Join Us On Social Media!

Germany

Recent Posts

📝 Question of the Day?

4 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 41 Views · 0 Likes

Flag

📝 Reply

Yet another 'cold barbecue' 🙄

😎

😎

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Just happened

5 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 52 Views · 8 Likes

Flag

📝 Reply

▲

⟩⟩

GARTH

Madwelshman

Ronald

pressonreguardless

Mike Stoney

jumpugly

DWBrinkman

hermank

📝 Just happened

5 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 51 Views · 8 Likes

Flag

📝 Reply

▲

⟩⟩

Steves-s

Madwelshman

pressonreguardless

Mike Stoney

jumpugly

xtramaths

DWBrinkman

hermank

📝 Question of the Day?

5 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 45 Views · 2 Likes

Flag

📝 Reply

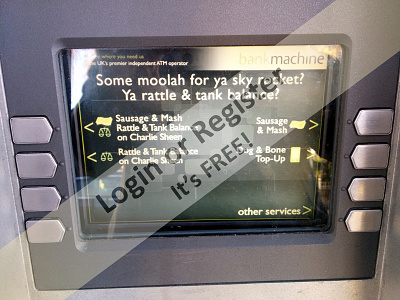

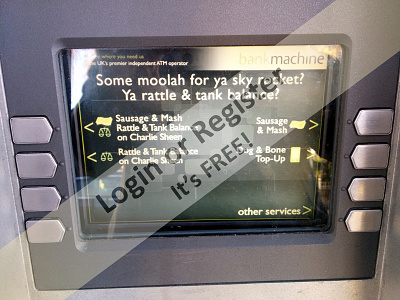

Some Cockney Rhyming slang.😉

Dirt - Dicky dirt - Shirt.

Cobblers - Cobblers awls - Balls. (Derogatory🙉 As in 'What a load of cobblers' etc.)

Roots - Daisy roots - Boots.

Dog and bone - Phone.

Mince pies - Eyes.

Bees and honey - Money.

Pork pie - Lie. Porkies - Lies.

Bacon and Eggs - Legs.

Brown bread - Dead. (More common Down Under?)

Plates of meat - Feet.

Bristol city - Titty. Bristols - Tits / Breasts.

Whistle and flute - Suit.

Jam (or Raspberry) tart - Fart🙊😮😠

And so on😉😎

There's even an ATM in East London with a 'language' option of Rhyming slang!😮

See pic.

Dirt - Dicky dirt - Shirt.

Cobblers - Cobblers awls - Balls. (Derogatory🙉 As in 'What a load of cobblers' etc.)

Roots - Daisy roots - Boots.

Dog and bone - Phone.

Mince pies - Eyes.

Bees and honey - Money.

Pork pie - Lie. Porkies - Lies.

Bacon and Eggs - Legs.

Brown bread - Dead. (More common Down Under?)

Plates of meat - Feet.

Bristol city - Titty. Bristols - Tits / Breasts.

Whistle and flute - Suit.

Jam (or Raspberry) tart - Fart🙊😮😠

And so on😉😎

There's even an ATM in East London with a 'language' option of Rhyming slang!😮

See pic.

▲

⟩⟩

DuncanP

Doogle

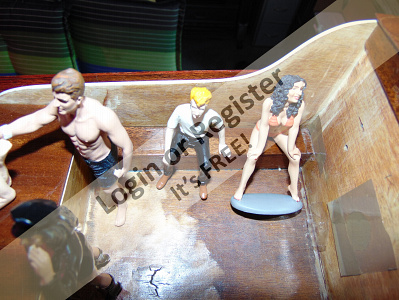

📝 Glynn Guest models

11 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 61 Views · 3 Likes

Flag

📝 Reply

Ron, see link below😉

Cheers, Doug😎

Cheers, Doug😎

▲

⟩⟩

Rookysailor

Doogle

hermank

📝 Question of the Day?

11 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 48 Views · 2 Likes

Flag

📝 Reply

From the 'Spud' Disambiguation page on Wiki-

"Spud, steel pile that can be lowered to penetrate the bottom to hold a spud barge in position, often deployed at each corner of the barge. Also used to position a dredge - see Dredging#Grab dredgers."

They were also used on sections of the Mulberry Harbours deployed on the D Day landing beaches.

I first heard about them in a docu (History Channel?) about the Mulberries and D Day.

😎

"Spud, steel pile that can be lowered to penetrate the bottom to hold a spud barge in position, often deployed at each corner of the barge. Also used to position a dredge - see Dredging#Grab dredgers."

They were also used on sections of the Mulberry Harbours deployed on the D Day landing beaches.

I first heard about them in a docu (History Channel?) about the Mulberries and D Day.

😎

▲

⟩⟩

Steves-s

RossM

📝 Question of the Day?

12 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 49 Views · 0 Likes

Flag

📝 Reply

Yep!🙄

😎

😎

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Question of the Day?

23 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 53 Views · 3 Likes

Flag

📝 Reply

Just to restore the 'six pack' Phil ...

I'm a Brit (a Man of Kent), I just live in Germany😉

Cheers, Doug😎

I'm a Brit (a Man of Kent), I just live in Germany😉

Cheers, Doug😎

▲

⟩⟩

Steves-s

Newby7

Nickthesteam

📝 Question of the Day?

23 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 45 Views · 0 Likes

Flag

📝 Reply

So what else would a 'Conning Officer' do?🙄

"Exec/Number One you have the conn."

😎

"Exec/Number One you have the conn."

😎

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Question of the Day?

24 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 40 Views · 5 Likes

Flag

📝 Reply

We've been around this barbecue before as well🙄

😎

😎

▲

⟩⟩

SimpleSailor

DWBrinkman

Steves-s

RossM

Nickthesteam

📝 Question of the Day?

25 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 43 Views · 1 Like

Flag

📝 Reply

Another memory test !🤔🙄

Hoorah, a duff answer (red) cancelled😀

😎

Hoorah, a duff answer (red) cancelled😀

😎

▲

⟩⟩

Steves-s

Login To

Remove Ads

Remove Ads

💬 Re: On research ...

28 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 33 Views · 1 Like

Flag

💬 Add Comment

Miaow🐱

😁😎

😁😎

▲

⟩⟩

hermank

📝 Question of the Day?

30 days ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 39 Views · 0 Likes

Flag

📝 Reply

Pook🐱☹️🤕

😎

😎

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Marian Belle' Empire class tug (Mobile Marine.)

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 26 Views · 2 Likes

Flag

💬 Add Comment

Ye Gods and little fishes Gary,

These are even better than museum or yard model quality😮

Superlative👍👍👍

Would really like to see some video of her huffing and puffing😉

I envy you guys with the knowledge and GUTS to drive your models with true to original steam power. A mystic black art to me.

Cheers, Doug😎

These are even better than museum or yard model quality😮

Superlative👍👍👍

Would really like to see some video of her huffing and puffing😉

I envy you guys with the knowledge and GUTS to drive your models with true to original steam power. A mystic black art to me.

Cheers, Doug😎

▲

⟩⟩

stevedownunder

GaryLC

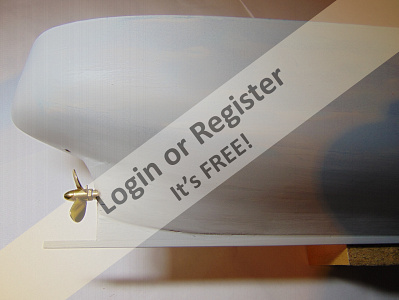

📝 RTTL2755 having a run out

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 66 Views · 5 Likes

Flag

📝 Reply

She rides well Rogal, looks good👍Great build. Hat off😉

At that speed she'd sure keep the gunners on their toes!😮💥💥💥 💥💥💥 💥💥💥

(If the target doesn't collapse first🤔)

😎

At that speed she'd sure keep the gunners on their toes!😮💥💥💥 💥💥💥 💥💥💥

(If the target doesn't collapse first🤔)

😎

▲

⟩⟩

cumbrae

Ronald

hermank

jumpugly

Rogal118

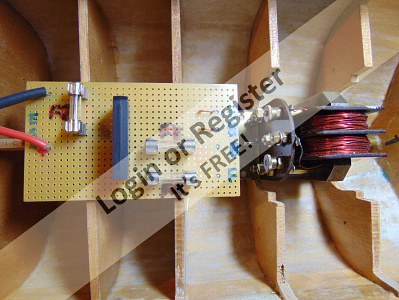

💬 Re: Classic Model Power Boats

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 96 Views · 2 Likes

Flag

💬 Add Comment

Thanks Bob👍

That was the final iteration with a 3S LiPo.

Scroll down a bit further and there are 3 more videos of initial trials with NIMH batteries, heavier🙄 and competition from the local swans!

Sadly the videos and my sea trials Captains Report have disappeared from my Harbour😠

QUESTION TO STEPHEN (Fireboat)- Why is that?

Cheers, Doug😎

That was the final iteration with a 3S LiPo.

Scroll down a bit further and there are 3 more videos of initial trials with NIMH batteries, heavier🙄 and competition from the local swans!

Sadly the videos and my sea trials Captains Report have disappeared from my Harbour😠

QUESTION TO STEPHEN (Fireboat)- Why is that?

Cheers, Doug😎

▲

⟩⟩

Madwelshman

hermank

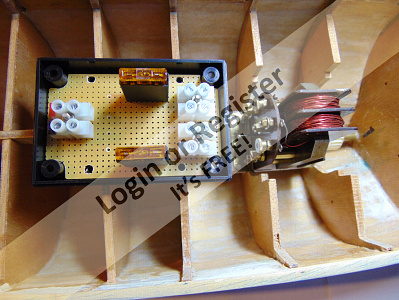

💬 Re: Classic Model Power Boats

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 97 Views · 4 Likes

Flag

💬 Add Comment

Hi Dutton,

I can also confirm that you definitely have a Sea Scout there👍

Attached are links to my Blog of the restoration of a Sea Scout built by my Dad in the early 60s. Also a link to my Harbour. 3rd link shows the boat on sea trials. You'll need to scroll down a bit!

Bon chance mon ami👍

Cheers, Doug😎

I can also confirm that you definitely have a Sea Scout there👍

Attached are links to my Blog of the restoration of a Sea Scout built by my Dad in the early 60s. Also a link to my Harbour. 3rd link shows the boat on sea trials. You'll need to scroll down a bit!

Bon chance mon ami👍

Cheers, Doug😎

▲

⟩⟩

Madwelshman

Dutton73

zooma

hermank

📝 Question of the Day?

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 57 Views · 4 Likes

Flag

📝 Reply

Roy,

"I am running out of brain area to take in new facts and I may have to forget something to make space!"

I know the feeling🙄

Curiously, rather than the FIFO system used by computer systems as we get older our brains start to work on a LIFO system🤔

Cheers, Doug😎

"I am running out of brain area to take in new facts and I may have to forget something to make space!"

I know the feeling🙄

Curiously, rather than the FIFO system used by computer systems as we get older our brains start to work on a LIFO system🤔

Cheers, Doug😎

▲

⟩⟩

SimpleSailor

Steves-s

luckyduck

DWBrinkman

📝 Question of the Day?

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 53 Views · 3 Likes

Flag

📝 Reply

Hi Stephen,

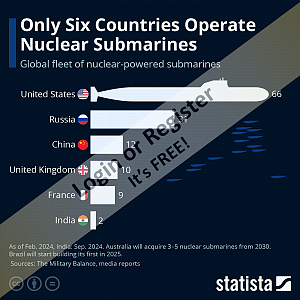

Re the submarine question of 4th December-

Despite various complaints please do not change anything.

Answer C was correct, see my post to Roy.

The question simply needs to be read and interpreted correctly.

Admittedly some knowledge of Naval Operational Requirements and Operational Areas helps😉

Cheers, Doug😎

Re the submarine question of 4th December-

Despite various complaints please do not change anything.

Answer C was correct, see my post to Roy.

The question simply needs to be read and interpreted correctly.

Admittedly some knowledge of Naval Operational Requirements and Operational Areas helps😉

Cheers, Doug😎

▲

⟩⟩

SimpleSailor

Steves-s

roycv

💬 Re: M. N. Golo, 1300 Tonne Coastal Freighter

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 46 Views · 3 Likes

Flag

💬 Add Comment

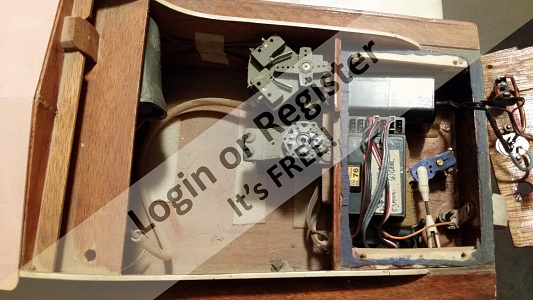

'FIRE IN THE HOLD' or ...🙊Phew😠???

Looks like an interesting project RP👍

Looking forward to reading your Build Blog😉

Cheers, Doug😎

Looks like an interesting project RP👍

Looking forward to reading your Build Blog😉

Cheers, Doug😎

▲

⟩⟩

Peejay

jumpugly

hermank

📝 Question of the Day?

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 51 Views · 0 Likes

Flag

📝 Reply

BTW Roy,

Re your post #5207 "Can't see the Americans abandoning Nuclear subs in favour of these."

You forget the Operational Requirement!

Sweden has no desire to play World Policeman like the USA.

Their main requirement is defence against the Russian Baltic Fleet not world cruises with a nuclear deterrent.

Cheers, Doug😎

Re your post #5207 "Can't see the Americans abandoning Nuclear subs in favour of these."

You forget the Operational Requirement!

Sweden has no desire to play World Policeman like the USA.

Their main requirement is defence against the Russian Baltic Fleet not world cruises with a nuclear deterrent.

Cheers, Doug😎

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 50 Views · 1 Like

Flag

📝 Reply

Hi Roy,

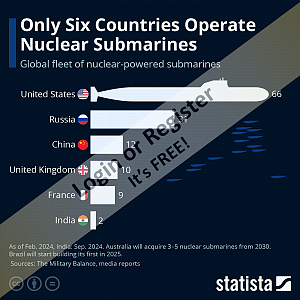

Scarcely hundreds!

I make it around 130, although it is highly questionable how many of the Russian subs are actually operational.🙄

Re Swedish subs-

Actually their diesel electric Gotland class (3 boats) has been happily operating Stirling Motors for nearly 30 years. The successor is already being built, 2 for Sweden and 3 for Poland, also using Stirling Motors from the Kockums yard.

Sure they are not going to win any speed competitions running on the Stirlings alone. But that's not the point.😉

When submerged the Gotlands can make 20 knots running the electric motors off batteries. Or tootle around at 5 to 6 knots on the Stirling motors driving a 75kW generator.

Alternately the Stirlings are used to recharge the batteries without the need to surface. Thus 'EXTENDING' the underwater endurance from a few days to a few weeks. And that is the key to this question!!

It asks about 'EXTENDED' operation NOT unlimited as per nuclear power.

Nuclear powered propulsion has never been designated AIP as it has never been dependent on air in the first place.

As for as acoustic stealth goes, the weak point of nuclear systems has always been the pumps in the essential cooling water circulation.

Sorry Roy but no cigar this time😉

Cheers, Doug😎

Scarcely hundreds!

I make it around 130, although it is highly questionable how many of the Russian subs are actually operational.🙄

Re Swedish subs-

Actually their diesel electric Gotland class (3 boats) has been happily operating Stirling Motors for nearly 30 years. The successor is already being built, 2 for Sweden and 3 for Poland, also using Stirling Motors from the Kockums yard.

Sure they are not going to win any speed competitions running on the Stirlings alone. But that's not the point.😉

When submerged the Gotlands can make 20 knots running the electric motors off batteries. Or tootle around at 5 to 6 knots on the Stirling motors driving a 75kW generator.

Alternately the Stirlings are used to recharge the batteries without the need to surface. Thus 'EXTENDING' the underwater endurance from a few days to a few weeks. And that is the key to this question!!

It asks about 'EXTENDED' operation NOT unlimited as per nuclear power.

Nuclear powered propulsion has never been designated AIP as it has never been dependent on air in the first place.

As for as acoustic stealth goes, the weak point of nuclear systems has always been the pumps in the essential cooling water circulation.

Sorry Roy but no cigar this time😉

Cheers, Doug😎

▲

⟩⟩

Steves-s

📝 Contacting peterd in Australia

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 31 Views · 5 Likes

Flag

📝 Reply

Good to hear from you Peter👍

Living a life of liquid luxury eh?

(Although my version would include some single malt😉)

Chin up Peter, we are all rooting for you🤞🤞🤞

All the best, Doug😎

Living a life of liquid luxury eh?

(Although my version would include some single malt😉)

Chin up Peter, we are all rooting for you🤞🤞🤞

All the best, Doug😎

▲

⟩⟩

peterd

DWBrinkman

roycv

Mike Stoney

hermank

📝 Help is needed guys, Robbe Atlantis

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 40 Views · 3 Likes

Flag

📝 Reply

Hi Ron,

The plans and building instructions are still available from Krick, who took over the marine models when Robbe collapsed. They market them under the romarin brand name.

Cheers, Doug😎

The plans and building instructions are still available from Krick, who took over the marine models when Robbe collapsed. They market them under the romarin brand name.

Cheers, Doug😎

▲

⟩⟩

jumpugly

Ronald

hermank

📝 Question of the Day?

1 month ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 52 Views · 3 Likes

Flag

📝 Reply

Rear Admiral Sir Francis has breezed in😁and graced us with his presence before!

😎

😎

▲

⟩⟩

hermank

Nickthesteam

Steves-s

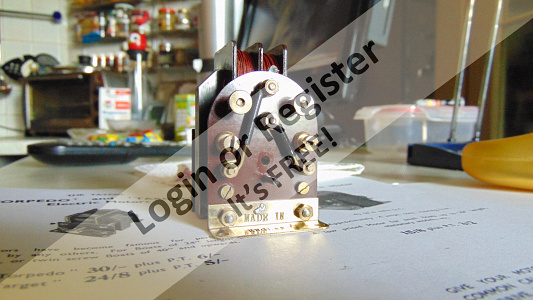

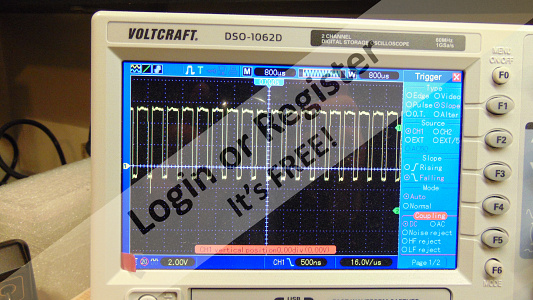

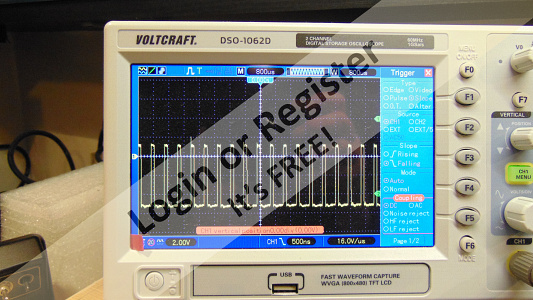

📝 Help Please Graupner 2351 Navy Sound Module

2 months ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 41 Views · 3 Likes

Flag

📝 Reply

Guten Morgen Bruce,

Found the manual (in German) on RC Groups site.

First off-

Lead #2 is labelled 'Blitzerausgang' = Flasher output.

Seems to be intended for a flashing light, i.e. police or emergency service boat.

Probably a mini light bulb back then as LEDs were still exotica and expensive.

It has nothing to do with RPM variation of the diesel sound. So not needed unless you want to go flashing😮🙈

Unfortunately there is absolutely no reference to Lead 2 in the manual!🤔

"Should the sound of the RPM speed up when you advance the throttle?"

Yes😉 The module takes it's input for this directly from the terminals of the motor, i.e. voltage being applied via the ESC. So you need a mating connector for lead 3 wired to the motor - brushed only I suspect. Polarity is not important - logical since the motor can run both forward and backward.😉

"adjustment switches" these are actually adjustment potentiometers, variable resistors (known as pots).

Diesel Drehzahl (RPM) - is used to set the diesel sound RPM to your taste when the motor is running full chat on a bench test.

Diesel Lautstarke (volume) - is used to set the max volume of the diesel sound.

Gesamt-lautstarke (total volume) - is used to set the total output volume , i.e. when all available sounds (diesel, horn, ship's bell, wave slap🤔) are in use.

NOTE: there are warnings about setting this too high as it risks damage to loudspeaker and/or the module amplifier. More about that later.

For now; you need a minimum 4Watt loudspeaker.

Have looked at the module specs ... but more tomorrow as it's now 2am here and I'm starting to nod off😴💤💤

Cheers, Doug😎

Found the manual (in German) on RC Groups site.

First off-

Lead #2 is labelled 'Blitzerausgang' = Flasher output.

Seems to be intended for a flashing light, i.e. police or emergency service boat.

Probably a mini light bulb back then as LEDs were still exotica and expensive.

It has nothing to do with RPM variation of the diesel sound. So not needed unless you want to go flashing😮🙈

Unfortunately there is absolutely no reference to Lead 2 in the manual!🤔

"Should the sound of the RPM speed up when you advance the throttle?"

Yes😉 The module takes it's input for this directly from the terminals of the motor, i.e. voltage being applied via the ESC. So you need a mating connector for lead 3 wired to the motor - brushed only I suspect. Polarity is not important - logical since the motor can run both forward and backward.😉

"adjustment switches" these are actually adjustment potentiometers, variable resistors (known as pots).

Diesel Drehzahl (RPM) - is used to set the diesel sound RPM to your taste when the motor is running full chat on a bench test.

Diesel Lautstarke (volume) - is used to set the max volume of the diesel sound.

Gesamt-lautstarke (total volume) - is used to set the total output volume , i.e. when all available sounds (diesel, horn, ship's bell, wave slap🤔) are in use.

NOTE: there are warnings about setting this too high as it risks damage to loudspeaker and/or the module amplifier. More about that later.

For now; you need a minimum 4Watt loudspeaker.

Have looked at the module specs ... but more tomorrow as it's now 2am here and I'm starting to nod off😴💤💤

Cheers, Doug😎

▲

⟩⟩

Rookysailor

bruce1946

hermank

📝 Dutch sailing barge

2 months ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 40 Views · 3 Likes

Flag

📝 Reply

Simply exquisite Andy👍 A 'proper job'.

Our dear departed Fleet Admiral Nerys would have been ecstatic!

Looking forward to the Sea Trials🤓

KUTGW

Doug😎

Our dear departed Fleet Admiral Nerys would have been ecstatic!

Looking forward to the Sea Trials🤓

KUTGW

Doug😎

▲

⟩⟩

AndyB2

hermank

Ronald

📝 How do you create the coiled ropes?

2 months ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 37 Views · 2 Likes

Flag

📝 Reply

Nice one Chug👍

As my German mates would say 'Klein aber fein' (small but fine)

😎

As my German mates would say 'Klein aber fein' (small but fine)

😎

▲

⟩⟩

jumpugly

hermank

📝 Question of the Day?

2 months ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 45 Views · 3 Likes

Flag

📝 Reply

Oh hell. Another damn sailing ship question.☹️

I'm 'all at sea' again🤔

Late 19th century??

Do I really look that old?

Answers please in a sealed envelope together with a pony (a 20 pound note for the uninitiated😉) to ... PM me for PayPal info😁

😎

I'm 'all at sea' again🤔

Late 19th century??

Do I really look that old?

Answers please in a sealed envelope together with a pony (a 20 pound note for the uninitiated😉) to ... PM me for PayPal info😁

😎

▲

⟩⟩

LewZ

DuncanP

SimpleSailor

📝 How do you create the coiled ropes?

2 months ago by 🇩🇪 RNinMunich ( Fleet Admiral)

Fleet Admiral)

Fleet Admiral)

Fleet Admiral)✧ 34 Views · 3 Likes

Flag

📝 Reply

Alessandro,

Sorry if I appear pedantic BUT-

Those are not concentric circles but spirals.

Concentric circles do not intersect with each other.

They simply have the same central point, or axis, but different radii.

They are not formed from a continuous line as a spiral is.

Translator cock up?

Ciao, Doug😎

Sorry if I appear pedantic BUT-

Those are not concentric circles but spirals.

Concentric circles do not intersect with each other.

They simply have the same central point, or axis, but different radii.

They are not formed from a continuous line as a spiral is.

Translator cock up?

Ciao, Doug😎

▲

⟩⟩

Mike Stoney

LewZ

hermank

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Commodore)

Commodore)

Sub-Lieutenant)

Sub-Lieutenant)

Leading Seaman)

Leading Seaman)

Midshipman)

Midshipman)

Petty Officer 1st Class)

Petty Officer 1st Class)

Rear Admiral)

Rear Admiral)

Captain)

Captain)

Lieutenant)

Lieutenant)

Warrant Officer)

Warrant Officer)

Recruit)

Recruit)

Commander)

Commander)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Admiral)

Admiral)