Join Us On Social Media!

Czech Republic

Recent Posts

💬 Re: SMS Embden plus maiden video

13 days ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 14 Views · 2 Likes

Flag

💬 Add Comment

It is a truly beautiful model, unfortunately with mixed feelings I take the liberty of correcting the name of the model. It is the SMS Emden..

See >

See >

▲

⟩⟩

hermank

HappyHaggis

Login To

Remove Ads

Remove Ads

📝 Question of the Day?

23 days ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 41 Views · 0 Likes

Flag

📝 Reply

I was initially considering a bowline knot, but my choice was questioned by the claim that it could be easily untied...which I don't think.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Royal Naval Steam Pinnace

5 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 22 Views · 0 Likes

Flag

💬 Add Comment

Hi,here is another interesant source

I wish you success in finding details and constructing the model.

Tom

I wish you success in finding details and constructing the model.

Tom

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: Royal Naval Steam Pinnace

5 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 29 Views · 1 Like

Flag

💬 Add Comment

▲

⟩⟩

SouthportPat

📝 MIAOW

6 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 4 Views · 14 Likes · 3 Comments

Flag

💬 Add Comment

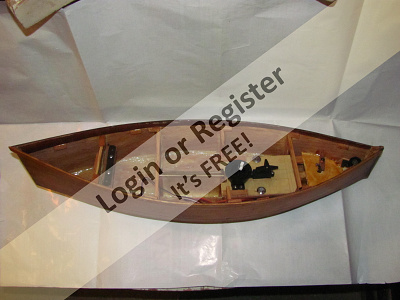

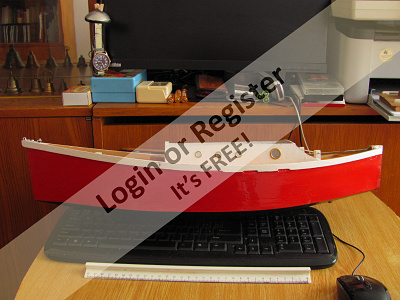

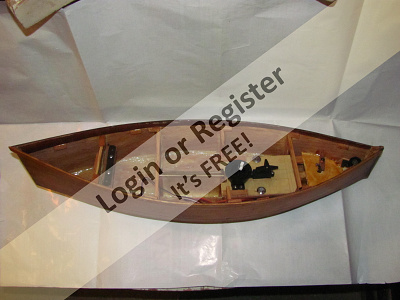

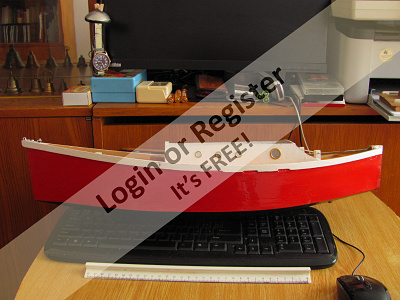

A friend gave me a thin(1 mm) plywood sheet measuring about 60x40 cm. I didn't know what to build with it, until I finally chose a model, Emma by Gary Webb (Bearospace Industries). Is it a semi-scale portrayal of a sprit-rigged cruising sloop from the mid 20th century, designed for RC sailing, reduced to 60% so that the individual parts fit on the plywood.

The total length of the model is ultimately 58.5 cm (23").

Due to this, I had to improvise a lot, instead of a lever servo I used a sail winch, but even so there is unexpectedly little space under the deck. I had to come up with a different arrangement for the sail sheets and adjust the location of the rudder servo.

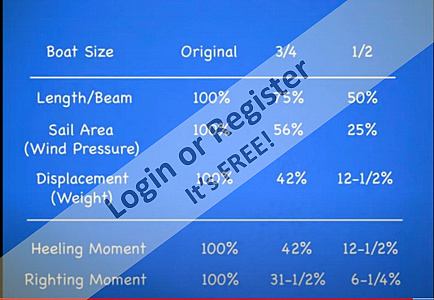

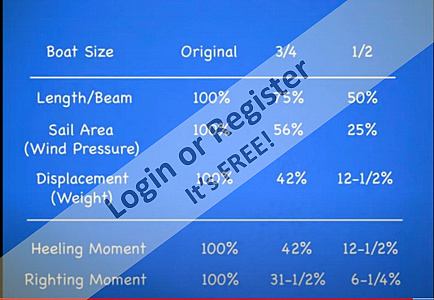

By reducing the length to approximately 60%, the sail area has decreased to 36% and the displacement to 22% compared to the original model.

This is because when increasing or decreasing the length changes linearly, the area changes quadratically and the weight (displacement) changes cubically.

I used 1mm and 3mm plywood (for the ribs) for the model. I glued everything with polyurethane glue, and the finished model was impregnated with diluted epoxy.

For the mast and spars I used carbon fiber tubes with a diameter of 6mm, 4mm and 3mm, the spar is made of bamboo.

The sails are made of Ripstop nylon.

The fin keel is made of 2mm aluminum, with a lead bomb it weighs 980 grams.

The hull of the model with full equipment and sails (without keel) weighs 1060 grams.

Surface treatment - nitro spray, deck and superstructures Revell colors. After much deliberation, I named the model MIAOW

More photos at: tomarack rajce net

Dear friends

I have to declare here...

If I had known in advance what problems I would have to solve, I would have probably built Emma in the recommended size (1 meter) as Gary Webb recommends.

On the other hand..the model fits in a bag even with a stand and fin keel + transmitter in a backpack..

To my surprise, it sails quite well even in very light winds, and I am happy with it.

The total length of the model is ultimately 58.5 cm (23").

Due to this, I had to improvise a lot, instead of a lever servo I used a sail winch, but even so there is unexpectedly little space under the deck. I had to come up with a different arrangement for the sail sheets and adjust the location of the rudder servo.

By reducing the length to approximately 60%, the sail area has decreased to 36% and the displacement to 22% compared to the original model.

This is because when increasing or decreasing the length changes linearly, the area changes quadratically and the weight (displacement) changes cubically.

I used 1mm and 3mm plywood (for the ribs) for the model. I glued everything with polyurethane glue, and the finished model was impregnated with diluted epoxy.

For the mast and spars I used carbon fiber tubes with a diameter of 6mm, 4mm and 3mm, the spar is made of bamboo.

The sails are made of Ripstop nylon.

The fin keel is made of 2mm aluminum, with a lead bomb it weighs 980 grams.

The hull of the model with full equipment and sails (without keel) weighs 1060 grams.

Surface treatment - nitro spray, deck and superstructures Revell colors. After much deliberation, I named the model MIAOW

More photos at: tomarack rajce net

Dear friends

I have to declare here...

If I had known in advance what problems I would have to solve, I would have probably built Emma in the recommended size (1 meter) as Gary Webb recommends.

On the other hand..the model fits in a bag even with a stand and fin keel + transmitter in a backpack..

To my surprise, it sails quite well even in very light winds, and I am happy with it.

▲

⟩⟩

Steves-s

hermank

Zdenek

jumpugly

IanL1

AlessandroSPQR

xtramaths

RodC

algon

roycv

EdW

philcaretaker

SimpleSailor

Wolle

💬 Re: Emily

8 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 26 Views · 5 Likes

Flag

💬 Add Comment

Yesterday I also finished and tested the scaled down model of Emma by Gary Webb.

Length 58 cm, sail winch, rudder servo.

If I had known in advance what tricks the scaled-down version offers, I would have preferred to build the large model...

Length 58 cm, sail winch, rudder servo.

If I had known in advance what tricks the scaled-down version offers, I would have preferred to build the large model...

▲

⟩⟩

EdW

Len1

AlessandroSPQR

hermank

Ronald

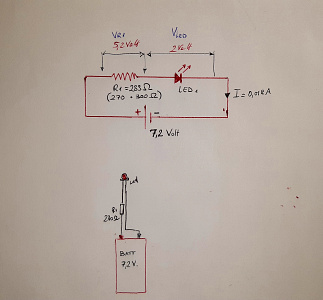

📝 various electrical connection diagrams for two motors

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 5 Views · 2 Likes

Flag

💬 Add Comment

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo.

I wanted to add some articles in Word (doc) but they wouldn't open here.

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo.

I wanted to add some articles in Word (doc) but they wouldn't open here.

Tom K

▲

⟩⟩

Steves-s

AlessandroSPQR

📝 various electrical connection diagrams for two motors

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 5 Views · 2 Likes

Flag

💬 Add Comment

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo.

I wanted to add some articles in Word (doc) but they wouldn't open here.

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo.

I wanted to add some articles in Word (doc) but they wouldn't open here.

Tom K

▲

⟩⟩

AlessandroSPQR

premecekcz

📝 various electrical connection diagrams for two motors

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 5 Views · 1 Like

Flag

💬 Add Comment

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo.

I wanted to add some articles in Word (doc) but they wouldn't open here.

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo.

I wanted to add some articles in Word (doc) but they wouldn't open here.

Tom K

▲

⟩⟩

AlessandroSPQR

📝 various electrical connection diagrams for two motors

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 5 Views · 1 Like

Flag

💬 Add Comment

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo

I add some articles related to the topic.

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo

I add some articles related to the topic.

Tom K

▲

⟩⟩

AlessandroSPQR

📝 Help with wiring 2 motors please

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 2 Likes

Flag

📝 Reply

Hi Alessandro,

I did it...see> how to >various electrical connection diagrams for two motors <

I had problems with transferring images, basically, my entire post is there, it is possible to join it and add your comments and other useful diagrams... I put the wiring for my RC Lulonga quarterwheeler too. I am sorry, I don't have a better graphic design at the moment.

Tom

I did it...see> how to >various electrical connection diagrams for two motors <

I had problems with transferring images, basically, my entire post is there, it is possible to join it and add your comments and other useful diagrams... I put the wiring for my RC Lulonga quarterwheeler too. I am sorry, I don't have a better graphic design at the moment.

Tom

▲

⟩⟩

Len1

AlessandroSPQR

Login To

Remove Ads

Remove Ads

📝 various electrical connection diagrams for two motors

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 5 Views · 0 Likes

Flag

💬 Add Comment

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Lulonga schema -wiring for my RC quarter wheeler,fog horn and siren switching via canal 2, prop servo switches microswitches, see color photo

Tom K

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 various electrical connection diagrams for two motors

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 5 Views · 0 Likes

Flag

💬 Add Comment

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Tom K

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Help with wiring 2 motors please

10 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 54 Views · 11 Likes

Flag

📝 Reply

HI,

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Tom K

I think I've already posted this here, but it never hurts to repeat it. On my Lulonga quarter-wheeler model, I use the connection according to Figure 7 with the difference that instead of a separate battery I use the BEC from the ESC. The motors are controlled on the receiver Th 3 channel and Ail 1 . channel via the V-tail mixer. So I can control the model with a single stick ( Th ). I have the rudder connected to channel 4 as usual. Of course, you can control the boat with just the rudder, but in my case, this is only of little effectiveness.

This connection with an external V-tail mixer seemed the easiest to me, but I was unable to program this connection option appropriately.

Basically, by moving the Th stick (channel 3) forward and backward, we control the power of both engines. By moving the same stick left or right, we control the direction of their rotation—it's similar to the ailerons on an aeroplane.

It's interesting - if I want to turn the model on the spot, I don't "give gas", I just tilt the stick left or right. At that moment (in my case) one wheel turns forward and the other one turns back (and vice versa) so the model stops and just turns.

greetings!!

Tom K

▲

⟩⟩

premecekcz

ToraDog

Len1

SimpleSailor

Doogle

AlessandroSPQR

chugalone100

RNinMunich

roycv

DuncanP

hermank

💬 Re: 5. Old Stern wheel steamer

12 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 85 Views · 5 Likes

Flag

💬 Add Comment

Hi,

I was a little surprised that one of the options is for your model to turn into a submarine.

Well...it's been almost 50 years since I got the plans for the sternwheeler Chaperon from a friend in the US. I remembered...and planned to build that model.

American river sternwheelers generally had a low hull and shallow draft.

Given the construction materials I had available, I was worried that the model would be too heavy.

Therefore, I started calculating how much displacement the model would have - and it scared me quite a bit. It turned out to be very low for a model length of around 120cm.

To ensure sufficient draft (+ sufficient reserve), the draft of the model would have to be increased at least 2x - regardless of the similarity to the original.

I don't know what draft you're counting on for your model, and I don't know if you've already tried putting your model in the water (maybe first the hull itself without the superstructure).

Try to at least virtually recalculate the displacement and then compare it with the weight of the superstructure and all the equipment.

I solved this problem with some of my models (e.g., Ned Kelly) by adding (gluing and laminating) a polystyrene foam board of suitable thickness to the bottom of the model so that the displacement of the model increased.

It's barbaric, but the model floats and you won't know it on the water anyway.

I hope you have a nice model, not a submarine!!

I didn't build that model in the end for various reasons.. I like it.

I was a little surprised that one of the options is for your model to turn into a submarine.

Well...it's been almost 50 years since I got the plans for the sternwheeler Chaperon from a friend in the US. I remembered...and planned to build that model.

American river sternwheelers generally had a low hull and shallow draft.

Given the construction materials I had available, I was worried that the model would be too heavy.

Therefore, I started calculating how much displacement the model would have - and it scared me quite a bit. It turned out to be very low for a model length of around 120cm.

To ensure sufficient draft (+ sufficient reserve), the draft of the model would have to be increased at least 2x - regardless of the similarity to the original.

I don't know what draft you're counting on for your model, and I don't know if you've already tried putting your model in the water (maybe first the hull itself without the superstructure).

Try to at least virtually recalculate the displacement and then compare it with the weight of the superstructure and all the equipment.

I solved this problem with some of my models (e.g., Ned Kelly) by adding (gluing and laminating) a polystyrene foam board of suitable thickness to the bottom of the model so that the displacement of the model increased.

It's barbaric, but the model floats and you won't know it on the water anyway.

I hope you have a nice model, not a submarine!!

I didn't build that model in the end for various reasons.. I like it.

▲

⟩⟩

Peejay

AlessandroSPQR

hermank

RNinMunich

Mike Stoney

📝 What makes a Good Jib?

12 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 20 Views · 2 Likes

Flag

📝 Reply

Maybe too heavy canvass for such little sail,inappropriate cut.

Try using a lighter material and instead of sewing, stick the edges of the sails with double-sided tape. You can find many instructions online.

I wish you success.

Try using a lighter material and instead of sewing, stick the edges of the sails with double-sided tape. You can find many instructions online.

I wish you success.

▲

⟩⟩

AlessandroSPQR

hermank

💬 Re: 5. Old Stern wheel steamer

12 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 94 Views · 5 Likes

Flag

💬 Add Comment

I may have already written about it here, but now the Australian site for modelers building paddle steamers should be available again.

www.paddleducks.co.uk

You will find a number of interesting articles, plans and instructions there

When I built my paddle steamer I chose the "Australian" type... simple construction, good access to the steam engine - the engine room is usually open, similar to the paddle steamers on the

Mississippi.

When I was inserting text into the post, it disappeared after I inserted the images. So I'm repeating myself here.

www.paddleducks.co.uk

You will find a number of interesting articles, plans and instructions there

When I built my paddle steamer I chose the "Australian" type... simple construction, good access to the steam engine - the engine room is usually open, similar to the paddle steamers on the

Mississippi.

When I was inserting text into the post, it disappeared after I inserted the images. So I'm repeating myself here.

▲

⟩⟩

AlessandroSPQR

Peejay

hermank

Mike Stoney

Chuck

💬 Re: 5. Old Stern wheel steamer

12 months ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 94 Views · 8 Likes

Flag

💬 Add Comment

▲

⟩⟩

AlessandroSPQR

Peejay

Ronald

RNinMunich

hermank

chugalone100

Mike Stoney

Chuck

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 16 Views · 1 Like

Flag

📝 Reply

Hi gents, thanks for your help.

I use Libreoffice writer and the Czech keyboard.It seems that special characters are not very well understood when inserting text directly into the editor in MB.I am attaching the same post as .doc and .pdf documents.

The attachments contain text that I originally copied and pasted into MB.(with problems)

It can be seen that inserting this new way is without problems. I used a free program to convert to .pdf

>pdf 24 tools< https://tools.pdf24.org . However, the .doc format also transferred without any problems .

I use Libreoffice writer and the Czech keyboard.It seems that special characters are not very well understood when inserting text directly into the editor in MB.I am attaching the same post as .doc and .pdf documents.

The attachments contain text that I originally copied and pasted into MB.(with problems)

It can be seen that inserting this new way is without problems. I used a free program to convert to .pdf

>pdf 24 tools< https://tools.pdf24.org . However, the .doc format also transferred without any problems .

▲

⟩⟩

RNinMunich

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 16 Views · 1 Like

Flag

📝 Reply

Hi gents,

thanks for help. Sorely I use LibreOffice Writer and Czech keyboard mutation..something went wrong.

I'll try to insert the post as a separate text now. I'll see if everything is transferred correctly.

thanks for help. Sorely I use LibreOffice Writer and Czech keyboard mutation..something went wrong.

I'll try to insert the post as a separate text now. I'll see if everything is transferred correctly.

▲

⟩⟩

RNinMunich

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 4 Likes

Flag

📝 Reply

to RNinMunich > Many thanks for the correction and help!!!

I was not able to copy the math formulas from my editor correctly. How did you do it please?

to jumpugly > Scale Conversion Calculator .. interesting and helpful !!!

Greetings

Tom

I was not able to copy the math formulas from my editor correctly. How did you do it please?

to jumpugly > Scale Conversion Calculator .. interesting and helpful !!!

Greetings

Tom

▲

⟩⟩

AlessandroSPQR

Mike Stoney

RNinMunich

jumpugly

Login To

Remove Ads

Remove Ads

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 33 Views · 4 Likes

Flag

📝 Reply

to Ronald ..>oh yes, the lead bulb weight for my 60 cm model based on calculation 748g

for your model 28" will be lead bulb then 3 400(grams) x( 0.72x0.72x0.72)

3400 x 0,37 = 1258 g =

to AlessandroSPQR> .My lead batteries have reached the end of their useful life, so for my larger boats (Lulonga, barges) I use Li-Ion bat 3S1P12.6V, Models with ESC+BEC. For Minikitty NiMH Eneloop AAA 1.2V (min 750mAh) , for this my new project probably Eneloop AA 1.2V(4 pieces in a simple holder). These batteries are intended primarily for industrial use, they are very reliable.

There are also rechargeable Li-Ion 1.5V - I have them in my Canon camera.

for your model 28" will be lead bulb then 3 400(grams) x( 0.72x0.72x0.72)

3400 x 0,37 = 1258 g =

to AlessandroSPQR> .My lead batteries have reached the end of their useful life, so for my larger boats (Lulonga, barges) I use Li-Ion bat 3S1P12.6V, Models with ESC+BEC. For Minikitty NiMH Eneloop AAA 1.2V (min 750mAh) , for this my new project probably Eneloop AA 1.2V(4 pieces in a simple holder). These batteries are intended primarily for industrial use, they are very reliable.

There are also rechargeable Li-Ion 1.5V - I have them in my Canon camera.

▲

⟩⟩

Mike Stoney

hermank

AlessandroSPQR

Ronald

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 32 Views · 4 Likes

Flag

📝 Reply

You will use a slightly different procedure when choosing a model based on a large pattern.

We will use as the pattern the scale 1:200 =>(1/M)

Your model must be a reduction of this model (whether it is a motorboat, steamer, or military ship, always in a certain scale).

This default scale is the same for all dimensions of a large ship.

However, it is always true that lengths decrease linearly, for example, the scale M 1:200 means that all dimensions are divided by 200, and your model will have 1/200 the length of your representative. The optical appearance is absolutely the same as your model.

Areas – decrease quadratically, with the square power => 1/M²=>1/200²

1/200² = 1/200x200 = 1/40 000

this means that 1m² of the original => 10 000cm² /40 000 = 0.25 cm²

in scale M =1:100 then the area is 1/10 000 of the original, 1m² is then 10 cm² large

The same formula is used to calculate the area of sails.

Volumetric measures and weights are reduced cubically, with the third power.

1/200³ = 1/200x200x200 = 1/ 8 000 000

in scale 1:100 then it is only 1/1 000 000

A model in scale 1:200 whose model has a displacement of 10 000 t => 10 000 000 kg

then has a displacement of 10 000 000 / 8 000 000 = 1.25 kg

in scale 1:100 => 10 000 000 / 1 000 000 = 10 kg

Basically, only take into account the DISPLACEMENT !!!!.

This is mainly given for military ships, and only sometimes for others.

Regarding speed, the following relationship applies: Vm = Vo / √M

Example: Vo = 20 km/h

M = 1:100

then for model > Vm = 20 (km/h) / √100 = 20/10 = 2 km/h

= 33.4 m/min

=0.56 m/sec

We will use as the pattern the scale 1:200 =>(1/M)

Your model must be a reduction of this model (whether it is a motorboat, steamer, or military ship, always in a certain scale).

This default scale is the same for all dimensions of a large ship.

However, it is always true that lengths decrease linearly, for example, the scale M 1:200 means that all dimensions are divided by 200, and your model will have 1/200 the length of your representative. The optical appearance is absolutely the same as your model.

Areas – decrease quadratically, with the square power => 1/M²=>1/200²

1/200² = 1/200x200 = 1/40 000

this means that 1m² of the original => 10 000cm² /40 000 = 0.25 cm²

in scale M =1:100 then the area is 1/10 000 of the original, 1m² is then 10 cm² large

The same formula is used to calculate the area of sails.

Volumetric measures and weights are reduced cubically, with the third power.

1/200³ = 1/200x200x200 = 1/ 8 000 000

in scale 1:100 then it is only 1/1 000 000

A model in scale 1:200 whose model has a displacement of 10 000 t => 10 000 000 kg

then has a displacement of 10 000 000 / 8 000 000 = 1.25 kg

in scale 1:100 => 10 000 000 / 1 000 000 = 10 kg

Basically, only take into account the DISPLACEMENT !!!!.

This is mainly given for military ships, and only sometimes for others.

Regarding speed, the following relationship applies: Vm = Vo / √M

Example: Vo = 20 km/h

M = 1:100

then for model > Vm = 20 (km/h) / √100 = 20/10 = 2 km/h

= 33.4 m/min

=0.56 m/sec

▲

⟩⟩

Mike Stoney

hermank

AlessandroSPQR

Ronald

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 32 Views · 5 Likes

Flag

📝 Reply

I would like to add a little theory here

Scaled down proportions, basic dimensions of original model = 100%

example on my model>

If Emma has length 1 meter, my model has length 60 cm => 60%=>L x 0,6 => 1x0.6 = 60 cm

sail area 3393sq.cm => sail area P/ 0.6x0.6 => 3393 x 0.36 => 1221.48 sq.cm,

ballast 3400 g => => P/ 0.6x0.6x0.6 =>3400 x 0.22 => 748 g .

Lengths are converted linearly, areas are converted to the square power, and weights are converted to the cube power.🤑

Scaled down proportions, basic dimensions of original model = 100%

example on my model>

If Emma has length 1 meter, my model has length 60 cm => 60%=>L x 0,6 => 1x0.6 = 60 cm

sail area 3393sq.cm => sail area P/ 0.6x0.6 => 3393 x 0.36 => 1221.48 sq.cm,

ballast 3400 g => => P/ 0.6x0.6x0.6 =>3400 x 0.22 => 748 g .

Lengths are converted linearly, areas are converted to the square power, and weights are converted to the cube power.🤑

▲

⟩⟩

Mike Stoney

hermank

peterd

AlessandroSPQR

jumpugly

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 34 Views · 8 Likes

Flag

📝 Reply

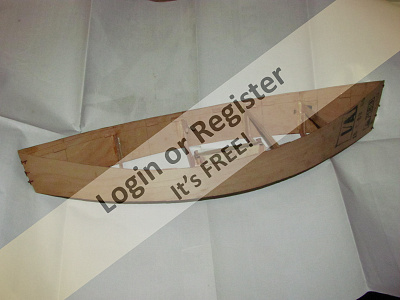

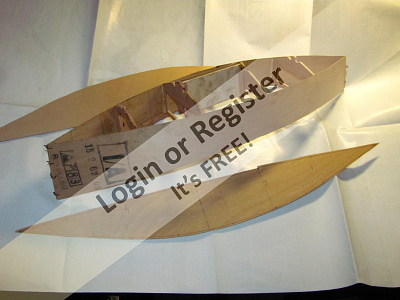

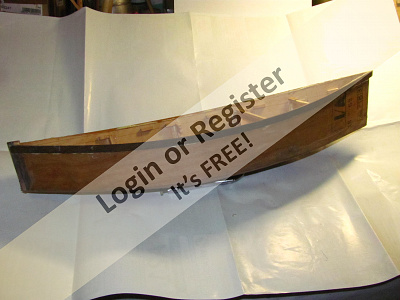

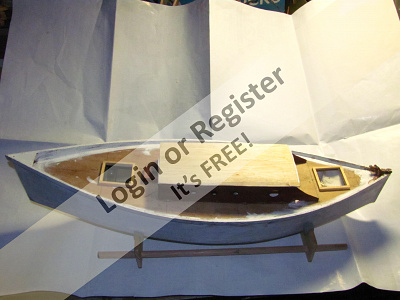

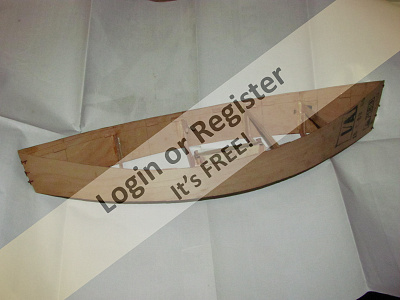

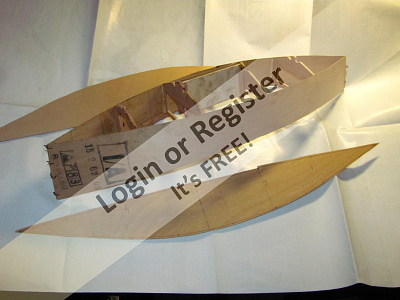

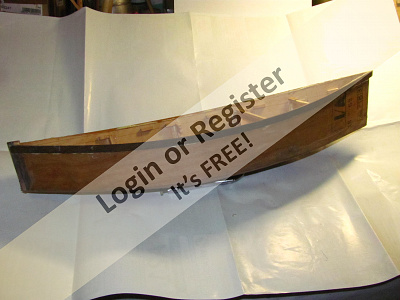

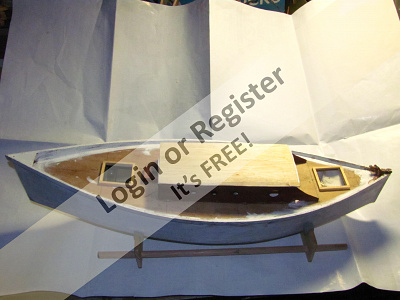

I'm slowly continuing with the construction of my "Miniemma". I have the sides glued, and I'm continuing with gluing the bow and stern of the model. I decided to adjust the location of the rudder - I'll put it on a hanger on the sternpost. I had to add sternpost due to a minor construction error too. It seems more convenient to me, for transportation.

The bottom parts come out optimally according to the drawing.

I intend to move the deck 5 mm up - see the glued stops. I am also considering adding a bowsprit (if necessary). It is one thing to build a model and another thing - to teach it to sail. It happened to me with my "Minikitty" model.I had to increase the rudder area incredibly to balance the rigging.

Especially when you make adjustments against the original plan - there's always a hitch. She sails well at present...

The bottom parts come out optimally according to the drawing.

I intend to move the deck 5 mm up - see the glued stops. I am also considering adding a bowsprit (if necessary). It is one thing to build a model and another thing - to teach it to sail. It happened to me with my "Minikitty" model.I had to increase the rudder area incredibly to balance the rigging.

Especially when you make adjustments against the original plan - there's always a hitch. She sails well at present...

▲

⟩⟩

Mike Stoney

hermank

roycv

peterd

Peejay

johnf

Ronald

jumpugly

📝 My newest sailboat project

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 35 Views · 4 Likes

Flag

📝 Reply

Hi, I see I'm not the only one building a scaled down copy of the RC sailing sloop Emma.

About a year ago I got 2 sheets of plywood measuring 60 x 40 cm from a friend. I didn't know what to use them for. It occurred to me that this plywood could be used to build a small model.

Some time ago, while searching the net, I visited the Bearospace Industries website again. It seemed to me that the scaled down plan for Emma could be used. When recalculating the dimensions, the length of the model came out to be about 58 cm, the side parts are just 60 cm long.

Currently, I have the middle part glued together - the fin box,and the parts are ready to be glued together.

A minor problem arose when recalculating the weight of the lead bulb - with the result of 750 grams at an estimated displacement of 1350g. There is quite a small reserve for the hull, rigging and RC equipment.

About a year ago I got 2 sheets of plywood measuring 60 x 40 cm from a friend. I didn't know what to use them for. It occurred to me that this plywood could be used to build a small model.

Some time ago, while searching the net, I visited the Bearospace Industries website again. It seemed to me that the scaled down plan for Emma could be used. When recalculating the dimensions, the length of the model came out to be about 58 cm, the side parts are just 60 cm long.

Currently, I have the middle part glued together - the fin box,and the parts are ready to be glued together.

A minor problem arose when recalculating the weight of the lead bulb - with the result of 750 grams at an estimated displacement of 1350g. There is quite a small reserve for the hull, rigging and RC equipment.

▲

⟩⟩

Mike Stoney

EdW

peterd

Ronald

📝 Paddle rpm

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 50 Views · 5 Likes

Flag

📝 Reply

It is possible that I did not directly address the content of your post.

Forget Froudé and Reynolds. I'm afraid there's a big problem with the theory in such models. You can theoretically calculate the length, speed, displacement from the scale of the model, but the speed of rotation of the wheels is too dependent on the design and efficiency, which can't be determined in advance.

More about paddle wheels rpm .. I also recommend you take a look at the website, www.paddleducks.co.uk ,

, which is mainly intended for paddle boat lovers.

Tom

Forget Froudé and Reynolds. I'm afraid there's a big problem with the theory in such models. You can theoretically calculate the length, speed, displacement from the scale of the model, but the speed of rotation of the wheels is too dependent on the design and efficiency, which can't be determined in advance.

More about paddle wheels rpm .. I also recommend you take a look at the website, www.paddleducks.co.uk ,

, which is mainly intended for paddle boat lovers.

Tom

▲

⟩⟩

hermank

RPLedm

Mike Stoney

SimpleSailor

RNinMunich

📝 Paddle rpm

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 51 Views · 8 Likes

Flag

📝 Reply

As for me and my models with paddle wheels, I think it is necessary to test the optimal speed setting, which depends on the size of the model and the design of the paddle wheels.

The lower limit is calculated from zero rpm, the optimal working speed of the wheels also depends on the type of ship - calculate around 80 - 150 rpm. In no case should the steamer sail at the speed of a racing boat - but I saw that on the video too.

For example, my model of the Lulonga steamer has, in my opinion, an optimal speed, as if you were walking at a slow pace.

It is built in 1:32 scale.

The lower limit is calculated from zero rpm, the optimal working speed of the wheels also depends on the type of ship - calculate around 80 - 150 rpm. In no case should the steamer sail at the speed of a racing boat - but I saw that on the video too.

For example, my model of the Lulonga steamer has, in my opinion, an optimal speed, as if you were walking at a slow pace.

It is built in 1:32 scale.

▲

⟩⟩

Steves-s

hermank

RPLedm

Mike Stoney

SimpleSailor

AlessandroSPQR

Ray

RNinMunich

📝 part13

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 25 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

When I finished the model, I was very excited and immediately took it to the lake in the park to test it out.

I didn't even have a fin with a 3 kg lead bomb at that time.

The model looked very good on the water, but it didn't want to respond to the rudder at all when it was powered only by sails. Fortunately... I have an auxiliary motor in the model, so it was no problem getting it to shore.

I finished the fin keel and thought it would be fine - but it wasn't. In a short time, a friend took me to a regatta at the Výrovice dam near Znojmo. After arriving, I completed the model and the next morning the race in the free category started.

The model swam to the start, and instead of starting to race, it just drifted sideways away from the start. First run - 0 .

Now all my construction mistakes were added up. I had to come up with something quickly. The easiest thing seemed to me to use a large outer jib sail on the bow instead of the original small one. After this modification, my Capricorn finally went out on the race course - even though it had no chance against the others. During the last run, the battery failed, and I only managed to reach the shore from the starting point. This time it was a bitter end...

At home I put the model on the shelf and devoted myself to building other models. I only occasionally took the model to the water.

Gradually, however, I adjusted the rigging of the front sails. I left only the fore sail and only one - the big one - jib sail. Because there was little space to pull the sails when tacking, I made a new bowsprit 50 cm long - 10 cm longer than the original one. The model now behaves as expected.

I wondered why the model didn't want to sail under sails the first time. The answer was probably the simplest...my mistake when building the model, when I placed the fin right behind the main mast. According to experienced modelers

it should have been at least 3" ( 7.5 cm). The center of gravity of the sails was thus above the center of gravity of the side surface, instead of being a little in front of it.

There was probably another option - to lower the mizzen sail, but that didn't occur to me at the time.

As an attachment, I am attaching photos of the model on the water...how it has progressed over the years.

If anyone has any questions, I'd be happy to answer them.

I didn't even have a fin with a 3 kg lead bomb at that time.

The model looked very good on the water, but it didn't want to respond to the rudder at all when it was powered only by sails. Fortunately... I have an auxiliary motor in the model, so it was no problem getting it to shore.

I finished the fin keel and thought it would be fine - but it wasn't. In a short time, a friend took me to a regatta at the Výrovice dam near Znojmo. After arriving, I completed the model and the next morning the race in the free category started.

The model swam to the start, and instead of starting to race, it just drifted sideways away from the start. First run - 0 .

Now all my construction mistakes were added up. I had to come up with something quickly. The easiest thing seemed to me to use a large outer jib sail on the bow instead of the original small one. After this modification, my Capricorn finally went out on the race course - even though it had no chance against the others. During the last run, the battery failed, and I only managed to reach the shore from the starting point. This time it was a bitter end...

At home I put the model on the shelf and devoted myself to building other models. I only occasionally took the model to the water.

Gradually, however, I adjusted the rigging of the front sails. I left only the fore sail and only one - the big one - jib sail. Because there was little space to pull the sails when tacking, I made a new bowsprit 50 cm long - 10 cm longer than the original one. The model now behaves as expected.

I wondered why the model didn't want to sail under sails the first time. The answer was probably the simplest...my mistake when building the model, when I placed the fin right behind the main mast. According to experienced modelers

it should have been at least 3" ( 7.5 cm). The center of gravity of the sails was thus above the center of gravity of the side surface, instead of being a little in front of it.

There was probably another option - to lower the mizzen sail, but that didn't occur to me at the time.

As an attachment, I am attaching photos of the model on the water...how it has progressed over the years.

If anyone has any questions, I'd be happy to answer them.

▲

⟩⟩

Chuck

jbkiwi

hermank

luckyduck

📝 part 12

1 year ago by 🇨🇿 tomarack ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 37 Views · 7 Likes

Flag

💬 Add Comment

Anchor winch barrel I made from wood and gear wheels from the alarm clock.

To ensure its functionality (which was offered here), so bearings for shaft I made from brass tubes Ø 5/4 mm.

For the pinions, I made a "housing" of brass plate thickness 0.4 mm, soldered to the copper strip 5 x1 x 60 mm with required spacing .This strip it is glued and riveted to the back of the wooden winch knees on the bow.

When compiling the winch, I glued the reel in wrong way , so winch thus not functional. On the front of stem post of the model, I'm stuck copper stem band (with a cross-section 5 x 0.8 mm) and riveted it using short pins. This band is at the upper end provided with an eye for main mast forestay.

On the back of the stern post, I stuck the rudder hinges, and according to them, I placed and stuck the hinges on the rudder. and next.

The anchor is made from copper wire 3 mm dia. Painted black.

Main mast

The main mast is made of aluminum tubes of Ø14/12/10 mm inserted into each other and glued together, with a total length of 57 cm. The lower part of the mast was glued into a foot made of hardwood. Jackstay - auxiliary "stay" used for attaching the front edge of the main sail is made of brass wire Ø 1 mm, soldered to the heads of M2 screws, screwed and glued into the tubes from the back of the mast.

Main topmast

The topmast is made of a Ø8 - Ø6 mm laminate GRP cone from fishing rod with a length of 59 cm and reinforced with a Ø 4 mm carbon tube with a length of 63 cm, which passes through the entire length of the cone and at the same time fulfills the function of extending (the top) of the topmast. It is glued to the cone with PUR glue.

Crosstree

I simplified the crosstree a bit, I didn't have suitable brass profiles, so I made the arms from an old umbrella, so they are foldable, like the original.

Mizzen mast

it is sanded from a 10x10 spruce beam with a length of 28 / 30 cm according to the drawing.

The tabernacle of the mizzen mast, I cut out, bent and welded from copper sheet thickness. 0.5 mm. I drilled a Ø 3.5 mm hole in it for the axis of the rudder, and two Ø 3 mm holes in the feet for attachment to the superstructure. Painted green.

Mainsail sprit,(spreet )

The sprit is made from a beech log with a diameter of 8 mm and a length of 75 cm, ground towards the ends into a slight cone.

Mizzen sprit

it is made from a spruce log with a diameter of 4 mm and a length of 40 cm

The boom of the sail on the back mast

it is made of a spruce log with a diameter of 4 mm and a distance of 27 cm

Bowsprit

The bowsprit is ground from a 10x10 mm spruce beam, 40 cm long. This profile remained on the foot for a length of about 4 cm and was then ground above the foot into a round to Ø 9 mm and further as a cone to Ø 6 mm at the tip.

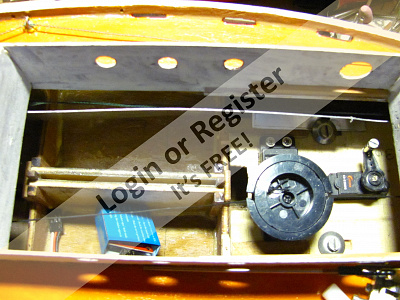

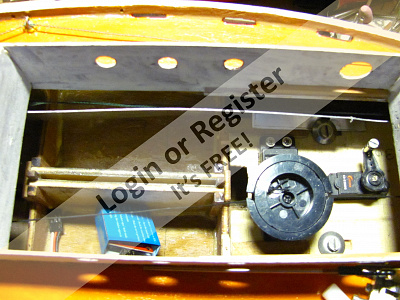

In the main cargo area there is a winch with runneer on rail for main sheet, a lever servo for vangs, auxiliary motor, battery, sound module and relay board, ESC and 8-channel receiver.

I made a bar with a spring in an aluminum holder from U profiles. I fixed there also a runner on a steel rod, from which the sheets will lead on deck to the sail. I set the winch using a servo tester.. it now seems to me to be the most important thing for setting the servos in the model, which otherwise I would have to do with the RC equipment turned on and with the possibility of damaging the servo.

Next I made the base of the sheet winch and base plates for the mizzen servos.

To control the main sheet I bought a 6 turn servo winch with a drum and attached this to the base rail. I stretched the auxiliary loop between two pulleys, one fixed, the other a removable plate for fixing the servo for the rudder

I planned to use additional zwo servos to control the mizzen sail as per Ivor Bittle.

In the end, however, I had to choose a simpler design without the aforementioned servos due to space, by attaching the mizzen sheets directly to the rudder , as far back as possible, as practiced by most English modellers.

Electrical equipment - battery, ESC

I chose a 12V/2.3 Ah gel battery as the battery. I chose this type, among other things, also because it creates a functional load for me. I placed it in the centerline of the boat just behind the fin box. It is built vertically, but I had to lower it as low as possible to guide the reins. For this reason, it was necessary to partially cut off a piece from the height of the keel, fortunately the strength of the structure did not suffer. The 12V voltage distributions to the individual electrical units are controlled by manual switches located on the distribution board (ESC (motor), lighting, sound module, sound module relay, 5V auxiliary power supply for the mini camera). For more convenient switching off of the equipment in the model on the water, the main switch is located behind the companionway hatch on the rear superstructure. Starting and stopping the engine is already done using RC equipment. The receiver of the Rc apparatus and the speaker of the sound module are fixed from below on the cover of the main hold. The electronic controller (ESC) and the relay panel of the engine are located on the side wall of the main cargo compartment.

A servo for controlling the jib sheets is located in the front cargo area. But how it will work is still a big unknown for me -

Installation of auxiliary engine.

During construction, I gathered additional experience from building barge models published on the Internet. I finally decided to add a 12V - 0.35/1.5A electric engine to the model. I can also use the battery capacity without further modifications. I measured everything so that a Ø 40 mm ship screw could be used, and because of the engine it was not necessary to cut the bulkheads. A similar solution was also applied to large barges, the engine was usually on the left side of the hull.

I drilled a hole in the hull, seated the shaft bushing and sealed with Mamut silicone adhesive. I glued the engine bed together from plywood and a wooden wedge to adjust the engine pitch. I couldn't buy the cardan coupling on time, so instead I successfully used a thick-walled PE tube Ø10/Ø4 mm. The engine is fixed to the bed in the shape of a wedge with metal clamps, the bed with the engine to the bottom of the boat with Velcro. The engine is controlled using the MD18DCRS electronic controller (ESC) in the basic setting. . The ESC and sound module (diesel engine) are controlled by one channel of the receiver and wired so that the ESC is in one branch and the sound module in the other branch of the Y cable.

Rig and rigging

I made the shrouds from black waxed cotton string with a diameter of 1mm, backstays from wound cords from parachute cords with a diameter of 0.8mm. I also used these cords for some parts of the moving rigging, as well as for boltropes.

I already had to wind the thinner "ropes" for the sheets and next ropes on the ropewalk (last two pictures)from thin black and brown threads, as well as the "ropes" with a larger diameter from the mentioned cords of Ø 0.8 mm and from the cord of Ø 1 mm. I stained some ropes and impregnated them with nitro varnish , possibly beeswax.

Canvas

I made the sails from a thin cotton sheet, which I dyed brown-red, more or less according to the patterns in the photos. I preliminarily determined the dimensions according to the working drawing on a scale of 1:24. Basically, they are like a trial with the fact that they can be modified.

According to the working drawing, I made paper cuts of the sails, and according to them I cut out the shape of the sails from the fabric with an allowance for edging. Since "here are not people", I folded the hems on the sails myself, pinned them, attached them with thread and sewed them on a sewing machine.On the outer edge of the hems, I again created a reinforcement with a fine "entl" on the sewing machine, which replaced the laborious sewing of the hems with wire for this set of test sails. Large ships have the edges of their sails reinforced with boltrope, which has a different diameter depending on the type and size of the sail, and for Thames barges, using longitudinal sails, it is always sewn on the left side of the sail. In the end, I sewed only the front face of the foresail for the test. It took me almost the whole afternoon…When making the sails on the next model, I already used adhesive tape instead of laboriously sewing the edges of the sails.

To ensure its functionality (which was offered here), so bearings for shaft I made from brass tubes Ø 5/4 mm.

For the pinions, I made a "housing" of brass plate thickness 0.4 mm, soldered to the copper strip 5 x1 x 60 mm with required spacing .This strip it is glued and riveted to the back of the wooden winch knees on the bow.

When compiling the winch, I glued the reel in wrong way , so winch thus not functional. On the front of stem post of the model, I'm stuck copper stem band (with a cross-section 5 x 0.8 mm) and riveted it using short pins. This band is at the upper end provided with an eye for main mast forestay.

On the back of the stern post, I stuck the rudder hinges, and according to them, I placed and stuck the hinges on the rudder. and next.

The anchor is made from copper wire 3 mm dia. Painted black.

Main mast

The main mast is made of aluminum tubes of Ø14/12/10 mm inserted into each other and glued together, with a total length of 57 cm. The lower part of the mast was glued into a foot made of hardwood. Jackstay - auxiliary "stay" used for attaching the front edge of the main sail is made of brass wire Ø 1 mm, soldered to the heads of M2 screws, screwed and glued into the tubes from the back of the mast.

Main topmast

The topmast is made of a Ø8 - Ø6 mm laminate GRP cone from fishing rod with a length of 59 cm and reinforced with a Ø 4 mm carbon tube with a length of 63 cm, which passes through the entire length of the cone and at the same time fulfills the function of extending (the top) of the topmast. It is glued to the cone with PUR glue.

Crosstree

I simplified the crosstree a bit, I didn't have suitable brass profiles, so I made the arms from an old umbrella, so they are foldable, like the original.

Mizzen mast

it is sanded from a 10x10 spruce beam with a length of 28 / 30 cm according to the drawing.

The tabernacle of the mizzen mast, I cut out, bent and welded from copper sheet thickness. 0.5 mm. I drilled a Ø 3.5 mm hole in it for the axis of the rudder, and two Ø 3 mm holes in the feet for attachment to the superstructure. Painted green.

Mainsail sprit,(spreet )

The sprit is made from a beech log with a diameter of 8 mm and a length of 75 cm, ground towards the ends into a slight cone.

Mizzen sprit

it is made from a spruce log with a diameter of 4 mm and a length of 40 cm

The boom of the sail on the back mast

it is made of a spruce log with a diameter of 4 mm and a distance of 27 cm

Bowsprit

The bowsprit is ground from a 10x10 mm spruce beam, 40 cm long. This profile remained on the foot for a length of about 4 cm and was then ground above the foot into a round to Ø 9 mm and further as a cone to Ø 6 mm at the tip.

In the main cargo area there is a winch with runneer on rail for main sheet, a lever servo for vangs, auxiliary motor, battery, sound module and relay board, ESC and 8-channel receiver.

I made a bar with a spring in an aluminum holder from U profiles. I fixed there also a runner on a steel rod, from which the sheets will lead on deck to the sail. I set the winch using a servo tester.. it now seems to me to be the most important thing for setting the servos in the model, which otherwise I would have to do with the RC equipment turned on and with the possibility of damaging the servo.

Next I made the base of the sheet winch and base plates for the mizzen servos.

To control the main sheet I bought a 6 turn servo winch with a drum and attached this to the base rail. I stretched the auxiliary loop between two pulleys, one fixed, the other a removable plate for fixing the servo for the rudder

I planned to use additional zwo servos to control the mizzen sail as per Ivor Bittle.

In the end, however, I had to choose a simpler design without the aforementioned servos due to space, by attaching the mizzen sheets directly to the rudder , as far back as possible, as practiced by most English modellers.

Electrical equipment - battery, ESC

I chose a 12V/2.3 Ah gel battery as the battery. I chose this type, among other things, also because it creates a functional load for me. I placed it in the centerline of the boat just behind the fin box. It is built vertically, but I had to lower it as low as possible to guide the reins. For this reason, it was necessary to partially cut off a piece from the height of the keel, fortunately the strength of the structure did not suffer. The 12V voltage distributions to the individual electrical units are controlled by manual switches located on the distribution board (ESC (motor), lighting, sound module, sound module relay, 5V auxiliary power supply for the mini camera). For more convenient switching off of the equipment in the model on the water, the main switch is located behind the companionway hatch on the rear superstructure. Starting and stopping the engine is already done using RC equipment. The receiver of the Rc apparatus and the speaker of the sound module are fixed from below on the cover of the main hold. The electronic controller (ESC) and the relay panel of the engine are located on the side wall of the main cargo compartment.

A servo for controlling the jib sheets is located in the front cargo area. But how it will work is still a big unknown for me -

Installation of auxiliary engine.

During construction, I gathered additional experience from building barge models published on the Internet. I finally decided to add a 12V - 0.35/1.5A electric engine to the model. I can also use the battery capacity without further modifications. I measured everything so that a Ø 40 mm ship screw could be used, and because of the engine it was not necessary to cut the bulkheads. A similar solution was also applied to large barges, the engine was usually on the left side of the hull.

I drilled a hole in the hull, seated the shaft bushing and sealed with Mamut silicone adhesive. I glued the engine bed together from plywood and a wooden wedge to adjust the engine pitch. I couldn't buy the cardan coupling on time, so instead I successfully used a thick-walled PE tube Ø10/Ø4 mm. The engine is fixed to the bed in the shape of a wedge with metal clamps, the bed with the engine to the bottom of the boat with Velcro. The engine is controlled using the MD18DCRS electronic controller (ESC) in the basic setting. . The ESC and sound module (diesel engine) are controlled by one channel of the receiver and wired so that the ESC is in one branch and the sound module in the other branch of the Y cable.

Rig and rigging

I made the shrouds from black waxed cotton string with a diameter of 1mm, backstays from wound cords from parachute cords with a diameter of 0.8mm. I also used these cords for some parts of the moving rigging, as well as for boltropes.

I already had to wind the thinner "ropes" for the sheets and next ropes on the ropewalk (last two pictures)from thin black and brown threads, as well as the "ropes" with a larger diameter from the mentioned cords of Ø 0.8 mm and from the cord of Ø 1 mm. I stained some ropes and impregnated them with nitro varnish , possibly beeswax.

Canvas

I made the sails from a thin cotton sheet, which I dyed brown-red, more or less according to the patterns in the photos. I preliminarily determined the dimensions according to the working drawing on a scale of 1:24. Basically, they are like a trial with the fact that they can be modified.

According to the working drawing, I made paper cuts of the sails, and according to them I cut out the shape of the sails from the fabric with an allowance for edging. Since "here are not people", I folded the hems on the sails myself, pinned them, attached them with thread and sewed them on a sewing machine.On the outer edge of the hems, I again created a reinforcement with a fine "entl" on the sewing machine, which replaced the laborious sewing of the hems with wire for this set of test sails. Large ships have the edges of their sails reinforced with boltrope, which has a different diameter depending on the type and size of the sail, and for Thames barges, using longitudinal sails, it is always sewn on the left side of the sail. In the end, I sewed only the front face of the foresail for the test. It took me almost the whole afternoon…When making the sails on the next model, I already used adhesive tape instead of laboriously sewing the edges of the sails.

▲

⟩⟩

Chuck

hermank

ChrisF

SimpleSailor

EdW

Mike Stoney

Wolle

Master Seaman)

Master Seaman)

Leading Seaman)

Leading Seaman)

Rear Admiral)

Rear Admiral)

Admiral)

Admiral)

Liked Testing LED diodes 7 days ago

Liked Testing LED diodes 7 days ago

Liked Re: SMS Embden plus maiden video 13 days ago

Liked Re: SMS Embden plus maiden video 13 days ago