Join Us On Social Media!

Scratchbuilt Esso Deutschland 1:150

15 Posts · 10 Followers · 54 Photos · 123 Likes

Began 2 years ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 21 days ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Superstructure

21 days ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 30 Views · 11 Likes · 8 Comments

Flag

💬 Add Comment

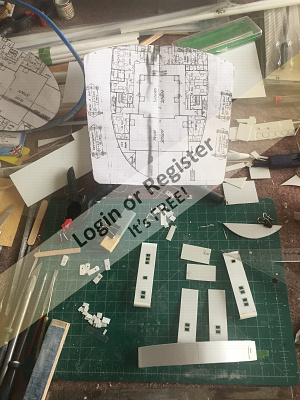

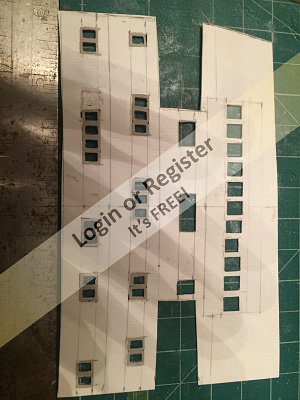

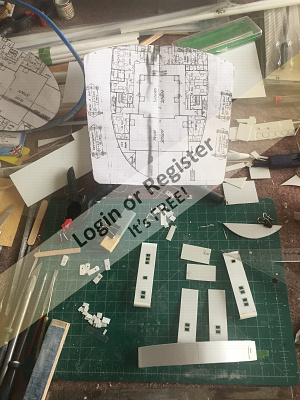

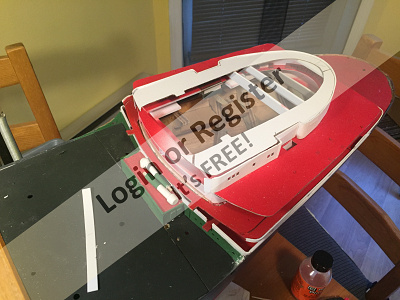

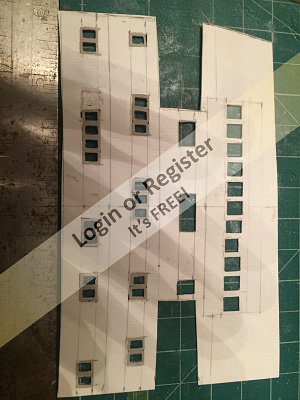

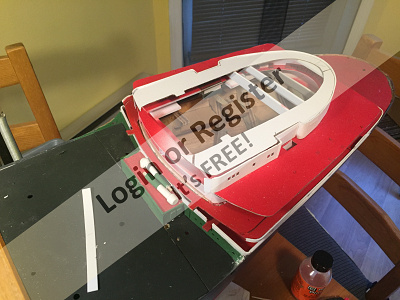

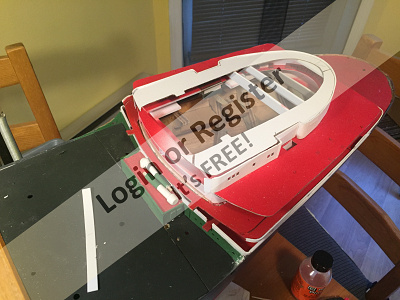

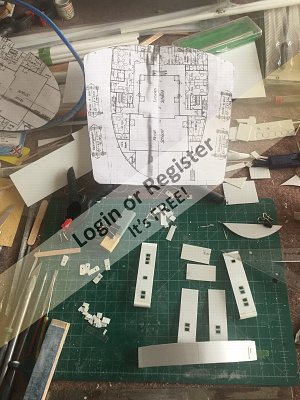

I had hoped to finish the superstructure by Christmas but far from it. I finally managed to cut out the front wall and with adjustments and fine tuning finally felt comfortable to glue it in place. I had to do a lot of filling small spaces on the existing structure. As already mention previously the deck walls are styrene. I went for .5mm material for the outside. I wanted to achieve a (almost) flush appearance for the windows, gave it a few coat of white paint and followed with clear material where the windows are and laminated another layer of material to strengthen the structure. BTW the windows are inserts cut from 6.5x5.5mm tubular material and individual sanded to

▲

⟩⟩

premecekcz

JOHN

Mike Stoney

RodC

Commodore-H

hermank

AlessandroSPQR

GaryLC

EdW

SimpleSailor

jumpugly

|

💬 Re: Superstructure

20 days ago by 🇨🇭 Mike Stoney (

Rear Admiral) Rear Admiral)✧ 20 Views · 3 Likes

Flag

Wow, compliments!

May I bring you my basement skeleton? Best regards, Michel -C. ▲

⟩⟩

hermank

JockScott

AlessandroSPQR

|

|

Login To

Remove Ads 💬 Re: Superstructure

20 days ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 21 Views · 3 Likes

Flag

Jock, don't worry.

This hobby should be a pleasure, not a chore. Don't worry about the end result and enjoy every moment you dedicate to it; when it's over, it'll be over. I understand you because I'm slower than you. No offense to anyone, but I prefer very ambitious and complex projects like yours and Ross's. You could have made a kit and built it quickly, following the instructions, but instead you've attempted a much more complex project. I enjoy watching everyone's models come to fruition; everyone contributes their own skill, but I also enjoy the intermediate stages and the problems that arise along the way; they're very instructive. So far, you're doing great, and remember that perfection isn't of this world. ▲

⟩⟩

hermank

JockScott

RodC

|

|

💬 Re: Superstructure

21 days ago by 🇨🇦 JockScott (

Warrant Officer) Warrant Officer)✧ 21 Views · 4 Likes

Flag

Thank you all for your comments and compliments. Alessandro, I find your project with your quest for authenticity, sparing no efforts and pain to reproduce according to the original most inspiring and in line with my own endeavours. This is not to diminish the excellent work portrayed by others here on this forum, but your attention to detail is outstanding. Unfortunately my experience is limited and other than a Billings 'Blue Nose', started in the '70's never finished due to career and family and moving across the continent, beyond rigging and sails, I have never attempted a project in this magnitude. As I run into issues and dissatisfaction with my shortcomings I do wonder if I may have cut off too much at this stage in my life. I am 4 years into the 10 years I was giving myself to start and while I am quasi happy with what I have accomplished and willing to live with the warts and inaccuracies, I had hoped for a bit better but unless I start over, it will not correct. Maybe nobody will ever see those but it bugs me what I know. Maybe I need counselling when I am done. I have reserved finishing the 'Blue Nose' when and if I get utterly frustrated.

Today I am picking up my RC set from a local hobby shop as I hope to initiate maiden voyage in early Spring before I tackle the monumental task of replicating fittings and few meters of tubing. I thought of buying a small metal lathe for making what I need but still hoping I can save myself by finding some sources for getting it done or maybe somebody local with 3-D printing capability. ▲

⟩⟩

hermank

premecekcz

RodC

AlessandroSPQR

|

|

💬 Re: Superstructure

21 days ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 25 Views · 2 Likes

Flag

Hi Jock, I'm happy to see how they are resuming and continuing the work on one of the most interesting naval models for me.

▲

⟩⟩

JockScott

hermank

|

|

💬 Re: Superstructure

21 days ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 31 Views · 3 Likes

Flag

Wow, quality workmanship. My hands would ache from doing that type of precision cutting. I hope you enjoy the praise you have earned!

▲

⟩⟩

Commodore-H

JockScott

hermank

|

|

💬 Re: Superstructure

21 days ago by 🇨🇦 JockScott (

Warrant Officer) Warrant Officer)✧ 30 Views · 2 Likes

Flag

sorry for the duplication in some of the pictures

▲

⟩⟩

hermank

AlessandroSPQR

|

|

💬 Re: Superstructure

21 days ago by 🇨🇦 JockScott (

Warrant Officer) Warrant Officer)✧ 30 Views · 2 Likes

Flag

why is half my original text left from the posting?

▲

⟩⟩

hermank

AlessandroSPQR

|

Login To

Remove Ads

Remove Ads

📝 Superstructure

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 40 Views · 3 Likes

Flag

💬 Add Comment

Thank you Jumpugly for the kind words. I will try to add more pictures as things are getting a bit easier. I had never done anything in this magnitude, so it is a steep learning curve.

▲

⟩⟩

hermank

AlessandroSPQR

jumpugly

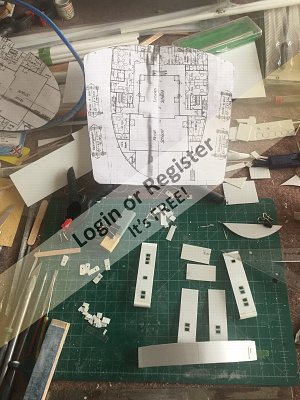

📝 Superstructure coming together

4 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 41 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

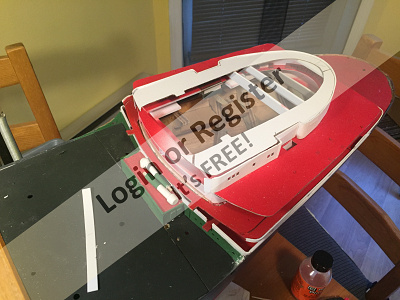

Made some progress with the superstructure having completed the transition of the removable Bootsdeck. This turned out to be more difficult than thought but with a lot of adjustments and 'building on the fly' so to speak, I think I found the workable solution.

Issues I have found were the different materials. Since I have selected to arbourite for deck material but side walls are styrene. I found some issues with the styrene as it will somewhat deform when too much solvent for the glue is applied. Also I am using .5mm material as I attempting to make the windows appear as in the original (no frame and very small margin in thickness). Fortunately I had some styrene rectangular tubing with the exact inside dimensions to be inserted flush to the wall and paint before applying the window acrylic from the back.

Issues I have found were the different materials. Since I have selected to arbourite for deck material but side walls are styrene. I found some issues with the styrene as it will somewhat deform when too much solvent for the glue is applied. Also I am using .5mm material as I attempting to make the windows appear as in the original (no frame and very small margin in thickness). Fortunately I had some styrene rectangular tubing with the exact inside dimensions to be inserted flush to the wall and paint before applying the window acrylic from the back.

▲

⟩⟩

JOHN

RodC

hermank

jumpugly

EdW

AlessandroSPQR

|

💬 Re: Superstructure coming together

4 months ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 44 Views · 4 Likes

Flag

Great workmanship Jock! Coming together beautifully. Don’t know what I’d do without my styrene stash! I use CA on it or the Tamiya thin brush on, just keep the CA away from the window clear. It can haze it.

Keep those pix coming! 👍 ▲

⟩⟩

RodC

hermank

AlessandroSPQR

JockScott

|

📝 ...some progress

7 months ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 51 Views · 13 Likes · 3 Comments

Flag

💬 Add Comment

Since the last time posting I was at it almost daily but despite my best efforts had very little to show for. However I managed to tackle the inside fo'c's'le bulwark and prepared to openings for the fairleads I did over year ago. In the attempt to achieve a higher degree of an accuracy I keep going back to make adjustments and corrections. I managed to install the aft bridgedeck super structure and glue in next deck level. The sidewalls took some time to paint (still having problems with white paint and required a lot of sanding and redoing). Meanwhile I experimented with building the Anchor chain guide ways. I had to cut individiual supports and glue into the centreline. But eventually I succeeded. I may have to redo some of them as they deformed after glueing and the long guide way from the anchor spill develops a bow not intended. Hope this even itself out once glued to the deck. Although I made up some anchor spills, I tried to replicate the notched grove to fit the chain, I may just redo them again to improve on the appearance. The picture shows them in its raw condition and unpainted.

I have enclosed a few pics to illustrate my story and hope you enjoy reading about my trials and tribulation.

I need to mention that I spent a few weeks in Germany with stays in Hamburg (obligatory visit at the IMM) Berlin, Prag and Dortmund to attend the Inter Modellbau in April. Interesting but I was disappointed about the ships model segment being a bit sparse. Lots of Model rail and R/C trucks.

I have enclosed a few pics to illustrate my story and hope you enjoy reading about my trials and tribulation.

I need to mention that I spent a few weeks in Germany with stays in Hamburg (obligatory visit at the IMM) Berlin, Prag and Dortmund to attend the Inter Modellbau in April. Interesting but I was disappointed about the ships model segment being a bit sparse. Lots of Model rail and R/C trucks.

▲

⟩⟩

premecekcz

JOHN

Mike Stoney

RodC

SimpleSailor

LeeA

Len1

EdW

hermank

AlessandroSPQR

Wolle

RNinMunich

jumpugly

|

💬 Re: ...some progress

4 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 42 Views · 0 Likes

Flag

I'm really happy to see this work again.

It's one of the most interesting for me. Jock, I'm personally interested in all the construction phases and all the details. Perhaps you learn much more from mistakes than from successes. I'll soon tell you about a very big one I made, due to haste. ▲

⟩⟩

No likes yet

This member will receive 1 point for every like received |

|

Login To

Remove Ads 💬 Re: ...some progress

7 months ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 54 Views · 3 Likes

Flag

Hi Jock, a very welcome and long-awaited return.

You're doing a great job, don't worry if you're making slow progress. ▲

⟩⟩

Len1

JockScott

hermank

|

|

💬 Re: ...some progress

7 months ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 52 Views · 7 Likes

Flag

Jock welcome back! Aye, really like the chain guide and the superstructure work is falling into place nicely. I scraped the whole superstructure except the floors on my freighter and got out the styrene and haven't regretted that move (below). Keep the pix coming when you can...really liking this resto a ton; trials and tribulations included!

👍😉

▲

⟩⟩

Len1

JockScott

EdW

hermank

AlessandroSPQR

Wolle

RNinMunich

|

📝 Lifeboats and superstructure

1 year ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 61 Views · 10 Likes

Flag

💬 Add Comment

In my exercise in model build learning, experimenting with ideas and realizing it won't work, discovering what works and what doesn't, my patience and endurance gets tested to the limit. In that context and with the inspiration of Alessandro's post about lifeboats, I dared to try again, with new ideas, and renewed my attempt to come up with a way to create the lifeboats in the shape I wanted. I cut out the 'blanks" for the 2 halves and rough shaped them on the sander and refined by hand with sand paper and files. The first attempt seems it is working.

As so often I will put aside one object when I am not happy with the result and go to something else only to go back days later when I have 'recovered' from my 'defeat' and recharged with new ideas.

This what happened the last few days. I see the way forward for the lifeboats clear in my mind and went back to my attempt to fit the handrails (cause of much frustration) for the poop deck superstructure. I am now satisfied I have found the workable solution

As so often I will put aside one object when I am not happy with the result and go to something else only to go back days later when I have 'recovered' from my 'defeat' and recharged with new ideas.

This what happened the last few days. I see the way forward for the lifeboats clear in my mind and went back to my attempt to fit the handrails (cause of much frustration) for the poop deck superstructure. I am now satisfied I have found the workable solution

▲

⟩⟩

JOHN

RodC

LeeA

EdW

hermank

Wolle

RNinMunich

jumpugly

AlessandroSPQR

Ronald

📝 Surgery Break

1 year ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 68 Views · 5 Likes · 1 Comment

Flag

💬 Add Comment

I had to have a cancerous kidney removed. Surgeon is confident he got it all and I should be able to finish the model 🤔 which requires at least another 5 years.

▲

⟩⟩

Commodore-H

hermank

RNinMunich

AlessandroSPQR

jumpugly

|

💬 Re: Surgery Break

1 year ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 72 Views · 4 Likes

Flag

Good news Jock! Yet, anything invasive is a big job. Lay low and heal for a bit. It’s good to have that project to jump back into. It’ll aid in recovery; worked for me every time!

👍😉 ▲

⟩⟩

hermank

jbkiwi

JockScott

AlessandroSPQR

|

📝 Paint issues

1 year ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 81 Views · 4 Likes · 3 Comments

Flag

💬 Add Comment

I have seen Krylon in the stores and certainly will give it a try. I have to give it a rest for a few days as I have to into surgery tomorrow.

▲

⟩⟩

hermank

Peejay

AlessandroSPQR

jumpugly

|

💬 Re: Paint issues

1 year ago by 🇩🇪 RNinMunich (

Fleet Admiral) Fleet Admiral)✧ 79 Views · 3 Likes

Flag

GWS Jock🤞

Stiff upper lip old chap😐 😎 ▲

⟩⟩

hermank

JockScott

Peejay

|

|

Login To

Remove Ads 💬 Re: Paint issues

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 84 Views · 4 Likes

Flag

Hi Jock, I hope it's nothing serious.

Happy recovery and good luck. ▲

⟩⟩

hermank

Peejay

Mike Stoney

DuncanP

|

|

💬 Re: Paint issues

1 year ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 84 Views · 6 Likes

Flag

Stay looped in and best wishes on a solid surgery and speedy recovery Jock!

👍 ▲

⟩⟩

JOHN

hermank

Peejay

Mike Stoney

DuncanP

AlessandroSPQR

|

📝 Paint issues

1 year ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 81 Views · 9 Likes · 1 Comment

Flag

💬 Add Comment

Thank you Alessandro.

Having advanced to the first Deck structure I had already cut out the deck material from Arborite. For you Modellers a very unusual choice but I like its finish, hardness

and virtually indestructibity. When I did the back (foc'sal), midships, main and poop (aft) decks the Tamiya paint, I had chosen for colour preference, not adhering and easily chipping off. I then painted all decks with standard Hardware shop spray paint first and second the Tamiya on top which worked great.

I tried the same when finishing the styrene deck walls for the first deck (white) but noticed the regular spray paint seems to react with the styrene giving it a rubbery feel

and in some places. After sanding it and reapplying I wasn't at all satisfied with the result. As I couldn't get Tamiya white in the rattle can bought Revell acrylic with disastrous effect. The paint's texture seem to become mottled although I had sanded all surfaces. Does anybody have any experience with painting Styrene. I also can't find Tamiya white at my local stores and I am not sure using the Revell. I could resand everything and try the Revell again since I already have otherwise I need to find Tamiya

somewhere else around town.

Having advanced to the first Deck structure I had already cut out the deck material from Arborite. For you Modellers a very unusual choice but I like its finish, hardness

and virtually indestructibity. When I did the back (foc'sal), midships, main and poop (aft) decks the Tamiya paint, I had chosen for colour preference, not adhering and easily chipping off. I then painted all decks with standard Hardware shop spray paint first and second the Tamiya on top which worked great.

I tried the same when finishing the styrene deck walls for the first deck (white) but noticed the regular spray paint seems to react with the styrene giving it a rubbery feel

and in some places. After sanding it and reapplying I wasn't at all satisfied with the result. As I couldn't get Tamiya white in the rattle can bought Revell acrylic with disastrous effect. The paint's texture seem to become mottled although I had sanded all surfaces. Does anybody have any experience with painting Styrene. I also can't find Tamiya white at my local stores and I am not sure using the Revell. I could resand everything and try the Revell again since I already have otherwise I need to find Tamiya

somewhere else around town.

▲

⟩⟩

JOHN

hermank

Wolle

Peejay

DuncanP

Mike Stoney

EdW

AlessandroSPQR

jumpugly

|

💬 Re: Paint issues

1 year ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 84 Views · 4 Likes

Flag

Hey there Jock! Fantastic hull, I only hope my American Scout can be as smooth!

On styrene I'd give the Krylon Fusion line a shot. Smells to high heaven, but drys hard with a high gloss...will require multiple light coats as opposed to the Rustoleum line of Painter's Touch paints which cover well in one shot. I am a fan of the Tamiya paints, but not of the Testors spray paints, although they do have decent coverage. It's the least they can do considering the can size. As per usual, always do test strips and let everything gas out completely. Any gloss clear top coats should be tested on whatever you use to avoid any horrible unforeseen mishaps. Remember, if you think it's dry, it's not. ▲

⟩⟩

hermank

Peejay

AlessandroSPQR

JockScott

|

📝 Port Hole installation

1 year ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 83 Views · 9 Likes · 1 Comment

Flag

💬 Add Comment

Since my Summer break, I have been working on the aft superstructure. Before I can proceed I have to finalize the porthole. I was unable to find anything I could use on the model supply market suitable as the port holes on the original are flush with the hull and just the window recession. To simulate I thought to drill the holes in the 1mm siding with the acrylic glued in place. This imposed problems as I found out as there is not much space to properly place the acrylic and secure in place. Next option was to construct port holes from alu tubing, filed and sanded to 1mm thickness. I used a tool to cut 3mm holes in leather belts to cut out the acrylic windows which I superglued to the back of the port hole frames. As some drill holes were not quite properly aligned, I had to drill them I bit larger to adjust position and for that expanded the porthole frames with a larger ring of aluminum tubing into which the smaller ring with the acrylic window would fit. A tedious operation with many duds redoing numerous pieces. I had to strengthen some of the siding when the larger port holes didn't leave much material in between. After many attempts, failures and frustration I managed to get them to the point I was finally able to move on to the next stage.

More to come shortly

More to come shortly

▲

⟩⟩

JOHN

hermank

Wolle

Peejay

Mike Stoney

DuncanP

EdW

jumpugly

AlessandroSPQR

|

💬 Re: Port Hole installation

1 year ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 84 Views · 4 Likes

Flag

Hi Jock, I'm very happy that you continued the work on this model.

I love that you updated us on your progress. This account is very informative. ▲

⟩⟩

hermank

Peejay

DuncanP

JockScott

|

📝 Ballast Question

2 years ago by 🇨🇦 JockScott ( Warrant Officer)

Warrant Officer)

Warrant Officer)

Warrant Officer)✧ 96 Views · 4 Likes · 2 Comments

Flag

💬 Add Comment

Alessandro, if I will sail the model how have I intended it remains to be seen. Definitely I'll start in Ballast condition, then try loaded as planned. If everything goes as hoped I will subject it to water dousing. If it proves to keep the water out I will go further. One tiny step at a time

▲

⟩⟩

Peejay

hermank

Len1

AlessandroSPQR

|

💬 Re: Ballast Question

2 years ago by 🇮🇹 AlessandroSPQR (

Fleet Admiral) Fleet Admiral)✧ 92 Views · 4 Likes

Flag

More than right, Jock.

I look forward to enjoying the developments of ESSO Deutschland. ▲

⟩⟩

Peejay

Len1

hermank

JockScott

|

|

💬 Re: Ballast Question

2 years ago by 🇺🇸 LewZ (

Vice Admiral) Vice Admiral)✧ 98 Views · 5 Likes

Flag

When I use ballast I keep it simple. I don't generally use strict calculations as to ballast density, just approximate, so that the ballast is underweight. Then add trim ballast. Do a test run first. Fill some plastic bags with dirt/sand, or ? to see what it takes to trim the boat, then work out the amount of ballast you need. Kind of like using a balance scale to weigh something. Put the item on one side then start adding weights to the other side. Common sense will tell you what to do and what materials to use, depending on what is available, cost and effectiveness.

I add ballast to have the boat float evenly at or slightly above the waterline. This is done in a tub, usually outdoors. when there is no wind blowing. As a boat will not usually float evenly (fore-aft and/or port-starboard) when completed, several locations for ballast might be warranted. Floating unevenly might be caused by either the details on the boat being not symmetrical or perhaps some off center internal components. One can use fixed ballast or removable ballast, or both. My preference is usually removable ballast as who knows what changes might be added or removed in the future. For heavier boats both fixed and movable might be a good choice. The movable ballast is usually for trimming and fine tuning. The most common type of ballast I use is usually non-rusting metal. What kind of ballast material depends on the amount I need and the size of the boat, and of course how much volume is available as well as the shape. Again, here is where common sense into play. We all know that the ballast should be added at the lowest point(s) available. That could define the overall shape of the ballast. IMPORTANT: For better stability keep the ballast as low as possible. So, here are some examples: SMALL BOATS: (Boats generally under ~20".) Here the ballast is usually minimal in amount needed and placed into small spaces. BBs, small ball bearings (balls only), hardware (nuts, washers, etc.). MEDIUM BOATS (~20-35".) More freedom of ballast locations allow a larger variety of materials. Perhaps a mixture of materials depending on if it is fixed or removable. LARGE BOATS: (>~35".) Here is where cement (concrete) might come into play as well as other options for inexpensive materials including water itself. TIPS: 💡 I had a large barge I wanted to trim out to about 100 pounds (45 kg). I brought some empty plastic soda bottles with me and filled them at the pond. Then I placed them inside the barge (photo) along with some bricks after it was in the water. 💡One of the SSMBC members has a "whaleback freighter" and uses a pump to add ballast after launching. Pumps it back out before lifting it out of the water when done. 💡 Coins. Here is the US the common copper penny can be used. Its inexpensive and stacks very well into a tubular shape. 💡 Velcro is a handy way of holding a ballast box in place. 💡 Many times I will make a 3D printed box and fill it with a ballast material and seal it. Often this is attached with Velcro. 💡 Cement (concrete) works just fine. I recommend "casting" it in a container which is the shape you want. Let it cure well (a week?) then paint it with several coats. I used urethane varnish. The best concrete to use is the kind without aggregate (powder only). The better the finish on your casting box is the better the finish on the ballast will be. I personally would not pour the concrete directly into the hull. Note that these are just suggestions and can vary depending on the type of boat you have. Hope this helps. Lew Florida 😎, USA

▲

⟩⟩

Wolle

Peejay

DuncanP

hermank

Len1

|

Canada

Canada