Join Us On Social Media!

Another tug🤣 Dumas ST74 Army Tug

11 Posts · 6 Followers · 79 Photos · 84 Likes

Began 1 year ago by

Follow This Thread

Not currently following

> Click to follow

> Click to follow

Latest Post 12 months ago by

| Most recent posts shown first (Show Oldest First) | (Print Booklet) |

📝 Ready for ballast and leak check.

12 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 23 Views · 4 Likes

Flag

💬 Add Comment

Well y’all, the ST74 is almost ready to go to work. I finished up the towing bitts, manhole covers and mast, decals are in place, just needs some tidying up and buttoning up. I built the towing bitts today, and the masts. I did NOT use the 1/8th wood dowel for the aft mast as I would probably break it handling the boat..so I cheated. I used a styrene tube with a piece of fiberglass rod inserted and glued in, for the tip I glued on a bb. Y’all, there’s a lot of things I’m capable of, but carvings not one of them. I can carve balsa block to profile for a fuselage or hull, but there’s no way I’m going to be successful at carvin a round knob on the end of 1/8 diameter dowel. Just no. I admire people who can do that, and people who carve their own free flight propellers I’m just in awe of….but I know my limitations, hence the cheat. I used the 1/8th dowel for the fwd staff, and glued a bb on top too.

The kit uses steel washers for life preservers, I have quite a few of the righ size that I cut off the plastic line surround, sanded smooth, painted, decaled and installed.

At this point she’s pretty well done. I’m going to need about a pound of ballast, and I need to secure the fantail grate and do a little touch up here and there. Also, my waterline is off, I’ll probably repaint it at some point, but aside from the aforementioned tasks and rigging the flag, she’s done, and ready for the test tank!

Cash

The kit uses steel washers for life preservers, I have quite a few of the righ size that I cut off the plastic line surround, sanded smooth, painted, decaled and installed.

At this point she’s pretty well done. I’m going to need about a pound of ballast, and I need to secure the fantail grate and do a little touch up here and there. Also, my waterline is off, I’ll probably repaint it at some point, but aside from the aforementioned tasks and rigging the flag, she’s done, and ready for the test tank!

Cash

▲

⟩⟩

RodC

chugalone100

jumpugly

luckyduck

Login To

Remove Ads

Remove Ads

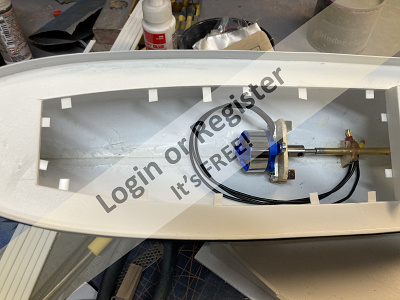

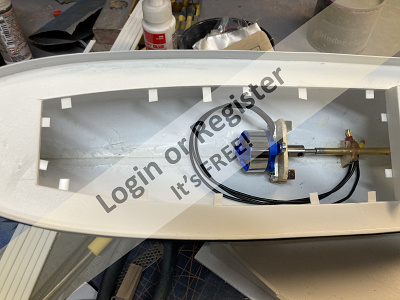

📝 Under deck done, most paint is finished.

12 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 41 Views · 6 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. The ST is getting very close to be ready for her maiden. Hive the under deck equipment installed. First thing was soldering connectors on my ESC, a Hobbywing EZrun 18amp brushless, and then I programmed it. Y’all, I’ve been messing around with models since I was 12 or so, free flight and control line airplanes then, rc when I was older and could afford it. Most of my planes were glow or diesel, but all my cars and boats have been electric. I still have my Graupner PowerMos 30 esc from 1991 that I used in an electric plane, and a couple of Tekin, Novak and Futaba escs from my racing days. But the HobbyWing line of escs are the bees knees, inexpensive, well made, and easily understood manuals. Plus the customer service is great. I have not had any issues with HobbyWing escs, brushed or brushless. Anyway, enough gushing. Once I had the esc ready I made sure everything worked then set about getting it all installed. I’m keeping this one simple, just throttle and rudder, no lights or sound.

First thing in was a battery floor from scrap basswood. I Velcro my packs in, and since the ST’s hull is a little thin I didn’t relish the idea of the hull flexing when i uninstall a battery, so I made supports on the underside of a piece of 1/8th basswood sheet, and used Stabilit to bond it in place.

The instructions call for a full sized servo for rudder, which is overkill, and there’s parts to build a servo mount in the kit. I used those pars and some scrap wood to build a mount for an HS81 clone, then installed that and the rudder linkage. I then cut a block of 1 inch square balsa for a mount for the ESC. Both the ESC mount and the servo mount butt up to the motor mount and are all glued together. The receiver is velcroed in place to the underside of the deck.

When that was done my next job was paint. It’s mostly all done, my waterline aft is a little off but I’ll live with it for the time being. All that’s left is a few more details like the towing bitts and mast, then it’s off to the test tank for a leak check and ballast.

Cash

First thing in was a battery floor from scrap basswood. I Velcro my packs in, and since the ST’s hull is a little thin I didn’t relish the idea of the hull flexing when i uninstall a battery, so I made supports on the underside of a piece of 1/8th basswood sheet, and used Stabilit to bond it in place.

The instructions call for a full sized servo for rudder, which is overkill, and there’s parts to build a servo mount in the kit. I used those pars and some scrap wood to build a mount for an HS81 clone, then installed that and the rudder linkage. I then cut a block of 1 inch square balsa for a mount for the ESC. Both the ESC mount and the servo mount butt up to the motor mount and are all glued together. The receiver is velcroed in place to the underside of the deck.

When that was done my next job was paint. It’s mostly all done, my waterline aft is a little off but I’ll live with it for the time being. All that’s left is a few more details like the towing bitts and mast, then it’s off to the test tank for a leak check and ballast.

Cash

▲

⟩⟩

chugalone100

MouldBuilder

MartyV

luckyduck

jumpugly

RNinMunich

|

💬 Re: Under deck done, most paint is finished.

12 months ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 35 Views · 1 Like

Flag

Every time I look at this build Cash, I WANT TO DO A TUG NEXT!!!!!!

👍😉 P.s. Thanks for the support on my Scout page. 😊 ▲

⟩⟩

Cashrc

|

📝 Ships boat built, cradles and davits installed.

12 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 44 Views · 4 Likes

Flag

💬 Add Comment

Hi y’all, I’ll keep this brief. I got the ships boat done, didn’t like the way the cover sat on the hull, was able to pry/cut/curse it off, sand and reinstall. Not perfect though but will work for now. Cut the cradles, installed the boat, davits and necessary rigging. Again, not perfect but looks okay. Skylight now permanently glued down. I. Hoping to have all under deck equipment and a battery floor done this weekend, then the hull will be ready for paint.

Cash

Cash

▲

⟩⟩

chugalone100

MouldBuilder

RNinMunich

Wolle

📝 Funnel done and skylight decaled

12 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 51 Views · 7 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. Had some time this morning so I did a bit. First thing I did was to clean up the pilot house to cabin joint. I took a sanding stick and was able to clean up the glue joint a bit, then used Vallejo filler to take care of any voids, and touched up the paint. I then built the funnel. It’s an easy affair, one molded part that is cut out in entirety, then cut to sections and glued together along with wood reinforcement inside at the joints. A cap is cut out and 2 small ferrules similar to servo eyelets are glued on top. The assembly is painted, a baseplate is glued in place after trimming to fit, then the funnel is glued over that and to the skylight. I then added the decals and started the ships boat.

Cash

Cash

▲

⟩⟩

RodC

RNinMunich

Mike Stoney

chugalone100

hermank

Wolle

jumpugly

|

💬 Re: Funnel done and skylight decaled

12 months ago by 🇺🇸 chugalone100 (

Lieutenant Commander) Lieutenant Commander)✧ 48 Views · 2 Likes

Flag

Coming along BEAUTIFULLY 😎

▲

⟩⟩

Cashrc

Mike Stoney

|

📝 Pilothouse and cabin detailed, pilothouse installed

12 months ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 52 Views · 7 Likes · 2 Comments

Flag

💬 Add Comment

Hi y’all. Had some time to do a bit today. I made up the hinges for the cabin doors, but I used a smaller styrene rod as I think it looks better. Then it was time to paint the assembly’s. While the paint dried, I cleaned the litter boxes!!🐱

Once I did that I installed the decal windows and portholes, then built up the mast, the nav lights and searchlight, and glued down the pilothouse. I had sanded the bottom to match the curve of the cabin roof, and I THOUGHT I had a decent fit, but when the time came, I had a gap. Tried to fill it with thick CA and touch up with a brush, and it looks…ok. I’m thinking I’m going to try to sand that down a bit with a sanding stick and retouch, but it’s difficult to do with the railing installed. In retrospect, I think it would make more sense to install the house, making sure it’s a good fit THEN do the railings, but I did it “by the book”.

Oh. I used an old paintbrush handle for the mast, as it’s already tapered. Yeah, I cheated…😁

Next up is touching up my mistakes, then it’s funnel and ships boat time.

Cash

Once I did that I installed the decal windows and portholes, then built up the mast, the nav lights and searchlight, and glued down the pilothouse. I had sanded the bottom to match the curve of the cabin roof, and I THOUGHT I had a decent fit, but when the time came, I had a gap. Tried to fill it with thick CA and touch up with a brush, and it looks…ok. I’m thinking I’m going to try to sand that down a bit with a sanding stick and retouch, but it’s difficult to do with the railing installed. In retrospect, I think it would make more sense to install the house, making sure it’s a good fit THEN do the railings, but I did it “by the book”.

Oh. I used an old paintbrush handle for the mast, as it’s already tapered. Yeah, I cheated…😁

Next up is touching up my mistakes, then it’s funnel and ships boat time.

Cash

▲

⟩⟩

chugalone100

RNinMunich

Mike Stoney

EdW

Chum444

jumpugly

hermank

|

💬 Re: Pilothouse and cabin detailed, pilothouse installed

12 months ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 51 Views · 1 Like

Flag

Thank for the kind comments Jump, I truly appreciate it!!

Hey, you can borrow any idea of mine you like… just send the royalty checks to: Ima Greedy Sucker 1234 Ripoff Blvd Norefunds Tx, 00000 🤣🤣🤣 Happy New Year to you too Jump, and all of the other members of this board. Cash ▲

⟩⟩

hermank

|

|

💬 Re: Pilothouse and cabin detailed, pilothouse installed

12 months ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 52 Views · 2 Likes

Flag

Looks terrific Cash! Love the use of the styrene rod!!! Gonna swipe that idea if it's ok?! Keep the pix coming! Happy New Year!

👍😉 ▲

⟩⟩

hermank

Cashrc

|

📝 Pilothouse safety railing, stair rails, ladder and primer

1 year ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 66 Views · 9 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. Did a little early this week and today. I did the safety railing on the pilot house earlier this week. The author of the instructions makes it quite clear that this assembly, while looking quite simple, can make you want to pull your hair out, but persevere and you’ll get it done. He’s right. The main thing is getting all the railing pins at the right height and the railing lined up…and STAYING that way while you glue it all together. The manual instructs you to squeeze the eyelet of the pin that’s the railing support to secure it, I tried once, didn’t like the outcome so I ca’d it.

This morning I did the fwd stairwell rails, then soldered up, bent to shape and installed the ladder. The ladder was actually easier to build up than the safety railing. Once that was done I installed the doors and steps to the pilot house and gave it, the cabin and skylight a good coat of primer. Once I get a chance to look it over I’ll correct any blemishes the re-primer, and paint.

Cash

This morning I did the fwd stairwell rails, then soldered up, bent to shape and installed the ladder. The ladder was actually easier to build up than the safety railing. Once that was done I installed the doors and steps to the pilot house and gave it, the cabin and skylight a good coat of primer. Once I get a chance to look it over I’ll correct any blemishes the re-primer, and paint.

Cash

▲

⟩⟩

chugalone100

EdW

GARTH

roycv

RodC

Chum444

RNinMunich

hermank

jumpugly

|

💬 Re: Pilothouse safety railing, stair rails, ladder and primer

1 year ago by 🇨🇦 Ronald (

Fleet Admiral) Fleet Admiral)✧ 70 Views · 3 Likes

Flag

Looks very well with uniform rails, you being the builder will see or know, point something not right. But don’t! The model looks very nice.👍

If you intend to do any towing with it, best to strengthen the Double Bullocks possibly using brass tubing rather than the wooden dowels provided in the kit.. ▲

⟩⟩

Cashrc

hermank

RodC

|

📝 Rails finished and installed

1 year ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 79 Views · 7 Likes · 2 Comments

Flag

💬 Add Comment

So, today was suppose to be our bi-monthly fun sail at Towne Lake. Got there about 8am along with my good bud Larry Buchwalter, and it was foggy and damp. We decided to run but there were “minefields “ of leaves all over the lake. I played avoid the minefield with my Dumas Whitehall, while Larry put a sailboat in the water. Very little breeze that died when Larry was about 20 feet to shore, so I genned up my little “Mystery” tug and pushed him in…we called it soon after. So…I went home and finished the railings.

The ST instructions tell you the measurements for drilling each stanchion hole, but the author states it’s better to use the called out starting holes then mark using the railing as that takes into account variance in soldering and also paper shrinkage of the plans. Worked a treat, took me a couple of hours to solder up the rear railings, make the required bends, drill and glue in place, plus wolfing down 2 Whataburger Sausage egg and cheese taquitos and hash browns😀

Cash

The ST instructions tell you the measurements for drilling each stanchion hole, but the author states it’s better to use the called out starting holes then mark using the railing as that takes into account variance in soldering and also paper shrinkage of the plans. Worked a treat, took me a couple of hours to solder up the rear railings, make the required bends, drill and glue in place, plus wolfing down 2 Whataburger Sausage egg and cheese taquitos and hash browns😀

Cash

▲

⟩⟩

chugalone100

Peejay

EdW

RNinMunich

flaxbybuck

hermank

jumpugly

|

💬 Re: Rails finished and installed

1 year ago by 🇬🇧 flaxbybuck (

Captain) Captain)✧ 76 Views · 3 Likes

Flag

Nice job ! 😉

▲

⟩⟩

Peejay

Cashrc

hermank

|

|

💬 Re: Rails finished and installed

1 year ago by 🇺🇸 Chum444 (

Captain) Captain)✧ 74 Views · 2 Likes

Flag

👍👍

▲

⟩⟩

Peejay

Cashrc

|

📝 Handrails and upper railing

1 year ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 81 Views · 9 Likes · 2 Comments

Flag

💬 Add Comment

Hi y’all. Spent the last 2 days making up the deckhouse grab rails and spent most of this morning soldering up the rails.

The hand rails were fairly simple. Brass wire is bent to the supplied template, then the cabin is marked for drilling. The measurements are taken from the bottom edge of the deckhouse up, and you use the bent handrails as a guide. Now, this is going into plastic that is barely 2 mm thick, so I used scrap material to give the handrails a better gluing area. I really don’t like knocking details off my boats when I’m handling them.🤣

Now, the railings for the deck house, that’s another story. The railings are soldered up from supplied brass wire, no stanchions, etc. The railings also match the curve of the deckhouse roof. So, in my mind you have 2 options-build a jig, or use the supplied template and….”use the Book of Instructions!!”. I chose the latter.

Basically the procedure is this. Cut the uprights to length, tape in place, procure wood or card in the same thickness as the supplied wire, tape in place, tape rails in place, solder your derrière off🤣🤣.

Really didn’t turn out too bad, but it took me longer to jig everything up than it did to solder the assembly.

Also, you build up a left and right side, and the aft railings, as the wire supplied is too short to make a use piece unit, and making the appropriate bends and matching the deckhouse curve might be challenging. However, apparently once you get everything in place you’re supposed to solder the aft railing to the side rails. I don’t see this happening, as I can just about guarantee you that once you get the brass hot enough to stick you’re going to loosen up the closest upright. So, I’ll install the left and right sides then once I make up the aft railing, I’ll CA the butt joint and add very small gussets to support. That’s my plan, we’ll see how it goes. I still have to clean up the railings and do a little filing on some of the solder joints before that however.

Cash

The hand rails were fairly simple. Brass wire is bent to the supplied template, then the cabin is marked for drilling. The measurements are taken from the bottom edge of the deckhouse up, and you use the bent handrails as a guide. Now, this is going into plastic that is barely 2 mm thick, so I used scrap material to give the handrails a better gluing area. I really don’t like knocking details off my boats when I’m handling them.🤣

Now, the railings for the deck house, that’s another story. The railings are soldered up from supplied brass wire, no stanchions, etc. The railings also match the curve of the deckhouse roof. So, in my mind you have 2 options-build a jig, or use the supplied template and….”use the Book of Instructions!!”. I chose the latter.

Basically the procedure is this. Cut the uprights to length, tape in place, procure wood or card in the same thickness as the supplied wire, tape in place, tape rails in place, solder your derrière off🤣🤣.

Really didn’t turn out too bad, but it took me longer to jig everything up than it did to solder the assembly.

Also, you build up a left and right side, and the aft railings, as the wire supplied is too short to make a use piece unit, and making the appropriate bends and matching the deckhouse curve might be challenging. However, apparently once you get everything in place you’re supposed to solder the aft railing to the side rails. I don’t see this happening, as I can just about guarantee you that once you get the brass hot enough to stick you’re going to loosen up the closest upright. So, I’ll install the left and right sides then once I make up the aft railing, I’ll CA the butt joint and add very small gussets to support. That’s my plan, we’ll see how it goes. I still have to clean up the railings and do a little filing on some of the solder joints before that however.

Cash

▲

⟩⟩

chugalone100

Peejay

EdW

Dibdawg

hermank

Commodore-H

jumpugly

RNinMunich

Mike Stoney

|

💬 Re: Handrails and upper railing

1 year ago by 🇺🇸 Cashrc (

Admiral) Admiral)✧ 79 Views · 1 Like

Flag

Thank you Jumpugly, I appreciate it!!

▲

⟩⟩

Peejay

|

📝 Cabin, pilot house and skylight

1 year ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 86 Views · 8 Likes · 1 Comment

Flag

💬 Add Comment

Hi y’all. Was able to squeeze in some time this weekend to start knocking out some sub assemblies for the S T74. I started with the main cabin first. Dumas uses a built up wood frame that is then sheeted over with die cut plastic for a lot of their superstructures that are meant to replicate metal, vs say, Billings, which provides very nicely precut parts in wood, but then one has to spend a lot of time filling and sanding to get the exterior to have a smooth, metal look. Don’t get me wrong, as I think Billings makes great kits, I just get a little lazy on occasion .

Anyway, the frame is built up over the deck opening, with the fore and aft formers nestled up to the coaming. This way you get a nice snug fit. Once the framework is built, the directions advise to tape it down snug against the deck so that the sheeting, once glued in place, will need minimal trimming or sanding to make with the deck. Nothing groundbreaking here, hardest part was getting the plastic strip roof cap glued on flush with the top of the roof. Not a hard job, just a little fiddly.

Now, at this point the instructions direct you to adding doors, rails, etc. I went ahead and built up the subsequent sub assemblies to get a look at what I’ll be facing when I do the details. Before I started the pilothouse I had to glue 3 wood pieces on the cabin roof..these are there to locate the pilothouse and the skylight once built. I then started the pilothouse. It too is built up of wood then plastic sheeted. Although the instructions don’t mention it, I gently contoured the bottom of the framework of both upper assemblies before I sheeted them, as the cabin roof as a slight curve to it. This makes a better join to the roof and will require less filling on my part. The skylight is built up much the same as the cabin and pilothouse.the pilothouse roof is a vacuum molded part, and is a very thin abs or maybe styrene…not difficult but you need to take your time cutting and sanding it before installation.

Last thing I did was the forward steps that lead to the cabins roof and the pilothouse. Don’t know if I’m entirely satisfied with it, I’m going to take a sanding stick to the steps to even them out before I attempt any sort of do-over. Also, I had it in my mind to cut out the windows, and drill holes for actual portholes vs using the supplied decals, but I’ve decided to use what’s provided. I’m keeping this boat relatively simple. However….I might do maST and nav lights. Still on the fence about that..

Next up will be fiddly bits..railings and such.

Cash

Anyway, the frame is built up over the deck opening, with the fore and aft formers nestled up to the coaming. This way you get a nice snug fit. Once the framework is built, the directions advise to tape it down snug against the deck so that the sheeting, once glued in place, will need minimal trimming or sanding to make with the deck. Nothing groundbreaking here, hardest part was getting the plastic strip roof cap glued on flush with the top of the roof. Not a hard job, just a little fiddly.

Now, at this point the instructions direct you to adding doors, rails, etc. I went ahead and built up the subsequent sub assemblies to get a look at what I’ll be facing when I do the details. Before I started the pilothouse I had to glue 3 wood pieces on the cabin roof..these are there to locate the pilothouse and the skylight once built. I then started the pilothouse. It too is built up of wood then plastic sheeted. Although the instructions don’t mention it, I gently contoured the bottom of the framework of both upper assemblies before I sheeted them, as the cabin roof as a slight curve to it. This makes a better join to the roof and will require less filling on my part. The skylight is built up much the same as the cabin and pilothouse.the pilothouse roof is a vacuum molded part, and is a very thin abs or maybe styrene…not difficult but you need to take your time cutting and sanding it before installation.

Last thing I did was the forward steps that lead to the cabins roof and the pilothouse. Don’t know if I’m entirely satisfied with it, I’m going to take a sanding stick to the steps to even them out before I attempt any sort of do-over. Also, I had it in my mind to cut out the windows, and drill holes for actual portholes vs using the supplied decals, but I’ve decided to use what’s provided. I’m keeping this boat relatively simple. However….I might do maST and nav lights. Still on the fence about that..

Next up will be fiddly bits..railings and such.

Cash

▲

⟩⟩

Peejay

EdW

Mike Stoney

chugalone100

Chum444

hermank

AlessandroSPQR

jumpugly

|

💬 Re: Cabin, pilot house and skylight

1 year ago by 🇺🇸 jumpugly (

Admiral) Admiral)✧ 85 Views · 5 Likes

Flag

Awesome work Cash! Straight and true. She’s gonna be a beauty! 👍🏻

▲

⟩⟩

Peejay

Mike Stoney

Cashrc

hermank

AlessandroSPQR

|

📝 Rub rails, coaming and more

1 year ago by 🇺🇸 Cashrc ( Admiral)

Admiral)

Admiral)

Admiral)✧ 92 Views · 9 Likes

Flag

💬 Add Comment

Hi y’all. So, usually I do groceries Saturday morning around 630-7 am, go home, unload, go to the bench. I was a little late getting there as on the way home, my 2012 Abarth lost its mind. When I turned on the lights, I heard a “thump” from the speakers, radios off. Then, right near the house, my instrument cluster started going haywire. I got messages about the hill holder (which I have turned off), my temp gauge pegged then went back down, speedo bouncing, esc light flashing, then goes into limp mode. It came out of limp mode a minute later, set a light and drove normally after that. I’m suspecting a failing alternator, we’ll see Monday when I get to work….if I get there🤣

Anyway, that rattled me, it took a bit to get started on the ST74, but I got quite a bit accomplished. I did the rub rails first. The rails are made up of a provided half round rubber strip. I would have preferred half round plastic in the same size, but ya work with what ya got. The top rail goes from the fwd post down the side of the hull, around the stern and back to the post on the other side. I found the best way was to tack down the end, pull it with a littl tension and use thin ca to secure. Except for the very front it’s actually pretty straight. You then cut successfully shorter strips and work your way down.

I then did the coaming. The instructions has the builder cut 1/8 square wood and glue under the deck, and projecting past where the coaming is installed, this way it’s sure to be flushed up to the deck. Then you’re supposed to remove the strips. I used 2x5 mm plastic, as I decided to keep them in place for added support, and cut and sanded them flush when done.

The fantail is built up of a die cut plastic part with thin styrene strips glued down, using another strip to space them. It’s not glued in so you can access the rudder tiller and linkage, and I think it just wedges between the deck riser and the aft bulwark rail, but I might use a magnet, or maybe even a small drop of glue at front. If I have to remove it for any reason I can get an xacto to the glue dot and pop it off with no damage.

Last thing was the bulwark rail. Needed a slight amount of trimming but fit well.

I’m very close to being able to spray the ull, need to touching up and a couple of minor details done, then I can get the hull primered and start hitting the cabin.

Cash

Anyway, that rattled me, it took a bit to get started on the ST74, but I got quite a bit accomplished. I did the rub rails first. The rails are made up of a provided half round rubber strip. I would have preferred half round plastic in the same size, but ya work with what ya got. The top rail goes from the fwd post down the side of the hull, around the stern and back to the post on the other side. I found the best way was to tack down the end, pull it with a littl tension and use thin ca to secure. Except for the very front it’s actually pretty straight. You then cut successfully shorter strips and work your way down.

I then did the coaming. The instructions has the builder cut 1/8 square wood and glue under the deck, and projecting past where the coaming is installed, this way it’s sure to be flushed up to the deck. Then you’re supposed to remove the strips. I used 2x5 mm plastic, as I decided to keep them in place for added support, and cut and sanded them flush when done.

The fantail is built up of a die cut plastic part with thin styrene strips glued down, using another strip to space them. It’s not glued in so you can access the rudder tiller and linkage, and I think it just wedges between the deck riser and the aft bulwark rail, but I might use a magnet, or maybe even a small drop of glue at front. If I have to remove it for any reason I can get an xacto to the glue dot and pop it off with no damage.

Last thing was the bulwark rail. Needed a slight amount of trimming but fit well.

I’m very close to being able to spray the ull, need to touching up and a couple of minor details done, then I can get the hull primered and start hitting the cabin.

Cash

▲

⟩⟩

Peejay

chugalone100

Rogal118

jumpugly

hermank

EdW

Mike Stoney

Wolle

Chum444

United States

United States