Join Us On Social Media!

Fairey huntsman ladder

9 Posts · 6 Followers · 10 Photos · 50 Likes

Began 11 months ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 11 months ago by

( Newest Posts Shown First )

📝 Fairey huntsman ladder

33 Views · 4 Likes

Country: 🇩🇪 Germany

Online: 3 days ago

Online: 3 days ago

I agree with you John👍

The two joints we can see are a bit lumpy, indicating that the solder did not flow and attach to both parts properly. Typical sign of not enough heat, or possibly the parts and/or iron tip are not clean.

If the parts are not clean surface oxidation can prevent proper flow and bonding. I always clean both parts with 600 grit wet and dry paper.

Typical multicore resin solder needs an iron bit temperature of around 250-270°C.

I use 0.5mm diameter solder for electronic work, 1mm for brass/copper work.

25W iron for electronics, 50W or mini gas torch for metalwork.

Wez; A proper joint should show a clean, smooth, shiny curve between both parts.

Any 'joint' that looks dull grey or silver is a bad/cold one.

A clean iron tip is also paramount! When it's hot, and any residual solder has melted, clean the tip on a damp sponge. Then 'tin' the tip with a little fresh solder which should flow around the tip IF it is hot enough. If not the solder collects in a ball on the tip indicating that the tip needs cleaning and/or more heat.

This thin film of fresh solder is necessary to ensure proper heat flow to the two parts to be joined.

Your first attempt is quite creditable Wez. 👍

Hope this info helps with your next creations Wez.

Cheers, Doug😎

@Barry: Like you I spent many years working in electronics, 47 to be precise. Tempus fugit🙄

And just as many years as a hobby, home made ESCs, special function switch controllers etc. etc.😉Nowadays with inexpensive 'thumbnail' size modules it's hardly worth the effort, BUT I still like the challenge😁

The two joints we can see are a bit lumpy, indicating that the solder did not flow and attach to both parts properly. Typical sign of not enough heat, or possibly the parts and/or iron tip are not clean.

If the parts are not clean surface oxidation can prevent proper flow and bonding. I always clean both parts with 600 grit wet and dry paper.

Typical multicore resin solder needs an iron bit temperature of around 250-270°C.

I use 0.5mm diameter solder for electronic work, 1mm for brass/copper work.

25W iron for electronics, 50W or mini gas torch for metalwork.

Wez; A proper joint should show a clean, smooth, shiny curve between both parts.

Any 'joint' that looks dull grey or silver is a bad/cold one.

A clean iron tip is also paramount! When it's hot, and any residual solder has melted, clean the tip on a damp sponge. Then 'tin' the tip with a little fresh solder which should flow around the tip IF it is hot enough. If not the solder collects in a ball on the tip indicating that the tip needs cleaning and/or more heat.

This thin film of fresh solder is necessary to ensure proper heat flow to the two parts to be joined.

Your first attempt is quite creditable Wez. 👍

Hope this info helps with your next creations Wez.

Cheers, Doug😎

@Barry: Like you I spent many years working in electronics, 47 to be precise. Tempus fugit🙄

And just as many years as a hobby, home made ESCs, special function switch controllers etc. etc.😉Nowadays with inexpensive 'thumbnail' size modules it's hardly worth the effort, BUT I still like the challenge😁

▲

⟩⟩

Peejay

Len1

hermank

BarryS

Young at heart 😉 Slightly older in other places.😊 Cheers Doug

📝 Fairey huntsman ladder

41 Views · 4 Likes

Country: 🇳🇿 New Zealand

Online: 2 days ago

Online: 2 days ago

Making jigs for this sort of work pays off. well done Cheers Ian

▲

⟩⟩

Len1

hermank

RNinMunich

Wez

Ian Langley

📝 Fairey huntsman ladder

46 Views · 3 Likes

Country: 🇬🇧 United Kingdom

Online: 9 months ago

Online: 9 months ago

You've done well, I struggle on straight forward electrical soldering. Neil

▲

⟩⟩

Len1

hermank

Wez

📝 Fairey huntsman ladder

48 Views · 4 Likes

Country: 🇬🇧 United Kingdom

Online: 8 months ago

Online: 8 months ago

I'm pretty sure it's a lot better than I could do and I was in electronics for over 20 years, both as a hobby and as my career.

Nicely done.

Nicely done.

▲

⟩⟩

Len1

hermank

RNinMunich

Wez

📝 Fairey huntsman ladder

52 Views · 4 Likes

Country: 🇺🇸 United States

Online: 4 hours ago

Online: 4 hours ago

Wez, the ladder looks really good.

If I might offer a suggestion, I looked at the solder joints

and it appears that the joints need to be a bit hotter than

you are getting them.

The solder should be very smooth connecting to each brass

part.

Try some scrap brass pieces and see the difference in a

"cold joint" and one that is hot enough.

Congratulations on taking on a new challenge and enjoy the experience!

Barry

If I might offer a suggestion, I looked at the solder joints

and it appears that the joints need to be a bit hotter than

you are getting them.

The solder should be very smooth connecting to each brass

part.

Try some scrap brass pieces and see the difference in a

"cold joint" and one that is hot enough.

Congratulations on taking on a new challenge and enjoy the experience!

Barry

▲

⟩⟩

Len1

hermank

RNinMunich

Wez

📝 Fairey huntsman ladder

60 Views · 3 Likes

Country: 🇺🇸 United States

Online: 8 hours ago

Online: 8 hours ago

📝 Fairey huntsman ladder

68 Views · 4 Likes

Country: 🇬🇧 United Kingdom

Online: 13 days ago

Online: 13 days ago

You've made an excellent job of the ladder. A very good finishing touch to the boat.

▲

⟩⟩

jumpugly

Len1

Wez

hermank

📝 Fairey huntsman ladder

69 Views · 8 Likes

Country: 🇩🇪 Germany

Online: 3 days ago

Online: 3 days ago

Young at heart 😉 Slightly older in other places.😊 Cheers Doug

📝 Fairey huntsman ladder

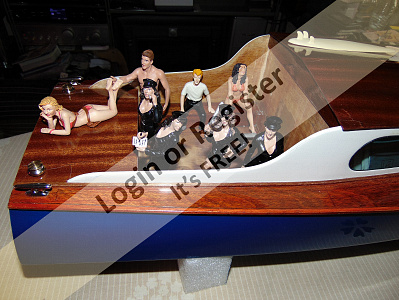

75 Views · 16 Likes

Country: 🇬🇧 United Kingdom

Online: 7 months ago

Online: 7 months ago

So last couple of days has ended in this finish ,I hope it’s up to scratch as it’s my very first time soldering ,after making a jig well an old sale board with a couple of holes in to keep the frame straight and a few washers and bits of wood finally think I’m getting the hang of soldering ,bit of clean up to do but I’m pleased

▲

⟩⟩

Rookysailor

IanL1

roycv

DuncanP

JohnJ1

ChrisF

RogerA1

Mike Stoney

Ray

jumpugly

Len1

hermank

Wolle

Razor1955

DWBrinkman

RNinMunich

Midshipman

Midshipman United Kingdom

United Kingdom Fleet Admiral

Fleet Admiral Germany

Germany Recruit

Recruit Petty Officer 2nd Class

Petty Officer 2nd Class Warrant Officer

Warrant Officer Admiral

Admiral

Chief Petty Officer 2nd Class

Chief Petty Officer 2nd Class