Join Us On Social Media!

United Kingdom

Recent Posts

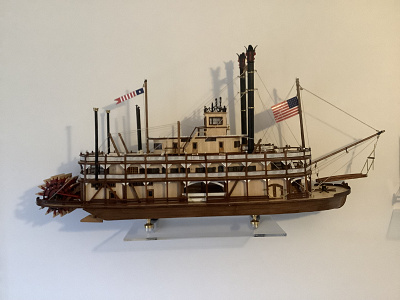

📝 3D Printed Models

9 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 31 Views · 4 Likes

Flag

📝 Reply

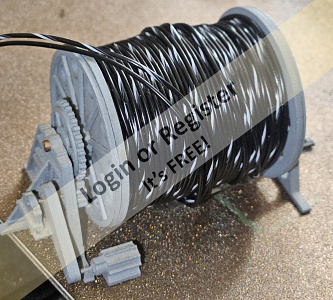

I have made "kits" of parts in the past, like the LL sweep winch pictured down the thread somewhere, but I prefer to use a combination of all disciplines. Who remembers the "gummed paper tape" construction method?

▲

⟩⟩

hermank

AlessandroSPQR

EdW

tim morland

Login To

Remove Ads

Remove Ads

📝 3D Printed Models

9 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 32 Views · 6 Likes

Flag

📝 Reply

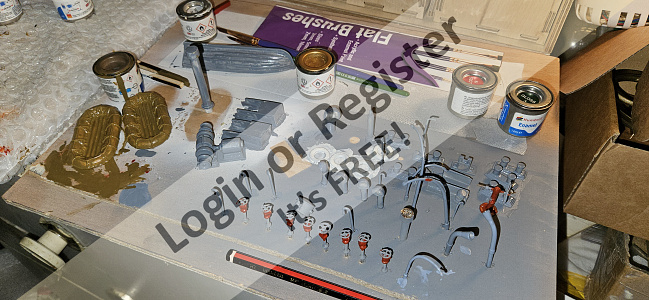

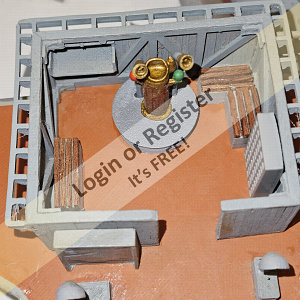

Nice funnel! Good to use different techniques and materials. At the end of the day, it matters not how a quality piece like that is produced, it is the end result that counts.

▲

⟩⟩

BobbyN

RodC

hermank

EdW

jumpugly

AlessandroSPQR

📝 3D Printed Models

11 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 43 Views · 3 Likes

Flag

📝 Reply

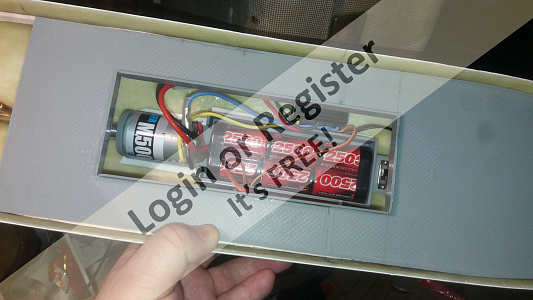

Lew. You need an enclosure for ABS. Also turn off the part cooling fan, layers stay sticky for longer. My first enclosure was literally a cardboard box set over my printer. I eventually built one from an Iker Lac coffee table. I had great success once I got the measure of it.

▲

⟩⟩

hermank

RodC

LewZ

📝 Question of the Day?

13 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 46 Views · 1 Like

Flag

📝 Reply

I must confess to researching answers, but not fron Gurgle. I have several books dealing with nautical matters, for example, the 1956 edition of The Admiralty Manual of Seamanship, several RYA training manuals, Advanced Powerboat, Yachtmaster etc so I use books only when I have to. I still get stuff wrong and have never got to first place, second place for about 3 days is the highest I've been.

▲

⟩⟩

Steves-s

📝 Question of the Day?

13 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 43 Views · 0 Likes

Flag

📝 Reply

Phew, lucky stab produced results!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Fascinating piece on Shackleton's Endurance today...

13 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 22 Views · 1 Like

Flag

📝 Reply

Agreed! The tv docudrama is very good....

▲

⟩⟩

jumpugly

📝 Question of the Day?

14 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 41 Views · 0 Likes

Flag

📝 Reply

Repeat question...

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Question of the Day?

19 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 44 Views · 3 Likes

Flag

📝 Reply

Hey Ed, I thought we are all merticalated now, all terms unified and done away with...🤔🤔🤔

▲

⟩⟩

SimpleSailor

Steves-s

roycv

📝 Question of the Day?

19 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 43 Views · 2 Likes

Flag

📝 Reply

I chose the answer where "speed" was mentioned in both the question and the answer.

▲

⟩⟩

hermank

Steves-s

📝 Question of the Day?

19 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 43 Views · 2 Likes

Flag

📝 Reply

Ah! A Froudian slip perhaps?

▲

⟩⟩

hermank

Steves-s

📝 Question of the Day?

21 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 42 Views · 4 Likes

Flag

📝 Reply

I knew it was the Soviets that reached the Noeth Pole, but not the ship name, until now!

▲

⟩⟩

hermank

SimpleSailor

Steves-s

RNinMunich

Login To

Remove Ads

Remove Ads

📝 QOD for Alessandro

23 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 34 Views · 2 Likes

Flag

📝 Reply

Summat to do with anti gravity and the universe if I remember rightly. It came up in a computer game I used to play years ago..

▲

⟩⟩

SimpleSailor

hermank

📝 Are there any kits of this Scottish fishing vessel?

27 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 51 Views · 3 Likes

Flag

📝 Reply

Caldercraft for the MFV, Mobile Marine Models for the modern one...

▲

⟩⟩

hermank

AlessandroSPQR

jumpugly

📝 Ammusement

30 days ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 29 Views · 3 Likes

Flag

📝 Reply

I recently found an old RAF safety film from the 80s, starring none other than Windsor Davis!

▲

⟩⟩

GaryLC

peterd

hermank

📝 Ammusement

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 49 Views · 1 Like

Flag

📝 Reply

"Tug" cartoon! (Pat's post from earlier)

▲

⟩⟩

SouthportPat

📝 Ammusement

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 73 Views · 5 Likes

Flag

📝 Reply

Madwelshman, my mate says it doesn't matter who you vote for, you get The Government....

▲

⟩⟩

Oxford-Dave

Ray

SouthportPat

Steves-s

Madwelshman

📝 Ammusement

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 74 Views · 6 Likes

Flag

📝 Reply

What a load of bollox! It even says toward the end that MOB is still acceptable to raise the initial alarm but then you change to "person in the water". By the time you say "goodness me there's a person in the water" the poor bugger will probably drown"!

▲

⟩⟩

Doogle

Ray

SouthportPat

jumpugly

Steves-s

Madwelshman

📝 Speedline Models is back in business!

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 43 Views · 2 Likes

Flag

📝 Reply

Will you be reviving your landing craft kits?

▲

⟩⟩

hermank

Steve P

📝 Falkirk Wheel

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 24 Views · 1 Like

Flag

📝 Reply

Lots of Maritime stuff in Glasgow!

▲

⟩⟩

hermank

📝 Falkirk Wheel

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 39 Views · 5 Likes

Flag

📝 Reply

Great record of your adventures in Scotland. I can recommend the Irvine Maritime Museum in Irving. It is housed in the Linthouse, the engine works in Alexander Stephens yard. It was dismantled brick by brick and rebuilt in Irvine. There is also the Museum of Shipbuilding and the Denny Test Tank in Glasgow. All worth a visit... I have added a little video showing the English boat lift.

▲

⟩⟩

Steves-s

hermank

Chum444

Madwelshman

Ronald

📝 Question of the Day?

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 48 Views · 6 Likes

Flag

📝 Reply

That particular navigational technique has served me well in the past, it's got me safely across our lake many a time...

▲

⟩⟩

SimpleSailor

Steves-s

SouthportPat

AlessandroSPQR

roycv

RNinMunich

Login To

Remove Ads

Remove Ads

💬 Re: 36" Veron Thames Police Launch

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 53 Views · 2 Likes

Flag

💬 Add Comment

I have the up to date version from The Vintage Model Company, manufactured with permission of ans input from the family of the original designer. All nicely laser cut. God only knows when I will get round to building it!

▲

⟩⟩

Madwelshman

hermank

📝 Question of the Day?

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 47 Views · 4 Likes

Flag

📝 Reply

And A for auxilliaries.l, eg RFA vessels. Allesandro, Flower Class were built in Canada and the UK, the Canadian ships named after small Canadian cities...

▲

⟩⟩

SimpleSailor

Steves-s

SouthportPat

AlessandroSPQR

📝 Question of the Day?

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 46 Views · 4 Likes

Flag

📝 Reply

Hi Allesandro. I think you might find this helpful. Copied directly from the Internet...

"On a Royal Navy Flower-class corvette's pennant number, the "K" prefix designated miscellaneous vessels within the naval classification system, though Flower-class corvettes were often designated with an "F" for frigate-like vessels as well. However, many Flower-class corvettes, such as HMS Sunflower (K41), did indeed have the "K" prefix.

The Pennant Numbering System Explained

The Royal Navy's pennant numbering system used a letter prefix to categorize ships by their class or function.

F - Frigates:

This prefix was often used for corvettes, which were essentially smaller, anti-submarine escort vessels.

K - Miscellaneous Vessels:

This was a broad category that could include vessels not fitting neatly into other groups.

Other examples:

D - Destroyers

L - Amphibious warfare ships

M - Minesweepers

R - Aircraft carriers

S - Submarines

Why a "K" Prefix?

While corvettes like the Flower-class were generally considered frigates, the "K" prefix could be used for various reasons. For example:

Some vessels were built or used in a role that didn't fit the standard classifications, leading them to be designated as "miscellaneous".

There might have been overlapping roles or special designations that resulted in a "K" prefix for these ships. "

"On a Royal Navy Flower-class corvette's pennant number, the "K" prefix designated miscellaneous vessels within the naval classification system, though Flower-class corvettes were often designated with an "F" for frigate-like vessels as well. However, many Flower-class corvettes, such as HMS Sunflower (K41), did indeed have the "K" prefix.

The Pennant Numbering System Explained

The Royal Navy's pennant numbering system used a letter prefix to categorize ships by their class or function.

F - Frigates:

This prefix was often used for corvettes, which were essentially smaller, anti-submarine escort vessels.

K - Miscellaneous Vessels:

This was a broad category that could include vessels not fitting neatly into other groups.

Other examples:

D - Destroyers

L - Amphibious warfare ships

M - Minesweepers

R - Aircraft carriers

S - Submarines

Why a "K" Prefix?

While corvettes like the Flower-class were generally considered frigates, the "K" prefix could be used for various reasons. For example:

Some vessels were built or used in a role that didn't fit the standard classifications, leading them to be designated as "miscellaneous".

There might have been overlapping roles or special designations that resulted in a "K" prefix for these ships. "

▲

⟩⟩

SimpleSailor

SouthportPat

Steves-s

AlessandroSPQR

📝 Question of the Day?

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 46 Views · 2 Likes

Flag

📝 Reply

A ship's pennant number is a means to identify a particular ship for signalling purposes. The letter defines ship type, eg R for aircraft carrier D for destroyer etc, and the number is the ships number within that class. For example R-08 was R = HMS Ark Royal, 08 being the ships number in that group or squadron. Hope that is clear...

▲

⟩⟩

Steves-s

AlessandroSPQR

📝 Question of the Day?

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 34 Views · 3 Likes

Flag

📝 Reply

After a logical sift through the proposed answers the solution revealed it's self...

▲

⟩⟩

Steves-s

jumpugly

AlessandroSPQR

📝 Historic ships on the Baltic coast.

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 31 Views · 5 Likes

Flag

📝 Reply

Survey/diving support vessels? I see one of the last photos show a cage for lowering divers into and out of, the water...

▲

⟩⟩

RodC

hermank

Wolle

Ronald

jumpugly

📝 Historic ships on the Baltic coast.

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 38 Views · 4 Likes

Flag

📝 Reply

Great photos! Love the one of the duty seagull! Seagulls are actually reincarnated Chief Petty Officers, hence their fearless and belligerent behavior...

▲

⟩⟩

AlessandroSPQR

Wolle

jumpugly

Ray

📝 Question of the Day?

1 month ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 44 Views · 2 Likes

Flag

📝 Reply

A-Ha! The old breakwater ploy eh?

▲

⟩⟩

AlessandroSPQR

SimpleSailor

📝 Question of the Day?

2 months ago by 🇬🇧 Nickthesteam ( Commodore)

Commodore)

Commodore)

Commodore)✧ 49 Views · 3 Likes

Flag

📝 Reply

Ed, it is correct, I have been there, the warehouses are massive. However, I would have gone with hydraulic cranes has they been listed in the answer selection...

▲

⟩⟩

AlessandroSPQR

SouthportPat

hermank

Fleet Admiral)

Fleet Admiral)

Rear Admiral)

Rear Admiral)

Vice Admiral)

Vice Admiral)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Captain)

Captain)

Lieutenant)

Lieutenant)