Join Us On Social Media!

Hopper Barge

7 Posts · 6 Followers · 15 Photos · 41 Likes

Began 9 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 7 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 That didn't end well

7 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 38 Views · 5 Likes · 4 Comments

Flag

💬 Add Comment

Here I was just testing the motor and ESC (Brushed) on the bench. All was going well, until I switched the ESC off. Then, poof it went, a cloud of white smoke coming from it and a spray of hot solder. See picture. Now the house stinks of burnt electronics (Wife not impressed). It was an Mtroniks Viper Marine 40A ESC which I have had for a number of years and has never been stressed. I don't think it ever had more than 8 Amps through it. It was also a replacement, as the first one blew up. I have never bought another. They are now £53 so it was not going to be replaced. Luckily the slow blow 10 Amp inline fuse blew otherwise I might have had a bigger problem. This was going in the Kort Nozzle test rig. So back to the drawing board. 😁 Before anyone asks. Yes it was running within spec. IE.. correct input voltage etc.....😁

▲

⟩⟩

Len1

EdW

peterd

SouthportPat

AlessandroSPQR

|

💬 Re: That didn't end well

7 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 23 Views · 1 Like

Flag

Hey SS. Any progress getting operational? I mentioned you were building an ATB but what you’re building, as you previously mentioned, is a powered barge.

This will be a very interesting build, especially when you are kindly testing two different Kort configurations. ▲

⟩⟩

Len1

|

|

Login To

Remove Ads 💬 Re: That didn't end well

7 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 31 Views · 3 Likes

Flag

Too bad. Not altogether surprising given that

there are at least four or five lengthy threads about problems with Mtroniks escs in a U.S. forum. Most issues related to failures when they are used with twin motors. I myself had failure problems using their escs in a twin motor application. Mtroniks replaced about four esc’s that failed. Working directly with tech support we were unable to resolve the problem; finally gave up even after optically isolating them. Small consolation but you are not alone…… by a long shot. ▲

⟩⟩

Len1

AlessandroSPQR

SimpleSailor

|

|

💬 Re: That didn't end well

7 months ago by 🇬🇧 SouthportPat (

Commodore) Commodore)✧ 33 Views · 2 Likes

Flag

I have always found Mtronics to be good at replacing defective units - give them a try - they are too expensive to just write it off

▲

⟩⟩

Len1

SimpleSailor

|

|

💬 Re: That didn't end well

7 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 33 Views · 3 Likes

Flag

Hi Simple Sailor, you meant (brushed) not (brushless), right?

▲

⟩⟩

Len1

SimpleSailor

Trident73

|

Login To

Remove Ads

Remove Ads

📝 Caught by the Kort

7 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 46 Views · 7 Likes · 5 Comments

Flag

💬 Add Comment

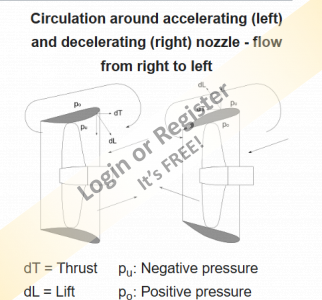

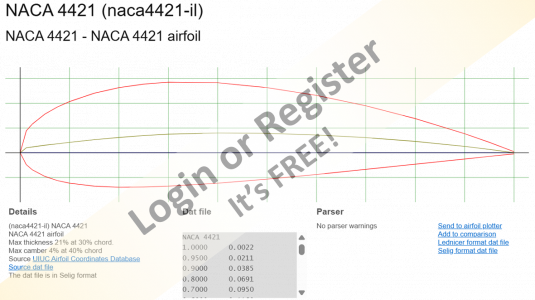

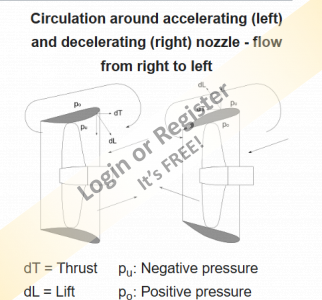

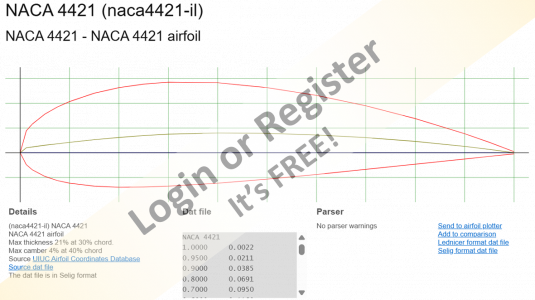

Well after Chum444 suggestion I thought I would venture into Kort type nozzles. Little did I know I would be getting into such an interesting subject. So I have learned that it is not just "stick a pipe over the propeller and that will do" As always I try not to buy parts when I can use CAD and 3D. So now I have got into hydrodynamics, or at least bit of an understanding. I am used to looking at NACA (National Advisory Committee for Aeronautics) aerofoil sections as I have been designing a 3D printed sail wing. I hadn't realised they use NACA sections in Kort design (Makes sense I suppose). The pictures show where I am at. (1) is my own idea before I found out about NACA. (2) is NACA 4421 profile from a professional design, but I got the cord alignment wrong. (3) is the same with the cord aligned in the correct manner. (4) Is what I think will be the best as it is based on the diagram in picture HE-Kort (3rd from left). All will be tested.

▲

⟩⟩

Commodore-H

LewZ

DuncanP

EdW

AlessandroSPQR

hermank

Chum444

|

💬 Re: Caught by the Kort

7 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 31 Views · 1 Like

Flag

SS; I just saw this post.Way cool idea! After you get by the esc failure your results will be very interesting. 👍👍

▲

⟩⟩

Len1

|

|

Login To

Remove Ads 💬 Re: Caught by the Kort

7 months ago by 🇬🇧 SimpleSailor (

Lieutenant) Lieutenant)✧ 36 Views · 3 Likes

Flag

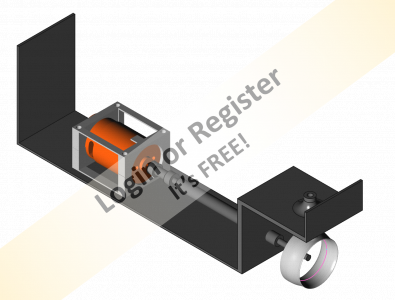

Hi Chum444. Are you a mind reader ?😁. I am just designing a test rig where I can measure in Kg the thrust produced. I will use the same prop in all cases and start with a none Kort as the reference. The picture is just the start. I will post the finished rig when done and eventually the results.

▲

⟩⟩

Len1

Chum444

AlessandroSPQR

|

|

💬 Re: Caught by the Kort

7 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 38 Views · 6 Likes

Flag

Good afternoon SS. Interested in an experiment? Since you are versed in 3D printing, you could create two Korts; one with an airfoil internal diameter, the second with a constant (straight) diameter. Try them both on your ATB to see if you notice a difference in maneuverability. All of this if set up on the printer is not too onerous.

Interestingly I read that the Korts were originally used to reduce erosion of the banks & bottom of European canals. In addition, their main value in 1:1 vessels is to increase thrust per shaft horsepower. I had thought they were employed to improve maneuverability. Shows what I know! ▲

⟩⟩

Len1

Commodore-H

AlessandroSPQR

SimpleSailor

hermank

Ronald

|

|

💬 Re: Caught by the Kort

7 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 44 Views · 4 Likes

Flag

Hi Simple Sailor, your study and practical application of Kort nozzles is truly interesting and commendable.

By the way, a quick aside: did you know that even though it bears the name Kort, it was developed in 1930 by the Italian aeronautical engineer Luigi Stipa and perfected by the German naval architect Ludwig Kort? You're doing great things with the 3D printer. I believe you're the most advanced and skilled among us in this field. You don't just make small parts, but entire boats—well done. To the question I asked in another thread about tools, you'd answer: just a 3D printer, hahaha. You don't need anything else. You also need a PC, of course. I'll be following further developments on Kort nozzles with interest. ▲

⟩⟩

Len1

Steves-s

hermank

SimpleSailor

|

|

💬 Re: Caught by the Kort

7 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 46 Views · 3 Likes

Flag

SS, you are really into the concept! I’m certain you will love the Kort. However, you will need to change your user name from SS. How about Hydro D Sailor?

▲

⟩⟩

AlessandroSPQR

hermank

SimpleSailor

|

📝 Next challenge.

7 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 51 Views · 7 Likes · 2 Comments

Flag

💬 Add Comment

Having been successful with my 3D printed hull concept I have decided to make the the next project a self propelled Hopper Barge. I have just started the design work which is loosely based on the attached pictures. It works out at about 1/54 scale which is a bit odd but suites my printer. Although the pictured barge uses a 360° Schottle drive and bow thruster I will be going with a conventional inline 480 brushed motor.

▲

⟩⟩

Len1

EdW

hermank

ToraDog

peterd

Chum444

AlessandroSPQR

|

💬 Re: Next challenge.

7 months ago by 🇬🇧 SimpleSailor (

Lieutenant) Lieutenant)✧ 49 Views · 4 Likes

Flag

Hi Chum444. Yes I have and I might well make that an option. I am just messing with the rudder design at the moment and have opted for a symmetrical aerofoil section with upper and lower plates. It is supposed to be very manoeuvrable and lessen cavitation. Not that cavitation would really be a problem on a thing this size.😁

▲

⟩⟩

Len1

EdW

hermank

Chum444

|

|

💬 Re: Next challenge.

7 months ago by 🇺🇸 Chum444 (

Commodore) Commodore)✧ 49 Views · 2 Likes

Flag

Nice project. Have you considered a single steerable Kort nozzle? The difference in maneuverability over an open screw will please you.

▲

⟩⟩

hermank

SimpleSailor

|

📝 New blog

8 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 56 Views · 2 Likes

Flag

💬 Add Comment

Having not done a build blog before I didn't realise I could have just updated this blog. However I ended up creating a new blog "Update to Hybrid Hull" so this continues there..🤔

▲

⟩⟩

hermank

AlessandroSPQR

📝 Hull ideas

9 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 60 Views · 3 Likes

Flag

💬 Add Comment

While looking into hull design to reduce print time I have come up with another idea. So Fig 1. is the original idea where the ply/balsa was sandwiched between the hull walls and Fig 2. has the ply/balsa as cladding on the outside of the hull. They both take about the same amount of time to print: 2.5 hours per 50mm height. This is better than the solid plastic hull at 7.25 Hours per 50mm. It is just a case of which one would be nicer to work with.

▲

⟩⟩

EdW

hermank

AlessandroSPQR

📝 New idea for printing

9 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 65 Views · 5 Likes · 2 Comments

Flag

💬 Add Comment

Having just put the barge design into the slicer and looked at the printing times which were very long (30 odd hours) I had a thought 😀. Why not print the hull in Spiralised Vase Mode. This gives one wall (0.8mm thick) on the inner and outer. It has no change of level steps as it prints a continues line and gives a very smooth surface. So the experiment goes on. The infill is only suitable for the long lengths of the hull. The stern and bow will still be normal plastic prints with infill. The infill can be 3mm ply or Balsa. Maybe ply as it will give it some weight. The hull will of course be sealed and painted.

▲

⟩⟩

EdW

hermank

LazyFerret

BOATSHED

RNinMunich

|

💬 Re: New idea for printing

9 months ago by 🇬🇧 SimpleSailor (

Lieutenant) Lieutenant)✧ 64 Views · 1 Like

Flag

Hi Boatshed. It is a difficult thing to quantify without putting a Watt meter in circuit with the printer. However my printer has a 300 Watt power supply. That does not mean it uses 300 Watts, it is what is available. The heated bed and the hot nozzle are controlled by a PWM (Pulse Width Modulated) signal so are not on all the time. The average power used would have to be taken. I might actually measure the AC current one day and work it out. As an estimate, if you were paying £0.26 per KWH (per 1000 watt hour) and the printer used an average of 200 Watts it would cost £0.052 per hour, so 30 hours of print time would be £1.56. For me it is about the time hanging around waiting for it to print. The cost does not bother me. I try and design my items to be robust but print fast.

▲

⟩⟩

hermank

|

|

💬 Re: New idea for printing

9 months ago by 🇬🇧 BOATSHED (

Commander) Commander)✧ 64 Views · 1 Like

Flag

Ian confused with the 3d printing, you say 30 odd hours??

What does that add to your electric bill ?? ▲

⟩⟩

hermank

|

📝 Hopper Barge

9 months ago by 🇬🇧 SimpleSailor ( Lieutenant)

Lieutenant)

Lieutenant)

Lieutenant)✧ 91 Views · 12 Likes · 3 Comments

Flag

💬 Add Comment

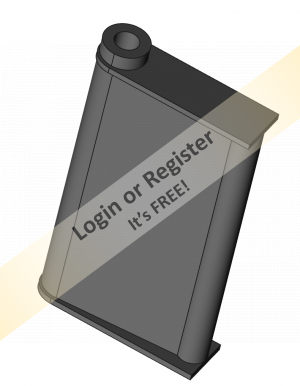

A friend of mine has asked me to make him a Hopper type barge to tow behind his tug. He already has a scratch built shoe box, but it does not tow well and doesn't look the part. I will be 3D printing it and I have designed it in FreeCAD. Attached is my first attempt. I should mention that it has to fit in his transport box. It is, length-542 x beam-150 x depth-120 mm. The sections are glued together and use the 1.75mm filament as location pins. The bow section can be used as a stern.

▲

⟩⟩

RNinMunich

Len1

xtramaths

Mike Stoney

EdW

hermank

MartyV

LeeA1

AlessandroSPQR

Ronald

SouthportPat

Wolle

|

💬 Re: Hopper Barge

9 months ago by 🇬🇧 PeterJ (

Chief Petty Officer 1st Class) Chief Petty Officer 1st Class)✧ 69 Views · 2 Likes

Flag

Looks good can you make these for sale ?

▲

⟩⟩

SimpleSailor

Len1

|

|

Login To

Remove Ads 💬 Re: Hopper Barge

9 months ago by 🇦🇺 B rian J ames (

Petty Officer 2nd Class) Petty Officer 2nd Class)✧ 82 Views · 3 Likes

Flag

Keep it 'Simple Sailor'?, Have U tried skeg(s), aft, & or a 'yoke & or bridle' forward? 'B J', 'B'ad Dad 'J'oke???). 🤔 ( No 'Yoke' intended, let alone a pun. I'm normally very 'punny'? 🤣 All the best.

▲

⟩⟩

Len1

SimpleSailor

hermank

|

|

💬 Re: Hopper Barge

9 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 84 Views · 4 Likes

Flag

Bravo SimpleSailor, well done.

I am very interested in the program you mentioned FreeCad, but I do not know it. I assume it is free, according to its name. How do you like FreeCad? Can you make hulls with more curved lines? ▲

⟩⟩

Len1

SimpleSailor

Mike Stoney

hermank

|

United Kingdom

United Kingdom