Join Us On Social Media!

United Kingdom

Recent Posts

📝 Some good glue

7 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 21 Views · 4 Likes

Flag

💬 Add Comment

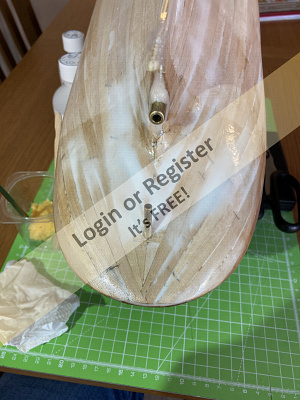

I have done a bit more on the Ton 12. I have re-built the cabin roof from 1.5mm grp sheet and painted it. I stupidly managed to snap the wooden one where the wood was so brittle with age. I have also glazed the cabin windows.

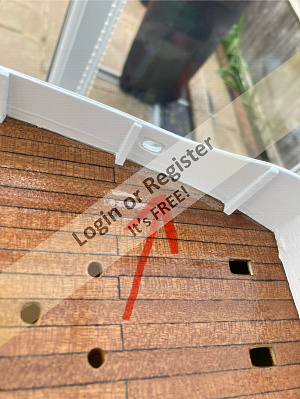

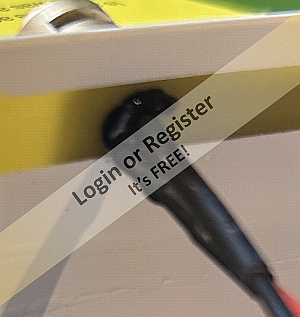

Also I have discovered a rather good glue that I am quite impressed with. It is called T-7000 and I got it on Amazon for about £5. What I like about it is that it is opaque black and sort of rubbery when dry. It is excellent for bonding in LEDs as shown in my picture as it also prevents any light bleeding out at the glue joint. I think it is the sort of thing you find holding in electronic components in phones and the like.

Also I have discovered a rather good glue that I am quite impressed with. It is called T-7000 and I got it on Amazon for about £5. What I like about it is that it is opaque black and sort of rubbery when dry. It is excellent for bonding in LEDs as shown in my picture as it also prevents any light bleeding out at the glue joint. I think it is the sort of thing you find holding in electronic components in phones and the like.

▲

⟩⟩

Len1

RNinMunich

Wolle

AlessandroSPQR

Login To

Remove Ads

Remove Ads

📝 A bit more completed

7 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 27 Views · 6 Likes

Flag

💬 Add Comment

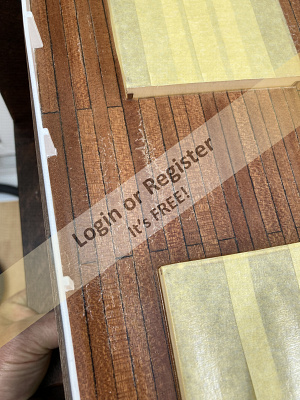

I have varnished the deck and wheelhouse, made up some of the other superstructures and built the crab cooker. I have ‘borrowed’ a winch from a now worse for wear crab fishing boat (Billing boats version) my dad made in the late 60’s - early 70’s. Might borrow some other bits too…

▲

⟩⟩

GavJ

Len1

EdW

Wolle

AlessandroSPQR

jumpugly

📝 Starting to look like a boat now….

8 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 42 Views · 10 Likes

Flag

💬 Add Comment

▲

⟩⟩

GARTH

GavJ

Len1

EdW

jumpugly

AlessandroSPQR

Mike Stoney

hermank

Wolle

SimpleSailor

💬 Re: Graupner Ton 12 Krabbekutter

8 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 46 Views · 8 Likes

Flag

💬 Add Comment

Thanks Alessandro for your comments. I came late to model boats as I have always been an RC plane builder and flyer for about 35 years, so that was my first passion I guess. Appreciating that this is a model boat site so I wont overdo it on photos but I just completed a ducted fan English Electric Lightning (flies well but very fast) and am now working on an RBC Kits P47…

▲

⟩⟩

xtramaths

EdW

Len1

hermank

Wolle

RNinMunich

peterd

AlessandroSPQR

💬 Re: Graupner Ton 12 Krabbekutter

8 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 71 Views · 6 Likes

Flag

💬 Add Comment

Hi Wolle. Those pictures are great! Thanks very much. It is all going well so far although I suspect what I have done so far is the easy bit as I have not yet started the masts and rigging 🙂

▲

⟩⟩

hermank

Mike Stoney

Len1

jumpugly

Wolle

AlessandroSPQR

📝 Graupner Ton 12 Krabbekutter

8 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 73 Views · 19 Likes · 8 Comments

Flag

💬 Add Comment

Last year I was given a well-worn but mostly intact Graupner Ton 12 Krabbekutter kit by a neighbour clearing out his parents old home. I have decided to start it. Much of the wood is brittle and fairly well warped (but should be ok with some love and attention). The packs of smaller deck fittings were missing but I managed to purchase them on ebay (amazing that someone had the unused bags of fittings up for sale on their own). It is the first time I have built an ABS plastic hull. I have fitted a small MFA 2.5:1 geared motor I had aside for another project and a 2mm propshaft to a 30mm 3 blade prop. I will be using 6v and an initial test in the hot tub shows this will probably be fine. I’m not going to rush this project as I am also completing an RC plane at the same time but I will post pictures as the various elements take shape… so far I have installed the gear, built the wheelhouse shell and framed the underside of the deck.

▲

⟩⟩

GavJ

DWBrinkman

SimpleSailor

RNinMunich

Rookysailor

IanL1

Ray

roycv

Len1

LeeA1

BarryS

SouthportPat

jumpugly

DuncanP

AlessandroSPQR

Wolle

hermank

Mike Stoney

EdW

💬 Re: Ulises Tug (Occre kit) : Aged 66¼ 🙂

9 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 68 Views · 6 Likes

Flag

💬 Add Comment

Hiya.

Looking good!

It is reasonably pointy and made sharper with the addition of the keel strip (in your kit this is in three parts, one of which is ‘u’ shaped to fit the profile of the bow.)

Have attached a couple of pics of mine.

Looking good!

It is reasonably pointy and made sharper with the addition of the keel strip (in your kit this is in three parts, one of which is ‘u’ shaped to fit the profile of the bow.)

Have attached a couple of pics of mine.

▲

⟩⟩

SouthportPat

SimpleSailor

hermank

GARTH

RodC

Wolle

💬 Re: On the water

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 27 Views · 2 Likes

Flag

💬 Add Comment

▲

⟩⟩

Mike Stoney

AlessandroSPQR

📝 On the water

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 43 Views · 10 Likes · 2 Comments

Flag

💬 Add Comment

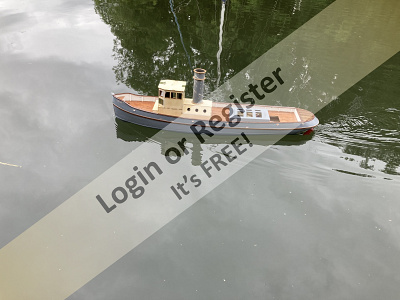

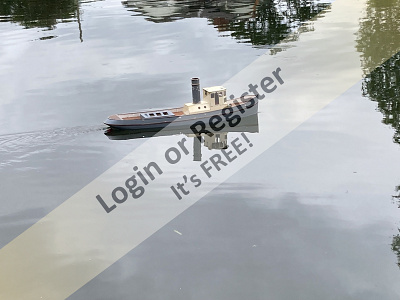

Managed to get out and test the Occre Ulisis today. I added one of the super cheap plug and play sound modules that Garth mentioned in his blog post a week or so ago (from Aliexpress). Water was a bit choppy but I am really pleased with how she looks on the water.

▲

⟩⟩

luckyduck

hermank

Isaac

RNinMunich

Mike Stoney

Doogle

Commodore-H

Wolle

Len1

AlessandroSPQR

💬 Re: Modified Lesro Stiletto

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 64 Views · 3 Likes

Flag

💬 Add Comment

That looks great!

▲

⟩⟩

jbkiwi

Len1

hermank

💬 Re: Jimwilder Tug diesel sound generator

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 271 Views · 2 Likes

Flag

💬 Add Comment

Just ordered one. Will be interested to experiment with it…

▲

⟩⟩

hermank

Len1

Login To

Remove Ads

Remove Ads

💬 Re: 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 61 Views · 2 Likes

Flag

💬 Add Comment

Many thanks RN - I dunno about Neptune, but I am very pleased with how she has turned out 🙂 Thoughts now turn to what to do next 🤔

▲

⟩⟩

hermank

RNinMunich

💬 Re: 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 67 Views · 1 Like

Flag

💬 Add Comment

Thanks so much Doogle. Appreciated.

▲

⟩⟩

hermank

💬 Re: 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 81 Views · 1 Like

Flag

💬 Add Comment

Thanks Isaac, it has been a fun kit to build.

▲

⟩⟩

hermank

💬 Re: 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 87 Views · 3 Likes

Flag

💬 Add Comment

Thanks DW and Alessandro. Appreciate your comments 👍

▲

⟩⟩

Mike Stoney

hermank

AlessandroSPQR

💬 Re: 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 87 Views · 2 Likes

Flag

💬 Add Comment

Thanks Phil and Michel 🙏🏻

▲

⟩⟩

Mike Stoney

hermank

💬 Re: 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 88 Views · 3 Likes

Flag

💬 Add Comment

Thank you Ronald

▲

⟩⟩

Mike Stoney

hermank

Len1

📝 99% finished

12 months ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 88 Views · 17 Likes · 15 Comments

Flag

💬 Add Comment

I’m just waiting for the frame that supports the lifeboats to dry and then I can add those. Hopefully the next update will be of her on the water…

▲

⟩⟩

MartyV

cjanik001

luckyduck

RNinMunich

peterd

AlessandroSPQR

Doogle

Chuck

Isaac

hermank

DWBrinkman

RossM

Wolle

BarryS

Len1

Mike Stoney

Ronald

📝 A bit more progress

1 year ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 94 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

I’ve been a bit quiet on the forum for a while as life’s other priorities are dealt with. On occasion I have found time to do bits and pieces on the tug however. I have pretty much finished the woodwork and am now awaiting a decent day to do some varnishing of the planking on the wheelhouse.

▲

⟩⟩

Chuck

hermank

Wolle

Len1

Mike Stoney

Isaac

AlessandroSPQR

RNinMunich

📝 Hull painted

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 108 Views · 10 Likes · 5 Comments

Flag

💬 Add Comment

Well that is the hull done now I think. The green took several coats to get right. I decided Humbrol gloss #3 was a bit too bright for my liking so I mixed in some gloss black before I sprayed it until it looked about right to my tastes and I am quite happy with the result.

▲

⟩⟩

Chuck

hermank

Len1

EdW

MartinW

Mike Stoney

flaxbybuck

RNinMunich

Wolle

AlessandroSPQR

📝 It has been a while

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 115 Views · 9 Likes

Flag

💬 Add Comment

I have had limited time to build recently, but in the recent run of good weather I have made a start to the painting of the hull and superstructure on the Occre Ulises. All the paints are either Humbrol or Revell enamels and have been thinned about 40-50% for airbrushing. I still have to do another coat of the antifouling red and then I am going for a dark green upper hull to leave a thin white waterline between the two.

▲

⟩⟩

jbkiwi

MartyV

EdW

Mike Stoney

RNinMunich

Len1

Wolle

Peejay

PhilH

Login To

Remove Ads

Remove Ads

📝 Fibreglassing a wooden hull

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 57 Views · 6 Likes

Flag

📝 Reply

Regarding whether to use the cloth or not. This is just my preference but I always would as it has lots of pros… It is easy once you get used to it. It helps give a uniform surface. It adds a lot of strength to woods like balsa and other softer types (but if anyone is worried about protection from their boat being hit by another - well it wont really save you from that resultant damage depending on speeds etc). I guess ultimately it is up to yourself. If you are after a beautiful wood finish maybe avoid the cloth as in the right lights and on close inspection you can sometimes still see some weave. Like someone said earlier maybe best to do a test piece and see what you think after that. Best of luck with it whichever route you go 👍🏻

▲

⟩⟩

Commodore-H

Len1

robbob

hermank

DuncanP

AlessandroSPQR

📝 Fibreglassing a wooden hull

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 57 Views · 7 Likes

Flag

📝 Reply

Hi Roy.

I use halfords spray paint (cans) over my glassed hulls also with no problems. I have also used airbrushed Humbrol enamels. No problems with either. I also tend to use the halfords grey primer ( several coats rubbed down with wet and dry) as a base coat regardless of whether I am ultimately finishing with enamel or other halfords colours.

I have never used pigments to colour any epoxy resin I have used so I cannot advise on that one I am afraid. Cheers.

I use halfords spray paint (cans) over my glassed hulls also with no problems. I have also used airbrushed Humbrol enamels. No problems with either. I also tend to use the halfords grey primer ( several coats rubbed down with wet and dry) as a base coat regardless of whether I am ultimately finishing with enamel or other halfords colours.

I have never used pigments to colour any epoxy resin I have used so I cannot advise on that one I am afraid. Cheers.

▲

⟩⟩

Commodore-H

Len1

robbob

hermank

roycv

DuncanP

AlessandroSPQR

📝 Fibreglassing a wooden hull

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 52 Views · 3 Likes

Flag

📝 Reply

Hi roy, when i rub down the initial coat the first time it is just a very light touch done dry, just to knock any sharp high spots off. Ie where a glass strand may have protruded slightly or whatever . After that when i have put the second coat of resin on , yes I do that wet with a bit of washing up liquid in the water.

If you were resining without cloth, I am guessing it would be similar and you could go for wet sanding after a couple of coats of resin…

If you were resining without cloth, I am guessing it would be similar and you could go for wet sanding after a couple of coats of resin…

▲

⟩⟩

DuncanP

roycv

AlessandroSPQR

📝 Fibreglassing a wooden hull

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 67 Views · 8 Likes

Flag

📝 Reply

Hi. I do a lot of glass fibre covering on both boats and planes. I would use 0.6 oz or 1oz per sq yard weight cloth. Take a look at my blog of my occre ulises as it shows how i do it.

In a nutshell:

I use bucks composites resin or finishing resin from Zap./pacer

Once mixed i personally add a bit of meths to thin it.

Be precise with the mix ratios as the instructions specify. This is critical. I mix by weight and use a digital scale that i got off ebay.

Once I have mixed it I tend to let it sit for a few minutes, maybe 5, before I start to work with it.

Personally I lay the cloth on dry, having first made sure the surface of the wood is smooth and blemish free

I dab the mixed epoxy resin on with a bit of torn sponge. With fine cloths, if you use a brush you can snag and wrinkle it, hence the sponge and dabbing technique. You can also use an old credit card to scrape the resin around on the cloth if you are careful.

Once it is saturated i keep dabbing to remove as much excess resin as poss. You only need enough to get it to stick at this stage. Too much anf you will have a lot more rubbing down to do which should really be unnecessary. Looking along the wet cloth, if it is a sort of ‘satin’ finish then it is about right, if it is glossy in places there is a bit too much resin there and you can dab that off with toilet tissue (see below).

You may need to make small snips in the cloth in places where the curves are severe, but it is pretty good with compound curves.

I then use toilet tissue wadded up to dab any additional excess resin away. It will not stick to the epoxy in its pre-cured state.

The epoxy mix will be workable for about 30 mins. The warmer the environment the faster it will go off.

Let it dry overnight. I sometimes put my covered components in the airing cupboard where the HW tank is if it is a cold day.

Once dry and no longer tacky….

320 grit glasspaper to cut the excess off that overhangs the edges

A REALLY light sanding with 320 grit all over to remove any roughness. Not too much as you don’t want to sand off the cloth.

Mix some more epoxy resin up and paint it on or dab it on with another bit of torn sponge. This fills what is left of the weave.

Wet and dry sanding to give a glass like finish for painting

H&S: do wear a mask for sanding. You dont want epoxy and glass dust in your lungs!

Lots of youtube videos out there showing methods similar to described above.

Oh, one more tip. Get a box of nitrile gloves from amazon or somewhere. You will go through a lot of them. Use meths to clean up scissors and other tools.

In a nutshell:

I use bucks composites resin or finishing resin from Zap./pacer

Once mixed i personally add a bit of meths to thin it.

Be precise with the mix ratios as the instructions specify. This is critical. I mix by weight and use a digital scale that i got off ebay.

Once I have mixed it I tend to let it sit for a few minutes, maybe 5, before I start to work with it.

Personally I lay the cloth on dry, having first made sure the surface of the wood is smooth and blemish free

I dab the mixed epoxy resin on with a bit of torn sponge. With fine cloths, if you use a brush you can snag and wrinkle it, hence the sponge and dabbing technique. You can also use an old credit card to scrape the resin around on the cloth if you are careful.

Once it is saturated i keep dabbing to remove as much excess resin as poss. You only need enough to get it to stick at this stage. Too much anf you will have a lot more rubbing down to do which should really be unnecessary. Looking along the wet cloth, if it is a sort of ‘satin’ finish then it is about right, if it is glossy in places there is a bit too much resin there and you can dab that off with toilet tissue (see below).

You may need to make small snips in the cloth in places where the curves are severe, but it is pretty good with compound curves.

I then use toilet tissue wadded up to dab any additional excess resin away. It will not stick to the epoxy in its pre-cured state.

The epoxy mix will be workable for about 30 mins. The warmer the environment the faster it will go off.

Let it dry overnight. I sometimes put my covered components in the airing cupboard where the HW tank is if it is a cold day.

Once dry and no longer tacky….

320 grit glasspaper to cut the excess off that overhangs the edges

A REALLY light sanding with 320 grit all over to remove any roughness. Not too much as you don’t want to sand off the cloth.

Mix some more epoxy resin up and paint it on or dab it on with another bit of torn sponge. This fills what is left of the weave.

Wet and dry sanding to give a glass like finish for painting

H&S: do wear a mask for sanding. You dont want epoxy and glass dust in your lungs!

Lots of youtube videos out there showing methods similar to described above.

Oh, one more tip. Get a box of nitrile gloves from amazon or somewhere. You will go through a lot of them. Use meths to clean up scissors and other tools.

▲

⟩⟩

jumpugly

PirateJohn

AlessandroSPQR

robbob

DuncanP

johnf

roycv

hermank

📝 Wordle of the Day?

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 43 Views · 0 Likes

Flag

📝 Reply

Was about to hit rock bottom when I got it on 5 😀

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Wordle of the Day?

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 42 Views · 1 Like

Flag

📝 Reply

In three…⛵️

▲

⟩⟩

Doogle

📝 Brushless setup

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 63 Views · 6 Likes

Flag

📝 Reply

I did a setup with a shark esc recently.

Ensure receiver is bound first to the transmitter

Turn on tx

Put throttle to high

Connect main drive battery

Return throttle to neutral after first beep

Wait for startup tones

It should then work ‘normally’

Stay clear of prop though throughout in case it runs up!

After that it should all be fine and you can next time just turn on tx and connect battery. The first time you are basically teaching the esc the ‘high point’ of your throttle range

IF it runs the wrong way i.e goes in reverse instead of forward then simply swap over two of the three wires from the esc to motor. Do NOT reverse the throttle on the transmitter

Ensure receiver is bound first to the transmitter

Turn on tx

Put throttle to high

Connect main drive battery

Return throttle to neutral after first beep

Wait for startup tones

It should then work ‘normally’

Stay clear of prop though throughout in case it runs up!

After that it should all be fine and you can next time just turn on tx and connect battery. The first time you are basically teaching the esc the ‘high point’ of your throttle range

IF it runs the wrong way i.e goes in reverse instead of forward then simply swap over two of the three wires from the esc to motor. Do NOT reverse the throttle on the transmitter

▲

⟩⟩

Razor1955

flaxbybuck

hermank

RogerA1

Len1

AlessandroSPQR

📝 Wordle of the Day?

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 47 Views · 1 Like

Flag

📝 Reply

In 4

▲

⟩⟩

cumbrae

📝 Battery's

2 years ago by 🇬🇧 Trident73 ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 95 Views · 12 Likes

Flag

📝 Reply

I’m not 100% sure on this one but my understanding was that Lipos can better withstand the higher discharge loads that a brushless motor will place on the pack. Like I say, I am not totally sure and others will certainly know better but you may find that your voltage under load drops more with a nimh and that the pack discharges a bit faster than with a lipo. Personally I have only used Lipos with my brushless setups.

▲

⟩⟩

Razor1955

Commodore-H

Doogle

Fred

RodC

RNinMunich

PirateJohn

algon

Len1

PhilH

hermank

AlessandroSPQR

Commodore)

Commodore)

Rear Admiral)

Rear Admiral)

Fleet Admiral)

Fleet Admiral)

Vice Admiral)

Vice Admiral)

Midshipman)

Midshipman)

Liked Coat of paint 8 months ago

Liked Coat of paint 8 months ago