Join Us On Social Media!

Pride of Baltimore 1981

17 Posts · 15 Followers · 114 Photos · 112 Likes

Began 4 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 6 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Pride of Paint

6 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 13 Views · 1 Like

Flag

💬 Add Comment

▲

⟩⟩

RNinMunich

Login To

Remove Ads

Remove Ads

📝 Wet Bulb

9 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 30 Views · 4 Likes

Flag

💬 Add Comment

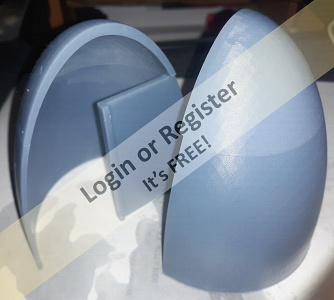

The bulb, aside from paint drying, is basically done!

In total, 3 coats of epoxy, 2 coats of primer, and 2 coats of Moss Green paint, to match the hull.

The thin epoxy ran all over the place with me, brush in hand, chasing it, best I could; but there's still drags and runs, but it's encased in epoxy and functional. Now to see it in the boat.

In total, 3 coats of epoxy, 2 coats of primer, and 2 coats of Moss Green paint, to match the hull.

The thin epoxy ran all over the place with me, brush in hand, chasing it, best I could; but there's still drags and runs, but it's encased in epoxy and functional. Now to see it in the boat.

▲

⟩⟩

RodC

DuncanP

SouthportPat

RossM

📝 Epoxying the bulb

9 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 33 Views · 5 Likes

Flag

💬 Add Comment

It turned out to be a nice day, so after mowing, I got out the disk sander and sanded the lumpy bulb out in the driveway. It was quicker work than I expected, so I mixed up some epoxy (without sawdust) and coated the thing. This is sold as "pouring epoxy" so it's pretty runny, and takes a while to set.

Once it set , it got a sand and another lite coat of epoxy; then it was sanded and primed - twice; then sanded and painted Moss Green - twice. I think that just about does it for the ballast bulb.

Once it set , it got a sand and another lite coat of epoxy; then it was sanded and primed - twice; then sanded and painted Moss Green - twice. I think that just about does it for the ballast bulb.

▲

⟩⟩

RodC

premecekcz

Peejay

SouthportPat

RossM

📝 Epoxy on the Bulb

9 months ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 42 Views · 4 Likes · 1 Comment

Flag

💬 Add Comment

I mixed up epoxy and sawdust for gluing on Constellation's pin-rails, and made some extra to"glass" Pride's ballast-bulb. Instead of glass cloth, I use a piece of pantyhose. Despite the sawdust, the epoxy was still rather thin, and kept running out of the gap I was trying to fill, while I chased it with a stick trying to keep it in there.

It's going to require some sanding, but it'll have to wait till it decides to quit raining, cause I'm not doing that inside.

It's going to require some sanding, but it'll have to wait till it decides to quit raining, cause I'm not doing that inside.

▲

⟩⟩

Peejay

hermank

SouthportPat

RossM

|

💬 Re: Epoxy on the Bulb

9 months ago by 🇨🇦 RossM (

Captain) Captain)✧ 44 Views · 3 Likes

Flag

Thanks Jerry, You are at the stage I want to go to next. I watch with great interest

▲

⟩⟩

Peejay

Jerry Todd

SouthportPat

|

📝 Egg Delayed

1 year ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 52 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

It got really hot for a while there, and I was waiting for a day not-so-hot to work with glassing the egg, instead, I went and had a stroke on June 22nd.

It wasn't as bad as it could have been, but I'm still working back from it. I was away the whole month of September in the US South-east, visiting family, the beach, and a nice museum in Savannah GA which I get into more in my Constellation thread.

Anyway, now I'm home and I'll try getting back to Pride's egg and maybe getting her sailing by spring, or even a nice winter day if I can.

It wasn't as bad as it could have been, but I'm still working back from it. I was away the whole month of September in the US South-east, visiting family, the beach, and a nice museum in Savannah GA which I get into more in my Constellation thread.

Anyway, now I'm home and I'll try getting back to Pride's egg and maybe getting her sailing by spring, or even a nice winter day if I can.

▲

⟩⟩

premecekcz

Peejay

SouthportPat

Mike Stoney

EdW

hermank

Len1

jbkiwi

LewZ

|

💬 Re: Egg Delayed

1 year ago by 🇨🇭 Mike Stoney (

Rear Admiral) Rear Admiral)✧ 51 Views · 5 Likes

Flag

Hello Jerry!

Get well soon on my part, recover well! Best wishes, Michel-C. ▲

⟩⟩

Peejay

SouthportPat

Len1

Jerry Todd

hermank

|

|

💬 Re: Egg Delayed

1 year ago by 🇺🇸 Len1 (

Lieutenant Commander) Lieutenant Commander)✧ 66 Views · 6 Likes

Flag

sorry to hear about your stroke. Keep up the recovery and regain your strength and mobility. I know as I seek from experience as I had a mild stroke last month.

Len ▲

⟩⟩

Peejay

SouthportPat

Mike Stoney

Jerry Todd

hermank

AlessandroSPQR

|

📝 Pride's Egg

2 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 60 Views · 8 Likes

Flag

💬 Add Comment

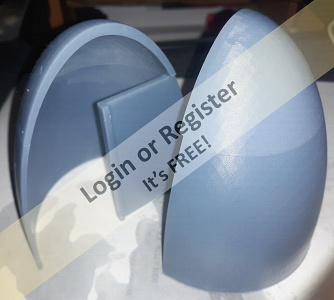

Finally the temperatures and my time have coincided enough that I may finally get closer to getting this ostrich egg finished.

It seems the resin egg deformed a little from the weight, so the two halves don't lay flat to each other any more. If I do this again, and for you folks thinking of using this method, I'ill model ribs inside the bulb to stiffen it, and maybe fashion some sort of cradle for it to sit it on that supports it so the bulb doesn't try to flatten out as the lead and epoxy set-up.

There were also dry pockets in the bulb that resin hadn't gotten to and I could hear the shot rattling around inside. If there's a next time, I'll place shot and pour resin in layers to ensure the resin gets everywhere it needs to be. What sounded like the biggest of these pockets was behind the flange I had modeled in for the plate to slide into. I opened the holes here to pour more resin in and hopefully fill this void.

I re-drilled the holes for the pin that will keep the bulb from sliding off the plate, and cut about a 3 inch length of 3/16" brass rod for the pin.

I mixed very fine sawdust from my band-saw with the epoxy to make a paste of it, buttered both sides of the bulb, placed the pin, and plate, and put the other half on.

I used a wood shim at he bottom to hold the seam closed on top, where the plate enters, as close as I could, so most of the gap is at the bottom. The epoxy butter filled this in fairly well, but the seam's still open almost all the way around, which I'll fill with more epoxy butter.

The bulb also needs some clean-up from epoxy runs and cardboard that stuck to it; though I intend to wrap it in some 6oz glass cloth as that'll be stronger than the resin alone if the boat should hit a rock or something.

It seems the resin egg deformed a little from the weight, so the two halves don't lay flat to each other any more. If I do this again, and for you folks thinking of using this method, I'ill model ribs inside the bulb to stiffen it, and maybe fashion some sort of cradle for it to sit it on that supports it so the bulb doesn't try to flatten out as the lead and epoxy set-up.

There were also dry pockets in the bulb that resin hadn't gotten to and I could hear the shot rattling around inside. If there's a next time, I'll place shot and pour resin in layers to ensure the resin gets everywhere it needs to be. What sounded like the biggest of these pockets was behind the flange I had modeled in for the plate to slide into. I opened the holes here to pour more resin in and hopefully fill this void.

I re-drilled the holes for the pin that will keep the bulb from sliding off the plate, and cut about a 3 inch length of 3/16" brass rod for the pin.

I mixed very fine sawdust from my band-saw with the epoxy to make a paste of it, buttered both sides of the bulb, placed the pin, and plate, and put the other half on.

I used a wood shim at he bottom to hold the seam closed on top, where the plate enters, as close as I could, so most of the gap is at the bottom. The epoxy butter filled this in fairly well, but the seam's still open almost all the way around, which I'll fill with more epoxy butter.

The bulb also needs some clean-up from epoxy runs and cardboard that stuck to it; though I intend to wrap it in some 6oz glass cloth as that'll be stronger than the resin alone if the boat should hit a rock or something.

▲

⟩⟩

premecekcz

SouthportPat

Mike Stoney

hermank

Len1

Razor1955

Peejay

EdW

📝 Ballast Eggs and Inflato Boats

2 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 82 Views · 10 Likes · 2 Comments

Flag

💬 Add Comment

After throwing the boat in the tub and figuring out how much weight she needs to put on to sail pretty, I had to figure out how to form that weight. I already planned an ostrich egg shaped lead bulb, but I needed to figure the size of the thing to get the weight I wanted, and then make a plug of it to sand-cast the lead.

It popped into my head to 3D model and print the form for the bulb, then I could change the size and shape to get the volume to get 25 pounds. I have 50 pounds of reclaimed lead shot laying around just for this purpose, but I don't have the tools and materials for melting and casting. Then I figured, why not make the 3D printed bulb a container for the lead, just like my Constellation uses a 2" ID PVC pipe filled with lead shot for ballast, I'll make a plastic egg shaped version of that.

I started by making a ball in Anim8or (my 3D modeling software) with it's surfaces facing inward. Then I looked up how to calculate the volume and found a nice Ellipsoid Calculator where I could plug in numbers in millimeters (what Anim8or uses) and get an answer in cubic inches (what my brain uses). Lead weighs .41 of a pound per cubic inch, meaning I need a volume of about 61 cubic inches. Playing with the numbers on the site, I settled on a=50mm, b=105mm, and c=45mm, giving me 60.62 cubic inches, or 24.9 pounds. The weight of the metal fin, the resin shell, the epoxy fill, etc should put this really close to 25 pounds.

Adjusting my 3D ball into an ellipsoid of those dimensions gave me the inner surface of my bulb. I copied that, enlarged it, and flipped the surface to face outward, giving me the outer surface of the bulb and making it slightly over 1/8" thick. I closed the gaps between the two surfaces, and added a slot and some structure for the fin to sit on. Even in two halves, it wasn't going to fit in the 3D printer, so I divided it into quarters and then I could print 2 parts, or half the bulb at a time.

Once printed, the pieces were bonded together to form a left and a right half. These were filled with lead shot, and epoxy poured into each half to bond everything together and make it solid. The fin has a hole that will be inside the bulb with a metal pin so when the halves are bonded together, that pin removes any chance of the bulb coming off the fin.

The two halves haven't been bonded together yet as it's been too cold in my unheated shop.

In the warm house, I've been 3D modeling boats for Constellation, and a kind of generic inflatable boat for Pride. When I was on board, Pride had four boats;

Two inflatables; a beat-up old faded red or orange one, and a new gray one meant to replace it.

The "Bequia Boat" that went into storage soon after I reported on board, and came back out just before I left the boat.

A lapstrake boat about 16 foot, that sat inverted on the stern davits my whole time aboard. I was told it would need to soak for a month to swell up, and even then it would leak like a sieve.

Aside from the orange inflatable, I'll only be modeling the stern-boat. I have a 3D model of a boat with about the right shape, I just need to scale it to size and print it.

Ellipsoid Calculator:

It popped into my head to 3D model and print the form for the bulb, then I could change the size and shape to get the volume to get 25 pounds. I have 50 pounds of reclaimed lead shot laying around just for this purpose, but I don't have the tools and materials for melting and casting. Then I figured, why not make the 3D printed bulb a container for the lead, just like my Constellation uses a 2" ID PVC pipe filled with lead shot for ballast, I'll make a plastic egg shaped version of that.

I started by making a ball in Anim8or (my 3D modeling software) with it's surfaces facing inward. Then I looked up how to calculate the volume and found a nice Ellipsoid Calculator where I could plug in numbers in millimeters (what Anim8or uses) and get an answer in cubic inches (what my brain uses). Lead weighs .41 of a pound per cubic inch, meaning I need a volume of about 61 cubic inches. Playing with the numbers on the site, I settled on a=50mm, b=105mm, and c=45mm, giving me 60.62 cubic inches, or 24.9 pounds. The weight of the metal fin, the resin shell, the epoxy fill, etc should put this really close to 25 pounds.

Adjusting my 3D ball into an ellipsoid of those dimensions gave me the inner surface of my bulb. I copied that, enlarged it, and flipped the surface to face outward, giving me the outer surface of the bulb and making it slightly over 1/8" thick. I closed the gaps between the two surfaces, and added a slot and some structure for the fin to sit on. Even in two halves, it wasn't going to fit in the 3D printer, so I divided it into quarters and then I could print 2 parts, or half the bulb at a time.

Once printed, the pieces were bonded together to form a left and a right half. These were filled with lead shot, and epoxy poured into each half to bond everything together and make it solid. The fin has a hole that will be inside the bulb with a metal pin so when the halves are bonded together, that pin removes any chance of the bulb coming off the fin.

The two halves haven't been bonded together yet as it's been too cold in my unheated shop.

In the warm house, I've been 3D modeling boats for Constellation, and a kind of generic inflatable boat for Pride. When I was on board, Pride had four boats;

Two inflatables; a beat-up old faded red or orange one, and a new gray one meant to replace it.

The "Bequia Boat" that went into storage soon after I reported on board, and came back out just before I left the boat.

A lapstrake boat about 16 foot, that sat inverted on the stern davits my whole time aboard. I was told it would need to soak for a month to swell up, and even then it would leak like a sieve.

Aside from the orange inflatable, I'll only be modeling the stern-boat. I have a 3D model of a boat with about the right shape, I just need to scale it to size and print it.

Ellipsoid Calculator:

▲

⟩⟩

SouthportPat

Peejay

RobW1

Len1

RossM

Fred

EdW

hermank

Colin H

River Rat

|

💬 Re: Ballast Eggs and Inflato Boats

2 years ago by 🇺🇸 Jerry Todd (

Sub-Lieutenant) Sub-Lieutenant)✧ 73 Views · 5 Likes

Flag

There's a hole in the fin near it's bottom, same size as the holes towards the top of it. After the lead went in, using that hole as a guide, I drilled into, but not through, each half of the bulb. A metal rod about 6cm or so will be captured in these holes to prevent the bulb from sliding off. It will also be epoxied in when the two halves are epoxied together.

When it warms up enough to do all that, I'll post pictures of the process here.

▲

⟩⟩

RodC

SouthportPat

hermank

EdW

Len1

|

|

💬 Re: Ballast Eggs and Inflato Boats

2 years ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 79 Views · 2 Likes

Flag

How does the bulb attach to the fin?

▲

⟩⟩

SouthportPat

Len1

|

📝 Long time no see

2 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 90 Views · 11 Likes · 1 Comment

Flag

💬 Add Comment

I was going to slap together a temporary trough to float the model in to determine what the weight the bulb on her fin would need to be, but I'm either up to my neck with other stuff or too worn out to motivate myself through the shop door.

I finally put the model in the tub, in which she barely fit, and figured out the bulb will need to be 25 pounds (11kg) to sit about 1/2" below her painted water line. Adding the battery and some lead-shot bean-bags will trim her where I want her for sailing.

I'm still up in the air on how to make the bulb; whether to melt and cast the lead, or cast the lead in epoxy. I'm leaning toward the epoxy casting, and have ordered the epoxy to do the job (and to do some other jobs like repair the pram).

In either case it will be made in two halves and somewhat "wing" shaped; something like this model's, though Pride's fin is longer, wider?

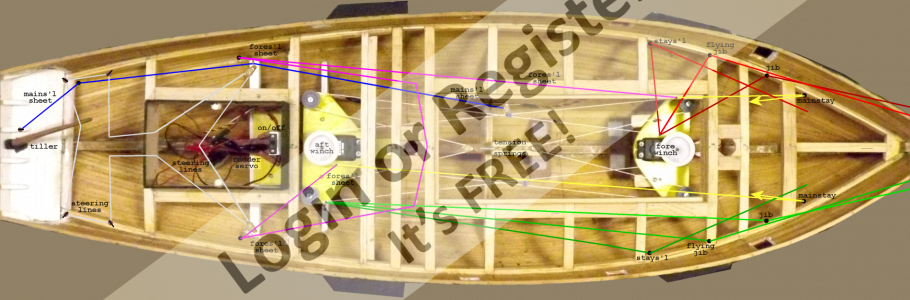

Meanwhile, the masts are back in and I've been playing with the sail controls again. I seized dress hook loops to the winch lines (red arrows) to attach the sheets and figure out how to keep everything neat and untangled.

I finally put the model in the tub, in which she barely fit, and figured out the bulb will need to be 25 pounds (11kg) to sit about 1/2" below her painted water line. Adding the battery and some lead-shot bean-bags will trim her where I want her for sailing.

I'm still up in the air on how to make the bulb; whether to melt and cast the lead, or cast the lead in epoxy. I'm leaning toward the epoxy casting, and have ordered the epoxy to do the job (and to do some other jobs like repair the pram).

In either case it will be made in two halves and somewhat "wing" shaped; something like this model's, though Pride's fin is longer, wider?

Meanwhile, the masts are back in and I've been playing with the sail controls again. I seized dress hook loops to the winch lines (red arrows) to attach the sheets and figure out how to keep everything neat and untangled.

▲

⟩⟩

SouthportPat

Mike Stoney

Peejay

EdW

Colin H

AlessandroSPQR

AndyN

Len1

MartinW

TonyAsh

luckyduck

|

💬 Re: Long time no see

2 years ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 86 Views · 1 Like

Flag

Salute Jerry.

Che spettacolo! Devo ancora guardarmi tutto questo lavoro fin dall'inizio con calma, ma sono rimasto affascinato dal sistema di comando delle vele. Non ci ho capito ancora niente in quell'intrigo di cavi, ma sono rimasto affascinato, troppo bello. Osservando piano piano, capirò. Almeno spero. Seguirò il tuo lavoro con molto piacere e curiosità. Hallo Jerry. What a show! I still have to watch all this work from the beginning calmly, but I was fascinated by the control system of the sails. I still didn't understand anything about that tangle of cables, but I was fascinated, too beautiful. By observing little by little, I will understand. At least I hope. I will follow your work with great pleasure and curiosity. ▲

⟩⟩

SouthportPat

|

📝 The Roll Bar

4 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 98 Views · 5 Likes

Flag

💬 Add Comment

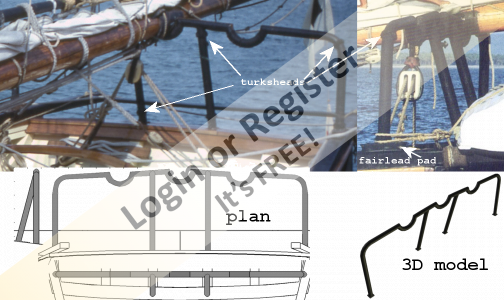

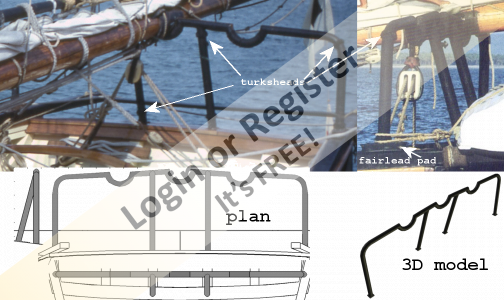

Early on in Pride's career, there apparently was concern about her main boom hanging from it's lifts when the sail was down. Swinging side to side, and the weight pulling at the mast head of that sharply raked mast, probably gave somebody bad dreams. Sometime in later 77 or early 78 they installed a welded steel tube frame for the boom to rest on when the mains'l wasn't set. Because of it's construction and appearance, it was always known as the "Roll Bar."

Any model of the first Pride of Baltimore isn't complete without this identifying piece of equipment.

I originally intended to make it from brass rod (a lot easier than tubing to put together) and I may still, but I couldn't resist taking a shot at printing it in resin.

Comparing the two; brass would definitely be significantly stronger, but if it were bumped enough to be damaged, would probably do more damage to the model; rails, bulwarks, etc; than the roll-bar itself.

Resin will break with much less effort than the brass version would require, but the damage would probably be entirely taken by the resin part without much, or any, being imparted to the model. It would be easy to reprint and replace the roll-bar.

I'd probably be replacing the resin roll-bar more often than repairing the hull from the brass one taking a hit.

That said, I had to model and print a resin one, right? I made the model in two halves because it wouldn't fit in the printer in one piece. I "glued" the two halves together with some resin and a zap of UV light.

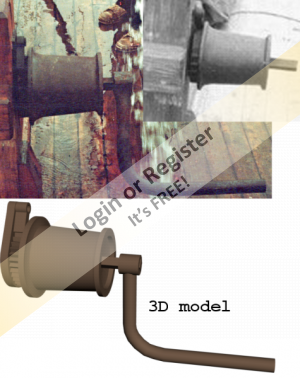

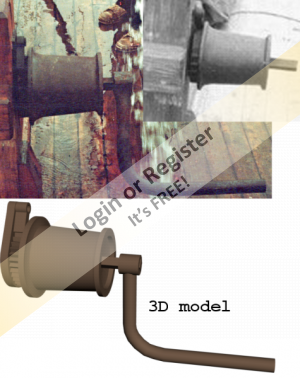

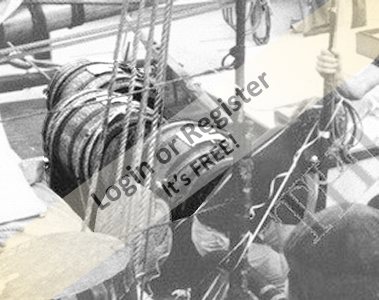

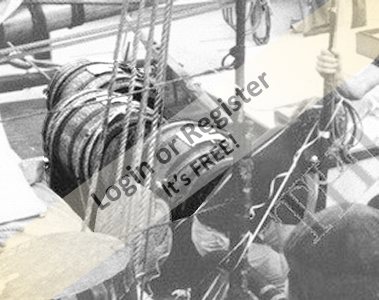

The bitts at the base of the main mast have had a rod installed for a long time intended for the winch. After printing a pair of winch drums for my friends schooner model, I thought I'd use those here, but they're a completely different style; so using photos, I model a winch drum and handle for Pride. These are nearly done printing as I type here, so I'll post those pictures in a little while.

Any model of the first Pride of Baltimore isn't complete without this identifying piece of equipment.

I originally intended to make it from brass rod (a lot easier than tubing to put together) and I may still, but I couldn't resist taking a shot at printing it in resin.

Comparing the two; brass would definitely be significantly stronger, but if it were bumped enough to be damaged, would probably do more damage to the model; rails, bulwarks, etc; than the roll-bar itself.

Resin will break with much less effort than the brass version would require, but the damage would probably be entirely taken by the resin part without much, or any, being imparted to the model. It would be easy to reprint and replace the roll-bar.

I'd probably be replacing the resin roll-bar more often than repairing the hull from the brass one taking a hit.

That said, I had to model and print a resin one, right? I made the model in two halves because it wouldn't fit in the printer in one piece. I "glued" the two halves together with some resin and a zap of UV light.

The bitts at the base of the main mast have had a rod installed for a long time intended for the winch. After printing a pair of winch drums for my friends schooner model, I thought I'd use those here, but they're a completely different style; so using photos, I model a winch drum and handle for Pride. These are nearly done printing as I type here, so I'll post those pictures in a little while.

▲

⟩⟩

SouthportPat

Peejay

EdW

Colin H

RonBMK2

📝 Back into the sauna, I mean shop

4 years ago by 🇺🇸 Jerry Todd ( Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)

Sub-Lieutenant)✧ 102 Views · 8 Likes

Flag

💬 Add Comment

Been away a few days, and except for a couple of days when it rained it's been 30°c or above, mostly above. In the shop it's a chilly 27°, but so humid you're drenched from the exertion of picking up a pencil.

Pride had three barrels forward of the cabin trunk in '81. I reworked and re-scaled that barrel I found on Thingiverse and printed three of them which came out very nice except re-scaling them apparently made the end too thin and they didn't print.

I'm gonna use those as napkin holders. 😉

I tried to fix the 3D model, but it was easier to just start from scratch. These three came out fine. Along with them I printed a 25mm 2-blade prop. It'll just spin on a screw since there's no longer a motor in the model.

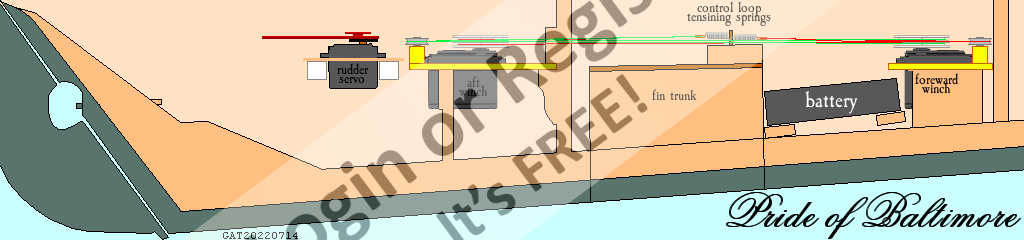

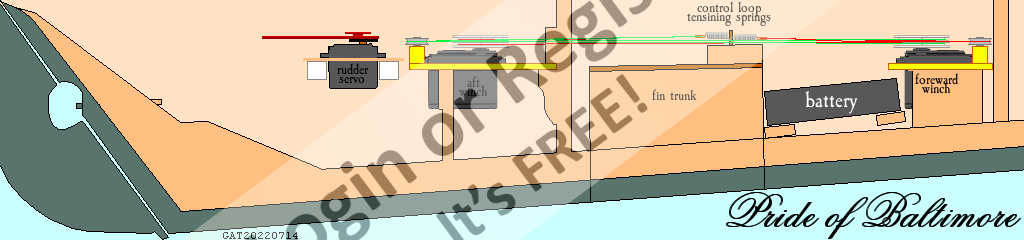

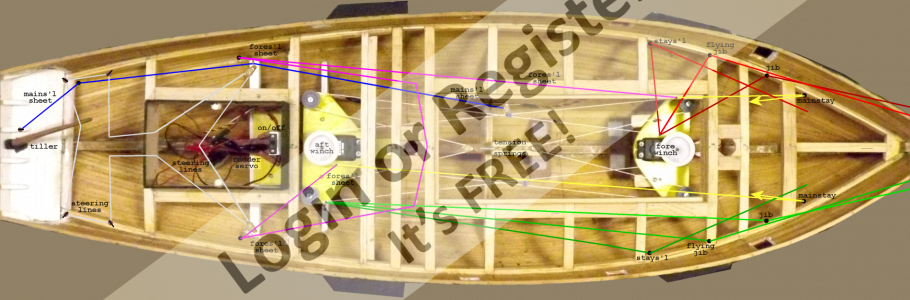

I updated the cutaway drawing to show the new servo layout.

Not having the screws to assemble the tensioning blocks I printed, I got some 1.5mm braided polyester cord for the control loops, and used a pair of brass blocks I got from RB Model a long time ago. These were attached to springs both mounted to a screw-eye in a wood block on the fin trunk. These blocks are obviously lighter than the 25mm printed ones, so won't weigh down the loops.

Rigged up the radio gear and ran them through some tests. Except for one channel needing some reprogramming to get it's full 3.5 turns, the whole thing worked as it should.

Now I need to work out how all the sheets and things that connect to the loops will be routed and go through the deck.

To help with that I made a diagram of the model to mark out what went where. The black spots are the thru-deck positions where I'll need to install some blocking and run a brass tube through. Not shown are the main top-mast running back stays and the braces for the squares. The main-stays shown are the running main-stays typical of Baltimore-Clippers and any boat with such raked masts.

When sailing, the windward one would be brought up taught, and the leeward one slacked, and usually tied to a main shroud out of the way. The model's mast are strong enough to be unstayed, but this set-up is a signature item on a Baltimore Clipper, and a big part of the tacking procedure when I was sailing aboard, so I want it to appear functional on my model.

I gave the steering some attention as well. A pair of blocks get mounted port and starboard of the rudder servo to turn the steering cables aft. Because rudder servo's arm travels in an arc, these blocks make the most use of that travel. Confirming the position of the blocks, which are another pair of brace blocks I cobbled together for Constellation back in '16, I'm going to use screw hook/eyes rather than the brass wire eyes shown in the picture, as they're stronger.

The above-deck portion of the steering has to wait till I can fasten down the aft section of sub-deck before I can install anything.

Pride had three barrels forward of the cabin trunk in '81. I reworked and re-scaled that barrel I found on Thingiverse and printed three of them which came out very nice except re-scaling them apparently made the end too thin and they didn't print.

I'm gonna use those as napkin holders. 😉

I tried to fix the 3D model, but it was easier to just start from scratch. These three came out fine. Along with them I printed a 25mm 2-blade prop. It'll just spin on a screw since there's no longer a motor in the model.

I updated the cutaway drawing to show the new servo layout.

Not having the screws to assemble the tensioning blocks I printed, I got some 1.5mm braided polyester cord for the control loops, and used a pair of brass blocks I got from RB Model a long time ago. These were attached to springs both mounted to a screw-eye in a wood block on the fin trunk. These blocks are obviously lighter than the 25mm printed ones, so won't weigh down the loops.

Rigged up the radio gear and ran them through some tests. Except for one channel needing some reprogramming to get it's full 3.5 turns, the whole thing worked as it should.

Now I need to work out how all the sheets and things that connect to the loops will be routed and go through the deck.

To help with that I made a diagram of the model to mark out what went where. The black spots are the thru-deck positions where I'll need to install some blocking and run a brass tube through. Not shown are the main top-mast running back stays and the braces for the squares. The main-stays shown are the running main-stays typical of Baltimore-Clippers and any boat with such raked masts.

When sailing, the windward one would be brought up taught, and the leeward one slacked, and usually tied to a main shroud out of the way. The model's mast are strong enough to be unstayed, but this set-up is a signature item on a Baltimore Clipper, and a big part of the tacking procedure when I was sailing aboard, so I want it to appear functional on my model.

I gave the steering some attention as well. A pair of blocks get mounted port and starboard of the rudder servo to turn the steering cables aft. Because rudder servo's arm travels in an arc, these blocks make the most use of that travel. Confirming the position of the blocks, which are another pair of brace blocks I cobbled together for Constellation back in '16, I'm going to use screw hook/eyes rather than the brass wire eyes shown in the picture, as they're stronger.

The above-deck portion of the steering has to wait till I can fasten down the aft section of sub-deck before I can install anything.

▲

⟩⟩

SouthportPat

Mike Stoney

Peejay

Colin H

AndyN

EdW

jbkiwi

AndyB

United States

United States