag

💬 Add Comment

Very inventive way of cutting out the windows, I did exactly the same when cutting my window frames for the Marlin only using a mini pedestal drill

▲

⟩⟩

Len1

stevedownunder

Wolle

💬 Re: MV Sarinda

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 62 Views · 0 Likes

Flag

💬 Add Comment

Some great pictures as they say-

"A picture paints a thousand words", however some words would be good to explain your building techniques, that would help others in their quest to improve their building skills.

"A picture paints a thousand words", however some words would be good to explain your building techniques, that would help others in their quest to improve their building skills.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Sea rover cabin cruiser

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 101 Views · 1 Like

Flag

📝 Reply

Hi Schmango it would have been nice to see some pictures of the detailed work you carried out.

▲

⟩⟩

Len1

💬 Re: Kathryn - a Thames Bawley - 5

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 6 Likes

Flag

💬 Add Comment

Hi Flax, your system is very much like mine as you say it needs to be removed easily I also have just 2 screws to remove the whole winch system

▲

⟩⟩

AndyB2

Len1

Colin H

flaxbybuck

RNinMunich

Peejay

💬 Re: Rigging

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 54 Views · 3 Likes

Flag

💬 Add Comment

Hi flaxbybuck the 4mm eyes will screw down into the hull, the only part visible will be the three eyes on each fitting that attach to the turnbuckles along with a touch of epoxy

PS I may put a nut directly under the brass fitting as well

PS I may put a nut directly under the brass fitting as well

▲

⟩⟩

flaxbybuck

RNinMunich

RossM

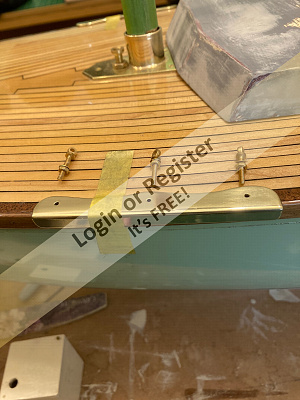

📝 Rigging

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 73 Views · 14 Likes · 5 Comments

Flag

💬 Add Comment

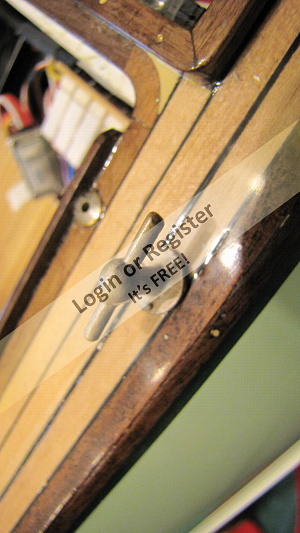

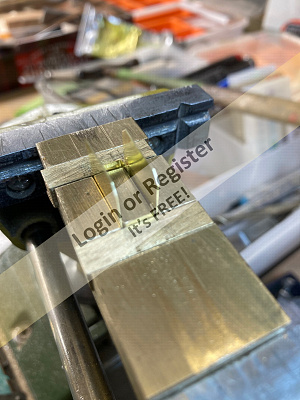

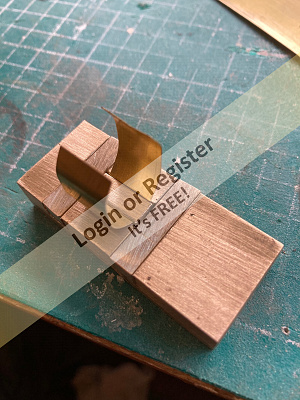

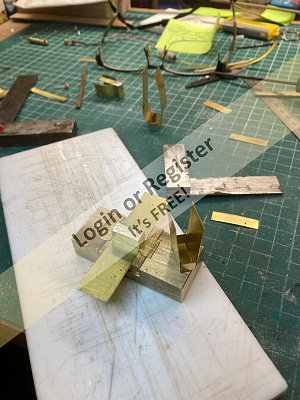

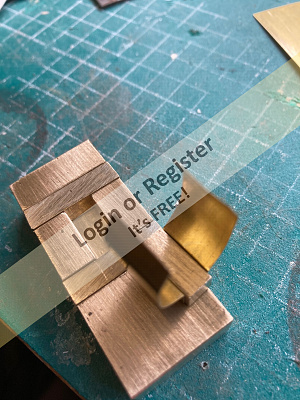

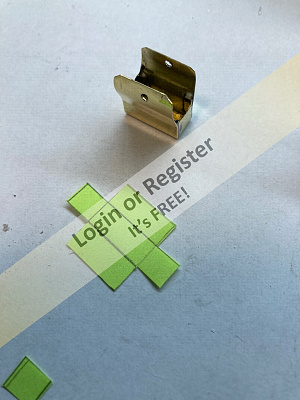

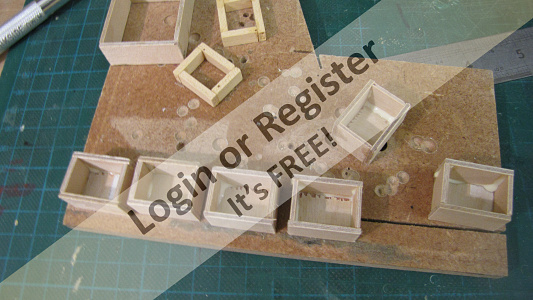

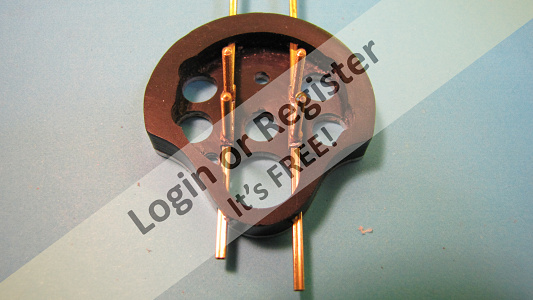

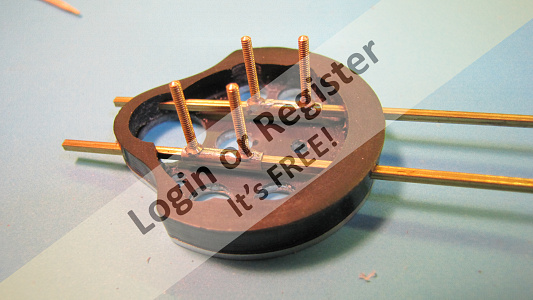

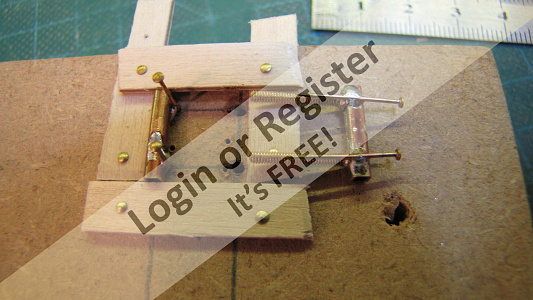

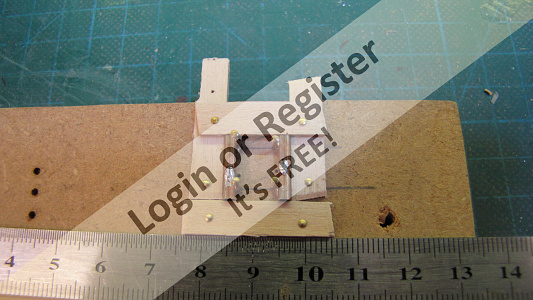

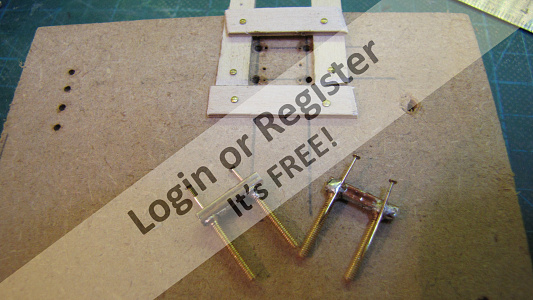

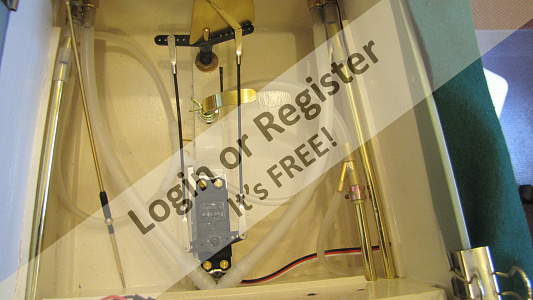

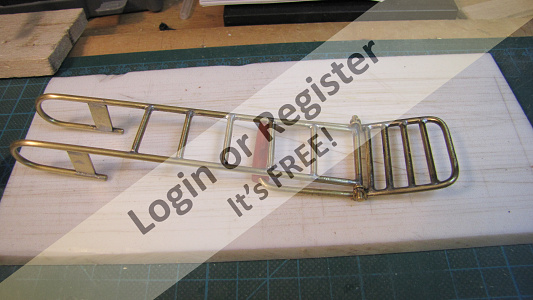

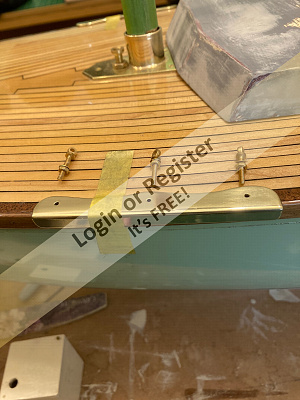

The rigging for each mast was originally fastened to the deck with a rather unsightly piece of brass wire looped through the deck and glued underneath. I was sure I could improve on this however it may not be to everybody’s taste but a you may have noticed if there’s an easy way and a hard way I usually go for the hard way which tends to be much more time consuming and more difficult but for me much more enjoyable.

I wanted the rigging to be easily assembled at the lakeside so attaching the wires must be easily done; each wire has a turnbuckle at its end to tension the wires with an attachment point directly by a 4mm eye. I have decided to use a fishermen’s device, which is normally for attaching a trace wire (I think) it’s just a quick way of attaching the wire (this may change on final assembly it could end up as a simple hook (picture later)) This device then attaches to the eye, which is fastened to the deck. As I said in the original plan, it shows a piece of 1mm brass wire pushed through the deck and epoxied under the deck leaving a loop on deck. Although this works, I wanted to do something a bit more robust and challenging and bring a bit of finesse to the yacht. Therefore, I produced a fitting for each of the four securing positions.

These were made from 1.5mm brass sheet which was cut and filed to the double bulge on deck and straight on the sides the joint line was also filed to the curve of the sides to make a snug fit the two pieces were then silver soldered to form an angle piece. After trimming and polishing each piece had the 3 holes drilled and tapped M2 to take treaded eye bolt fitting, these will go through the deck and help make a secure fitting

I wanted the rigging to be easily assembled at the lakeside so attaching the wires must be easily done; each wire has a turnbuckle at its end to tension the wires with an attachment point directly by a 4mm eye. I have decided to use a fishermen’s device, which is normally for attaching a trace wire (I think) it’s just a quick way of attaching the wire (this may change on final assembly it could end up as a simple hook (picture later)) This device then attaches to the eye, which is fastened to the deck. As I said in the original plan, it shows a piece of 1mm brass wire pushed through the deck and epoxied under the deck leaving a loop on deck. Although this works, I wanted to do something a bit more robust and challenging and bring a bit of finesse to the yacht. Therefore, I produced a fitting for each of the four securing positions.

These were made from 1.5mm brass sheet which was cut and filed to the double bulge on deck and straight on the sides the joint line was also filed to the curve of the sides to make a snug fit the two pieces were then silver soldered to form an angle piece. After trimming and polishing each piece had the 3 holes drilled and tapped M2 to take treaded eye bolt fitting, these will go through the deck and help make a secure fitting

▲

⟩⟩

Nickthesteam

GaryLC

cenbeth

RNinMunich

Graham93

Len1

stevedownunder

JockScott

Rogal118

Colin H

flaxbybuck

hermank

ChrisG

Mike Stoney

📝 Best sail material for yachts ?

2 years ago by 🇬🇧 mturpin013 ( Admiral)

Admiral)

Admiral)

Admiral)✧ 66 Views · 1 Like

Flag

📝 Reply

▲

⟩⟩

hermank

Commodore)

Commodore)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Able Seaman)

Able Seaman)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Commander)

Commander)

Rear Admiral)

Rear Admiral)

Petty Officer 2nd Class)

Petty Officer 2nd Class)

Midshipman)

Midshipman)

Petty Officer 1st Class)

Petty Officer 1st Class)

Fleet Admiral)

Fleet Admiral)