Join Us On Social Media!

GLYNN GUEST KNOCKER WHITE TUG

5 Posts · 3 Followers · 59 Photos · 48 Likes

Began 5 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 2 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 AND FINALLY...

2 months ago by 🇳🇿 Nick Ward ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 38 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

Since I've had two weeks holiday over the Christmas period for the first time in several years, I've managed to complete this project (at least for the time being - I may add a few more details in the future as and when they occur to me...🤔) more quickly than I previously thought.

So this will be my last entry into this build log;

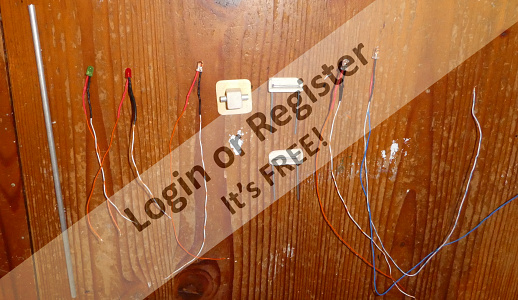

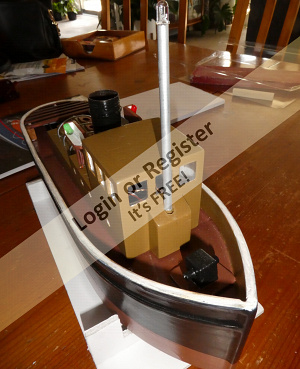

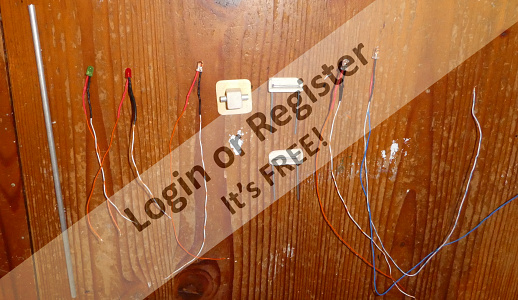

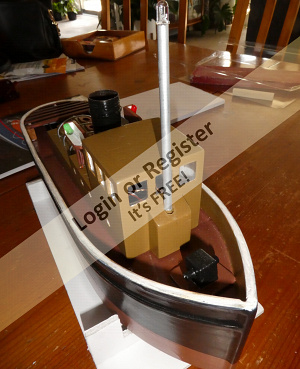

42)The main emphasis here was to finish some details to the superstructure/hatch, starting with soldering up several LEDs for the navigation lights, red(port), green(starboard) two white for the front mast and one white for a stern facing light. The masts were to be from 5mm aluminium tube. A windlass and the port/starboard light mountings were fabricated from scrap balsa/ply/wire etc. General internal cabin lighting was to be provided by a 'cutting' from cheap set of LED christmas lights.

43-45)To ensure some level of neatness, I had to come up with a way to clamp the wiring inside the hatch. I used U-hooks fashioned from old dressmakers/modelling pins. These could be fairly easily pushed into the inside walls of the hatch and secured with a drop of thin cyano. The outside LEDs had their wires threaded through holes to the inside of the hatch, then their respective +ve and -ve wires bunched together and soldered so they could be secured in a standard 'choc-bloc' screw contact fitting.

The other side had the 2 x AAA Nimh battery box connections attached, together with the Xmas lights in parallel, allowing everything to be activated by the same built-in battery box switch. The battery box sits in the rear compartment next to the rudder servo and can be easily activated prior to sailing.

Note, the inside of the hatch had been already painted gloss white to help reflect the internal LED lights.

Glazing material had also been glued to the inside of the hatch windows/portholes prior to the fitting of the lights.

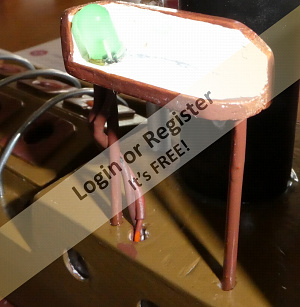

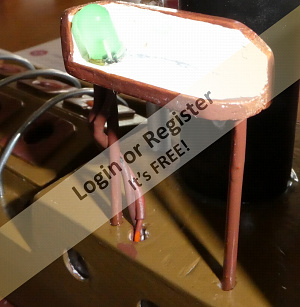

46-50) Here are a few close-ups of the fittings including port/starboard lights, forward mast with white light (single one at top of mast - wanted two pointing forward at different heights, but struggled to get this to work with the aluminium tube, so went with single lamp at top option; may come up with a small enclosure in the future to focus the light more forward), rear light behind funnel, protective metal bars over engine room skylights.

DISCLAIMER....I acknowledge that close-up these all look a little 'rough', however from only a short distance away when sailing, they certainly add sufficient character to the model to justify the effort making them.😉

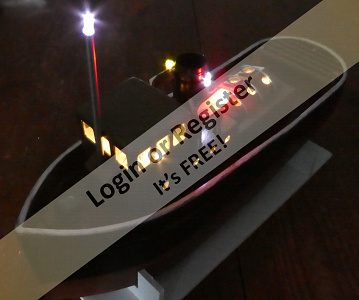

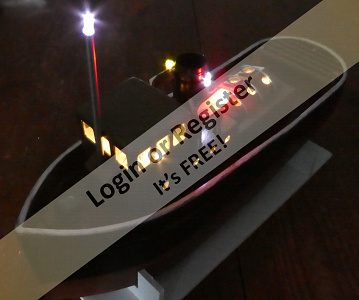

51-52)Knocker White complete for a trial twilight sailing session, lights on!

53)Video clip of later evening sailing session (around 8-30pm, I think) - actually there was still a little too much light to get the best effect from the LEDs, but they are just about visible, so you should get a fairly good idea of their potential effect.

Apologies for the abrupt sneeze a short way into the video, and as you can see, our cocker spaniel Molly was as mesmerized as we were.🐶

54-57)Since reading Glynn Guest's 'Box Clever' article, I have started to build protective cases for any new boats I build. These are usually constructed from thin MDF/ply scraps left over from other projects, with rope handles and covers that can easily be removed/opened for access, but secured with velcro straps. I usually waterproof them with a couple of coats of slightly thinned polyurethane varnish. I try to source clear plastic sheet to include on one side of the case, so the models can be viewed while in storage.

As GG suggests, the extra time and effort to complete one of these is a fraction of the effort spent on the model itself, yet it provides long term protection during transport/storage/display - I thoroughly recommend this.

58)Knocker White takes her place in the expanding 'dockyard' in our house...😉

Well, that's it. Thanks to all who have followed this build, hopefully you have found something useful from it.

Best regards for 2026 and beyond.

Nick

So this will be my last entry into this build log;

42)The main emphasis here was to finish some details to the superstructure/hatch, starting with soldering up several LEDs for the navigation lights, red(port), green(starboard) two white for the front mast and one white for a stern facing light. The masts were to be from 5mm aluminium tube. A windlass and the port/starboard light mountings were fabricated from scrap balsa/ply/wire etc. General internal cabin lighting was to be provided by a 'cutting' from cheap set of LED christmas lights.

43-45)To ensure some level of neatness, I had to come up with a way to clamp the wiring inside the hatch. I used U-hooks fashioned from old dressmakers/modelling pins. These could be fairly easily pushed into the inside walls of the hatch and secured with a drop of thin cyano. The outside LEDs had their wires threaded through holes to the inside of the hatch, then their respective +ve and -ve wires bunched together and soldered so they could be secured in a standard 'choc-bloc' screw contact fitting.

The other side had the 2 x AAA Nimh battery box connections attached, together with the Xmas lights in parallel, allowing everything to be activated by the same built-in battery box switch. The battery box sits in the rear compartment next to the rudder servo and can be easily activated prior to sailing.

Note, the inside of the hatch had been already painted gloss white to help reflect the internal LED lights.

Glazing material had also been glued to the inside of the hatch windows/portholes prior to the fitting of the lights.

46-50) Here are a few close-ups of the fittings including port/starboard lights, forward mast with white light (single one at top of mast - wanted two pointing forward at different heights, but struggled to get this to work with the aluminium tube, so went with single lamp at top option; may come up with a small enclosure in the future to focus the light more forward), rear light behind funnel, protective metal bars over engine room skylights.

DISCLAIMER....I acknowledge that close-up these all look a little 'rough', however from only a short distance away when sailing, they certainly add sufficient character to the model to justify the effort making them.😉

51-52)Knocker White complete for a trial twilight sailing session, lights on!

53)Video clip of later evening sailing session (around 8-30pm, I think) - actually there was still a little too much light to get the best effect from the LEDs, but they are just about visible, so you should get a fairly good idea of their potential effect.

Apologies for the abrupt sneeze a short way into the video, and as you can see, our cocker spaniel Molly was as mesmerized as we were.🐶

54-57)Since reading Glynn Guest's 'Box Clever' article, I have started to build protective cases for any new boats I build. These are usually constructed from thin MDF/ply scraps left over from other projects, with rope handles and covers that can easily be removed/opened for access, but secured with velcro straps. I usually waterproof them with a couple of coats of slightly thinned polyurethane varnish. I try to source clear plastic sheet to include on one side of the case, so the models can be viewed while in storage.

As GG suggests, the extra time and effort to complete one of these is a fraction of the effort spent on the model itself, yet it provides long term protection during transport/storage/display - I thoroughly recommend this.

58)Knocker White takes her place in the expanding 'dockyard' in our house...😉

Well, that's it. Thanks to all who have followed this build, hopefully you have found something useful from it.

Best regards for 2026 and beyond.

Nick

▲

⟩⟩

chugalone100

robbob

Cashrc

Steves-s

hermank

SimpleSailor

EdW

Mike Stoney

|

💬 Re: AND FINALLY...

2 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 23 Views · 2 Likes

Flag

I have Mr Guests book with this tug in it. I have a lot of projects ahead of me, but I just might have to add this to the list. You did a grand job on her!!

Cash ▲

⟩⟩

Mike Stoney

hermank

|

Login To

Remove Ads

Remove Ads

📝 KNOCKER WHITE LEADING UP TO CHRISTMAS DAY 'OFFICIAL' MAIDEN VOYAGE

2 months ago by 🇳🇿 Nick Ward ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 51 Views · 6 Likes

Flag

💬 Add Comment

Further progress...

33) 03-08 Dec, hull painted matt black upper, brick red lower, white bulwark tops.

Actually, there were a few 'test' voyages for the hull prior to the xmas day sailing... . After sealing/painting the hull, I thought I would try out how she floated just with the running gear. I was initially worried that the forward position of the 5-cell AA drive pack would cause her to be nose heavy, but was pleasantly surprised to find she sat quite evenly in the water.

There was about an extra centimetre of freeboard below the intended waterline, so clearly lead ballast was required, yet I couldn't resist having a dabble with the throttle in this state; my neat looking little tugboat surged forward and rose up on the plane when the throttle was fully opened - quite hilarious to see her half out of the water, as agile as a small runabout! (It has inspired me to look into a simple runabout build for the pond in the future...😉). Anyways, enough of that!

34)13Dec - After drying her off I traced the hull planform onto squared paper and calculated she required about 300grams of ballast, 210 of which was added with roofing lead scraps.

35)22Dec - The remaining weight was to be provided with a 2-cell AA battery pack intended for LED lights, which proved to be a bit of a squeeze into the rear compartment; I had experimented with cutting down some cheap xmas LEDs to light up the inside of the superstructure, but also intended to use red/green LEDs for the navigation lights and white LEDs for head/tail lights - I thought these might add interest to future twilight backyard pond sailing sessions.

36/37/38 23Dec - After further hull tests, I found that while the hull was lower in the water, the double AA pack actually sank the rear a little too much, as well as being difficult to stuff into the rear compartment. As a result of this, I opted to buy some cheap(ish) AAA rechargeables, as these were both lighter and more compact for fitting. A further hull test proved this combination was just about right, and the video clip included in this episode shows a very satisfactory performance.

39 & 40)While all the hull testing was going on, the superstructure rear engine compartment housing was added, the tiller cover was made up from card, and the funnel from a plastic pill bottle was sourced. These were all subsequently sealed and painted with enamels following suggested colours from Glynn Guest's book. The inside of the superstructure was given a coat of gloss white enamel to reflect the LED light from inside once lit up.

41) The video clip of the official 'maiden voyage' on Xmas morning, taken by my wife on our recently completed back yard pond.

Although having achieved the aim of sailing by xmas day, I will post again once I have completed further details such as final superstructure painting/glazing/fittings/LEDs etc. These often take longer than the basic build...

Merry Christmas to you all and all the best for 2026,

Nick

33) 03-08 Dec, hull painted matt black upper, brick red lower, white bulwark tops.

Actually, there were a few 'test' voyages for the hull prior to the xmas day sailing... . After sealing/painting the hull, I thought I would try out how she floated just with the running gear. I was initially worried that the forward position of the 5-cell AA drive pack would cause her to be nose heavy, but was pleasantly surprised to find she sat quite evenly in the water.

There was about an extra centimetre of freeboard below the intended waterline, so clearly lead ballast was required, yet I couldn't resist having a dabble with the throttle in this state; my neat looking little tugboat surged forward and rose up on the plane when the throttle was fully opened - quite hilarious to see her half out of the water, as agile as a small runabout! (It has inspired me to look into a simple runabout build for the pond in the future...😉). Anyways, enough of that!

34)13Dec - After drying her off I traced the hull planform onto squared paper and calculated she required about 300grams of ballast, 210 of which was added with roofing lead scraps.

35)22Dec - The remaining weight was to be provided with a 2-cell AA battery pack intended for LED lights, which proved to be a bit of a squeeze into the rear compartment; I had experimented with cutting down some cheap xmas LEDs to light up the inside of the superstructure, but also intended to use red/green LEDs for the navigation lights and white LEDs for head/tail lights - I thought these might add interest to future twilight backyard pond sailing sessions.

36/37/38 23Dec - After further hull tests, I found that while the hull was lower in the water, the double AA pack actually sank the rear a little too much, as well as being difficult to stuff into the rear compartment. As a result of this, I opted to buy some cheap(ish) AAA rechargeables, as these were both lighter and more compact for fitting. A further hull test proved this combination was just about right, and the video clip included in this episode shows a very satisfactory performance.

39 & 40)While all the hull testing was going on, the superstructure rear engine compartment housing was added, the tiller cover was made up from card, and the funnel from a plastic pill bottle was sourced. These were all subsequently sealed and painted with enamels following suggested colours from Glynn Guest's book. The inside of the superstructure was given a coat of gloss white enamel to reflect the LED light from inside once lit up.

41) The video clip of the official 'maiden voyage' on Xmas morning, taken by my wife on our recently completed back yard pond.

Although having achieved the aim of sailing by xmas day, I will post again once I have completed further details such as final superstructure painting/glazing/fittings/LEDs etc. These often take longer than the basic build...

Merry Christmas to you all and all the best for 2026,

Nick

▲

⟩⟩

Cashrc

Steves-s

SimpleSailor

Chum444

EdW

hermank

📝 A BIT MORE PROGRESS....

3 months ago by 🇳🇿 Nick Ward ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 56 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

Apologies to all - this little build has taken a little longer than expected as other projects/chores have got in the way, not least, further progress on the backyard boating pond.

So the current goal is to finish Knocker White and sail her on my pond by Christmas, before getting stuck into the Vivacity build (of which there has been a little progress, but just cutting out of bulkheads, keel pieces, and the sourcing of plywood and prop shaft/tube/75mm prop).

So here it is;

22)Basswood bow & keel strip pieces glued on, as well as skeg fill-in piece.

23)&24) Hull sanded smooth, corners slightly rounded, bulwarks trimmed

25)Over the course of a week of evenings, hull superstructure made up from thin ply offcuts and scrap sheet, including the tricky part of making portholes and cabin windows without tearing wood...yep, I swore a couple of times when I broke stuff!

26)&27) 1.5mm card strips cut and glued/clamps all around top of gunwales - card a more workable, and cheaper, option in this situation. (GG would have approved, I'm sure, as the original had card sides)

28) Gluing and pinning 1.5mm card rubbing strips

29)Freeing ports cut out

30) Tiller grating mounting blocks glued into place, then acrylic filler used wherever necessary to smooth over the inevitable nicks & blemishes on a balsa hull under construction😉

31) After fine sanding the whole hull, 3-4 coats of 50/50 dope/thinners mix used to seal hull inside and out, cutting back the raised grain between coats, then hull tissue covered , brushing through the thinned dope, again lightly sanding before further sealing with slightly thicker (I guess 75/25 dope/thinners ish) with another 3-4 coats until nice smooth finish produced, ready for painting with Humbrol enamels.

32) And this is where I'm currently at - lower hull with first coat of brick red. I've put the superstructure hatch on just to see how she looks...

Until the next post best regards to you all,

Nick

So the current goal is to finish Knocker White and sail her on my pond by Christmas, before getting stuck into the Vivacity build (of which there has been a little progress, but just cutting out of bulkheads, keel pieces, and the sourcing of plywood and prop shaft/tube/75mm prop).

So here it is;

22)Basswood bow & keel strip pieces glued on, as well as skeg fill-in piece.

23)&24) Hull sanded smooth, corners slightly rounded, bulwarks trimmed

25)Over the course of a week of evenings, hull superstructure made up from thin ply offcuts and scrap sheet, including the tricky part of making portholes and cabin windows without tearing wood...yep, I swore a couple of times when I broke stuff!

26)&27) 1.5mm card strips cut and glued/clamps all around top of gunwales - card a more workable, and cheaper, option in this situation. (GG would have approved, I'm sure, as the original had card sides)

28) Gluing and pinning 1.5mm card rubbing strips

29)Freeing ports cut out

30) Tiller grating mounting blocks glued into place, then acrylic filler used wherever necessary to smooth over the inevitable nicks & blemishes on a balsa hull under construction😉

31) After fine sanding the whole hull, 3-4 coats of 50/50 dope/thinners mix used to seal hull inside and out, cutting back the raised grain between coats, then hull tissue covered , brushing through the thinned dope, again lightly sanding before further sealing with slightly thicker (I guess 75/25 dope/thinners ish) with another 3-4 coats until nice smooth finish produced, ready for painting with Humbrol enamels.

32) And this is where I'm currently at - lower hull with first coat of brick red. I've put the superstructure hatch on just to see how she looks...

Until the next post best regards to you all,

Nick

▲

⟩⟩

Steves-s

SimpleSailor

Ronald

premecekcz

GaryLC

EdW

JOHN

hermank

|

💬 Re: A BIT MORE PROGRESS....

3 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 56 Views · 1 Like

Flag

Good progress Nick - you should be out playing with the goldfish in your garden boating pond in no time at all 🤣

Bob. ▲

⟩⟩

hermank

|

📝 Running gear and hull sheeting

4 months ago by 🇳🇿 Nick Ward ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 64 Views · 9 Likes

Flag

💬 Add Comment

So this is how the build has progressed over the last 10 days or so;

11)Rudder tube cut from brass stock tube (5/32" internal dia) and glued using superglue after roughing up metal surface - epoxy could be used, but if the hole is a snug fit, I have started using super glue, as it wicks nicely into the wood fibres and scratched metal surface. The motor was test fitted so I could see if the battery pack could still squeeze through the hatch - it was at this point I broke off one of the contacts so had to get another motor🙄!

12)Rudder made up from 0.5mm thick brass sheet soldered to 5/32" piano wire; I cut a tight slot in the brass, and cut a slot into the end of the rod, so there is a mechanical fixing between the rod and sheet before securing with solder. The steering arm is a standard nose-gear steering arm from Dubro, with a grub screw that locates into a filed indentation on the piano wire.

13) Close up of the rudder assembly fitted.

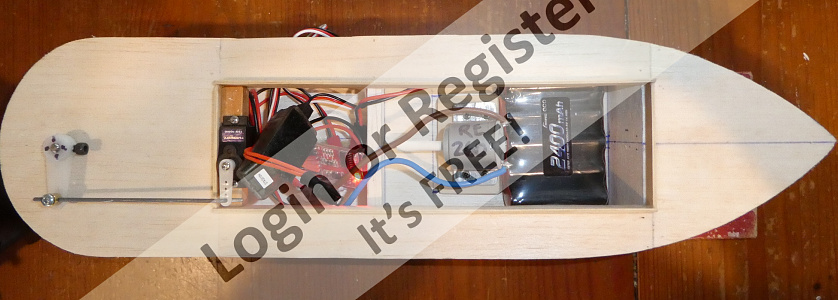

14,15 & 16)Time to completely fit and test all the radio gear before sheeting the hull sides; looking to check the 5-cell AA 2400mAh battery can be removed/inserted easily, glue in spruce blocks to mount the steering servo, a 10gram item, fit a replacement motor(RS260 I think, more than enough for this little boat), plug into a Spektrum AR410 RX and 20amp ESC and wiggle the transmitter sticks - all seemed to work well.

17, 18, 19) Once satisfied all was well, the radio/powertrain etc was removed and hull side sheeting commenced. The pinning and glueing was carried out over 3 evenings, using 3/32 balsa vertical grain sheet for the sides up to the bow, then 1/8 sheet strips to form the rounded stern, as this would require more material removal for a smooth curved shape. Note I tried to cut the pieces to reflect the height of the bulwarks according to the plan - its actually quite hard to get it exactly right on both sides, so some sanding will be required later. Note also, the original used thick (1mm I believe) card for the sides, a nice cheap option, but I prefer to use balsa as the cost on a boat this size is very low anyway. I also like balsa as it can be reinforced easily with thin ply (see next pics) or thin balsa glued with the grain at 90degrees to form a 'lite-ply' - this is how I planned to reinforce the bulwarks to get a much sturdier structure, probably a good idea if I am to let my grand-daughter loose on this boat some day in the future!😉

20) Hull given a rough sanding to achieve the basic hull shape.

21) Bulwark reinforcement strips from 1/32" ply strips to allow handling without fracturing the vertical grain balsa. Ply was cut with outer grain vertical at the stern to assist the curve - without thinking I did the same for the rest, but the straighter sections would probably have benefitted more from the outer grain being longitudinal. Still, it will be plenty strong, I think.

That's all for now, just have rubbing strakes to do and final sanding/filling and I'll have completed the basic hull.

rgds to all, Nick

11)Rudder tube cut from brass stock tube (5/32" internal dia) and glued using superglue after roughing up metal surface - epoxy could be used, but if the hole is a snug fit, I have started using super glue, as it wicks nicely into the wood fibres and scratched metal surface. The motor was test fitted so I could see if the battery pack could still squeeze through the hatch - it was at this point I broke off one of the contacts so had to get another motor🙄!

12)Rudder made up from 0.5mm thick brass sheet soldered to 5/32" piano wire; I cut a tight slot in the brass, and cut a slot into the end of the rod, so there is a mechanical fixing between the rod and sheet before securing with solder. The steering arm is a standard nose-gear steering arm from Dubro, with a grub screw that locates into a filed indentation on the piano wire.

13) Close up of the rudder assembly fitted.

14,15 & 16)Time to completely fit and test all the radio gear before sheeting the hull sides; looking to check the 5-cell AA 2400mAh battery can be removed/inserted easily, glue in spruce blocks to mount the steering servo, a 10gram item, fit a replacement motor(RS260 I think, more than enough for this little boat), plug into a Spektrum AR410 RX and 20amp ESC and wiggle the transmitter sticks - all seemed to work well.

17, 18, 19) Once satisfied all was well, the radio/powertrain etc was removed and hull side sheeting commenced. The pinning and glueing was carried out over 3 evenings, using 3/32 balsa vertical grain sheet for the sides up to the bow, then 1/8 sheet strips to form the rounded stern, as this would require more material removal for a smooth curved shape. Note I tried to cut the pieces to reflect the height of the bulwarks according to the plan - its actually quite hard to get it exactly right on both sides, so some sanding will be required later. Note also, the original used thick (1mm I believe) card for the sides, a nice cheap option, but I prefer to use balsa as the cost on a boat this size is very low anyway. I also like balsa as it can be reinforced easily with thin ply (see next pics) or thin balsa glued with the grain at 90degrees to form a 'lite-ply' - this is how I planned to reinforce the bulwarks to get a much sturdier structure, probably a good idea if I am to let my grand-daughter loose on this boat some day in the future!😉

20) Hull given a rough sanding to achieve the basic hull shape.

21) Bulwark reinforcement strips from 1/32" ply strips to allow handling without fracturing the vertical grain balsa. Ply was cut with outer grain vertical at the stern to assist the curve - without thinking I did the same for the rest, but the straighter sections would probably have benefitted more from the outer grain being longitudinal. Still, it will be plenty strong, I think.

That's all for now, just have rubbing strakes to do and final sanding/filling and I'll have completed the basic hull.

rgds to all, Nick

▲

⟩⟩

Steves-s

SimpleSailor

premecekcz

JOHN

hermank

Doogle

EdW

Mike Stoney

Madwelshman

📝 GLYNN GUEST KNOCKER WHITE TUG

5 months ago by 🇳🇿 Nick Ward ( Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)

Chief Petty Officer 2nd Class)✧ 109 Views · 17 Likes · 4 Comments

Flag

💬 Add Comment

I mentioned in the Vic Smeed Vivacity forum I would do a few smaller builds while chugging through the Vivacity project; the first of these I have started (while waiting on certain components/materials for Vivacity), based on Glynn Guest's Knocker White tugboat plan from his book 'Small Radio Control Boats'.

The Driving force behind choosing this particular design was the fact I had just filled my Backyard Model Boating Pond for the first time and sailed a couple of small free-running boats in it.

I had already made Arcady and Bredette many years ago when they were first issued as free plans in Model Boats, so Knocker White was the next project from the book with the necessary compact dimensions to sail happily on my pond, the first of (hopefully) several small such boat projects.

Here are the first stages of the build shown in the photos;

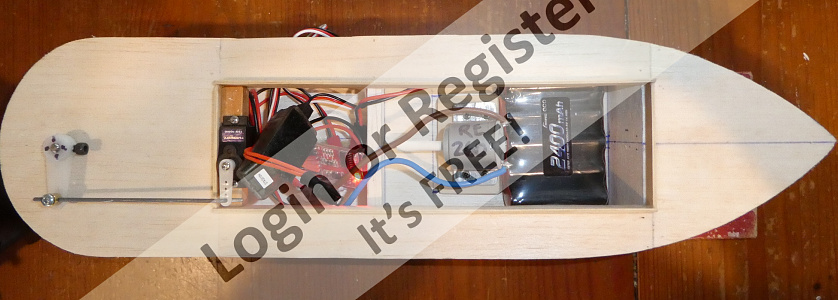

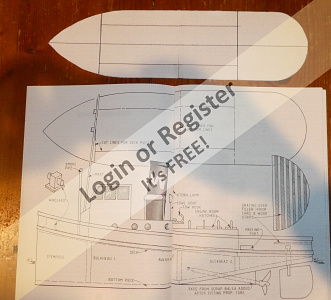

1) Paper template traced/assembled from the book - a little 'guestimation' was required as the plan was over two pages that didn't quite align...

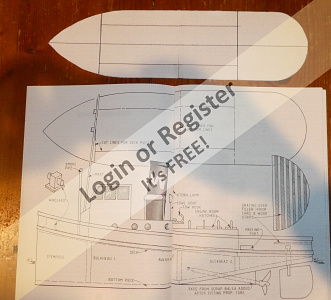

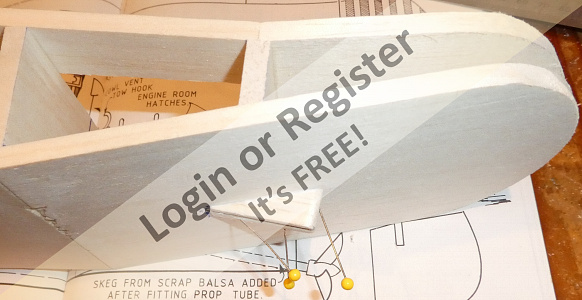

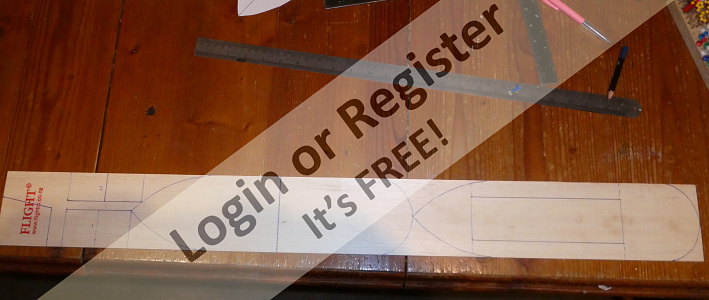

2)Carcass pieces (deck, bottom, bulkheads, stem) marked out on 1/4" sheet

3)Carcass pieces cut out

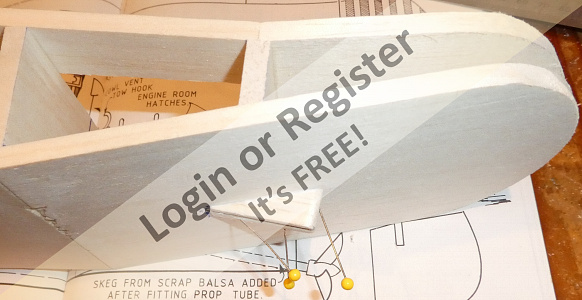

4 & 5) carcass glued together, care taken to get as square as possible - note extra piece placed in stern to support rudder tube, making stern slightly deeper than original

6)Power train/RC components; Specktrum 410 RX, Ali Express 20A esc, RS 280 motor (was eventually replaced with an RS260 type when I clumsily broke off one of the contacts while trying to fit the battery), 100mm prop shaft/tube assembly with 25mm 3-blade prop.

7)Power train set up & tested on the bench to ensure everything worked

8)Prop tube skeg/support added

9)Prop tube epoxied in place, sandwiched between skeg support and lower skeg piece.

10)6mm ply motor mount glued into position after checking alignment.

More pics and comments to follow soon,

Best regards to all following this,

Nick

The Driving force behind choosing this particular design was the fact I had just filled my Backyard Model Boating Pond for the first time and sailed a couple of small free-running boats in it.

I had already made Arcady and Bredette many years ago when they were first issued as free plans in Model Boats, so Knocker White was the next project from the book with the necessary compact dimensions to sail happily on my pond, the first of (hopefully) several small such boat projects.

Here are the first stages of the build shown in the photos;

1) Paper template traced/assembled from the book - a little 'guestimation' was required as the plan was over two pages that didn't quite align...

2)Carcass pieces (deck, bottom, bulkheads, stem) marked out on 1/4" sheet

3)Carcass pieces cut out

4 & 5) carcass glued together, care taken to get as square as possible - note extra piece placed in stern to support rudder tube, making stern slightly deeper than original

6)Power train/RC components; Specktrum 410 RX, Ali Express 20A esc, RS 280 motor (was eventually replaced with an RS260 type when I clumsily broke off one of the contacts while trying to fit the battery), 100mm prop shaft/tube assembly with 25mm 3-blade prop.

7)Power train set up & tested on the bench to ensure everything worked

8)Prop tube skeg/support added

9)Prop tube epoxied in place, sandwiched between skeg support and lower skeg piece.

10)6mm ply motor mount glued into position after checking alignment.

More pics and comments to follow soon,

Best regards to all following this,

Nick

▲

⟩⟩

Steves-s

premecekcz

Doogle

EdW

Mike Stoney

Madwelshman

Ray

SimonB2

hermank

zooma

jumpugly

BarryS

Ronald

muddy

ChrisF

Nickthesteam

cjanik001

|

💬 Re: GLYNN GUEST KNOCKER WHITE TUG

4 months ago by 🇳🇿 Nick Ward (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 61 Views · 3 Likes

Flag

|

|

Login To

Remove Ads 💬 Re: GLYNN GUEST KNOCKER WHITE TUG

4 months ago by 🇳🇿 Nick Ward (

Chief Petty Officer 2nd Class) Chief Petty Officer 2nd Class)✧ 61 Views · 2 Likes

Flag

Already there, Bob, already there👍😊.

Warm Spring evening, glass of bubbly and a pootle around the pond with my Springer...the tug that is, not one of my dogs😆. Question is, could this be construed as 'Drink Driving'?🤔 The Springer is a little large but manageable - Knocker White and similar sized models should go well - of course, the pond surround is still a work in progress - might have to do a little blog when it's a bit more finished... rgds, Nick

▲

⟩⟩

hermank

zooma

|

|

💬 Re: GLYNN GUEST KNOCKER WHITE TUG

4 months ago by 🇬🇧 zooma (

Vice Admiral) Vice Admiral)✧ 63 Views · 2 Likes

Flag

That’s nice Nick, and it will be perfect for running-in your new pond with …🤣

Bob. ▲

⟩⟩

hermank

Nick Ward

|

|

💬 Re: GLYNN GUEST KNOCKER WHITE TUG

5 months ago by 🇬🇧 ChrisF (

Vice Admiral) Vice Admiral)✧ 107 Views · 3 Likes

Flag

Similar concept to the Sprite Plus that Bob will be building and myself later on. Relatively quick and simple that can be built and on the water whilst finishing other builds off.

▲

⟩⟩

Nick Ward

Madwelshman

hermank

|

New Zealand

New Zealand