Join Us On Social Media!

United Kingdom

Recent Posts

💬 Re: VIC SMEED'S VIVACITY

1 month ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 62 Views · 4 Likes

Flag

💬 Add Comment

Very nice to see a construction of this great model. I did start one and had a fram, but disaster struck and i fell over the frame and it was at its most fragile state, but could not regain the courage, to restart, so following with great interest..Regards Muddy.

▲

⟩⟩

EdW

jumpugly

premecekcz

hermank

Login To

Remove Ads

Remove Ads

📝 Glynn Guest models

2 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 36 Views · 3 Likes

Flag

📝 Reply

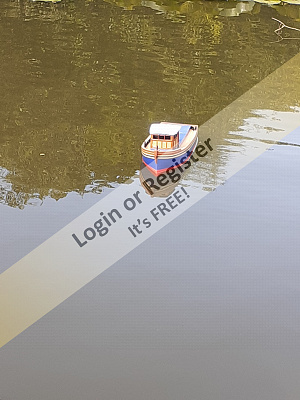

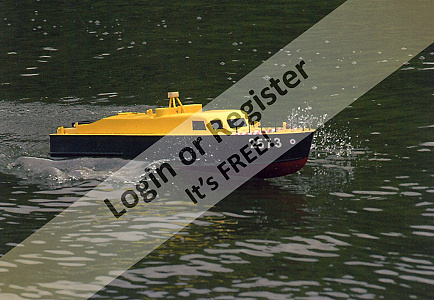

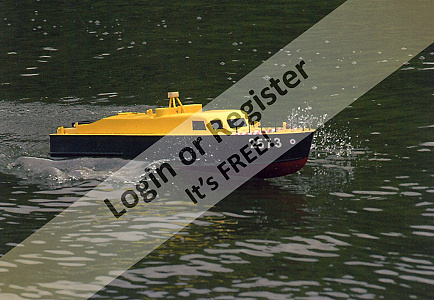

The original Miami at 1/32 nd scale , i think.. One of the quickest builds i have know and easy. Just a note, all my GG models were direct drive single and twin screw..

ATB Muddy..

ATB Muddy..

▲

⟩⟩

chugalone100

hermank

Doogle

📝 Glynn Guest models

2 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 39 Views · 3 Likes

Flag

📝 Reply

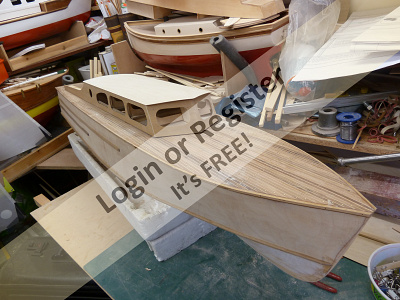

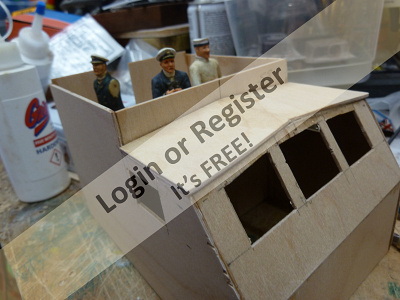

Found another GG model, but at twice size which i think is 1/24th scale.. There shud be a 1/32 nd scale also, but pics elude me at the moment.. The wheelhouse of the 24th scale PT Boat and a Air Sea Rescue launch built on the Glyn Guest style in Balsa of course. ATB Muddy ....

▲

⟩⟩

chugalone100

hermank

Doogle

📝 Glynn Guest models

2 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 55 Views · 6 Likes

Flag

📝 Reply

Hi Roy.. It was Glyn Guest who revitalized my interest in Model Boats In 1999, with his PT 109, Elco 80 footer, after somewhat 40 years lay-off since 1958. It was was the full build description and pictures that accompanied the plan in Model Boats magazine. People frown upon Balsa Wood for model boats but the majority of my builds in the early 2000's were Balsa Wood, and some are still around and sailing, with no leaks lol..

Pic's show the original 1/32 nd scale and a Blown-up version at 1/24 th scale, the 24 th scale was with all the original sizes of wood for keel and hull skins, powered by 2 x 540 direct drive motors, just about managed to get a scale looking speed on the 24 th but the 32nd was lively.. ATB Muddy ( Brian )

Pic's show the original 1/32 nd scale and a Blown-up version at 1/24 th scale, the 24 th scale was with all the original sizes of wood for keel and hull skins, powered by 2 x 540 direct drive motors, just about managed to get a scale looking speed on the 24 th but the 32nd was lively.. ATB Muddy ( Brian )

▲

⟩⟩

chugalone100

EdW

hermank

Steves-s

Ronald

Doogle

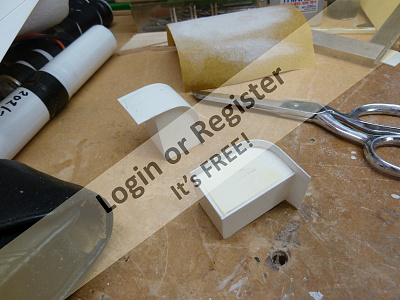

💬 Re: Fairmile Type C - ML ..MGB MM Plan No:585 Part 2

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 50 Views · 5 Likes

Flag

💬 Add Comment

Thanks AlessandroSPQR. Pleased someone has read the notes/Blog.. I think pictures tell a different story more than text, several things were missed out by me, mainly I forgot. One stuck out imediatly that was the Bow, Cut back about 1/2" the sharp end, and replace it with a piece of hard wood, Balsa is tough but dents easily so a hard wood bow is certainly a must in my opinion.. This bow strengthener is made up of mahogony strip about 6mm x 3mm laminated widthwise and in depth, then sanded to shape...

..............

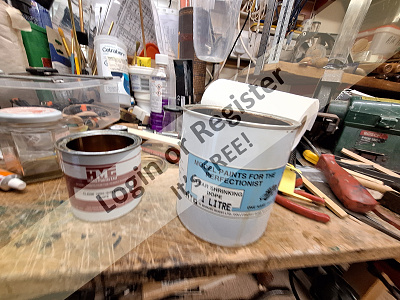

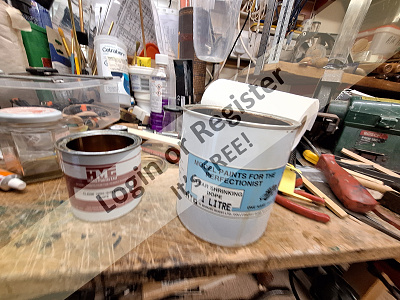

The interior bottom skins upto the chine usually is painted with resin, the rest of the inside has a coat of Dope thinned of course, The exterior has about 3 to 5 coats of thinned Dope, to fill in the grain and then tissue is applied with dope, good practice for wallpapering, then a further 3-5 coats again thinned dope with a light sanding between all coats, I was surprised by how strong balsa hulls are if they are treated especially tissue covered, and finaly paint it on the outside, usually use a spray can from the local car accessory shop of DIY type shop ...TNX .. Muddy

..............

The interior bottom skins upto the chine usually is painted with resin, the rest of the inside has a coat of Dope thinned of course, The exterior has about 3 to 5 coats of thinned Dope, to fill in the grain and then tissue is applied with dope, good practice for wallpapering, then a further 3-5 coats again thinned dope with a light sanding between all coats, I was surprised by how strong balsa hulls are if they are treated especially tissue covered, and finaly paint it on the outside, usually use a spray can from the local car accessory shop of DIY type shop ...TNX .. Muddy

▲

⟩⟩

Steves-s

premecekcz

EdW

Wolle

AlessandroSPQR

💬 Re: Fairmile Type C - ML .. M.G.B. MM Plan No: 585 Part 1

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 50 Views · 1 Like

Flag

💬 Add Comment

Thank you for the comments Steves-s.. Its a Model Boat Plan, No: MM 585 Fairmile C .. Not sure of the scale, have a look on Cornwall model boat site they list a lot of model boat plans or Google it, just found info on Sarik hobbies site they say the scale is 1/24 th ... Go for it, winter is coming plenty of build time.. ATB

▲

⟩⟩

Steves-s

📝 Fairmile Type C - ML .. MGB MM Plan No: 585 Part 8

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 7 Likes

Flag

💬 Add Comment

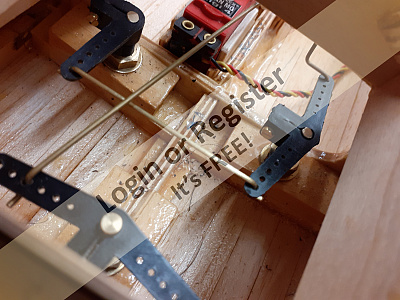

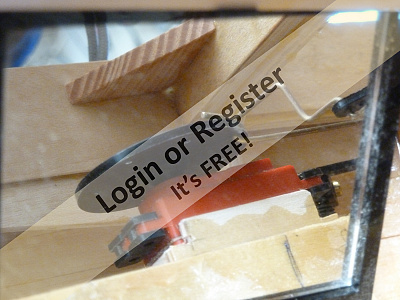

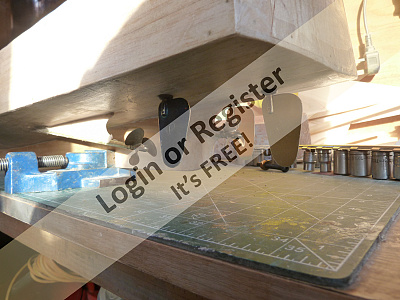

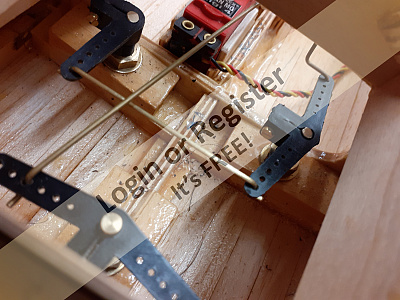

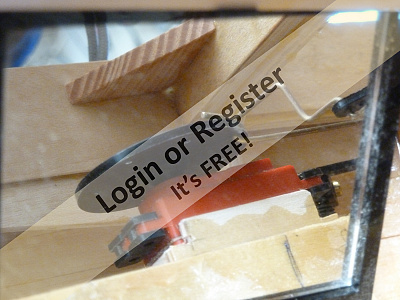

Motor Mounts and Rudders, have always used 2 UJ couplings to a shaft from motor, and the brass bar is just drilled out either end to suite the motor shaft or the drive shaft, just an alignment assistant really. Then came the rudders.. Ohh deary me, what a performance trying to get them all to rotate in the same direction with the commercial types I had chosen, but finaly made it with the help of a mirror jiggery poker'ed into the hull to assist the fitting. One of the last things to be done was to fit the Transom ( shaped ) and rubbing strips..

So we are nearly there...! Regards Muddy happy Building..

So we are nearly there...! Regards Muddy happy Building..

▲

⟩⟩

premecekcz

EdW

RNinMunich

Wolle

hermank

AlessandroSPQR

Steves-s

📝 Fairmile Type C - ML .. MGB MM Plan No: 585 Part 7

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 6 Likes

Flag

💬 Add Comment

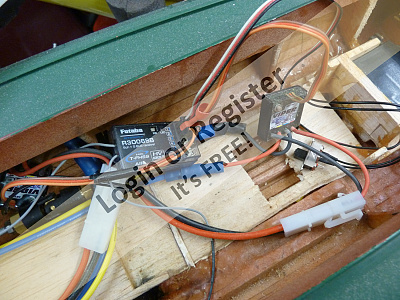

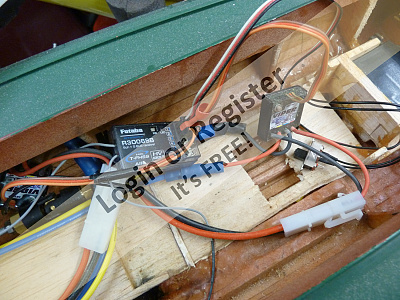

Motors and drive shafts. 3 drive motors fitted and independently controlled. Managed to get hold of an old Futaba Navy with marine sticks fitted, so the outboard motors were controlled from the twin stick's andd the centre screw was controlled off the rudder stick, hopefully giving a one stick operation on the rudder side, if required and the twin stick if wanted giving extra propulsion, although having a slender hull not a very big beam, 3 drive motors made it a bit tight, for me that is.. Also the rudders are not fitted as scale, i wanted more control of the steering. so they were moved forward towards the screws. Several motor types were tested for fit, but i settled on some 386, with the opertunity of slightly larger and more powerful motors.

▲

⟩⟩

EdW

RNinMunich

Wolle

hermank

AlessandroSPQR

Steves-s

📝 Fairmile Type C - ML .. MGB MM Plan No: 585 Part 6

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

▲

⟩⟩

premecekcz

EdW

RNinMunich

Wolle

hermank

AlessandroSPQR

Steves-s

📝 Fairmile Type C - ML .. MGB MM Plan No: 585 Part 5

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 7 Likes

Flag

💬 Add Comment

▲

⟩⟩

premecekcz

EdW

RNinMunich

Wolle

hermank

AlessandroSPQR

Steves-s

📝 Fairmile Type C - ML ..MGB MM Plan No: 585 Part 4

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 7 Likes

Flag

💬 Add Comment

Planking the Hull in 1/2" x 1/8" Balsa and tissue covering the hull. Start with 3-5 coats of dope and thinners 50/50 then apply the tissue with dope again thinned and finally about 3-5 coats of dope/thinners, lightly sanding between coats.

▲

⟩⟩

premecekcz

EdW

RNinMunich

Wolle

hermank

AlessandroSPQR

Steves-s

Login To

Remove Ads

Remove Ads

📝 Fairmile Type C - ML ..MGB. MM Plan No:585 Part 3

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 58 Views · 6 Likes

Flag

💬 Add Comment

▲

⟩⟩

premecekcz

EdW

Wolle

hermank

AlessandroSPQR

Steves-s

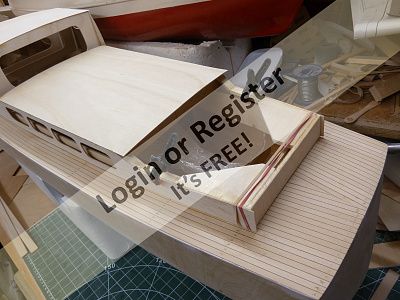

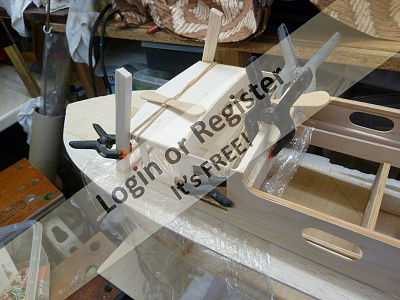

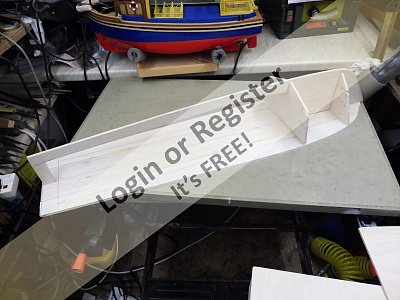

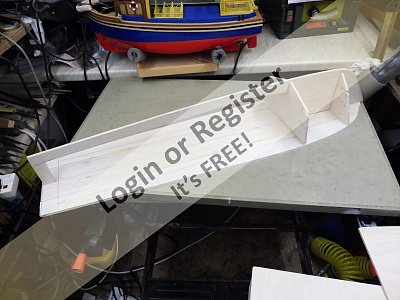

📝 Fairmile Type C - ML ..MGB MM Plan No:585 Part 2

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 59 Views · 6 Likes · 2 Comments

Flag

💬 Add Comment

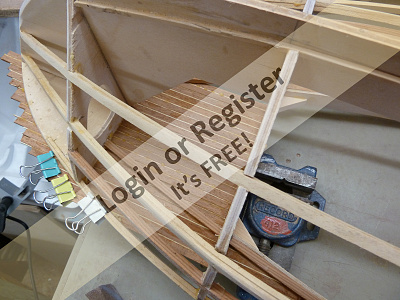

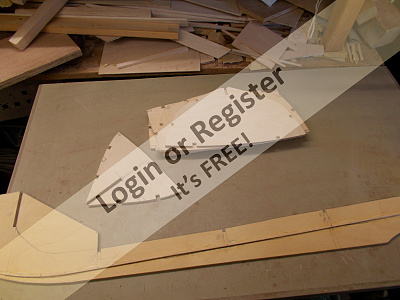

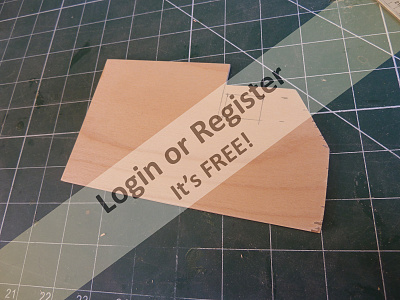

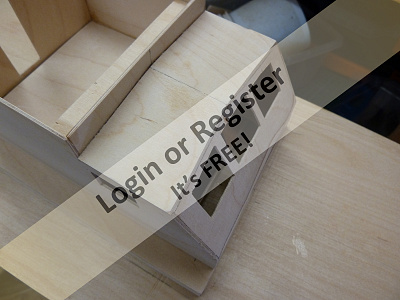

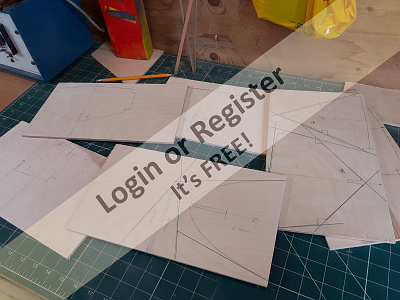

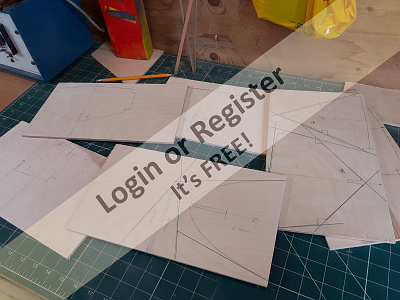

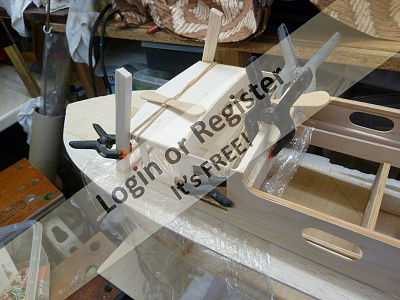

Cutting out the keel and bulkheads , lightening wherever possible by removing the innards of the bulkheads.

Stringers tacked in or onto a dry fit trying to keep the whole square.

Stringers tacked in or onto a dry fit trying to keep the whole square.

▲

⟩⟩

premecekcz

EdW

Wolle

hermank

AlessandroSPQR

Steves-s

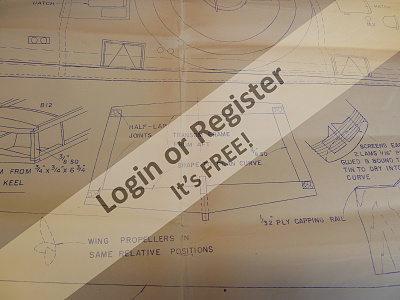

📝 Fairmile Type C - ML .. M.G.B. MM Plan No: 585 Part 1

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 61 Views · 8 Likes · 3 Comments

Flag

💬 Add Comment

The comment was passed that there was not a warship in the club. Muggin's here decided to have a go.

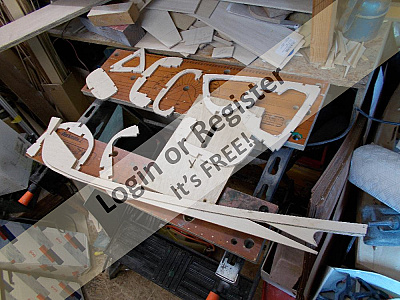

A Drawing was found by another member, I'll just call him TC. Having built this boat in the mid 1980's with a single screw, and a variable speed controller from a car, which gave FULL speed in reverse or the alternative was a Bob's Board, I hate them things, but they work, to a degree, if you match the motor Current to the model of board. This all drove a 540 motor, this was all in a balsa hull and upperworks/cabin. Its fate was a Viking funeral, not planned, the speed control must have overheated and it all caught fire, most sank, a few remnants surfaced but it was all scrap.. Anyway here we go again. Decided on a 6mm ply keel and Bulkheads and planked in 1/2" x 1/8" Balsa with a .8mm ply deck and upperworks, details probably in plasticard and wire.

A Drawing was found by another member, I'll just call him TC. Having built this boat in the mid 1980's with a single screw, and a variable speed controller from a car, which gave FULL speed in reverse or the alternative was a Bob's Board, I hate them things, but they work, to a degree, if you match the motor Current to the model of board. This all drove a 540 motor, this was all in a balsa hull and upperworks/cabin. Its fate was a Viking funeral, not planned, the speed control must have overheated and it all caught fire, most sank, a few remnants surfaced but it was all scrap.. Anyway here we go again. Decided on a 6mm ply keel and Bulkheads and planked in 1/2" x 1/8" Balsa with a .8mm ply deck and upperworks, details probably in plasticard and wire.

▲

⟩⟩

premecekcz

EdW

Wolle

Frankiesays1953

hermank

AlessandroSPQR

Steves-s

cenbeth

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 10

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 23 Views · 3 Likes

Flag

💬 Add Comment

A few more pics of the tissue being applied, plenty of overlapping at the tissue joints, let it all dry and will be easily cut away with a craft knife after. Did fit a couple of side rubbing strips besides the spray rails and deck level strips, basically to support the sides against collision, always carry a tube of balsa cement, if the unfortunate occurance of such things and splits or cracks appear, just rub some balsa cement into the crack and it will reseal the hull for you, its waterproof, so no thinning of the glue, and is easily repaired apon return to boat yard .. Happy sailing and enjoy the unorthodox quick build. Regards Muddy ..

▲

⟩⟩

Steve P

EdW

peterd

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 9

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 22 Views · 1 Like

Flag

💬 Add Comment

Now the furniture is all lined up and fixed plus the steering servo, one can start on the side skins again verticaly sheeting, this will give the hull a lot of strength, again best left overnight to thoroughly dry and glue set. only the Bow to infill with block balsa or any left over bits of sheet, i think the more glue joints the stronger the bow will be ? maybe. Again this part of the build is best left overnight for the glue to set. Next step is to Dope and tissue the hull all over, best give the hull about 3 coats minimum well thinned about 25% is good, a quick rub with the sandpaper between coats. Then apply the tissue, i have found that using small patches of tissue, say about 4-6 inch squares according to the depth of the sides and bottom skins, but Ripped or Torn NOT cut with scissors of a craft knife, when the tissue is ripped it just blends in when the overlaps are brushed on, i did tend to use long pieces of tissue on this hull and it didnt really work, so another lesson learnt, practice what you preach, was probably in a hurry, but it took more time to sand out the creases after. Another min: of 3 coats of tinned dope to be applied, by this time all the lines in the bals should have disappeared and there will be a nice smooth skin ready to accept the paint, again as many coats of primer as you feel is best, but a min: of 3 again, ready for a top coat of 1..

▲

⟩⟩

EdW

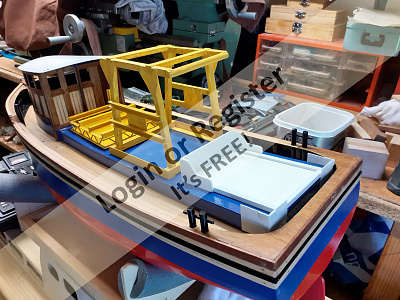

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 8

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 26 Views · 2 Likes

Flag

💬 Add Comment

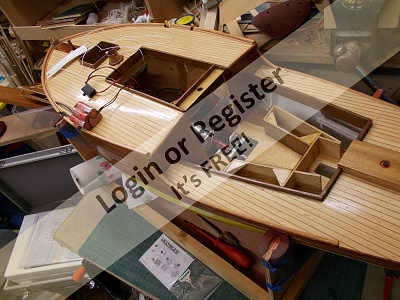

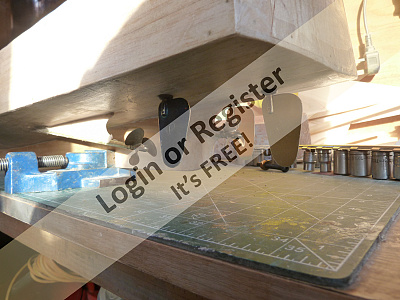

One thing to note if you build as you go the cabin/upperworks on the deck, it will be a very good fit !

Now we are getting somewhere near , its time to fit the motors. with the side skins off makes life easy for alignment's.

Now we are getting somewhere near , its time to fit the motors. with the side skins off makes life easy for alignment's.

▲

⟩⟩

EdW

thadlietz

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 7

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 26 Views · 2 Likes

Flag

💬 Add Comment

Continuing with the bottom skins, always glue and pin both sides of the hull equally, Port and Starboard. This is best left overnight to let the glue set right off and then one can start the sanding and cutting to profile the next day. Its a good time to start thinking about the upperworks/cabin etc: .... I like the open access type, or one big hole in the deck with a removable top, something to get your hands into, especially if you are going to experiment with motors and radio gear are to be contemplated. You really need as much room for access as possible. And as this is an experimental boat i did exactly thay. The cabin is not to drawing as the hull is also, not to drawing or its construction. Just an outline to shape that worked, note the "that" .. in previous model a 30" Telectra. Lierally it was place everything but stretch lengthwise and widthwise, decided on a deck combing, about 1/2" high and lined the top rim with 3/16" square to act as a water diverter, we hope. Although a wet deck is not a good sign on a calm pond. First thing was to lay Cling Film all over the deck covering the motor and drive shaft access/aperture. Space the sides off the deck combing and measure the cabin formers, balsa is my preferred wood for this, its a lot easier and quicker than ply. Basically its a build as go, but keeping the windows and windscreen in prospective to suit. ... .8mm ply was used for the cabin roof, if one watches the grain it forms very nicely thank you, and use some odd lengths of timber laid over the length of the roof's to stop them "Barreling" .. Elastic bands are great for this job, and if yours aint long enough just join a couple together like a daisy chain.

▲

⟩⟩

EdW

thadlietz

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 6

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 29 Views · 2 Likes

Flag

💬 Add Comment

Propulsion, once glue is dry on all the fittings and supports for motors shafts and rudder, time to start on skins, normally i will go for the bottom ones first, they consist of 1/8" sheet balsa laid and glued across the underside, keel to chine, this will give the model a lot of strength. But first, get the Dumbells out and a bit of a workout, cos the edges of the deck , keil and chine have to match in angles for the sheet balsa to be applied , and fit well.. Have used for years a piece of 3/8" ply about 8" x 3", this is my sanding block, apply a piece of sandpaper to it just by hold, it's folded around on one face of the 3/8 ply, the idea is to span the chine and keel so there is only one edge for the balsa skin to sit on. This is also used to sand to shape the edges of the deck and chine. Again i use the Aliphatic glue for this. ( think its Titbond ). Have always cut the skin span to long, when the glue is applied and pinned, one can trim the overlength after the glue drying process. The bottom skins are fitted all the way up to the bow first bulkhead, as the bow will be balsa blocked, its a lot quicker and easier, moreso easily repaired..

▲

⟩⟩

thadlietz

EdW

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 5

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 3 Likes

Flag

💬 Add Comment

▲

⟩⟩

thadlietz

EdW

Steve P

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 4

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 3 Likes

Flag

💬 Add Comment

Once the main frame/Hull frame glue is dry, one has to start thinking about the Furniture, ie: Propulsion and steering. Tend to use Twin Screw arrangement with a single Rudder, just my choice, but i did find that a single Rudder with Twin Screws made the steering "Softer" , stopped the bow digging in on tight turns, the rudder acts more like a trim tab, that is as long as there is not to much throw, I always use about 20-25 Degrees either way works great for me, and the boat. As the construction is balsa use plenty of wood around the prop shaft exit from the hull and the rudder shaft, there is a lot of stress at this point, or maybe more if one fits Brushless motors.. The other major point is where the motors are to be mounted, try to align motors to shafts as accurately as possible, if one makes up a motor platform and then shims motor mountings with wedges, at this point I have always used an Epoxy glue for the mounting plate and in 6mm ply full hull width if possible. it is well advisable to fit "Furniture" before the skins are applied, but fitting the bottom skins can be advantageous, it will strengthen the hull, before one sets about the Furniture install with a 4 lb hammer and cold chiesel.. ( just a funny ).. Included is a pic of prop to be used , from Prop shop, i like these props and they have served me well in all of my models.

▲

⟩⟩

thadlietz

EdW

Steve P

Login To

Remove Ads

Remove Ads

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 3

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 2 Likes

Flag

💬 Add Comment

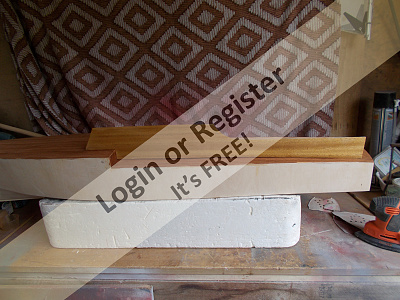

When all the bulkheads are cut out and the chines. Construction can actually start by laying the Deck onto a flat surface and dry fitting the keel and bulkheads in place, it feels a bit funny at first as one is constructing upside down, but dont worry it grows on you. If the dry fit is ok, then pull it all apart and apply glue where appropriate, have always used an Aliphatic, these glues i think are PVA family but they do dry hard and not rubbery, presumably resin based. Also use a Cyno type of glue for tacking parts into place then line the joint with the Alphatic. One the keel, bulkheads and chines are glue in place weigh it all down on the flat surface, use anthing heavy , old batterys , files engineering blocks, my transom split, another one, so quickly found a piece of 1/2" balsa and cut to shape, inserted and glued. Now is the time for a cuppa, and scrounging, your looking for a piece of polystyrene, the sort that is premoulded from a TV, CD player or tape recorder packaging, use this as a building stand in place of the usual ply frame, the reason for the polystyrene is, its soft and wont damage the delicate balsa even if you drop the frame onto the poly: if neccesary cut a couple of V shapes in the poly: to match the hull shape, that helps a lot.

▲

⟩⟩

thadlietz

EdW

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417 - Part 2

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 45 Views · 2 Likes · 1 Comment

Flag

💬 Add Comment

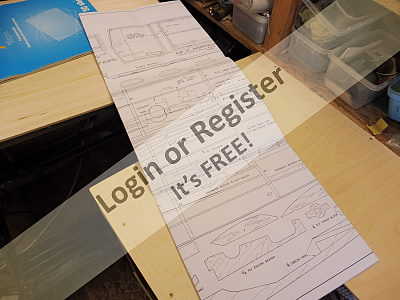

A bad explanation on my part concerning Grease proof paper and cling film. Just like to put the record straight, Before Cling Film, being used as protection for a Drawing or worktop/bench, we used grease proof paper or rubbed soap over the drawing which hopefully left a wax'y film on the drawing or bench worksurface preventing glues stickng to the drawing /worktop, but since clingfilm which is a lot better to use and out performs soap and greaseproof paper by keeping glues off the valuable drawings/worktop's. Continuing on, when one traces the outlines of the deck at close to 36" long, the A3 size of draft film aint big enough to cover this length, join a couple of A3 film together using a Selotape type of bond, i tend to use 3M Scotch Magic Tape, it has an opaque look and matt finish, this is great for drawing on either in pencil or Ballpoint pen.

Whereas standard Sellotape type of tape has a gloss finish and pencil lines do not adhere or ball point pen ink. Once you have traced the Deck outline, place it over the Balsa deck and copy it onto the balsa, some folks like Carbon copy paper and copy that way, i prefer to use a pin and prick through the tracing paper into the wood, then remove the film and join up the pricked marks, ( I love this bit ), now do the same for the Keel, being careful not to break off the upright at the Transom end, if this happens do not worry, a small amount of super glue/cyno will do an instant repair then fit a couple of 1/8" Balsa doublers. Next is to the same with the Bulkheads , trace onto the wood mark out and cut out, i did have trouble with one of these bulkheads, spliting with the grain, i scrapped it, and recut the bulkhead in 1/8" times 2, laminating these two together.

Whereas standard Sellotape type of tape has a gloss finish and pencil lines do not adhere or ball point pen ink. Once you have traced the Deck outline, place it over the Balsa deck and copy it onto the balsa, some folks like Carbon copy paper and copy that way, i prefer to use a pin and prick through the tracing paper into the wood, then remove the film and join up the pricked marks, ( I love this bit ), now do the same for the Keel, being careful not to break off the upright at the Transom end, if this happens do not worry, a small amount of super glue/cyno will do an instant repair then fit a couple of 1/8" Balsa doublers. Next is to the same with the Bulkheads , trace onto the wood mark out and cut out, i did have trouble with one of these bulkheads, spliting with the grain, i scrapped it, and recut the bulkhead in 1/8" times 2, laminating these two together.

▲

⟩⟩

thadlietz

EdW

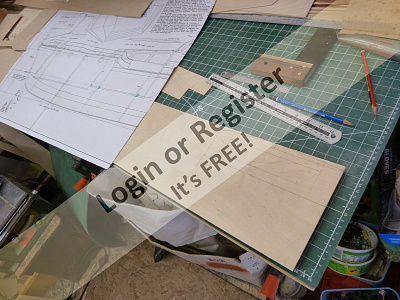

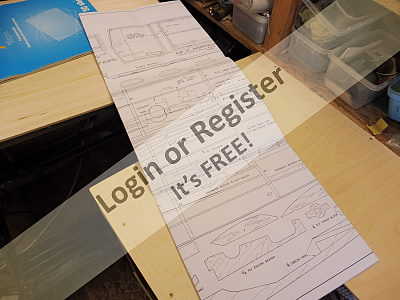

📝 Telectra 2 Standoff scale Police/Customs launch or Service Tender MM Plan No: MM417

5 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 67 Views · 9 Likes · 4 Comments

Flag

💬 Add Comment

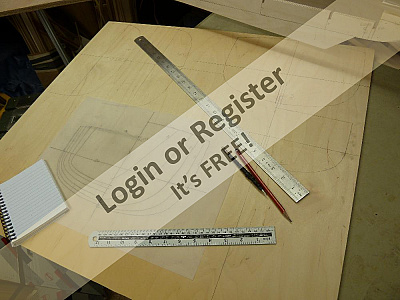

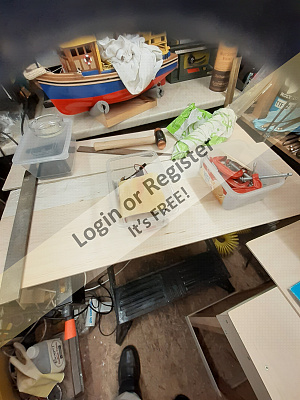

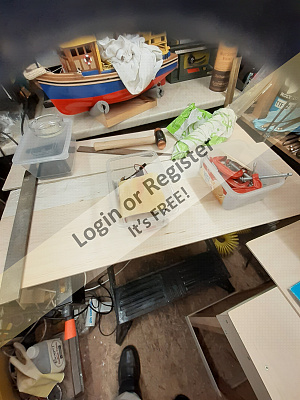

Part 1 - 7 Pictures ...

Made up a Spec for something light twin screw and not to big in length. Having built and sailed this model earlier about 2014 ish... with twin 777 Brushed drive motors, it's performance was in my opinion good.

But decided to lengthen the hull from abt 30 inches to 36 inch, why, I dont know, just for a bit of fun and thought the earlier version looked a bit short and sweet, and the build would be in Balsa.. Some folks frown upon this timber but i love it, easy to work, cut and sand and if tissue covered will be quite strong. First set of pics show the drawing, Drafting Film/Tracing Paper and joining of three sheets of balsa to form the deck which are laid on Cling Film, good stuff this, a lot better than the old grease proof paper. 3 x 3" sheets of balsa were glued up together edgewise on.. To be continued -

Made up a Spec for something light twin screw and not to big in length. Having built and sailed this model earlier about 2014 ish... with twin 777 Brushed drive motors, it's performance was in my opinion good.

But decided to lengthen the hull from abt 30 inches to 36 inch, why, I dont know, just for a bit of fun and thought the earlier version looked a bit short and sweet, and the build would be in Balsa.. Some folks frown upon this timber but i love it, easy to work, cut and sand and if tissue covered will be quite strong. First set of pics show the drawing, Drafting Film/Tracing Paper and joining of three sheets of balsa to form the deck which are laid on Cling Film, good stuff this, a lot better than the old grease proof paper. 3 x 3" sheets of balsa were glued up together edgewise on.. To be continued -

▲

⟩⟩

IanL1

Nick Ward

Steves-s

Steve P

Doogle

hermank

EdW

jumpugly

thadlietz

💬 Re: Expensive hole!

6 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 77 Views · 4 Likes

Flag

💬 Add Comment

Different lengths of drill bit are available from engineers suppliers, at a cost of course, I tend to use a prop shaft tube with one bush removed, this bush-less end can be cut across the face maybe twice then formed with a small file to the shape of a carpenters woodbite or ripsaw cutting edges, with the now 2 or 4 formed pointed edges bent very slightly outward to form a ringsaw shape. Sometimes with a bit of thought a twist drill can be placed down the centre of the tube to act as a drilling guide, this is best undertaken with a hand drill/brace or a very slow pistol drill, you may have to remove the device to place a new cutting edge on the tube end severel times, I have only ever used a brass tube but i,m sure a steel tube would work just as well if not better. Muddy....

▲

⟩⟩

PeterL3

hermank

zooma

RodC

💬 Re: Just for fun !

8 months ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 168 Views · 1 Like

Flag

💬 Add Comment

Ohh dear.. Pleased you managed to rescue all the gear though Phil.. My apologies for the nosiness of this question, but what was the other boat involved, the green and white one ? the motor sailer, or thats what it looked like to me.. Thanks for the post.. ATB Muddy..

▲

⟩⟩

hermank

📝 Death of a member.

2 years ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 79 Views · 8 Likes

Flag

📝 Reply

Hello Colin, Very sorry to hear about your sad loss, condolences to all family..

Best Regards Muddy..

Best Regards Muddy..

▲

⟩⟩

Scratchbuilder

jumpugly

BOATSHED

Colin H

stevedownunder

Peejay

hermank

Len1

📝 Sealing Balsa & Ply

2 years ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 50 Views · 2 Likes

Flag

📝 Reply

Sorry.. There is a PS to my last Post..

After applying the tissue and dope, you will have to apply another 3 coats of the 50/50 Dope/Thinners concoction, and of course rubbing down between coats, just to give the new applied coat a "key".. Once completed , a paint of your choice can be applied, I tend to use Acrilic paint from Halfords, starting with a couple of coats of Grey primer, rubbing down between all coats, then apply colours of your coice, if more than one coat is required, dont forget to rub it down for next coat to have a key..

ATB Muddy..

After applying the tissue and dope, you will have to apply another 3 coats of the 50/50 Dope/Thinners concoction, and of course rubbing down between coats, just to give the new applied coat a "key".. Once completed , a paint of your choice can be applied, I tend to use Acrilic paint from Halfords, starting with a couple of coats of Grey primer, rubbing down between all coats, then apply colours of your coice, if more than one coat is required, dont forget to rub it down for next coat to have a key..

ATB Muddy..

▲

⟩⟩

Len1

Colin H

📝 Sealing Balsa & Ply

2 years ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 50 Views · 2 Likes

Flag

📝 Reply

HEllo... Sealing Balsa wood or Ply..

Balsa I have always given the wood about 6 coats of Cellulose Dope but thinned 50/50 with Cellulose Thinners available from most car Paint supplies/Motor Factors, The Thinners is not cheap. That is for sealing Balsa, but to help strengthen the Balsa Use about 3 coats of 50/50 dope /thinners, then apply some Medium grade Tissue Paper as was/is used by aero modelers.

Place the Tissue on the pre-treated wood and paint over and into the tissue , just like hanging wallpaper, Dont have any "Cut" joints, tear the paper to size, the teared joints will be near to invisable apon completion of the dopeing process..

Good luck, and dont forget a mask, the thinners and Dope can be very strong in the odure range. Do it outside or in a drafty place..

ATB Muddy..

Balsa I have always given the wood about 6 coats of Cellulose Dope but thinned 50/50 with Cellulose Thinners available from most car Paint supplies/Motor Factors, The Thinners is not cheap. That is for sealing Balsa, but to help strengthen the Balsa Use about 3 coats of 50/50 dope /thinners, then apply some Medium grade Tissue Paper as was/is used by aero modelers.

Place the Tissue on the pre-treated wood and paint over and into the tissue , just like hanging wallpaper, Dont have any "Cut" joints, tear the paper to size, the teared joints will be near to invisable apon completion of the dopeing process..

Good luck, and dont forget a mask, the thinners and Dope can be very strong in the odure range. Do it outside or in a drafty place..

ATB Muddy..

▲

⟩⟩

Len1

Colin H

📝 Plank Race

3 years ago by 🇬🇧 muddy ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 44 Views · 3 Likes

Flag

📝 Reply

Hello Roger... It's great to see some local news.. lol

Straight runners, without a body shell..

But what a laugh..

This is a great place for news and knowledge/information..

ATB M...

Straight runners, without a body shell..

But what a laugh..

This is a great place for news and knowledge/information..

ATB M...

▲

⟩⟩

RNinMunich

hermank

RogerA1

Commodore)

Commodore)

Liked Esc failure, explore and rescue by REAL Pilot boat 20 days ago

Liked Esc failure, explore and rescue by REAL Pilot boat 20 days ago

Liked Sailing at the Toronto Boat Show 1 month ago

Liked Sailing at the Toronto Boat Show 1 month ago

Liked Re: VIC SMEED'S VIVACITY 1 month ago

Liked Re: VIC SMEED'S VIVACITY 1 month ago

Liked VIC SMEED'S VIVACITY 1 month ago

Liked VIC SMEED'S VIVACITY 1 month ago

Liked Re: Wave master boat 4 months ago

Liked Re: Wave master boat 4 months ago