Join Us On Social Media!

United Kingdom

Recent Posts

💬 Re: Starting to add the cabin exterior details …

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 105 Views · 1 Like

Flag

💬 Add Comment

Thanks Trev, it’s making the small details in enjoy the most, brings the model to life.

Cheers, Sy

Cheers, Sy

▲

⟩⟩

pressonreguardless

Login To

Remove Ads

Remove Ads

💬 Re: Starting to add the cabin exterior details …

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 106 Views · 0 Likes

Flag

💬 Add Comment

Cheers Rick 👌

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

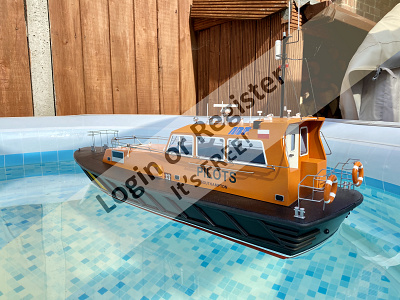

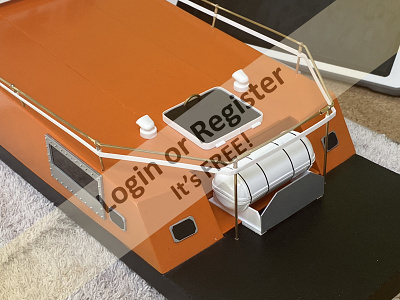

📝 Starting to add the cabin exterior details …

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 111 Views · 10 Likes · 5 Comments

Flag

💬 Add Comment

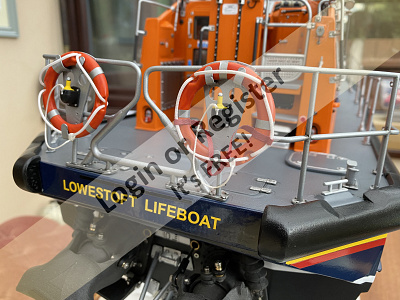

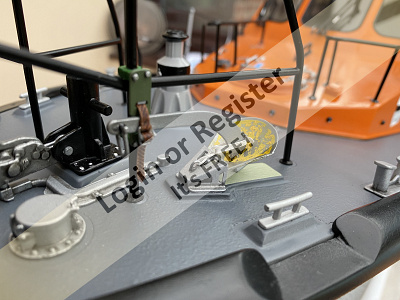

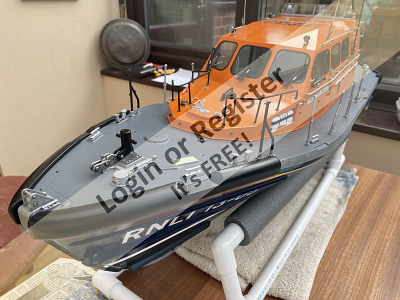

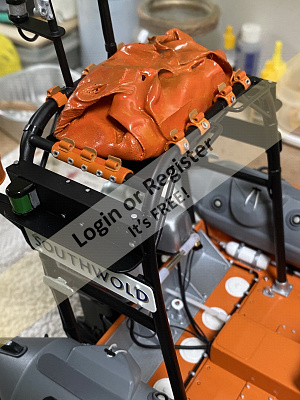

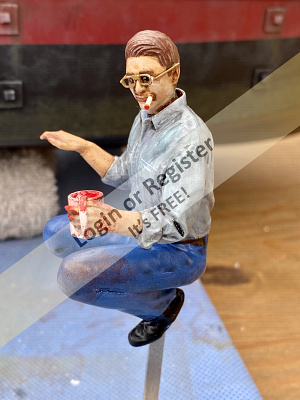

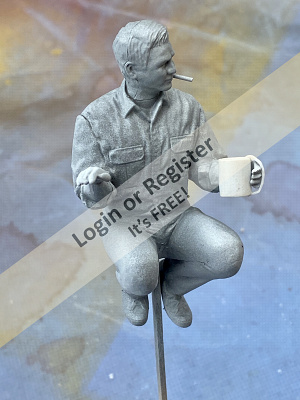

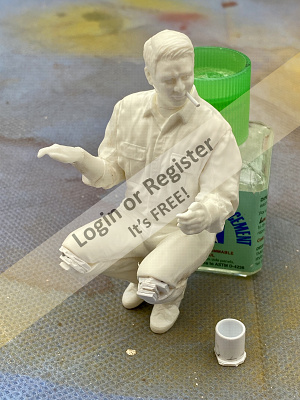

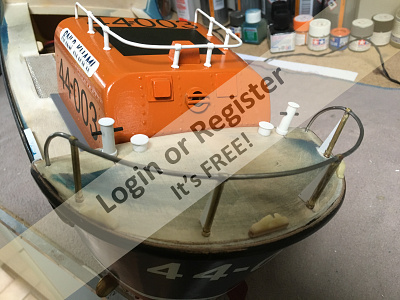

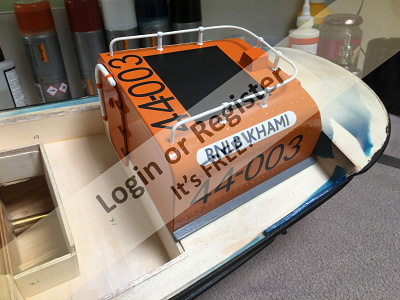

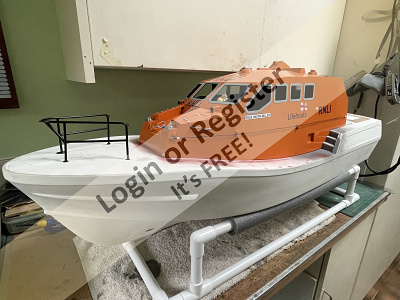

Now that the cabin has had its orange coats and lacquer, time to start making and adding all the details. About 70% I scratch made, the kit parts being the photo etched parts. Things like the kit cabin lights, mounting parts for the safety cable have been scraped as wrong and re-made.

As for the cat on the instrument combing, those that know the “Haydn Miller” in Tenby know? At the weekend I shall start making the multitude of aft cabin parts and the side parts including handrails, MOB cranes ect…

As for the cat on the instrument combing, those that know the “Haydn Miller” in Tenby know? At the weekend I shall start making the multitude of aft cabin parts and the side parts including handrails, MOB cranes ect…

▲

⟩⟩

hermank

Northernflotsam

rolfman2000

stevedownunder

jbkiwi

pressonreguardless

Rookysailor

Newby7

Colin H

Rover

💬 Re: Cabin interior and exterior…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 111 Views · 0 Likes

Flag

💬 Add Comment

If you use a slightly darker colour in the crevices Mike it acts like preshading that airbrush painters use 👌

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Cabin structure nears completion…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 123 Views · 1 Like

Flag

💬 Add Comment

Cheers Gary, I must admit I can work with most materials, but plastic is just the best for making modern boats and requires a lot less work to prepare for paint unlike wood. The kit supplied superstructure is accurate and with time and effort builds easily into the complex angles on a modern Tamar, the fun really starts when you start to add scratch built extras, that’s my pleasure, it’s amazing what can be made from sheet, strips and tube, as for the bolt heads, the Ming ones are perfect!

▲

⟩⟩

GaryLC

💬 Re: Cabin interior and exterior…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 132 Views · 1 Like

Flag

💬 Add Comment

Cheers Stephen, more bolt heads to come 😂

▲

⟩⟩

stevedownunder

📝 Cabin interior and exterior…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 133 Views · 9 Likes · 4 Comments

Flag

💬 Add Comment

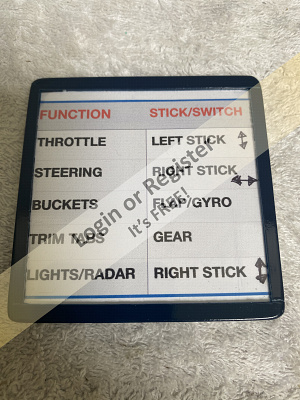

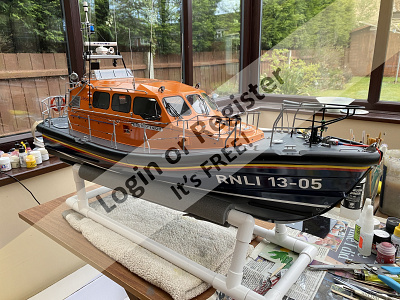

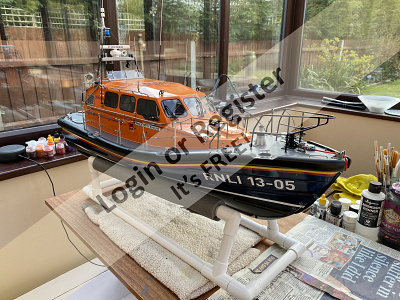

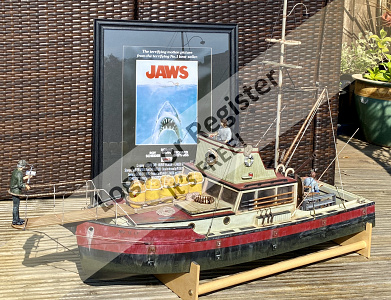

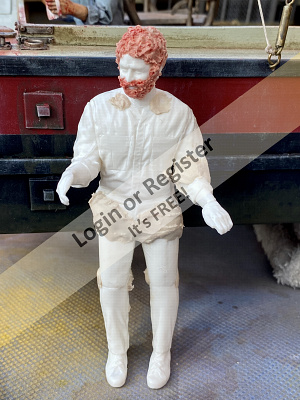

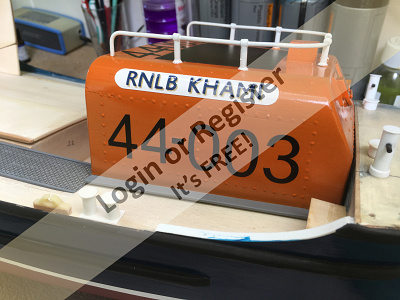

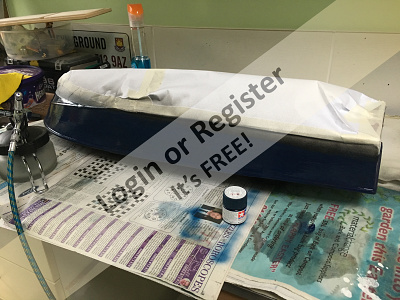

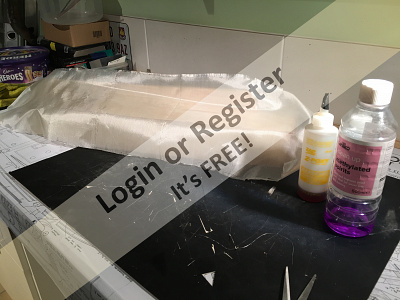

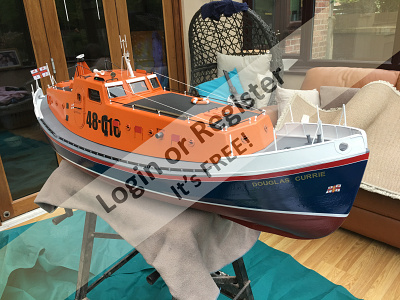

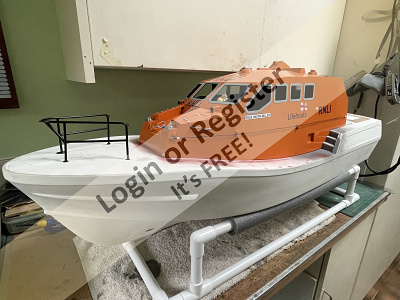

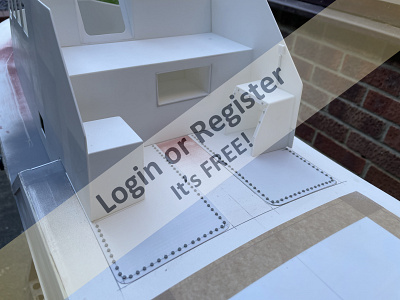

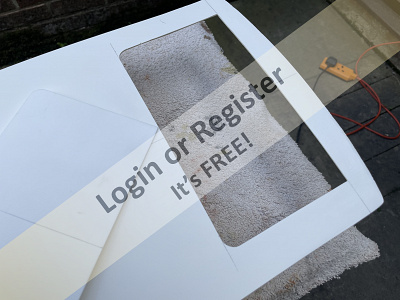

4 long days has seen most of the interior basics built. I’ve still got a few instruments to make and that will be it inside. I’ve installed a 3 light 12v in the roof which will come on via switch along with the nav lights. It illuminates nicely but not too bright, perfect on the mostly black interior.

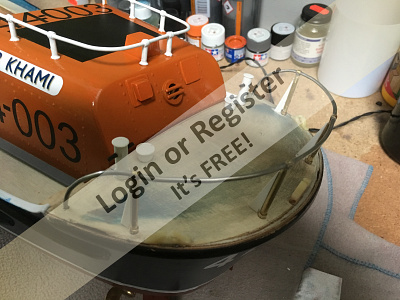

The cabin was sanded, filled, sanded again and primed in white before 3 thin coats of VW Orange after having painted all the nooks and cranny’s with thinnned orange acrylic. This means that once you start painting the main coat, your not trying to fight what is quite thick paints into the corners and gives a nicer finish. I shall gloss laquer the cabin once all the decals are on as I’m waiting for the RNLI decals in the post. All the remaining hundreds of cabin parts that I’ve yet to make and paint will go on after the main lacquer coat as they are mostly a Matt finished including the window frames.

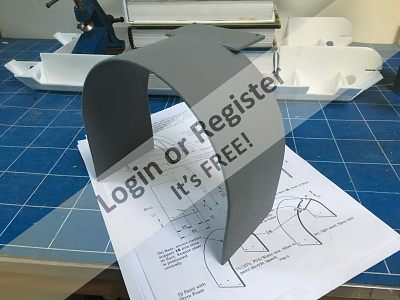

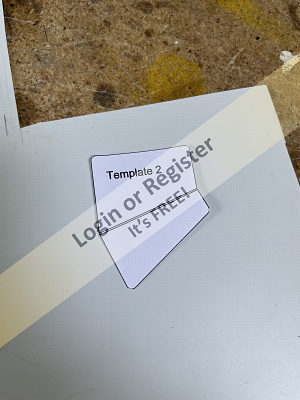

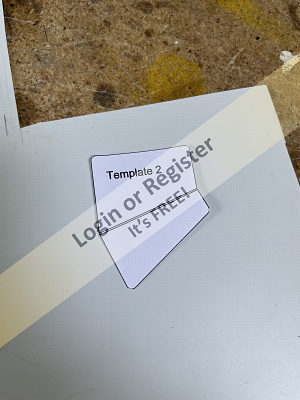

For anyone wanting to know how I got the rear upper deck floor so neat, I cheated! I cut a paper template, then made the floor from 0.20mm styrene before texture painting and a coat of grey primer and Matt varnish! For the eagle eyed amongst you, the rear cabin door is upside down, but fea4 not, it’s not glued yet! That’s it now for a few days, need a rest 😂😂

The cabin was sanded, filled, sanded again and primed in white before 3 thin coats of VW Orange after having painted all the nooks and cranny’s with thinnned orange acrylic. This means that once you start painting the main coat, your not trying to fight what is quite thick paints into the corners and gives a nicer finish. I shall gloss laquer the cabin once all the decals are on as I’m waiting for the RNLI decals in the post. All the remaining hundreds of cabin parts that I’ve yet to make and paint will go on after the main lacquer coat as they are mostly a Matt finished including the window frames.

For anyone wanting to know how I got the rear upper deck floor so neat, I cheated! I cut a paper template, then made the floor from 0.20mm styrene before texture painting and a coat of grey primer and Matt varnish! For the eagle eyed amongst you, the rear cabin door is upside down, but fea4 not, it’s not glued yet! That’s it now for a few days, need a rest 😂😂

▲

⟩⟩

hermank

pressonreguardless

Peejay

stevedownunder

GaryLC

Rookysailor

Colin H

jbkiwi

robbob

💬 Re: Cabin structure nears completion…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 137 Views · 0 Likes

Flag

💬 Add Comment

Nickel plating Mike, that sounds interesting? Like to see that in detail 👌

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Cabin structure nears completion…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 145 Views · 0 Likes

Flag

💬 Add Comment

Cheers Stephen, she’s an enjoyable build. Kind regards Sy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

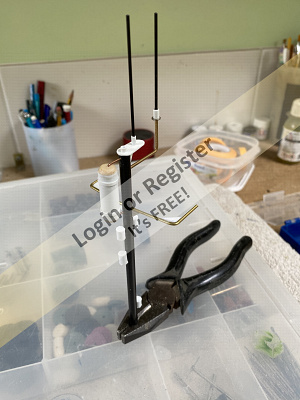

📝 Cabin structure nears completion…

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 147 Views · 8 Likes · 6 Comments

Flag

💬 Add Comment

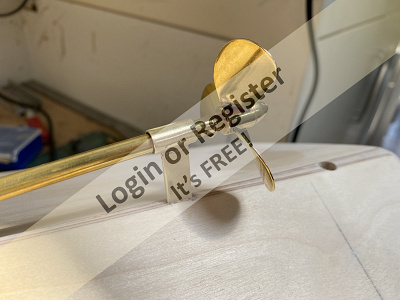

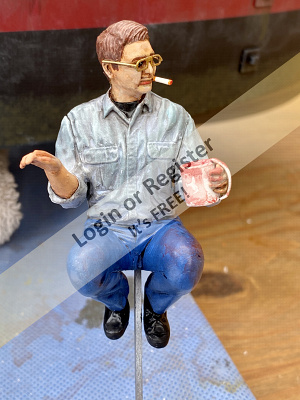

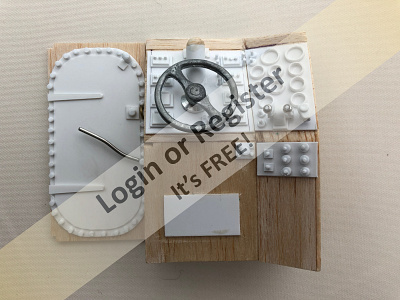

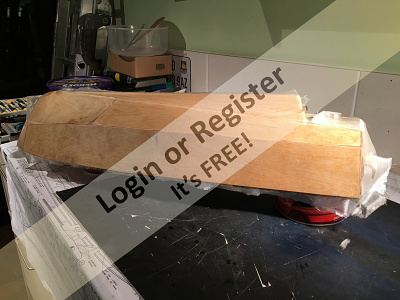

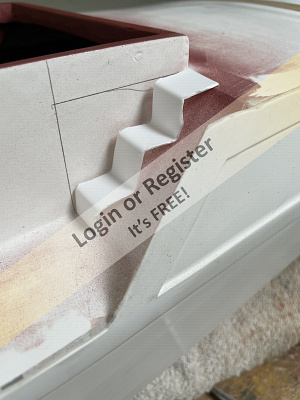

I’ve had a Busy 3 days progressing the cabin structure to basic completion. The last of the panels are now fitted, glued, sanded, filled and sanded. What I’ve also done is studying lots of photos, added as many scratch built extra details that are painted orange. There are a couple more bits to add before final sanding and painting, hopefully the cabin will be complete next weekend. There will be a lot of detailing to add once the cabin is in its orange coat, but that’s a while away yet.

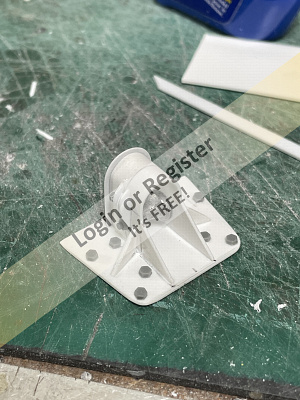

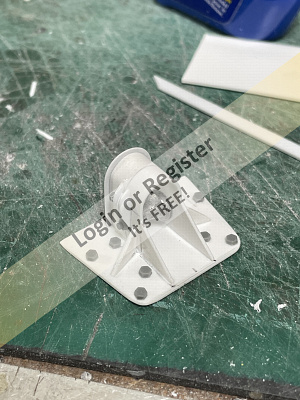

Whilst waiting for cabin panels to set, I set about building and completing a few of the fittings that include the towing bollards and I really wanted to build the upstairs crew entry door, so did so to completion. It also gave me the opportunity to add a lot of my new favourite Meng bolt heads!the kits parts are nowhere near cake accurate so modified where needed using reference.

Something else I discovered was a chrome permanent marker pen, available in 1mm, 2mm and 4mm. There are a lot of chrome parts on the Tamar and having tried this pen out on a sample, it’s the business! I need to see if any lacquer or clear coats dull it, but I’ll experiment with it. You can buy a 30ml refill, but that’s expensive at £20. Apparently the liquid inside the pen can be used in an airbrush, so may play with that too! EBay was the source and YouTube has plenty of videos on this stuff!

That’s it until Friday guys……

Whilst waiting for cabin panels to set, I set about building and completing a few of the fittings that include the towing bollards and I really wanted to build the upstairs crew entry door, so did so to completion. It also gave me the opportunity to add a lot of my new favourite Meng bolt heads!the kits parts are nowhere near cake accurate so modified where needed using reference.

Something else I discovered was a chrome permanent marker pen, available in 1mm, 2mm and 4mm. There are a lot of chrome parts on the Tamar and having tried this pen out on a sample, it’s the business! I need to see if any lacquer or clear coats dull it, but I’ll experiment with it. You can buy a 30ml refill, but that’s expensive at £20. Apparently the liquid inside the pen can be used in an airbrush, so may play with that too! EBay was the source and YouTube has plenty of videos on this stuff!

That’s it until Friday guys……

▲

⟩⟩

hermank

robbob

Rookysailor

jbkiwi

rolfman2000

stevedownunder

pressonreguardless

Colin H

💬 Re: More cabin work

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 151 Views · 1 Like

Flag

💬 Add Comment

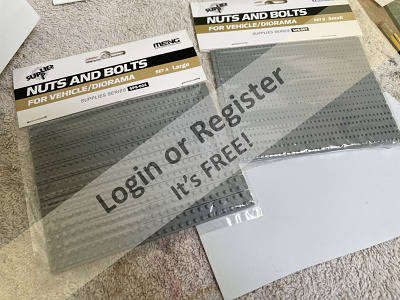

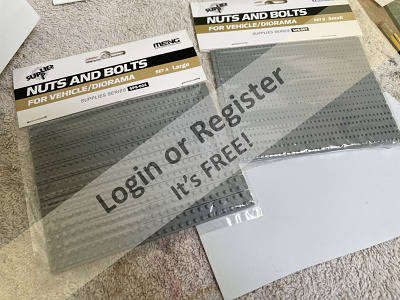

Hi Mike, many thanks as always for your comments. Found those Meng nuts on eBay, I got 2 different size packs which contain assorted sizes within, every size I need for this boat and probably a couple more, you get loads!

▲

⟩⟩

stevedownunder

Login To

Remove Ads

Remove Ads

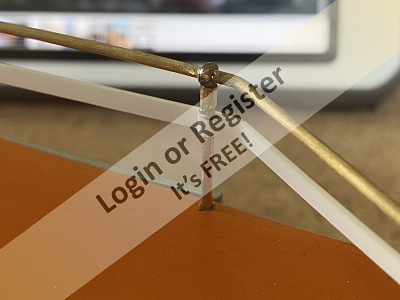

📝 More cabin work

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 156 Views · 7 Likes · 3 Comments

Flag

💬 Add Comment

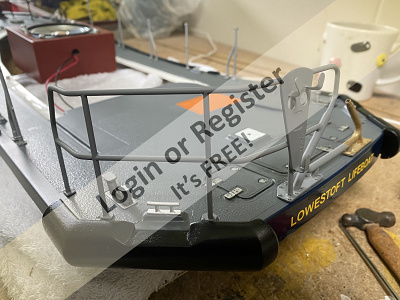

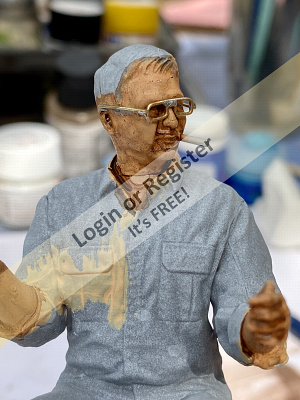

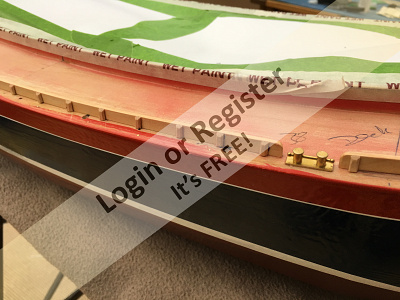

After having to work for 3 days, managed to get a full day in today as “wifey” was away on a works party (no plus ones allowed! Bonus😂)

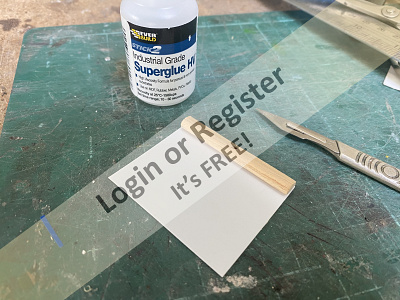

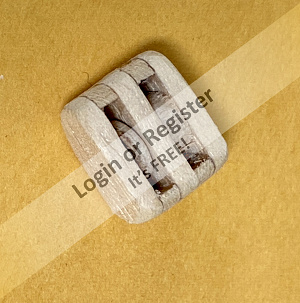

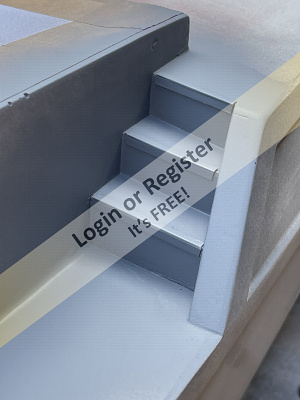

The postman bought me some Meng scale bolts in various sizes. Just a simple case of cutting them free with a new scalpel blade and they are good to go. They are simply fantastic, there is no way I could get such accurate bolt heads cutting hex rod as I’ve done in th past. So putting them to use, I replaced the bolt heads on the transom fittings and made the aft deck access panels with all the bolt heads, really happy how they’ve come out.

The rest of the day has been a case of adding more panels to the cabin, which is time consuming but well worth the effort, she’s started to really take shape now. I’ve added some extra scale details using reference pictures, but will add a whole load more as I go. More progress tomorrow……

The postman bought me some Meng scale bolts in various sizes. Just a simple case of cutting them free with a new scalpel blade and they are good to go. They are simply fantastic, there is no way I could get such accurate bolt heads cutting hex rod as I’ve done in th past. So putting them to use, I replaced the bolt heads on the transom fittings and made the aft deck access panels with all the bolt heads, really happy how they’ve come out.

The rest of the day has been a case of adding more panels to the cabin, which is time consuming but well worth the effort, she’s started to really take shape now. I’ve added some extra scale details using reference pictures, but will add a whole load more as I go. More progress tomorrow……

▲

⟩⟩

hermank

RNinMunich

stevedownunder

jbkiwi

Rookysailor

Colin H

robbob

📝 Building the cabin….

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 158 Views · 4 Likes

Flag

💬 Add Comment

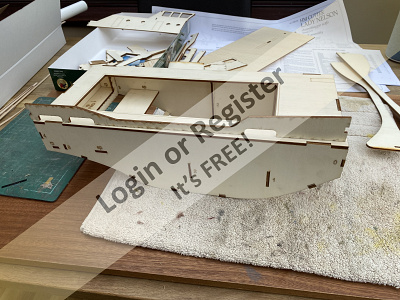

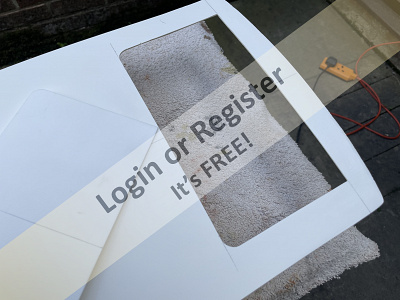

A few hours work today has seen the basic cabin structure built. It’s worth taking the time to cut out the CNC parts carefully, followed by any trimming and sanding all surfaces. This gives a good key for gluing and eventually painting. What we have here is basically a giant Airfix kit and it’s one of the tasks I enjoy most as it gives instant results!

As mentioned in my last post, I am making the forward stowage bins function instead of being marked to represent. Using the paper template included I made a .5mm styrene template and the plans to position and mark the hatch opening. This was then cut out and cleaned up. Once I add the upper facet plates, I shall cut the remaining door positions and then make the bins and line the rims to take the hatches. One thing I haven’t figured out yet is how to make time working scale hinges, so if anyone has a solution, I’m all ears!

Tomorrow I’m going to return to finishing the steps and make a start on the kick boards….

As mentioned in my last post, I am making the forward stowage bins function instead of being marked to represent. Using the paper template included I made a .5mm styrene template and the plans to position and mark the hatch opening. This was then cut out and cleaned up. Once I add the upper facet plates, I shall cut the remaining door positions and then make the bins and line the rims to take the hatches. One thing I haven’t figured out yet is how to make time working scale hinges, so if anyone has a solution, I’m all ears!

Tomorrow I’m going to return to finishing the steps and make a start on the kick boards….

▲

⟩⟩

Colin H

Rookysailor

stevedownunder

robbob

💬 Re: Finishing the basic deck and starting cabin structure

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 159 Views · 3 Likes

Flag

💬 Add Comment

I can beat your cyano finger sticking Trev! I Once glued my bottom lip to my upper teeth because of putting the ca cap in my mouth, the taking part was painful and bloody 😂

▲

⟩⟩

stevedownunder

Colin H

pressonreguardless

💬 Re: Finishing the basic deck and starting cabin structure

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 159 Views · 1 Like

Flag

💬 Add Comment

Your welcome Colin 👌

▲

⟩⟩

Colin H

💬 Re: Finishing the basic deck and starting cabin structure

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 2 Likes

Flag

💬 Add Comment

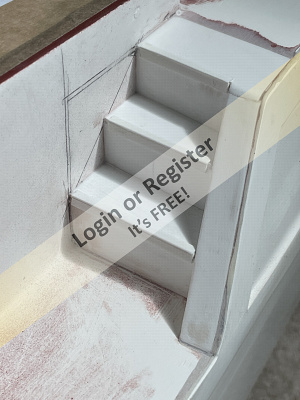

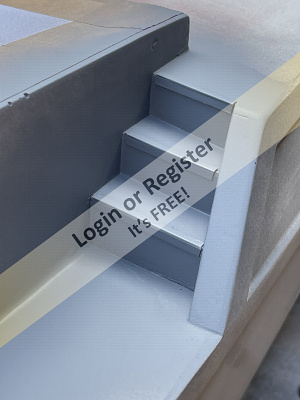

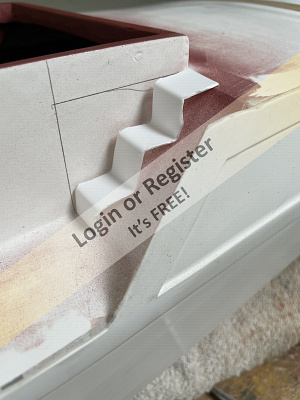

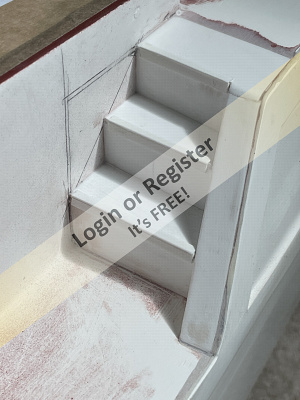

Cheers trev, I agree with the improvement over the vacform version but might re-do the step edges with folded strips of .25mm styrene

▲

⟩⟩

stevedownunder

pressonreguardless

💬 Re: Finishing the basic deck and starting cabin structure

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 2 Likes

Flag

💬 Add Comment

Hi Colin, my weapons of choice with glue for styrene is revell and tamiya plastic cement, both superb. If the nozzle blocks on the revell cement, just heat up with a disposable lighter and hey presto! Kind regards sy

▲

⟩⟩

stevedownunder

mturpin013

📝 Finishing the basic deck and starting cabin structure

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 7 Likes · 10 Comments

Flag

💬 Add Comment

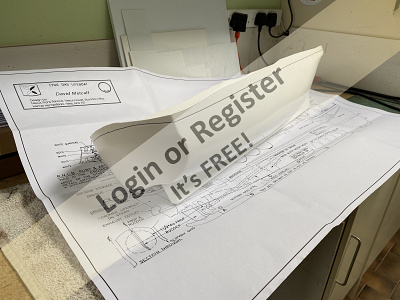

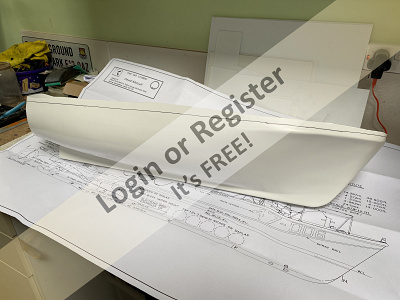

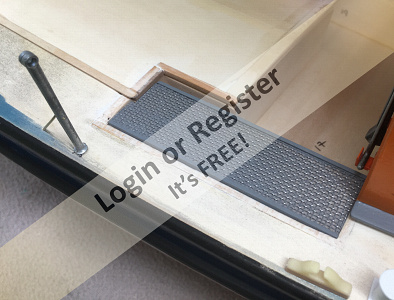

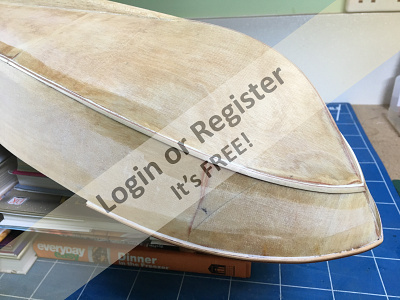

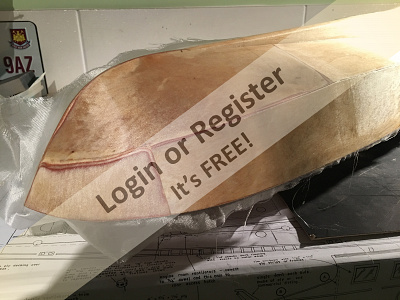

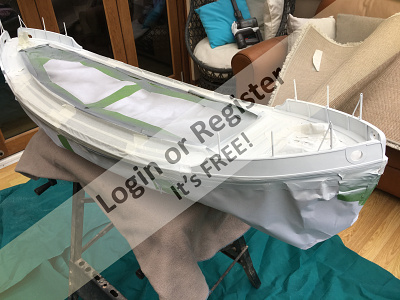

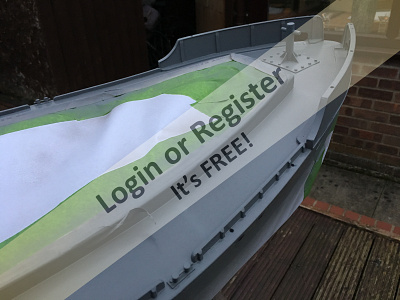

The last couple of days has seen the deck set solid followed by all the labour intensive sanding, filling and filling to make good any joins ect. I’m now happy that the deck is a cracking fit around all points of the hull.

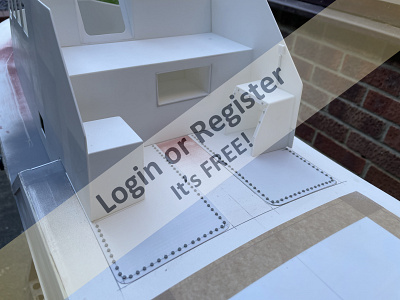

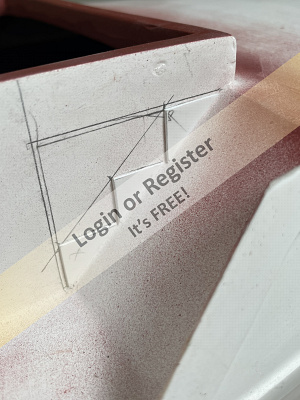

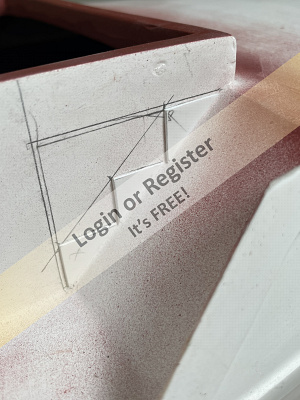

Next step was to start making the steps from the lower to upper deck. The kit supplied hideous vacform steps were used as a starting point to assess how to make new steps from 1.5mm styrene. After several hours of cutting, measuring, fettling and many discarded parts, the port side steps were fashioned, glued, filed, sanded and primed to see if any issues stood out. As for the starboard steps, I shall start on them tomorrow as I needed something else to break up the monotony! The manual calls for making the kick boards next, however I didn’t fancy that and they can be made anytime relatively early in the build, so shall possibly look at them Tuesday before work Wednesday!

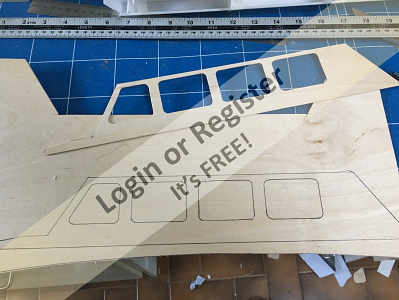

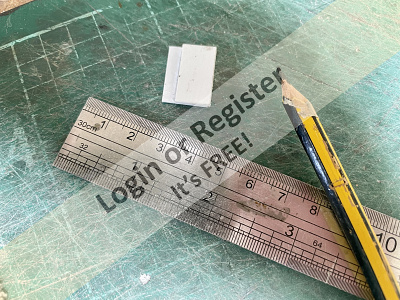

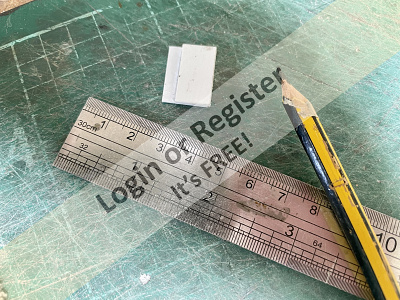

So, I made a start on the cabin. The main parts are CNC cut styrene and just needed a little effort with a new scalpel blade and steel ruler to free them from the main sheet. The cabin sides are different in that the rear windows are positioned differently, so double checking with the manual was called for to make sure I identified the correct sides! Start8ng with the port side, all windows were cut out and the whole piece sanded. Last job was to cut the base former and cabin. Wall upright , sand and glue together at right angles and leave to set over night. Before gluing the first side to the base, I must ensure that my next modification of cutt8ng out the forward stowage hatch doors on both hull sides as i intend to make these function unlike the kit version which is drawn on, I shall show that when I do it.

So, tomorrow I shall build the other steps and more work on the cabin …

Next step was to start making the steps from the lower to upper deck. The kit supplied hideous vacform steps were used as a starting point to assess how to make new steps from 1.5mm styrene. After several hours of cutting, measuring, fettling and many discarded parts, the port side steps were fashioned, glued, filed, sanded and primed to see if any issues stood out. As for the starboard steps, I shall start on them tomorrow as I needed something else to break up the monotony! The manual calls for making the kick boards next, however I didn’t fancy that and they can be made anytime relatively early in the build, so shall possibly look at them Tuesday before work Wednesday!

So, I made a start on the cabin. The main parts are CNC cut styrene and just needed a little effort with a new scalpel blade and steel ruler to free them from the main sheet. The cabin sides are different in that the rear windows are positioned differently, so double checking with the manual was called for to make sure I identified the correct sides! Start8ng with the port side, all windows were cut out and the whole piece sanded. Last job was to cut the base former and cabin. Wall upright , sand and glue together at right angles and leave to set over night. Before gluing the first side to the base, I must ensure that my next modification of cutt8ng out the forward stowage hatch doors on both hull sides as i intend to make these function unlike the kit version which is drawn on, I shall show that when I do it.

So, tomorrow I shall build the other steps and more work on the cabin …

▲

⟩⟩

hermank

RNinMunich

stevedownunder

mturpin013

pressonreguardless

robbob

Colin H

💬 Re: Fitting Y-Boat compartment and deck

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 1 Like

Flag

💬 Add Comment

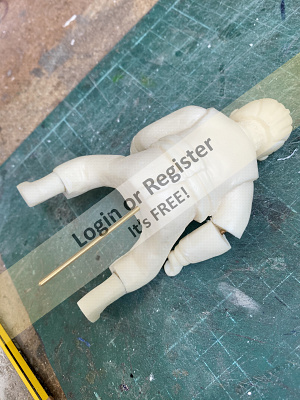

Hi Rob, yes there is a basic Y-Boat in the kit, consisting of a couple of vacform parts for the sponsons and a couple of fittings for the motor, paddles ect. It is a good starting point for super detailing which is what I intend to do.

The only issue is displaying it! They spend their life inside the compartment under the hinged doors unless in use. I’ve seen some models with them sitting on the hatch doors, but I don’t think that’s ever practiced in real life unless anyone knows different?

The only issue is displaying it! They spend their life inside the compartment under the hinged doors unless in use. I’ve seen some models with them sitting on the hatch doors, but I don’t think that’s ever practiced in real life unless anyone knows different?

▲

⟩⟩

robbob

💬 Re: Y-Boat compartment and other things….

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 0 Likes

Flag

💬 Add Comment

The inside of the hull is cavernous JB, plenty of room for all the electronics and ballast as required 👌

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Y-Boat compartment and other things….

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 165 Views · 1 Like

Flag

💬 Add Comment

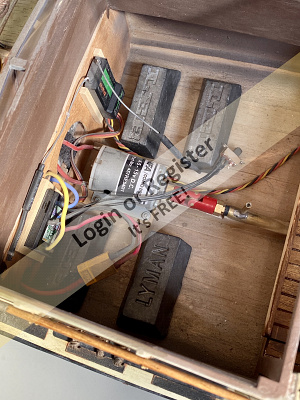

Indeed Mike, 4 screws and the tray lifts out, all the plugs are hidden underneath 👌

▲

⟩⟩

pressonreguardless

Login To

Remove Ads

Remove Ads

📝 Fitting Y-Boat compartment and deck

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 165 Views · 8 Likes · 2 Comments

Flag

💬 Add Comment

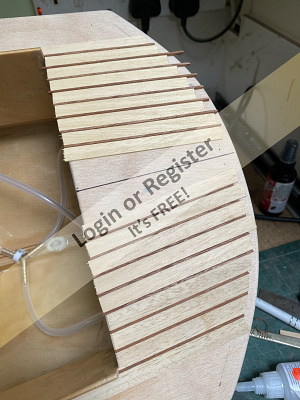

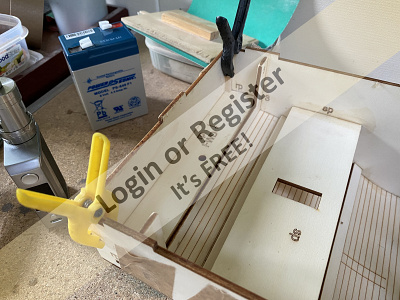

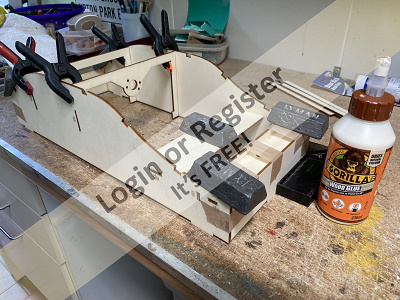

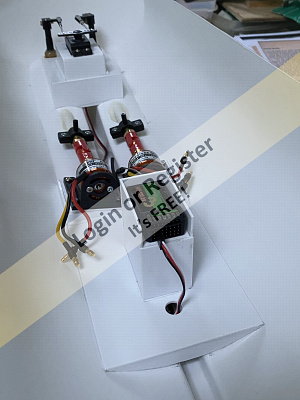

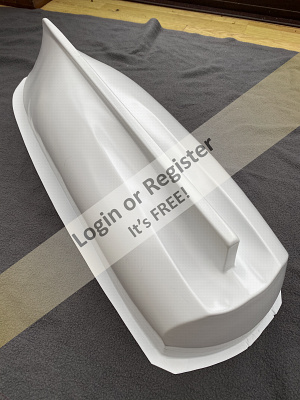

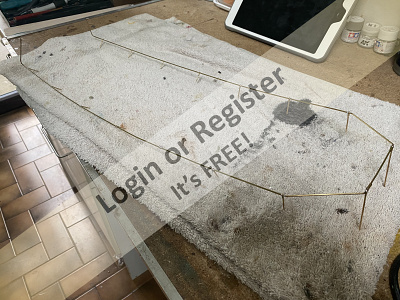

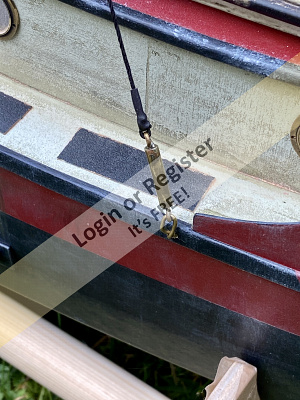

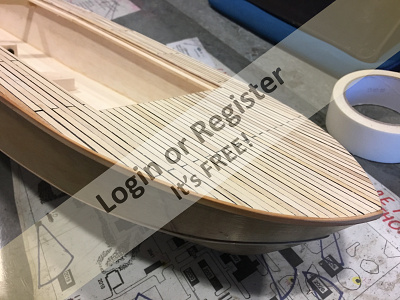

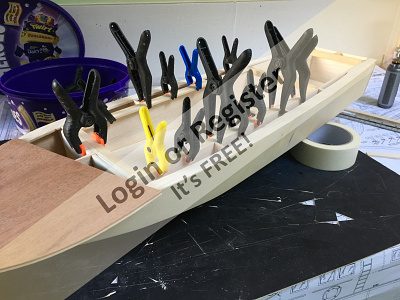

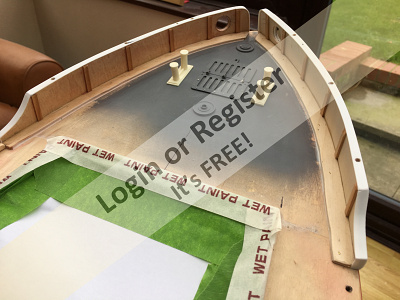

Good progress today starting with filing out the hole for the Y-Boat hatch in the stern of the deck. I took the added precaution of supporting the GRP surround with wood and clamps to add strength while filing as I didn’t want a nasty accident accidentally breaking it. It took about an hour of filing and sanding checking often to get a good fit for the hatch which will hinge in 4 pieces later.

Once happy with that I then marked the position of the compartment on the underside of the deck and fitted it with 5 min epoxy and clamps and beefed up the join with a fillet of liquid steel.

Next was to make a 2mm template to mark the inside of the hull where the 3x6mm deck bearers will sit. This was followed by fitting strips of 6x3mm styrene that had been roughened and scored, the first layer being fitted with 5 min epoxy and every clamp in the box! This was followed by a second layer fitted with styrene cement and my trusty clamps again and then once hard enough, a large fillet of liquid steel all around to beef it up ready to fit the deck.

The styrene strips where sanded flat with the Dremel sanding drum and then a couple of hours of fine fettling of the deck before fitting with 30 min epoxy, lots of tape and weights and checking for true before leaving overnight to fully harden. Next job is the sand and fill the deck flush with the hull and fit the steps on the deck…..

Once happy with that I then marked the position of the compartment on the underside of the deck and fitted it with 5 min epoxy and clamps and beefed up the join with a fillet of liquid steel.

Next was to make a 2mm template to mark the inside of the hull where the 3x6mm deck bearers will sit. This was followed by fitting strips of 6x3mm styrene that had been roughened and scored, the first layer being fitted with 5 min epoxy and every clamp in the box! This was followed by a second layer fitted with styrene cement and my trusty clamps again and then once hard enough, a large fillet of liquid steel all around to beef it up ready to fit the deck.

The styrene strips where sanded flat with the Dremel sanding drum and then a couple of hours of fine fettling of the deck before fitting with 30 min epoxy, lots of tape and weights and checking for true before leaving overnight to fully harden. Next job is the sand and fill the deck flush with the hull and fit the steps on the deck…..

▲

⟩⟩

hermank

MouldBuilder

mturpin013

robbob

Colin H

Rookysailor

stevedownunder

pressonreguardless

💬 Re: Y-Boat compartment and other things….

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 166 Views · 1 Like

Flag

💬 Add Comment

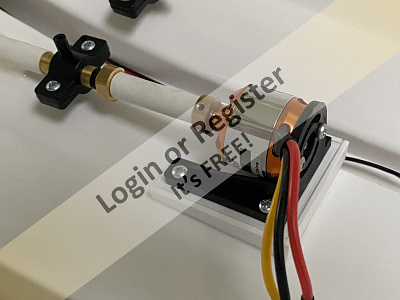

Hi Trev, welcome to the party! My pick ups are located in line between props and rudder were hopefully the props and forward momentum will generate enough thrust to get the water flowing? I’ll take a photo for the next update 👌

Kind regards Sy

Kind regards Sy

▲

⟩⟩

pressonreguardless

💬 Re: Y-Boat compartment and other things….

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 166 Views · 1 Like

Flag

💬 Add Comment

Hi Mike, I only plan on the compartment being grubby, it will spend most of the time with the hatch closed! Any other weathering will be light in keeping with the care and tenderness that the crews keep their RNLI boat in 👌

▲

⟩⟩

Colin H

📝 Y-Boat compartment and other things….

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 166 Views · 6 Likes · 10 Comments

Flag

💬 Add Comment

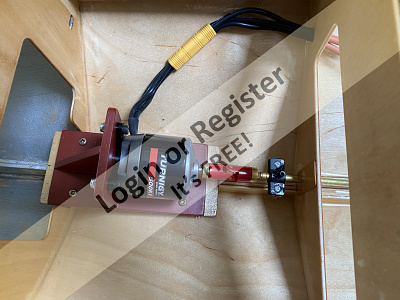

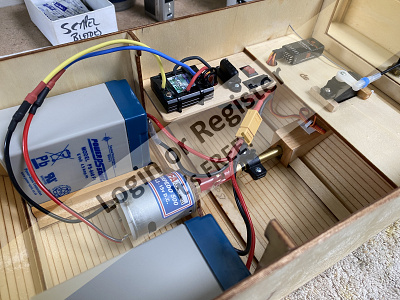

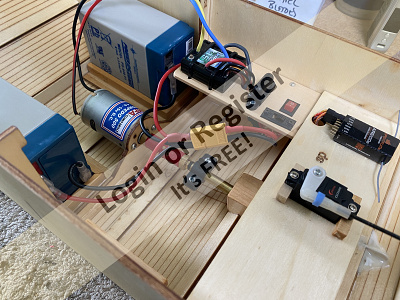

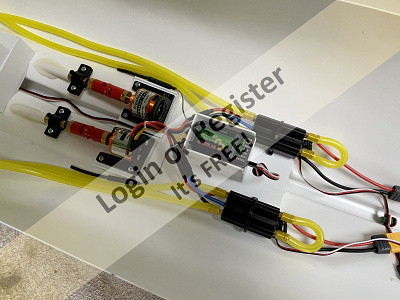

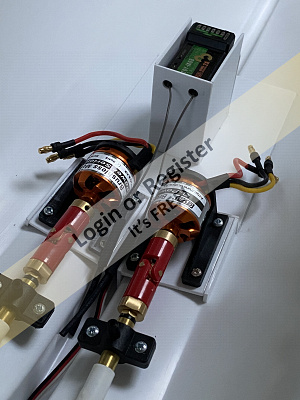

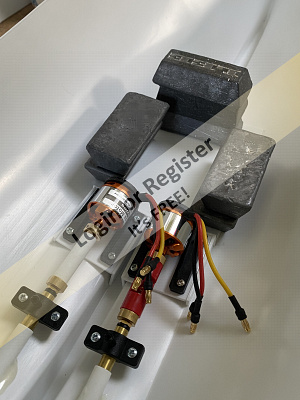

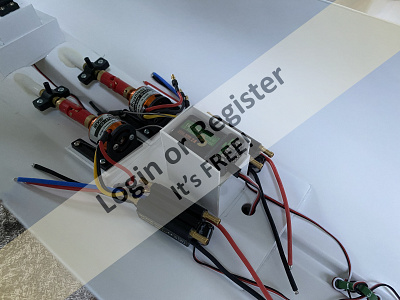

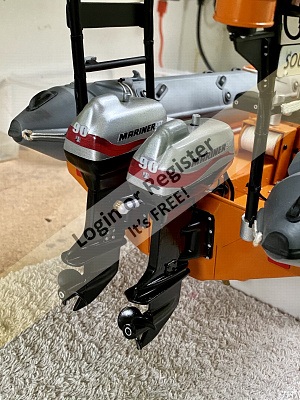

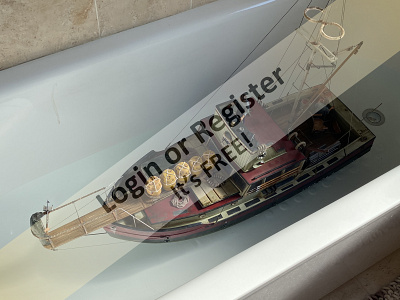

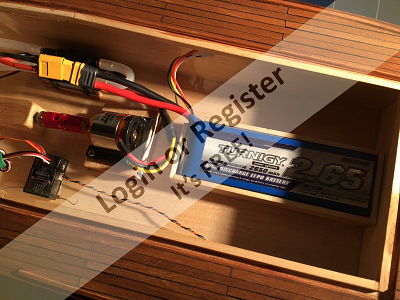

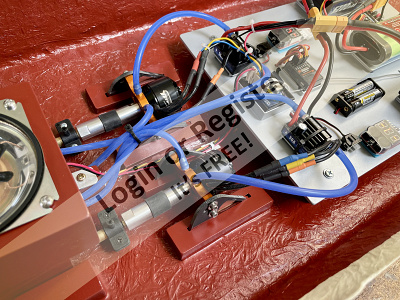

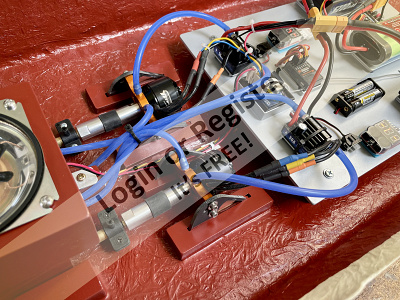

So, back from a cheeky break in Tenby with the Mrs and it’s straight back on it! Having got some good reference shots, I decided to add some extra detail to the Y-Boat compartment which includes some wall panels, step and some pipe work. All made from good old styrene, it adds some interest to an otherwise plane box if left as kit form. This was then painted with various weathering techniques as unlike the exterior of the boat, this area on the real thing is quite grubby!

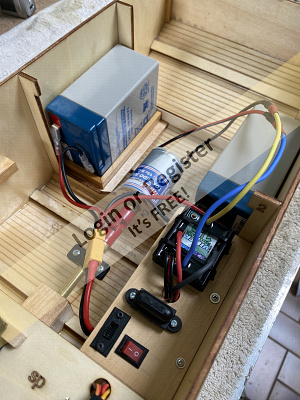

A few other little jobs included fitting a blue strip of water cooling pipe that had arrived in the post along with fitting the heavy duty propshaft couplings, lipo checkers and the new lipos. I now consider the internal workings about done part from maybe a couple of tweaks if needed.

Tomorrow’s project will be to start fitting the deck…….

A few other little jobs included fitting a blue strip of water cooling pipe that had arrived in the post along with fitting the heavy duty propshaft couplings, lipo checkers and the new lipos. I now consider the internal workings about done part from maybe a couple of tweaks if needed.

Tomorrow’s project will be to start fitting the deck…….

▲

⟩⟩

hermank

jbkiwi

pressonreguardless

Rookysailor

stevedownunder

Colin H

💬 Re: Model Slipway RNLI Tamar class lifeboat 1:16 scale

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 146 Views · 0 Likes

Flag

💬 Add Comment

Hi JB, always a bonus if you can get the shots of the boat your actually building, takes hours off trying to find suitable shots on Google 👌😂

Kind regards Sy

Kind regards Sy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Reference photos from RNLI Tenby

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 174 Views · 5 Likes

Flag

💬 Add Comment

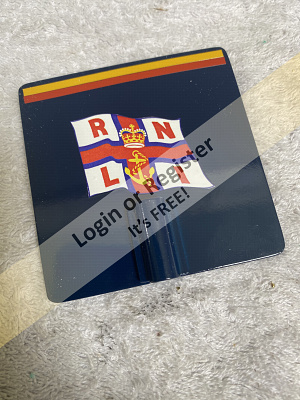

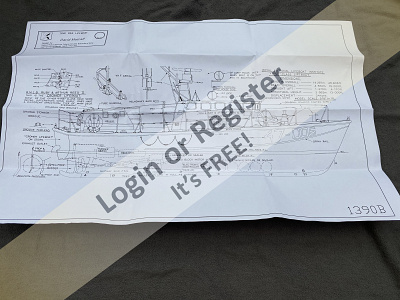

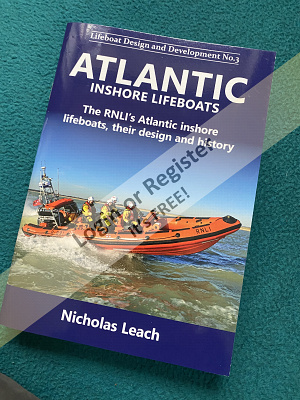

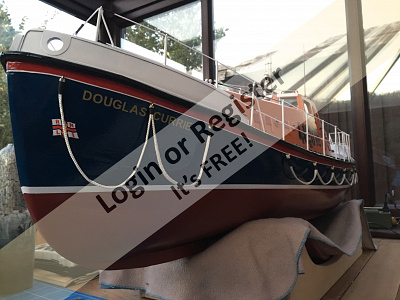

What a fantastic visit to the station at Tenby yesterday. Managed to get a wealth of shots of external features on their Tamar. Unfortunately no crew were on site so unable to get a shot at getting on board. What is clear is that as fantastic as the kit is by MS, I’ve now got plenty of shots of all the extra “bells and whistles” I can scratch build.

The 2 lovely ex-Yorkshire ladies running the shop kindly informed me that coming back Monday evening when they are due to go out on a practice sortie will give me the opportunity to film the launch process and with crew being about a good chance to get on board.

I shall be there like a geek and hour earlier than the launch time slot!…..

The 2 lovely ex-Yorkshire ladies running the shop kindly informed me that coming back Monday evening when they are due to go out on a practice sortie will give me the opportunity to film the launch process and with crew being about a good chance to get on board.

I shall be there like a geek and hour earlier than the launch time slot!…..

▲

⟩⟩

hermank

Mike Stoney

DWBrinkman

Colin H

MouldBuilder

💬 Re: Model Slipway RNLI Tamar class lifeboat 1:16 scale

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 1 Like

Flag

💬 Add Comment

Hi Pete, I deliberate over what to build next out of the stockpile of kits I have, but the loyal is favourite for next up 👌

▲

⟩⟩

Rookysailor

💬 Re: Model Slipway RNLI Tamar class lifeboat 1:16 scale

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 0 Likes

Flag

💬 Add Comment

Hi Rob, good to “see” you again also…

Very much looking forward to your next build, any spoiler alerts or is it a surprise! Please let me know when you post the blog so I can keep an eye on that. Kind regards Sy

Very much looking forward to your next build, any spoiler alerts or is it a surprise! Please let me know when you post the blog so I can keep an eye on that. Kind regards Sy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Model Slipway RNLI Tamar class lifeboat 1:16 scale

4 years ago by 🇬🇧 Skydive130 ( Rear Admiral)

Rear Admiral)

Rear Admiral)

Rear Admiral)✧ 160 Views · 1 Like

Flag

💬 Add Comment

hi Peter, good to “see” you again. By all means use whatever you can from my build if it helps you in your build, please ask if you have any questions. As for finishing in 3 months, that’s probably realistic ha ha! Kind regards Sy

▲

⟩⟩

MouldBuilder

Commodore)

Commodore)

Captain)

Captain)

Midshipman)

Midshipman)

Lieutenant)

Lieutenant)

Fleet Admiral)

Fleet Admiral)

Liked Brass 3 bladed prop.. 1 year ago

Liked Brass 3 bladed prop.. 1 year ago