Join Us On Social Media!

Canada

Recent Posts

📝 Question of the Day?

11 months ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 44 Views · 0 Likes

Flag

📝 Reply

Got it wrong, but good question. Caused us to think and the explanation was interesting.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

12 months ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 54 Views · 2 Likes

Flag

📝 Reply

Rubbish!

▲

⟩⟩

cenbeth

AndyN

📝 Question of the Day?

12 months ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 53 Views · 3 Likes

Flag

📝 Reply

Wonder why, as I get more correct answers, my score goes down?

▲

⟩⟩

AndyN

GARTH

cenbeth

📝 Question of the Day?

1 year ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 64 Views · 4 Likes

Flag

📝 Reply

Another ridiculous answer. I sailed dingies for years, never carried a bilge pump, too heavy. Every dingy carried a bucket though.

▲

⟩⟩

DPTrainer

luckyduck

hermank

Newby7

📝 Question of the Day?

1 year ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 55 Views · 4 Likes

Flag

📝 Reply

The Costa Concordia did not catch fire

▲

⟩⟩

jumpugly

DuncanP

AustinG

Nickthesteam

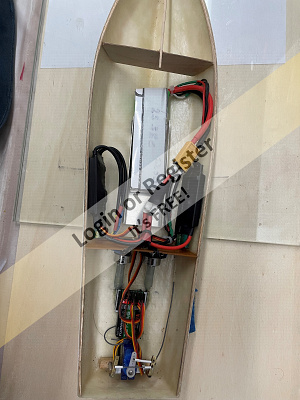

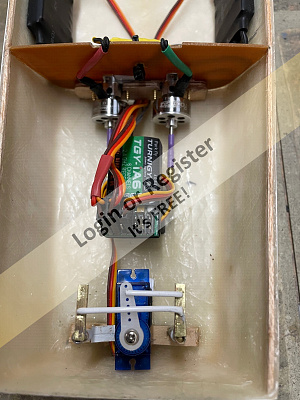

📝 Brushless motors battery

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 61 Views · 5 Likes

Flag

📝 Reply

Yes, in principle.

Be careful of the power consumption. Brushless can consume many watts, which may be beyond the capacity of your cells

Be careful of the power consumption. Brushless can consume many watts, which may be beyond the capacity of your cells

▲

⟩⟩

AlessandroSPQR

Len1

hermank

Peejay

peterd

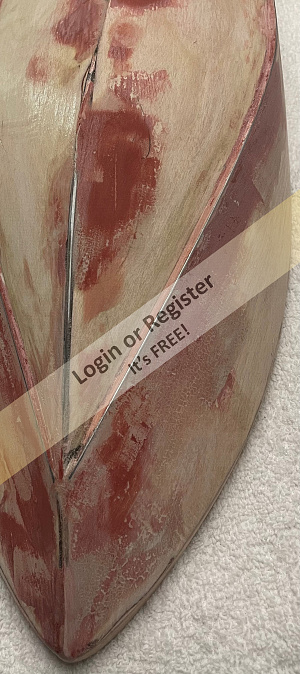

📝 How do I bend plywood

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 85 Views · 4 Likes

Flag

📝 Reply

On thin ply, such as hull skins. Have found using a heat gun quite adequate. Heat bend, clamp then reheat😌 l

▲

⟩⟩

Razor1955

Len1

SimpleSailor

Fred

📝 Yorkshire Belle

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 34 Views · 1 Like

Flag

📝 Reply

Hi Doug, Alive and well but spent most of this last winter trying to sort a misfire out on my Jaguar XJS V12.

Not quite sure if entirely cured. Am hampered in my ability to run it at full throttle by the local Police forces! No understanding of my quest for perfection.

Did potter along with my waterjet powered Swedish Interceptor based yacht. Nearly done, hence my YB inquiry.

Thanks for the SARIK lead. Had already seen that but recognising the frugality of my heritage was trying to avoid paying for them! If all else fails!

Keep seeing your notes on the site, so assumed all was well.

Best Rowen

Not quite sure if entirely cured. Am hampered in my ability to run it at full throttle by the local Police forces! No understanding of my quest for perfection.

Did potter along with my waterjet powered Swedish Interceptor based yacht. Nearly done, hence my YB inquiry.

Thanks for the SARIK lead. Had already seen that but recognising the frugality of my heritage was trying to avoid paying for them! If all else fails!

Keep seeing your notes on the site, so assumed all was well.

Best Rowen

▲

⟩⟩

Len1

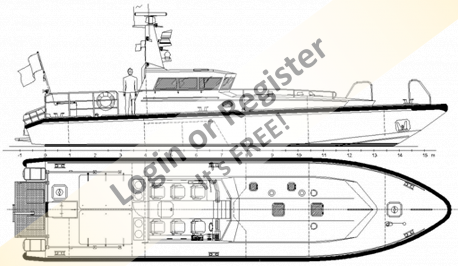

📝 Yorkshire Belle

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 62 Views · 6 Likes

Flag

📝 Reply

Have fond memories of sailing off the Yorkshire coast in this vessel with my late father.

Have often thought of building a model and somebody, very kindly, sent me a GA and side elevation.

All I need now are the section drawings, does anybody have a copy?

Thanks

Rowen

Have often thought of building a model and somebody, very kindly, sent me a GA and side elevation.

All I need now are the section drawings, does anybody have a copy?

Thanks

Rowen

▲

⟩⟩

Len1

flaxbybuck

hermank

AlessandroSPQR

Wolle

Peejay

💬 Re: Russian K100D waterjet work boat project, Improvements

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 67 Views · 4 Likes

Flag

💬 Add Comment

As a fellow frugal Yorkshireman to Rogal, heartily agree!

▲

⟩⟩

jbkiwi

hermank

AlessandroSPQR

Rogal118

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 55 Views · 3 Likes

Flag

📝 Reply

That assumes your boat has a bilge pump. Buckets are almost standard equipment on small boats. Just another question where the answer does not reflect the question.

▲

⟩⟩

Commodore-H

DuncanP

Nickthesteam

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 58 Views · 8 Likes

Flag

📝 Reply

Not in North America, Super glue Reigns supreme

▲

⟩⟩

Commodore-H

River Rat

Colin H

Mike Stoney

Nickthesteam

jumpugly

AustinG

Isaac

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 52 Views · 7 Likes

Flag

📝 Reply

Costa Concordia did not catch fire

▲

⟩⟩

DuncanP

MouldBuilder

Nickthesteam

Mike Stoney

RNinMunich

roycv

Commodore-H

📝 Orca and Jaws the chase, cought on video.

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 73 Views · 3 Likes

Flag

📝 Reply

Bet the shark could not catch your Brave Borderer up!

Rowen

Rowen

▲

⟩⟩

Len1

GaryLC

Rogal118

📝 Servos going crazy

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 59 Views · 3 Likes

Flag

📝 Reply

Seem to recall servos and Rxs work best between 4.5 and rather less that 6v. Think you have just proved it!

Sounds like they were overpowered and, then, odd things happen

Sounds like they were overpowered and, then, odd things happen

▲

⟩⟩

Colin H

Len1

AndyN

📝 Servos going crazy

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 89 Views · 5 Likes

Flag

📝 Reply

Have used a shared power supply on several models. Usually also fit a voltage regulator to reduce cell voltage to RX.

Works well for me and saves weight and complexity

Works well for me and saves weight and complexity

▲

⟩⟩

Len1

Colin H

hermank

AndyN

Mike Stoney

💬 Re: Newbie Model Slipway 1/16th Tamar Build

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 88 Views · 2 Likes

Flag

💬 Add Comment

BECC Flags will provide lettering. It is available through Cornwall Model Boats in the UK

▲

⟩⟩

hermank

RNinMunich

📝 Jet Pump Thrusters

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 78 Views · 1 Like

Flag

📝 Reply

Have used several of the smaller ones. They work well and have never had a debris ingress issue.

▲

⟩⟩

Spence

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 71 Views · 0 Likes

Flag

📝 Reply

Of course!

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 69 Views · 1 Like

Flag

📝 Reply

None of above. HMS Argus

▲

⟩⟩

hermank

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 73 Views · 4 Likes

Flag

📝 Reply

Why not drop the number of questions to, say, one a week?

Then the quizmaster might have time to make sure the answer relates to the question?

There are too many mistakes and ambiguities as it is.

Then the quizmaster might have time to make sure the answer relates to the question?

There are too many mistakes and ambiguities as it is.

▲

⟩⟩

Rookysailor

hermank

AustinG

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 58 Views · 2 Likes

Flag

📝 Reply

Not according to Wikipedia, all the suggestions are wrong.Should be Manchias

▲

⟩⟩

Rogal118

RNinMunich

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 65 Views · 3 Likes

Flag

📝 Reply

Nickthestream got it right.

Just another question with an inapplicable answer!

Just another question with an inapplicable answer!

▲

⟩⟩

hermank

Mike Stoney

RNinMunich

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 53 Views · 0 Likes

Flag

📝 Reply

It is a beam reach, so got it wrong!

The idea of a quiz was quite entertaining,but as the questions and answers are unrelated think it has lived it’s time.

Suggest close it down whilst still ahead

The idea of a quiz was quite entertaining,but as the questions and answers are unrelated think it has lived it’s time.

Suggest close it down whilst still ahead

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Question of the Day?

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 63 Views · 3 Likes

Flag

📝 Reply

Rubbish!

▲

⟩⟩

Mike Stoney

RNinMunich

Rogal118

📝 Things that never work right

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 69 Views · 4 Likes

Flag

📝 Reply

Suggest remove that little slide switch and put it in the bin.

They give innumerable problems once in a damp atmosphere, such as a model boat.

Replace with a good quality toggle or push switch. You will save yourself a stack of frustration

They give innumerable problems once in a damp atmosphere, such as a model boat.

Replace with a good quality toggle or push switch. You will save yourself a stack of frustration

▲

⟩⟩

Scamp

Colin H

AlessandroSPQR

RNinMunich

📝 Things that never work right

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 73 Views · 3 Likes

Flag

📝 Reply

After using Tamiya and Deans have settled on the XT60.

Tamiya are rubbish, hard to solder and give sporadic conductivity.

Deans hard to solder. XT 60 are not perfect but the sleeves can be extracted, soldered properly and then refitted. Also relatively compact where the XT 90 is quite bulky

Tamiya are rubbish, hard to solder and give sporadic conductivity.

Deans hard to solder. XT 60 are not perfect but the sleeves can be extracted, soldered properly and then refitted. Also relatively compact where the XT 90 is quite bulky

▲

⟩⟩

ARL58

Len1

Colin H

📝 Austal Cape 58

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 39 Views · 0 Likes

Flag

📝 Reply

Thanks Malcolm,

Another nice vessel. Very similar to my Daman Stan 4207, so would rather keep searching for the Cape 58.

Rowen

Another nice vessel. Very similar to my Daman Stan 4207, so would rather keep searching for the Cape 58.

Rowen

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Austal Cape 58

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 71 Views · 4 Likes

Flag

📝 Reply

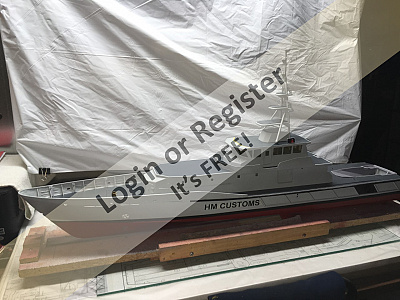

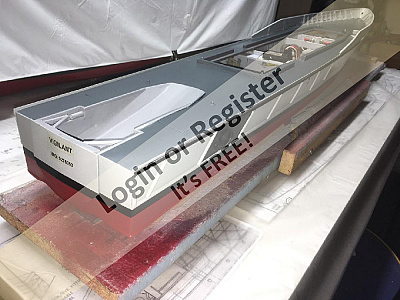

Just thinking, what a nice model this vessel would make.

Has anybody ever found a set of plans or know where they could be obtained?

Thanks

Rowen

Has anybody ever found a set of plans or know where they could be obtained?

Thanks

Rowen

▲

⟩⟩

Peejay

AustinG

Doogle

roycv

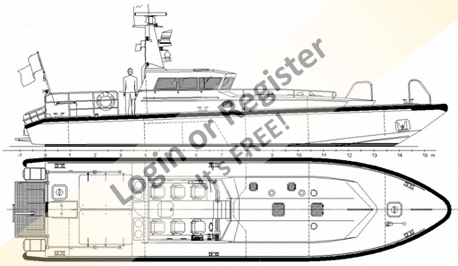

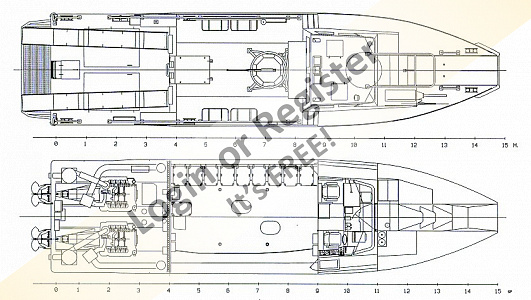

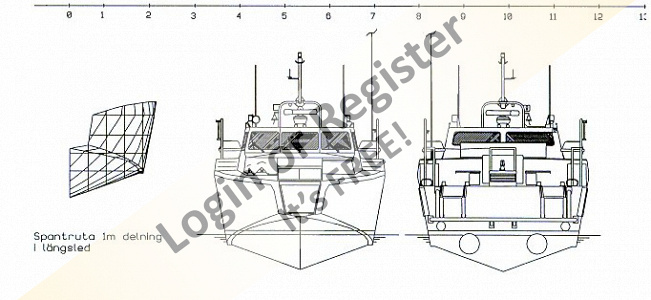

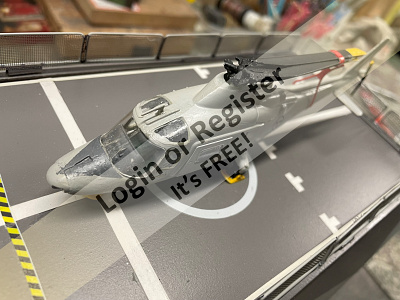

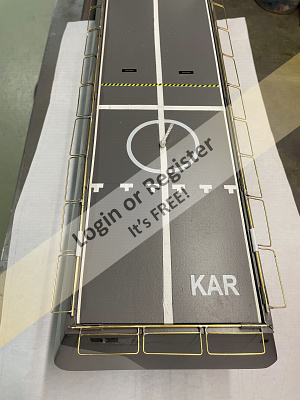

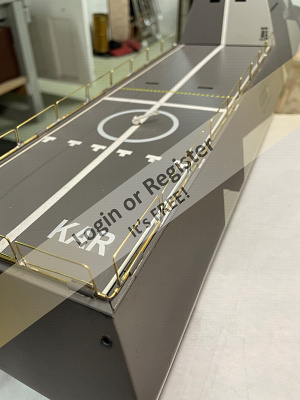

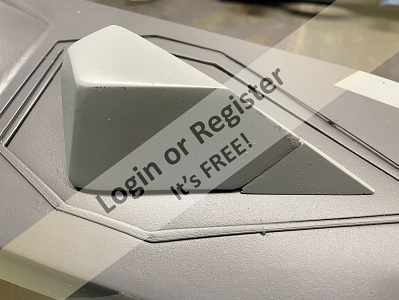

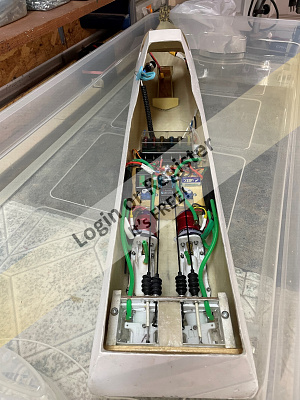

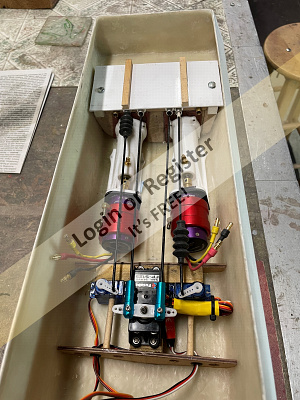

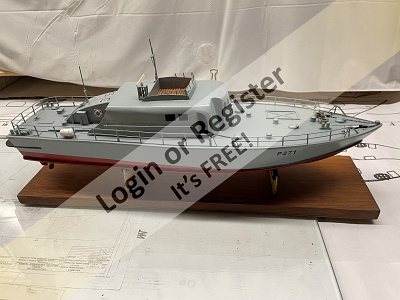

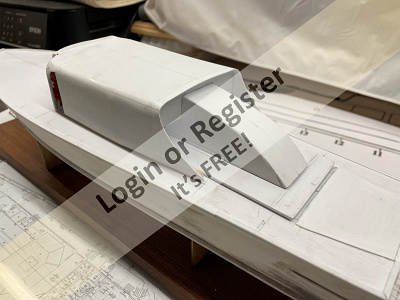

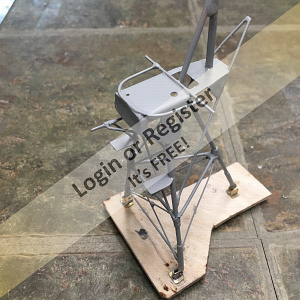

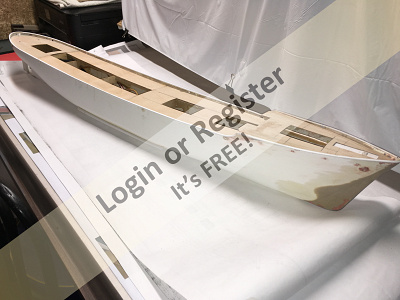

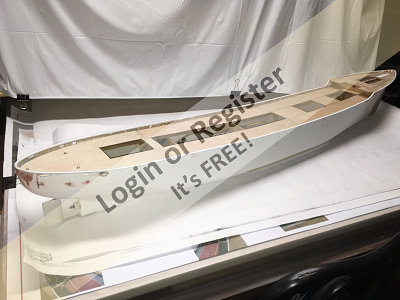

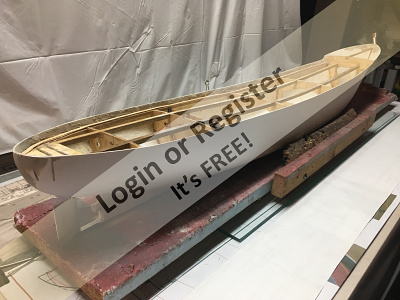

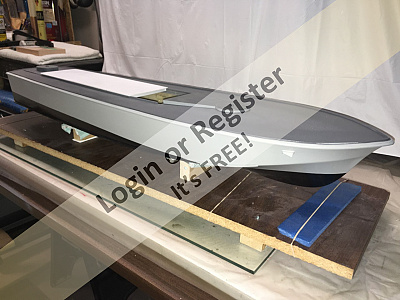

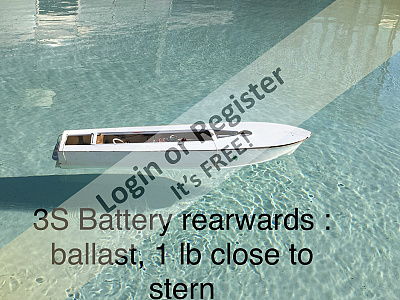

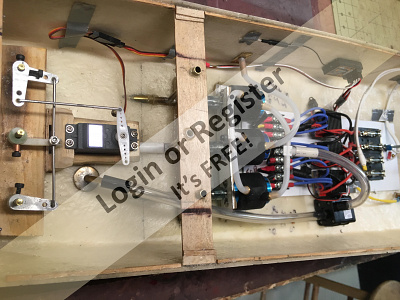

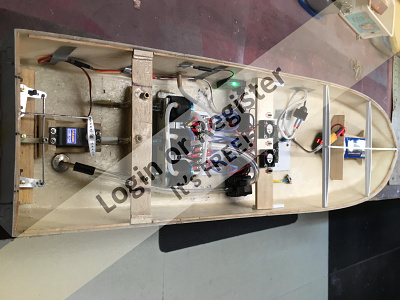

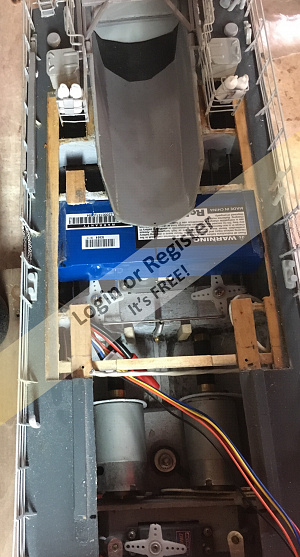

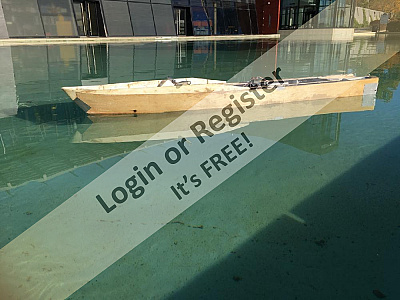

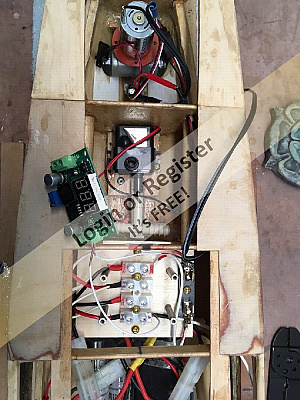

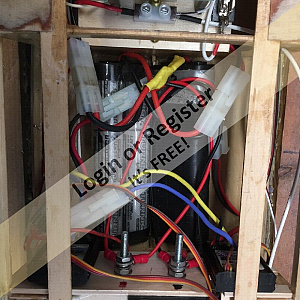

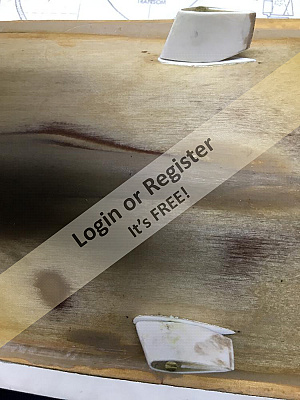

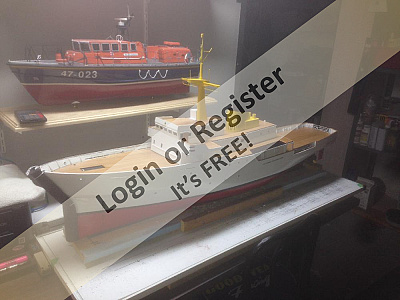

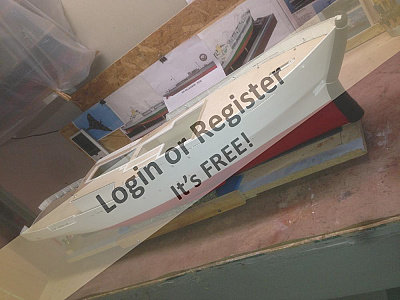

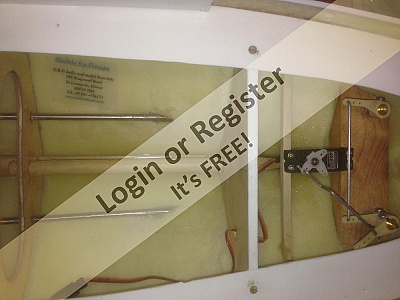

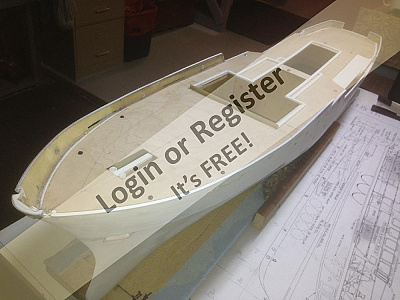

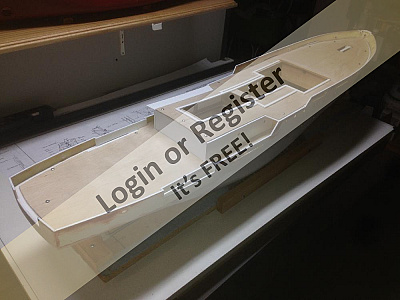

📝 SWEDISH 16M

2 years ago by 🇨🇦 Rowen ( Captain)

Captain)

Captain)

Captain)✧ 47 Views · 5 Likes

Flag

💬 Add Comment

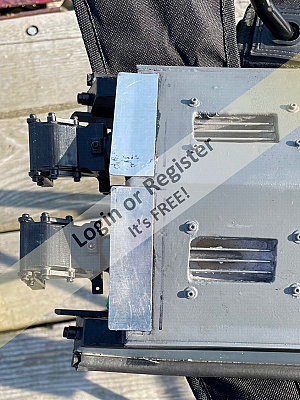

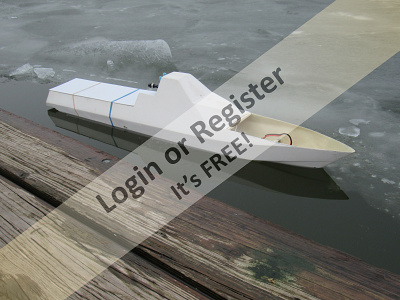

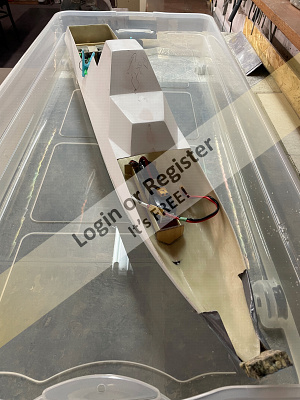

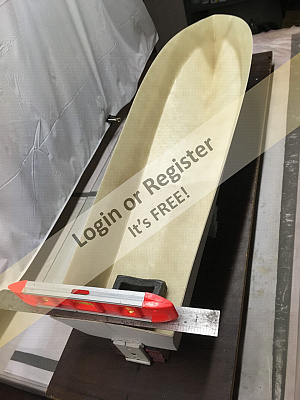

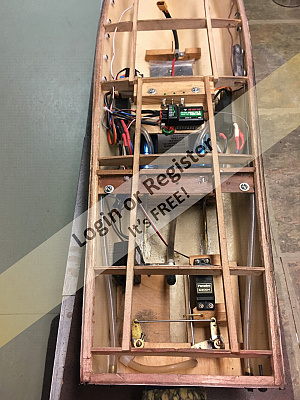

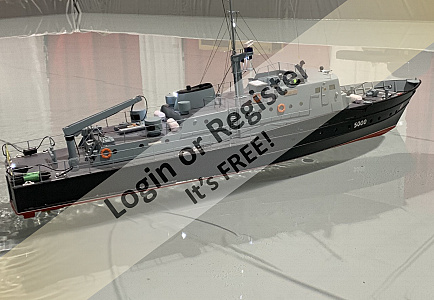

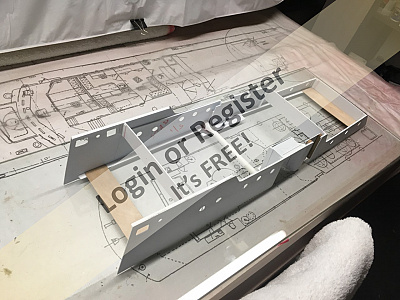

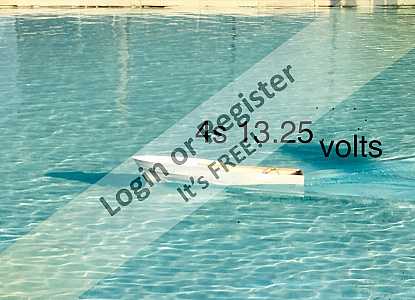

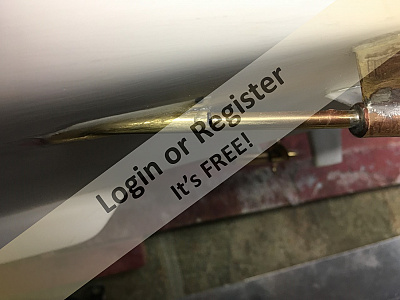

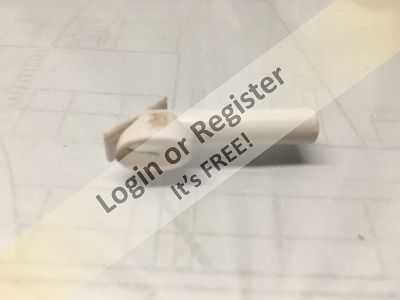

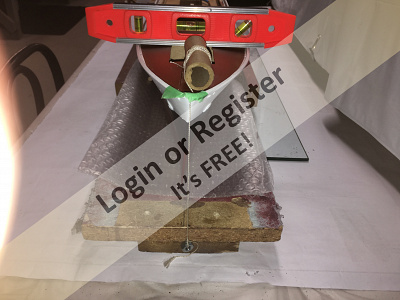

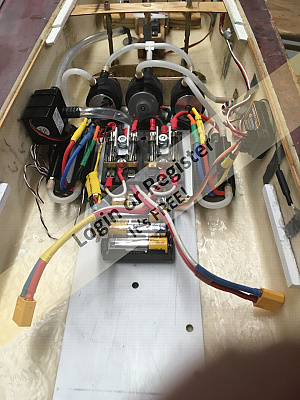

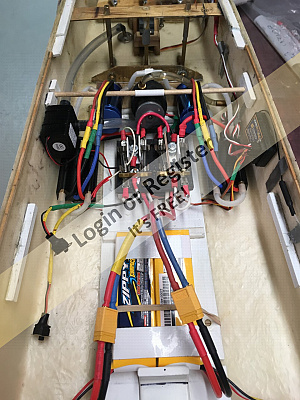

Decided to do another water test and concluded the noise and poor performance had to be addressed. Removed the solid couplings that fastened the two motors to the Waterjets and, with some fettling, managed to squeeze a scroll coupling onto each unit.

This improved both the noise and performance. Was running the model through its paces and noticed a sudden drop in noise, performance seemed unaffected.

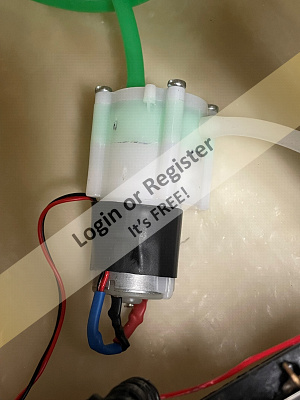

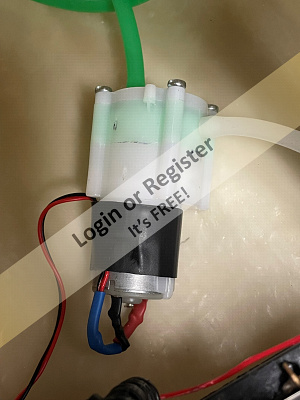

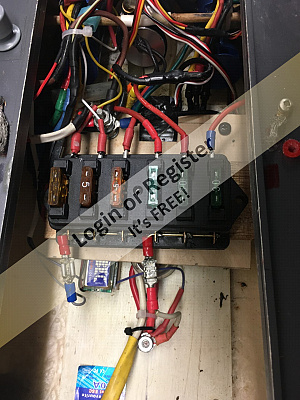

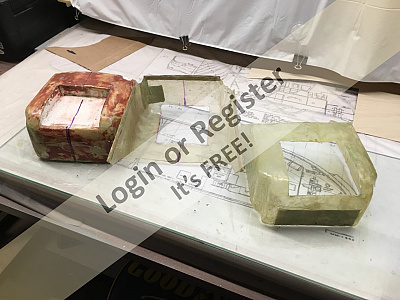

On examination found one of the couplings had disintegrated. (see picture).

Upon further examination also found the motor / WJ mounting had fractured. This misaligned the motor / WJ. With great difficulty exchanged the mounting and replaced the coupling. On a bench test note the noise had reduced markedly, as anticipated.

All needed now was a quick water test to confirm noise reduction and review performance before working to complete the project.

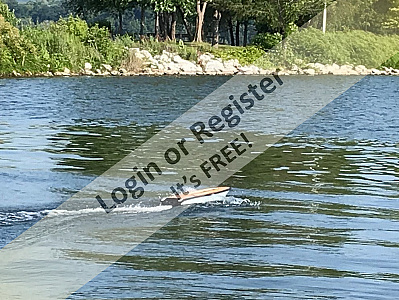

The weather Gods were kind and managed to get a quick test in a few days ago. Noise, whist still evident, is at an acceptable level. Performance was adequate. Unfortunately, the test was curtailed by a wiring connection that pulled apart. Simple fix, but not at the waterside.

A fellow sailor videoed the test. Interesting to note that once the model had accelerated the transom flaps force the bow down so the plane is level.

Feel confident that the model can be further developed and will complete the many outstanding details over the winter.

This improved both the noise and performance. Was running the model through its paces and noticed a sudden drop in noise, performance seemed unaffected.

On examination found one of the couplings had disintegrated. (see picture).

Upon further examination also found the motor / WJ mounting had fractured. This misaligned the motor / WJ. With great difficulty exchanged the mounting and replaced the coupling. On a bench test note the noise had reduced markedly, as anticipated.

All needed now was a quick water test to confirm noise reduction and review performance before working to complete the project.

The weather Gods were kind and managed to get a quick test in a few days ago. Noise, whist still evident, is at an acceptable level. Performance was adequate. Unfortunately, the test was curtailed by a wiring connection that pulled apart. Simple fix, but not at the waterside.

A fellow sailor videoed the test. Interesting to note that once the model had accelerated the transom flaps force the bow down so the plane is level.

Feel confident that the model can be further developed and will complete the many outstanding details over the winter.

▲

⟩⟩

BOATSHED

mturpin013

Scratchbuilder

Colin H

Rogal118

Commodore)

Commodore)

Lieutenant Commander)

Lieutenant Commander)

Rear Admiral)

Rear Admiral)

Leading Seaman)

Leading Seaman)

Recruit)

Recruit)

Liked Question of the Day? 9 months ago

Liked Question of the Day? 9 months ago