Join Us On Social Media!

Sprite

235 Posts · 9 Followers · 143 Photos · 551 Likes

Began 5 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 1 hour ago by

( Newest Posts Shown First )

📝 Sprite

2 Views

Country: 🇬🇧 United Kingdom

Online: 19 minutes ago

Online: 19 minutes ago

Soon be ready for painting!

Blimey, what's the engine mounting for, a V8! 🤣

I'm going to be putting some paint on Fisherman soon, so that might be a good time to start on Sprite Plus OB! 🤔

Blimey, what's the engine mounting for, a V8! 🤣

I'm going to be putting some paint on Fisherman soon, so that might be a good time to start on Sprite Plus OB! 🤔

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Scratch building 7 Faireys at a scale of 1:12

📝 Sprite

3 Views

Country: 🇬🇧 United Kingdom

Online: 6 minutes ago

Online: 6 minutes ago

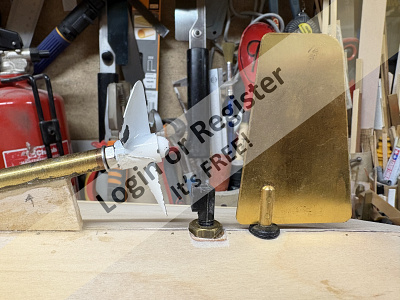

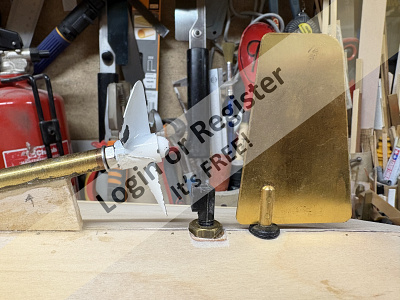

Sprite Plus Prototype.

With the rear deck insert trimmed to size, the hull was turned over and drilled to take the water inlet scoop.

Both the rudder and the water scoop pick-up and the brass rudder tube were epoxy glued into position to seal them against any water ingress.

The next job will be to cut some fibreglass cloth to cover the engine mounting plate and bond it with resin.

The super-glue that was used to bond the epoxy side plates (for the water-cooled alloy mount) onto the engine plate made a very strong joint that was further reinforced by smearing 24 hour Araldite to make a fillet around the base that was also pushed into the series of drilled holes that were drilled along their base lines.

Fibreglass resin will further reinforce the motor mounting as the cloth will also be fitted against the lower sides of these mounting plates to cover the epoxy fillets and to flow smoothly around them to make a strong integrated motor mounting assembly.

Some P38 will be bought to smooth the area where the prop shaft enters the hull on the inside - and around the prop support fillet on the outside to make these areas look a little neater.

Once the hull build is completed, attention can be given to fitting it out with a LiPo supporting tray, and mounting the ESC and rudder servo.

A cabin lift-off cabin roof assembly needs to be constructed at some stage - and this may be started when some of the glass fibre is curing.

Bob.

With the rear deck insert trimmed to size, the hull was turned over and drilled to take the water inlet scoop.

Both the rudder and the water scoop pick-up and the brass rudder tube were epoxy glued into position to seal them against any water ingress.

The next job will be to cut some fibreglass cloth to cover the engine mounting plate and bond it with resin.

The super-glue that was used to bond the epoxy side plates (for the water-cooled alloy mount) onto the engine plate made a very strong joint that was further reinforced by smearing 24 hour Araldite to make a fillet around the base that was also pushed into the series of drilled holes that were drilled along their base lines.

Fibreglass resin will further reinforce the motor mounting as the cloth will also be fitted against the lower sides of these mounting plates to cover the epoxy fillets and to flow smoothly around them to make a strong integrated motor mounting assembly.

Some P38 will be bought to smooth the area where the prop shaft enters the hull on the inside - and around the prop support fillet on the outside to make these areas look a little neater.

Once the hull build is completed, attention can be given to fitting it out with a LiPo supporting tray, and mounting the ESC and rudder servo.

A cabin lift-off cabin roof assembly needs to be constructed at some stage - and this may be started when some of the glass fibre is curing.

Bob.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Never too old to learn

📝 Sprite

9 Views

Country: 🇬🇧 United Kingdom

Online: 6 minutes ago

Online: 6 minutes ago

Sprite Plus Prototype.

I started to sand the end profiles of the deck edge chine rails and spray rails where they ended (and over-lapped slightly) onto the balsa wood laminated "nose cone".

This was not quite as easy as I expected it to be, because I was a little wary about sanding a hardwood strip end when it was a glued on to a comparatively soft balsa wood nose.

A couple of layers of masking tape were placed on the balsa wood so I could protect it from being touched by the Perma Grit sanding block. When the cutting edge touched the masking tape it made a distinctive sound to alert me that I was getting a bit too close for comfort.

I think with a little bit of filler to complete the fairing-in of these chine strip ends it will look OK.

While I was out in the workshop(shed), I cut and fitted the final small section of deck skinning to cover the last open area of the hull, so all the decking is now fitted.

When the glue drys I can cut-off the selvage edge that I have left over transom so the hull will be ready to be prepped for final finishing.

The length of the hull on this prototype has worked-out at being 30 5/8" overall.

Bob.

I started to sand the end profiles of the deck edge chine rails and spray rails where they ended (and over-lapped slightly) onto the balsa wood laminated "nose cone".

This was not quite as easy as I expected it to be, because I was a little wary about sanding a hardwood strip end when it was a glued on to a comparatively soft balsa wood nose.

A couple of layers of masking tape were placed on the balsa wood so I could protect it from being touched by the Perma Grit sanding block. When the cutting edge touched the masking tape it made a distinctive sound to alert me that I was getting a bit too close for comfort.

I think with a little bit of filler to complete the fairing-in of these chine strip ends it will look OK.

While I was out in the workshop(shed), I cut and fitted the final small section of deck skinning to cover the last open area of the hull, so all the decking is now fitted.

When the glue drys I can cut-off the selvage edge that I have left over transom so the hull will be ready to be prepped for final finishing.

The length of the hull on this prototype has worked-out at being 30 5/8" overall.

Bob.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Never too old to learn

📝 Sprite

13 Views

Country: 🇬🇧 United Kingdom

Online: 19 minutes ago

Online: 19 minutes ago

That's good to hear. As I said the bow is usually well clear of the water, unless going through a chop so job done.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Scratch building 7 Faireys at a scale of 1:12

📝 Sprite

13 Views

Country: 🇬🇧 United Kingdom

Online: 6 minutes ago

Online: 6 minutes ago

Sprite Plus Prototype.

Morning Chris.

I popped out to the workshop(shed) last night and looked at fitting some spray rails to the hull.....and revised my first thoughts.

As long as they stop just before the balsa wood "nose cone" they would not have any severe curves to shape or worry about - so I bunged a pair on!

When the glue has dried, the ends will need shaping etc, but fixing them with PVA was no problem at all. The brass tacks had their heads cut off and the shafts were then driven down into the spray rails to give a mechanical fixing to supplement the glue bond.

Bob.

Morning Chris.

I popped out to the workshop(shed) last night and looked at fitting some spray rails to the hull.....and revised my first thoughts.

As long as they stop just before the balsa wood "nose cone" they would not have any severe curves to shape or worry about - so I bunged a pair on!

When the glue has dried, the ends will need shaping etc, but fixing them with PVA was no problem at all. The brass tacks had their heads cut off and the shafts were then driven down into the spray rails to give a mechanical fixing to supplement the glue bond.

Bob.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Never too old to learn

📝 Sprite

15 Views

Country: 🇬🇧 United Kingdom

Online: 6 minutes ago

Online: 6 minutes ago

I have considered both methods Chris.

The wood strip has to be bent across its width, so maybe some saw cuts would be best as it is not the natural way for the wood to bend.

When In get out to the workshop(shed) later I will take a look at it again.

Interesting that it may not be necessary though............

Bob.

The wood strip has to be bent across its width, so maybe some saw cuts would be best as it is not the natural way for the wood to bend.

When In get out to the workshop(shed) later I will take a look at it again.

Interesting that it may not be necessary though............

Bob.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Never too old to learn

📝 Sprite

16 Views

Country: 🇬🇧 United Kingdom

Online: 19 minutes ago

Online: 19 minutes ago

Steaming or saw cuts?

But I found a video on YouTube of one with an IC engine which was going quite quickly and no real problem with water as the bow is clear of the water and water is being thrown outwards quite far back where the curve of the hull then goes flat.

But I found a video on YouTube of one with an IC engine which was going quite quickly and no real problem with water as the bow is clear of the water and water is being thrown outwards quite far back where the curve of the hull then goes flat.

▲

⟩⟩

No likes yet

This member will receive 1 point

for every like received

This member will receive 1 point

for every like received

Scratch building 7 Faireys at a scale of 1:12

📝 Sprite

18 Views · 1 Like

Country: 🇬🇧 United Kingdom

Online: 6 minutes ago

Online: 6 minutes ago

Sprite Plus Prototype.

I did briefly lay a strip of 1/8 x 1/4 along the joint between the bottom and side skins and noticed that it will not be quite as easy to bend it along the curvature at the bows as I thought it would be.

The curvature at this point is more severe than it looks, and without the usual extended curve to the point of the bows there is less opportunity to persuade the strip to conform.

A suitable method will need to be devised.

Bob.

I did briefly lay a strip of 1/8 x 1/4 along the joint between the bottom and side skins and noticed that it will not be quite as easy to bend it along the curvature at the bows as I thought it would be.

The curvature at this point is more severe than it looks, and without the usual extended curve to the point of the bows there is less opportunity to persuade the strip to conform.

A suitable method will need to be devised.

Bob.

▲

⟩⟩

Madwelshman

Never too old to learn

📝 Sprite

19 Views · 1 Like

Country: 🇬🇧 United Kingdom

Online: 19 minutes ago

Online: 19 minutes ago

Hi Bob

No, the original Sprite doesn't have chine/spray rails and as you say it isn't a deep vee hull so the corner between the bottom and side skins is quite sharp so will act as a chine rail and help with turning.

But spray/water coming up the sides and over the deck is another matter. OK the rubbing strips will stop/deflect some of it and in theory the shallow angle of the hull and lack of flare at the bow should mean that water will be deflected outwards but you never know. So perhaps a good idea to fit them now rather than later and they do finish off the corner?

Worth a look at the video for Sprite but as Sprite Plus will be going faster then maybe they will be a good idea! 🤔😂

No, the original Sprite doesn't have chine/spray rails and as you say it isn't a deep vee hull so the corner between the bottom and side skins is quite sharp so will act as a chine rail and help with turning.

But spray/water coming up the sides and over the deck is another matter. OK the rubbing strips will stop/deflect some of it and in theory the shallow angle of the hull and lack of flare at the bow should mean that water will be deflected outwards but you never know. So perhaps a good idea to fit them now rather than later and they do finish off the corner?

Worth a look at the video for Sprite but as Sprite Plus will be going faster then maybe they will be a good idea! 🤔😂

▲

⟩⟩

Madwelshman

Scratch building 7 Faireys at a scale of 1:12

📝 Sprite

19 Views · 4 Likes

Country: 🇬🇧 United Kingdom

Online: 6 minutes ago

Online: 6 minutes ago

Sprite Plus Prototype.

Hi Chris,

The deck edges have been fixed in place - maybe slightly further forwards than you plan to stop yours on your outboard driven type, as mine actually overlap where the balsa nose blocks start - but only slightly.

I wanted to use them to further "tie-in" the balsa wood blocks to the hull side skins, but this may not work-out due to the curvature at the bows.

These deck edges may need to be sanded back as they join near the balsa part of the bows, but I will take another look tomorrow when the glue has set.

I see no spray rails drawn on your plan, and I am not sure whether to add them to the prototype build or not?

If fitted, the spray rails will help to lift the bows more easily, and that could be advantageous with such a flat nosed hull, but the design may not need them as I don't think the original LesRo Sprite had any?

I have no plans to make or fit any strakes to this hull as it is not a deep "V" type and my similar shaped shallow Remora hull drives beautifully without them.....but it does have spray rails.

Something to ponder over while the glue dries on the deck edges........

Bob.

Hi Chris,

The deck edges have been fixed in place - maybe slightly further forwards than you plan to stop yours on your outboard driven type, as mine actually overlap where the balsa nose blocks start - but only slightly.

I wanted to use them to further "tie-in" the balsa wood blocks to the hull side skins, but this may not work-out due to the curvature at the bows.

These deck edges may need to be sanded back as they join near the balsa part of the bows, but I will take another look tomorrow when the glue has set.

I see no spray rails drawn on your plan, and I am not sure whether to add them to the prototype build or not?

If fitted, the spray rails will help to lift the bows more easily, and that could be advantageous with such a flat nosed hull, but the design may not need them as I don't think the original LesRo Sprite had any?

I have no plans to make or fit any strakes to this hull as it is not a deep "V" type and my similar shaped shallow Remora hull drives beautifully without them.....but it does have spray rails.

Something to ponder over while the glue dries on the deck edges........

Bob.

▲

⟩⟩

Madwelshman

EdW

ChrisF

robbob

Never too old to learn

Vice Admiral

Vice Admiral United Kingdom

United Kingdom