Join Us On Social Media!

United Kingdom

Recent Posts

📝 Battery Box and Receiver Cover

1 year ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 39 Views · 3 Likes

Flag

📝 Reply

Even if you do use a sealed box it’s always a good back up to put a rubber balloon over your receiver and battery pack with a elastic band sealing were the cables enter. 😎

▲

⟩⟩

Mike Stoney

firefighter

hermank

Login To

Remove Ads

Remove Ads

💬 Re: THE END

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 211 Views · 1 Like

Flag

💬 Add Comment

Great Job 😎JT

▲

⟩⟩

Martin555

📝 Home Brew Motor Mount for a Outrunner

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 2 Likes

Flag

📝 Reply

Hi Boatshed thanks for your interest.

It’s the Aerokits Fast Patrol Boat. I do have some pictures and a short video on another thread on this forum called What Watts/Kg and Cooling.

Here are some more.

Good luck with your mount.

JT

It’s the Aerokits Fast Patrol Boat. I do have some pictures and a short video on another thread on this forum called What Watts/Kg and Cooling.

Here are some more.

Good luck with your mount.

JT

▲

⟩⟩

BOATSHED

Martin555

📝 Home Brew Motor Mount for a Outrunner

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 8 Views · 5 Likes

Flag

📝 Reply

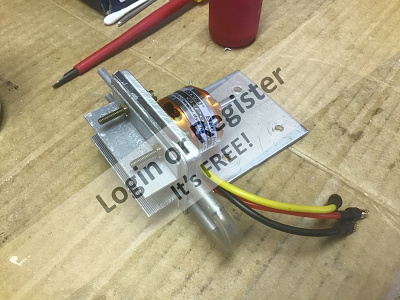

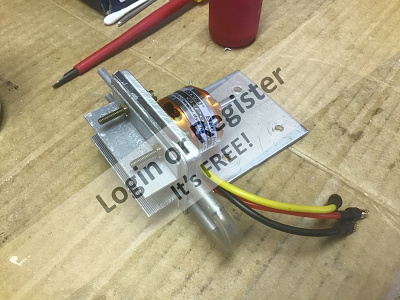

I needed to come up with a solution to adding water cooling to a outrunner motor mount.

I decided to use some 3.5mm aluminium tubing as it was a good size and a good conductor of heat. Only two tubes were used as the mount is small but more tubes could be added to larger mounts. 3mm aluminium was used for the packing in-between the tubes, being slightly smaller meant the tubes clamped nicely in place when the mount was assembled (see picture below).

Finally L shaped cooling fins were added to the back of the mounting to improve cooling.

The mount seems to be doing its job as my little motor is now running cool.

JT 😎

I decided to use some 3.5mm aluminium tubing as it was a good size and a good conductor of heat. Only two tubes were used as the mount is small but more tubes could be added to larger mounts. 3mm aluminium was used for the packing in-between the tubes, being slightly smaller meant the tubes clamped nicely in place when the mount was assembled (see picture below).

Finally L shaped cooling fins were added to the back of the mounting to improve cooling.

The mount seems to be doing its job as my little motor is now running cool.

JT 😎

▲

⟩⟩

jbkiwi

BOATSHED

RNinMunich

marky

Graham93

📝 What Watts/KG and Motor Cooling

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 3 Likes

Flag

📝 Reply

AEROKITS FAST PATROL BOAT SEA TRIALS

High pressure and calm conditions yesterday evening gave me perfect conditions for initial sea trials of my little fast patrol boat on our local lake.

As you can see from the video below the tiny out-runner brushless motor used has a amazing amount of power. I used the smaller 2 blade propeller and even half throttle brought the little fast patrol boat onto a scale like plane.

Coming back to the original question posed by this thread What Watts/Kg ? I would conclude that in my case a good rule of thumb would be 50 watts/kg for a sports model boat like this.

MY TRANSMITTER SET UP.

I found setting the rudder up at 50% on the transmitter aileron rate switch was ideal for cruising around I then flicked the switch to full throw for slow speed manoeuvring this worked well for me.

I also set up a timer for 15 mins but even after a 20 minute run there was plenty of power left in the 2200mAh 3 cell LiPo pack so this power train set up works well.

COOL RUNNING.

The original bath test caused the motor to overheat. I have now rectified the problem by carrying out the following 3 steps below.

MOTOR PROP-SHAFT ALINEMENT. Although this was originally OK, I have fine tuned it by using some cuttings of old credit cards as shims to pack up the motor mount.

PROP-SHAFT LUBRICANT. Originally I was using old school grease. There is a great guide on drive trains (by Glynn Guest) on the Model Boat Magazine website. As a result of reading the article I removed the grease, fabricated a prop-shaft oiler, and I am now using 3 in 1 oil to lubricate the shaft.

These two steps have really reduced the prop-shaft drag and friction thus reducing the noise the motor makes and the power it draws.

High pressure and calm conditions yesterday evening gave me perfect conditions for initial sea trials of my little fast patrol boat on our local lake.

As you can see from the video below the tiny out-runner brushless motor used has a amazing amount of power. I used the smaller 2 blade propeller and even half throttle brought the little fast patrol boat onto a scale like plane.

Coming back to the original question posed by this thread What Watts/Kg ? I would conclude that in my case a good rule of thumb would be 50 watts/kg for a sports model boat like this.

MY TRANSMITTER SET UP.

I found setting the rudder up at 50% on the transmitter aileron rate switch was ideal for cruising around I then flicked the switch to full throw for slow speed manoeuvring this worked well for me.

I also set up a timer for 15 mins but even after a 20 minute run there was plenty of power left in the 2200mAh 3 cell LiPo pack so this power train set up works well.

COOL RUNNING.

The original bath test caused the motor to overheat. I have now rectified the problem by carrying out the following 3 steps below.

MOTOR PROP-SHAFT ALINEMENT. Although this was originally OK, I have fine tuned it by using some cuttings of old credit cards as shims to pack up the motor mount.

PROP-SHAFT LUBRICANT. Originally I was using old school grease. There is a great guide on drive trains (by Glynn Guest) on the Model Boat Magazine website. As a result of reading the article I removed the grease, fabricated a prop-shaft oiler, and I am now using 3 in 1 oil to lubricate the shaft.

These two steps have really reduced the prop-shaft drag and friction thus reducing the noise the motor makes and the power it draws.

▲

⟩⟩

RNinMunich

BOATSHED

peterd

📝 Retro Cutting Holes in Bulkheads

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 3 Likes

Flag

📝 Reply

Just to conclude this thread I finally retro fitted some holes in the bulkheads of my fast patrol boat today to install water cooling.

Below in one picture are the pin drills, reamers and the micro sander used to make some very neat holes for the tubing. I started small with a sharp 1.5mm drill in the pin drill to make the pilot holes. Next I enlarged the holes up to 3mm which allowed me to start using a step reamer which neatly enlarged the holes up to 6mm for the tubing. I highly recommend a set of step reamers if you don’t own some already, the small set shown in the picture were purchased on eBay quite cheaply, they cut holes well as they are very sharp. Finally my newly fabricated electric toothbrush (turned micro sander) tidied things up.

When using the small hand tools I found I needed to take my time, it also gave my fingers and thumbs a good work out. It is was worth it tho as I ended up with some very tidy holes in exactly the right places.😎

I would like to thank all those who contributed some great ideas and solutions to this thread.

ATB JT 😊

Below in one picture are the pin drills, reamers and the micro sander used to make some very neat holes for the tubing. I started small with a sharp 1.5mm drill in the pin drill to make the pilot holes. Next I enlarged the holes up to 3mm which allowed me to start using a step reamer which neatly enlarged the holes up to 6mm for the tubing. I highly recommend a set of step reamers if you don’t own some already, the small set shown in the picture were purchased on eBay quite cheaply, they cut holes well as they are very sharp. Finally my newly fabricated electric toothbrush (turned micro sander) tidied things up.

When using the small hand tools I found I needed to take my time, it also gave my fingers and thumbs a good work out. It is was worth it tho as I ended up with some very tidy holes in exactly the right places.😎

I would like to thank all those who contributed some great ideas and solutions to this thread.

ATB JT 😊

▲

⟩⟩

Martin555

RNinMunich

Colin H

📝 Retro Cutting Holes in Bulkheads

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 4 Likes

Flag

📝 Reply

Thanks all for some great ideas.

JACOBS CHUCK

I liked Joes Jacobs Chucks Idea so much that I fabricated my own. 👍

See the picture below. The Chuck was originally fitted to a old Expo 12v miniature drill (Many years ago I replaced it with a bigger more versatile chuck). For the thumb turn knob I cut down a plastic glue spout, I also found some plastic pipe that had the right diameter to rotate the drill in while holding it in position. It’s great to make the old chuck useful once again turning it into a handy compact hand drill.

I will use the miniature drill to drill small pilot holes in the bulkheads. Once the pilot holes are drilled the holes will be enlarged to the correct diameter with a Step Reamer which should produce a nice neat hole. Thanks Robbob you gave me the idea of using a reamer 😎

MICRO ORBITAL SANDER. (see picture below)

Returning to the dental theme of my earlier Post (thanks to the idea on YouTube) I have repurposed this old electric toothbrush head into a miniature orbital sander. The sanding disk were easy to make with a hole punch. Velcro is also cut with the punch then glued with CA onto the back of the industrial abrasive paper disk.

If you fancy making one yourself don’t try cutting of the brush material, I found it easier to pull it out of the brush head with some pliers. A velcro hook disk can then be glued with CA onto the head.

I luckily have a old unused Braun toothbrush, but as another option you could always purchase a cheep battery powered alternative. 🤔

Should make it easy to sand in tight spaces.

JT 😊

JACOBS CHUCK

I liked Joes Jacobs Chucks Idea so much that I fabricated my own. 👍

See the picture below. The Chuck was originally fitted to a old Expo 12v miniature drill (Many years ago I replaced it with a bigger more versatile chuck). For the thumb turn knob I cut down a plastic glue spout, I also found some plastic pipe that had the right diameter to rotate the drill in while holding it in position. It’s great to make the old chuck useful once again turning it into a handy compact hand drill.

I will use the miniature drill to drill small pilot holes in the bulkheads. Once the pilot holes are drilled the holes will be enlarged to the correct diameter with a Step Reamer which should produce a nice neat hole. Thanks Robbob you gave me the idea of using a reamer 😎

MICRO ORBITAL SANDER. (see picture below)

Returning to the dental theme of my earlier Post (thanks to the idea on YouTube) I have repurposed this old electric toothbrush head into a miniature orbital sander. The sanding disk were easy to make with a hole punch. Velcro is also cut with the punch then glued with CA onto the back of the industrial abrasive paper disk.

If you fancy making one yourself don’t try cutting of the brush material, I found it easier to pull it out of the brush head with some pliers. A velcro hook disk can then be glued with CA onto the head.

I luckily have a old unused Braun toothbrush, but as another option you could always purchase a cheep battery powered alternative. 🤔

Should make it easy to sand in tight spaces.

JT 😊

▲

⟩⟩

Colin H

RNinMunich

Martin555

jbkiwi

📝 Retro Cutting Holes in Bulkheads

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 8 Views · 3 Likes

Flag

📝 Reply

Interestingly Ian Looking on eBay the Chinese dental drills, hoses and diamond bits are quite cheep. They run on just 30 psi.

This guy has modified one to run at home of his workshop compressor. 🤔

See video below 😎 JT

This guy has modified one to run at home of his workshop compressor. 🤔

See video below 😎 JT

▲

⟩⟩

Joe727

Colin H

Martin555

📝 Retro Cutting Holes in Bulkheads

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 2 Likes

Flag

📝 Reply

Yes Ian very much like working through a letterbox. 😁

You got me thinking tho dentist work in very small spaces drilling precision holes with yes a right angle drill. Looking at their drills they seem to be pneumatically powered by compressed air. 😎 JT

You got me thinking tho dentist work in very small spaces drilling precision holes with yes a right angle drill. Looking at their drills they seem to be pneumatically powered by compressed air. 😎 JT

▲

⟩⟩

Colin H

Martin555

📝 Retro Cutting Holes in Bulkheads

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 2 Likes

Flag

📝 Reply

Hi Martin,

this is a problem that many boat modellers must face. In my case I am planning to make 4 holes of approx 4mm dia for the water cooling silicon tubing. The cabin is just over 12cm long and the holes will be drilled 9cm down just above the floor the cabin.

JT 👍

this is a problem that many boat modellers must face. In my case I am planning to make 4 holes of approx 4mm dia for the water cooling silicon tubing. The cabin is just over 12cm long and the holes will be drilled 9cm down just above the floor the cabin.

JT 👍

▲

⟩⟩

Colin H

Martin555

📝 Retro Cutting Holes in Bulkheads

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 7 Views · 3 Likes

Flag

📝 Reply

Someone out there with a brilliant model building mind must have come up with a neat solution for retro cutting holes in bulkheads. 😎

I need to make several holes to install tubing for water cooling.

Model boats can have very limited space for drilling a hole at a right angle. I have looked at several right angle drill attachments, including the Dremel, and they are just too big. Flexible attachments also take too much space by the time you have turned them through a right angle.

Thanks for any ideas JT 🤔

I need to make several holes to install tubing for water cooling.

Model boats can have very limited space for drilling a hole at a right angle. I have looked at several right angle drill attachments, including the Dremel, and they are just too big. Flexible attachments also take too much space by the time you have turned them through a right angle.

Thanks for any ideas JT 🤔

▲

⟩⟩

Colin H

Graham93

Martin555

Login To

Remove Ads

Remove Ads

📝 What Watts/KG and Motor Cooling

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 8 Views · 4 Likes

Flag

📝 Reply

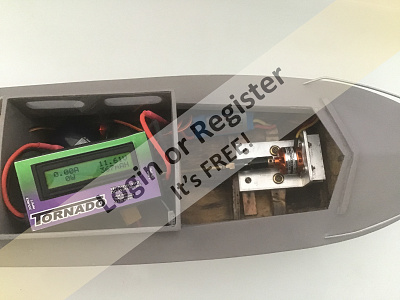

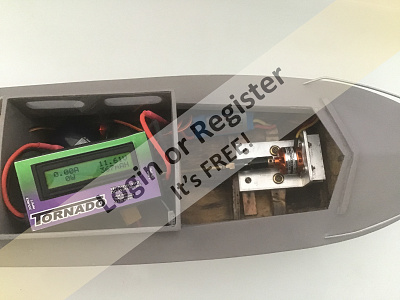

The bath test I carried out today of my fast patrol boat was mostly successful. No leaks and balance in the water was level with the battery pack situated at the rear of the cabin.

I thought the following may be of interest to other’s who are looking at using small brushless out-runners in their boats.

WHAT WATTS Are Required.

I have fitted a DYS D2822-17 brushless out-runner. These little Chinese motors are widely available and as cheap as chips on line. The motor is mounted on a homemade mount with cooling fins. The motor is 1100KV with a max power of 102 watts. A fully charged 3 cell (11.1V) 2200mAh LiPo battery was used for the test again this is a popular size battery pack readily available. The sailing weight of the 20” Fast Patrol Boat which I would class as a sports model is 1.323kg.

First Static test was with a 4 blade 30mm prop here are the results;

Current drawn 8A giving a impressive 90 watts (102 watts max for motor).This works out at approx 68watts/kg.

Second Static test was with a worn out old 2 blade 30 mm prop here are the results;

Current drawn 5.7A giving 64 watts giving approx 48watts/kg.

There has been a lot of talk on model boat forums about the importance of KV (rpm/V). But I believe equally important is the watts/kg. Those who fly electric powered model aircraft will know that aero modellers have even come up with some rules of thumb for watts/kg.

Trainers scale models 100 watts/kg

Sport aerobatic models 150 watts/kg

Out and out 3D aerobatic models 200watts/kg.

The weight of our boats determine how much water is displaced and proportionally how much drag is created that needs to be overcome by our power set ups. If a boat gets up on the plane the water displaced and the drag is reduced but it still has to get fast enough to get up on the plane.

Hopefully this will get a interesting discussion going. Maybe eventually model boat builders will also develop some rules of thumb for watts/kg for different types of model boats.

MOTOR COOLING.

This was the bit of the static bath test that did not go so well. Although the brushless controller stayed nice and cool the motor got extremely hot especially with the 4 bladed prop. Even with the smaller 2 blade prop the motor was running too hot. These out-runner motors are used to getting a good blast of air over them when fitted to model aircraft or drones. Even tho I have fabricated cooling fins on the motor mount used it looks like water cooling will be necessary.

All very interesting results and test were worth doing.🤔

Please Feel free to comment. JT

I thought the following may be of interest to other’s who are looking at using small brushless out-runners in their boats.

WHAT WATTS Are Required.

I have fitted a DYS D2822-17 brushless out-runner. These little Chinese motors are widely available and as cheap as chips on line. The motor is mounted on a homemade mount with cooling fins. The motor is 1100KV with a max power of 102 watts. A fully charged 3 cell (11.1V) 2200mAh LiPo battery was used for the test again this is a popular size battery pack readily available. The sailing weight of the 20” Fast Patrol Boat which I would class as a sports model is 1.323kg.

First Static test was with a 4 blade 30mm prop here are the results;

Current drawn 8A giving a impressive 90 watts (102 watts max for motor).This works out at approx 68watts/kg.

Second Static test was with a worn out old 2 blade 30 mm prop here are the results;

Current drawn 5.7A giving 64 watts giving approx 48watts/kg.

There has been a lot of talk on model boat forums about the importance of KV (rpm/V). But I believe equally important is the watts/kg. Those who fly electric powered model aircraft will know that aero modellers have even come up with some rules of thumb for watts/kg.

Trainers scale models 100 watts/kg

Sport aerobatic models 150 watts/kg

Out and out 3D aerobatic models 200watts/kg.

The weight of our boats determine how much water is displaced and proportionally how much drag is created that needs to be overcome by our power set ups. If a boat gets up on the plane the water displaced and the drag is reduced but it still has to get fast enough to get up on the plane.

Hopefully this will get a interesting discussion going. Maybe eventually model boat builders will also develop some rules of thumb for watts/kg for different types of model boats.

MOTOR COOLING.

This was the bit of the static bath test that did not go so well. Although the brushless controller stayed nice and cool the motor got extremely hot especially with the 4 bladed prop. Even with the smaller 2 blade prop the motor was running too hot. These out-runner motors are used to getting a good blast of air over them when fitted to model aircraft or drones. Even tho I have fabricated cooling fins on the motor mount used it looks like water cooling will be necessary.

All very interesting results and test were worth doing.🤔

Please Feel free to comment. JT

▲

⟩⟩

RNinMunich

Martin555

MouldBuilder

Colin H

📝 Glue for Deck Fittings ?

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 10 Views · 5 Likes

Flag

📝 Reply

I used Rob’s solution for the plastic fairleads. In my case I had to use miniature brass tacks. Luckily I have some watch makers drills and a useful pin drill to drill the clearance holes in the fairleads and pilot holes in the deck.

The fairleads were fixed with CA and some dabs of silver hammerite have blended in the tack heads nicely.

Build now complete. 😎 JT

The fairleads were fixed with CA and some dabs of silver hammerite have blended in the tack heads nicely.

Build now complete. 😎 JT

▲

⟩⟩

BOATSHED

marky

Joe727

robbob

Martin555

📝 Glue for Deck Fittings ?

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 8 Views · 3 Likes

Flag

📝 Reply

For a master class on making and fixing fittings see Robbob’s 36” Thames River Police Launch build blog.

It’s inspired me to make some more deck fittings. 😊😎

JT

It’s inspired me to make some more deck fittings. 😊😎

JT

▲

⟩⟩

BOATSHED

robbob

Martin555

📝 Glue for Deck Fittings ?

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 11 Views · 6 Likes

Flag

📝 Reply

Thanks all for your help. 👍😎

Yes Pete’s idea of making studs is the way forward for the handrails.

In my case the handrails are small so cocktail sticks worked well. First I drilled 1.5mm holes in the rails then short but oversize studs were glued in the holes with canopy glue. These were later sanded back to the thickness of the cabin roofs.

I found an easy way to transfer the position of studs to the roof was by blacking the bottom of the studs with a pencil. This left clear marks on masking tape where I drilled 2mm clearance holes to secure the handrails. I will expoxy them in position.

Plastic fairleads next ?

JT

Yes Pete’s idea of making studs is the way forward for the handrails.

In my case the handrails are small so cocktail sticks worked well. First I drilled 1.5mm holes in the rails then short but oversize studs were glued in the holes with canopy glue. These were later sanded back to the thickness of the cabin roofs.

I found an easy way to transfer the position of studs to the roof was by blacking the bottom of the studs with a pencil. This left clear marks on masking tape where I drilled 2mm clearance holes to secure the handrails. I will expoxy them in position.

Plastic fairleads next ?

JT

▲

⟩⟩

Joe727

robbob

ianed57

Rookysailor

Martin555

Graham93

📝 Glue for Deck Fittings ?

4 years ago by 🇬🇧 Xcpilot ( Leading Seaman)

Leading Seaman)

Leading Seaman)

Leading Seaman)✧ 10 Views · 5 Likes

Flag

📝 Reply

My final hurdle on my lockdown project (Aerokits Fast Patrol Boat) is the deck fittings. What is the most suitable glue to secure deck fittings. The deck and cabin roofs have been finished with 2K acrylic car paint to which I will be attaching plastic fairleads and my scratch made wooden hand rails.

I particularly want to properly secure the hand rails as they took quite a bit of time to fabricate.

I have been testing the obvious choices with a old lolly stick glued to a old CD. In order of best adhesion here is what I found.

Worst adhesion but friendliest to use Canopy glue, 12 min epoxy was ok, finally cyanoacrylate gave the best adhesion but I feel still It was not secure enough.

Has anyone tried Silicone sealant or other building adhesives say Grip-fill or the other derivatives like No-nails or (I like the name of this one) Sticks like Sh*t.😎

Thanks in advance JT

I particularly want to properly secure the hand rails as they took quite a bit of time to fabricate.

I have been testing the obvious choices with a old lolly stick glued to a old CD. In order of best adhesion here is what I found.

Worst adhesion but friendliest to use Canopy glue, 12 min epoxy was ok, finally cyanoacrylate gave the best adhesion but I feel still It was not secure enough.

Has anyone tried Silicone sealant or other building adhesives say Grip-fill or the other derivatives like No-nails or (I like the name of this one) Sticks like Sh*t.😎

Thanks in advance JT

▲

⟩⟩

BOATSHED

robbob

Colin H

Rookysailor

Martin555

Lieutenant Commander)

Lieutenant Commander)

Liked Chris Craft Sport Fisherman 4 years ago

Liked Chris Craft Sport Fisherman 4 years ago

Liked Home Brew Motor Mount for a Outrunner 4 years ago

Liked Home Brew Motor Mount for a Outrunner 4 years ago

Liked Home Brew Motor Mount for a Outrunner 4 years ago

Liked Home Brew Motor Mount for a Outrunner 4 years ago

Liked More windows .... 4 years ago

Liked More windows .... 4 years ago

Liked Home Brew Motor Mount for a Outrunner 4 years ago

Liked Home Brew Motor Mount for a Outrunner 4 years ago