Join Us On Social Media!

Kathryn - a Thames Bawley - 8

1 Post · 2 Followers · 7 Photos · 12 Likes

Began 4 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 4 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Kathryn - a Thames Bawley - 8

4 months ago by 🇬🇧 flaxbybuck ( Captain)

Captain)

Captain)

Captain)✧ 49 Views · 12 Likes · 2 Comments

Flag

💬 Add Comment

You will have gathered that I spent a lot of time planning how everything should be; where it should go; its size; the sequence of work to be done; how I wanted it to look; the compromises made; how it should operate; the convenience etc etc. That's not to say I was happy with things first time around. On the contrary, some items were made and re made several times before I was satisfied.

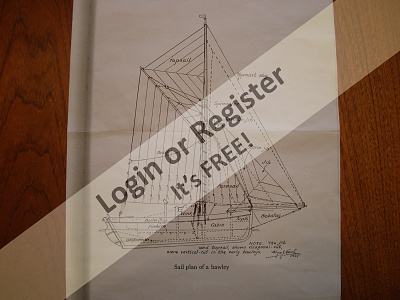

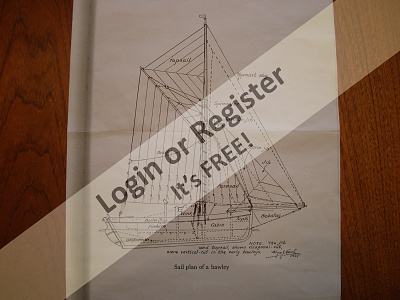

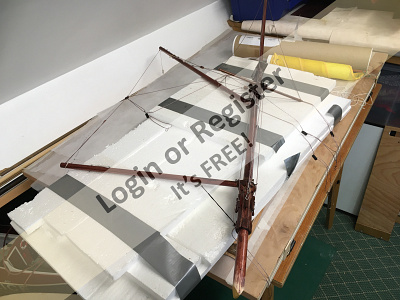

Working to the sail plan (see photo 1) I decided which sails I would like, and which would not be needed. Throughout this build I was mindful that this was to be a sailing model rather than an accurate and detailed model. I wanted to be able to attach sails or remove them easily at the pondside, and to accommodate different wind speeds opted for two sizes of mainsail and headsail; a staysail, one jib and a flying jib, also a large staysail that would take the place of the last three sails.

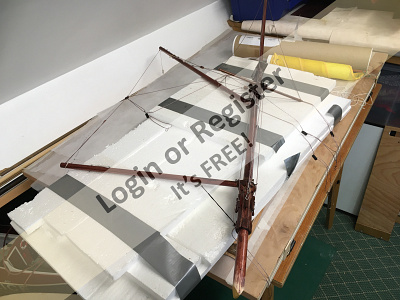

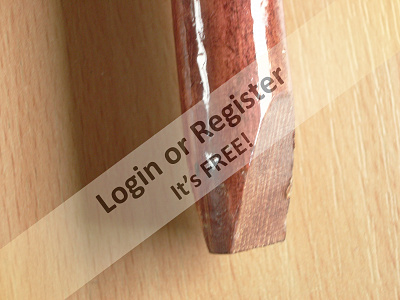

The mast is made from 18mm dowel; the topmast, boom, bowsprit, and gaff from 12mm dowel and the spreader from 6mm dowel. Dowels were first shaped and smoothed, then stained and varnished. (photo 2)

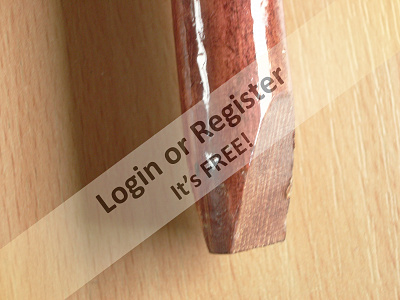

The foot of the mast was shaped (photo 4) and in the bottom of the hull a 'mound' of car body filler created with a matching socket. This prevents the mast from turning or swivelling whilst in use.

A wooden ring was made and slid down the mast where it was glued into place. Beneath this and reaching down to the deck I glued vertical timbers encircling the mast with brackets supporting the ring. This ring supports the jaws of the boom. (Photos 5 and 6).

In photo 7 can be seen the cleats and mouldings below the ring for tying off various sheets and ropes. The cleats are made by shaping a long piece of wood to create a shallow 'C' section, then sawing off each cleat to the desired thickness, and finally sanding to shape. They are attached to the mast with both glue (PVA), and screw eyes. I use these because they are available in very small sizes, are simpler to screw into place than normal screws, and also provide an additional eye to which things can be attached. Hidden from view is an 'O' ring on the mast that prevents water getting into the hull.

Photo 3 shows some of the sails laid out. Sails are made of cotton (old bed sheets I believe). The material was first dyed, the light colour using tea, the dark brown using Dylon fabric dye. Full size patterns for all sails were drawn up. From these drawings patterns were made of stiff paper, the actual size of the finished sail. After marking out the material was cut using a steel straight edge and sharp knife. These 'proofs' were then checked against the drawings before proceeding.

The first operation on the sewing machine was to cut out and sew on the corner reinforcing patches. Narrow bias binding (5/8" I believe) was sewn onto all sides and the corners trimmed off. Small eyelets were then put into each corner.

Working to the sail plan (see photo 1) I decided which sails I would like, and which would not be needed. Throughout this build I was mindful that this was to be a sailing model rather than an accurate and detailed model. I wanted to be able to attach sails or remove them easily at the pondside, and to accommodate different wind speeds opted for two sizes of mainsail and headsail; a staysail, one jib and a flying jib, also a large staysail that would take the place of the last three sails.

The mast is made from 18mm dowel; the topmast, boom, bowsprit, and gaff from 12mm dowel and the spreader from 6mm dowel. Dowels were first shaped and smoothed, then stained and varnished. (photo 2)

The foot of the mast was shaped (photo 4) and in the bottom of the hull a 'mound' of car body filler created with a matching socket. This prevents the mast from turning or swivelling whilst in use.

A wooden ring was made and slid down the mast where it was glued into place. Beneath this and reaching down to the deck I glued vertical timbers encircling the mast with brackets supporting the ring. This ring supports the jaws of the boom. (Photos 5 and 6).

In photo 7 can be seen the cleats and mouldings below the ring for tying off various sheets and ropes. The cleats are made by shaping a long piece of wood to create a shallow 'C' section, then sawing off each cleat to the desired thickness, and finally sanding to shape. They are attached to the mast with both glue (PVA), and screw eyes. I use these because they are available in very small sizes, are simpler to screw into place than normal screws, and also provide an additional eye to which things can be attached. Hidden from view is an 'O' ring on the mast that prevents water getting into the hull.

Photo 3 shows some of the sails laid out. Sails are made of cotton (old bed sheets I believe). The material was first dyed, the light colour using tea, the dark brown using Dylon fabric dye. Full size patterns for all sails were drawn up. From these drawings patterns were made of stiff paper, the actual size of the finished sail. After marking out the material was cut using a steel straight edge and sharp knife. These 'proofs' were then checked against the drawings before proceeding.

The first operation on the sewing machine was to cut out and sew on the corner reinforcing patches. Narrow bias binding (5/8" I believe) was sewn onto all sides and the corners trimmed off. Small eyelets were then put into each corner.

▲

⟩⟩

Frankiesays1953

Graham93

Len1

jumpugly

boatmam

River Rat

hermank

Colin H

luckyduck

Cashrc

AndyN

AlessandroSPQR

|

💬 Re: Kathryn - a Thames Bawley - 8

4 months ago by 🇮🇹 AlessandroSPQR (

Rear Admiral) Rear Admiral)✧ 50 Views · 2 Likes

Flag

Flaxbybuck you truly are a master.

Exceptional and thorough work. A guide for all of us. ▲

⟩⟩

flaxbybuck

Len1

|

|

💬 Re: Kathryn - a Thames Bawley - 8

4 months ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 46 Views · 2 Likes

Flag

Very nicely done FB👍

But rather you than me Gungadin! Hat off🤓 Cheers, Doug😎 ▲

⟩⟩

flaxbybuck

Len1

|

United Kingdom

United Kingdom