Join Us On Social Media!

Canada

Recent Posts

📝 Lines plan

8 months ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 31 Views · 3 Likes

Flag

📝 Reply

The vessel in question is the Isle of Man ferry "Ben-my-chree" of 1927. I found two sources for the plans I need, but neither of them had the lines plan. Nor did they have the lines plans for their close sisters "Lady of Mann" 1930 and "Mona's Queen", 1934.

My google searching has displayed many pictures and sketches of a counter stern, but no lines plans. There was one body plan shown, but that was for a single screw vessel, not twin screw.

My google searching has displayed many pictures and sketches of a counter stern, but no lines plans. There was one body plan shown, but that was for a single screw vessel, not twin screw.

▲

⟩⟩

SimpleSailor

Len1

hermank

Login To

Remove Ads

Remove Ads

📝 Lines plan

8 months ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 38 Views · 3 Likes

Flag

📝 Reply

Does anyone have a lines plan for a twin-screw vessel with a counter stern? I have all the plans I need to build a scale model, except the lines plan. If someone has a lines plan I'm hoping I can tweak it to suit my model.

▲

⟩⟩

Len1

SimpleSailor

hermank

📝 Ben-my-chree(4) plan

9 months ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 15 Views · 3 Likes

Flag

📝 Reply

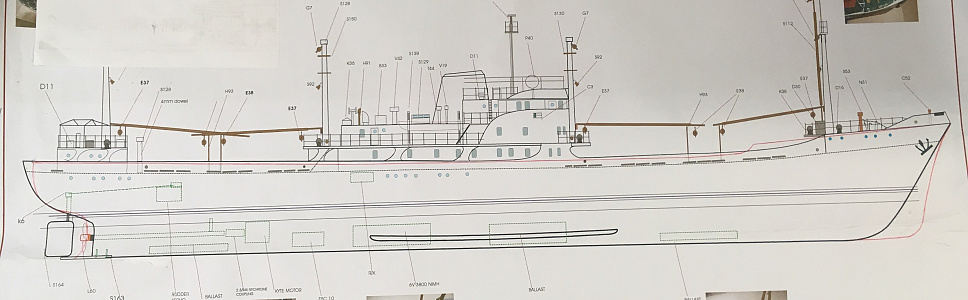

I am happy to learn that Wirral Archives have a complete set of the GA drawings for this vessel, so I will be able to obtain the copies I need.

Roy

Roy

▲

⟩⟩

RossM

alexandre

SouthportPat

📝 Ben-my-chree(4) plan

9 months ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 38 Views · 2 Likes

Flag

📝 Reply

Yes, the fourth ship bearing the name of "Ben-my-chree" built in 1927 by Cammell Laird at Birkenhead. Scrapped in 1965. The Manx Museum in Douglas have a copy of the required drawing but are unable to copy or photograph it.

Roy

Roy

▲

⟩⟩

alexandre

SouthportPat

📝 Ben-my-chree(4) plan

9 months ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 40 Views · 3 Likes

Flag

📝 Reply

I'm looking for a profile plan, labelled "Rigging Plan" by the shipbuilder, of this vessel. Happy to pay for a any costs associated with providing a copy.

Also interested in any details of the modifications made to the vessel for D-Day,

Roy

Also interested in any details of the modifications made to the vessel for D-Day,

Roy

▲

⟩⟩

alexandre

hermank

SouthportPat

📝 GLynn Guest's IJN Kirisame

2 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 35 Views · 0 Likes

Flag

📝 Reply

Does anyone have a copy of the Model Boats magazine from February 2015, complete with the plan for the Kirisame free plan? If so, I would like to obtain a copy of the plan. I can buy the accompanying article from the internet but have not found the plan for sale.

My 11-year old grandson is keen to build a model of a Japanese destroyer and this model would suit him well.

I'll be happy to reimburse any costs involved.

Roy

My 11-year old grandson is keen to build a model of a Japanese destroyer and this model would suit him well.

I'll be happy to reimburse any costs involved.

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Re: SS Empress of Canada

3 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 69 Views · 1 Like

Flag

💬 Add Comment

Thanks, it is indeed.

▲

⟩⟩

Peejay

💬 Re: SS Empress of Canada

3 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 78 Views · 2 Likes

Flag

💬 Add Comment

Thanks. The model is substantially scratchbuilt. Some parts, such as the photo-etched railings, were purchased.The VIc Smeed plan was actually of the Empress of Britain, an earlier and very similar vessel. I used Smeed's plan as well as low resolution profile and deck plans on the TyneBuiltShips website and photos as the basis for the model.

The final Empress of Japan entered service in 1929, was renamed Empress of Scotland in 1942 (for obvious reasons) and was sold and renamed Hanseatic in 1957.

The final Empress of Japan entered service in 1929, was renamed Empress of Scotland in 1942 (for obvious reasons) and was sold and renamed Hanseatic in 1957.

▲

⟩⟩

Colin H

RedCatcher

📝 SS Empress of Canada

3 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 6 Views · 15 Likes · 8 Comments

Flag

💬 Add Comment

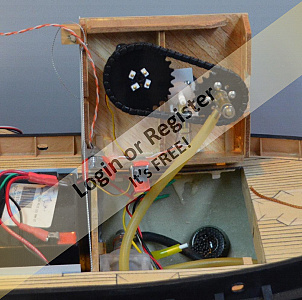

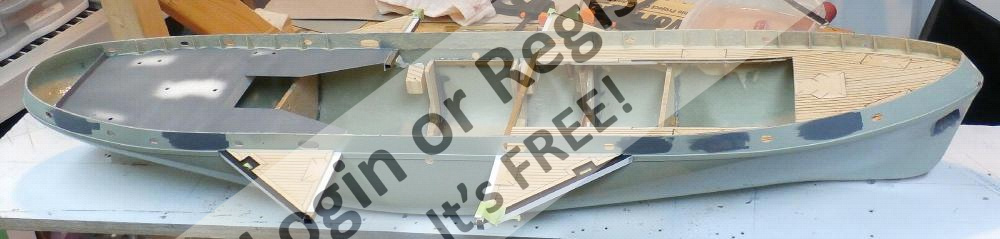

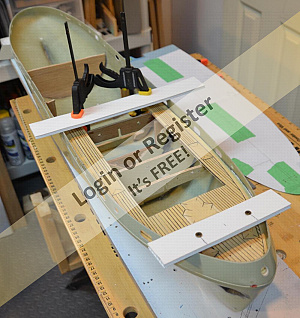

Canadian Pacific Steamships last passenger liner and Carnival's first cruise ship Mardi Gras. The model is 1:160 scale, 49" long, 17lbs, powered by twin 40mm props and two RE385 motors via 1:2 ratio timing belts.The power source is 12V using packs of Eneloop Pro NiMH batteries, giving a running time of about one hour. Auxiliaries include motor driven radar scanner and steam unit, the latter scratchbuilt using styrene for the tank plus working parts from eBay etc.

▲

⟩⟩

Double Rum

MouldBuilder

Ronald

RNinMunich

RodC

TonyAsh

pressonreguardless

Colin H

johnymontana

PeterJ

Rowen

River Rat

roycv

Peejay

Graham93

💬 Re: RN. DARK CLASS

4 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 247 Views · 0 Likes

Flag

💬 Add Comment

Why did I build the 'Wahine'?

I can still recall where I was when news of the ship's sinking played out on TV. A few years later, my first job as a student engineer at then-AEI in Manchester UK was working beside the engineer responsible for the design of it's successor, the Rangatira's, main steam turbines. When I considered building a model of the Rangatira I thought the looks of her were spoilt by the funnel shape and, since it was almost a duplicate of the Wahine, I opted to build the Wahine.

Roy

PS. I have seen Rowen's models up close and his posts here do not do justice to the quality and detail that he puts into every model. Every detail is scratcbuilt and accurately constructed.

I can still recall where I was when news of the ship's sinking played out on TV. A few years later, my first job as a student engineer at then-AEI in Manchester UK was working beside the engineer responsible for the design of it's successor, the Rangatira's, main steam turbines. When I considered building a model of the Rangatira I thought the looks of her were spoilt by the funnel shape and, since it was almost a duplicate of the Wahine, I opted to build the Wahine.

Roy

PS. I have seen Rowen's models up close and his posts here do not do justice to the quality and detail that he puts into every model. Every detail is scratcbuilt and accurately constructed.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 IOMSPC's catamaran ferry "Manannan"

7 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 9 Views · 1 Like

Flag

💬 Add Comment

▲

⟩⟩

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Mtronics W-tail marine mixer connections.

7 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 11 Views · 2 Likes

Flag

📝 Reply

Hi Colin,

I have just been catching up on this commentary which was prompted by your initial question. in running my 'Forceful' tug I found that varying paddle speeds, i.e. a mixer, is unnecessary for steering. I run it with the paddles at the same speed, and the rudder handles the steering alone just fine. I wonder if you have run your model, and confirmed that you have to vary paddle speeds to turn? if so, another option is to replace the rudder with a bigger one.

Roy

I have just been catching up on this commentary which was prompted by your initial question. in running my 'Forceful' tug I found that varying paddle speeds, i.e. a mixer, is unnecessary for steering. I run it with the paddles at the same speed, and the rudder handles the steering alone just fine. I wonder if you have run your model, and confirmed that you have to vary paddle speeds to turn? if so, another option is to replace the rudder with a bigger one.

Roy

▲

⟩⟩

Colin H

RNinMunich

📝 Empress of Canada 1961

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 0 Likes

Flag

📝 Reply

I am interested in getting in touch with anyone who has built a sailing model of "Empress of Britain" or "Empress of England" to Vic Smeed's plan. I'd like to know if they built to scale draft, and if the model was stable and sat at waterline depth.

Roy

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Steam sound unit (variable speed)

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 0 Likes

Flag

📝 Reply

Eric,

Here's another option to consider:

Here's another option to consider:

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Props

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 0 Likes

Flag

📝 Reply

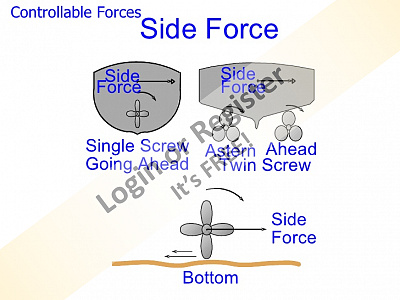

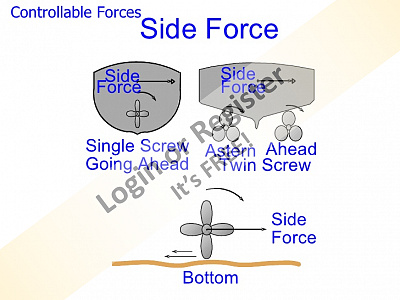

This rotation question seems to pop up regularly.

Probably for a model, rotation direction doesn't really matter, but one authoritative answer can be found here:

Probably for a model, rotation direction doesn't really matter, but one authoritative answer can be found here:

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 HMS Dreadnought

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 0 Likes

Flag

💬 Add Comment

I sympathise Norm. I contacted the Tyne and Wear Museum for plans of the "Empress of Canada". I would need 5 sheets, 4 at £42 each and one at £63. £231!!! Not economical for a retired model builder.

Roy

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 MV TEAKWOOD

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 14 Views · 0 Likes

Flag

💬 Add Comment

It's looking really good. The superstructure front looks like the most difficult part of the whole model. What thickness of styrene did you use?

Roy

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 lots of sanding

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 15 Views · 0 Likes

Flag

💬 Add Comment

The main advantage of Eze-kote may be its main disadvantage: it's water-based. As stated on the Great Hobbies website, "This product may be damaged by freezing. Shipping during periods of weather below zero is not recommended." So in Canada, shipping between December and May is not recommended. it does not state "Protect from freezing" on the bottle, but it would be helpful if someone who has tried it can confirm it's OK after freezing.

There are 4 Great Hobbies stores in Canada if you are lucky enough to be able to visit and pick up the product.

Roy

There are 4 Great Hobbies stores in Canada if you are lucky enough to be able to visit and pick up the product.

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 Prop Shaft Grease

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 10 Views · 1 Like

Flag

📝 Reply

Doug, you are correct. Another CRAFT moment.

Roy

Roy

▲

⟩⟩

onetenor

📝 Prop Shaft Grease

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 10 Views · 1 Like

Flag

📝 Reply

Yes, if it is one of the type identified as "totally maintenance-free and watertight".

Roy

Roy

▲

⟩⟩

onetenor

📝 Prop Shaft Grease

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 10 Views · 1 Like

Flag

📝 Reply

Hi Dave,

I guess I have not run my models long enough yet since I have had no wear in either shafts, bearings or seals. I did have one seal in a Raboesch assembly, in a twin shaft model, which didn't leak but seemed to be deteriorating. Raboesch supplied a replacement free of charge. I had used Goop adhesive to attach the seal/bearing cap so it was a 5 minute job to soften the adhesive with a heat gun and fit the replacement.

Roy

I guess I have not run my models long enough yet since I have had no wear in either shafts, bearings or seals. I did have one seal in a Raboesch assembly, in a twin shaft model, which didn't leak but seemed to be deteriorating. Raboesch supplied a replacement free of charge. I had used Goop adhesive to attach the seal/bearing cap so it was a 5 minute job to soften the adhesive with a heat gun and fit the replacement.

Roy

▲

⟩⟩

onetenor

Login To

Remove Ads

Remove Ads

📝 Prop Shaft Grease

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 11 Views · 2 Likes

Flag

📝 Reply

Every time I see a post about lubricating a prop shaft I wonder why more people don't used sealed prop shafts, such as those made by Raboesch and others. it's clearly not an option if your model has the prop shaft already in place but for new construction it's a case of 'fit and forget'. I have not used anything else, ever. is the extra cost the only disincentive to their universal adoption?

Roy

Roy

▲

⟩⟩

onetenor

RNinMunich

💬 M.V. TEAKWOOD

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 14 Views · 0 Likes

Flag

💬 Add Comment

It's one of the facets of scratchbuilding that is little talked about. it seems inevitable that undesirable features (I don't want to say errors) will occur and then there's some serious head-scratching about whether to ignore, cover up, fix (and how to) or start again. This is a great encouragement to others facing similar dilemmas to figure out a fix.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

📝 rotating radars off mast

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 0 Likes

Flag

📝 Reply

Dave,

Thanks for the tip about using the stepper motors. I found some 6mm x 6mm motors on ebay which will be ideal for mast mounted radars on a future project.

Roy

Thanks for the tip about using the stepper motors. I found some 6mm x 6mm motors on ebay which will be ideal for mast mounted radars on a future project.

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 HMS Dreadnought

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 8 Views · 0 Likes

Flag

💬 Add Comment

Norm,

Going by the picture you posted it looks like you are building the Dreadnought that was commissioned in 1884. is that correct?

Roy

Going by the picture you posted it looks like you are building the Dreadnought that was commissioned in 1884. is that correct?

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 HMS Illustrious Aircraft carrier

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 13 Views · 0 Likes

Flag

💬 Add Comment

Well up to your usual high standard,Norm. Too modest as usual, looks great.

Roy

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Klondike

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 15 Views · 3 Likes

Flag

💬 Add Comment

Great work. A superb example of how a scale model gives viewers a 3D view of something that exists now only in 2D images.

▲

⟩⟩

Dave M

Brucef102

Brightwork

💬 paddle tug Aid

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 10 Views · 0 Likes

Flag

💬 Add Comment

A really intriguing choice of model, and a great example of where inspiration can be found for a scratch-built model. I will look forward to seeing a picture of the finished vessel. I notice that the book does not contain any information on the hull lines; what did you use as the source for the shape of your frames?

Roy

Roy

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

💬 Lights all wired up

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 12 Views · 1 Like

Flag

💬 Add Comment

Hi NPJ,

You may find the reference here to LED's and resistors useful.

Roy

You may find the reference here to LED's and resistors useful.

Roy

▲

⟩⟩

NPJ

📝 web site

8 years ago by 🇨🇦 Trillium ( Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)

Chief Petty Officer 1st Class)✧ 37 Views · 1 Like

Flag

💬 Add Comment

In view of Doug's experience, we contacted Godaddy. They advised us that we need SSL certification for our site. I'm a complete novice when it comes to website design and security but I learnt two things. One is that SSL is indicated by the green padlock and the 's' in https in the address bar. The second is that it's considered vital if sensitive information is being transmitted, such as credit card data, usernames and passwords, etc. And of course, SSL costs money. A scan of the list of clubs on this website showed that only one has SSL and they are using Google Sites, Google being actively pushing for SSL on everything. We are a group of model boaters whose website is simply making available for viewing some of our activities, we are not collecting anything from visitors. in conclusion, we will not be making any changes, and so McAfee users will continue to receive the message Doug reported.

Roy

Roy

▲

⟩⟩

RNinMunich

Fleet Admiral)

Fleet Admiral)

Liked rotating radars off mast 8 years ago

Liked rotating radars off mast 8 years ago

Liked M.V. TEAKWOOD 9 years ago

Liked M.V. TEAKWOOD 9 years ago